JP2006205423A - Thermal direct drawing-type lithographic printing plate - Google Patents

Thermal direct drawing-type lithographic printing plate Download PDFInfo

- Publication number

- JP2006205423A JP2006205423A JP2005017850A JP2005017850A JP2006205423A JP 2006205423 A JP2006205423 A JP 2006205423A JP 2005017850 A JP2005017850 A JP 2005017850A JP 2005017850 A JP2005017850 A JP 2005017850A JP 2006205423 A JP2006205423 A JP 2006205423A

- Authority

- JP

- Japan

- Prior art keywords

- printing plate

- lithographic printing

- layer

- ink

- hydrophilic

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Abstract

Description

本発明は、サーマルレーザー及び熱印字プリンタを用いて製版を行い、オフセット印刷に用いられる感熱直描型平版印刷版に関する。 The present invention relates to a heat-sensitive direct-drawing lithographic printing plate that is used for offset printing by making a plate using a thermal laser and a thermal printing printer.

平版印刷版は、油脂性のインキを受理する親油性の画像部分と、インキを受理しない撥油性の非画像部分からなり、一般に非画像部分は水を受け付ける親水性部分から構成されている。通常の平版印刷では、水とインキの両方を版面に供給し、画像部はインキを、非画像部は水を選択的に受け入れ、画像部上のインキを例えば紙等の被印刷体に転写させることによって印刷がなされる。 The lithographic printing plate is composed of an oleophilic image portion that accepts oil-based ink and an oleophobic non-image portion that does not accept ink, and the non-image portion is generally composed of a hydrophilic portion that accepts water. In normal lithographic printing, both water and ink are supplied to the printing plate, ink is selectively received in the image area, and water is selectively received in the non-image area, and the ink on the image area is transferred to a printing medium such as paper. By doing so, printing is performed.

現在、平版印刷版は表面を親水化処理したアルミニウム板、亜鉛板、紙等の基材上に親油性のインク受理層を設けることにより製造される。これらの中では、PS版と呼ばれる表面を親水性処理した金属製支持体上にジアゾ化合物やフォトポリマー等の感光材料を用いたものや、紙やプラスチック支持体上にハロゲン化銀を感光材料として銀錯塩拡散転写法(DTR法)を利用し画像形成するものなどが一般的である。 Currently, a lithographic printing plate is produced by providing an oleophilic ink-receiving layer on a substrate such as an aluminum plate, a zinc plate, or paper whose surface has been hydrophilized. Among these, a photosensitive material such as a diazo compound or a photopolymer is used on a metal support having a hydrophilic surface treated as a PS plate, or silver halide is used as a photosensitive material on a paper or plastic support. In general, an image is formed using a silver complex diffusion transfer method (DTR method).

ジアゾ化合物やフォトポリマーによってインク受理層(以降画像層という)を形成する方法は、まず金属板、紙、積層板、絶縁性基板等の基材上にジアゾ化合物やフォトポリマー等の感光材料を塗布する。次いで、光を照射して感光材料に化学変化を生じさせて、現像液に対する溶解性を変化させる。感光材料は化学変化の種類によって二つに分類される。光が照射された部分が重合・硬化して、現像液に対して不溶性になるネガ型と、逆に光が照射された部分の官能基が変化して、現像液に対する溶解性を有するようになるポジ型である。何れの場合にも、現像液による処理後に基材上に残存する、現像液に不溶の感光材料が画像層となる。 In order to form an ink receiving layer (hereinafter referred to as an image layer) with a diazo compound or a photopolymer, first, a photosensitive material such as a diazo compound or a photopolymer is coated on a substrate such as a metal plate, paper, laminated plate, or insulating substrate. To do. Next, light is irradiated to cause a chemical change in the photosensitive material, thereby changing the solubility in the developer. Photosensitive materials are classified into two types depending on the type of chemical change. The negative part that becomes polymerized and hardened when irradiated with light and becomes insoluble in the developer, and conversely the functional group of the part that is irradiated with light changes to have solubility in the developer. It is a positive type. In any case, the photosensitive material insoluble in the developer that remains on the substrate after processing with the developer becomes the image layer.

一方、DTR法を用いた平版印刷版、特にハロゲン化銀乳剤層の上に物理現像核層を有する平版印刷版は、例えば、米国特許第3,728,114号、同第4,134,769号、同第4,160,670号、同第4,336,321号、同第4,501,811号、同第4,510,228号、同第4,621,041号明細書等に記載されており、露光されたハロゲン化銀結晶は、DTR現像により化学現像を生起し黒色の銀となり親水性の非画像部を形成し、一方、未露光のハロゲン化銀結晶は現像液中の錯化剤により銀塩錯体になって表面の物理現像核層まで拡散し、核の存在により物理現像を生起してインキ受容性の物理現像銀を主体とする画像部を形成する。 On the other hand, a lithographic printing plate using the DTR method, particularly a lithographic printing plate having a physical development nucleus layer on a silver halide emulsion layer is disclosed in, for example, US Pat. Nos. 3,728,114 and 4,134,769. No. 4,160,670, No. 4,336,321, No. 4,501,811, No. 4,510,228, No. 4,621,041, etc. As described, the exposed silver halide crystals undergo chemical development by DTR development to form black silver to form hydrophilic non-image areas, while unexposed silver halide crystals are contained in the developer. A silver salt complex is formed by the complexing agent and diffused to the physical development nucleus layer on the surface, and the physical development is caused by the presence of the nucleus to form an image portion mainly composed of ink-accepting physical development silver.

上記のような感光材料を用いて画像層を形成する場合に、露光方法が解像性を決定する重要な因子の一つとなっている。従来は、露光用フィルムを作製し、次いで紫外光または白色光を使用した密着露光方法を行うのが主流であった。しかし、コンピュータの進歩に伴って、コンピュータ情報からのディジタル信号を露光装置へと送信(コンピュータ・ツゥ・プレート)し、レーザを用いて直接感光材料を露光するレーザ直接描画方法が行われるようになっている。レーザ直接描画方法は、コストが安い、速度が速い、多品種少ロット品での生産性が高い等の利点がある。 When forming an image layer using the photosensitive material as described above, the exposure method is one of the important factors that determine the resolution. Conventionally, it has been the mainstream to produce a film for exposure and then perform a contact exposure method using ultraviolet light or white light. However, with the advancement of computers, a laser direct writing method in which a digital signal from computer information is transmitted to an exposure apparatus (computer-to-plate) and a photosensitive material is directly exposed using a laser has been performed. ing. The laser direct writing method has advantages such as low cost, high speed, and high productivity with many kinds and small lots.

このレーザ直接描画方法に対応するためには、感光材料の光学感度を高くしなければならない。ジアゾ化合物やフォトポリマーでは、光化学反応を伴うために、光学感度は低く、数〜数百mJ/cm2である。そのため、レーザ出力装置が高出力でなければならず、装置が大きくなったり、コストが高くなるなどの問題があった。 In order to cope with this laser direct writing method, the optical sensitivity of the photosensitive material must be increased. Since diazo compounds and photopolymers involve a photochemical reaction, the optical sensitivity is low, being several to several hundred mJ / cm 2 . For this reason, the laser output device must have a high output, which causes problems such as an increase in the size of the device and an increase in cost.

また、ハロゲン化銀を用いたDTR法により画像形成するものでは、感度は数μJ/cm2であり簡便な半導体レーザなどでも十分露光可能であるが、逆に、露光工程を行う前までの保存、基材への塗布工程等を、暗中もしくはセーフティライト下で行わなければならないという、製造及び製版作業の効率を著しく悪くする欠点があった。また、ジアゾ化合物やフォトポリマーにおいても、室内光や太陽光下でも反応が進行するし、高温下でも反応性に変化が生じる。さらに、酸素が存在すると、反応の阻害剤となる。したがって、露光及び現像前までは同様に暗室処置や低酸素状態化での保存が必要となっていた。 In addition, in the case of forming an image by the DTR method using silver halide, the sensitivity is several μJ / cm 2 and it can be sufficiently exposed with a simple semiconductor laser or the like, but conversely, it is stored before performing the exposure process. In addition, there has been a drawback that the efficiency of manufacturing and plate making operations is remarkably deteriorated, in that the coating process to the substrate must be performed in the dark or under a safety light. In addition, in diazo compounds and photopolymers, the reaction proceeds even under room light or sunlight, and the reactivity changes even at high temperatures. In addition, the presence of oxygen becomes an inhibitor of the reaction. Therefore, before exposure and development, it is necessary to store in a dark room treatment or in a low oxygen state.

さらに、上述の画像形成方法では、現像液を用いる等の液体処理を行うことが一般的であり、当然廃液処理が必要となり、コストアップやエコロジーの観点から負荷を生じさせていた。 Further, in the above-described image forming method, it is common to perform liquid processing such as using a developing solution, and naturally, waste liquid processing is necessary, which causes a load from the viewpoint of cost increase and ecology.

一方で最近では、半導体レーザー、固体レーザーの技術が進歩し、安価で入手できるようになったため、高出力、高パワーのレーザーを照射し、その光エネルギーを効率的に熱に変換することによって、化学変化や相変化、構造変化を起こしそれによって平版上に画像形成する熱モードでかつ化学的な現像処理が不要であるプロセスレスCTPとして複数発表されている。 On the other hand, recently, the technology of semiconductor lasers and solid-state lasers has progressed, and it has become available at a low price. By irradiating high-power, high-power lasers and efficiently converting the light energy into heat, A plurality of processless CTPs are disclosed as a thermal mode in which a chemical change, a phase change, and a structural change are caused to form an image on a lithographic plate, and no chemical development process is required.

熱モードによって製版するタイプの版材は、画像部もしくは非画像部をアブレーションにより除去するタイプ(特開平6−199064号、特開2001−54985号公報など)、印刷機上でプレダンプニングにより剥離するタイプ(特開9−136395号公報など)、表面の親水性/疎水性の性質を変換する相変換タイプ(特開平07−1849号、特開平10−24547号、特開2003−43674号公報など)が数多く提案されている(特許文献1〜6)。

The plate material of the type that makes the plate in the heat mode is a type in which the image portion or the non-image portion is removed by ablation (Japanese Patent Laid-Open Nos. 6-199064, 2001-54985, etc.), and is peeled off by pre-dampening on a printing press. Type (Japanese Patent Laid-Open No. 9-136395), phase conversion type for converting hydrophilic / hydrophobic properties of the surface (Japanese Patent Laid-Open Nos. 07-1849, 10-24547, and 2003-43674) Etc.) have been proposed (

しかしながら、これらの版材は非画像性能が必ずしも十分ではなく、用いられる印刷機、インキ、湿し水等の印刷条件により地汚れの発生、耐刷力の不足など問題点があった。 However, these plate materials do not necessarily have sufficient non-image performance, and have problems such as generation of background stains and insufficient printing durability depending on printing conditions such as a printing machine, ink, and dampening water used.

特に支持体上に中間層を有し、最表層が親水性であり、熱描画により親水性表面をインキ受理性として画像部とする版材の場合には、画像部のインク受理性と非画像部の親水性の印刷中の継続的な確保、及び支持体及びその上層との接着性による耐刷力の確保がポイントとなっている。

従って、本発明の目的は、支持体上に、少なくとも中間層と、最表層として親水性層を設け、画像部を加熱により親水性を低下せしめインク受理性として形成する感熱直描型平版印刷版において、多数枚の印刷に渡って安定に非画像部の地汚れを抑制し、かつインキ乗り性を確保できる感熱直描型平版印刷版を提供することである。 Accordingly, an object of the present invention is to provide a heat-sensitive direct-drawing lithographic printing plate in which at least an intermediate layer and a hydrophilic layer as the outermost layer are provided on a support, and the image portion is formed to have ink acceptability by reducing hydrophilicity by heating. The present invention provides a heat-sensitive direct-drawing lithographic printing plate that can stably suppress background stains in a non-image area over a large number of sheets and can ensure ink transportability.

本発明の上記目的は、以下の発明によって達成された。

1)支持体上に、少なくとも中間層と、最表層として親水性層を設け、画像部を加熱により親水性を低下せしめインク受理性として形成する感熱製版平版印刷版において、中間層にコロイダルシリカ複合合成高分子エマルションを含有することを特徴とする感熱直描型平版印刷版。

2)前記中間層が更に疎水性の熱溶融微粒子を含有する上記1)記載の感熱直描型平版印刷版。

The above object of the present invention has been achieved by the following invention.

1) In a thermosensitive lithographic printing plate in which at least an intermediate layer and a hydrophilic layer as an outermost layer are provided on a support, and the image portion is heated to lower the hydrophilicity and formed as ink acceptability, the intermediate layer is made of colloidal silica composite A heat-sensitive direct-drawing lithographic printing plate comprising a synthetic polymer emulsion.

2) The heat-sensitive direct-drawing lithographic printing plate as described in 1) above, wherein the intermediate layer further contains hydrophobic hot-melt fine particles.

本発明によれば、長期に渡って安定に印字製版することが可能であり、低コストで生産効率の向上が図られる感熱直描型平版印刷版が提供出来る。多数枚の印刷に渡って安定に非画像部の地汚れを抑制し、かつインキ乗り性を確保できるため、生産性の向上が得られる等秀逸な効果がある。 According to the present invention, it is possible to provide a heat-sensitive direct-drawing lithographic printing plate that can stably perform plate-making for a long period of time and can improve production efficiency at low cost. Since it is possible to stably suppress background stains in the non-image area over a large number of printed sheets and to ensure ink transportability, there are excellent effects such as improvement in productivity.

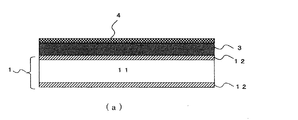

以下図面を用いて本発明の構成について説明する。図1は感熱直描型平版印刷版の概略断面図である。本発明に係わる感熱直描型平版印刷(a)は、支持体1の紙ベース11の表裏面上に疎水性である樹脂12が被覆するように設けてあり、片側に中間層3とその上層(最表層)として親水性層4が設けられている。本発明の平版印刷版の製版方法としては、まず、平版印刷版(a)に熱ヘッドによる印字加熱もしくはサーマルレーザにより所望する画像様に照射加熱を行う。ここで、加熱された部分の親水性層3が熱溶融及び/または熱分解され、表面の親水性が低下することでインキ受理性となり製版が完了する。この後に、平版印刷機に装着すれば、加熱した部分にインキが、また非加熱部分の親水性層4には水がそれぞれ受理され、オフセット印刷が可能となる。

The configuration of the present invention will be described below with reference to the drawings. FIG. 1 is a schematic sectional view of a heat-sensitive direct drawing type lithographic printing plate. The heat-sensitive direct-drawing lithographic printing (a) according to the present invention is provided so that a hydrophobic resin 12 is coated on the front and back surfaces of a paper base 11 of a

本発明の平版印刷版の中間層は、最上層が加熱により熱溶融及び/または熱分解、最終的に中間層が露出もありインク受理性とするため、また、支持体と上層の親水性層との接着力の確保も必要であり、上層よりも親水性が低い(疎水性が高い)皮膜形成ポリマーを用いるが、一方であまり疎水性を高くすると多数枚印刷中に非画像部の地汚れが発生する場合がある。また疎水性が低いとインキ乗りが悪く非画像部とのコントラストが低くなるため、バランスを確保する必要がある。このため、コロイダルシリカ複合合成高分子エマルションを含有させることが必要である。 The intermediate layer of the lithographic printing plate of the present invention has an upper layer that is thermally melted and / or thermally decomposed by heating, and finally the intermediate layer is exposed to make the ink receptive. It is also necessary to secure the adhesive strength of the film and use a film-forming polymer that is less hydrophilic (higher hydrophobicity) than the upper layer. May occur. Further, if the hydrophobicity is low, the ink loading is poor and the contrast with the non-image portion is low, so it is necessary to ensure the balance. For this reason, it is necessary to contain a colloidal silica composite synthetic polymer emulsion.

本発明に係るコロイダルシリカ複合合成高分子エマルションとは、水が主な分散媒であって、固形分としてその表面がコロイダルシリカの粒子で被覆された合成高分子微粒子、その他必要に応じて分散安定剤、防腐剤等の添加剤で構成される。ポリマー微粒子へのコロイダルシリカの被覆は、合成高分子微粒子にシランカップリング剤を用いて固定化することができる。また予め合成高分子微粒子を合成する段階でシラン基を有するモノマーから重合、造粒させた後にコロイダルシリカと混合することで容易に被覆することができる。 The colloidal silica composite synthetic polymer emulsion according to the present invention is a dispersion medium in which water is the main dispersion medium, the surface of which is coated with colloidal silica particles as a solid content, and other dispersion stability as required It is composed of additives such as preservatives and preservatives. The coating of the colloidal silica on the polymer fine particles can be immobilized on the synthetic polymer fine particles using a silane coupling agent. Moreover, it can coat | cover easily by mixing with colloidal silica after superposing | polymerizing and granulating from the monomer which has a silane group in the step which synthesize | combines a synthetic polymer fine particle previously.

上述の合成高分子微粒子としては、例えばアクリル酸、メタクリル酸、アクリル酸エステル、メタクリル酸エステル、スチレン、アクリロニトリル、クロトン酸エステル、マレイン酸エステル、酢酸ビニル等のエチレン性モノマーを乳化重合したものや、予めシラン基を有するものとしては、エチレン性モノマーと例えばビニルトリメトオキシシラン、ビニルトリエトオキシシラン、ビニルトリス(2−メトキシ−エトオキシ)シラン、ビニルトリアセトオキシシラン、γ−メタクリロキシプロピルトリメトオキシシラン、ビニルトリクロルシラン等のアクリルシランもしくはビニルシランを乳化重合して得られたもの、エチレン性モノマーと例えば不飽和カルボン酸または不飽和多価カルボン酸エステル類や不飽和カルボン酸アミド類、不飽和グリシジル化合物類、アルキロール化不飽和化合物類等のカルボキシル基、グリシジル基、アミノ基等の官能基を有するエチレン性モノマーを乳化重合して得られたものにアミノシラン類やエポキシシラン類等の反応性シラン化合物を反応させたものを適宜用いることができる。 Examples of the synthetic polymer fine particles include emulsion polymerization of ethylenic monomers such as acrylic acid, methacrylic acid, acrylic acid ester, methacrylic acid ester, styrene, acrylonitrile, crotonic acid ester, maleic acid ester, vinyl acetate, Those having a silane group in advance include ethylenic monomers such as vinyltrimethoxysilane, vinyltriethoxysilane, vinyltris (2-methoxy-ethoxy) silane, vinyltriacetoxysilane, γ-methacryloxypropyltrimethoxy. Those obtained by emulsion polymerization of acrylic silane or vinyl silane such as silane, vinyltrichlorosilane, etc., ethylenic monomers and unsaturated carboxylic acids or unsaturated polycarboxylic esters, unsaturated carboxylic amides, Reactions such as aminosilanes and epoxysilanes to those obtained by emulsion polymerization of ethylenic monomers having functional groups such as carboxyl groups, glycidyl groups, amino groups such as glycidyl compounds and alkylolated unsaturated compounds What reacted the reactive silane compound can be used suitably.

またコロイダルシリカとしては、コロイド状に水に分散させた超微粒子シリカゾル、または超微粒子粉末シリカであり、好ましくは一次粒子の平均粒径が100nm以下のものである。 The colloidal silica is ultrafine silica sol or ultrafine powder silica dispersed in water in a colloidal form, and preferably has an average primary particle size of 100 nm or less.

上述のコロイダルシリカ複合合成高分子エマルションは、形成した皮膜中に細孔を生じる。このために、印刷中の給湿液が最表層の親水性層を通じて進入し、毛細管現象により細孔中に保水され、結果として対地汚れ性が向上する。この成膜したポリマー皮膜に細孔が生じるメカニズムについては、合成高分子微粒子を被覆しているコロイダルシリカの粒子が成膜過程で合成高分子同士の融着を阻害し、コロイダルシリカ粒子で包囲された細孔を生じさせるものと推測される。従って、細孔の大きさも、用いる合成高分子微粒子及びコロイダルシリカの粒径によってコントロールすることが可能である。 The colloidal silica composite synthetic polymer emulsion described above generates pores in the formed film. For this reason, the dampening liquid during printing enters through the outermost hydrophilic layer and is retained in the pores by capillary action, resulting in improved soil resistance. Regarding the mechanism by which pores are formed in this polymer film, the colloidal silica particles that cover the synthetic polymer particles inhibit the fusion of the synthetic polymers during the film formation process and are surrounded by the colloidal silica particles. It is presumed that a fine pore is formed. Accordingly, the size of the pores can also be controlled by the particle diameter of the synthetic polymer fine particles and colloidal silica used.

また加熱印字された画像部では、その成膜した合成高分子により疎水性が高く、また細孔部は受理したインキにより被覆隠蔽されており、多数枚印刷でも安定したインキ受理性となる。 In addition, the heat-printed image portion is highly hydrophobic due to the formed synthetic polymer, and the pores are covered and concealed with the received ink, so that the ink acceptability is stable even when printing a large number of sheets.

また本発明の平版印刷版の中間層には、より好ましくは加熱により親水性がより低下(疎水性がより増加)する物質の含有であり、疎水性の熱溶性融微粒子を存在させておけば、加熱により上述の皮膜形成する合成高分子と混融及び/または混合して、形成される皮膜の親水性がより低下(疎水性がより増加)する。 Further, the intermediate layer of the lithographic printing plate of the present invention preferably contains a substance whose hydrophilicity is lowered (hydrophobicity is increased) by heating, and if hydrophobic heat-soluble fused fine particles are present. When heated and mixed with and / or mixed with the synthetic polymer that forms the above-described film, the hydrophilicity of the formed film is further lowered (hydrophobicity is further increased).

本発明に係わる熱溶融性微粒子は少なくとも常温では微粒子状で加熱により、溶融定着することによって密なフィルム構造となる性質を有するもので、この様な熱溶融性微粒子層を形成する素材の例としては、(メタ)アクリル樹脂、酢酸ビニル樹脂、ポリエチレン樹脂、ポリプロピレン樹脂、ポリブタジエン樹脂、塩化ビニル樹脂、ビニルアセタール樹脂、塩化ビニリデン樹脂、スチレン樹脂、ポリエステル樹脂、ポリアミド樹脂、フェノール樹脂、キシレン樹脂、アルキッド樹脂、ゼラチン、セルロース、ワックス、蝋等を挙げることができる。画像形成層内の熱溶融性微粒子は一種類だけ選択しても良いし、複数選択しても良い。また、内側の核と外殻の成分が異なっている微粒子、いわゆるコアシェルタイプの熱溶融性微粒子も好適に用いることが出来る。さらに保存性を向上させる目的で少なくとも50℃以上のガラス転移温度を持つ成分が一種類以上含まれていることが好ましい。二種類以上の熱溶融性微粒子を混合して用いることや、コアシェルタイプの様な一個の粒子が複数の成分から構成されている場合には、それらの内の一種類のガラス転移温度が50℃以上であることでも良い。 The heat-meltable fine particles according to the present invention are in the form of fine particles at room temperature and have a property of forming a dense film structure by being melted and fixed by heating. As an example of a material for forming such a heat-meltable fine particle layer, (Meth) acrylic resin, vinyl acetate resin, polyethylene resin, polypropylene resin, polybutadiene resin, vinyl chloride resin, vinyl acetal resin, vinylidene chloride resin, styrene resin, polyester resin, polyamide resin, phenol resin, xylene resin, alkyd resin , Gelatin, cellulose, wax, wax and the like. Only one kind of heat-meltable fine particles in the image forming layer may be selected or a plurality of fine particles may be selected. Further, fine particles having different inner core and outer shell components, so-called core-shell type heat-meltable fine particles, can also be suitably used. Furthermore, it is preferable that at least one component having a glass transition temperature of 50 ° C. or higher is contained for the purpose of improving the storage stability. When two or more kinds of heat-meltable fine particles are mixed and used, or when one particle such as a core-shell type is composed of a plurality of components, one of them has a glass transition temperature of 50 ° C. It may be above.

また本発明の平版印刷版の中間層には、さらに印刷地汚れ性を向上する目的で、ゼラチン、ポリビニルアルコール樹脂、ポリビニルピロリドン樹脂、カルボキシメチルセルロース樹脂等の親水性樹脂や酸化チタン、二酸化ケイ素、酸化アルミニウム等の無機物を含有させることができる。含有させる割合は、印刷に用いる印刷インキや湿し水等や印刷速度や印刷圧など各種条件により適宜所望の範囲で決められる。 In addition, the intermediate layer of the lithographic printing plate of the present invention has a hydrophilic resin such as gelatin, polyvinyl alcohol resin, polyvinyl pyrrolidone resin, carboxymethyl cellulose resin, titanium oxide, silicon dioxide, oxide for the purpose of further improving printing stain resistance. An inorganic substance such as aluminum can be contained. The ratio to be contained is appropriately determined in a desired range depending on various conditions such as printing ink, dampening water, printing speed, and printing pressure used for printing.

また本発明の平版印刷版の中間層には、視認性向上及びサーマルレーザによる感受性のために染料、顔料等の色材や塗布性改善のための各種界面活性剤、防腐剤を含有させることも出来る。 Further, the intermediate layer of the lithographic printing plate of the present invention may contain coloring materials such as dyes and pigments and various surfactants and preservatives for improving coating properties in order to improve visibility and sensitivity by a thermal laser. I can do it.

次に本発明に係わる平版印刷原版の親水性層について説明する。親水性層は、皮膜形成能を有する親水性ポリマーを主体としてなり、少なくとも最表層が親水性層となるように塗設される。この親水性層は複数あっても差し支えない。また親水性層を構成する親水性ポリマーの量としては0.5〜10g/m2の範囲であれば良い。 Next, the hydrophilic layer of the lithographic printing original plate according to the present invention will be described. The hydrophilic layer is mainly composed of a hydrophilic polymer having a film forming ability, and is coated so that at least the outermost layer is a hydrophilic layer. There may be a plurality of hydrophilic layers. And it may be in the range of 0.5 to 10 g / m 2 as the amount of the hydrophilic polymer constituting the hydrophilic layer.

このような親水性層を形成する親水性ポリマーとしては、以下の例が挙げられ、これらは地汚れ性や耐刷性など印刷性能を鑑みて2種以上混合して用いることができる。 Examples of the hydrophilic polymer that forms such a hydrophilic layer include the following examples, and these can be used in combination of two or more in view of printing performance such as soiling and printing durability.

天然物では、澱粉類、海藻マンナン、寒天およびアルギン酸ナトリウム等の藻類から得られるもの、マンナン、ペクチン、トラガントガム、カラヤガム、キサンチンガム、グアービンガム、ローカストビンガム、アラビアガム等の植物性粘質物、デキストラン、グルカン、キサンタンガム、およびレバンなどのホモ多糖類、サクシノグルカン、プルラン、カードラン、およびザンタンガムなどのヘテロ多糖等の微生物粘質物、にかわ、ゼラチン、カゼインおよびコラーゲン等のタンパク質、キチンおよびその誘導体等が挙げられる。 Natural products include starches, seaweed mannan, agar, and algae such as sodium alginate, mannan, pectin, tragacanth gum, karaya gum, xanthine gum, guarbin gum, locust bin gum, gum arabic, and other plant mucus, dextran, glucan , Such as homopolysaccharides such as xanthan gum and levan, microbial mucilage such as heteropolysaccharides such as succinoglucan, pullulan, curdlan and xanthan gum, glue, proteins such as gelatin, casein and collagen, chitin and its derivatives, etc. It is done.

また、半天然物(半合成物)類としては、セルロース誘導体、カルボキシメチルグアーガム等の変性ガム、並びにデキストリン等の培焼澱粉類、酸化澱粉類、エステル化澱粉類等の加工澱粉等が挙げられる。 Semi-natural products (semi-synthetic products) include cellulose derivatives, modified gums such as carboxymethyl guar gum, cultured starches such as dextrin, processed starches such as oxidized starches and esterified starches. .

合成品には、ポリビニルアルコール、部分アセタール化ポリビニルアルコール、アリル変性ポリビニルアルコール、ポリビニルメチルエーテル、ポリビニルエチルエーテル、ポリビニルイソブチルエーテル等の変性ポリビニルアルコール、ポリアクリル酸塩、ポリアクリル酸エステル部分けん化物、ポリメタクリル酸塩、及びポリアクリルアミド等のポリアクリル酸誘導体及びポリメタクリル酸誘導体、ポリエチレングリコール、ポリエチレンオキサイド、ポリビニルピロリドン、ビニルピロリドン/酢酸ビニル共重合物、カルボキシビニル重合物、スチレン/マレイン酸共重合物、スチレン/クロトン酸共重合物等が挙げられる。 Synthetic products include polyvinyl alcohol, partially acetalized polyvinyl alcohol, allyl-modified polyvinyl alcohol, modified polyvinyl alcohol such as polyvinyl methyl ether, polyvinyl ethyl ether, polyvinyl isobutyl ether, polyacrylate, polyacrylic ester partial saponified product, poly Methacrylates and polyacrylic acid derivatives and polymethacrylic acid derivatives such as polyacrylamide, polyethylene glycol, polyethylene oxide, polyvinylpyrrolidone, vinylpyrrolidone / vinyl acetate copolymer, carboxyvinyl polymer, styrene / maleic acid copolymer, Examples thereof include styrene / crotonic acid copolymers.

これらの中でも、特にゼラチン、変性及び無変性のポリビニルアルコール、及びセルロース誘導体が有利に使用できる。 Among these, gelatin, modified and non-modified polyvinyl alcohol, and cellulose derivatives can be advantageously used.

本発明の平版印刷版に係わる親水性層に用いるゼラチンとしては、動物のコラーゲンを原料としたゼラチンであれば全て使用できるが、豚皮、牛皮、及び牛骨から得られるコラーゲンを原料としたゼラチンが好ましい。また、ゼラチンの種類も特に制限はないが、石灰処理ゼラチン及び酸処理ゼラチンの他、特公昭38−4854号、同39−5514号、同40−12237号、及び同42−26345号公報、米国特許第2,525,753号、同第2,594,293号、同第2,614,928号、同第2,763,639号、同第3,118,766号、同第3,132,945号、同第3,186,846号、同第3,312,553号明細書、英国特許第1,033,189号明細書等に記載のゼラチン誘導体等が挙げられ、これらは1種または2種以上を組合わせて用いることができる。 As the gelatin used in the hydrophilic layer related to the lithographic printing plate of the present invention, any gelatin can be used as long as it is made from animal collagen, but gelatin made from collagen obtained from pig skin, cow skin, and cow bones. Is preferred. The type of gelatin is not particularly limited, but in addition to lime-processed gelatin and acid-processed gelatin, JP-B-38-4854, JP-A-39-5514, JP-A-40-12237, and JP-A-42-26345, US Patent No. 2,525,753, No. 2,594,293, No. 2,614,928, No. 2,763,639, No. 3,118,766, No. 3,132 No. 3,945, No. 3,186,846, No. 3,312,553, British Patent No. 1,033,189, and the like. Alternatively, two or more kinds can be used in combination.

ゼラチンを親水性層に用いる場合には、ゼラチン硬膜剤で硬化することができる。ゼラチン硬膜剤としては、例えば、クロム明ばんのような無機化合物、ホルマリン、グリオキサール、マレアルデヒド、グルタルアルデヒドのようなアルデヒド類、尿素やエチレン尿素等のN−メチラール化合物、ムコクロル酸、2,3−ジヒドロキシ−1,4−ジオキサンのようなアルデヒド類縁化合物、2,4−ジクロロ−6−ヒドロキシ−S−トリアジン塩や、2,4−ジヒドロキシ−6−クロロ−S−トリアジン塩のような活性ハロゲンを有する化合物、ジビニルスルホン、ジビニルケトンやN,N,N−トリアクリロイルヘキサヒドロトリアジン、活性な三員環であるエチレンイミノ基やエポキシ基を分子中に二個以上有する化合物類、高分子硬膜剤としてのジアルデヒド澱粉等の種々の化合物の1種もしくは2種以上を用いることができる。 When gelatin is used for the hydrophilic layer, it can be hardened with a gelatin hardener. Gelatin hardeners include, for example, inorganic compounds such as chromium alum, aldehydes such as formalin, glyoxal, malealdehyde, glutaraldehyde, N-methylal compounds such as urea and ethylene urea, mucochloric acid, 2, 3 Aldehyde-related compounds such as dihydroxy-1,4-dioxane, active halogens such as 2,4-dichloro-6-hydroxy-S-triazine salt and 2,4-dihydroxy-6-chloro-S-triazine salt , Divinyl sulfone, divinyl ketone, N, N, N-triacryloyl hexahydrotriazine, compounds having two or more active three-membered ethyleneimino groups and epoxy groups in the molecule, and polymer dura mater Use one or more of various compounds such as dialdehyde starch as an agent. Can.

また、特にアクリルアミドとビニルイミダゾールの共重合ポリマーは、皮膜強度と親水性のバランスに優れ、高い製版感度と対地汚れ性能のが得られるため好適に用いられる。親水性層における上記共重合ポリマーの含有量は300mg/m2以下が好ましく、より好ましくは2〜150mg/m2の範囲であり、分子量としては塗液安定性や塗布性を考えて、1万〜50万、より好ましくは5万〜30万の範囲のものである。 In particular, a copolymer of acrylamide and vinylimidazole is preferably used because it has an excellent balance between film strength and hydrophilicity, and can provide high plate-making sensitivity and soil resistance. The content of the copolymer polymer in the hydrophilic layer is preferably 300 mg / m 2 or less, more preferably in the range of 2 to 150 mg / m 2 , and the molecular weight is 10,000 in consideration of coating solution stability and coatability. ˜500,000, more preferably in the range of 50,000 to 300,000.

本発明に係わる平版印刷版の親水性層には、印刷地汚れ性を防止する目的で酸化チタン、二酸化ケイ素、酸化アルミニウム等の無機物を含有させることができる。含有させる割合は、印刷に用いる印刷インキや湿し水等や印刷速度や印刷圧など各種条件により適宜所望の範囲で決められる。 The hydrophilic layer of the lithographic printing plate according to the present invention may contain an inorganic substance such as titanium oxide, silicon dioxide, aluminum oxide or the like for the purpose of preventing printing stains. The ratio to be contained is appropriately determined in a desired range depending on various conditions such as printing ink, dampening water, printing speed, and printing pressure used for printing.

また、本発明に係わる平版印刷原版の親水性層を塗設するために、助剤としてアニオン系、カチオン系もしくはノニオン系界面活性剤のいくつかを用いても良いし、マット剤、増粘剤、帯電防止剤等を用いることも出来る。またサーマルレーザに対する感受性のために染料及び顔料を含有させることも出来る。 In order to coat the hydrophilic layer of the lithographic printing plate precursor according to the present invention, an anionic, cationic or nonionic surfactant may be used as an auxiliary agent, a matting agent, a thickening agent. An antistatic agent or the like can also be used. Dyes and pigments can also be included for sensitivity to thermal lasers.

本発明の平版印刷版に係わる支持体について説明する。支持体としては、樹脂被覆紙、合成紙、ポリエチレンテレフタレートなどの合成もしくは半合成高分子フィルム、アルミニウムや鉄等の金属板で、オフセット印刷に耐えるものであれば良い。また、これらの支持体の表面は、上層として塗設される層との接着を良くするために表面処理を行うことや、レーザ光吸収性を向上させるため染色処理をすることも可能である。 The support relating to the lithographic printing plate of the present invention will be described. The support may be a resin-coated paper, synthetic paper, a synthetic or semi-synthetic polymer film such as polyethylene terephthalate, or a metal plate such as aluminum or iron that can withstand offset printing. In addition, the surface of these supports can be subjected to a surface treatment for improving adhesion with a layer to be coated as an upper layer, or can be subjected to a dyeing treatment to improve laser light absorption.

以下、本発明を実施例にて詳細に説明する。

135g/m2の両面ポリエチレン被覆紙(RC紙)の片面に平均粒子サイズ5μmの二酸化ケイ素粒子を含有するマット化層を設け、反対側の面に下記成分からなる中間層、親水性層を順に塗設した。

〔中間層〕

1)カーボンブラック 2質量部

2)平均粒径7μmの二酸化ケイ素粒子 2質量部

3)水性エマルション:アクリル酸ブチル、メタクリル酸メチル、アクリル酸、γ−メタクリロキシプロピルトリメトキシシランを原料として乳化重合を行い得られた粒径0.5μmのポリマー微粒子に粒子径10nmのコロイダルシリカを加えて得られたもの。 90質量部

4)ゼラチン 6質量部

以上に水を加えて塗液を作成し、固形分塗布量が3g/m2となるように塗布、乾燥させた。

〔親水性層〕

N−ビニルイミダゾールとアクリルアミドの共重合体(重合比は2:98)を20mg/m2となるように塗布、乾燥させた。

Hereinafter, the present invention will be described in detail with reference to examples.

A matted layer containing silicon dioxide particles having an average particle size of 5 μm is provided on one side of a 135 g / m 2 double-sided polyethylene-coated paper (RC paper), and an intermediate layer and a hydrophilic layer comprising the following components are arranged in this order on the opposite side. Painted.

[Middle layer]

1)

[Hydrophilic layer]

A copolymer of N-vinylimidazole and acrylamide (with a polymerization ratio of 2:98) was applied and dried at 20 mg / m 2 .

次いで、半導体レーザ照射装置(830nm)で画像部に相当する部分のレーザ照射を上記平版印刷版(親水性層を最表層とする面)に行い、印刷版を得た。この印刷版を用いて、オフセット印刷機(リョービイマジクス(株)製 3200MCD)にて紫色インキ(大日本インキ化学工業(株)製 ニューチャンピオンFグロス紫)を用いて印刷を行ったところ、印刷の初段階から画像部には良好にインキが着肉しており、3千枚まで非画像部汚れ等が生じない良好な印刷物を得ることができた。 Next, laser irradiation of a portion corresponding to an image portion was performed on the lithographic printing plate (surface having a hydrophilic layer as the outermost layer) with a semiconductor laser irradiation apparatus (830 nm) to obtain a printing plate. Using this printing plate, printing was performed using purple ink (New Champion F gloss purple, manufactured by Dainippon Ink & Chemicals, Inc.) on an offset printing machine (3200MCD manufactured by Ryobi Imagics Co., Ltd.). From the initial stage, the ink was satisfactorily applied to the image area, and up to 3,000 sheets, a good printed matter with no non-image area smearing could be obtained.

また、市販の感熱プリンタを用いて上記の平版印刷版を印字し、同様に印刷したところ、印刷の初段階から画像部には良好にインキが着肉しており、3千枚まで非画像部汚れ等が生じなく、画像部も安定したインキ乗りが確保された良好な印刷物を得ることができた。 In addition, when the above lithographic printing plate was printed using a commercially available thermal printer and printed in the same manner, the ink was satisfactorily adhered to the image area from the initial stage of printing, and up to 3,000 non-image areas were printed. It was possible to obtain a good printed matter in which no smearing or the like occurred and a stable ink transfer was ensured in the image area.

実施例1の中間層に、更にスチレン微粒子エマルション(ガラス転移温度100℃)を20質量部加えた他は、実施例1と同様に実施したところ、印刷の初段階から画像部には良好にインキが着肉しており、8千枚まで非画像部汚れ等が生じなく、画像部も安定したインキ乗りが確保された良好な印刷物を得ることができた。 The same procedure as in Example 1 was conducted except that 20 parts by mass of a styrene fine particle emulsion (glass transition temperature 100 ° C.) was further added to the intermediate layer of Example 1. As a result, the non-image area was not stained up to 8,000 sheets, and a good printed matter in which the image area was secured with a stable ink transfer could be obtained.

〔比較例1〕

実施例1の中間層の成分の内、3)をスチレン微粒子エマルション(ガラス転移温度100℃)に全て置き換えた以外は、実施例1と同様に実施したところ、印刷の初段階から画像部には良好にインキが着肉していたが、非画像部汚れが300枚程度から生じ始め、良好な印刷物を得ることができなかった。

[Comparative Example 1]

The same procedure as in Example 1 was performed except that 3) of the intermediate layer components in Example 1 were all replaced with a styrene fine particle emulsion (glass transition temperature 100 ° C.). Although the ink was satisfactorily satisfactorily, the non-image area stain started to occur from about 300 sheets, and a good printed matter could not be obtained.

〔比較例2〕

実施例1の中間層成分の内、3)をスチレン微粒子エマルション(ガラス転移温度100℃)に全量置き換え、さらにコロイダルシリカ(日産化学工業(株)製 スノーテックスC)を10質量部加えた他は実施例1と同様に実施した。印刷の初段階から画像部には良好にインキが着肉していたが、非画像部汚れが500枚程度から生じ始め、良好な印刷物を得ることができなかった。

[Comparative Example 2]

Of the intermediate layer components of Example 1, 3) was replaced with a styrene fine particle emulsion (glass transition temperature 100 ° C.) in total amount, and 10 parts by mass of colloidal silica (Snowtex C manufactured by Nissan Chemical Industries, Ltd.) was added. The same operation as in Example 1 was performed. Although the ink was satisfactorily deposited on the image area from the initial stage of printing, the non-image area contamination started to occur from about 500 sheets, and a good printed matter could not be obtained.

1 支持体

11 紙ベース

12 樹脂

3 中間層

4 親水性層

DESCRIPTION OF

Claims (2)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005017850A JP2006205423A (en) | 2005-01-26 | 2005-01-26 | Thermal direct drawing-type lithographic printing plate |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005017850A JP2006205423A (en) | 2005-01-26 | 2005-01-26 | Thermal direct drawing-type lithographic printing plate |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2006205423A true JP2006205423A (en) | 2006-08-10 |

| JP2006205423A5 JP2006205423A5 (en) | 2007-11-08 |

Family

ID=36962775

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2005017850A Pending JP2006205423A (en) | 2005-01-26 | 2005-01-26 | Thermal direct drawing-type lithographic printing plate |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2006205423A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101012277B1 (en) | 2008-11-19 | 2011-02-07 | 미쓰비시 세이시 가부시키가이샤 | Lithographic surface processing solution for heat-sensitive lithographic printing plate and printing method of heat-sensitive lithographic printing plate |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH11301130A (en) * | 1998-04-22 | 1999-11-02 | Konica Corp | Material for lithographic printing plate and method for engraving lithographic printing plate |

| JP2000190649A (en) * | 1998-12-28 | 2000-07-11 | Konica Corp | Heat sensitive lithographic printing plate and manufacture thereof |

| JP2001138652A (en) * | 1999-09-03 | 2001-05-22 | Konica Corp | Lithographic printing original plate and printing method using same |

| JP2001315453A (en) * | 2000-05-10 | 2001-11-13 | Fuji Photo Film Co Ltd | Lithographic printing original film |

-

2005

- 2005-01-26 JP JP2005017850A patent/JP2006205423A/en active Pending

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH11301130A (en) * | 1998-04-22 | 1999-11-02 | Konica Corp | Material for lithographic printing plate and method for engraving lithographic printing plate |

| JP2000190649A (en) * | 1998-12-28 | 2000-07-11 | Konica Corp | Heat sensitive lithographic printing plate and manufacture thereof |

| JP2001138652A (en) * | 1999-09-03 | 2001-05-22 | Konica Corp | Lithographic printing original plate and printing method using same |

| JP2001315453A (en) * | 2000-05-10 | 2001-11-13 | Fuji Photo Film Co Ltd | Lithographic printing original film |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101012277B1 (en) | 2008-11-19 | 2011-02-07 | 미쓰비시 세이시 가부시키가이샤 | Lithographic surface processing solution for heat-sensitive lithographic printing plate and printing method of heat-sensitive lithographic printing plate |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN101272914A (en) | Method for making a lithographic printing plate | |

| JP2001519262A (en) | Improved lithographic printing plate with light-to-heat conversion material | |

| US6165691A (en) | Method for lithographic printing by use of a lithographic printing plate provided by a heat sensitive non-ablatable wasteless imaging element and a fountain containing water-insoluble compounds | |

| CN104730865A (en) | Negative image treatment-free lithograph plate | |

| JPH09141819A (en) | Manufacture of lithographic printing plate by heating in accordance with image of image forming element using thermalhead | |

| JPH10180976A (en) | Plate-making method for planographic printing plate | |

| EP0924102B1 (en) | A method for lithographic printing by use of a lithographic printing plate provided by a heat sensitive non-ablatable wasteless imaging element and a fountain containing water-insoluble compounds | |

| ZA200304580B (en) | Thermally convertible lithographic printing precursor. | |

| ZA200304581B (en) | Method for obtaining a lithographic printing surface. | |

| JP2006205423A (en) | Thermal direct drawing-type lithographic printing plate | |

| EP1442895B1 (en) | A method for preparation of a lithographic printing plate and a lithographic printing plate produced by said method | |

| JPH11338156A (en) | Method of making lithographic printing plate | |

| EP0924065B1 (en) | A heat sensitive non-ablatable wasteless imaging element for providing a lithographic printing plate | |

| JP3522450B2 (en) | Plate making method of lithographic printing plate | |

| JP4638265B2 (en) | Lithographic printing plate | |

| ZA200306215B (en) | Thermally convertible lithographic printing precursor and imageable medium with coalescence inhibitor. | |

| CN1494480A (en) | Ther mally convertible lithographic printing master and precursor comprising metal complex | |

| JP2006272942A (en) | Lithographic printing original plate | |

| JP2006281470A (en) | Original lithographic printing plate | |

| JPH10119230A (en) | Image forming method | |

| JP2003043674A (en) | Planographic printing original plate and method for making the same | |

| CN1494481A (en) | Thermally convertible lithographic printing precursor and master comprising organic acid | |

| KR101012277B1 (en) | Lithographic surface processing solution for heat-sensitive lithographic printing plate and printing method of heat-sensitive lithographic printing plate | |

| EP1409250A1 (en) | Thermally-convertible lithographic printing precursor and imageable medium with coalescence inhibitor | |

| JP2001514591A (en) | How to image a lithographic printing plate with a high intensity laser |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Effective date: 20070920 Free format text: JAPANESE INTERMEDIATE CODE: A523 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20070920 |

|

| A131 | Notification of reasons for refusal |

Effective date: 20100706 Free format text: JAPANESE INTERMEDIATE CODE: A131 |

|

| A521 | Written amendment |

Effective date: 20100902 Free format text: JAPANESE INTERMEDIATE CODE: A523 |

|

| A131 | Notification of reasons for refusal |

Effective date: 20101005 Free format text: JAPANESE INTERMEDIATE CODE: A131 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20101203 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20110118 |