JP2007100697A - 二層先端キャップ - Google Patents

二層先端キャップ Download PDFInfo

- Publication number

- JP2007100697A JP2007100697A JP2006270518A JP2006270518A JP2007100697A JP 2007100697 A JP2007100697 A JP 2007100697A JP 2006270518 A JP2006270518 A JP 2006270518A JP 2006270518 A JP2006270518 A JP 2006270518A JP 2007100697 A JP2007100697 A JP 2007100697A

- Authority

- JP

- Japan

- Prior art keywords

- cap

- shield

- tip cap

- tip

- based alloy

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 239000000463 material Substances 0.000 claims abstract description 28

- 230000003647 oxidation Effects 0.000 claims abstract description 18

- 238000007254 oxidation reaction Methods 0.000 claims abstract description 18

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 claims description 16

- 239000000956 alloy Substances 0.000 claims description 16

- 229910045601 alloy Inorganic materials 0.000 claims description 15

- 229910052759 nickel Inorganic materials 0.000 claims description 8

- 229910000531 Co alloy Inorganic materials 0.000 claims description 7

- 239000000843 powder Substances 0.000 claims description 5

- 238000001556 precipitation Methods 0.000 claims description 4

- 229910000601 superalloy Inorganic materials 0.000 claims description 4

- 238000003466 welding Methods 0.000 description 5

- 238000001816 cooling Methods 0.000 description 4

- 238000000576 coating method Methods 0.000 description 3

- 239000007789 gas Substances 0.000 description 3

- 239000000654 additive Substances 0.000 description 2

- 230000000996 additive effect Effects 0.000 description 2

- 238000005219 brazing Methods 0.000 description 2

- 239000011248 coating agent Substances 0.000 description 2

- 239000000567 combustion gas Substances 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 229910001235 nimonic Inorganic materials 0.000 description 2

- 238000007747 plating Methods 0.000 description 2

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical group [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 238000005266 casting Methods 0.000 description 1

- 238000005253 cladding Methods 0.000 description 1

- 229910017052 cobalt Inorganic materials 0.000 description 1

- 239000010941 cobalt Substances 0.000 description 1

- GUTLYIVDDKVIGB-UHFFFAOYSA-N cobalt atom Chemical compound [Co] GUTLYIVDDKVIGB-UHFFFAOYSA-N 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 239000002826 coolant Substances 0.000 description 1

- 238000005260 corrosion Methods 0.000 description 1

- 230000007797 corrosion Effects 0.000 description 1

- 238000009713 electroplating Methods 0.000 description 1

- 239000000945 filler Substances 0.000 description 1

- 238000005242 forging Methods 0.000 description 1

- 239000000446 fuel Substances 0.000 description 1

- 229910052746 lanthanum Inorganic materials 0.000 description 1

- FZLIPJUXYLNCLC-UHFFFAOYSA-N lanthanum atom Chemical compound [La] FZLIPJUXYLNCLC-UHFFFAOYSA-N 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 238000003801 milling Methods 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 238000007750 plasma spraying Methods 0.000 description 1

- 238000009419 refurbishment Methods 0.000 description 1

- 238000010008 shearing Methods 0.000 description 1

- 229910052710 silicon Inorganic materials 0.000 description 1

- 239000010703 silicon Substances 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D5/00—Blades; Blade-carrying members; Heating, heat-insulating, cooling or antivibration means on the blades or the members

- F01D5/12—Blades

- F01D5/14—Form or construction

- F01D5/20—Specially-shaped blade tips to seal space between tips and stator

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2230/00—Manufacture

- F05D2230/30—Manufacture with deposition of material

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2230/00—Manufacture

- F05D2230/90—Coating; Surface treatment

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2260/00—Function

- F05D2260/95—Preventing corrosion

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Turbine Rotor Nozzle Sealing (AREA)

- Other Surface Treatments For Metallic Materials (AREA)

Abstract

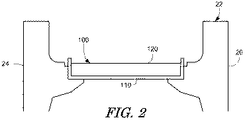

【解決手段】本先端キャップ(100)は、耐酸化性材料のシールド(110)およびシールド(110)内に配置される高強度材料のキャップ(120)を含むことができる。

【選択図】図2

Description

"NIMONIC alloy 263",Special Metals,12pgs. "Haynes 230 Alloy",Haynes International,28pgs.

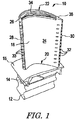

12 ダブテール

14 シャンク

16 プラットフォーム

18 エーロフォイル

20 ルート部

22 先端部

24 圧力側壁

26 吸引側壁

28 前縁

30 後縁

32 後縁冷却孔

33 前縁冷却孔

34、100 先端キャップ

36 スクイーラ先端部

110 シールド

120 キャップ

Claims (9)

- 耐酸化性材料を含むシールド(110)と、

前記シールド(110)内に配置され、高強度材料を含むキャップ(120)と

を備える、タービン動翼(10)に使用される先端キャップ(100)。 - 前記耐酸化性材料が、ニッケル基合金またはコバルト基合金を含む、請求項1記載の先端キャップ(100)。

- 前記高強度材料が、ニッケル基合金またはコバルト基合金を含む、請求項1記載の先端キャップ(100)。

- 前記シールド(110)の厚さが、0.025〜0.762ミリメートル(0.001〜0.030インチ)である、請求項1記載の先端キャップ(100)。

- 前記キャップ(120)の厚さが、0.762〜3ミリメートル(0.030〜0.120インチ)である、請求項1記載の先端キャップ(100)。

- 前記シールド(110)がカップ形を含み、前記キャップ(120)が前記シールド(110)内に嵌合する、請求項1記載の先端キャップ(100)。

- 前記シールド(110)が平板を含み、前記キャップ(120)が前記シールド(110)に取り付けられる、請求項1記載の先端キャップ(100)。

- 前記シールド(110)が粉末を含み、前記粉末が前記キャップ(120)に被着される、請求項1記載の先端キャップ(100)。

- 前記高強度材料が、耐クリープ性の析出強化型超合金を含む、請求項1記載の先端キャップ(100)。

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US11/163,067 | 2005-10-04 | ||

| US11/163,067 US7556477B2 (en) | 2005-10-04 | 2005-10-04 | Bi-layer tip cap |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2007100697A true JP2007100697A (ja) | 2007-04-19 |

| JP2007100697A5 JP2007100697A5 (ja) | 2009-11-19 |

| JP4998690B2 JP4998690B2 (ja) | 2012-08-15 |

Family

ID=37192618

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2006270518A Expired - Fee Related JP4998690B2 (ja) | 2005-10-04 | 2006-10-02 | 二層先端キャップ |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US7556477B2 (ja) |

| EP (1) | EP1772593B1 (ja) |

| JP (1) | JP4998690B2 (ja) |

| CN (1) | CN1978868B (ja) |

| CA (1) | CA2561474C (ja) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2015517625A (ja) * | 2012-05-09 | 2015-06-22 | シーメンス エナジー インコーポレイテッド | タービンブレード先端の修理方法 |

Families Citing this family (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102008047043A1 (de) * | 2008-09-13 | 2010-03-18 | Mtu Aero Engines Gmbh | Ersatzteil für eine Gasturbinen-Schaufel einer Gasturbine, Gasturbinen-Schaufel sowie ein Verfahren zur Reparatur einer Gasturbinen-Schaufel |

| US20100200189A1 (en) * | 2009-02-12 | 2010-08-12 | General Electric Company | Method of fabricating turbine airfoils and tip structures therefor |

| US8454310B1 (en) * | 2009-07-21 | 2013-06-04 | Florida Turbine Technologies, Inc. | Compressor blade with tip sealing |

| US8371817B2 (en) * | 2009-09-15 | 2013-02-12 | General Electric Company | Apparatus and method for a turbine bucket tip cap |

| US8734107B2 (en) | 2011-05-31 | 2014-05-27 | General Electric Company | Ceramic-based tip cap for a turbine bucket |

| CH705187A1 (de) * | 2011-06-17 | 2012-12-31 | Alstom Technology Ltd | Gegossene Turbinenschaufel. |

| US8985956B2 (en) | 2011-09-19 | 2015-03-24 | General Electric Company | Compressive stress system for a gas turbine engine |

| US20130236318A1 (en) * | 2012-03-06 | 2013-09-12 | General Electric Company | Fabricated turbine airfoil |

| US9050769B2 (en) * | 2012-04-13 | 2015-06-09 | General Electric Company | Pre-form ceramic matrix composite cavity and method of forming and method of forming a ceramic matrix composite component |

| EP2700788A1 (en) | 2012-08-21 | 2014-02-26 | Alstom Technology Ltd | Vane or blade with tip cap |

| GB201313596D0 (en) * | 2013-07-30 | 2013-09-11 | Composite Technology & Applic Ltd | A tip cap for a fan blade |

| WO2015065606A1 (en) * | 2013-10-30 | 2015-05-07 | United Technologies Corporation | Laser powder deposition weld rework for gas turbine engine non-fusion weldable nickel castings |

| US20150308449A1 (en) * | 2014-03-11 | 2015-10-29 | United Technologies Corporation | Gas turbine engine component with brazed cover |

| US10202854B2 (en) | 2014-12-18 | 2019-02-12 | Rolls-Royce North America Technologies, Inc. | Abrasive tips for ceramic matrix composite blades and methods for making the same |

| GB201514801D0 (en) * | 2015-08-20 | 2015-10-07 | Rolls Royce Plc And Rolls Royce Deutschland Ltd & Co Kg | Method of manufacture of a turbine component |

| US10677067B2 (en) * | 2016-09-29 | 2020-06-09 | General Electric Company | Airfoil and method of assembling same |

| US11143033B2 (en) * | 2018-11-08 | 2021-10-12 | General Electric Company | Turbomachine blade tip attachment |

| US11203938B2 (en) | 2018-11-08 | 2021-12-21 | General Electric Company | Airfoil coupon attachment |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS63212703A (ja) * | 1986-12-29 | 1988-09-05 | ユナイテッド・テクノロジーズ・コーポレイション | 溶融金属セラミック研摩材先端部を有するタービンブレード及びその製造方法 |

| JPH06184685A (ja) * | 1992-07-23 | 1994-07-05 | Abb Res Ltd | 析出硬化性ニッケル系超合金およびこの合金を調整凝固された構造用部材の製造の際の材料として使用する方法 |

| US5752802A (en) * | 1996-12-19 | 1998-05-19 | Solar Turbines Incorporated | Sealing apparatus for airfoils of gas turbine engines |

| JPH11350094A (ja) * | 1998-06-12 | 1999-12-21 | Hitachi Ltd | ガスタービン動翼 |

| US20020141869A1 (en) * | 2001-03-27 | 2002-10-03 | Ching-Pang Lee | Turbine blade tip having thermal barrier coating-formed micro cooling channels |

| US20030118445A1 (en) * | 2001-12-20 | 2003-06-26 | Ching-Pang Lee | Foil formed structure for turbine airfoil |

| JP2004332116A (ja) * | 2003-05-09 | 2004-11-25 | General Electric Co <Ge> | ニッケル基合金 |

| JP2005248958A (ja) * | 2004-03-02 | 2005-09-15 | General Electric Co <Ge> | ガスタービンバケット先端キャップ |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3785809A (en) * | 1971-06-15 | 1974-01-15 | United Aircraft Corp | Nickel-base superalloy |

| US4020538A (en) * | 1973-04-27 | 1977-05-03 | General Electric Company | Turbomachinery blade tip cap configuration |

| US3899267A (en) * | 1973-04-27 | 1975-08-12 | Gen Electric | Turbomachinery blade tip cap configuration |

| US4589824A (en) * | 1977-10-21 | 1986-05-20 | United Technologies Corporation | Rotor blade having a tip cap end closure |

| US4214355A (en) * | 1977-12-21 | 1980-07-29 | General Electric Company | Method for repairing a turbomachinery blade tip |

| GB2028928B (en) * | 1978-08-17 | 1982-08-25 | Ross Royce Ltd | Aerofoil blade for a gas turbine engine |

| US4247254A (en) * | 1978-12-22 | 1981-01-27 | General Electric Company | Turbomachinery blade with improved tip cap |

| US4390320A (en) * | 1980-05-01 | 1983-06-28 | General Electric Company | Tip cap for a rotor blade and method of replacement |

| US4411597A (en) * | 1981-03-20 | 1983-10-25 | The United States Of America As Represented By The Administrator Of The National Aeronautics And Space Administration | Tip cap for a rotor blade |

| US4540339A (en) * | 1984-06-01 | 1985-09-10 | The United States Of America As Represented By The Secretary Of The Air Force | One-piece HPTR blade squealer tip |

| US5359770A (en) * | 1992-09-08 | 1994-11-01 | General Motors Corporation | Method for bonding abrasive blade tips to the tip of a gas turbine blade |

| US6231307B1 (en) * | 1999-06-01 | 2001-05-15 | General Electric Company | Impingement cooled airfoil tip |

| US6616410B2 (en) * | 2001-11-01 | 2003-09-09 | General Electric Company | Oxidation resistant and/or abrasion resistant squealer tip and method for casting same |

| US7059834B2 (en) * | 2003-01-24 | 2006-06-13 | United Technologies Corporation | Turbine blade |

| DE10326541A1 (de) * | 2003-06-12 | 2005-01-05 | Mtu Aero Engines Gmbh | Verfahren zur Schaufelspitzenpanzerung der Laufschaufeln eines Gasturbinentriebwerkes und Vorrichtung zur Durchführung des Verfahrens |

-

2005

- 2005-10-04 US US11/163,067 patent/US7556477B2/en not_active Expired - Fee Related

-

2006

- 2006-09-28 CA CA2561474A patent/CA2561474C/en not_active Expired - Fee Related

- 2006-09-29 EP EP06255037.1A patent/EP1772593B1/en not_active Ceased

- 2006-09-29 CN CN2006101447431A patent/CN1978868B/zh not_active Expired - Fee Related

- 2006-10-02 JP JP2006270518A patent/JP4998690B2/ja not_active Expired - Fee Related

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS63212703A (ja) * | 1986-12-29 | 1988-09-05 | ユナイテッド・テクノロジーズ・コーポレイション | 溶融金属セラミック研摩材先端部を有するタービンブレード及びその製造方法 |

| JPH06184685A (ja) * | 1992-07-23 | 1994-07-05 | Abb Res Ltd | 析出硬化性ニッケル系超合金およびこの合金を調整凝固された構造用部材の製造の際の材料として使用する方法 |

| US5752802A (en) * | 1996-12-19 | 1998-05-19 | Solar Turbines Incorporated | Sealing apparatus for airfoils of gas turbine engines |

| JPH11350094A (ja) * | 1998-06-12 | 1999-12-21 | Hitachi Ltd | ガスタービン動翼 |

| US20020141869A1 (en) * | 2001-03-27 | 2002-10-03 | Ching-Pang Lee | Turbine blade tip having thermal barrier coating-formed micro cooling channels |

| US20030118445A1 (en) * | 2001-12-20 | 2003-06-26 | Ching-Pang Lee | Foil formed structure for turbine airfoil |

| JP2004332116A (ja) * | 2003-05-09 | 2004-11-25 | General Electric Co <Ge> | ニッケル基合金 |

| JP2005248958A (ja) * | 2004-03-02 | 2005-09-15 | General Electric Co <Ge> | ガスタービンバケット先端キャップ |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2015517625A (ja) * | 2012-05-09 | 2015-06-22 | シーメンス エナジー インコーポレイテッド | タービンブレード先端の修理方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1772593A2 (en) | 2007-04-11 |

| CA2561474C (en) | 2014-07-15 |

| US20070077143A1 (en) | 2007-04-05 |

| CN1978868A (zh) | 2007-06-13 |

| JP4998690B2 (ja) | 2012-08-15 |

| EP1772593A3 (en) | 2012-11-14 |

| EP1772593B1 (en) | 2019-04-10 |

| CA2561474A1 (en) | 2007-04-04 |

| US7556477B2 (en) | 2009-07-07 |

| CN1978868B (zh) | 2011-04-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4998690B2 (ja) | 二層先端キャップ | |

| JP6692609B2 (ja) | タービンバケット組立体及びタービンシステム | |

| JP4181793B2 (ja) | タービン翼形部並びにその製造及び修理方法 | |

| US6634860B2 (en) | Foil formed structure for turbine airfoil tip | |

| EP3115147A1 (en) | Systems and methods for turbine blade repair | |

| JP2005248958A (ja) | ガスタービンバケット先端キャップ | |

| US7731809B2 (en) | Activated diffusion brazing alloys and repair process | |

| US6837687B2 (en) | Foil formed structure for turbine airfoil | |

| US6838190B2 (en) | Article with intermediate layer and protective layer, and its fabrication | |

| JP2016000994A (ja) | タービンバケットアッセンブリおよびタービンシステム | |

| EP3848142B1 (en) | Superalloy part and method of processing | |

| JP2017115859A (ja) | 深い先端の割れを修理するためのシステムおよび方法 | |

| JP6067216B2 (ja) | 接合タービンバケット先端シュラウド及び関連する方法 | |

| JP2005201242A (ja) | ガスタービンロータブレードを修理する方法 | |

| JP2015224636A (ja) | タービンバケットアッセンブリおよびタービンシステム | |

| US11939879B2 (en) | Blade repair method, blade, and gas turbine | |

| JP2015224631A (ja) | タービンバケット組立体及びタービンシステム | |

| US11946389B2 (en) | Turbine rotor blade and contact surface manufacturing method | |

| PL217698B1 (pl) | Sposób naprawiania metalowego elementu składowego turbiny i metalowy element składowy turbiny | |

| US8371817B2 (en) | Apparatus and method for a turbine bucket tip cap | |

| CN101133173A (zh) | 合金,防止构件高温腐蚀和/或氧化的保护层及构件 | |

| JP2022527776A (ja) | 複合先端ホウ素ベースの予備焼結プリフォームを使用するタービンコンポーネントの先端補修 | |

| JP2018091333A (ja) | 垂直亀裂遮熱コーティングを形成する方法および垂直亀裂遮熱コーティングを含む物品 | |

| JP2005016523A (ja) | タービン外側ケースと支持式タービンベーンとの間の支持領域の耐摩耗性を改善する方法 | |

| JP2015224635A (ja) | タービンバケット組立体及びタービンシステム |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20091002 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20091002 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20091002 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20091002 |

|

| A072 | Dismissal of procedure [no reply to invitation to correct request for examination] |

Free format text: JAPANESE INTERMEDIATE CODE: A072 Effective date: 20100126 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100924 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20110413 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110419 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20110719 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20110829 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20111013 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120207 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120313 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20120403 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20120501 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4998690 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20150525 Year of fee payment: 3 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |