EP4350102A1 - Nivellierteil - Google Patents

Nivellierteil Download PDFInfo

- Publication number

- EP4350102A1 EP4350102A1 EP22815421.7A EP22815421A EP4350102A1 EP 4350102 A1 EP4350102 A1 EP 4350102A1 EP 22815421 A EP22815421 A EP 22815421A EP 4350102 A1 EP4350102 A1 EP 4350102A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- inverted

- shaped element

- base

- levelling

- thickening

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04F—FINISHING WORK ON BUILDINGS, e.g. STAIRS, FLOORS

- E04F21/00—Implements for finishing work on buildings

- E04F21/0092—Separate provisional spacers used between adjacent floor or wall tiles

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04F—FINISHING WORK ON BUILDINGS, e.g. STAIRS, FLOORS

- E04F15/00—Flooring

- E04F15/02—Flooring or floor layers composed of a number of similar elements

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04F—FINISHING WORK ON BUILDINGS, e.g. STAIRS, FLOORS

- E04F21/00—Implements for finishing work on buildings

- E04F21/18—Implements for finishing work on buildings for setting wall or ceiling slabs or plates

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04F—FINISHING WORK ON BUILDINGS, e.g. STAIRS, FLOORS

- E04F21/00—Implements for finishing work on buildings

- E04F21/20—Implements for finishing work on buildings for laying flooring

Definitions

- the present invention relates to a levelling piece for cladding panels, such as wall tiles, floor tiles, or paving tiles, intended for facilitating the installation of constructive elements of this type.

- the levelling piece has an inverted T-shaped profile configuration with a flat base from which an inverted U-shaped element which has a thickening of variable thickness emerges perpendicularly.

- the object of the invention is to provide use in addition to that commonly envisaged for the levelling piece.

- the inverted U-shaped element which is part of the levelling piece, is used for a second use as a result of its novel configuration.

- Levelling pieces which, when used in combination with a wedge, facilitate the placement of cladding panels and their uniform arrangement on floors, walls, or other surfaces, are known in the state of the art. To that end, there is provided a bonding material, such as mortar or an adhesive, on which the panels which will clad the surface are placed. Said operation involves as many levelling pieces as necessary for the perfect separation and levelling of the cladding panels.

- levelling pieces have an inverted T-shaped configuration with a flat base from which an inverted U-shaped element, commonly known as a horseshoe spacer, emerges perpendicularly, and wherein the inverted U-shaped element is provided with an opening. These levelling pieces are supported at their base on the bonding material.

- Cladding panels are then arranged such that there are at least two levelling pieces on each side.

- the wedge is introduced through the opening of each levelling piece which separates two cladding panels. Upon hitting the wedge, a force is generated on the inverted U-shaped element tending to separate the levelling piece and the surface to be clad, which will also cause the separation of the cladding panels, with the panels being levelled out.

- the described operation requires the use and breakage of a large number of levelling pieces which causes the removal of a large amount of polymer material to be disposed of without any additional application envisaged for same. Therefore, the applicant of the present utility model detects the need to provide an invention which offers an environmentally friendly solution which involves reusing the inverted U-shaped element after its separation from the levelling piece.

- the configuration of the proposed levelling piece enables a second function of that part which is unusable once the levelling of cladding panels has been performed and the bonding material is dry, specifically a wedge-like separating function.

- the levelling piece for cladding panels has an inverted T-shaped profile with a flat base from which an inverted U-shaped element of the known types emerges perpendicularly.

- the inverted U-shaped element is joined to the base by respective arms defining an opening.

- the arms optionally have notches at the ends which are joined to the base. These notches are what allow the arms of the inverted U-shaped element to break once the cladding panels have been properly installed and levelled as a result of the levelling piece.

- the levelling piece has in the upper middle region of the inverted U-shaped element a thickening of variable thickness. It is precisely said thickening of variable thickness that generates a separating or spacing function in any of the preferred embodiments of the invention that are described in detail below.

- said thickening of variable thickness is defined by a perimeter of variable thickness in the upper middle region of the inverted U-shaped element or by a projection extending from one side to the opposite side of the inverted U-shaped element, generating a thickening in a plane parallel to the base the thickness of which decreases gradually as it approaches the end opposite the base, defining a pointed termination.

- the thickening in a perimeter of variable thickness or at a pointed termination defines a spacing wedge shape which allows the introduction thereof between the cladding panels to keep them separated during installation.

- the inverted U-shaped element once the inverted U-shaped element is separated from of the rest of the levelling piece, it can be used as a spacing wedge for other elements for cladding installation.

- part of the levelling piece is utilized for another function, in contrast to the known levelling pieces in which the inverted U-shaped element is disposed of once separated from the rest of the levelling piece, with the subsequent material wastage and environmental impact.

- the use of the inverted U-shaped element which includes the mentioned thickening of variable thickness, offers a versatile and environmentally friendly levelling piece.

- the levelling piece has an inverted T-shaped profile with a flat base (2) from which an inverted U-shaped element (3) emerges perpendicularly, and wherein the inverted U-shaped element (3) is joined to the base (2) by respective arms (4) defining an opening (5).

- the levelling pieces of the present invention have in the preferred embodiment thereof notches (6) arranged at the ends of the arms (4) which are joined to the base (2), in order to facilitate the weakening and breakage of the inverted U-shaped element with respect to the base (2).

- the ends of the base (2) farthest away from the inverted U-shaped element (3) preferably have a reduction in thickness and/or bevelled corners (2') in the base (2), included for the purpose of minimising the amount of material used per levelling piece manufactured, always maintaining the mechanical strength necessary for performing its function.

- this section illustrates up to four preferred embodiments of the invention having in the upper middle region of the inverted U-shaped element (3) a thickening of variable thickness in order to serve as a spacing wedge for use once it has been separated from the base (2) after the levelling of the cladding panels and the drying of the bonding material.

- a first preferred embodiment of the invention can be seen in the indicated Figures 1 to 3 , wherein the thickening of the levelling piece (1) has a gradual increase in thickness extending in the radial direction (7) in the upper middle region of the inverted U-shaped element (3).

- the thickening in this first preferred embodiment of the invention is defined by a perimeter of variable thickness in the upper middle region of the inverted U-shaped element (3).

- Figures 4 and 5 depict the second preferred embodiment of the invention, wherein the thickening of the levelling piece (10) is defined by a projection (11) extending from one side to the opposite side of the inverted U-shaped element (3), generating a thickening in a plane parallel to the base (2).

- the thickness of the inverted U-shaped element decreases gradually as it approaches the end opposite the base (2), in this sense

- Figure 5 shows the thickness (e11) of the projection (11) which decreases until defining a pointed termination (12) having a smaller thickness (e12) than the thickness (e11) of the projection (11).

- the thickening is defined by a projection (21) as can be seen in Figures 6 and 7 .

- Said projection (21) extends from one side to the opposite side of the inverted U-shaped element (3) and generates a thickening in a plane parallel to the base (2).

- the thickness of the thickening in the third preferred embodiment decreases by way of steps (23) as it approaches the end opposite the base (2), defining a pointed termination (22).

- the thickness (e21) of the projection (21) is greater than the thickness (e23) of the step (23), whereas the thickness (e23) of the step (23) is greater than the thickness (e22) of the pointed termination (22).

- Figure 6 depicts a step (23) located between the projection (21) and the pointed termination (22), however, said embodiment is not limiting of the present protection.

- the levelling piece can have more than one step (23) in order to decrease the thickness of the thickening.

- the fourth preferred embodiment of the invention depicted in Figures 8 and 9 allows observing that the levelling piece (30) has a thickening defined by a projection (31) arranged centred in the upper middle region of the inverted U-shaped element (3).

- the thickness of the projection (31) decreases gradually as it approaches the end opposite the base (2), defining a pointed termination (32) of thickness (e32), as depicted in Figure 9 .

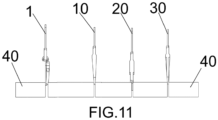

- any of the proposed levelling pieces (1), (10), (20), (30) has a configuration such that they enable subsequent use for placement between the cladding panels (40), performing a spacing or separating function.

- it is a significant use which involves reusing that portion of the levelling piece which, up until now, was unusable once levelling between the cladding panels (40) had been performed.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Finishing Walls (AREA)

- On-Site Construction Work That Accompanies The Preparation And Application Of Concrete (AREA)

- Road Paving Structures (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| ES202131155U ES1272199Y1 (es) | 2021-06-03 | 2021-06-03 | Pieza de nivelación |

| PCT/ES2022/070343 WO2022254072A1 (es) | 2021-06-03 | 2022-06-02 | Pieza de nivelación |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP4350102A1 true EP4350102A1 (de) | 2024-04-10 |

| EP4350102A4 EP4350102A4 (de) | 2025-07-02 |

Family

ID=76578264

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP22815421.7A Pending EP4350102A4 (de) | 2021-06-03 | 2022-06-02 | Nivellierteil |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US20240247503A1 (de) |

| EP (1) | EP4350102A4 (de) |

| CA (1) | CA3221013A1 (de) |

| ES (1) | ES1272199Y1 (de) |

| WO (1) | WO2022254072A1 (de) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| USD1088812S1 (en) * | 2022-05-23 | 2025-08-19 | Q.E.P. Co. Inc. | Clip for tile leveler |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20120297714A1 (en) * | 2011-05-27 | 2012-11-29 | Tavy Enterprises, Llc | Wege-Shaped Tile Spacer |

| ES1075226Y (es) | 2011-06-10 | 2011-11-18 | Serrano Luis Miguel Perales | Dispositivo para nivelar placas rigidas de revestimiento |

| ES1214135Y (es) * | 2018-05-14 | 2018-09-13 | Haro Garcia Antonio Luis | Pieza de nivelacion de placas de revestimiento |

| WO2020191470A1 (pt) * | 2019-03-27 | 2020-10-01 | Andrade Jefferson Prestes De | Kit para espaçamento e nivelamento de peças de revestimento |

-

2021

- 2021-06-03 ES ES202131155U patent/ES1272199Y1/es active Active

-

2022

- 2022-06-02 CA CA3221013A patent/CA3221013A1/en active Pending

- 2022-06-02 US US18/566,358 patent/US20240247503A1/en active Pending

- 2022-06-02 EP EP22815421.7A patent/EP4350102A4/de active Pending

- 2022-06-02 WO PCT/ES2022/070343 patent/WO2022254072A1/es not_active Ceased

Also Published As

| Publication number | Publication date |

|---|---|

| CA3221013A1 (en) | 2022-12-08 |

| EP4350102A4 (de) | 2025-07-02 |

| ES1272199U (es) | 2021-07-01 |

| ES1272199Y1 (es) | 2022-03-17 |

| US20240247503A1 (en) | 2024-07-25 |

| WO2022254072A1 (es) | 2022-12-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US10724254B1 (en) | Wedge leveling system | |

| CN101939245B (zh) | 用于具有保持分开的分支的结构件的操纵锚固件 | |

| US20210180337A1 (en) | Tile laying accessory | |

| US20200063448A1 (en) | Tile positioning device | |

| EP4350102A1 (de) | Nivellierteil | |

| EP2966239B1 (de) | Ein abstandselement für verkleidungselemente | |

| EP3569793A1 (de) | Nivellierteil für verkleidungsplatten | |

| US6119431A (en) | Method of moving heavy materials | |

| KR100585503B1 (ko) | 유공 및/또는 서로 엇갈리게 찢은 강판을 이용한 전단연결재 | |

| IT202000012022A1 (it) | Dispositivo distanziatore livellante | |

| JP2022515231A (ja) | コンクリートフロアのためのアンカー | |

| EP4350101A1 (de) | Nivellierteil | |

| WO2019071183A1 (en) | BASE AND TILT LEVELING BASE MANUFACTURED ONLY | |

| ITRM20130722A1 (it) | Connettore antiscorrimento secondo le sollecitazioni prevalenti a trazione e compressione | |

| CN107327136A (zh) | 一种组合式模板与木模板结合使用的安装及拆卸方法 | |

| KR101551130B1 (ko) | 복합말뚝의 연결부 | |

| EP2341198A2 (de) | Modulare Kabeldurchführung | |

| JP6945911B1 (ja) | 透かしレンガ積み壁材の構築方法 | |

| US20100006722A1 (en) | Brace for retaining panels during cement distribution | |

| EP4166734A1 (de) | Vorrichtung zum nivellieren von flächigen verkleidungsteilen auf vertikalen oder horizontalen flächen | |

| CN222139687U (zh) | 可拼装式工地便道 | |

| SE439045B (sv) | Forfarande for att genom slag forankra en kilbult i ett hal samt kilbultanordning | |

| JP3068197U (ja) | 床下地材支持具 | |

| JP3221282U (ja) | タイル敷設補助具 | |

| CN109537802B (zh) | 一种叠合梁结构 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE INTERNATIONAL PUBLICATION HAS BEEN MADE |

|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20231227 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| DAX | Request for extension of the european patent (deleted) | ||

| RAV | Requested validation state of the european patent: fee paid |

Extension state: MA Effective date: 20231227 |

|

| A4 | Supplementary search report drawn up and despatched |

Effective date: 20250602 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: E04F 21/18 20060101ALI20250526BHEP Ipc: E04F 15/02 20060101ALI20250526BHEP Ipc: E04F 13/08 20060101ALI20250526BHEP Ipc: E04F 21/20 20060101ALI20250526BHEP Ipc: E04F 21/00 20060101AFI20250526BHEP |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20250916 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |