JP2005299301A - Corrugated plate mounting structure and synthetic resin corrugated plate used for same - Google Patents

Corrugated plate mounting structure and synthetic resin corrugated plate used for same Download PDFInfo

- Publication number

- JP2005299301A JP2005299301A JP2004119896A JP2004119896A JP2005299301A JP 2005299301 A JP2005299301 A JP 2005299301A JP 2004119896 A JP2004119896 A JP 2004119896A JP 2004119896 A JP2004119896 A JP 2004119896A JP 2005299301 A JP2005299301 A JP 2005299301A

- Authority

- JP

- Japan

- Prior art keywords

- synthetic resin

- corrugated plate

- locking

- resin corrugated

- corrugated sheet

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 229920003002 synthetic resin Polymers 0.000 title claims abstract description 108

- 239000000057 synthetic resin Substances 0.000 title claims abstract description 108

- 239000000463 material Substances 0.000 claims description 44

- 238000009751 slip forming Methods 0.000 claims description 4

- 238000005452 bending Methods 0.000 claims 1

- 239000011324 bead Substances 0.000 abstract 2

- 210000000078 claw Anatomy 0.000 description 6

- 238000010276 construction Methods 0.000 description 4

- 229910052751 metal Inorganic materials 0.000 description 4

- 239000002184 metal Substances 0.000 description 4

- 229920005989 resin Polymers 0.000 description 4

- 239000011347 resin Substances 0.000 description 4

- 229910000838 Al alloy Inorganic materials 0.000 description 3

- 229910052782 aluminium Inorganic materials 0.000 description 3

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 3

- 229920005668 polycarbonate resin Polymers 0.000 description 3

- 239000004431 polycarbonate resin Substances 0.000 description 3

- 239000004925 Acrylic resin Substances 0.000 description 1

- 229920000178 Acrylic resin Polymers 0.000 description 1

- 235000012012 Paullinia yoco Nutrition 0.000 description 1

- BZHJMEDXRYGGRV-UHFFFAOYSA-N Vinyl chloride Chemical compound ClC=C BZHJMEDXRYGGRV-UHFFFAOYSA-N 0.000 description 1

Images

Landscapes

- Roof Covering Using Slabs Or Stiff Sheets (AREA)

Abstract

Description

本発明は、簡易建物の屋根やバス停留所、カーポート、或いは、屋外通路上に設けられる採光性を有する屋根を構成するための合成樹脂製波板及びその取付構造に関するものである。 TECHNICAL FIELD The present invention relates to a synthetic resin corrugated plate and a mounting structure thereof for constituting a roof having a daylighting property provided on a roof of a simple building, a bus stop, a carport, or an outdoor passage.

合成樹脂製波板は軽量で取扱性に優れ、特に、ポリカーボネート樹脂よりなる波板は耐候性においても優れているので、屋外の簡易建物の屋根材として広く採用されている。この合成樹脂製波板によって屋根を構成するには、例えば、特許文献1に記載されているように、一定幅と長さを有する長方形状の波板において、幅方向に連続する山部と谷部との進行方向を母屋(横木)の長さ方向に向けた状態にして母屋の上面間に架設し、隣接する波板の対向端部における山部や谷部同士を順次重ね合わせることによって連続させると共にその重ね合わせ部と幅方向の中間部を波板の長さ方向に所定間隔毎に釘やボルトを母屋に打ち込むことによって固着している。

Synthetic resin corrugated sheets are lightweight and excellent in handling, and in particular, corrugated sheets made of polycarbonate resin are also excellent in weather resistance, and are therefore widely used as roofing materials for outdoor simple buildings. In order to form a roof with this synthetic resin corrugated sheet, for example, as described in

しかしながら、上記のような合成樹脂製波板の取付構造によれば、合成樹脂製波板を釘やボルトによって母屋に固着しているために、合成樹脂製波板に設けられている多数の釘孔やボルト孔が弱体部となり、耐候性を有するにもかかわらず亀裂等の発生によって長期の使用に供することができなくなる虞れがあり、その上、これらの孔から雨水が浸入するので、雨漏りを防止するための処理を必要とする。また、多数の釘打ち或いはボルト止め作業を要するので、施工期間が長くなるばかりでなく、正確に釘打ち、ボルト止めを行うには熟練を要するといった問題点があった。 However, according to the synthetic resin corrugated plate mounting structure as described above, since the synthetic resin corrugated plate is fixed to the purlin with nails or bolts, a large number of nails provided on the synthetic resin corrugated plate are provided. Holes and bolt holes become weak parts and may not be able to be used for a long period of time due to the occurrence of cracks, etc. despite having weather resistance. Need to be processed to prevent Further, since a large number of nailing or bolting operations are required, not only the construction period is lengthened, but also there is a problem that skill is required for accurately nailing and bolting.

本発明はこのような問題点に鑑みてなされたもので、その目的とするところは、合成樹脂製波板の施工が釘着等によることなく簡単且つ正確に行うことができる波板の取付構造及びこれに使用する合成樹脂製波板を提供するにある。 The present invention has been made in view of such problems, and the object of the present invention is to provide a corrugated plate mounting structure in which the construction of a synthetic resin corrugated plate can be performed easily and accurately without using nailing or the like. And providing a synthetic resin corrugated sheet used therefor.

上記目的を達成するために、本発明の波板の取付構造は、請求項1に記載したように、幅方向に山部と谷部とを連続的に形成している合成樹脂製波板の両側端部を梁材に固定してなる波板の取付構造であって、合成樹脂製波板の両側端部に下方に向かって係止端部を屈折、形成している一方、上記梁材にその係止端部の固定部を設けてあり、この固定部に上記合成樹脂製波板の係止端部を係止させた状態で固定していることを特徴とする。 In order to achieve the above object, the corrugated sheet mounting structure according to the present invention is a corrugated sheet made of synthetic resin in which a crest and a trough are continuously formed in the width direction. A corrugated plate mounting structure in which both end portions are fixed to a beam material, and a locking end portion is refracted and formed downward on both side end portions of a synthetic resin corrugated plate. The fixing end portion is provided with a fixing portion, and the fixing end portion of the synthetic resin corrugated plate is fixed to the fixing portion in a fixed state.

このように構成した波板の取付構造において、請求項2に係る発明は、梁材に設けている波板固定部の構造であって、上向きに開口した係止溝と梁材の上面に装着する押し縁とからなり、上記係止溝に合成樹脂製波板の係止端部を挿入、係止させた状態で梁材の上面に支持されている波板の側端部を押し縁の下面と梁材の上面とで挟着、固定するように構成している。また、請求項3に係る発明は、両側の梁材の対向側面間に該梁材の長さ方向に所定間隔毎に桟材を固着し、この桟材に合成樹脂製波板を釘着等により固着することなく該合成樹脂製波板の谷部の下面を支持させた構造としている。

In the corrugated plate mounting structure configured as described above, the invention according to

さらに、請求項4に係る発明は、一定幅を有する合成樹脂製波板間に配設する中間梁材の構造であって、この梁材の両側部に係止溝を形成してあり、これらの係止溝に該梁材の両側方に配設した上記合成樹脂製波板の対向する係止端部を係止させた構造を有している。また、請求項5に係る発明は、上記梁材を、所定間隔毎に並設している母屋上に該母屋の長さ方向に所定間隔毎に架設状態で固着してあり、隣接する梁材の上面間に合成樹脂製波板を張設していることを特徴とする。

Furthermore, the invention according to

このような波板の取付構造に使用する合成樹脂製波板は、請求項6に記載したように、山部と谷部とが連続的に形成されていると共に、両側端の山部から下方に向かって屈折してなる係止端部を形成していることを特徴とする。

In the corrugated sheet made of synthetic resin used for such a corrugated plate mounting structure, as described in

本発明の波板取付構造によれば、合成樹脂製波板の両側端部に下方に向かって係止端部を屈折、形成してあり、この係止端部を梁材に設けている固定部に係止状態で固定するように構成しているので、合成樹脂製波板に釘孔やボルト孔を設けることなく該合成樹脂製波板の両側係止端部を両側の梁にそれぞれ固定することによって、何等の熟練を要することなく簡単且つ正確に波板の取付作業を行うことができ、その上、両側の梁材間に張設状態で取付けられた波板には釘孔やボルト孔などを設けられていないので、優れた外観を呈する上に、雨漏りや亀裂等が生じる虞れもないので、屋根材として長期の使用に供することができる。 According to the corrugated plate mounting structure of the present invention, the locking end portions are refracted and formed downward on both side end portions of the synthetic resin corrugated plate, and the locking end portions are provided on the beam material. Since the synthetic resin corrugated plate is fixed to the beam on both sides, the synthetic resin corrugated plate is fixed to the beams on both sides without providing nail holes and bolt holes. By doing so, the corrugated sheet can be easily and accurately attached without any skill, and in addition, the corrugated sheet mounted in a stretched state between the beam members on both sides has nail holes and bolts. Since there is no hole or the like, it has an excellent appearance, and there is no possibility of rain leaks, cracks, etc., so that it can be used for a long time as a roofing material.

さらに、上記梁材に設けている波板固定部の構造は、請求項2に記載したように、上向きに開口した係止溝と梁材の上面に装着する押し縁とからなり、上記係止溝に合成樹脂製波板の係止端部を挿入、係止させた状態で梁材の上面に支持されている波板の側端部を押し縁の下面と梁材の上端面とで挟着、固定するように構成してなるものであるから、合成樹脂製波板における下向きに屈折している係止端部を梁材の上向きに開口した係止溝に挿入するだけで、梁材間に合成樹脂製波板を架設状態で簡単に取付けることができると共に押し縁によって抜け止め状態に且つ強固に固定した取付構造を形成することができる。 Furthermore, the structure of the corrugated plate fixing portion provided in the beam material comprises a locking groove that opens upward and a pushing edge that is attached to the upper surface of the beam material. The side end of the corrugated plate supported by the upper surface of the beam member is inserted between the lower end of the pushing edge and the upper end surface of the beam member with the engaging end of the synthetic resin corrugated plate inserted and locked into the groove. Since it is configured to be attached and fixed, the beam material can be simply inserted into the locking groove opened upward of the beam material by inserting the locking end portion bent downward in the synthetic resin corrugated sheet. A synthetic resin corrugated sheet can be easily mounted in an erected state, and an attachment structure can be formed in which the corrugated sheet is securely attached and firmly fixed by a pushing edge.

また、請求項3に係る発明によれば、上記両側の梁材の対向側面間に該梁材の長さ方向に所定間隔毎に桟材を固着し、この桟材に合成樹脂製波板を釘着等により固着することなく該合成樹脂製波板の谷部の下面を支持させているので、合成樹脂製波板は、その両側の係止端部を梁材の係止溝に挿入、固定していることと相まって、両側係止端部間の下面が桟材に支持されているから垂れ下がることなく、さらには風圧等によってバタつくことなく常に安定した取付状態を維持することができる。

According to the invention of

請求項4に係る発明は、一定幅を有する上記合成樹脂製波板間に配設する中間梁材であって、この梁材の両側部に係止溝を形成してあり、これらの係止溝に該梁材の両側方に配設した上記合成樹脂製波板の対向する係止端部を係止させるように構成しているので、一定幅を有する合成樹脂製波板をこの梁材を介して順次、幅方向に連続させることができ、幅広い採光性を有する屋根を正確に且つ能率よく施工することができる。

The invention according to

さらに、請求項5に係る発明によれば、所定間隔毎に並設している母屋上に上記梁材を該母屋の長さ方向に所定間隔毎に架設状態で固着し、隣接する梁材の上面間に合成樹脂製波板を張設しているので、一定幅と長さを有する合成樹脂製波板を母屋上に該合成樹脂製波板の幅間隔を存して架設した梁材を介して精度よく且つ強固に施工することができるものである。

Further, according to the invention according to

また、請求項6に係る発明によれば、山部と谷部とを連続的に形成していると共に、両側端の山部から下方に向かって屈折してなる係止端部を形成しているので、この係止端部を梁材の係止溝に挿入し、その上面を押し縁で固定するだけで取付けることができる波板とすることができる。

Moreover, according to the invention which concerns on

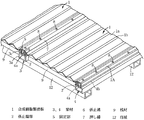

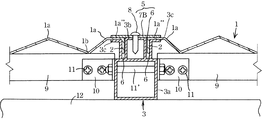

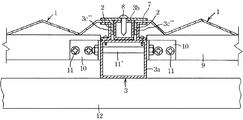

次に本発明の具体的な実施の形態を図面について説明すると、図1、図2において、1は一定幅と長さを有する平面長方形状に形成された合成樹脂製波板であって、幅方向に一定幅毎に山部1aと谷部1bとを連続的に形成していると共に両側端部を下方に向かって垂直に屈折して一定の縦幅を有する係止端部2、2に形成している。この合成樹脂製波板1は、透光性及び強度に優れたアクリル樹脂、塩化ビニル樹脂、ポリカーボネート樹脂等の合成樹脂よりなるものであるが、耐衝撃性に優れているポリカーボネート樹脂製の波板であることが好ましい。

Next, a specific embodiment of the present invention will be described with reference to the drawings. In FIGS. 1 and 2,

また、山部1aと谷部1bとの形状としては、図においては直線状に傾斜した一定幅の上向き傾斜板部と下向き傾斜板部とを幅方向にジグザグ状に連続形成した形状としているが、上向きに円弧状に湾曲した板部と下向きに円弧状に湾曲した板部とを幅方向に連続形成してなる形状や、上向き台形状と下向き台形状との板部を幅方向に連続形成してなる形状等、適宜な形状を採用することができる。なお、この合成樹脂製波板1の両側端部に屈折形成している上記係止端部2、2は、該波板1の山部1a、即ち、上向きに傾斜した板部の上傾端部1a' (図3、図4参照)から下方に向かって垂直に屈折している。

In addition, as the shape of the peak portion 1a and the valley portion 1b, in the figure, the upward inclined plate portion and the downward inclined plate portion that are linearly inclined are continuously formed in a zigzag shape in the width direction. , A shape formed by continuously forming a plate portion curved in an arc shape upward and a plate portion curved in an arc shape downward, or a plate portion of an upward trapezoidal shape and a downward trapezoidal shape continuously in the width direction Appropriate shapes such as the shapes formed can be employed. The

このように形成した合成樹脂製波板1は、その両側係止端部2、2を該合成樹脂製波板1の幅間隔を存して並設した梁材3、4の固定部5にそれぞれ固定されることによって架設状態で取付けられる。この場合、合成樹脂製波板1を2枚以上、幅方向に並設することによって所定幅の屋根を構成するものであり、該屋根の幅方向の中間部には上記一方の梁材3が中間梁材として配設され、屋根の両端部には上記他方の梁材4が端部梁材として配設される。なお、これらの梁材3、4はアルミニウム又はアルミ合金製の中空フレーム材からなり、合成樹脂製波板1の長さに略等しい長さを有している。

The synthetic resin

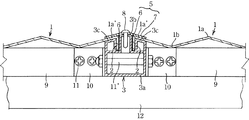

上記中間梁材3は図3に示すように、断面矩形状の中空枠部3aの上面中央部に一定幅と高さを有し且つ両側面が垂直面に形成されている中央突条部3bを全長に亘って一体に突設していると共に、上面両側部にこの中央突条部3bの側面から小間隔を存して高さが該中央突条部3bの高さよりも上記合成樹脂製波板1の厚み分だけ低い両側突条部3c、3cを全長に亘って一体に突設してあり、中央突条部3bの両側面と両側突条部3c、3cの垂直な内側面間の上記小間隔部によって合成樹脂製波板1の係止端部2が挿入、係止可能な上向きに開口した係止溝6、6を形成している。なお、両側突条部3c、3cの上端面は合成樹脂製波板1の上方に向かって傾斜した山部と同じ傾斜度の傾斜面に形成して該合成樹脂製波板1の両側上傾端部1a' の下面を全面的に支持するようにしているが、この上傾端部1a' が水平端部に屈折、形成されている場合には、当然、その上端面は水平面に形成される。

As shown in FIG. 3, the

7はこの中間梁材3の上面に装着する押し縁で、中間梁材3と略同一幅で同一長さのアルミニウム又はアルミ合金製帯板材からなり、中間梁材3の上記両側係止溝6、6にこの中間梁材3の両側に配した合成樹脂製波板1における相対する係止端部2、2をそれぞれ挿入、係止させた状態で、この押し縁7の下面中央部を上記中央突条部3bの上端面に、下面両側部を合成樹脂製波板1、1の相対する上傾端部1a' 、1a' 上にそれぞれ押しつけ、その中央部を長さ方向に一定間隔毎にビス8によって中央突条部3bに固定することにより、この押し縁7の下面両側部と中間梁材3の両側突条部3c、3cの上端面とで合成樹脂製波板1、1の上記上傾端部1a' 、1a' を挟着、固定するように構成している。そして、上記係止溝6とこの押し縁7によって合成樹脂製波板1の係止端部2の固定部5を形成している。

一方、上記端部梁材4は図4に示すように、上記中間梁材3において、両側突条部3c、3cのうち、一方の突条部3cを削除した構造を有している。即ち、断面矩形状の中空枠部4aの上面中央部に上記中間梁材3の中央突条部3bと同大、同形の中央突条部4bを全長に亘って一体に突設していると共に、上面一側部にこの中央突条部4bの側面から小間隔を存して上記中間梁材3の突条部3cと同大、同形の側方突条部4cを全長に亘って一体に突設してなるもので、これらの中央突条部4bと側方突条部4cとの垂直な内側面間の上記小間隔部によって合成樹脂製波板1の係止端部2が挿入、係止可能な上向きに開口した係止溝6を形成している。

On the other hand, as shown in FIG. 4, the

また、この端部梁材4における係止溝6と共に押し縁7Aによって合成樹脂製波板1の係止端部2の固定部5を形成してあり、この押し縁7Aは、上記中間梁材3側の押し縁7と同一材料で同一長さを有している一方、その幅は、側方突条部4c上に受止される合成樹脂製波板1の上傾端部1a' と中央突条部4bを全面的に被覆できる幅に形成されてあり、さらに、その外側端部を下方に屈折して中央突条部4bの外側面を被覆する垂直な側片部7aに形成している。そして、上記係止溝6に合成樹脂製波板1の係止端部2を挿入、係止させた状態で、この押し縁7Aの下面を側方突条部4c上に受止されている合成樹脂製1の上記上傾端部1a' 上から中央突条部4bの上端面に押しつけた状態にして、該中央突条部4bの複数箇所に押し縁7Aをビス8によって固定するように構成している。

Further, a fixing

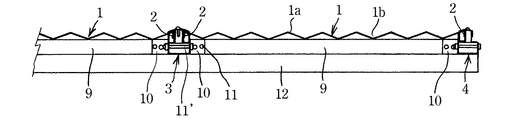

9は合成樹脂製波板1の幅間隔を存して互いに平行に配設した隣接する中間梁材3、3の対向する側面間、又は中間梁材3と端部梁材4の対向する側面間に連結、固定された桟材であって、梁材3、4と同一材料より形成されてあり、この桟材9を梁材3、4の長さ方向に所定間隔毎に梁材3、3又は3、4の対向側面間に連結、固定して、その上面で該上面に対向する合成樹脂製波板1の谷部1bの屈曲下端部を釘着、或いは、ボルト止めすることなく支持している。

9 is between the opposing side surfaces of the adjacent

桟材9の長さ方向の端部を梁材3又は梁材4の側面に固着するには、平面L字状に屈折してなる金具10を使用して行われ、この金具10の互いに直角に連設している一半部と他半部とを梁材3、4の側面とこの側面部に端面が当接している桟材9の側面とにそれぞれ当てがってビス11又はボルト11' により固着してなるものである。この場合、中間梁材3においては、その両側面に端面を突き合わせた状態で桟材9、9が一直線上に配設され、これらの梁材9、9の対向端部に一半部を固着している金具10、10の他半部同士を該中間梁材3を貫通した共通する一本の共通するボルト11' によって一体に固着されている。

The end of the

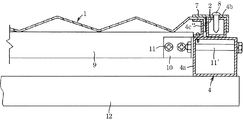

上記梁材3、4は、一定間隔毎に並設されている母屋12、12・・・上に直交するように合成樹脂製波板1の幅間隔毎に順次架設され、隣接する梁材3、4上間に上述したように合成樹脂製波板1を張設することによって屋根を構成している。

The

この屋根の施工方法を簡単に説明すると、屋根の両端側に端部梁材4、4を配置すると共にこれらの端部梁材4、4間に中間梁材3、3・・・を配置して釘やボルト、或いは適宜な金具によって母屋12上に固着する作業と、隣接する中間梁材3と端部梁材4との対向側面間、及び隣接する中間梁材3、3の対向側面間に桟材9を長さ方向に所定間隔毎に連結する作業と、隣接する梁材の固定部5、5間に合成樹脂製波板1を架設状態で張設する作業とによって行われる。この場合、母屋12、 12上に梁材3、4を施工した後、合成樹脂製波板1の張設作業を行ってもよく、梁材3、4や桟材9を施工しながら母屋12、12間に平行に固定した梁材間に合成樹脂製波板1を順次、張設してもよい。なお、隣接する梁材3、3間又は3、4間の対向側面間を連結する上記桟材9は、母屋12上に位置するように配置させることが好ましい。

This roof construction method will be briefly described.

隣接する中間梁材3と端部梁材4の上面間に合成樹脂製波板1を張設するには、該合成樹脂製波板1の谷部1bの下端面を桟材9、9上に受止させた状態にしてその両側係止端部2、2を端部梁材4の固定部5における係止溝6と、中間梁材3の一方(端部梁材4側)の固定部5における係止溝6とにそれぞれ挿入、係止させたのち、端部梁材4の上面に押し縁7Aを当てがって該端部梁材4の側方突条部4c上に支持されている合成樹脂製波板1における一方の上傾端部1a' を押さえた状態でビス8により、該押し縁7Aを端部梁材4の中央突条部4bに固着し、次いで、上記中間梁材3とこの中間梁材3に隣接する中間梁材3との対向する固定部5、5の係止溝6、6内に次の合成樹脂製波板1の両側係止端部2、2を挿入、係止させたのち、両側の係止溝6、6に両側の合成樹脂製波板1の係止端部2、2を挿入、係止させている上記中間梁材3上に押し縁7を当てがって両側の合成樹脂製波板1の対向する上傾端部1a' 、1a' を該押し縁7により押さえた状態にしてビス8によりこの押し縁7を中央突条部3bに固着して、隣接する中間梁材3と端部梁材4間に合成樹脂製波板1を張設する。

In order to stretch the synthetic resin corrugated

以下、隣接する中間梁材3、3間に対する合成樹脂製波板1の張設作業も上記同様にして順次行われるものである。このようにして施工された屋根は、屋根材である合成樹脂製波板1の両側係止端部2、2が梁材3、3又は3、4の固定部5、5によって挟着、固定され、且つ、該合成樹脂製波板1の下面が梁材間を連結している桟材9上に支持されているから、強風によっても上下方向にバタつく虞れがなく、従って、この合成樹脂製波板1を釘やボルト等によって桟材9に固定する必要はない。

Hereinafter, the operation of stretching the synthetic resin corrugated

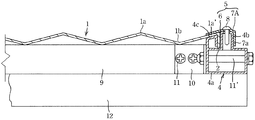

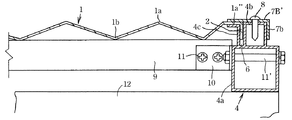

図5〜図7は、本発明の別な実施の形態を示すもので、上記実施の形態においては梁材3、4の突条部3c、4c上に支持される、合成樹脂製波板1における両側端部の上傾端部1a' 、1a' を山部1aの傾斜面と同一角度でもって連続的に傾斜させているが、この実施の形態においては、合成樹脂製波板1における両側山部1aの外側部を一定幅、水平状に屈折して上傾端部1a''、1a''を形成し、外側端部をこの上傾端部1a''、1a''(山部1a)の外側端から下方に向かって垂直に屈折させて両側係止端部2、2に形成してなるものである。

5 to 7 show another embodiment of the present invention. In the above embodiment, the synthetic resin corrugated

従って、この合成樹脂製波板1を張設する中間梁材3及び梁材4としては、断面矩形状の中空枠部3a、4aの上面中央部に両側面が垂直面に形成され、且つ、上端面が水平面に形成されている一定高さの中央突条部3b、4bをそれぞれ突設していると共に、中間梁材3においては中空枠部3aの上面両側部に上記中央突条部3bの側面から小間隔を存して高さが該中央突条部3bの高さよりも上記合成樹脂製波板1の厚み分だけ低い両側突条部3c、3cを全長に亘って一体に突設してあり、この両側突状部3c、3cの上端面を上記水平な上傾端部1a''、1a''を支持する水平上端面に形成していると共に、中央突条部3bの両側面とこれらの両側突条部3c、3cの垂直な内側面間の隙間によって合成樹脂製波板1の係止端部2が挿入、係止可能な上向きに開口した係止溝6、6を形成している。

Therefore, as the

一方、端部梁材4においては、断面矩形状の中空枠部4aの上面中央部に上記中間梁材3の中央突条部3bと同大、同形の上記中央突条部4bを全長に亘って一体に突設していると共に、上面一側部にこの中央突条部4bの側面から小間隔を存して上記中間梁材3の突条部3cと同大、同形の側方突条部4cを全長に亘って一体に突設してなるもので、これらの中央突条部4bと側方突条部4cとの垂直な内側面間の上記小間隔部によって合成樹脂製波板1の係止端部2が挿入、係止可能な上向きに開口した係止溝6を形成している。

On the other hand, in the

そして、係止溝6と共に合成樹脂製波板1の両側係止端部2の固定部5を形成する押し縁としては、中間梁材3の上面を装着する押し縁7Bにおいては、両側突条部3c、3cの外側端間の幅と略同一幅で中間梁材3と同一長さのアルミニウム又はアルミ合金製平帯板材からなり、中間梁材3の上記両側係止溝6、6にこの中間梁材3の両側に配した合成樹脂製波板1における相対する係止端部2、2をそれぞれ挿入、係止させた状態で、この押し縁7Bの下面中央部を上記中央突条部3bの上端面に、下面両側部を合成樹脂製波板1、1の相対する上傾端部1a''、1a''上にそれぞれ押しつけ、その中央部を長さ方向に一定間隔毎にビス8によって中央突条部3bに固定することにより、この押し縁7Bの下面両側部と中間梁材3の両側突条部3c、3cの上端面とで合成樹脂製波板1、1の上記上傾端部1a''、1a''を挟着、固定するように構成している。

And as a pushing edge which forms the fixing |

一方、係止溝6と共に端部梁材4の固定部を形成する押し縁7B' としては、図7に示すように、その幅は、側方突条部4c上に受止される合成樹脂製波板1の上傾端部1a''の上端面から中央突条部4bの上端面を全面的に被覆できる幅に形成されてあり、さらに、その外側端部を下方に屈折して中央突条部4bの外側面を被覆する垂直な側片部7bに形成している。そして、上記係止溝6に合成樹脂製波板1の係止端部2を挿入、係止させた状態で、この押し縁7B' の下面を側方突条部4cの水平な上端面上に受止されている合成樹脂製波板1の上記上傾端部1a''上から中央突条部4bの水平な上端面に押しつけた状態にして、該中央突条部4bの複数箇所に押し縁7B' をビス8によって固定するように構成している。隣接する梁材の対向側面間を連結してその上面で合成樹脂製波板1の谷部下端を支持する桟材9の連結構造や、母屋12に対する梁材3、4の取付構造等は上記実施の形態と同様であるので、同一部分に同一符号を付して詳細な説明を省略する。

On the other hand, as shown in FIG. 7, the width of the pushing

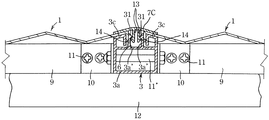

図8、図9は、本発明のさらに別な実施の形態を示すもので、上記いずれの実施の形態においても、合成樹脂製波板1の係止端部2の固定手段としての押し縁7(7A、7B、7B' )等を梁材3、4の中央突条部3b、4bに固着するにはビス8によって行っているが、この実施の形態においてはビスを使用することなく押し縁7C、7C' を固着している。

8 and 9 show still another embodiment of the present invention. In any of the above embodiments, the pushing

即ち、梁材3、4における中央突条部3b、4bに代えて、中空枠部3a、4aの上面中央部に幅方向に一定間隔を存して上端部の相対する内側面にフック形状の係止爪31、31;41、41をそれぞれ形成している一定高さの一対の係止突条部3a' 、3a' ;4a' 、4a' を突設している一方、中間梁材3側の押し縁7Cにおいてはその下面中央部に、上記係止突条部3a' 、3a' 間に挿入可能で下端部対向内側面に上記係止爪31、31に係止する係止爪14、14をそれぞれ形成している一対の係止片13、13を下方に向かって突設してあり、端部梁材4側の押し縁7C' においてはその下面に、上記係止突条部4a' 、4a' 間に挿入可能で下端部対向内側面に上記係止爪41、41に係止する係止爪14、14をそれぞれ形成している一対の係止片13、13を下方に向かって突設していると共に該押し縁7Cの一側部を下方に向かって垂直に屈折させて外側係止突条部4a' の外側面に係止状態で当接させる垂直な側片部7cに形成している。

That is, instead of the

そして、梁材3、4における中空枠部3aの上面側部に突設している突条部3c、4cと上記係止突状部3a' 、4a' との対向する側面間の隙間によって合成樹脂製波板1の係止端部2を挿入、係止させる係止溝6を形成している。その他の構成については、上記実施の形態と同様であるので、同一部分には同一符号を付して詳細な説明を省略する。

The

このように構成したので、隣接する梁材3、3又は3、4の係止溝6に合成樹脂製波板1の係止端部2を挿入、係止させたのち、上記押し縁7C、7C' の下面に突設している一対の係止片13、13を梁材3、4の上記一対の係止突状部3a' 、3a' 間又は4a' 、4a' 間に挿入して互いに係止爪13、31;13、41同士を抜け止め状態で係止させることにより、これらの押し縁7C、7C' の下面と側部の突条部3c、4cの上面間で合成樹脂製波板1の係止端部2を挟着、固定させるものである。

Since it comprised in this way, after inserting and latching the

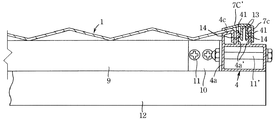

なお、以上のいずれの実施の形態においても、梁材3、4として中空枠部3a、4aの上面に中央突条部3b、4bと側方の突条部3c、4cとを一体に形成しているが、図10、図11に示すように、少なくとも側方の突条部3c''、4c''を別体に形成しておき、合成樹脂製波板1の施工時に、中央突条部3b(4b)と該突条部3c''(4c'')とで合成樹脂製波板1の係止端部2を挟着するようにこの突条部3c''(4c'')を中空枠部3a、4aの上面側部上にビス止めすることにより固着してもよい。この場合、突条部3c''(4c'')としては、断面コ字状に形成しておき、その下端水平フランジ部を中空枠部3a、4aの上面側部上に重ね合わせてビス止めするように構成しておくことが望ましい。

In any of the above embodiments, the

1 合成樹脂製波板

2 係止端部

3、4 梁材

5 固定部

6 係止溝

7 押し縁

9 桟材

12 母屋

DESCRIPTION OF

12 Purlin

Claims (6)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004119896A JP2005299301A (en) | 2004-04-15 | 2004-04-15 | Corrugated plate mounting structure and synthetic resin corrugated plate used for same |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004119896A JP2005299301A (en) | 2004-04-15 | 2004-04-15 | Corrugated plate mounting structure and synthetic resin corrugated plate used for same |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| JP2005299301A true JP2005299301A (en) | 2005-10-27 |

Family

ID=35331185

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004119896A Pending JP2005299301A (en) | 2004-04-15 | 2004-04-15 | Corrugated plate mounting structure and synthetic resin corrugated plate used for same |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2005299301A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR200446045Y1 (en) | 2009-06-04 | 2009-09-21 | 김학수 | Sewer odor reverse protection trench cover |

-

2004

- 2004-04-15 JP JP2004119896A patent/JP2005299301A/en active Pending

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR200446045Y1 (en) | 2009-06-04 | 2009-09-21 | 김학수 | Sewer odor reverse protection trench cover |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4954746B2 (en) | Skylight support structure | |

| US7546708B2 (en) | Light transmission panels, retaining clip and a combination thereof | |

| US8056289B1 (en) | Dual glazing panel system | |

| US5390453A (en) | Structural members and structures assembled therefrom | |

| US6164024A (en) | Architectural glazing panel system and retaining clip therefor | |

| CN101227988B (en) | A cladding sheet and cladding component | |

| US5867949A (en) | Building structure | |

| AU2011232748B2 (en) | Truss System | |

| US9528266B2 (en) | Dual glazing panel system | |

| US9151056B2 (en) | Dual glazing panel system | |

| AU8272387A (en) | Panel mounting system | |

| JP3894931B2 (en) | Solar panel mounting base | |

| EP1493877B1 (en) | Waterproof structure of building | |

| JP2005299301A (en) | Corrugated plate mounting structure and synthetic resin corrugated plate used for same | |

| JP5821084B2 (en) | Folded plate roof material, connection structure of the folded plate roof material, and a coupling tool used for connecting the folded plate roof material. | |

| US7591115B2 (en) | Roof tile support arrangement | |

| JP2561411Y2 (en) | Assembled buildings such as carports | |

| JP2927709B2 (en) | Roof structure such as greenhouse | |

| CA2885428C (en) | Dual glazing panel system | |

| JP7721133B2 (en) | Ceiling support bracket, its installation method, ceiling material mounting structure using this ceiling support bracket, and exterior structure | |

| JP4264419B2 (en) | Roof panel | |

| JP2006144318A (en) | Daylighting roof | |

| JP2898244B2 (en) | Support structure for folded roof | |

| JP3389167B2 (en) | Roof repair structure and repair method | |

| JPH10259650A (en) | Roof structure of building and its construction method |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Effective date: 20070406 Free format text: JAPANESE INTERMEDIATE CODE: A621 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20090715 |

|

| A131 | Notification of reasons for refusal |

Effective date: 20090728 Free format text: JAPANESE INTERMEDIATE CODE: A131 |

|

| A02 | Decision of refusal |

Effective date: 20091124 Free format text: JAPANESE INTERMEDIATE CODE: A02 |