EP4283003A1 - Procédé de fabrication d'une pièce moulée en tôle - Google Patents

Procédé de fabrication d'une pièce moulée en tôle Download PDFInfo

- Publication number

- EP4283003A1 EP4283003A1 EP22175105.0A EP22175105A EP4283003A1 EP 4283003 A1 EP4283003 A1 EP 4283003A1 EP 22175105 A EP22175105 A EP 22175105A EP 4283003 A1 EP4283003 A1 EP 4283003A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- wop

- wgb

- weight

- sheet metal

- content

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 229910052751 metal Inorganic materials 0.000 title claims abstract description 94

- 239000002184 metal Substances 0.000 title claims abstract description 94

- 238000004519 manufacturing process Methods 0.000 title abstract description 13

- 238000000034 method Methods 0.000 claims abstract description 65

- 238000005096 rolling process Methods 0.000 claims abstract description 53

- 229910052739 hydrogen Inorganic materials 0.000 claims abstract description 31

- 239000001257 hydrogen Substances 0.000 claims abstract description 31

- 229910000831 Steel Inorganic materials 0.000 claims description 161

- 239000010959 steel Substances 0.000 claims description 161

- 238000000576 coating method Methods 0.000 claims description 77

- 239000011248 coating agent Substances 0.000 claims description 72

- 229910052782 aluminium Inorganic materials 0.000 claims description 51

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 claims description 46

- 238000005260 corrosion Methods 0.000 claims description 45

- 239000000758 substrate Substances 0.000 claims description 42

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 claims description 38

- 230000007797 corrosion Effects 0.000 claims description 34

- 229910045601 alloy Inorganic materials 0.000 claims description 29

- 239000000956 alloy Substances 0.000 claims description 29

- 229910052710 silicon Inorganic materials 0.000 claims description 26

- 238000001816 cooling Methods 0.000 claims description 25

- 238000010438 heat treatment Methods 0.000 claims description 23

- 229910052748 manganese Inorganic materials 0.000 claims description 23

- 229910052784 alkaline earth metal Inorganic materials 0.000 claims description 22

- 238000005452 bending Methods 0.000 claims description 22

- 239000002585 base Substances 0.000 claims description 21

- 229910052759 nickel Inorganic materials 0.000 claims description 21

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 claims description 19

- 229910052802 copper Inorganic materials 0.000 claims description 17

- 229910052750 molybdenum Inorganic materials 0.000 claims description 16

- 230000008569 process Effects 0.000 claims description 16

- 230000002787 reinforcement Effects 0.000 claims description 16

- 239000012535 impurity Substances 0.000 claims description 15

- 229910052720 vanadium Inorganic materials 0.000 claims description 15

- 229910052804 chromium Inorganic materials 0.000 claims description 14

- 229910052742 iron Inorganic materials 0.000 claims description 14

- 150000001342 alkaline earth metals Chemical class 0.000 claims description 12

- 229910052796 boron Inorganic materials 0.000 claims description 12

- 229910052758 niobium Inorganic materials 0.000 claims description 12

- 150000002431 hydrogen Chemical class 0.000 claims description 11

- 229910052757 nitrogen Inorganic materials 0.000 claims description 11

- 239000003513 alkali Substances 0.000 claims description 10

- 229910052721 tungsten Inorganic materials 0.000 claims description 10

- 239000012298 atmosphere Substances 0.000 claims description 9

- 229910052719 titanium Inorganic materials 0.000 claims description 9

- 229910052785 arsenic Inorganic materials 0.000 claims description 6

- 229910052698 phosphorus Inorganic materials 0.000 claims description 6

- 229910052717 sulfur Inorganic materials 0.000 claims description 6

- 229910052718 tin Inorganic materials 0.000 claims description 6

- 238000012546 transfer Methods 0.000 claims description 5

- 238000000465 moulding Methods 0.000 claims description 3

- 125000004435 hydrogen atom Chemical class [H]* 0.000 abstract description 3

- 239000000047 product Substances 0.000 description 72

- 239000011572 manganese Substances 0.000 description 36

- 239000010955 niobium Substances 0.000 description 30

- PXHVJJICTQNCMI-UHFFFAOYSA-N nickel Substances [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 28

- 230000015572 biosynthetic process Effects 0.000 description 22

- 239000011148 porous material Substances 0.000 description 22

- 239000011651 chromium Substances 0.000 description 21

- 229910052799 carbon Inorganic materials 0.000 description 18

- 239000010949 copper Substances 0.000 description 18

- 229910000859 α-Fe Inorganic materials 0.000 description 16

- 230000000694 effects Effects 0.000 description 15

- 229910000734 martensite Inorganic materials 0.000 description 15

- 239000011575 calcium Substances 0.000 description 14

- 239000011777 magnesium Substances 0.000 description 14

- 239000010703 silicon Substances 0.000 description 14

- 239000000463 material Substances 0.000 description 13

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 12

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 12

- 239000002244 precipitate Substances 0.000 description 12

- 239000010936 titanium Substances 0.000 description 12

- PWHULOQIROXLJO-UHFFFAOYSA-N Manganese Chemical compound [Mn] PWHULOQIROXLJO-UHFFFAOYSA-N 0.000 description 11

- 239000000155 melt Substances 0.000 description 11

- 229910001566 austenite Inorganic materials 0.000 description 10

- 239000000203 mixture Substances 0.000 description 9

- ZOXJGFHDIHLPTG-UHFFFAOYSA-N Boron Chemical compound [B] ZOXJGFHDIHLPTG-UHFFFAOYSA-N 0.000 description 8

- GUCVJGMIXFAOAE-UHFFFAOYSA-N niobium atom Chemical compound [Nb] GUCVJGMIXFAOAE-UHFFFAOYSA-N 0.000 description 8

- 230000036961 partial effect Effects 0.000 description 8

- 238000003466 welding Methods 0.000 description 8

- 229910001563 bainite Inorganic materials 0.000 description 7

- 229910052791 calcium Inorganic materials 0.000 description 7

- 238000003618 dip coating Methods 0.000 description 7

- 229910052749 magnesium Inorganic materials 0.000 description 7

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 6

- 238000011161 development Methods 0.000 description 6

- 230000018109 developmental process Effects 0.000 description 6

- 238000012545 processing Methods 0.000 description 6

- 230000009467 reduction Effects 0.000 description 6

- 230000035882 stress Effects 0.000 description 6

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 5

- 238000010276 construction Methods 0.000 description 5

- 238000012360 testing method Methods 0.000 description 5

- 230000007704 transition Effects 0.000 description 5

- LEONUFNNVUYDNQ-UHFFFAOYSA-N vanadium atom Chemical compound [V] LEONUFNNVUYDNQ-UHFFFAOYSA-N 0.000 description 5

- 239000011701 zinc Substances 0.000 description 5

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 description 4

- 238000005520 cutting process Methods 0.000 description 4

- 238000004147 desorption mass spectrometry Methods 0.000 description 4

- 238000002474 experimental method Methods 0.000 description 4

- 150000004679 hydroxides Chemical class 0.000 description 4

- 239000011733 molybdenum Substances 0.000 description 4

- 230000006911 nucleation Effects 0.000 description 4

- 238000010899 nucleation Methods 0.000 description 4

- TWNQGVIAIRXVLR-UHFFFAOYSA-N oxo(oxoalumanyloxy)alumane Chemical compound O=[Al]O[Al]=O TWNQGVIAIRXVLR-UHFFFAOYSA-N 0.000 description 4

- 230000002829 reductive effect Effects 0.000 description 4

- 238000009864 tensile test Methods 0.000 description 4

- FYYHWMGAXLPEAU-UHFFFAOYSA-N Magnesium Chemical compound [Mg] FYYHWMGAXLPEAU-UHFFFAOYSA-N 0.000 description 3

- ZOKXTWBITQBERF-UHFFFAOYSA-N Molybdenum Chemical compound [Mo] ZOKXTWBITQBERF-UHFFFAOYSA-N 0.000 description 3

- UJXVAJQDLVNWPS-UHFFFAOYSA-N [Al].[Al].[Al].[Fe] Chemical class [Al].[Al].[Al].[Fe] UJXVAJQDLVNWPS-UHFFFAOYSA-N 0.000 description 3

- -1 are heated Substances 0.000 description 3

- 238000010586 diagram Methods 0.000 description 3

- 238000009792 diffusion process Methods 0.000 description 3

- 230000000977 initiatory effect Effects 0.000 description 3

- 239000007788 liquid Substances 0.000 description 3

- 230000008092 positive effect Effects 0.000 description 3

- 239000002436 steel type Substances 0.000 description 3

- 230000009466 transformation Effects 0.000 description 3

- WFKWXMTUELFFGS-UHFFFAOYSA-N tungsten Chemical compound [W] WFKWXMTUELFFGS-UHFFFAOYSA-N 0.000 description 3

- 239000010937 tungsten Substances 0.000 description 3

- 229910052725 zinc Inorganic materials 0.000 description 3

- 229910052582 BN Inorganic materials 0.000 description 2

- OYPRJOBELJOOCE-UHFFFAOYSA-N Calcium Chemical compound [Ca] OYPRJOBELJOOCE-UHFFFAOYSA-N 0.000 description 2

- 241000282994 Cervidae Species 0.000 description 2

- VYZAMTAEIAYCRO-UHFFFAOYSA-N Chromium Chemical compound [Cr] VYZAMTAEIAYCRO-UHFFFAOYSA-N 0.000 description 2

- 229910015372 FeAl Inorganic materials 0.000 description 2

- HCHKCACWOHOZIP-UHFFFAOYSA-N Zinc Chemical compound [Zn] HCHKCACWOHOZIP-UHFFFAOYSA-N 0.000 description 2

- XLOMVQKBTHCTTD-UHFFFAOYSA-N Zinc monoxide Chemical compound [Zn]=O XLOMVQKBTHCTTD-UHFFFAOYSA-N 0.000 description 2

- 238000009825 accumulation Methods 0.000 description 2

- 238000004026 adhesive bonding Methods 0.000 description 2

- 238000005275 alloying Methods 0.000 description 2

- 238000006243 chemical reaction Methods 0.000 description 2

- 238000005336 cracking Methods 0.000 description 2

- 230000007547 defect Effects 0.000 description 2

- 238000009826 distribution Methods 0.000 description 2

- 230000029142 excretion Effects 0.000 description 2

- 230000002401 inhibitory effect Effects 0.000 description 2

- 238000003698 laser cutting Methods 0.000 description 2

- 239000000395 magnesium oxide Substances 0.000 description 2

- CPLXHLVBOLITMK-UHFFFAOYSA-N magnesium oxide Inorganic materials [Mg]=O CPLXHLVBOLITMK-UHFFFAOYSA-N 0.000 description 2

- AXZKOIWUVFPNLO-UHFFFAOYSA-N magnesium;oxygen(2-) Chemical compound [O-2].[Mg+2] AXZKOIWUVFPNLO-UHFFFAOYSA-N 0.000 description 2

- 230000003647 oxidation Effects 0.000 description 2

- 238000007254 oxidation reaction Methods 0.000 description 2

- 229910001562 pearlite Inorganic materials 0.000 description 2

- 238000004080 punching Methods 0.000 description 2

- 238000007670 refining Methods 0.000 description 2

- 230000000717 retained effect Effects 0.000 description 2

- 230000003068 static effect Effects 0.000 description 2

- 238000007669 thermal treatment Methods 0.000 description 2

- 229910000838 Al alloy Inorganic materials 0.000 description 1

- 229910000851 Alloy steel Inorganic materials 0.000 description 1

- 229910000640 Fe alloy Inorganic materials 0.000 description 1

- 229910021328 Fe2Al5 Inorganic materials 0.000 description 1

- 229910017372 Fe3Al Inorganic materials 0.000 description 1

- 229910001182 Mo alloy Inorganic materials 0.000 description 1

- GRYLNZFGIOXLOG-UHFFFAOYSA-N Nitric acid Chemical compound O[N+]([O-])=O GRYLNZFGIOXLOG-UHFFFAOYSA-N 0.000 description 1

- OAICVXFJPJFONN-UHFFFAOYSA-N Phosphorus Chemical compound [P] OAICVXFJPJFONN-UHFFFAOYSA-N 0.000 description 1

- 244000089486 Phragmites australis subsp australis Species 0.000 description 1

- 235000014676 Phragmites communis Nutrition 0.000 description 1

- NINIDFKCEFEMDL-UHFFFAOYSA-N Sulfur Chemical compound [S] NINIDFKCEFEMDL-UHFFFAOYSA-N 0.000 description 1

- ATJFFYVFTNAWJD-UHFFFAOYSA-N Tin Chemical compound [Sn] ATJFFYVFTNAWJD-UHFFFAOYSA-N 0.000 description 1

- 238000002441 X-ray diffraction Methods 0.000 description 1

- XACAZEWCMFHVBX-UHFFFAOYSA-N [C].[Mo] Chemical class [C].[Mo] XACAZEWCMFHVBX-UHFFFAOYSA-N 0.000 description 1

- 238000010521 absorption reaction Methods 0.000 description 1

- 238000007792 addition Methods 0.000 description 1

- 239000000853 adhesive Substances 0.000 description 1

- 230000001070 adhesive effect Effects 0.000 description 1

- 230000032683 aging Effects 0.000 description 1

- 230000001476 alcoholic effect Effects 0.000 description 1

- JZQOJFLIJNRDHK-CMDGGOBGSA-N alpha-irone Chemical compound CC1CC=C(C)C(\C=C\C(C)=O)C1(C)C JZQOJFLIJNRDHK-CMDGGOBGSA-N 0.000 description 1

- 238000004458 analytical method Methods 0.000 description 1

- RQNWIZPPADIBDY-UHFFFAOYSA-N arsenic atom Chemical compound [As] RQNWIZPPADIBDY-UHFFFAOYSA-N 0.000 description 1

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 230000004888 barrier function Effects 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 239000010960 cold rolled steel Substances 0.000 description 1

- 238000005097 cold rolling Methods 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 230000032798 delamination Effects 0.000 description 1

- 230000003111 delayed effect Effects 0.000 description 1

- 230000001627 detrimental effect Effects 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 230000001747 exhibiting effect Effects 0.000 description 1

- 238000007731 hot pressing Methods 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 238000005304 joining Methods 0.000 description 1

- 230000007774 longterm Effects 0.000 description 1

- VCTOKJRTAUILIH-UHFFFAOYSA-N manganese(2+);sulfide Chemical class [S-2].[Mn+2] VCTOKJRTAUILIH-UHFFFAOYSA-N 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 238000002844 melting Methods 0.000 description 1

- 229910017604 nitric acid Inorganic materials 0.000 description 1

- 229910052760 oxygen Inorganic materials 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 230000035515 penetration Effects 0.000 description 1

- 239000011574 phosphorus Substances 0.000 description 1

- 238000012805 post-processing Methods 0.000 description 1

- 238000001556 precipitation Methods 0.000 description 1

- 230000001681 protective effect Effects 0.000 description 1

- 230000000979 retarding effect Effects 0.000 description 1

- 230000035945 sensitivity Effects 0.000 description 1

- 239000006104 solid solution Substances 0.000 description 1

- 230000002269 spontaneous effect Effects 0.000 description 1

- 230000000087 stabilizing effect Effects 0.000 description 1

- 239000000161 steel melt Substances 0.000 description 1

- 238000005728 strengthening Methods 0.000 description 1

- 239000011593 sulfur Substances 0.000 description 1

- 238000006557 surface reaction Methods 0.000 description 1

- 238000000844 transformation Methods 0.000 description 1

- 238000011282 treatment Methods 0.000 description 1

- 238000009966 trimming Methods 0.000 description 1

- 238000009827 uniform distribution Methods 0.000 description 1

- 238000009736 wetting Methods 0.000 description 1

- 239000011787 zinc oxide Substances 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/001—Ferrous alloys, e.g. steel alloys containing N

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D1/00—General methods or devices for heat treatment, e.g. annealing, hardening, quenching or tempering

- C21D1/74—Methods of treatment in inert gas, controlled atmosphere, vacuum or pulverulent material

- C21D1/76—Adjusting the composition of the atmosphere

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D9/00—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor

- C21D9/46—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor for sheet metals

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/02—Ferrous alloys, e.g. steel alloys containing silicon

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/04—Ferrous alloys, e.g. steel alloys containing manganese

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/06—Ferrous alloys, e.g. steel alloys containing aluminium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/12—Ferrous alloys, e.g. steel alloys containing tungsten, tantalum, molybdenum, vanadium, or niobium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/14—Ferrous alloys, e.g. steel alloys containing titanium or zirconium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/48—Ferrous alloys, e.g. steel alloys containing chromium with nickel with niobium or tantalum

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/50—Ferrous alloys, e.g. steel alloys containing chromium with nickel with titanium or zirconium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/54—Ferrous alloys, e.g. steel alloys containing chromium with nickel with boron

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/58—Ferrous alloys, e.g. steel alloys containing chromium with nickel with more than 1.5% by weight of manganese

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C2/00—Hot-dipping or immersion processes for applying the coating material in the molten state without affecting the shape; Apparatus therefor

- C23C2/04—Hot-dipping or immersion processes for applying the coating material in the molten state without affecting the shape; Apparatus therefor characterised by the coating material

- C23C2/12—Aluminium or alloys based thereon

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C2/00—Hot-dipping or immersion processes for applying the coating material in the molten state without affecting the shape; Apparatus therefor

- C23C2/26—After-treatment

- C23C2/28—Thermal after-treatment, e.g. treatment in oil bath

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C2/00—Hot-dipping or immersion processes for applying the coating material in the molten state without affecting the shape; Apparatus therefor

- C23C2/34—Hot-dipping or immersion processes for applying the coating material in the molten state without affecting the shape; Apparatus therefor characterised by the shape of the material to be treated

- C23C2/36—Elongated material

- C23C2/40—Plates; Strips

Definitions

- the present invention relates to a method for producing a sheet metal part comprising a substrate with a corrosion protection coating, a corresponding sheet metal part and its use in the automotive sector.

- components that are hot-formed from high-strength steel are now used in areas of the body that can be exposed to particularly high loads in the event of a crash.

- hot forming also known as hot press hardening

- steel blanks also referred to as sheet metal blanks

- a deformation temperature that is generally above the austenitization temperature of the respective steel

- the sheet metal blank or the component formed from it experiences rapid cooling through contact with the cool tool.

- the cooling rates are set so that a hardness structure (i.e. martensitic structure) results in the component.

- a “flat steel product” or a “sheet metal product” refers to rolled products, such as steel strips or sheets, from which “sheet metal blanks” (also called blanks) are cut off for the production of body components, for example.

- sheet metal blanks also called blanks

- sheet metal components of the type according to the invention are made from such sheet metal blanks, the terms “sheet metal part” and “sheet metal component” being used synonymously here.

- the structure was determined on longitudinal sections that were etched with 3% Nital (alcoholic nitric acid). The proportion of retained austenite was determined by X-ray diffractometry.

- WO 2015/036151 A1 discloses a method for producing a sheet metal part provided with a metallic coating that protects against corrosion and a corresponding sheet metal part.

- the method according to this document includes coating a flat steel product with an alloy of aluminum, zinc, magnesium and optionally silicon and iron, cutting a blank from the flat steel product, heating the blank and forming the blank to obtain the desired sheet metal part.

- DE 699 07 816 T2 discloses a method for producing a coated hot and cold rolled steel sheet with very high strength after thermal treatment.

- a flat steel product is provided with a coating and thermally treated.

- the workpiece is heated to a temperature of over 750 °C.

- EP 2 993 248 A1 discloses a flat steel product with an aluminum-containing coating, which contains 0.005 to 0.7% by weight of at least one alkali and / or alkaline earth metal, and a process for its production. In this process, the coated flat steel product is heated to a temperature of 700 to 900 °C for 360 s, 600 s or 800 s and then formed.

- the sheet metal blanks consisting of a steel substrate and an aluminum-based, metallic corrosion protection coating

- hydrogen diffuses through the metallic coating into the steel substrate as a result of the surface reaction of the moisture present in the oven with the aluminum coating.

- the hydrogen can no longer escape from the steel substrate because the metallic coating represents a barrier for the diffusible hydrogen H diff at room temperature.

- the H diff content reduces the stresses that the steel can bear in the long term, and spontaneous "hydrogen-induced" fractures can occur in the presence of tensile stresses in the sheet, so-called hydrogen embrittlement.

- the diffusible hydrogen content should be below a component-specific value.

- the amount H diff remaining after processing should preferably be ⁇ 0.4 ppm (parts per million) before critical body-in-white processes.

- the degree of rolling only applies to a rolling process in which the coating with the anti-corrosion coating is already present on the substrate.

- the rolled areas with a smaller sheet thickness compared to the sheet thickness existing before rolling have a significantly higher density of defects in the steel substrate due to the rolling. This allows diffusible hydrogen to accumulate better in the rolled areas than in the unrolled areas, so that after hot forming and press hardening there is a higher diffusible hydrogen content.

- a known method of reducing the content of diffusible hydrogen in the component is to lower the dew point in the furnace in which the steel sheet is heated before forming, in order to thereby prevent the formation of diffusible hydrogen from the existing moisture during the oxidation of the substrate To reduce the furnace atmosphere and thereby also lower the H diff recording of the sheet metal part.

- lowering the dew point is more complex the lower the dew point has to be set. It is therefore desirable not to influence the dew point if possible and, if necessary, not to lower it too much.

- the present invention is therefore based on the object of providing a method for producing sheet metal parts comprising a substrate with a corrosion protection coating, with which corresponding sheet metal parts can be obtained which have the lowest possible H diff content in order to reduce the risk of hydrogen-induced Minimize cracking after hot forming and during subsequent use. Furthermore, it is one The object of the present invention is to provide a method with which it is possible not to exceed a certain H diff content in a hot-formed component by selecting different furnace parameters depending on the degree of rolling and the sheet thickness of the flat steel product used.

- a corresponding sheet metal part and by using the sheet metal part according to the invention in the automotive sector, in particular as a bumper support/reinforcement, door reinforcement, B-pillar reinforcement, A-pillar reinforcement, roof frame or sill.

- the method according to the invention serves to produce a sheet metal part with a content of diffusible hydrogen H diff of up to 0.4 ppm, preferably 0.01 to 0.4 ppm, particularly preferably 0.05 to 0.4 ppm, for example 0.1, 0 ,2, 0.3, or 0.4 ppm, each in the material after hot forming.

- H diff describes the amount of hydrogen atoms that are present in dissolved form in the steel substrate after hot forming.

- the diffusible hydrogen content is based on the mass (analogous to the weight percent information for alloy elements). Methods for determining the H diff content are known to those skilled in the art, for example desorption mass spectrometry with heated samples (thermal desorption mass spectrometry (TDMS)).

- TDMS thermal desorption mass spectrometry

- the content of diffusible hydrogen H diff is determined within 48 hours after hot forming.

- the steel substrate has a steel with an aluminum content that is at least 0.06% by weight, preferably at least 0.07% by weight, in particular at least 0.08% by weight.

- the aluminum content is preferably at least 0.10% by weight, particularly preferably at least 0.11% by weight, in particular at least 0.12% by weight, preferably at least 0.16% by weight.

- the maximum aluminum content is 1.0% by weight, in particular a maximum of 0.8% by weight.

- the aluminum content is at least 0.07% by weight, in particular at least 0.08% by weight, preferably at least 0.10% by weight, particularly preferably at least 0.11% by weight, in particular at least 0.12% by weight, preferably at least 0.16% by weight.

- the maximum aluminum content in this variant is a maximum of 0.50% by weight, in particular a maximum of 0.35% by weight, preferably a maximum of 0.25% by weight, in particular a maximum of 0.24% by weight.

- the aluminum content is at least 0.50% by weight, preferably at least 0.60% by weight, preferably at least 0.70% by weight.

- the maximum aluminum content in this variant is a maximum of 1.0% by weight, in particular a maximum of 0.90% by weight, preferably a maximum of 0.80% by weight.

- Aluminum is known to be added as a deoxidizer in the production of steel. At least 0.01% by weight of Al is required to securely bind the oxygen contained in the steel melt. Al can also be used to bind undesirable but unavoidable levels of N due to production reasons. Comparatively high aluminum contents have so far been avoided because the aluminum content also shifts the Ac3 temperature upwards. This has a negative effect on austenitization, which is important for hot forming. However, it has been shown that increased aluminum contents surprisingly lead to positive effects in conjunction with an aluminum-based corrosion protection coating.

- iron diffuses from the steel substrate into the liquid anti-corrosion coating.

- iron-aluminide compounds with higher density are formed via a multistage phase transformation (Fe 2 Al 5 ⁇ Fe 2 Al ⁇ FeAl ⁇ Fe 3 Al).

- the formation of such denser phases is associated with higher aluminum consumption than with less dense phases.

- This locally higher aluminum consumption leads to the formation of pores (vacancies) in the resulting phase.

- These pores preferably form in the transition area between the steel substrate and the corrosion protection coating, where the proportion of aluminum available is strongly influenced by the aluminum content of the steel substrate. In particular, there may be an accumulation of pores in the form of a band in the transition area.

- the Al content is too high, in particular if the Al content is more than 1.0% by weight, there is a risk that Al oxides will form on the surface of a product made from steel material alloyed according to the invention, which would worsen the wetting behavior during hot-dip coating .

- higher Al contents promote the formation of non-metallic Al-based inclusions, which, as coarse inclusions, have a negative impact on crash behavior.

- the Al content is therefore preferably chosen to be below the upper limits already mentioned.

- the bending behavior of the sheet metal component is particularly supported by the niobium content ("Nb") according to the invention of at least 0.001% by weight.

- the niobium content is preferably at least 0.005% by weight, in particular at least 0.010% by weight, preferably at least 0.015% by weight, particularly preferably at least 0.020% by weight, in particular at least 0.024% by weight, preferably at least 0.025% by weight .-%.

- the specified niobium content leads to a distribution of niobium carbonitrides, which leads to a particularly fine hardened structure during subsequent hot forming.

- the coated flat steel product is kept in a temperature range of 400 °C and 300 °C for a certain time. In this temperature range there is still a certain rate of diffusion of carbon in the steel substrate, while the thermodynamic solubility is very low. Thus, carbon diffuses to lattice defects and accumulates there.

- Lattice disturbances are caused in particular by dissolved niobium atoms, which expand the atomic lattice due to their significantly higher atomic volume and thus increase the tetrahedral and octahedral gaps in the atomic lattice, so that the local solubility of C is increased.

- clusters of C and Nb arise in the steel substrate, which then transform into very fine precipitates in the subsequent austenitization step of hot forming and act as additional austenite nuclei. This results in a refined austenite structure with smaller austenite grains and thus also a refined hardening structure.

- the refined ferritic structure in the interdiffusion layer supports the reduction of crack initiation tendencies under bending loads.

- the Nb content is a maximum of 0.2% by weight.

- the niobium content is preferably a maximum of 0.20% by weight, in particular a maximum of 0.15% by weight, preferably a maximum of 0.10% by weight, in particular a maximum of 0.05% by weight.

- the formation of AIN is thermodynamically favored compared to the formation of NbN or NbC.

- the precipitation of AIN has a grain-refining effect in the austenite and thus improves toughness. Increasing Al/Nb ratios improve this effect.

- the preferred ratio is Al/Nb ⁇ 2, in particular ⁇ 3.

- the ratio of Al/Nb is too high, the AlN formation is no longer as advantageously fine, but increasingly coarser AlN particles appear, which again reduces the grain refining effect . It has been shown that this effect occurs earlier at low manganese levels than at higher manganese levels, as the AC3 temperature decreases as the manganese level increases.

- a ratio of Al/Nb for low manganese contents of less than or equal to 1.6% by weight, for which the following applies: Al/Nb ⁇ 20 .0 , which roughly corresponds to an atomic ratio of both elements ⁇ 6.

- Al/Nb ⁇ 18.0, in particular ⁇ 16.0, preferably ⁇ 14.0, particularly preferably ⁇ 12.0, in particular ⁇ 10.0, preferably ⁇ 9.0, in particular ⁇ 8.0, preferably ⁇ 7.0 is preferred.

- the ratio Al/Nb is preferably ⁇ 18.0, in particular ⁇ 16.0, preferably ⁇ 14.0, particularly preferably ⁇ 12.0, in particular ⁇ 10.0, preferably ⁇ 9.0, in particular ⁇ 8.0, preferably ⁇ 7.0.

- Carbon is contained in the steel substrate of the flat steel product in amounts of 0.06 - 0.5% by weight. C contents set in this way contribute to the hardenability of the steel by delaying the formation of ferrite and bainite and stabilizing the residual austenite in the structure. A carbon content of at least 0.06% by weight is required to achieve sufficient hardenability and the associated high strength.

- the carbon content can be set to 0.5% by weight, preferably at most 0.50% by weight, particularly preferably at most 0.40% by weight, preferably at most 0.38% by weight, in particular at most 0.35% by weight can be set.

- C contents of at least 0.10% by weight, preferably 0.11% by weight, in particular at least 0.13% by weight, preferably at least 0 .15% by weight can be provided.

- tensile strengths of the sheet metal part of at least 1000 MPa, in particular at least 1100 MPa can be safely achieved after hot pressing.

- the C content is at least 0.10% by weight, preferably 0.11% by weight, in particular at least 0.13% by weight, preferably at least 0.15% by weight.

- the maximum C content in this variant is a maximum of 0.30% by weight, in particular a maximum of 0.25% by weight, preferably a maximum of 0.25% by weight.

- the C content is at least 0.25% by weight, preferably at least 0.30% by weight, in particular at least 0.32% by weight.

- the maximum C content in this variant is a maximum of 0.5% by weight, in particular a maximum of 0.50% by weight, preferably a maximum of 0.40% by weight, preferably a maximum of 0.38% by weight, in particular a maximum of 0.35% by weight. -%.

- the C content is at least 0.30% by weight, preferably at least 0.35% by weight, in particular at least 0.40% by weight, preferably at most 0.44% by weight.

- the maximum C content in this variant is a maximum of 0.5% by weight, in particular a maximum of 0.50% by weight, preferably a maximum of 0.48% by weight.

- Silicon is used to further increase the hardenability of the flat steel product as well as the strength of the press-hardened product via solid solution strengthening. Silicon also enables the use of ferro-silizio-manganese as an alloying agent, which has a beneficial effect on production costs.

- a hardening effect occurs from an Si content of 0.05% by weight. From an Si content of at least 0.15% by weight, in particular at least 0.20% by weight, a significant increase in strength occurs. Si contents above 0.6% by weight have a detrimental effect on the coating behavior, especially with Al-based coatings. Si contents of at most 0.50% by weight, in particular at most 0.30% by weight, are preferably set in order to improve the surface quality of the coated flat steel product.

- Manganese acts as a hardening element by greatly retarding ferrite and bainite formation. With manganese contents of less than 0.4% by weight, significant proportions of ferrite and bainite are formed during press hardening, even at very fast cooling rates, which should be avoided. Mn contents of at least 0.7% by weight, preferably at least 0.8% by weight, in particular at least 0.9% by weight, particularly preferably at least 1.10% by weight, are advantageous if A martensitic structure should be ensured, especially in areas of larger forming.

- Manganese contents of more than 3.0% by weight have a disadvantageous effect on the processing properties, which is why the Mn content of flat steel products according to the invention is limited to a maximum of 3.0% by weight, preferably a maximum of 2.5% by weight. In particular, weldability is severely limited, which is why the Mn content is preferably limited to a maximum of 1.6% by weight and in particular to 1.3% by weight. Manganese contents of less than or equal to 1.6% by weight are also preferred for economic reasons.

- Titanium is a microalloy element that is alloyed to contribute to grain refinement, with at least 0.001% by weight of Ti, in particular at least 0.004% by weight, preferably at least 0.010% by weight of Ti, should be added for sufficient availability. From 0.10% by weight of Ti, cold rolling and recrystallizability deteriorate significantly, which is why larger Ti contents should be avoided. In order to improve the cold-rollability, the Ti content can preferably be limited to 0.08% by weight, in particular to 0.038% by weight, particularly preferably to 0.020% by weight, in particular 0.015% by weight. Titanium also has the effect of binding nitrogen and thus allowing boron to develop its strong ferrite-inhibiting effect. Therefore, in a preferred development, the titanium content is more than 3.42 times the nitrogen content in order to achieve sufficient binding of nitrogen.

- B Boron

- B Boron

- a clear effect on hardenability occurs at levels of at least 0.0005% by weight, preferably at least 0.0007% by weight, in particular at least 0.0010% by weight, in particular at least 0.0020% by weight.

- boron carbides, boron nitrides or boron nitrocarbides are increasingly formed, which in turn represent preferred nucleation sites for the nucleation of ferrite and reduce the hardening effect again.

- the boron content is set to at most 0.01% by weight, preferably at most 0.0100% by weight, preferably at most 0.0050% by weight, in particular at most 0.0035% by weight, in particular at most 0. 0030% by weight, preferably at most 0.0025% by weight.

- Phosphorus (“P”) and sulfur (“S”) are elements that are introduced into steel as impurities by iron ore and cannot be completely eliminated in the large-scale steelworks process.

- the P content and the S content should be kept as low as possible, since the mechanical properties such as the impact energy deteriorate with increasing P content or S content. From P contents of 0.03% by weight, the martensite begins to become brittle, which is why the P content of a flat steel product according to the invention is limited to a maximum of 0.03% by weight, in particular a maximum of 0.02% by weight is.

- the S content of a flat steel product according to the invention is limited to a maximum of 0.02% by weight, preferably a maximum of 0.0010% by weight, in particular a maximum of 0.005% by weight.

- Nitrogen is also present in small amounts in steel as an impurity due to the steel manufacturing process.

- the N content should be kept as low as possible and should not exceed 0.02% by weight.

- Nitrogen is particularly harmful for alloys that contain boron, since it prevents the conversion-retarding effect of boron through the formation of boron nitrides, which is why the nitrogen content in this case should preferably be at most 0.010% by weight, in particular at most 0.007% by weight.

- Sn tin

- As arsenic

- Sn content is a maximum of 0.03% by weight, preferably a maximum of 0.02% by weight.

- As content is a maximum of 0.01% by weight, in particular a maximum of 0.005% by weight.

- impurities P, S, N, Sn and As other elements can also be present as impurities in the steel. These other elements are grouped under the “unavoidable impurities”.

- the total content of these “unavoidable impurities” is preferably a maximum of 0.2% by weight, preferably a maximum of 0.1% by weight.

- the optional alloying elements Cr, Cu, Mo, Ni, V, Ca and W described below, for which a lower limit is specified, can also occur in levels below the respective lower limit as unavoidable impurities in the steel substrate. In this case, they are also counted among the "unavoidable impurities", the total content of which is limited to a maximum of 0.2% by weight, preferably a maximum of 0.1% by weight.

- Chromium, copper, molybdenum, nickel, vanadium, calcium and tungsten can optionally be alloyed into the steel of a flat steel product according to the invention, individually or in combination with each other.

- Chromium suppresses the formation of ferrite and pearlite during accelerated cooling of a flat steel product according to the invention and enables complete martensite formation even at lower cooling rates, thereby achieving an increase in hardenability.

- the Cr content of the steel of one of the steel substrate is limited to a maximum of 1.0% by weight, in particular a maximum of 0.75% by weight, preferably a maximum of 0.50% by weight.

- Vanadium (V) can optionally be alloyed in amounts of 0.001 - 1.0% by weight.

- the vanadium content is preferably a maximum of 0.3% by weight. For cost reasons, a maximum of 0.2% by weight of vanadium is added.

- Copper (Cu) can optionally be alloyed in order to increase hardenability with additions of at least 0.01% by weight, preferably at least 0.010% by weight, in particular at least 0.015% by weight.

- copper improves the resistance to atmospheric corrosion of uncoated sheets or cut edges. If the Cu content is too high, the hot-rollability deteriorates significantly due to low-melting Cu phases on the surface, which is why the Cu content is limited to a maximum of 0.2% by weight, preferably a maximum of 0.1% by weight, in particular a maximum of 0. 10% by weight is limited.

- Molybdenum can optionally be added to improve process stability as it significantly slows ferrite formation. From a content of 0.002% by weight, dynamic molybdenum-carbon clusters up to ultrafine molybdenum carbides form on the grain boundaries, which significantly slow down the mobility of the grain boundary and thus diffusive phase transformations. Molybdenum also reduces the grain boundary energy, which reduces the nucleation rate of ferrite.

- the Mo content is preferably at least 0.004% by weight, in particular at least 0.01% by weight. Due to the high costs associated with a molybdenum alloy, the content should be at most 0.3% by weight, in particular at most 0.10% by weight, preferably at most 0.08% by weight.

- Nickel (Ni) stabilizes the austenitic phase and can optionally be alloyed to reduce the Ac3 temperature and suppress the formation of ferrite and bainite. Nickel also has a positive influence on hot-rollability, especially if the steel contains copper. Copper impairs hot-rollability. In order to counteract the negative influence of copper on hot-rollability, 0.01% by weight of nickel can be alloyed into the steel; the Ni content is preferably at least 0.020% by weight. For economic reasons, the nickel content should remain limited to a maximum of 0.5% by weight, in particular a maximum of 0.20% by weight. The Ni content is preferably a maximum of 0.10% by weight.

- a flat steel product according to the invention can optionally contain at least 0.0005% by weight of Ca, in particular at least 0.0010% by weight, preferably at least 0.0020% by weight.

- the maximum Ca content is 0.01% by weight, in particular a maximum of 0.007% by weight, preferably a maximum of 0.005% by weight. If too high Ca content increases the likelihood that non-metallic inclusions involving Ca will form, which will worsen the purity of the steel and also its toughness. For this reason, an upper limit of the Ca content of at most 0.005% by weight, preferably at most 0.003% by weight, in particular at most 0.002% by weight, preferably at most 0.001% by weight, should be maintained.

- Tungsten (W) can optionally be alloyed in amounts of 0.001 - 1.0% by weight to slow ferrite formation. A positive effect on hardenability occurs with W contents of at least 0.001% by weight. For cost reasons, a maximum of 1.0% by weight of tungsten is added.

- the sum of the Mn content and the Cr content (“Mn+Cr”) is more than 0.7% by weight, in particular more than 0.8% by weight, preferably more than 1.1% by weight .-%. Below a minimum sum of both elements, their necessary conversion-inhibiting effect is lost. Regardless of this, the sum of the Mn content and the Cr content is less than 3.5% by weight, preferably less than 2.5% by weight, in particular less than 2.0% by weight, particularly preferably less than 1.5% by weight.

- the upper limit values for both elements are created to ensure coating performance and to ensure sufficient welding behavior.

- the flat steel product includes an anti-corrosion coating to protect the steel substrate from oxidation and corrosion during hot forming and use of the formed sheet metal part.

- the flat steel product preferably comprises an aluminum-based anti-corrosion coating.

- the corrosion protection coating can be applied to one or both sides of the flat steel product.

- the two opposing large surfaces of the flat steel product are referred to as the two sides of the flat steel product.

- the narrow surfaces are called edges.

- Such a corrosion protection coating is preferably produced by hot-dip coating the flat steel product.

- the flat steel product is passed through a liquid melt, which consists of up to 15% by weight of Si, preferably more than 1.0%, optionally 2-4% by weight of Fe, optionally up to 5% by weight of alkali or alkaline earth metals, preferably up to 1.0% by weight.

- the Si content of the melt is 1.0-3.5% by weight or 7-12% by weight, in particular 8-10% by weight.

- the optional content of alkali or alkaline earth metals in the melt comprises 0.1 - 1.0% by weight of Mg, in particular 0.1 - 0.7% by weight of Mg, preferably 0.1 - 0. 5% by weight of Mg.

- the optional content of alkali or alkaline earth metals in the melt can comprise in particular at least 0.0015% by weight of Ca, in particular at least 0.01% by weight of Ca.

- the alloy layer lies on the steel substrate and is directly adjacent to it.

- the alloy layer is essentially formed from aluminum and iron.

- the remaining elements from the steel substrate or the melt composition do not accumulate significantly in the alloy layer.

- the alloy layer preferably consists of 35-60% by weight of Fe, preferably ⁇ -iron, optional further components, the total content of which is limited to a maximum of 5.0% by weight, preferably 2.0%, and the balance is aluminum, whereby the Al content increases preferably towards the surface.

- the optional further components include in particular the remaining components of the melt (i.e. silicon and optionally alkali or alkaline earth metals, in particular Mg or Ca) and the remaining components of the steel substrate in addition to iron.

- the Al base layer lies on the alloy layer and is directly adjacent to it.

- the composition of the Al base layer preferably corresponds to the composition of the melt of the melt pool. This means that it consists of 0.1 - 15% by weight of Si, optionally 2-4% by weight of Fe, optionally 5% by weight of alkali or alkaline earth metals, preferably up to 1.0% by weight. Alkaline or alkaline earth metals, optionally up to 15% Zn and optional other components, the total content of which is limited to a maximum of 2.0% by weight, and the balance aluminum.

- the optional content of alkali or alkaline earth metals comprises 0.1 - 1.0% by weight of Mg, in particular 0.1 - 0.7% by weight of Mg, preferably 0.1 - 0 .5% by weight of Mg.

- the optional content of alkali or alkaline earth metals in the Al base layer can comprise in particular at least 0.0015% by weight of Ca, in particular at least 0.1% by weight of Ca.

- the Si content in the alloy layer is lower than the Si content in the Al base layer.

- the anti-corrosion coating preferably has a thickness of 5 - 60 ⁇ m, in particular 10 - 40 ⁇ m.

- the application weight of the corrosion protection coating is in particular 30 ⁇ 360 G m 2 with corrosion protection coatings on both sides or 15 ⁇ 180 G m 2 in the one-sided variant.

- the coating weight of the corrosion protection coating is preferred 100 ⁇ 200 G m 2 for double-sided covers or 50 ⁇ 100 G m 2 for one-sided covers.

- the coating weight of the corrosion protection coating is particularly preferred 120 ⁇ 180 G m 2 for double-sided covers or 60 ⁇ 90 G m 2 for one-sided covers.

- the thickness of the alloy layer is preferably less than 20 ⁇ m, particularly preferably less than 16 ⁇ m, in particular less than 12 ⁇ m, particularly preferably less than 10 ⁇ m, preferably less than 8 ⁇ m, in particular less than 5 ⁇ m.

- the thickness of the Al base layer results from the difference in the thickness of the corrosion protection coating and the alloy layer.

- the thickness of the Al base layer is preferably at least 1 ⁇ m, even with thin corrosion protection coatings.

- the flat steel product comprises an oxide layer arranged on the corrosion protection coating.

- the oxide layer lies in particular on the Al base layer and preferably forms the outer end of the corrosion protection coating.

- the oxide layer consists in particular of more than 80% by weight of oxides, with the majority of the oxides (ie more than 50% by weight of the oxides) being aluminum oxide.

- hydroxides and/or magnesium oxide alone or as a mixture are present in the oxide layer.

- the remainder of the oxide layer not occupied by the oxides and optionally present hydroxides consists of silicon, aluminum, iron and/or magnesium metallic form.

- zinc oxide components are also present in the oxide layer.

- the oxide layer of the flat steel product preferably has a thickness that is greater than 50 nm.

- the thickness of the oxide layer is a maximum of 500 nm.

- the flat steel product has a diffusible hydrogen H diff content of up to 0.4 ppm, preferably 0.01 to 0.4 ppm, particularly preferably 0.05 to 0.4 ppm, for example 0.1, 0.2 , 0.3, or 0.4 ppm.

- H diff describes the amount of hydrogen atoms that are present in dissolved form in the steel substrate after the corrosion protection coating has been applied.

- the diffusible hydrogen content is based on the mass (analogous to the weight percent information for alloy elements). Methods for determining the H diff content are known to those skilled in the art, for example desorption mass spectrometry with heated samples (thermal desorption mass spectrometry (TDMS)).

- TDMS thermal desorption mass spectrometry

- the content of diffusible hydrogen H diff is determined within 48 hours after application of the corrosion protection coating.

- the flat steel product provided in step (A) of the method according to the invention has a rolling degree to sheet thickness ratio of 0.8 to 200, preferably greater than 0.8 to 180, particularly preferably greater than 0.8 to 150.

- the flat steel product provided according to the invention preferably has a degree of rolling of 0.5% to 75%, particularly preferably 2.5% to 60%.

- the degree of rolling is given in%.

- a flat steel product is used in step (A), which has areas that are rolled to a smaller sheet thickness than other areas.

- the greatest degree of rolling available is used as a basis for the respective component.

- WGB 1.5 ⁇ 1 + degree of rolling ⁇ 100 1 2 ⁇ 1 + sheet thickness / mm where the sheet thickness is set in mm and is identical to h 1 , the final thickness of the flat steel product after rolling.

- the flat steel products used in step (A) of the method according to the invention are preferably present in a sheet thickness (final thickness h 1 ) of 0.5 to 6 mm, in particular 0.5 to 4 mm, particularly preferably 0.8 to 3 mm. (particularly in the areas with the greatest degree of rolling).

- the coated flat steel product from step (A), after which process step (B) has been carried out is preferably transferred directly into process step (C) according to the invention.

- further steps to be carried out between steps (A) and (B) or (C), for example cutting off areas, in particular sheets or circuit boards, of the flat steel product, for example by shear cutting or laser cutting, introducing holes by laser processing or punching, and/or previous heat treatments to change the properties of the coating or substrate.

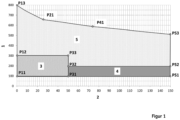

- Step (B) of the method according to the invention includes the determination of a WOP value depending on the degree of rolling to sheet thickness ratio WGB within an area spanned by straight connecting sections between points P11 (WGB 0.8, WOP 100) and P13 (WGB 0.8, WOP 800), P13 (WGB 0.8, WOP 800) and P21 (WGB 26, WOP 650), P21 (WGB 26, WOP 650) and P41 (WGB 74, WOP 590), P41 (WGB 74, WOP 590) and P53 (WGB 150, WOP 520), P53 (WGB 150, WOP 520) and P51 (WGB 150, WOP 100) as well as P51 (WGB 150, WOP 100) and P11 (WGB 0.8, WOP 100) in a coordinate system, in which the WOP value is plotted on the y-axis and the degree of rolling ratio to sheet thickness ratio on the x-axis, as preferred in Figure 1 shown.

- a suitable WOP value range is determined from which a WOP value can then be selected. According to the invention, however, all WOP values lying in the specific WOP value range meet the condition that a sheet metal part with a diffusible hydrogen content of a maximum of 0.4 ppm is obtained.

- Step (B) of the method according to the invention serves to determine a WOP value depending on the degree of rolling to sheet thickness ratio of the flat steel product used, where WOP means "hydrogen-related furnace parameter" and is unitless.

- the WOP value then provides information about the process parameters with which the heat treatment in step (C) should be carried out so that sheet metal parts with diffusible hydrogen contents of a maximum of 0.4 ppm are obtained.

- a range for suitable WOP values is determined via the degree of rolling to sheet thickness ratio.

- a WOP value can then preferably be selected from this range, which is then used to determine the corresponding value for T oven , t oven and T t point using the equation of the general formula (1).

- all values present in the correspondingly determined range of WOP values are suitable for being used in the equation of the general formula (1) in order to determine the corresponding values for T oven , t oven and T dew point .

- Step (B) of the method according to the invention is preferably carried out in that the WOP value is spanned within an area by straight connecting distances between the points P11 (WGB 0.8, WOP 100) and P13 (WGB 0.8, WOP 800), P13 ( WGB 0.8, WOP 800) and P21 (WGB 26, WOP 650), P21 (WGB 26, WOP 650) and P41 (WGB 74, WOP 590), P41 (WGB 74, WOP 590) and P53 (WGB 150, WOP 520), P53 (WGB 150, WOP 520) and P51 (WGB 150, WOP 100) as well as P51 (WGB 150, WOP 100) and P11 (WGB 0.8, WOP 100) in a coordinate system in which the WOP Value on the y-axis and the degree of rolling sheet thickness ratio are plotted on the x-axis, is determined graphically to a predetermined degree of rolling sheet thickness ratio (area A).

- the corresponding diagram is in Figure

- the WOP value is determined according to step (B) of the method according to the invention within an area spanned by straight connecting sections between the points P12 (WGB 0.8, WOP 300) and P13 (WGB 0.8, WOP 800), P13 (WGB 0.8, WOP 800) and P21 (WGB 26, WOP 650), P21 (WGB 26, WOP 650) and P41 (WGB 74, WOP 590), P41 (WGB 74, WOP 590) and P53 (WGB 150, WOP 520), P53 (WGB 150, WOP 520) and P52 (WGB 150, WOP 200), P52 (WGB 150, WOP 200) and P32 (WGB 50, WOP 200), P32 (WGB 50, WOP 200) and P33 (WGB 50, WOP 300) as well as P33 (WGB 50, WOP 300) and P12 (WGB 0.8, WOP 300) in a coordinate system in which the WOP value on

- step (B) of the method according to the invention it can then be determined according to the invention at which dew point temperature of the oven atmosphere T dew point , at which average oven temperature T oven and for what duration t oven step (C) of the method according to the invention is carried out.

- Step (C) of the method according to the invention comprises treating the flat steel product at an average oven temperature T oven (in K) for a duration t oven (in h), whereby the dew point temperature of the oven atmosphere T dew point (in K), the average oven temperature T oven ( in K) and the duration t oven (in h) according to the following equation of the general formula (1)

- WOP T Oven K ⁇ log t Oven H + 1.15 + T dew point K ⁇ 243.15 1.6 can be set so that the WOP value is in the using Figure 1 defined interval between the minimum and maximum WOP value.

- T oven (in K) is the temperature that prevails on average in the oven in which step (C) of the method according to the invention takes place.

- T oven can take on any value that a person skilled in the art considers appropriate.

- T oven AC1 is preferably up to 1373 K, preferably 1113 to 1253 K, particularly preferably 1133 to 1223 K, very particularly preferably 1153 to 1193 K.

- AC1 means the first austenitization temperature, which depends on the alloy composition.

- the duration t oven (in h) is the time over which the stated oven temperature T oven prevails in step (C).

- t oven can assume any value that a person skilled in the art considers suitable.

- t furnace describes in particular the period in which the flat steel product is moved through a continuous furnace or remains in a stationary furnace.

- t oven is preferably 0.04 to 0.5 h, in particular at least 0.060 h, preferably at least 0.067 h.

- the maximum time in the oven is preferably 0.4 h, in particular a maximum of 0.25 h.

- oven temperature T oven is used to calculate and then set the dew point temperature of the oven atmosphere of the oven T dew point using equation (1).

- the dew point temperature of the oven T dew point (in K) is, for example, 238.15 to 308.15 K, preferably 253.15 to 293.15 K, particularly preferably 263.15 to 283.15 K.

- the dew point temperature of the oven atmosphere of the oven T dew point , duration t oven and WOP value are used to calculate and then set the oven temperature T oven using equation (1).

- the dew point temperature of the oven atmosphere of the oven T dew point , oven temperature T oven and WOP value are used to calculate and then set the duration t oven using equation (1).

- Step (C) of the process according to the invention can generally be carried out in any furnace known to those skilled in the art, for example roller hearth furnaces, chamber furnaces, multi-layer chamber furnaces, walking beam furnaces.

- Step (D) of the method according to the invention includes forming the heated flat steel product from step (C) in a molding tool with simultaneous cooling in order to obtain the sheet metal part.

- step (D) of the method according to the invention for example described in hot forming in Automobile construction - processes, materials, surfaces, Landsberg/Lech: Verlag Moderne Industrie, 2012 , The Library of Technology.

- step (D) of the method according to the invention the desired sheet metal part is obtained from the flat steel product from step (C) by forming. So that the desired hardness structure, for example at least 80% martensite, remainder bainite, ferrite and retained austenite, is formed in the sheet metal part, the forming takes place with simultaneous cooling.

- the cooling in step (C) of the method according to the invention takes place, in particular over a period of twz more than 1 s, preferably with a cooling rate r WZ of 10 to 1000 K/s, preferably at least 27 K/s, in particular at least 30 K/s.

- the maximum cooling rate is preferably up to 500 K/s.

- the present invention therefore preferably relates to the method according to the invention, wherein the cooling in step (D) takes place at a cooling rate of 27 to 500 K/s.

- the flat steel product used is preferably a strip, in particular a hot strip or a cold strip, a sheet, i.e. H. a piece of hot strip or cold strip, or a circuit board made of hot strip or a circuit board made of cold strip.

- the present invention preferably relates to the method according to the invention, wherein the flat steel product is a blank made from a hot strip or a blank made from a cold strip.

- the coating with the anti-corrosion coating can be carried out by fire coating, electrolytic coating or by means of a piece coating process.

- the present invention therefore preferably relates to the method according to the invention, wherein the coating is carried out by hot-dip coating, electrolytic coating or by means of a piece coating process.

- the aluminum-silicon-iron alloy is preferably applied using a continuous hot-dip coating process. During the coating, the temperature of the aluminum molten bath is preferably between 660 °C and 720 °C.

- Silicon in the coating acts as a diffusion blocker and serves to calm the melt pool when the coating formed from the aluminum alloy is applied using hot-dip coating.

- the treatment in step (C) takes place in such a way that at the end of step (C) the AC3 temperature of the flat steel product is at least partially exceeded in the flat steel product. If a temperature is partially exceeded (here AC3)

- a temperature is partially exceeded (here AC3)

- AC3 a temperature is partially exceeded

- at least 30%, in particular at least 60%, of the volume of the blank exceeds a corresponding temperature.

- at least 30% of the blank has an austenitic structure, ie the conversion from ferritic to austenitic structure does not have to be complete when inserted into the forming tool.

- up to 70% of the volume of the blank when inserted into the forming tool can consist of other structural components, such as tempered bainite, tempered martensite and/or non-or partially recrystallized ferrite.

- certain areas of the blank can be specifically kept at a lower temperature level than others during heating.

- the heat supply can be directed only to certain sections of the blank or the parts that should be heated less can be shielded from the heat supply.

- no or only significantly less martensite is formed during the forming process in the tool, so that the structure there is significantly softer than in the other parts in which a martensitic structure is present.

- a softer area can be specifically set in the shaped sheet metal part, for example by having optimal toughness for the respective intended use, while the other areas of the sheet metal part have maximized strength.

- the temperature at least partially achieved in the flat steel product in step (C) is preferably between Ac3 and 1000 ° C, particularly preferably between 880 ° C and 950 ° C.

- the standardized average heating ⁇ norm is at least 5 Kmm/s, in particular at least 8 Kmm/s, preferably at least 10 Kmm/s.

- the maximum standardized average heating is 15 Kmm/s, in particular a maximum of 14 Kmm/s, preferably a maximum of 13 Kmm/s.

- the average heating rate ⁇ is the product of the average heating rate in Kelvin per second from 30°C to 700°C and the sheet thickness in millimeters.

- step (C) and step (D) the austenitized flat steel product is transferred from the heating device used in each case to the molding tool within a transfer time (t Trans ) of preferably a maximum of 20 s, in particular a maximum of 15 s. Such rapid transport is necessary to avoid excessive cooling before deformation.

- t Trans transfer time

- the mold When inserting the blank, the mold typically has a temperature between room temperature (RT) and 200 °C, preferably between 20 °C and 180 °C, in particular between 50 °C and 150 °C.

- the tool can be tempered at least in some areas to a temperature T WZ of at least 200 ° C, in particular at least 300 ° C, in order to only partially harden the component.

- the tool temperature Twz is preferably a maximum of 600 ° C, in particular a maximum of 550 ° C. It is only necessary to ensure that the tool temperature Twz is below the desired target temperature T target .

- the residence time in the tool twz is preferably at least 2 s, in particular at least 3 s, particularly preferably at least 5 s.

- the maximum residence time in the tool is preferably 25 s, in particular a maximum of 20 s, preferably a maximum of 15 s, in particular a maximum of 12 s.

- the target temperature T target of the sheet metal part is at least partially below 400 ° C, preferably below 300 ° C, in particular below 250 ° C, preferably below 200 ° C, especially preferably below 180 °C, in particular below 150 °C.

- the target temperature T target of the sheet metal part is particularly preferably below Ms-50 ° C, where Ms denotes the martensite starting temperature.

- the target temperature of the sheet metal part is preferably at least 20 °C, particularly preferably at least 50 °C.

- AC 1 ° C 739 ° C + ⁇ 22 * % C ⁇ 7 * % Mn + 2 * % Si + 14 * % Cr + 13 * % Mo ⁇ 13 * % Ni + 20 * % v ° C / wt .

- AC 3 ° C 902 ° C + ⁇ 225 * % C + 19 * % Si ⁇ 11 * % Mn ⁇ 5 * % Cr + 13 * % Mo ⁇ 20 * % Ni + 55 * % v ° C / wt .

- the sheet metal part After removing the sheet metal part following step (D), the sheet metal part is cooled to a cooling temperature TAB of less than 100 ° C within a cooling time t AB of 0.5 to 600 s. This is usually done by air cooling.

- the flat steel product has a high uniform elongation Ag of at least 10.0%, in particular at least 11.0%, preferably at least 11.5%, in particular at least 12.0%.

- the yield point of a specially designed flat steel product has a continuous course or only a slight extent.

- continuous progression means that there is no pronounced yield point.

- a yield point with a continuous course can also be referred to as a yield point Rp0.2.

- a low yield strength is understood to mean a pronounced yield strength in which the difference ⁇ Re between the upper yield strength value ReH and the lower yield strength value ReL is at most 45 MPa.

- a specially developed flat steel product has an elongation at break A80 of at least 15%, in particular at least 18%, preferably at least 19%, particularly preferably at least 20%.

- the present invention also relates to a sheet metal part produced by one of the aforementioned methods comprising a steel substrate made of steel which, in addition to iron and unavoidable impurities (in wt.%) C: 0.06-0.5%, Si: 0.05-0.6%, Mn: 0.4-3.0%, Al: 0.06-1.0%, Nb: 0.001-0.2%, Ti: 0.001-0.10% B: 0.0005-0.01% P: ⁇ 0.03%, S: ⁇ 0.02%, N: ⁇ 0.02%, Sn: ⁇ 0.03% As: ⁇ 0.01% and optionally one or more of the elements “Cr, Cu, Mo, Ni, V, Ca, W” in the following contents CR: 0.01-1.0%, Cu: 0.01 -0.2%, Mon: 0.002-0.3%, Ni: 0.01-0.5% V: 0.001-0.3% Approx.: 0.0005-0.005% W: 0.001-1.0% consists, wherein the steel substrate has an aluminum-based anti-corrosion coating on at least one side and the

- the anti-corrosion coating of the sheet metal part preferably comprises an alloy layer and an Al base layer.

- the alloy layer is often referred to as an interdiffusion layer.

- the thickness of the anti-corrosion coating is preferably at least 10 ⁇ m, particularly preferably at least 20 ⁇ m, in particular at least 30 ⁇ m.

- the thickness of the alloy layer is preferably less than 30 ⁇ m, particularly preferably less than 20 ⁇ m, in particular less than 16 ⁇ m, particularly preferably less than 12 ⁇ m.

- the thickness of the Al base layer results from the difference in the thickness of the corrosion protection coating and the alloy layer.

- the alloy layer lies on the steel substrate and is directly adjacent to it.

- the alloy layer of the sheet metal part preferably consists of 35 - 90% by weight of Fe, 0.1 - 10% by weight of Si, optionally up to 0.5% by weight of Mg and optional other components, the total content of which is limited to a maximum of 2.0% by weight, and the balance aluminum. Due to the further diffusion of iron into the alloy layer, the proportions of Si and Mg are correspondingly lower than their respective proportions in the melt of the melt pool.

- the alloy layer preferably has a ferritic structure.

- the Al base layer of the sheet metal part lies on the alloy layer of the sheet metal part and is directly adjacent to it.

- the Al base layer of the sheet metal part preferably consists of 35 - 55% by weight of Fe, 0.4 - 10% by weight of Si, optionally up to 0.5% by weight of Mg and optional other components, their contents in total a maximum of 2.0% by weight is limited, and the remainder is aluminum.

- the Al base layer can have a homogeneous element distribution in which the local element contents do not vary by more than 10%.

- Preferred variants of the Al base layer have low-silicon phases and silicon-rich phases.

- Low-silicon phases are areas whose average Si content is at least 20% less than the average Si content of the Al base layer.

- Silicon-rich phases are areas whose average Si content is at least 20% more than the average Si content of the Al base layer.

- the silicon-rich phases are arranged within the silicon-poor phase.

- the silicon-rich phases form at least a 40% continuous layer bounded by silicon-poor regions.

- the silicon-rich phases are arranged in an island shape in the silicon-poor phase.

- island-shaped is understood to mean an arrangement in which discrete, unconnected areas are enclosed by another material - i.e. there are “islands” of a certain material in another material.

- the sheet metal part comprises an oxide layer arranged on the corrosion protection coating.

- the oxide layer lies in particular on the Al base layer and preferably forms the outer end of the corrosion protection coating.

- the oxide layer of the sheet metal part consists in particular of more than 80% by weight of oxides, with the majority of the oxides (ie more than 50% by weight of the oxides) being aluminum oxide.

- aluminum oxide hydroxides and/or magnesium oxide alone or as a mixture are present in the oxide layer.

- the remainder of the oxide layer not occupied by the oxides and optionally present hydroxides consists of silicon, aluminum, iron and/or magnesium in metallic form.

- the oxide layer preferably has a thickness of at least 50 nm, in particular at least 100 nm. Furthermore, the thickness is a maximum of 4 ⁇ m, in particular a maximum of 2 ⁇ m.

- the steel substrate of the sheet metal part has a structure with at least partially more than 80% martensite, preferably at least partially more than 90% martensite, in particular at least partially more than 95%, particularly preferably at least partially more than 98%.

- the term “partially exhibits” means that there are areas of the sheet metal part that have the structure mentioned. In addition, there may also be areas of the sheet metal part that have a different structure. The sheet metal part therefore has the structure mentioned in sections or areas.

- the high martensite content allows very high tensile strengths and yield strengths to be achieved.

- the sheet metal part at least partially has a Vickers hardness of at least 340 HV, preferably at least 400 HV, in particular at least 500 HV.

- the steel substrate of the sheet metal part has a structure with a ferrite content of more than 5%, preferably more than 10%, in particular more than 20%.

- the ferrite content is preferably less than 85%, in particular less than 70%.

- the martensite content is less than 80%, in particular less than 50%.

- the structure can optionally contain bainite and/or pearlite. The exact ratio of the structural components depends on the level of the C content and the Mn content as well as on the cooling conditions during forming. The structure designed in this way has higher ductility and therefore leads to improved forming behavior.

- a corresponding sheet metal part preferably has an elongation at break A30 in a range of 8% to 25%, preferably between 10% and 22%, in particular between 12% and 20%.

- the sheet metal part at least partially has a yield strength of at least 750 MPa, in particular at least 950 MPa, preferably at least 1100 MPa, in particular at least 1250 MPa.

- the sheet metal part at least partially has a tensile strength of at least 1000 MPa, in particular at least 1100 MPa, preferably at least 1300 MPa, in particular at least 1800 MPa.

- the sheet metal part at least partially has an elongation at break A80 of at least 4%, preferably at least 5%, particularly preferably at least 6%.

- the sheet metal part can at least partially have a bending angle of at least 30°, in particular at least 40°, preferably at least 50°.

- the bending angle here means the bending angle corrected with regard to the sheet thickness.

- partially exhibiting means that there are areas of the sheet metal part that have the mechanical property mentioned.

- the sheet metal part therefore has the mechanical property mentioned in sections or areas. This is because different areas of the sheet metal part can undergo different heat treatments. For example, individual areas can be cooled more quickly than others, which means, for example, more martensite is formed in the areas that cooled more quickly. Therefore, different mechanical properties arise in the different areas.