この発明は、例えば、電気掃除機、換気扇等、各種家庭用電気製品に組み込む電動モータ、或いは各種自動車用補機等の回転支持部に組み込むラジアル玉軸受の様に、あまり高度の回転精度を要求されないラジアル玉軸受を構成する軌道輪とその製造方法の改良に関する。

This invention requires a high degree of rotational accuracy, such as an electric motor incorporated in various household electric appliances such as a vacuum cleaner and a ventilation fan, or a radial ball bearing incorporated in a rotation support portion of various auxiliary equipment for automobiles. TECHNICAL FIELD The present invention relates to an improvement in a bearing ring that constitutes a radial ball bearing that is not used and a manufacturing method thereof.

各種回転機器の回転支持部に、図25に示す様なラジアル玉軸受1が組み込まれている。このラジアル玉軸受1は、深溝型であって、互いに同心に配置された外輪2と内輪3との間に複数個の玉4、4を設置して成る。このうちの外輪2の内周面の軸方向中間部に深溝型の外輪軌道5を、内輪3の外周面の軸方向中間部に深溝型の内輪軌道6を、それぞれ全周に亙って形成している。上記各玉4、4は、保持器7により保持された状態で、上記外輪軌道5と上記内輪軌道6との間に転動自在に配置している。そして、この構成により、上記外輪2と上記内輪3との相対回転を自在としている。尚、図25に示した例では、上記保持器7として、金属製の波形保持器を使用しているが、合成樹脂製の冠型保持器を使用する場合も多い。又、上記外輪2の両端部内周面に形成した係止溝に、それぞれ密封板(接触型のシール板及び非接触型のシールド板を含む。本明細書全体で同じ。)の外周縁を係止する構造を採用する場合も多い。この場合に上記両密封板の内周縁は、上記内輪3の両端部外周面に、全周に亙って摺接若しくは近接対向させる。

A radial ball bearing 1 as shown in FIG. 25 is incorporated in a rotation support portion of various rotating devices. This radial ball bearing 1 is a deep groove type, and is formed by installing a plurality of balls 4, 4 between an outer ring 2 and an inner ring 3 that are arranged concentrically with each other. Of these, a deep groove type outer ring raceway 5 is formed on the axially intermediate portion of the inner peripheral surface of the outer ring 2, and a deep groove type inner ring raceway 6 is formed on the entire outer periphery of the inner ring 3. is doing. The balls 4 and 4 are arranged so as to be able to roll between the outer ring raceway 5 and the inner ring raceway 6 while being held by a cage 7. With this configuration, the outer ring 2 and the inner ring 3 can freely rotate relative to each other. In the example shown in FIG. 25, a metal corrugated cage is used as the cage 7, but a synthetic resin crown-shaped cage is often used. Further, the outer peripheral edge of each sealing plate (including a contact-type seal plate and a non-contact-type shield plate; the same applies throughout the present specification) is engaged with the engaging grooves formed on the inner peripheral surfaces of both ends of the outer ring 2. In many cases, a structure that stops is used. In this case, the inner peripheral edges of the both sealing plates are slidably contacted or closely opposed to the outer peripheral surfaces of both end portions of the inner ring 3 over the entire periphery.

上述の様なラジアル玉軸受1を構成する、上記外輪2や上記内輪3等の軌道輪を造るのに従来一般的には、先ず、鍛造加工と切削加工とにより完成品に近い形状及び寸法を有する中間素材を得ていた。そして、この中間素材に、表面を硬化させる為の熱処理を施してから、上記外輪軌道5や上記内輪軌道6等の軌道面を含む表面に、寸法及び表面粗さを所定のものにする為の研磨を施して、上記軌道輪としていた。この様な内輪の製造方法は、材料の歩留が悪くなる他、面倒で、コストが嵩む。

Conventionally, in order to construct the races such as the outer ring 2 and the inner ring 3 constituting the radial ball bearing 1 as described above, generally, first, the shape and dimensions close to the finished product are obtained by forging and cutting. Had an intermediate material to have. The intermediate material is subjected to a heat treatment for curing the surface, and then the surface and the surface including the raceway surface such as the outer ring raceway 5 and the inner ring raceway 6 are made to have predetermined dimensions and surface roughness. Polishing was performed to obtain the above-described race. Such an inner ring manufacturing method is not only troublesome in material yield, but also cumbersome and costly.

又、特許文献1、2には、ラジアル玉軸受の軌道輪を、鍛造加工を中心として造る方法が記載されている。

先ず、特許文献1に記載された発明の場合には、外輪を造る為の中間素材と内輪を造る為の中間素材とを一体とした複合中間素材を鍛造により造った後、この複合中間素材を外輪を造る為の外輪用中間素材と内輪を造る為の内輪用中間素材とに分割する発明が記載されている。又、この特許文献1に記載された発明の場合には、内輪を造る為の内輪用中間素材の一部の直径を押し拡げる事で、外周面に深溝型の内輪軌道を有する内輪を得る様にしている。

次に、特許文献2には、熱間押し出しにより造った鋼管を切断して成るリング状の素材を、縦型プレスにより冷間で軸方向に圧縮(据え込み加工)して、内周面に深溝型の外輪軌道を有する外輪用中間素材を造る方法に関する発明が記載されている。

Patent Documents 1 and 2 describe a method of making a raceway ring of a radial ball bearing centering on forging.

First, in the case of the invention described in Patent Document 1, a composite intermediate material in which an intermediate material for making an outer ring and an intermediate material for making an inner ring are integrated by forging, then the composite intermediate material is An invention is described in which an outer ring intermediate material for making an outer ring and an inner ring intermediate material for making an inner ring are divided. In the case of the invention described in Patent Document 1, an inner ring having a deep groove type inner ring raceway on the outer peripheral surface is obtained by expanding the diameter of a part of the intermediate material for the inner ring for making the inner ring. I have to.

Next, Patent Document 2 discloses that a ring-shaped material formed by cutting a steel pipe made by hot extrusion is axially cold-compressed (upsetting) by a vertical press to form an inner peripheral surface. An invention relating to a method for producing an intermediate material for an outer ring having a deep groove type outer ring raceway is described.

上述の様な特許文献1、2に記載されている発明のうち、特許文献1に記載されている発明の場合には、加工の初期段階で容積の大きな複合中間素材を鍛造により造る。この為、この複合中間素材を造る際の加工荷重及び鍛造装置のパンチや受型等を含む金型に加わる応力が高くなり、この金型を含む鍛造装置各部の弾性変形量が大きくなる。この結果、得られた複合中間素材並びにこの複合中間素材から造られる外輪及び内輪を造る為の中間素材、更にはこれら外輪及び内輪の、寸法精度及び形状精度を十分に良好にする事が難しい。特に、容積の大きな上記複合中間素材を造る加工を冷間鍛造により行なうと、上記金型等に加わる負荷が過大になり、この金型等の耐久性を確保する事が難しくなる。従って、上記複合中間素材の加工は、熱間鍛造或は温間鍛造で造る事になるが、熱間鍛造或は温間鍛造の場合には、温度膨張量の差に拘らず金型同士の嵌合を確実に行なわせるべく、嵌合部の隙間を冷間鍛造の場合に比べて大きめに設定しなければならない。この為、得られた複合中間素材の内外径の寸法並びに内外両周面同士の、同心度を中心とする形状・寸法精度を十分に確保する事が難しくなる。この結果、得られた外輪及び内輪の内外径の寸法精度及び振れ精度を、前述した様な、あまり高度の回転精度を要求しない用途に使用するにしても、十分に確保する事が難しくなる。又、外輪の内周面両端部に密封板の外周縁を係止する為の係止溝を塑性加工により形成する事はできず、この係止溝の加工は切削加工による事になる為、十分な製造コストの低減を図れない。

Among the inventions described in Patent Documents 1 and 2 as described above, in the case of the invention described in Patent Document 1, a composite intermediate material having a large volume is produced by forging at the initial stage of processing. For this reason, the processing load at the time of manufacturing this composite intermediate material and the stress applied to the die including the punch and receiving die of the forging device are increased, and the amount of elastic deformation of each part of the forging device including this die is increased. As a result, it is difficult to sufficiently improve the dimensional accuracy and shape accuracy of the obtained composite intermediate material, the intermediate material for manufacturing the outer ring and the inner ring made from the composite intermediate material, and further the outer ring and the inner ring. In particular, when the process of producing the composite intermediate material having a large volume is performed by cold forging, the load applied to the mold or the like becomes excessive, and it becomes difficult to ensure the durability of the mold or the like. Therefore, the processing of the composite intermediate material is made by hot forging or warm forging. In the case of hot forging or warm forging, the molds can be connected to each other regardless of the difference in temperature expansion. In order to ensure the fitting, the gap between the fitting portions must be set larger than in the case of cold forging. For this reason, it becomes difficult to sufficiently secure the shape and dimensional accuracy centered on the concentricity between the inner and outer diameters of the obtained composite intermediate material and the inner and outer peripheral surfaces. As a result, it is difficult to sufficiently secure the dimensional accuracy and run-out accuracy of the inner and outer diameters of the outer ring and inner ring obtained in the above-described applications that do not require a high degree of rotational accuracy. In addition, the locking groove for locking the outer peripheral edge of the sealing plate at both ends of the inner peripheral surface of the outer ring cannot be formed by plastic processing, and the processing of this locking groove is due to cutting, The manufacturing cost cannot be reduced sufficiently.

又、特許文献2に記載された発明の場合には、リング状の素材を、熱間押し出しにより造った鋼管を切断する事により得ている為、この素材の内外径の寸法並びに内外両周面同士の同心度を中心とする形状・寸法精度を高度に確保する事が難しい。この結果、得られた外輪の内外径の寸法精度及び振れ精度を高度に確保する事が難しくなる。又、鋼管を切断して上記リング状の素材とする作業は面倒で、生産性が悪く、コスト上昇の原因となる。更には、外輪用中間素材に、脱炭による切削を施す必要もあり、この面からもコストが高くなる。

Moreover, in the case of the invention described in Patent Document 2, since the ring-shaped material is obtained by cutting a steel pipe made by hot extrusion, the inner and outer diameter dimensions and both inner and outer peripheral surfaces of this material are obtained. It is difficult to ensure a high degree of shape and dimensional accuracy centering on the concentricity between each other. As a result, it becomes difficult to ensure high dimensional accuracy and runout accuracy of the inner and outer diameters of the obtained outer ring. Also, the work of cutting the steel pipe to make the ring-shaped material is troublesome, the productivity is poor, and the cost increases. Furthermore, it is necessary to perform cutting by decarburization on the intermediate material for the outer ring, which also increases the cost.

又、特許文献3、4には、造るべき軌道輪よりも小径のリング状素材の周面をマンドレルで押圧する事により、このマンドレルの外周面形状を上記リング状素材の周面に転写しつつ、このリング状素材の直径を広げて、所望の直径を有する軌道輪とする、ラジアル玉軸受用軌道輪の製造方法に関する発明が記載されている。但し、この様な特許文献3、4に記載された従来方法の場合には、マンドレルを押し付けた状態での、上記リング状素材の挙動が安定せず、このマンドレルの外周面の形状をこのリング状素材の周面に正確に転写できない。又、得られた軌道輪の真円度を十分に確保する事も難しい。この為、やはり、前述した様な、あまり高度の回転精度を要求しない用途に使用するにしても、得られた軌道輪の寸法精度等を十分に確保する事が難しくなる。又、特許文献4に記載された発明の場合には、塑性加工後に材料の除去が必要になり、コスト低減効果が限られる。

Further, in Patent Documents 3 and 4, by pressing the peripheral surface of a ring-shaped material having a smaller diameter than the raceway to be manufactured with a mandrel, the outer peripheral surface shape of the mandrel is transferred to the peripheral surface of the ring-shaped material. In addition, an invention relating to a method for manufacturing a radial ball bearing raceway, in which the diameter of the ring-shaped material is expanded to obtain a raceway having a desired diameter, is described. However, in the case of the conventional methods described in Patent Documents 3 and 4, the behavior of the ring-shaped material in a state where the mandrel is pressed is not stable, and the shape of the outer peripheral surface of the mandrel is changed to the ring. Cannot be accurately transferred onto the surface of the material. It is also difficult to ensure sufficient roundness of the obtained race. For this reason, it is difficult to sufficiently secure the dimensional accuracy of the obtained bearing ring even if it is used for an application that does not require a very high rotational accuracy as described above. Further, in the case of the invention described in Patent Document 4, it is necessary to remove the material after plastic working, and the cost reduction effect is limited.

特開平5−277615号公報Japanese Patent Laid-Open No. 5-277615

特開2001−150082号公報Japanese Patent Laid-Open No. 2001-150082

特開昭59−212142号公報JP 59-212142 A

特開昭56−111533号公報JP-A-56-111533

本発明は、上述の様な事情に鑑みて、例えば、前述した様な用途に使用される、あまり高度の回転精度を要求されないラジアル玉軸受を構成する軌道輪である内輪や外輪を、実用上十分な精度を確保しつつ低コストで得られる、ラジアル玉軸受用軌道輪及びその製造方法を実現すべく発明したものである。

In view of the circumstances as described above, the present invention is practically used as an inner ring and an outer ring, which are race rings that constitute a radial ball bearing that is used for the above-described applications and does not require a high degree of rotational accuracy. The present invention was invented to realize a radial ball bearing raceway ring and a manufacturing method thereof that can be obtained at low cost while ensuring sufficient accuracy.

本発明の対象となるラジアル玉軸受用軌道輪は、何れかの周面の軸方向中間部に断面円弧形の軌道面を全周に亙って形成している。

特に、請求項1に記載したラジアル玉軸受用軌道輪は、所定形状を有する中間素材に冷間で施されたローリング加工により加工されたものである。

上記中間素材は、完成品の容積と実質的に同じ容積を有する円筒状の素材を塑性変形させて成る。

そして、上記中間素材の外周面の形状は、例えば請求項2に記載した様に、最も外径が大きくなった部分から軸方向両端面に向け、この外径の変化方向が逆転せず、アンダカット部を持たない形状である。

更に、この様な請求項2に記載した発明の場合には、上記中間素材の内周面の形状は、最も内径が小さくなった部分から軸方向両端面に向け、この内径の変化方向が逆転せず、アンダカット部を持たない形状である。

The raceway ring for radial ball bearings that is the subject of the present invention has a raceway surface having an arc cross section in the middle of one of the peripheral surfaces in the axial direction.

In particular, the radial ball bearing raceway described in claim 1 is processed by a rolling process applied to an intermediate material having a predetermined shape.

The intermediate material is formed by plastically deforming a cylindrical material having substantially the same volume as the volume of the finished product.

And, as described in claim 2, for example, the shape of the outer peripheral surface of the intermediate material is such that the direction of change of the outer diameter is not reversed from the portion with the largest outer diameter toward both end surfaces in the axial direction, The shape does not have a cut part.

Further, in the case of the invention described in claim 2, the shape of the inner peripheral surface of the intermediate material is reversed from the portion having the smallest inner diameter toward both end surfaces in the axial direction, and the direction of change of the inner diameter is reversed. No shape with no undercut portion.

又、請求項3に記載したラジアル玉軸受用軌道輪の製造方法は、上述の請求項2に記載したラジアル玉軸受用軌道輪を造る為の製造方法であって、第一工程と、第二工程と、第三工程とを有する。

このうちの第一工程では、完成品の容積と実質的に同じ容積を有する円筒状の素材を軸方向に相対変位する1対の金型同士の間で押圧する、第一の冷間鍛造加工を施す。そして、この素材の軸方向片半部の直径を変化させて、軸方向中間部外周面に上記軌道面の一部となるべき断面円弧形の軌道面用曲面を形成する。これと共に、この軌道面用曲面を挟んで軸方向片半部を小径部とし、軸方向他半部を大径部として第一中間素材を得る。

又、上記第二工程では、この第一中間素材を、軸方向に相対変位する上記第一工程とは別の1対の金型同士の間で押圧する、第二の冷間鍛造を施す。そして、上記第一中間素材のうちで少なくとも上記軌道面を形成すべき部分の径方向に関する厚さ寸法の、軸方向に関する分布が、完成後の軌道輪の軌道面を形成した部分の分布と一致する第二中間素材を得る。

更に、上記第三工程では、上記第二中間素材を回転させながらこの第二中間素材の内周面と外周面とを互いに近づく方向に押圧するローリング加工により、この第二中間素材の一部を径方向に塑性変形させて上記軌道面を形成する。

尚、完成品の容積と実質的に同じ容積を有するとは、熱処理後に研磨等、材料の除去を伴う仕上加工を施す場合には、完成品の容積にこの仕上加工による取り代を加えた容積を言う。これに対して、上記材料の除去を伴う仕上加工を施さない場合には、不可避な製造誤差を除き、完成品の容積と同じ容積である事を言う。

又、上記素材は、その容積が上記完成品の容積と実質的に同じであるだけでなく、断面形状の縦横比(軸方向に関する長さ寸法と径方向に関する厚さ寸法との比)も、上記完成品の断面形状を造り出す為に最適な値にする事が好ましい。

A radial ball bearing raceway manufacturing method according to claim 3 is a manufacturing method for manufacturing the radial ball bearing raceway according to claim 2, wherein the first step and the second step A process and a third process.

Of these, in the first step, a first cold forging process is performed in which a cylindrical material having substantially the same volume as the finished product is pressed between a pair of dies that are relatively displaced in the axial direction. Apply. Then, the diameter of the half piece in the axial direction of the material is changed to form a curved surface for the raceway surface having a cross-sectional arc shape to be a part of the raceway surface on the outer peripheral surface in the axial direction. Along with this, a first intermediate material is obtained with the one half portion in the axial direction as the small diameter portion and the other half portion in the axial direction as the large diameter portion across the curved surface for the raceway surface.

In the second step, second cold forging is performed in which the first intermediate material is pressed between a pair of dies different from the first step in which the first intermediate material is displaced in the axial direction. And, the distribution in the axial direction of the thickness dimension in the radial direction of at least the portion where the raceway surface should be formed in the first intermediate material matches the distribution in the portion forming the raceway surface of the raceway ring after completion. To get a second intermediate material.

Further, in the third step, a part of the second intermediate material is partially rolled by a rolling process in which the inner peripheral surface and the outer peripheral surface of the second intermediate material are pressed toward each other while rotating the second intermediate material. The raceway surface is formed by plastic deformation in the radial direction.

It should be noted that the volume substantially the same as the volume of the finished product is a volume obtained by adding a machining allowance for the finished product to the volume of the finished product when finishing such as polishing after heat treatment is performed. Say. On the other hand, when the finishing process accompanied by the removal of the material is not performed, it means that the volume is the same as the volume of the finished product, excluding inevitable manufacturing errors.

In addition, the volume of the material is not only substantially the same as the volume of the finished product, but also the aspect ratio of the cross-sectional shape (the ratio of the length dimension in the axial direction to the thickness dimension in the radial direction) It is preferable to set the optimum value in order to create the sectional shape of the finished product.

更に、請求項5に記載した、ラジアル玉軸受用軌道輪の製造方法の発明の場合も、円筒状で、被加工側周面となる何れかの周面の軸方向中間部に、断面円弧形の軌道面を全周に亙って形成する。

特に、請求項5に記載したラジアル玉軸受用軌道輪の製造方法に於いては、完成品の容積と実質的に同じ容積を有し、上記軌道面を形成した面と反対側の周面である非加工側周面の直径を完成品の直径と実質的に同じとした円筒状の素材を、この非加工側周面を受部材に設けた支承側周面に実質的に(寸法誤差を除いて可能な限り)隙間なく嵌合する事によりこの受部材に支持する。

そして、上記被加工側周面に、完成品状態でのこの被加工側周面の母線形状と一致する母線形状を有する加工側回転部材の加工側周面を、上記素材の径方向に押圧しつつ、この加工側回転部材と上記受部材とを相対回転させる。

そして、この相対回転により、上記被加工側周面を、少なくとも上記軌道面を有する完成品としての形状に加工(加工側周面の形状を被加工側周面に転写)する。

Furthermore, in the case of the invention of the method for manufacturing a radial ball bearing raceway described in claim 5, a circular circular arc is formed at the axially intermediate portion of any one of the peripheral surfaces which are cylindrical and become the processed peripheral surface. A shaped raceway is formed over the entire circumference.

In particular, in the method for manufacturing a radial ball bearing raceway ring according to claim 5, it has a volume substantially the same as the volume of the finished product, and the circumferential surface on the side opposite to the surface on which the raceway surface is formed. A cylindrical material having a diameter of a non-processed side peripheral surface substantially the same as the diameter of the finished product is substantially equal to the support-side peripheral surface provided on the receiving member. It is supported by this receiving member by fitting without gaps (as much as possible).

Then, the processing side peripheral surface of the processing side rotating member having a bus bar shape that matches the bus bar shape of the processing side peripheral surface in a finished product state is pressed against the processing side peripheral surface in the radial direction of the material. Meanwhile, the processing-side rotating member and the receiving member are relatively rotated.

And by this relative rotation, the said process side peripheral surface is processed into the shape as a finished product which has at least the said track surface (the shape of the process side peripheral surface is transcribe | transferred to a process side peripheral surface).

上述の様に構成する本発明のラジアル玉軸受用軌道輪及びその製造方法によれば、例えば、前述した様な用途に使用される。あまり高度の回転精度を要求されないラジアル玉軸受を構成する軌道輪を、実用上十分な精度を確保しつつ、低コストで得られる。

即ち、造るべき軌道輪の容積に(材料の除去を伴う仕上加工を施す場合にはその取り代を勘案した状態で)一致させた容積を有する円筒状の素材(高精度素材)を冷間加工により塑性変形させて上記軌道輪とする為、この軌道輪の形状精度並びに寸法精度を高度に確保できる。

尚、加工精度を向上させる事で、前述した様な用途に比べて高精度を要求される玉軸受用の軌道輪に対する本発明の適用が可能である事は当然である。

The radial ball bearing raceway and the manufacturing method thereof according to the present invention configured as described above are used, for example, in the above-described applications. A bearing ring constituting a radial ball bearing that does not require a very high degree of rotational accuracy can be obtained at low cost while ensuring sufficient accuracy in practice.

That is, cold-working a cylindrical material (high-precision material) with a volume that matches the volume of the raceway to be manufactured (in the state where the machining allowance is accompanied by removal of the material). Therefore, the shape accuracy and dimensional accuracy of this race ring can be secured to a high degree.

Of course, by improving the processing accuracy, the present invention can naturally be applied to a bearing ring for a ball bearing that requires higher accuracy than the above-described applications.

請求項3に記載した発明を実施する場合に好ましくは、請求項4に記載した様に、軌道輪が、軌道面を形成した周面の軸方向両端部に密封板の周縁部を係止する為の係止溝を設けたものとする。そして、第一工程の前に、素材の軸方向両端部に軸方向中間部よりも径方向に凹んだ段差部を形成して予備中間素材とする予備工程を備え、第三工程でこの段差部に上記係止溝を形成する。

この様に構成すれば、密封板の周縁部を形成する為の係止溝を備えた軌道輪に関しても、低コストで造る事ができる。

Preferably, when the invention described in claim 3 is carried out, as described in claim 4, the bearing ring locks the peripheral edge portion of the sealing plate at both axial end portions of the peripheral surface forming the raceway surface. It is assumed that a locking groove is provided. Before the first step, a preliminary step is provided to form a preliminary intermediate material by forming step portions that are recessed in the radial direction from the axial intermediate portion at both axial end portions of the material. The above-mentioned locking groove is formed.

If comprised in this way, it can manufacture at low cost also about the bearing ring provided with the locking groove for forming the peripheral part of a sealing board.

又、請求項5に記載した発明を実施する場合に好ましくは、請求項6に記載した様に、完成品である軌道輪の被加工側周面の軸方向両端部に、この被加工側周面の軸方向中央寄り部分よりも径方向に凹んだ段部を全周に亙って形成する為、素材の被加工側周面の軸方向両端部に段差部を形成しておく。そして、これら両段差部を上記両段部に、この被加工側周面への加工側回転部材の押し付けに伴って、軌道面と同時に加工する。

この様な構成を採用すれば、シールリングを設置する為に必要となる、上記両段部を、容易に、しかも精度良く加工できる。

Further, when the invention described in claim 5 is carried out, preferably, as described in claim 6, this processed side periphery is provided at both ends in the axial direction of the processed side peripheral surface of the finished race. In order to form a step portion that is recessed in the radial direction from the axially central portion of the surface over the entire circumference, step portions are formed at both end portions in the axial direction of the processed peripheral surface of the material. Then, both the step portions are processed simultaneously with the raceway surface in accordance with the pressing of the processing side rotating member to the processing side peripheral surface.

If such a structure is employ | adopted, the said both step part required in order to install a seal ring can be processed easily and with sufficient precision.

又、上述の様な請求項6に記載した発明を実施する場合に好ましくは、請求項7に記載した様に、上記素材の被加工側周面の軸方向両端部に設けた両段差部と軸方向中央寄り部分との間に存在する段差面を、径方向に関して非加工側周面から離れるに従って互いに近付く方向に傾斜した傾斜面とする。そして、上記素材の中心軸に対し直交する方向に存在する仮想平面に対する、上記両段差面の傾斜角度を、完成後の軌道輪の対応する部分に存在する段差面の傾斜角度よりも、15度以下の範囲内で大きくしている。

これら両段差面をこの様に傾斜させれば、上記加工側回転部材に加わる力を低く抑えて、この加工側回転部材の耐久性並びに加工精度の向上を図れる。

Further, when carrying out the invention described in claim 6 as described above, preferably, as described in claim 7, both stepped portions provided at both end portions in the axial direction of the processed peripheral surface of the material, The step surface existing between the axially central portion is an inclined surface that is inclined in a direction approaching each other with increasing distance from the non-processed peripheral surface with respect to the radial direction. Then, the inclination angle of the two step surfaces with respect to a virtual plane existing in a direction orthogonal to the central axis of the material is 15 degrees from the inclination angle of the step surface existing in the corresponding part of the completed raceway ring. Increased within the following range.

If these two step surfaces are inclined in this manner, the force applied to the processing side rotating member can be kept low, and the durability and processing accuracy of the processing side rotating member can be improved.

更に、請求項5〜7に記載した発明を実施する場合に好ましくは、請求項8に記載した様に、軌道輪を造る為の素材の軸方向両端面を、非加工側周面から離れるに従って互いに近付く方向に傾斜した傾斜面とする。そして、上記素材の中心軸に対し直交する方向に存在する仮想平面に対する上記軸方向両端面の傾斜角度を、20度以下とする。

これら軸方向両端面をこの様に傾斜させる事によっても、上記加工側回転部材に加わる力を低く抑えて、この加工側回転部材の耐久性並びに加工精度の向上を図れる。

Further, when the inventions described in claims 5 to 7 are carried out, preferably, as described in claim 8, the axially opposite end surfaces of the material for making the race are separated from the non-processed side peripheral surface. The inclined surfaces are inclined in a direction approaching each other. And the inclination angle of the said axial direction both end surface with respect to the virtual plane which exists in the direction orthogonal to the central axis of the said raw material shall be 20 degrees or less.

By inclining these axial end faces in this way, the force applied to the processing-side rotating member can be kept low, and the durability and processing accuracy of the processing-side rotating member can be improved.

図1〜5は、請求項1〜4に対応する、本発明の実施例1として、本発明を外輪2a{図1の(E)参照}の製造に適用した場合に就いて示している。本実施例の特徴は、予め外輪2aの容積と実質的に同じ容積を有する円筒状の高精度素材8{図1の(A)参照}を造った後、冷間加工によりこの高精度素材8を塑性変形させて、上記外輪2aとする点にある。この高精度素材8を造る方法に就いては、特に限定しないが、材料の歩留を良好にしてコスト低減を図る面から、長尺な線材(コイル)を所定長さに切断してこれに冷間で塑性加工を施して造る事が好ましい。或は、板材を円輪状に打ち抜いてこの断面形状を90度捩る事により、上記高精度素材8とする事もできる。更には、金属板を円管状に巻いて突き合わせ部を溶接したものに旋削加工を施して容積を整えたものも、使用可能である。高精度素材8を何れの方法により造った場合でも、この高精度素材8を次の様な工程で冷間加工により塑性変形させ、上記外輪2aとする。

FIGS. 1 to 5 show the case where the present invention is applied to the manufacture of the outer ring 2a {see FIG. 1 (E)} as Embodiment 1 of the present invention corresponding to claims 1 to 4. The feature of the present embodiment is that a high-precision cylindrical material 8 {see FIG. 1A} having a volume substantially the same as the volume of the outer ring 2a is made in advance, and then this high-precision material 8 is cold-worked. Is plastically deformed to form the outer ring 2a. Although there is no particular limitation on the method for producing the high-accuracy material 8, a long wire (coil) is cut into a predetermined length from the viewpoint of improving the material yield and reducing the cost. It is preferable to produce by cold plastic working. Alternatively, the high-precision material 8 can be obtained by punching a plate material into a ring shape and twisting the cross-sectional shape by 90 degrees. Furthermore, it is also possible to use a metal plate wound in a circular tube shape and welded at a butt portion so that the volume is adjusted by turning. Even if the high-precision material 8 is made by any method, the high-precision material 8 is plastically deformed by cold working in the following steps to obtain the outer ring 2a.

本実施例の場合には、図1の(A)に示した上記高精度素材8を、(B)に示した予備中間素材9、(C)に示した第一中間素材10、(D)に示した第二中間素材11を経て、(E)に示した外輪2aとする。これら予備中間素材9、第一中間素材10、第二中間素材11は何れも、外周面の形状は、最も外径が大きくなった部分から軸方向両端面に向け、この外径の変化方向が逆転せず、アンダカット部を持たない形状である。又、内周面の形状は、最も内径が小さくなった部分から軸方向両端面に向け、この内径の変化方向が逆転せず、アンダカット部を持たない形状である。従って、上記各中間素材9〜11は何れも、軸方向に相対変位する金型同士の間で強く押圧する事により、精度良く造れる。就いては、それぞれの工程に就いて、以下に順番に説明する。

In the case of the present embodiment, the high-precision material 8 shown in FIG. 1A is replaced with the preliminary intermediate material 9 shown in (B), the first intermediate material 10 shown in (C), and (D). After passing through the second intermediate material 11 shown in FIG. 4, the outer ring 2a shown in FIG. All of the preliminary intermediate material 9, the first intermediate material 10, and the second intermediate material 11 have an outer peripheral surface whose shape is changed from the portion having the largest outer diameter toward both end surfaces in the axial direction. The shape does not reverse and does not have an undercut. Further, the shape of the inner peripheral surface is such that the direction of change of the inner diameter is not reversed from the portion having the smallest inner diameter toward both end surfaces in the axial direction and does not have an undercut portion. Therefore, each of the intermediate materials 9 to 11 can be made with high accuracy by strongly pressing between molds relatively displaced in the axial direction. The process will be described below in order.

上記高精度素材8を上記予備中間素材9とするには、この高精度素材8の外周面を図示しない抑え型の内周面に内嵌し、同じく内周面を中子に外嵌した状態で、この高精度素材8の軸方向(図1の上下方向)両端面の内径側半部に、やはり図示しないパンチの先端面を、全周に亙って押し付ける。この結果、上記高精度素材8の軸方向両端面の内径側半部が軸方向に凹んで、当該部分に、径方向外方に凹んだ段差部12、12を有する、上記予備中間素材9を得られる。この際、これら両段差部12、12を形成する事に伴って径方向(図1の左右方向)外方に流動した肉は、上記軸方向両端部の外径側半部が軸方向に突出する事で吸収される。尚、この様にして造られる、上記予備中間素材9の外径は、造るべき外輪2aの外径と一致している。

In order to use the high-precision material 8 as the preliminary intermediate material 9, the outer peripheral surface of the high-precision material 8 is fitted into an inner circumferential surface of a holding die (not shown), and the inner circumferential surface is also fitted onto the core. Then, the tip end face of the punch (not shown) is pressed over the entire circumference to the inner diameter side halves of both end faces in the axial direction (vertical direction in FIG. 1) of the high-precision material 8. As a result, the preliminary intermediate material 9 having the stepped portions 12 and 12 recessed in the radially outward direction in the inner diameter side halves of the axially opposite end surfaces of the high-precision material 8 is recessed in the axial direction. can get. At this time, the meat that has flowed outward in the radial direction (left-right direction in FIG. 1) with the formation of these stepped portions 12 and 12 has the outer-diameter-side halves at both ends in the axial direction projecting in the axial direction. It is absorbed by doing. In addition, the outer diameter of the preliminary intermediate material 9 manufactured in this way matches the outer diameter of the outer ring 2a to be manufactured.

そこで、この予備中間素材9の一部{軸方向一端部(図1の上端部)を除く部分}の径を、一度上記外輪2aの外径よりも小さい外径にまで縮める、縮管加工を、上記予備中間素材9に施す。この縮管加工は、図2に示す様にして行なう。

先ず、(A)に示す様に、この予備中間素材9を、ダイ13に設けた加工孔14の大径部15に内嵌(セット)する。次いで、(B)に示す様に、パンチ16により上記予備中間素材9を、上記加工孔14の奥にまで押し込む。この加工孔14は、上記大径部15とこの大径部15よりも奥側に設けた小径部17とを滑らかな曲面部18により連続させて成る。又、この大径部15の内径は、上記外輪2aの外径と一致させている。従って、上記パンチ16により上記加工孔14の奥部に存在する上記小径部17に押し込まれた、上記予備中間素材9の一部の外径は、上記外輪2aの外径よりも小さくなるまで縮められて、前記第一中間素材10となる。

Therefore, the diameter of the part of the preliminary intermediate material 9 {the part excluding one end in the axial direction (the upper end in FIG. 1)} is once reduced to an outer diameter smaller than the outer diameter of the outer ring 2a. The preliminary intermediate material 9 is applied. This contraction processing is performed as shown in FIG.

First, as shown in (A), the preliminary intermediate material 9 is fitted (set) into the large diameter portion 15 of the processing hole 14 provided in the die 13. Next, as shown in (B), the preliminary intermediate material 9 is pushed into the processed hole 14 by the punch 16. The machining hole 14 is formed by connecting the large-diameter portion 15 and a small-diameter portion 17 provided on the back side of the large-diameter portion 15 with a smooth curved surface portion 18. Further, the inner diameter of the large diameter portion 15 is matched with the outer diameter of the outer ring 2a. Therefore, the outer diameter of a part of the preliminary intermediate material 9 pushed into the small diameter portion 17 existing in the inner part of the processing hole 14 by the punch 16 is reduced until it becomes smaller than the outer diameter of the outer ring 2a. As a result, the first intermediate material 10 is obtained.

この様な第一中間素材10の内周面の直径は、外輪軌道5{図1の(E)参照}の底部となるべき部分から、この内周面を形成すべき上記パンチ16の挿入側軸方向端面に向け、拡大する方向にのみ変化する。上記内周面の直径は、軸方向に変化しない部分はあっても、小さくなる方向に変化する部分はない。言い換えれば、上記パンチ16の挿入方向に見て、アンダーカットとなる部分は存在しない。従って、このパンチ16と上記ダイ13とによる上記第一中間素材10の加工を、精度良く行なえる。

The diameter of the inner peripheral surface of the first intermediate material 10 is such that the inner peripheral surface of the outer ring raceway 5 {see FIG. It changes only in the direction of enlargement toward the axial end face. The diameter of the inner peripheral surface has a portion that does not change in the axial direction, but does not have a portion that changes in the smaller direction. In other words, there is no undercut portion when viewed in the direction in which the punch 16 is inserted. Therefore, the processing of the first intermediate material 10 by the punch 16 and the die 13 can be performed with high accuracy.

尚、図示の例では、上記パンチ16の先端面の一部に凸曲面部19を形成する事により、上記第一中間素材10の内周面の一部に断面円弧状の凹曲面部20を、全周に亙って形成する様にしている。上記パンチ16がこの凹曲面部20を形成するのは、上記予備中間素材9を上記第一中間素材10とする加工の初期段階で行なわれる。従って、上述の様に予備中間素材9の一部の外径を縮めて第一中間素材10とすべく、上記外径を縮める作業の進行の過程で、加工応力は、上記初期段階を除き、前記曲面部18と上記予備中間素材9の外周面との当接部にのみ加わる。従って、上記加工孔14の曲面部18による、上記第一中間素材10の外周面の塑性加工は、精度良く行なえる。この部分の加工を精度良く行なう事は、得られる外輪軌道5{図1の(E)或いは図25参照}の精度を確保する面から重要である。この様にして造られた、この第一中間素材10は、ノックアウトリング21により上記加工孔14から押し出して、次の工程に送る。

In the illustrated example, a convex curved surface portion 19 is formed on a part of the front end surface of the punch 16 so that a concave curved surface portion 20 having an arcuate cross section is formed on a part of the inner peripheral surface of the first intermediate material 10. , It is formed over the entire circumference. The punch 16 forms the concave curved surface portion 20 at an initial stage of processing using the preliminary intermediate material 9 as the first intermediate material 10. Therefore, in the course of the operation of reducing the outer diameter in order to reduce the outer diameter of a part of the preliminary intermediate material 9 as described above to the first intermediate material 10, the processing stress is excluding the initial stage, Only the contact portion between the curved surface portion 18 and the outer peripheral surface of the preliminary intermediate material 9 is added. Therefore, the plastic processing of the outer peripheral surface of the first intermediate material 10 by the curved surface portion 18 of the processing hole 14 can be performed with high accuracy. It is important to accurately process this portion from the standpoint of ensuring the accuracy of the outer ring raceway 5 obtained (see FIG. 1E or FIG. 25). The first intermediate material 10 made in this way is pushed out of the processed hole 14 by the knockout ring 21 and sent to the next step.

この次の工程では、上記第一中間素材10の内周面に、外輪軌道5の軸方向片半部(図1の下半部)の元となるべき部分を形成する為の、内径押出加工を施す。この内径押出加工は、図3に示す様にして行なう。

先ず、(A)に示す様に、上記第一中間素材10を、ダイ22に設けた加工孔23に内嵌すると共に、この第一中間素材10の軸方向一端面(図3の下端面)を、この加工孔23内に挿入したカウンターリング24の先端面(図3の上端面)に突き当てる(セットする)。この状態で、上記第一中間素材10の外周面は上記加工孔23の内周面に、同じく軸方向一端面は上記カウンターリング24の先端面に、それぞれ隙間なく当接する。又、このカウンターリング24と上記ダイ22との軸方向(図3の上下方向)に関する位置関係は、厳密に規制されている。

In this next step, an inner diameter extrusion process for forming a portion to be the origin of the axial half piece (the lower half portion in FIG. 1) of the outer ring raceway 5 on the inner peripheral surface of the first intermediate material 10. Apply. This inner diameter extrusion is performed as shown in FIG.

First, as shown in FIG. 3A, the first intermediate material 10 is fitted into a machining hole 23 provided in the die 22 and one end surface in the axial direction of the first intermediate material 10 (lower end surface in FIG. 3). Is abutted against (set to) the front end surface (the upper end surface in FIG. 3) of the counter ring 24 inserted into the processing hole 23. In this state, the outer peripheral surface of the first intermediate material 10 is in contact with the inner peripheral surface of the processing hole 23 and the one end surface in the axial direction is in contact with the front end surface of the counter ring 24 without any gap. The positional relationship between the counter ring 24 and the die 22 in the axial direction (vertical direction in FIG. 3) is strictly regulated.

上記第一中間素材10を上述の様にセットしたならば、次いで、(B)に示す様に、パンチ25により上記第一中間素材10の内周面を扱く。このパンチ25の先端部は、上記カウンターリング24内に隙間なく挿入した状態で(同心度を厳密に規制した状態で)このカウンターリング24に対する軸方向の変位を可能となる、小径部26としている。そして、この小径部26と、基端寄り(図3の上寄り)部分に設けた、この小径部26と同心の大径部27とを、凸曲面部28により連続させている。この凸曲面部28の断面形状は、上記加工すべき上記外輪軌道5の軸方向片半部の断面形状とほぼ一致する(完全には一致しない)、円弧状である。上記内径押出加工では、上記パンチ25の凸曲面部28を上記第一中間素材10の内周面に存在する前記凹曲面部20に突き当て、この凹曲面部20の形状を矯正しつつ、この凹曲面部20を上記第一中間素材10の軸方向一端部に向けて、所定位置にまで移動させる(内径寄り部分を扱く)。

When the first intermediate material 10 is set as described above, the inner peripheral surface of the first intermediate material 10 is then handled by the punch 25 as shown in FIG. The tip of the punch 25 is a small-diameter portion 26 that can be displaced in the axial direction with respect to the counter ring 24 while being inserted into the counter ring 24 without a gap (with the concentricity strictly regulated). . The small-diameter portion 26 and the small-diameter portion 26 and the concentric large-diameter portion 27 that are provided near the base end (upward in FIG. 3) are connected by the convex curved surface portion 28. The cross-sectional shape of the convex curved surface portion 28 is an arc shape that substantially matches (but does not completely match) the cross-sectional shape of one half of the axial direction of the outer ring raceway 5 to be processed. In the inner diameter extrusion process, the convex curved surface portion 28 of the punch 25 is abutted against the concave curved surface portion 20 existing on the inner peripheral surface of the first intermediate material 10, and the shape of the concave curved surface portion 20 is corrected while The concave curved surface portion 20 is moved to a predetermined position toward one end portion in the axial direction of the first intermediate material 10 (a portion closer to the inner diameter is handled).

この結果、内周面の軸方向一端寄り部分に、上記外輪軌道5の軸方向片半部の元となる凹曲面部20aを備えた、前記第二中間素材11を得られる。この様にしてこの第二中間素材11を造る際、上述の様に凹曲面部20の形状を矯正しつつ所定位置にまで移動させて上記外輪軌道5の軸方向片半部となる凹曲面部20aとする、扱き作業の進行の過程で、加工応力は、上記凸曲面部28と上記凹曲面部20との当接部にのみ加わる。従って、この凸曲面部28による、上記外輪軌道5の軸方向片半部となる凹曲面部20aの塑性加工は、精度良く行なえる。この様にして造られた上記第二中間素材11のうち、この凹曲面部20aを設けた軸方向一端寄り部分{図3の(B)の下半部}の形状は、造るべき外輪2aの該当部分の形状にほぼ一致している(完全には一致していない)。又、前記図2に示した縮管加工の際、加工孔14の中間部に設けた曲面部18により段付形状に加工された部分に関しては、上記図3に示した内径押出加工を終了した時点で、径方向に関する肉厚の軸方向に関する分布が、造るべき外輪2aの該当部分の分布に(次述する外輪軌道形成加工時に直径が拡がる事に伴う肉厚の変化分を勘案した上で)一致している。この為に、上記図2に示した縮管加工の際、上記曲面部18の形状、並びに、前記ダイ13に対する前記パンチ16の挿入量を厳密に規制している。

As a result, the second intermediate material 11 provided with the concave curved surface portion 20a that is the original half portion of the outer ring raceway 5 in the axial direction end portion of the inner peripheral surface can be obtained. In this way, when the second intermediate material 11 is manufactured, the concave curved surface portion that is moved to a predetermined position while correcting the shape of the concave curved surface portion 20 as described above and becomes one half of the axial direction of the outer ring raceway 5. In the process of progressing the handling operation, the processing stress is applied only to the contact portion between the convex curved surface portion 28 and the concave curved surface portion 20. Therefore, plastic working of the concave curved surface portion 20a, which is a half portion in the axial direction of the outer ring raceway 5, by the convex curved surface portion 28 can be performed with high accuracy. Of the second intermediate material 11 manufactured in this way, the shape of the portion near the one end in the axial direction {lower half of FIG. 3B) provided with the concave curved surface portion 20a is the shape of the outer ring 2a to be manufactured. It almost matches the shape of the corresponding part (not exactly). Further, in the contraction processing shown in FIG. 2, the inner diameter extrusion processing shown in FIG. 3 is completed for the portion processed into the stepped shape by the curved surface portion 18 provided in the intermediate portion of the processing hole 14. At that time, the axial distribution of the wall thickness in the radial direction is the distribution of the corresponding part of the outer ring 2a to be manufactured (after considering the change in the wall thickness as the diameter expands during the outer ring raceway forming process described below) )Match. For this reason, the shape of the curved surface portion 18 and the amount of the punch 16 inserted into the die 13 are strictly regulated during the contraction processing shown in FIG.

上述の様にして上記第二中間素材11を加工する際にも、内周面の直径が、外輪軌道5の底部となるべき部分から、この内周面を形成すべき前記パンチ25の挿入側軸方向端面に向け、拡大する方向にのみ変化する。上記内周面の直径は、軸方向に変化しない部分はあっても、小さくなる方向に変化する部分はない。言い換えれば、上記パンチ25の挿入方向に見て、アンダーカットとなる部分は存在しない。従って、このパンチ25と前記ダイ22とによる上記第二中間素材11の加工を精度良く行なえる。

この様にして造られた、この第二中間素材11は、前記カウンターリング24により前記加工孔23から押し出して、次の工程に送る。

Even when the second intermediate material 11 is processed as described above, the diameter of the inner peripheral surface from the portion that should become the bottom of the outer ring raceway 5, the insertion side of the punch 25 that should form this inner peripheral surface It changes only in the direction of enlargement toward the axial end face. The diameter of the inner peripheral surface has a portion that does not change in the axial direction, but does not have a portion that changes in the smaller direction. In other words, there is no undercut portion when viewed in the direction in which the punch 25 is inserted. Therefore, the processing of the second intermediate material 11 by the punch 25 and the die 22 can be performed with high accuracy.

The second intermediate material 11 manufactured in this way is pushed out of the processing hole 23 by the counter ring 24 and sent to the next step.

この次の工程では、上記第二中間素材11の軸方向他端寄り(図3、5の下端寄り)部分の外径を大きくして、外径を(両端縁部の面取り部を除いて)軸方向全長に亙って均一にすると共に、内周面に上記外輪軌道5を形成する、外輪軌道形成加工を行なう。この外輪軌道形成加工は、図4〜5に示す様な、ローリング加工により行なう。

In this next step, the outer diameter of the second intermediate material 11 near the other end in the axial direction (near the lower end in FIGS. 3 and 5) is increased, and the outer diameter is reduced (except for the chamfered portions at both ends). The outer ring raceway forming process is performed to make the outer ring raceway 5 uniform on the inner peripheral surface while making it uniform over the entire axial length. This outer ring raceway forming process is performed by a rolling process as shown in FIGS.

このローリング加工は、互いに平行に、且つ、逆方向に相対回転自在に支持された外接ローラ29と内接ローラ30との間で上記第二中間素材11の円周方向の一部を径方向に押圧する事で行なう。このうちの外接ローラ29は、厚肉円盤状で、径方向の変位を抑えた状態で、回転のみ自在に支持しており、造るべき外輪2aの幅(軸方向長さ)よりも大きな幅と、(回転中心軸と平行な)円筒状の外周面とを有する。又、上記内接ローラ30は、円柱状で、外周面の一部に、造るべき外輪2aの内周面の断面形状(母線形状)に一致する断面形状(母線形状)を有する、加工曲面部31を設けている。又、上記内接ローラ30は、図示しない駆動機構及び押圧機構により、上記外接ローラ29の外周面に向け押圧しつつ回転駆動自在とされている。

In this rolling process, a part of the second intermediate material 11 in the circumferential direction is radially arranged between the circumscribed roller 29 and the inscribed roller 30 that are supported in parallel with each other and relatively rotatable in opposite directions. This is done by pressing. Of these, the circumscribed roller 29 has a thick disk shape and is supported only for rotation in a state where radial displacement is suppressed, and has a width larger than the width (axial length) of the outer ring 2a to be manufactured. , And a cylindrical outer peripheral surface (parallel to the rotation center axis). Further, the inscribed roller 30 has a cylindrical shape, and has a processed curved surface portion having a cross-sectional shape (bus shape) that matches a cross-sectional shape (bus shape) of the inner peripheral surface of the outer ring 2a to be formed on a part of the outer peripheral surface. 31 is provided. Further, the inscribed roller 30 can be driven to rotate while being pressed against the outer peripheral surface of the inscribed roller 29 by a driving mechanism and a pressing mechanism (not shown).

上記第二中間素材11を上記外輪2aに加工するには、この第二中間素材11を上記内接ローラ30に緩く外嵌した状態で、この内接ローラ30を上記外接ローラ29の外周面に向け押圧しつつ回転駆動する。上記第二中間素材11は、上記内接ローラ30によりこの内接ローラ30と同方向に連れ回りしつつ上記外接ローラ29の外周面に押し付けられる。この為、この外接ローラ29が、上記第二中間素材11及び上記内接ローラ30と逆方向に連れ回り運動(回転)する。そして、この第二中間素材11は、その円周方向の一部が、これら両ローラ29、30の外周面同士の間で、径方向に押圧される。又、この様に径方向に押圧される部分は、円周方向に連続して変化する。この結果、上記第二中間素材11の軸方向他端寄り部分が、上記外接ローラ29の外周面に当接するまで、徐々に拡径される。

In order to process the second intermediate material 11 into the outer ring 2a, the inner roller 30 is placed on the outer peripheral surface of the outer roller 29 while the second intermediate material 11 is loosely fitted to the inner roller 30. Rotating drive while pressing. The second intermediate material 11 is pressed against the outer peripheral surface of the circumscribed roller 29 while being rotated in the same direction as the inscribed roller 30 by the inscribed roller 30. For this reason, the circumscribing roller 29 rotates (rotates) with the second intermediate material 11 and the inscribed roller 30 in the opposite direction. The second intermediate material 11 is partially pressed in the circumferential direction between the outer peripheral surfaces of the rollers 29 and 30. Further, the portion pressed in the radial direction in this way continuously changes in the circumferential direction. As a result, the diameter of the second intermediate material 11 is gradually increased until the portion near the other end in the axial direction contacts the outer peripheral surface of the circumscribed roller 29.

上記第二中間素材11の軸方向他端寄り部分が拡径し切り、この第二中間素材11の外径が(両端縁部の面取り部を除いて)軸方向全長に亙って均一になった後は、上記内接ローラ30の加工曲面部31の形状が上記第二中間素材11の内周面に転写される。この加工曲面部31は、その軸方向中央部に、前記外輪軌道5を形成すべき、断面円弧状の凸曲面部32を設けている。又、軸方向両端部には、前記各段差部12、12に密封板の外周縁を係止すべき係止溝を加工すべき突条33、33を形成している。従って、上記加工曲面部31の形状が上記第二中間素材11の内周面に転写された状態では、内周面の軸方向中央部に上記外輪軌道5を、同じく両端部に係止溝34、34を、それぞれ備えた、前記外輪2aを得られる。

The portion of the second intermediate material 11 near the other end in the axial direction is expanded in diameter, and the outer diameter of the second intermediate material 11 is uniform over the entire length in the axial direction (excluding the chamfered portions at both ends). After that, the shape of the processed curved surface portion 31 of the inscribed roller 30 is transferred to the inner peripheral surface of the second intermediate material 11. The processed curved surface portion 31 is provided with a convex curved surface portion 32 having an arcuate cross section in which the outer ring raceway 5 is to be formed at the central portion in the axial direction. Further, at both ends in the axial direction, ridges 33, 33 for forming locking grooves for locking the outer peripheral edge of the sealing plate are formed on the stepped portions 12, 12, respectively. Therefore, in a state where the shape of the processed curved surface portion 31 is transferred to the inner peripheral surface of the second intermediate material 11, the outer ring raceway 5 is formed at the axial center portion of the inner peripheral surface, and the locking grooves 34 are also formed at both end portions. , 34, respectively, can be obtained.

この様にして得られた外輪2aには、転がり疲れ寿命を確保する為に上記外輪軌道5部分を硬化させるべく、熱処理(焼き入れ)を施す。熱処理を施した外輪2aは、そのまま内輪3及び玉4、4と組み合わせて図25に示す様なラジアル玉軸受1とする事もできる。更に、回転精度、或いは回転時に振動及び騒音を低く抑える必要がある場合には、上記熱処理後、上記外輪軌道5部分に、表面粗さを向上させる為の研磨を施す事もできる。

The outer ring 2a thus obtained is subjected to heat treatment (quenching) in order to cure the outer ring raceway 5 portion in order to ensure a rolling fatigue life. The heat-treated outer ring 2a can be combined with the inner ring 3 and the balls 4 and 4 as they are to form a radial ball bearing 1 as shown in FIG. Further, when it is necessary to keep the rotation accuracy or vibration and noise low during rotation, the outer ring raceway 5 can be polished to improve the surface roughness after the heat treatment.

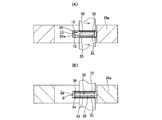

図6〜7は、やはり請求項1〜4に対応する、本発明の実施例2を示している。本実施例の場合には、前述の図1の(D)に示した第二中間素材11を同じく(E)に示した外輪2aに加工する為のローリング加工装置を構成する外接ローラ29aを、円環状に形成している。そして、この外接ローラ29aの内側に内接ローラ30を、回転中心軸を互いに平行に配置した状態で、且つ、回転中心軸を互いに偏心させた状態で挿入している。上記第二中間素材11を上記外輪2aに加工する為のローリング加工を行なう際には、上記内接ローラ30を上記外接ローラ29aの内周面に押圧しつつ回転させる。その他の部分の構成及び作用は、上述した実施例1と同様であるから、重複する図示並びに説明は省略する。

6 to 7 show a second embodiment of the present invention, which also corresponds to claims 1 to 4. In the case of the present embodiment, the circumscribed roller 29a constituting the rolling processing device for processing the second intermediate material 11 shown in FIG. 1D described above into the outer ring 2a shown in FIG. It is formed in an annular shape. The inscribed roller 30 is inserted inside the circumscribed roller 29a in a state where the rotation center axes are arranged in parallel with each other and the rotation center axes are decentered from each other. When performing the rolling process for processing the second intermediate material 11 into the outer ring 2a, the inscribed roller 30 is rotated while being pressed against the inner peripheral surface of the outer roller 29a. Since the configuration and operation of the other parts are the same as those of the first embodiment, overlapping illustrations and descriptions are omitted.

図8〜9は、やはり請求項1〜4に対応する、本発明の実施例3を示している。本実施例の場合には、前述の図1の(D)に示した第二中間素材11を同じく(E)に示した外輪2aに加工する為のローリング加工装置を構成する外接ローラ29bを円環状とし、且つ、この外接ローラ29bの内径を、上記外輪2aの外径(=上記第二中間素材11の最大外径)に一致させている。そして、この外接ローラ29bの内側に内接ローラ30を、回転中心軸を互いに平行に配置した状態で、且つ、回転中心軸を互いに偏心させた状態で挿入している。上記第二中間素材11を上記外輪2aに加工する為のローリング加工を行なう際には、この第二中間素材11を上記外接ローラ29bにがたつきなく内嵌した状態で上記内接ローラ30を、この外接ローラ29bの内周面に押圧しつつ回転させる。その他の部分の構成及び作用は、前述した実施例1及び上述した実施例2と同様であるから、重複する図示並びに説明は省略する。

8 to 9 show a third embodiment of the present invention, which also corresponds to claims 1 to 4. In the case of the present embodiment, the circumscribed roller 29b constituting the rolling processing device for processing the second intermediate material 11 shown in FIG. 1D to the outer ring 2a shown in FIG. The outer diameter of the circumscribed roller 29b is made to coincide with the outer diameter of the outer ring 2a (= the maximum outer diameter of the second intermediate material 11). The inscribed roller 30 is inserted inside the circumscribed roller 29b with the rotation center axes arranged in parallel to each other and with the rotation center axes decentered from each other. When performing the rolling process for processing the second intermediate material 11 into the outer ring 2a, the inscribed roller 30 is moved in a state in which the second intermediate material 11 is fitted in the outer roller 29b without rattling. Then, it is rotated while being pressed against the inner peripheral surface of the circumscribed roller 29b. Since the configuration and operation of other parts are the same as those of the first embodiment and the second embodiment described above, overlapping illustrations and descriptions are omitted.

図10〜14は、やはり請求項1〜4に対応する、本発明の実施例4として、本発明を内輪3aの製造に適用した場合に就いて示している。本実施例の特徴は、予め内輪3a{図10の(E)参照}の容積と実質的に同じ容積を有する円筒状の高精度素材8a{図1の(A)参照}を造った後、冷間加工によりこの高精度素材8aを塑性変形させて、上記内輪3aとする点にある。この高精度素材8aを造る方法に就いては、前述した実施例1の場合と同様であるが、高精度素材8aを何れの方法により造った場合でも、この高精度素材8aを次の様な工程で冷間加工により塑性変形させ、上記内輪3aとする。

FIGS. 10 to 14 show the case where the present invention is applied to the production of the inner ring 3a as the fourth embodiment of the present invention, which also corresponds to the first to fourth aspects. A feature of the present embodiment is that after a cylindrical high-precision material 8a {see FIG. 1 (A)} having a volume substantially the same as the volume of the inner ring 3a {see FIG. 10 (E)} is made in advance, This high precision material 8a is plastically deformed by cold working to form the inner ring 3a. The method for producing the high-precision material 8a is the same as that in the first embodiment described above. However, regardless of the method used to produce the high-precision material 8a, the high-precision material 8a is produced as follows. The inner ring 3a is formed by plastic deformation by cold working in the process.

本実施例の場合には、図10の(A)に示した上記高精度素材8aを、(B)に示した予備中間素材9a、(C)に示した第一中間素材10a、(D)に示した第二中間素材11aを経て、(E)に示した内輪3aとする。これら予備中間素材9a、第二中間素材11aは何れも、上述した各実施例と同様に、外周面及び内周面の形状は、それぞれアンダカット部を持たない形状である。従って、上記各中間素材9a〜11aは何れも、軸方向に相対変位する金型同士の間で強く押圧する事により、精度良く造れる。就いては、それぞれの工程に就いて、順番に説明する。

In the case of the present embodiment, the high-precision material 8a shown in FIG. 10A is replaced with the preliminary intermediate material 9a shown in FIG. 10B, the first intermediate material 10a shown in FIG. The inner ring 3a shown in (E) is obtained through the second intermediate material 11a shown in FIG. In both the preliminary intermediate material 9a and the second intermediate material 11a, the shapes of the outer peripheral surface and the inner peripheral surface are shapes that do not have an undercut portion, as in the above-described embodiments. Accordingly, each of the intermediate materials 9a to 11a can be made with high accuracy by strongly pressing between the dies that are relatively displaced in the axial direction. The process will be described in turn.

上記高精度素材8aを上記予備中間素材9aとするには、この高精度素材8aの外周面を図示しない抑え型の内周面に内嵌し、同じく内周面を中子に外嵌した状態で、この高精度素材8aの軸方向両端面の外径側半部に、やはり図示しないパンチの先端面を、全周に亙って押し付ける。この結果、上記高精度素材8aの軸方向両端面の外径側半部が軸方向に凹んで、当該部分に段差部12a、12aを有する、上記予備中間素材9aを得られる。この際、これら両段差部12a、12aを形成する事に伴って径方向内方に流動した肉は、上記軸方向両端部の内径側半部が軸方向に突出する事で吸収される。尚、この様にして造られる、上記予備中間素材9aの内径は、造るべき内輪3aの内径とほぼ同じである(厳密に同じである必要はない)。

In order to use the high-precision material 8a as the preliminary intermediate material 9a, a state in which the outer peripheral surface of the high-precision material 8a is fitted into an inner peripheral surface of a holding mold (not shown) and the inner peripheral surface is also fitted onto the core. Thus, the punch end surface (not shown) is pressed over the entire circumference on the outer diameter side half of both end surfaces in the axial direction of the high-precision material 8a. As a result, the preliminary intermediate material 9a is obtained in which the outer diameter side halves of both end surfaces in the axial direction of the high-accuracy material 8a are recessed in the axial direction and have stepped portions 12a and 12a in the portions. At this time, the flesh that has flowed radially inward along with the formation of the two stepped portions 12a and 12a is absorbed when the inner-diameter-side halves at both ends in the axial direction protrude in the axial direction. The inner diameter of the preliminary intermediate material 9a manufactured in this way is almost the same as the inner diameter of the inner ring 3a to be manufactured (it is not necessary to be exactly the same).

この様な予備中間素材9aには、その一部{軸方向一端部(図10の上端部)を除く部分}の外径を、上記内輪3aの中間部外周面に形成した内輪軌道6{図10の(E)及び図14参照}の溝底径(深溝型の内輪軌道6の幅方向中央部で最も外径が小さくなった部分の外径)にまで縮める縮管加工を施す。この縮管加工は、図11に示す様にして行なう。

先ず、(A)に示す様に、上記予備中間素材9aを、ダイ13aに設けた加工孔14aの大径部15aに内嵌(セット)する。次いで、(B)に示す様に、パンチ16aにより上記予備中間素材9aを、上記加工孔14aの奥にまで押し込む。この加工孔14aは、上記大径部15aとこの大径部15aよりも奥側に設けた小径部17aとを滑らかな曲面部18aにより連続させて成る。この曲面部18aの断面形状は、造るべき上記内輪3aの外周面に形成する、上記内輪軌道6の片半部(図10の上半部)の断面形状と一致しており、上記小径部17aの内径は、上記溝底径と一致させている。従って、上記パンチ16aにより上記加工孔14aの奥部に存在する上記小径部17aに押し込まれた、上記予備中間素材9aの一部の外径は、上記溝底径と一致する状態に縮められて、前記第一中間素材10aとなる。

In such a preliminary intermediate material 9a, an inner ring raceway 6 having a part {the part excluding one end in the axial direction (the upper end in FIG. 10) outer diameter formed on the outer peripheral surface of the intermediate part of the inner ring 3a {FIG. 10 (E) and FIG. 14} is performed to reduce the groove bottom diameter (the outer diameter of the portion where the outer diameter is the smallest at the center in the width direction of the deep groove type inner ring raceway 6). This contraction processing is performed as shown in FIG.

First, as shown in (A), the preliminary intermediate material 9a is fitted (set) into the large-diameter portion 15a of the processing hole 14a provided in the die 13a. Next, as shown in (B), the preliminary intermediate material 9a is pushed into the processed hole 14a by the punch 16a. The machining hole 14a is formed by connecting the large diameter portion 15a and the small diameter portion 17a provided on the back side of the large diameter portion 15a by a smooth curved surface portion 18a. The cross-sectional shape of the curved surface portion 18a coincides with the cross-sectional shape of one half portion (the upper half portion in FIG. 10) of the inner ring raceway 6 formed on the outer peripheral surface of the inner ring 3a to be manufactured, and the small diameter portion 17a. The inner diameter of the groove is matched with the groove bottom diameter. Accordingly, the outer diameter of a part of the preliminary intermediate material 9a pushed into the small-diameter portion 17a existing in the deep part of the processing hole 14a by the punch 16a is reduced to a state matching the groove bottom diameter. The first intermediate material 10a.

尚、図示の例では、上記パンチ16aの軸方向中間部の一部に凸曲面部19aを形成する事により、上記第一中間素材10aの内周面の一端寄り部分に断面円弧状の凹曲面部20bを、全周に亙って形成する様にしている。上記パンチ16aがこの凹曲面部20bを形成するのは、上記予備中間素材9aを上記第一中間素材10aとする加工の初期段階で行なわれる。従って、上述の様に予備中間素材9aの一部の外径を縮めて第一中間素材10aとすべく、上記外径を縮める作業の進行の過程で、加工応力は、上記初期段階を除き、上記曲面部18aと上記予備中間素材9aの外周面との当接部にのみ加わる。従って、上記加工孔14aの曲面部18aによる、上記第一中間素材10aの外周面の塑性加工は、精度良く行なえる。この部分の加工を精度良く行なう事は、得られる内輪軌道6{図10の(E)或いは図25参照}の精度を確保する面から重要である。この様にして造られた、上記第一中間素材10aは、ノックアウトリング21aにより上記加工孔14aから押し出して、次の工程に送る。

In the illustrated example, a convex curved surface portion 19a is formed in a part of the axially intermediate portion of the punch 16a, so that a concave curved surface having a circular arc cross section is formed at a portion near one end of the inner peripheral surface of the first intermediate material 10a. The part 20b is formed over the entire circumference. The punch 16a forms the concave curved surface portion 20b at an initial stage of processing using the preliminary intermediate material 9a as the first intermediate material 10a. Therefore, in the course of the progress of the work of reducing the outer diameter to reduce the outer diameter of a part of the preliminary intermediate material 9a as described above to the first intermediate material 10a, the processing stress is excluding the initial stage, Only the contact portion between the curved surface portion 18a and the outer peripheral surface of the preliminary intermediate material 9a is added. Therefore, the plastic working of the outer peripheral surface of the first intermediate material 10a by the curved surface portion 18a of the processing hole 14a can be performed with high accuracy. It is important from the aspect of ensuring the accuracy of the obtained inner ring raceway 6 {refer to (E) in FIG. 10 or FIG. 25} to accurately process this portion. The first intermediate material 10a thus produced is pushed out from the processed hole 14a by the knockout ring 21a and sent to the next step.

上述の様にして加工される、上記第一中間素材10aは、外周面の直径が、内輪軌道5{図10の(E)参照}の底部となるべき部分から、この外周面を形成すべき前記ダイ13aの挿入側軸方向端面に向け、拡大する方向にのみ変化する。上記外周面の直径は、軸方向に変化しない部分はあっても、大きくなる方向に変化する部分はない。言い換えれば、上記ダイ13aに対するの挿入方向に見て、アンダーカットとなる部分は存在しない。従って、このダイ13aと上記パンチ16aとによる上記第一中間素材10aの加工を精度良く行なえる。

The first intermediate material 10a processed as described above should form this outer peripheral surface from the portion where the diameter of the outer peripheral surface should be the bottom of the inner ring raceway 5 {see FIG. 10 (E)}. It changes only in the direction of expansion toward the insertion side axial end face of the die 13a. The diameter of the outer peripheral surface is not changed in the axial direction even though there is a portion that does not change in the axial direction. In other words, there is no undercut portion when viewed in the insertion direction with respect to the die 13a. Therefore, the first intermediate material 10a can be processed with high accuracy by the die 13a and the punch 16a.

上記次の工程では、上記第一中間素材10aのうちで上記内輪軌道6の軸方向他半部(図10の下半部)に対応する部分の径方向に関する肉厚の軸方向に関する分布を、造るべき上記内輪3aの該当部分の分布に一致させる為の内径押出加工を施す。この内径押出加工は、図12に示す様にして行なう。

先ず、(A)に示す様に、上記第一中間素材10aを、ダイ22aに設けた加工孔23aに内嵌すると共に、この第一中間素材10aの軸方向一端面(図12の下端面)を、この加工孔23a内に挿入したカウンターリング24aの先端面(図12の上端面)に突き当てる(セットする)。この状態で、上記第一中間素材10aの外周面は上記加工孔23aの内周面に、同じく軸方向一端面は上記カウンターリング24aの先端面に、それぞれ隙間なく当接する。又、このカウンターリング24aと上記ダイ22aとの軸方向(図12の上下方向)に関する位置関係は、厳密に規制されている。

In the next step, in the first intermediate material 10a, the distribution in the axial direction of the wall thickness in the radial direction of the portion corresponding to the other half part in the axial direction of the inner ring raceway 6 (the lower half part in FIG. 10), An inner diameter extrusion process is performed to match the distribution of the corresponding portion of the inner ring 3a to be manufactured. This inner diameter extrusion is performed as shown in FIG.

First, as shown in (A), the first intermediate material 10a is fitted into a machining hole 23a provided in the die 22a, and one end surface in the axial direction of the first intermediate material 10a (the lower end surface in FIG. 12). Is abutted against (set) the front end surface (upper end surface in FIG. 12) of the counter ring 24a inserted into the processing hole 23a. In this state, the outer peripheral surface of the first intermediate material 10a is in contact with the inner peripheral surface of the processing hole 23a and the one end surface in the axial direction is in contact with the front end surface of the counter ring 24a without any gap. Further, the positional relationship between the counter ring 24a and the die 22a in the axial direction (vertical direction in FIG. 12) is strictly regulated.

上記第一中間素材10aを上述の様にセットしたならば、次いで、(B)に示す様に、パンチ25aによりこの第一中間素材10aの内周面を扱く。このパンチ25aの先端部は、上記カウンターリング24a内に隙間なく挿入した状態で(同心度を厳密に規制した状態で)このカウンターリング24aに対する軸方向の変位を可能となる、小径部26aとしている。そして、この小径部26aと、基端寄り(図12の上寄り)部分に設けた、この小径部26aと同心の大径部27aとを、凸曲面部28aにより連続させている。この凸曲面部28aの断面形状は、前記内輪軌道6の軸方向他半部に対応する部分の径方向に関する肉厚の軸方向に関する分布を、造るべき上記内輪3aの該当部分の分布に一致させるべく、厳密に規制している。上記内径押出加工では、上記パンチ25aの凸曲面部28aを上記第一中間素材10aの内周面に存在する前記凹曲面部20bに突き当て、この凹曲面部20bの形状を矯正しつつ、この凹曲面部20bを上記第一中間素材10aの軸方向一端部に向けて、所定位置にまで移動させる(内径寄り部分を扱く)。

When the first intermediate material 10a is set as described above, the inner peripheral surface of the first intermediate material 10a is then handled by the punch 25a as shown in FIG. The tip of the punch 25a is a small-diameter portion 26a that can be displaced in the axial direction with respect to the counter ring 24a while being inserted into the counter ring 24a without any gap (with the concentricity strictly regulated). . The small-diameter portion 26a and the small-diameter portion 26a and the large-diameter portion 27a that are concentric with each other are provided on a portion near the base end (upward in FIG. 12) by a convex curved surface portion 28a. The cross-sectional shape of the convex curved surface portion 28a matches the distribution in the axial direction of the thickness in the radial direction of the portion corresponding to the other half portion in the axial direction of the inner ring raceway 6 with the distribution of the corresponding portion of the inner ring 3a to be formed. Therefore, it is strictly regulated. In the inner diameter extrusion process, the convex curved surface portion 28a of the punch 25a is abutted against the concave curved surface portion 20b existing on the inner peripheral surface of the first intermediate material 10a, and while correcting the shape of the concave curved surface portion 20b, The concave curved surface portion 20b is moved to a predetermined position toward the one end portion in the axial direction of the first intermediate material 10a (a portion closer to the inner diameter is handled).

この結果、内周面の軸方向一端寄り(図12の下寄り)部分に、上記内輪軌道6の軸方向他半部となるべき部分の肉厚分布を整える為の凹曲面部20cを備えた、前記第二中間素材11aを得られる。この様にしてこの第二中間素材11aを造る際、上述の様に凹曲面部20bの形状を矯正しつつ所定位置にまで移動させて、上記内輪軌道6の軸方向他半部となるべき部分の肉厚分布を整える為の凹曲面部20cとする扱き作業の進行の過程で、加工応力は、上記凸曲面部28aと上記凹曲面部20bとの当接部にのみ加わる。従って、この凸曲面部28aによる、上記肉厚分布を整える為の凹曲面部20cの塑性加工は、精度良く行なえる。この様にして造られた上記第二中間素材11aのうち、軸方向に関して上記凹曲面部20cを設けた部分と反対側の部分{図10の(D)及び図12の(B)の上半部分}の形状は、造るべき内輪3aの該当部分の形状に、ほぼ一致している。又、上記凹曲面部20cを形成した部分に関しては、径方向に関する肉厚の軸方向に関する分布が、造るべき内輪3aの該当部分の分布に一致している。この為に、上記内径押出加工の際、上記凸曲面部28aの形状、並びに、前記ダイ22aに対する上記パンチ25aの挿入量を厳密に規制している。この様にして造られた、上記第二中間素材11aは、前記カウンターリング24aにより前記加工孔23aから押し出して、次の工程に送る。

As a result, a concave curved surface portion 20c for adjusting the wall thickness distribution of the portion that should be the other half portion in the axial direction of the inner ring raceway 6 is provided near the axial end of the inner peripheral surface (lower side in FIG. 12). The second intermediate material 11a can be obtained. When the second intermediate material 11a is manufactured in this way, the portion to be moved to a predetermined position while correcting the shape of the concave curved surface portion 20b as described above, and to be the other half portion in the axial direction of the inner ring raceway 6 In the process of handling the concave curved surface portion 20c for adjusting the wall thickness distribution, the processing stress is applied only to the contact portion between the convex curved surface portion 28a and the concave curved surface portion 20b. Therefore, the plastic processing of the concave curved surface portion 20c for adjusting the thickness distribution by the convex curved surface portion 28a can be performed with high accuracy. Of the second intermediate material 11a thus produced, the portion on the opposite side to the portion provided with the concave curved surface portion 20c in the axial direction {the upper half of FIG. 10 (D) and FIG. 12 (B). The shape of the portion} substantially matches the shape of the corresponding portion of the inner ring 3a to be manufactured. Further, regarding the portion where the concave curved surface portion 20c is formed, the distribution in the axial direction of the wall thickness in the radial direction matches the distribution of the corresponding portion of the inner ring 3a to be manufactured. For this reason, at the time of the inner diameter extrusion processing, the shape of the convex curved surface portion 28a and the insertion amount of the punch 25a into the die 22a are strictly regulated. The second intermediate material 11a thus produced is pushed out of the processed hole 23a by the counter ring 24a and sent to the next step.

この次の工程では、上記第二中間素材11aの軸方向他端寄り(図12、14の下端寄り)部分の内径を大きくして、内径を(両端縁部の面取り部を除いて)軸方向全長に亙って均一にすると共に、外周面に上記内輪軌道6を形成する、内輪軌道形成加工を行なう。この内輪軌道形成加工は、図13〜14に示す様な、ローリング加工により行なう。

In this next step, the inner diameter of the second intermediate material 11a closer to the other end in the axial direction (near the lower end of FIGS. 12 and 14) is increased, and the inner diameter is increased in the axial direction (excluding the chamfered portions at both ends). The inner ring raceway forming process is performed to make the inner ring raceway 6 uniform on the outer peripheral surface while making it uniform over the entire length. This inner ring raceway forming process is performed by a rolling process as shown in FIGS.

このローリング加工は、互いに平行に、且つ、逆方向に相対回転自在に支持された外接ローラ29cと内接ローラ30aとの間で上記第二中間素材11aの円周方向の一部を径方向に押圧する事で行なう。このうちの外接ローラ29cは、厚肉円盤状で、径方向の変位を抑えた状態で、回転のみ自在に支持しており、造るべき内輪3aの幅(軸方向長さ)よりも大きな幅を有する。又、上記外接ローラ29cの外周面の軸方向中間部に、造るべき内輪3aの外周面の断面形状(母線形状)に一致する断面形状(母線形状)を有する、加工曲面部31aを設けている。一方、上記内接ローラ30aは、円柱状で、外周面は単なる(回転中心と平行な)円筒面としている。又、上記内接ローラ30aは、図示しない駆動機構及び押圧機構により、上記外接ローラ29cの内周面に向け押圧しつつ回転駆動自在とされている。

In this rolling process, a part of the second intermediate material 11a in the circumferential direction is radially formed between the circumscribed roller 29c and the inscribed roller 30a, which are supported in parallel with each other and relatively rotatable in opposite directions. This is done by pressing. Of these, the circumscribed roller 29c has a thick disk shape and is supported only for rotation in a state where radial displacement is suppressed, and has a width larger than the width of the inner ring 3a (the length in the axial direction) to be manufactured. Have. In addition, a processing curved surface portion 31a having a cross-sectional shape (bus shape) that matches the cross-sectional shape (bus shape) of the outer peripheral surface of the inner ring 3a to be manufactured is provided in the axially intermediate portion of the outer peripheral surface of the circumscribed roller 29c. . On the other hand, the inscribed roller 30a has a columnar shape, and the outer peripheral surface is a simple cylindrical surface (parallel to the rotation center). The inscribed roller 30a can be driven to rotate while being pressed against the inner peripheral surface of the outer roller 29c by a driving mechanism and a pressing mechanism (not shown).

上記第二中間素材11aを上記内輪3aに加工するには、この第二中間素材11aを上記内接ローラ30aに緩く外嵌した状態で、この内接ローラ30aを上記外接ローラ29cの外周面に向け押圧しつつ回転駆動する。上記第二中間素材11aは、上記内接ローラ30aによりこの内接ローラ30aと同方向に連れ回りしつつ上記外接ローラ29cの外周面に押し付けられる。この為、この外接ローラ29cが、上記第二中間素材11a及び上記内接ローラ30aと逆方向に連れ回り運動(回転)する。そして、この第二中間素材11aは、その円周方向の一部が、これら両ローラ29c、30aの外周面同士の間で、径方向に押圧される。又、この様に径方向に押圧される部分は、円周方向に連続して変化する。この結果、上記第二中間素材11aの軸方向他端寄り部分が、上記外接ローラ29cの外周面に当接するまで、徐々に拡径される。

In order to process the second intermediate material 11a into the inner ring 3a, the inner roller 30a is placed on the outer peripheral surface of the outer roller 29c while the second intermediate material 11a is loosely fitted to the inner roller 30a. Rotating drive while pressing. The second intermediate material 11a is pressed against the outer peripheral surface of the circumscribed roller 29c while being rotated in the same direction as the inscribed roller 30a by the inscribed roller 30a. For this reason, the circumscribed roller 29c rotates (rotates) along with the second intermediate material 11a and the inscribed roller 30a in the opposite direction. The second intermediate material 11a is partially pressed in the circumferential direction between the outer peripheral surfaces of the rollers 29c and 30a. Further, the portion pressed in the radial direction in this way continuously changes in the circumferential direction. As a result, the diameter of the second intermediate material 11a is gradually increased until a portion near the other end in the axial direction contacts the outer peripheral surface of the circumscribed roller 29c.

上記第二中間素材11aの軸方向他端寄り部分が拡径し切り、この第二中間素材11aの内径が(両端縁部の面取り部を除いて)軸方向全長に亙って均一になった後は、上記外接ローラ29cの加工曲面部31aの形状が上記第二中間素材11aの外周面に転写される。この加工曲面部31aは、その軸方向中央部に、前記内輪軌道6を形成すべき、断面円弧状の凸曲面部32aを設けている。又、軸方向両端部には、前記各段部12a、12aを、密封板の内周縁を摺接若しくは近接対向させる為のシール面に加工する為の加工面を形成している。従って、上記加工曲面部31aの形状が上記第二中間素材11aの内周面に転写された状態では、内周面の軸方向中央部に上記内輪軌道6を、同じく両端部に上記シール面を、それぞれ備えた、前記内輪3aを得られる。

The portion near the other end in the axial direction of the second intermediate material 11a is expanded in diameter, and the inner diameter of the second intermediate material 11a is uniform over the entire length in the axial direction (excluding the chamfered portions at both ends). Thereafter, the shape of the processed curved surface portion 31a of the circumscribed roller 29c is transferred to the outer peripheral surface of the second intermediate material 11a. The processed curved surface portion 31a is provided with a convex curved surface portion 32a having an arcuate cross section in which the inner ring raceway 6 is to be formed at the central portion in the axial direction. Further, on both ends in the axial direction, there are formed processing surfaces for processing the stepped portions 12a, 12a into sealing surfaces for making the inner peripheral edge of the sealing plate slidably contact or close to each other. Therefore, in a state where the shape of the processed curved surface portion 31a is transferred to the inner peripheral surface of the second intermediate material 11a, the inner ring raceway 6 is provided at the axial center portion of the inner peripheral surface, and the seal surfaces are also provided at both end portions. The inner ring 3a provided respectively can be obtained.

この様にして得られた内輪3aには、転がり疲れ寿命を確保する為に上記内輪軌道6部分を硬化させるべく、熱処理(焼き入れ)を施す。熱処理を施した内輪3aは、そのまま外輪2及び玉4、4と組み合わせて図25に示す様なラジアル玉軸受1とする事もできる。更に、回転精度、或いは回転時に振動及び騒音を低く抑える必要がある場合には、上記熱処理後、上記内輪軌道6部分に、表面粗さを向上させる為の研磨を施す事もできる。

The inner ring 3a thus obtained is subjected to heat treatment (quenching) in order to cure the inner ring raceway 6 portion in order to ensure a rolling fatigue life. The inner ring 3a subjected to the heat treatment can be directly combined with the outer ring 2 and the balls 4 and 4 to form a radial ball bearing 1 as shown in FIG. Further, when it is necessary to keep the rotation accuracy or vibration and noise low during rotation, the inner ring raceway 6 can be polished to improve the surface roughness after the heat treatment.

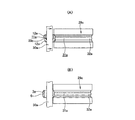

図15〜16は、やはり請求項1〜4に対応する、本発明の実施例5を示している。本実施例の場合には、前述の図10の(D)に示した第二中間素材11aを同じく(E)に示した内輪3aに加工する為のローリング加工装置を構成する外接ローラ29dを、円環状に形成している。そして、この外接ローラ29dの内側に内接ローラ30aを、回転中心軸を互いに平行に配置した状態で、且つ、回転中心軸を互いに偏心させた状態で挿入している。上記第二中間素材11aを上記内輪3aに加工する為のローリング加工を行なう際には、上記内接ローラ30aを上記外接ローラ29dの内周面に押圧しつつ回転させる。その他の部分の構成及び作用は、上述した実施例4と同様であるから、重複する図示並びに説明は省略する。

15 to 16 show a fifth embodiment of the present invention, which also corresponds to claims 1 to 4. In the case of the present embodiment, the circumscribed roller 29d constituting the rolling processing device for processing the second intermediate material 11a shown in FIG. 10D to the inner ring 3a shown in FIG. It is formed in an annular shape. The inscribed roller 30a is inserted inside the circumscribed roller 29d with the rotation center axes arranged in parallel to each other and with the rotation center axes decentered from each other. When performing the rolling process for processing the second intermediate material 11a into the inner ring 3a, the inscribed roller 30a is rotated while being pressed against the inner peripheral surface of the circumscribed roller 29d. Since the configuration and operation of other parts are the same as those in the above-described fourth embodiment, overlapping illustrations and descriptions are omitted.

図17〜18は、やはり請求項1〜4に対応する、本発明の実施例6を示している。本実施例の場合には、前述の図10の(D)に示した第二中間素材11aを同じく(E)に示した内輪3aに加工する為のローリング加工装置を構成する為に、それぞれが厚肉円盤状である外接ローラ29e、29eを1対設けている。又、内接ローラの代わりに、上記第二中間素材11aを回転自在に支持する為の、円柱状のマンドレル35を設けている。このマンドレル35の中心軸と上記両外接ローラ29e、29eの回転中心軸とは、単一の仮想平面上に存在し、互いに平行である。又、上記マンドレル35の外径は、加工すべき上記内輪3aの内径と一致している。尚、本実施例の場合、第二中間素材11aの軸方向一端寄り(図18の下寄り)部分の内径が、内輪3aの内径と一致する様に、この第二中間素材11aを形成している。

FIGS. 17 to 18 show Embodiment 6 of the present invention, which also corresponds to claims 1 to 4. In the case of the present embodiment, in order to constitute a rolling processing apparatus for processing the second intermediate material 11a shown in FIG. 10D described above into the inner ring 3a shown in FIG. A pair of circumscribed rollers 29e and 29e each having a thick disk shape are provided. Further, instead of the inscribed roller, a cylindrical mandrel 35 for rotatably supporting the second intermediate material 11a is provided. The central axis of the mandrel 35 and the rotational central axes of the two circumscribed rollers 29e and 29e are on a single virtual plane and are parallel to each other. Further, the outer diameter of the mandrel 35 coincides with the inner diameter of the inner ring 3a to be processed. In the case of this embodiment, the second intermediate material 11a is formed so that the inner diameter of the second intermediate material 11a near the one end in the axial direction (lower side in FIG. 18) matches the inner diameter of the inner ring 3a. Yes.

上記第二中間素材11aを上記外輪3aに加工する為のローリング加工を行なう際には、上記マンドレル35に上記第二中間素材11aを外嵌した状態で、上記両外接ローラ29e、29eを互いに近づく方向に押圧しつつ同じ方向に回転させる。この結果、上記第二中間素材11aの一部の外径が縮まりつつ、外周面に内輪軌道6及びシール面が形成される。その他の部分の構成及び作用は、前述した実施例4及び上述した実施例5と同様であるから、重複する図示並びに説明は省略する。

When performing the rolling process for processing the second intermediate material 11a into the outer ring 3a, both the circumscribed rollers 29e and 29e are brought close to each other with the second intermediate material 11a fitted on the mandrel 35. Rotate in the same direction while pressing in the direction. As a result, the inner ring raceway 6 and the seal surface are formed on the outer peripheral surface while the outer diameter of a part of the second intermediate material 11a is reduced. Since the configuration and operation of other parts are the same as those of the above-described fourth embodiment and the above-described fifth embodiment, overlapping illustrations and descriptions are omitted.

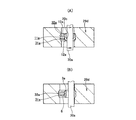

図19〜21は、請求項1、5〜8に対応する、本発明の実施例7を示している。本実施例の場合には、前述の図1の(B)に示した予備中間素材9から同(E)に示した外輪2aへの加工を、同(C)に示す様な縮径作業や同(D)に示す様な内径押出加工を行なわずに、ローリング加工のみで行なう様にしている。即ち、本実施例の場合には、図21の(A)に示す様な予備中間素材9を、受部材である、図19〜20に示す様なダイ22bに隙間なく内嵌する。即ち、非加工側周面である上記予備中間素材9の外周面を、支承側周面である上記ダイ22bの内周面に、全周に亙って当接若しくは近接対向させる。この状態で、被加工側周面である上記予備中間素材9の内周面に、加工側周面であるマンドレル35aの外周面を押し付けて、上記外輪2aを得る。このマンドレル35aが、特許請求の範囲に記載した加工側回転部材である。上記予備中間素材9の容積と、完成品であるこの外輪2aの容積とは互いに等しい。又、この予備中間素材9の外径D9 とこの外輪2aの外径D2aとは、ほぼ等しい(D9 ≒D2a)。又、この予備中間素材9の幅W9 とこの外輪2aの幅W2aとも、ほぼ等しい(W9 ≒W2a)。

19 to 21 show a seventh embodiment of the present invention corresponding to claims 1 and 5 to 8. In the case of the present embodiment, the processing from the preliminary intermediate material 9 shown in FIG. 1B to the outer ring 2a shown in FIG. The inner diameter extrusion process as shown in (D) is not performed, but only the rolling process is performed. That is, in the case of the present embodiment, the preliminary intermediate material 9 as shown in FIG. 21A is fitted into the die 22b as shown in FIGS. That is, the outer peripheral surface of the preliminary intermediate material 9 which is the non-processed peripheral surface is brought into contact with or close to the inner peripheral surface of the die 22b which is the support side peripheral surface over the entire periphery. In this state, the outer ring 2a is obtained by pressing the outer peripheral surface of the mandrel 35a which is the processing side peripheral surface against the inner peripheral surface of the preliminary intermediate material 9 which is the processing side peripheral surface. The mandrel 35a is the processing side rotating member described in the claims. The volume of the preliminary intermediate material 9 and the volume of the outer ring 2a that is a finished product are equal to each other. Further, the outer diameter D 9 of the pre-intermediate material 9 outer diameter D 2a of the outer ring 2a, substantially equal (D 9 ≒ D 2a). Further, both the width W 9 of the pre-intermediate material 9 width W 2a of the outer ring 2a, approximately equal (W 9 ≒ W 2a).

上記ダイ22bは、円環状で、上記予備中間素材9を実質的に隙間なく内嵌できる内径を有し、図示しない支持部に、径方向への変位を阻止された状態で、回転自在に支持されている。又、上記マンドレル35aは、この予備中間素材9及び上記外輪2aの内径側に抜き差し自在な外径を有する。又、上記マンドレル35aの中間部外周面で上記ダイ22bの内周面と対向する部分に、完成品状態での被加工側周面、即ち、上記外輪2aの内周面の母線形状と一致する母線形状を有する、加工側周面36を設けている。この様なマンドレル35aは、図示しない駆動装置により回転駆動されつつ、やはり図示しない押圧装置により、上記ダイ22bの内周面に向けて強く押し付けられる。

The die 22b is annular and has an inner diameter that allows the preliminary intermediate material 9 to be fitted substantially without gaps. The die 22b is rotatably supported by a support portion (not shown) while being prevented from being displaced in the radial direction. Has been. Further, the mandrel 35a has an outer diameter that can be freely inserted into and removed from the inner diameter side of the preliminary intermediate material 9 and the outer ring 2a. In addition, the portion of the mandrel 35a that faces the inner peripheral surface of the die 22b on the outer peripheral surface of the intermediate portion matches the generatrix shape of the processed peripheral surface in the finished product state, that is, the inner peripheral surface of the outer ring 2a. A processing side peripheral surface 36 having a bus bar shape is provided. Such a mandrel 35a is strongly driven toward the inner peripheral surface of the die 22b by a pressing device (not shown) while being rotated by a driving device (not shown).