EP4201614A1 - High-speed intelligent cutting machining center and method for replacing knife die plates - Google Patents

High-speed intelligent cutting machining center and method for replacing knife die plates Download PDFInfo

- Publication number

- EP4201614A1 EP4201614A1 EP21942800.0A EP21942800A EP4201614A1 EP 4201614 A1 EP4201614 A1 EP 4201614A1 EP 21942800 A EP21942800 A EP 21942800A EP 4201614 A1 EP4201614 A1 EP 4201614A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- die cutter

- die

- disposed

- plate

- locking

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000005520 cutting process Methods 0.000 title claims abstract description 82

- 238000000034 method Methods 0.000 title claims abstract description 15

- 238000003860 storage Methods 0.000 claims abstract description 54

- 238000007723 die pressing method Methods 0.000 claims description 68

- 238000003825 pressing Methods 0.000 claims description 27

- 230000001360 synchronised effect Effects 0.000 claims description 17

- 230000000903 blocking effect Effects 0.000 claims description 4

- 238000004891 communication Methods 0.000 claims description 3

- 230000001960 triggered effect Effects 0.000 claims description 3

- 230000008859 change Effects 0.000 abstract description 9

- 238000010586 diagram Methods 0.000 description 10

- 230000007246 mechanism Effects 0.000 description 6

- 230000008569 process Effects 0.000 description 5

- 230000009286 beneficial effect Effects 0.000 description 2

- 238000004904 shortening Methods 0.000 description 2

- 230000007547 defect Effects 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 230000008439 repair process Effects 0.000 description 1

- 230000004044 response Effects 0.000 description 1

- 238000006467 substitution reaction Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B26—HAND CUTTING TOOLS; CUTTING; SEVERING

- B26D—CUTTING; DETAILS COMMON TO MACHINES FOR PERFORATING, PUNCHING, CUTTING-OUT, STAMPING-OUT OR SEVERING

- B26D5/00—Arrangements for operating and controlling machines or devices for cutting, cutting-out, stamping-out, punching, perforating, or severing by means other than cutting

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B26—HAND CUTTING TOOLS; CUTTING; SEVERING

- B26D—CUTTING; DETAILS COMMON TO MACHINES FOR PERFORATING, PUNCHING, CUTTING-OUT, STAMPING-OUT OR SEVERING

- B26D7/00—Details of apparatus for cutting, cutting-out, stamping-out, punching, perforating, or severing by means other than cutting

- B26D7/08—Means for treating work or cutting member to facilitate cutting

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25H—WORKSHOP EQUIPMENT, e.g. FOR MARKING-OUT WORK; STORAGE MEANS FOR WORKSHOPS

- B25H3/00—Storage means or arrangements for workshops facilitating access to, or handling of, work tools or instruments

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B26—HAND CUTTING TOOLS; CUTTING; SEVERING

- B26D—CUTTING; DETAILS COMMON TO MACHINES FOR PERFORATING, PUNCHING, CUTTING-OUT, STAMPING-OUT OR SEVERING

- B26D7/00—Details of apparatus for cutting, cutting-out, stamping-out, punching, perforating, or severing by means other than cutting

- B26D7/26—Means for mounting or adjusting the cutting member; Means for adjusting the stroke of the cutting member

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B26—HAND CUTTING TOOLS; CUTTING; SEVERING

- B26D—CUTTING; DETAILS COMMON TO MACHINES FOR PERFORATING, PUNCHING, CUTTING-OUT, STAMPING-OUT OR SEVERING

- B26D7/00—Details of apparatus for cutting, cutting-out, stamping-out, punching, perforating, or severing by means other than cutting

- B26D7/26—Means for mounting or adjusting the cutting member; Means for adjusting the stroke of the cutting member

- B26D7/2614—Means for mounting the cutting member

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B26—HAND CUTTING TOOLS; CUTTING; SEVERING

- B26F—PERFORATING; PUNCHING; CUTTING-OUT; STAMPING-OUT; SEVERING BY MEANS OTHER THAN CUTTING

- B26F1/00—Perforating; Punching; Cutting-out; Stamping-out; Apparatus therefor

- B26F1/38—Cutting-out; Stamping-out

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B26—HAND CUTTING TOOLS; CUTTING; SEVERING

- B26F—PERFORATING; PUNCHING; CUTTING-OUT; STAMPING-OUT; SEVERING BY MEANS OTHER THAN CUTTING

- B26F1/00—Perforating; Punching; Cutting-out; Stamping-out; Apparatus therefor

- B26F1/38—Cutting-out; Stamping-out

- B26F1/40—Cutting-out; Stamping-out using a press, e.g. of the ram type

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B26—HAND CUTTING TOOLS; CUTTING; SEVERING

- B26F—PERFORATING; PUNCHING; CUTTING-OUT; STAMPING-OUT; SEVERING BY MEANS OTHER THAN CUTTING

- B26F1/00—Perforating; Punching; Cutting-out; Stamping-out; Apparatus therefor

- B26F1/38—Cutting-out; Stamping-out

- B26F1/40—Cutting-out; Stamping-out using a press, e.g. of the ram type

- B26F1/405—Travelling head presses

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B26—HAND CUTTING TOOLS; CUTTING; SEVERING

- B26D—CUTTING; DETAILS COMMON TO MACHINES FOR PERFORATING, PUNCHING, CUTTING-OUT, STAMPING-OUT OR SEVERING

- B26D7/00—Details of apparatus for cutting, cutting-out, stamping-out, punching, perforating, or severing by means other than cutting

- B26D7/26—Means for mounting or adjusting the cutting member; Means for adjusting the stroke of the cutting member

- B26D2007/2607—Means for mounting or adjusting the cutting member; Means for adjusting the stroke of the cutting member for mounting die cutters

Definitions

- the present invention relates to the technical field of smart cutting equipment, and in particular to a high-speed smart cutting and processing center and a method of changing a die cutter.

- the cutting machines require frequent change of die cutters based on cutting patterns and the die cutters are usually disposed on the die cutter plates.

- die cutters are changed by hand, which leads to long time and low efficiency.

- the position repeatability of the changed die cutters is poor and the size accuracy of the cut products is low.

- the die cutters are changed by using a pinion and rack mechanism, which brings up the working efficient and reduces the workload.

- the die cutter changing mechanism has the following defects: 1. the die cutter changing mechanism is located at a side of the cutting machine, leading to large land occupation area, long transverse movement distance and structural instability; 2.

- the working panel needs to rotate 90° to enable the die cutter to be in transverse state, leading to complex structure and occurrence of failures; 3. the pinion and rack mechanism can generate large noise during operation and has the disadvantages of complex structure and troublesome repairs; 4. after change, the die cutter may have displacement during movement or rotation, leading to inaccurate processing position, and unstable product quality; 5. the running speed is low and the time for changing a die cutter is long.

- the present invention provides a high-speed smart cutting and processing center and a method of changing a die cutter, which achieves fast change of a die cutter and stable operation of the die cutter changing mechanism. This not only shortens the time for changing a die cutter but also noticeably improves the use rate of the cutting machine. Further, the position repeatability and positioning accuracy of changing the die cutter are improved, and the size accuracy and size stability of the cut products are both increased, thus satisfying the needs of the users.

- the present invention is achieved by providing a high-speed smart cutting and processing center.

- the high-speed smart cutting and processing center includes a cutting machine, a die cutter magazine and a die cutter circulation table.

- the cutting machine includes a machine base, a working table and a cross beam, where the working table and the cross beam are disposed on the machine base.

- Punch slide rails are disposed on the cross beam.

- Matching punch slide seats are disposed on the punch slide rails respectively.

- a rotary cutting head is disposed under the punch slide seats.

- a die cutter fixing plate is disposed at the bottom of the rotary cutting head.

- a die cutter for cutting and a die cutter clamping and limiting device are disposed at the bottom of the rotary cutting head.

- the die cutter circulation table is located at the left side of the working table.

- the die cutter magazine includes a frame, a die cutter storage rack and a lifting device, where the die cutter storage rack and the lifting device are disposed within the frame.

- a plurality of die cutters are stacked up and down in different layers in the die cutter storage rack.

- Guide columns are disposed at four corners of the frame, and guide sleeves slidably cooperating with the guide columns are disposed on the die cutter storage rack.

- the lifting device drives the die cutter storage rack to move up and down along the guide columns.

- the lifting device includes a motor gear box provided with a dual-output shaft, driving belt wheels, a driven shaft, driven bearings, driven belt wheels and synchronous belts.

- the motor gear box is disposed on the top of the frame.

- Two driving belt wheels are respectively disposed on both ends of the output shaft.

- Two driven bearings are fixed at a lower portion of the frame and located below the die cutter storage rack.

- the driven shaft is penetrated through the two driven bearings, and the driven belt wheels are disposed on both ends of the driven shaft.

- the driving belt wheels drive the driven belt wheels to rotate by the synchronous belts.

- a synchronous belt is disposed on left and right sides of the frame respectively, and each synchronous belt is provided with a cutter rack fixing plate. One end of the cutter rack fixing plate is fixed on the synchronous belt, and the other end is fixed on the die cutter storage rack at this side.

- a plurality of slideways for placing the die cutters are disposed at the left and right sides of the die cutter storage rack respectively, and a die cutter locking device for positioning the die cutters in the slideways is disposed at the right side of the die cutter storage rack.

- the die cutter locking device includes a locking cylinder, a locking operation rod, locking bearings, driving rods, locking rods, locking rod rotary shafts, and a rotary shaft fixing rod.

- the locking cylinder is fixed on an upper portion of the die cutter storage rack, and the locking operation rod is fixedly connected with an output shaft of the locking cylinder.

- the locking operation rod is penetrated through two locking bearings which are fixed on the die cutter storage rack and respectively located both ends of the locking operation rod.

- the locking operation rod is slid up and down along the locking bearings under the drive of the locking cylinder.

- the rotary shaft fixing rod is fixed at a side of the die cutter storage rack, and the rotary shaft fixing rod is provided with a plurality of avoiding holes each corresponding to a placement position of the each layer of die cutter.

- the driving rods, the locking rods and the locking rod rotary shafts are disposed at a side of the placement position of each layer of die cutter respectively by sets.

- the locking rod is provided with a waist-shaped hole, a rotary shaft hole and an arc-shaped portion respectively.

- the locking rod rotary shafts are penetrated through the rotary shaft fixing rod and the rotary shaft holes of the locking rods to movably connect the locking rods in the locking rod avoiding holes.

- One end of the driving rods is fixed on the locking rods, and the other end is movable inserted into the waist-shaped holes of the locking rods.

- the arc-shaped portions of the locking rods are fitted into limiting grooves of side edges of the die cutters.

- the locking operation rod slides up and down, so as to drive the locking rods to rotate around the locking rod rotary shafts through the driving rods.

- the locking operation rod is provided with a contact block, and an upper travel switch and a lower travel switch cooperating with the contact block are respectively disposed on the frame.

- a stop switch triggered by the die cutter storage rack is disposed on the frame.

- the die cutter circulation table includes two raceway plates, a cylinder mounting plate, a primary thrust cylinder, a thrust slide rail, a thrust block, two lifting cylinders, a cylinder connection plate, a secondary thrust cylinder, and a hook plate with a pull hook.

- One end of the two raceway plates is connected to the die cutter magazine, and the other end is connected with the working table.

- the two raceway plates are separated left and right to form a channel for the die cutter to enter or exit the die cutter magazine.

- the cylinder mounting plate is fixed on the working table, and the primary thrust cylinder and the thrust slide rail are fixed on the cylinder mounting plate.

- the two lifting cylinders are respectively fixed at the left and right sides of the thrust block.

- the cylinder connection plate is linked to cylinder rods of the two lifting cylinders respectively.

- the secondary thrust cylinder is fixed on the cylinder connection plate, and the hook plate is disposed on a cylinder rod of the secondary thrust cylinder.

- the primary thrust cylinder drives, by the thrust block, the two lifting cylinders, the cylinder connection plate, the secondary thrust cylinder and the hook plate to reciprocate along the thrust slide rail at the same time.

- the clamping and limiting device includes a clamping assembly and a limiting assembly and is mounted on the die cutter fixing plate located at the bottom of the cutting machine.

- the clamping assembly includes a left die pressing plate, a right die pressing plate, and pressing cylinders.

- Two pressing cylinders are disposed at the right and left sides of the die cutter fixing plate respectively.

- the two pressing cylinders act simultaneously to press or release the die cutter.

- the left die pressing plate and the right die pressing plate are disposed on the left and right side edges of a lower surface of the die cutter fixing plate respectively.

- the pressing cylinders are disposed inside the die cutter fixing plate and drive the left die pressing plate and the right die pressing plate respectively to press the die cutter closely against the lower surface of the die cutter fixing plate.

- the limiting assembly includes front limiting components and rear limiting components located at front and rear side surfaces of the die cutter fixing plate. At least one of the front limiting component and the rear limiting component is a movable limiting component and the other is a fixed limiting component or movable limiting component.

- the movable limiting components perform limiting for the front and rear side surfaces of the die cutter in linkage with the left die pressing plate or the right die pressing plate.

- the pressing cylinder includes a cylindrical hole, a valve core shaft, an upper piston, a lower piston, an upper air chamber and a lower air chamber, where the cylindrical hole is disposed inside the die cutter fixing plate and the valve core shaft, the upper piston, the lower piston, the upper air chamber and the lower air chamber are disposed inside the cylindrical hole.

- the upper piston and the lower piston are disposed on the valve core shaft respectively.

- the upper air chamber is disposed between the upper piston and the top wall of the cylindrical hole.

- the lower air chamber is disposed between the upper piston and the lower piston.

- An upper air pipe connector and a lower air pipe connector are disposed on the die cutter fixing plate respectively.

- the upper air pipe connector and the lower air pipe connector are in communication with the upper air chamber and the lower air chamber through an upper channel and a lower channel disposed in the die cutter fixing plate.

- a stop washer is disposed on an inner wall of the cylindrical hole to limit a movement position of the lower piston.

- the movable limiting component includes a first connection bar, a second connection bar, a first rotary shaft, a second rotary shaft, and a third rotary shaft.

- the first rotary shaft is fixed on the die cutter fixing plate

- the third rotary shaft is fixed on the left die pressing plate or the right die pressing plate.

- the first rotary shaft is movable disposed in the middle of the first connection bar

- the second rotary shaft movably connects an end of the first connection bar to an end of the second connection bar.

- a blocking portion is disposed on the other end of the first connection bar to limit the die cutter, and the other end of the second connection bar is movably connected with the third rotary shaft.

- the fixed limiting component includes a limiting block and a fastening bolt.

- the limiting block limits the movement position of the die cutter, and the fastening bolt fixes the limiting block on a side surface of the die cutter fixing plate.

- limiting screws are disposed between the left die pressing plate/the right die pressing plate and the die cutter fixing plate.

- the limiting screws are used to limit a maximum distance between the left die pressing plate/the right die pressing plate and the die cutter fixing plate respectively.

- the present invention is achieved by providing a method of changing a die cutter, which is used on the above high-speed smart cutting and processing center.

- the method includes the following steps.

- the rotary cutting head is moved from a working region in the middle of the working table to be over the die cutter circulation table; the movable limiting components of the clamping and limiting device is moved close to the die cutter magazine; the rotary cutting head drives the die cutter to descend to a position for changing the die cutter; the pressing cylinders drive the left die pressing plate and the right die pressing plate to move down respectively to enable the movable limiting components to be in an unlocked state through linkage; the clamping assembly is in a released state, and the old die cutter waits for being changed.

- the primary thrust cylinder drives the secondary thrust cylinder and the hook plate to move from an initial position toward the rotary cutting head; at the same time, the secondary thrust cylinder also drives the hook plate toward the rotary cutting head until the hook plate is located below the old die cutter to be changed; two lifting cylinders drive the secondary thrust cylinder and the hook plate to move upward through the cylinder connection plate at the same time until the pull hook of the hook plate is inserted upward into the hook hole of the old die cutter.

- step 3 the secondary thrust cylinder and the primary thrust cylinder move toward the die cutter magazine at the same time; the old die cutter is pulled out of the clamping and limiting device in a released state in step 1 and moved to a set position in the die cutter magazine; next, two lifting cylinders drive the hook plate to move down and then the secondary thrust cylinder retreats to enable the hook plate to leave the die cutter magazine.

- the lifting device in the die cutter magazine acts to move a new die cutter to a proper position; the secondary thrust cylinder moves again toward the die cutter magazine, and the two lifting cylinders lift the hook plate again until the pull hook of the hook plate is inserted upward into the hook hole of the new die cutter.

- the primary thrust cylinder drives the secondary thrust cylinder and the hook plate toward the rotary cutting head; at the same time, the secondary thrust cylinder also drives the hook plate toward the rotary cutting head until the hook plate moves the new die cutter into the clamping and limiting device in a released state; the new die cutter is stopped by the fixed limiting component at the other side, and the clamping assembly acts reversely to clamp the new die cutter; the pressing cylinders drive the left die pressing plate and the right die pressing plate to move upward to enable the movable limiting components to be in a limiting state through linkage; thus, the new die cutter is clamped and limited; then, two lifting cylinders drive the hook plate to move down, and then the primary thrust cylinder and the second thrust cylinder retreat to their initial positions; the rotary cutting head is lifted up and returned to the working region in the middle of the working table, thereby completing the cycle of changing the die cutter.

- the high-speed smart cutting and processing center and the method of changing a die cutter in the present invention have the following advantages.

- a preferred embodiment of a high-speed smart cutting and processing center of the present invention includes a cutting machine 1, a die cutter magazine 2 and a die cutter circulation table 3.

- the cutting machine 1 includes a machine base, a working table 4 and a cross beam 5, where the working table 4 and the cross beam 5 are disposed on the machine base.

- the cross beam 5 is located above the working table 4.

- a punch slide rail 6 is disposed at the front and rear sides of the cross beam 5 respectively.

- a matching punch slide seat 7 is disposed on the two punch slide rails 6 respectively.

- a rotary cutting head 8 is disposed under the punch slide seats 7.

- a die cutter fixing plate 10 is disposed at the bottom of the rotary cutting head 8.

- a die cutter A for cutting and a die cutter clamping and limiting device 9 are disposed on the die cutter fixing plate 10. The clamping and limiting device 9 is used to achieve limiting and clamping on an imported die cutter A or achieve unlocking and release on a die cutter to be exported.

- the die cutter circulation table 3 is located at the left side of the working table 4. One end of the die cutter circulation table 3 is connected with the die cutter magazine 2 and the other end is connected with the working table 4.

- the rotary cutting head 8 may move to be above the die cutter circulation table 3.

- the die cutter circulation table 3 is used to pull out a die cutter A from the die cutter magazine 2 and mount it into the clamping and limiting device 9 of the rotary cutting head 8 or pull out and return the die cutter A in the clamping and limiting device 9 of the rotary cutting head 8 to the die cutter magazine 2.

- the die cutter magazine 2 includes a frame 21, a die cutter storage rack 22 and a lifting device 23, where the die cutter storage rack 22 and the lifting device 23 are disposed within the frame 21.

- An exit-entry portion 24 for the die cutter A to enter and exit the die cutter storage rack 22 is disposed at the front and rear sides of the frame 21 respectively.

- the exit-entry portion 24 at the front side is connected with the cutting machine 1 to provide a desired die cutter A to the cutting machine 1.

- the exit-entry portion 24 at the rear side is used to change and sequentially configure the die cutters A in the frame 21.

- a plurality of die cutters A are stacked up and down in different layers in the die cutter storage rack 22.

- Guide columns 25 are disposed at four corners of the frame 21, and guide sleeves 26 slidably cooperating with the guide columns 25 are disposed on the die cutter storage rack 22.

- the lifting device 23 drives the die cutter storage rack 22 to move up and down along the guide columns 25.

- the lifting device 23 includes a motor gear box 231 provided with a dual-output shaft, driving belt wheels 232, a driven shaft 233, driven bearings 234, driven belt wheels 235 and synchronous belts 236.

- the motor gear box 231 is disposed on the top of the frame 21.

- Two driving belt wheels 232 are respectively disposed on both ends of the output shaft.

- Two driven bearings 234 are fixed at a lower portion of the frame 21 and located below the die cutter storage rack 22.

- the driven shaft 233 is penetrated through the two driven bearings 234, and the driven belt wheels 235 are disposed on both ends of the driven shaft 233.

- the driving belt wheels 232 drive the driven belt wheels 235 to rotate by the synchronous belts 236.

- a synchronous belt 236 is disposed on left and right sides of the frame 21 respectively, and each synchronous belt 236 is provided with a cutter rack fixing plate 237.

- One end of the cutter rack fixing plate 237 is fixed on the synchronous belt 236, and the other end is fixed on the storage rack 22 at this side.

- the two synchronous belts 236 drive the die cutter storage rack 22 to move up and down along the guide columns 25 through respective cutter rack fixing plates 237 at the same time.

- a plurality of slideways 27 for placing the die cutters A are disposed at the left and right sides of the die cutter storage rack 22 respectively and a die cutter locking device 28 for positioning the die cutters A in the slideways 27 is disposed at the right side of the die cutter storage rack 22.

- the die cutter locking device 28 includes a locking cylinder 281, a locking operation rod 282, locking bearings 283, driving rods 284, locking rods 285, locking rod rotary shafts 286, and a rotary shaft fixing rod 287.

- the locking cylinder 281, the locking bearings 283, and the rotary shaft fixing rod 287 are respectively fixed to the die cutter storage rack 22.

- the locking cylinder 281 is fixed on an upper portion of the die cutter storage rack 22, and the locking operation rod 282 is fixedly connected with an output shaft of the locking cylinder 281.

- the locking operation rod 282 is penetrated through two locking bearings 283 which are fixed on the die cutter storage rack 22 and respectively located both ends of the locking operation rod 282.

- the locking operation rod 282 is slid up and down along the locking bearings 283 under the drive of the locking cylinder 281.

- the rotary shaft fixing rod 287 is fixed at a side of the die cutter storage rack 22, and the rotary shaft fixing rod 287 is provided with a plurality of avoiding holes 2871 each corresponding to a placement position of the each layer of die cutter A.

- the driving rods 284, the locking rods 285 and the locking rod rotary shafts 286 are disposed at a side of the placement position of each layer of die cutter A respectively by sets.

- the locking rod 285 is provided with a waist-shaped hole 2851, a rotary shaft hole 2852 and an arc-shaped portion 2853 respectively, where the waist-shaped hole 2851 and the arc-shaped portion 2853 are located at both sides of the rotary shaft hole 2852.

- the locking rod rotary shafts 286 are penetrated through the rotary shaft fixing rod 287 and the rotary shaft holes 2852 of the locking rods 285 to movably connect the locking rods 285 in the locking rod avoiding holes 2871 such that the locking rods 285 can rotate around the locking rod rotary shafts 286.

- One end of the driving rods 284 is fixed on the locking rods 85, and the other end is movable inserted into the waist-shaped holes 2851 of the locking rods 285.

- the arc-shaped portions 2853 of the locking rods 285 are fitted into limiting grooves B of side edges of the die cutters A, as shown in FIG. 8 .

- the locking operation rod 282 slides up and down and thus drives the locking rods 285 to rotate around the locking rod rotary shafts 286 through the driving rods 84, such that the arc-shaped portions 2853 of the locking rods 285 are fitted into the limiting grooves B of the die cutters A so as to lock up the die cutters A, or the arc-shaped portions 2853 of the locking rods 285 are released from the limiting grooves B of the die cutters A so as to unlock the die cutters A.

- the locking operation rod 282 is provided with a contact block 288, and an upper travel switch 210 and a lower travel switch 211 cooperating with the contact block 288 are respectively disposed on the frame 21.

- the contact block 288 moves up and down along with the locking operation rod 282 to trigger the upper travel switch 210 and the lower travel switch 211 respectively so as to limit the upper and lower positions for the movement of the locking operation rod 282, thereby improving the operation safety of the die cutter locking device 28.

- the response time of the die cutter locking device 28 can be shortened and the working efficiency of the die cutter supply system can be improved.

- a roller 29 is disposed at a sidewall of each slideway 27.

- the rollers 29 are located above the die cutters A and close to the exit-entry portion 24 at the back of the frame 21, so as to achieve limiting and guiding effect when the die cutters A are guided into or out of the die cutter storage rack 22.

- a cutter rack support column 212 is disposed at the bottom of the die cutter storage rack 22 and fixed on the frame 21.

- a cutter rack limiting column 213 is disposed on the top of the frame 21. In this embodiment, four cutter rack support columns 212 are disposed correspondingly at four corners of the bottom of the die cutter storage rack 22, and four cutter rack limiting columns 213 are disposed correspondingly at four corners of the top of the frame 21. In this way, the safety and stability of the die cutter storage rack 22 can be improved.

- a stop switch 214 triggered by the die cutter storage rack 22 is disposed on the frame 21.

- the stop switch 214 is used to limit a descending position of the die cutter storage rack 22, thereby improving the movement safety and stability of the die cutter storage rack 22.

- the die cutter circulation table 3 includes two raceway plates 31, a cylinder mounting plate 32, a primary thrust cylinder 33, a thrust slide rail 34, a thrust block 35, two lifting cylinders 36, a cylinder connection plate 37, a secondary thrust cylinder 38, and a hook plate 39 with a pull hook 310.

- One end of the two raceway plates 31 is connected to the die cutter magazine 2, and the other end is connected with the working table 4.

- the two raceway plates 31 are separated left and right to form a channel for the die cutter A to enter or exit the die cutter magazine 2.

- the cylinder mounting plate 32 is fixed on the working table 4, and the primary thrust cylinder 33 and the thrust slide rail 34 are fixed on the cylinder mounting plate 32.

- the primary thrust cylinder 33 is a rodless cylinder which drives the thrust block 35 to reciprocate along the thrust slide rail 34.

- the primary thrust cylinder 33 and the secondary thrust cylinder 38 are disposed, which not only shortens the length of the primary thrust cylinder 33 but also avoids excess length of the primary thrust cylinder 33, thereby saving costs and improving the movement stability of the thrust block 35. Furthermore, when the two stages of cylinders thrust or retreat, they can thrust or retreat at the same time, shortening the thrust or retreat time and achieving fast movement of the thrust block 35. Further, the die cutters A can be stably and quickly changed, thereby improving working efficiency.

- the disposal of the thrust slide rail 34 increases the stability of the thrust block 35 in quick thrust or retreat process.

- the two lifting cylinders 36 are respectively fixed at the left and right sides of the thrust block 35.

- the cylinder connection plate 37 is linked to cylinder rods of the two lifting cylinders 36 respectively.

- the secondary thrust cylinder 38 is fixed on the cylinder connection plate 37, and the hook plate 39 is disposed on a cylinder rod of the secondary thrust cylinder 38.

- the primary thrust cylinder 33 drives, by the thrust block 35, the two lifting cylinders 36, the cylinder connection plate 37, the secondary thrust cylinder 38 and the hook plate 39 to reciprocate along the thrust slide rail 34 at the same time.

- the pull hook 310 on the hook plate 39 is inserted into a hook hole C on the die cutter A as shown in FIG. 8 , such that the die cutter A is pushed into the released clamping and limiting device 9 or pulled out from the released clamping and limiting device 9.

- the clamping and limiting device 9 includes a clamping assembly 91 and a limiting assembly and is mounted on the die cutter fixing plate 10 located at the bottom of the cutting machine 1.

- the clamping assembly 91 includes a left die pressing plate 94, a right die pressing plate 95, and pressing cylinders 96.

- the left die pressing plate 94 and the right die pressing plate 95 are disposed on the left and right side edges of a lower surface of the die cutter fixing plate 10 respectively.

- the pressing cylinders 96 are disposed inside the die cutter fixing plate 10 and located at four corners of the die cutter fixing plate 10 in a manner of left-right and back-front symmetry.

- the pressing cylinders 96 drive the left die pressing plate 94 and the right die pressing plate 95 respectively to press the die cutter A closely against the lower surface of the die cutter fixing plate 10.

- the limiting assembly includes front limiting components and rear limiting components located at front and rear side surfaces of the die cutter fixing plate 10. At least one of the front limiting component and the rear limiting component is a movable limiting component 97 and the other is a fixed limiting component or movable limiting component 97.

- the movable limiting components 97 perform limiting or unlocking for the front and rear side surfaces of the die cutter A in linkage with the left die pressing plate 94 or the right die pressing plate 95. As shown in FIGS. 10 , 11, and 12 , movable limiting components 97 are disposed at the front and rear side surfaces of the die cutter fixing plate 10.

- the left die pressing plate 94 and the right die pressing plate 95 press the die cutter A closely against the lower surface of the die cutter fixing plate 10 along an up-down direction under the drive of the pressing cylinders 6.

- the limiting assembly performs limiting for the front and rear side surfaces of the die cutter A. In this way, the position repeatability and positioning accuracy of the die cutter is improved and the size accuracy of the cut products is also improved.

- the limiting assembly acts in the following process: when the left die pressing plate 94 and the right die pressing plate 95 of the clamping assembly 91 press the die cutter A closely against the lower surface of the die cutter fixing plate 10, the movable limiting components 97 perform limiting for the front side surface and/or rear side surface of the die cutter A immediately. On the contrary, when the left die pressing plate 94 and the right die pressing plate 95 of the clamping assembly 91 release the up-down press on the die cutter A, the movable limiting components 97 release limitation for the front side surface and/or the rear side surface of the die cutter A immediately.

- Two pressing cylinders 96 are disposed at the right and left sides of the die cutter fixing plate 10 respectively.

- the two pressing cylinders 96 act simultaneously to press or release the die cutter A.

- the pressing cylinder 96 includes a cylindrical hole 961, a valve core shaft 962, an upper piston 963, a lower piston 964, an upper air chamber 965 and a lower air chamber 966, where the cylindrical hole 61 is disposed inside the die cutter fixing plate 10 and the valve core shaft 962, the upper piston 963, the lower piston 964, the upper air chamber 965 and the lower air chamber 966 are disposed inside the cylindrical hole 961.

- the upper piston 963 and the lower piston 964 are disposed on the valve core shaft 962 respectively.

- the upper air chamber 965 is disposed between the upper piston 963 and the top wall of the cylindrical hole 961.

- the lower air chamber 966 is disposed between the upper piston 963 and the lower piston 964.

- An upper air pipe connector 98 and a lower air pipe connector 99 are disposed on the die cutter fixing plate 10 respectively.

- the upper air pipe connector 98 and the lower air pipe connector 99 are in communication with the upper air chamber 965 and the lower air chamber 966 through an upper channel 967 and a lower channel 968 disposed in the die cutter fixing plate 10.

- the pressing cylinders 96 are directly made inside the die cutter fixing plate 10, which simplifies the structure of the die cutter clamping and limiting device, reduces the weight of the die cutter fixing plate 10 and improves its stability.

- the pressing cylinders 96 act in the following process: when high pressure air is introduced into the upper air chamber 965 via the upper air pipe connector 98, the lower air chamber 966 recovers air via the lower air pipe connector 99, and then the valve core shaft 962 is driven to move down together with the upper piston 963 and the lower piston 964 disposed thereon, and then the valve core shaft 962 pushes open the left die pressing plate 94 or the right die pressing plate 95, thereby unlocking the die cutter A.

- the upper air chamber 965 recovers air via the upper air pipe connector 98, and then the valve core shaft 962 is driven to move up for resetting together with the upper piston 963 and the lower piston 964 disposed thereon, and then the valve core shaft 962 drives the left die pressing plate 94 or the right die pressing plate 95 closely against the die cutter A.

- a stop washer 969 is disposed on an inner wall of the cylindrical hole 961 to limit a movement position of the lower piston 964, so as to limit a movement position of the valve core shaft 962, thereby limiting a telescoping height of the pressing cylinder 96.

- the fixed limiting component includes a limiting block and a fastening bolt (not shown).

- the limiting block limits the movement position of the die cutter A, and the fastening bolt fixes the limiting block on a side surface of the die cutter fixing plate 10.

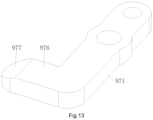

- the movable limiting component 97 includes a first connection bar 971, a second connection bar 972, a first rotary shaft 793, a second rotary shaft 974, and a third rotary shaft 975.

- the first rotary shaft 973 is fixed on the die cutter fixing plate 10

- the third rotary shaft 75 is fixed on the left die pressing plate 94 or the right die pressing plate 95.

- the first rotary shaft 73 is movable disposed in the middle of the first connection bar 971, and the second rotary shaft 74 movably connects an end of the first connection bar 971 to an end of the second connection bar 972.

- a blocking portion 976 is disposed on the other end of the first connection bar 971 to limit the die cutter A, and the other end of the second connection bar 972 is movably connected with the third rotary shaft 975.

- one segment of inclined surface or arc-shaped surface 977 is disposed on the blocking portion 976 of the first connection bar 971 , and thus it is convenient to push the die cutter A back to a correct limiting position when the first connection bar 971 performs limiting for the die cutter A.

- the movable limiting component 97 acts in the following process: when the pressing cylinders 96 drive the left die pressing plate 94 or the right die pressing plate 95 to move down, the third rotary shaft 975 and the second connection bar 972 move down accordingly, and the second connection bar 972 also drives, via the second rotary shaft 974, an end of the first connection bar 971 to move down.

- the first connection bar 971 rotates around the first rotary shaft 973, so as to lift up the other end of the first connection bar 971, thus releasing the limited die cutter A.

- the pressing cylinders 96 drive the left die pressing plate 94 or the right die pressing plate 95 to move up

- the third rotary shaft 975 and the second connection bar 972 move up accordingly

- the second connection bar 972 drives, via the second rotary shaft 974, an end of the first connection bar 971 to move up.

- the first connection bar 971 rotates around the first rotary shaft 973, so as to lower the other end of the first connection bar 971, thus limiting the die cutter A.

- Limiting screws 92 are disposed between the left die pressing plate 94/the right die pressing plate 95 and the die cutter fixing plate 10. The limiting screws 92 are used to adjust and limit a maximum distance between the left die pressing plate 94/the right die pressing plate 95 and the die cutter fixing plate 10 respectively.

- the die cutter A can be quickly limited and clamped, thus achieving quick change of the die cutter A. Further, good position repeatability and high positioning accuracy are ensured.

- the present invention further provides a method of changing a die cutter, which is used on the above high-speed smart cutting and processing center.

- the method includes the following steps.

- the rotary cutting head 8 is moved from a working region in the middle of the working table 4 to be over the die cutter circulation table 3; the movable limiting components 97 of the clamping and limiting device 9 is moved close to the die cutter magazine 2; the rotary cutting head 8 drives the die cutter A to descend to a position for changing the die cutter; the pressing cylinders 96 drive the left die pressing plate 94 and the right die pressing plate 95 to move down respectively to enable the movable limiting components 97 to be in an unlocked state through linkage; the clamping assembly 91 is in a released state, and the old die cutter A1 waits for being changed.

- the primary thrust cylinder 33 drives the secondary thrust cylinder 38 and the hook plate 39 to move from an initial position toward the rotary cutting head 8; at the same time, the secondary thrust cylinder 38 also drives the hook plate 39 toward the rotary cutting head 8 until the hook plate 39 is located below the old die cutter A1 to be changed; two lifting cylinders 36 drive the secondary thrust cylinder 38 and the hook plate 39 to move upward through the cylinder connection plate 37 at the same time until the pull hook 310 of the hook plate 39 is inserted upward into the hook hole C of the old die cutter A1.

- step 3 the secondary thrust cylinder 38 and the primary thrust cylinder 33 move toward the die cutter magazine 2 at the same time; the old die cutter A is pulled out of the clamping and limiting device 9 in a released state in step 1 and moved to a set position in the die cutter magazine 2; next, two lifting cylinders 36 drive the hook plate 39 to move down and then the secondary thrust cylinder 38 retreats to enable the hook plate 39 to leave the die cutter magazine 2.

- the lifting device 23 in the die cutter magazine 2 acts to move a new die cutter A2 to a proper position; the secondary thrust cylinder 38 moves again toward the die cutter magazine 2, and the two lifting cylinders 36 lift the hook plate 39 again until the pull hook 310 of the hook plate 39 is inserted upward into the hook hole C of the new die cutter A2.

- the primary thrust cylinder 33 drives the secondary thrust cylinder 38 and the hook plate 39 toward the rotary cutting head 8; at the same time, the secondary thrust cylinder 33 also drives the hook plate 39 toward the rotary cutting head 8 until the hook plate 39 moves the new die cutter A2 into the clamping and limiting device 9 in a released state; the new die cutter A2 is stopped by the fixed limiting component at the other side, and the clamping assembly 91 acts reversely to clamp the new die cutter A2; the pressing cylinders 96 drive the left die pressing plate 94 and the right die pressing plate 95 to move upward to enable the movable limiting components 97 to be in a limiting state through linkage; thus, the new die cutter A2 is clamped and limited; then, two lifting cylinders 36 drive the hook plate 39 to move down, and then the primary thrust cylinder 33 and the second thrust cylinder 38 retreat to their initial positions; the rotary cutting head 8 is lifted up and returned to the working region in the middle of the working table 4, thereby completing the cycle of changing the die cutter.

- the above process can be operated at high speed on the cutting machine of the present invention under the control of a smart operating system.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- Forests & Forestry (AREA)

- Perforating, Stamping-Out Or Severing By Means Other Than Cutting (AREA)

Abstract

Description

- The present invention relates to the technical field of smart cutting equipment, and in particular to a high-speed smart cutting and processing center and a method of changing a die cutter.

- The cutting machines require frequent change of die cutters based on cutting patterns and the die cutters are usually disposed on the die cutter plates. For most of the existing cutting machines, die cutters are changed by hand, which leads to long time and low efficiency. Furthermore, the position repeatability of the changed die cutters is poor and the size accuracy of the cut products is low. At present, the die cutters are changed by using a pinion and rack mechanism, which brings up the working efficient and reduces the workload. But, the die cutter changing mechanism has the following defects: 1. the die cutter changing mechanism is located at a side of the cutting machine, leading to large land occupation area, long transverse movement distance and structural instability; 2. before change of a die cutter by using the die cutter changing mechanism, the working panel needs to rotate 90° to enable the die cutter to be in transverse state, leading to complex structure and occurrence of failures; 3. the pinion and rack mechanism can generate large noise during operation and has the disadvantages of complex structure and troublesome repairs; 4. after change, the die cutter may have displacement during movement or rotation, leading to inaccurate processing position, and unstable product quality; 5. the running speed is low and the time for changing a die cutter is long.

- In order to address the above technical problems, the present invention provides a high-speed smart cutting and processing center and a method of changing a die cutter, which achieves fast change of a die cutter and stable operation of the die cutter changing mechanism. This not only shortens the time for changing a die cutter but also noticeably improves the use rate of the cutting machine. Further, the position repeatability and positioning accuracy of changing the die cutter are improved, and the size accuracy and size stability of the cut products are both increased, thus satisfying the needs of the users.

- The present invention is achieved by providing a high-speed smart cutting and processing center. The high-speed smart cutting and processing center includes a cutting machine, a die cutter magazine and a die cutter circulation table. The cutting machine includes a machine base, a working table and a cross beam, where the working table and the cross beam are disposed on the machine base. Punch slide rails are disposed on the cross beam. Matching punch slide seats are disposed on the punch slide rails respectively. A rotary cutting head is disposed under the punch slide seats. A die cutter fixing plate is disposed at the bottom of the rotary cutting head. A die cutter for cutting and a die cutter clamping and limiting device are disposed at the bottom of the rotary cutting head. The die cutter circulation table is located at the left side of the working table. One end of the die cutter circulation table is connected with the die cutter magazine and the other end is connected with the working table. The die cutter magazine includes a frame, a die cutter storage rack and a lifting device, where the die cutter storage rack and the lifting device are disposed within the frame. A plurality of die cutters are stacked up and down in different layers in the die cutter storage rack. Guide columns are disposed at four corners of the frame, and guide sleeves slidably cooperating with the guide columns are disposed on the die cutter storage rack. The lifting device drives the die cutter storage rack to move up and down along the guide columns. The lifting device includes a motor gear box provided with a dual-output shaft, driving belt wheels, a driven shaft, driven bearings, driven belt wheels and synchronous belts. The motor gear box is disposed on the top of the frame. Two driving belt wheels are respectively disposed on both ends of the output shaft. Two driven bearings are fixed at a lower portion of the frame and located below the die cutter storage rack. The driven shaft is penetrated through the two driven bearings, and the driven belt wheels are disposed on both ends of the driven shaft. The driving belt wheels drive the driven belt wheels to rotate by the synchronous belts. A synchronous belt is disposed on left and right sides of the frame respectively, and each synchronous belt is provided with a cutter rack fixing plate. One end of the cutter rack fixing plate is fixed on the synchronous belt, and the other end is fixed on the die cutter storage rack at this side.

- Furthermore, a plurality of slideways for placing the die cutters are disposed at the left and right sides of the die cutter storage rack respectively, and a die cutter locking device for positioning the die cutters in the slideways is disposed at the right side of the die cutter storage rack. The die cutter locking device includes a locking cylinder, a locking operation rod, locking bearings, driving rods, locking rods, locking rod rotary shafts, and a rotary shaft fixing rod. The locking cylinder is fixed on an upper portion of the die cutter storage rack, and the locking operation rod is fixedly connected with an output shaft of the locking cylinder. The locking operation rod is penetrated through two locking bearings which are fixed on the die cutter storage rack and respectively located both ends of the locking operation rod. The locking operation rod is slid up and down along the locking bearings under the drive of the locking cylinder. The rotary shaft fixing rod is fixed at a side of the die cutter storage rack, and the rotary shaft fixing rod is provided with a plurality of avoiding holes each corresponding to a placement position of the each layer of die cutter. The driving rods, the locking rods and the locking rod rotary shafts are disposed at a side of the placement position of each layer of die cutter respectively by sets. The locking rod is provided with a waist-shaped hole, a rotary shaft hole and an arc-shaped portion respectively. The locking rod rotary shafts are penetrated through the rotary shaft fixing rod and the rotary shaft holes of the locking rods to movably connect the locking rods in the locking rod avoiding holes. One end of the driving rods is fixed on the locking rods, and the other end is movable inserted into the waist-shaped holes of the locking rods. The arc-shaped portions of the locking rods are fitted into limiting grooves of side edges of the die cutters. The locking operation rod slides up and down, so as to drive the locking rods to rotate around the locking rod rotary shafts through the driving rods.

- Furthermore, the locking operation rod is provided with a contact block, and an upper travel switch and a lower travel switch cooperating with the contact block are respectively disposed on the frame. A stop switch triggered by the die cutter storage rack is disposed on the frame.

- Furthermore, the die cutter circulation table includes two raceway plates, a cylinder mounting plate, a primary thrust cylinder, a thrust slide rail, a thrust block, two lifting cylinders, a cylinder connection plate, a secondary thrust cylinder, and a hook plate with a pull hook. One end of the two raceway plates is connected to the die cutter magazine, and the other end is connected with the working table. The two raceway plates are separated left and right to form a channel for the die cutter to enter or exit the die cutter magazine. The cylinder mounting plate is fixed on the working table, and the primary thrust cylinder and the thrust slide rail are fixed on the cylinder mounting plate. The two lifting cylinders are respectively fixed at the left and right sides of the thrust block. The cylinder connection plate is linked to cylinder rods of the two lifting cylinders respectively. The secondary thrust cylinder is fixed on the cylinder connection plate, and the hook plate is disposed on a cylinder rod of the secondary thrust cylinder. The primary thrust cylinder drives, by the thrust block, the two lifting cylinders, the cylinder connection plate, the secondary thrust cylinder and the hook plate to reciprocate along the thrust slide rail at the same time.

- Furthermore, the clamping and limiting device includes a clamping assembly and a limiting assembly and is mounted on the die cutter fixing plate located at the bottom of the cutting machine. The clamping assembly includes a left die pressing plate, a right die pressing plate, and pressing cylinders. Two pressing cylinders are disposed at the right and left sides of the die cutter fixing plate respectively. The two pressing cylinders act simultaneously to press or release the die cutter. The left die pressing plate and the right die pressing plate are disposed on the left and right side edges of a lower surface of the die cutter fixing plate respectively. The pressing cylinders are disposed inside the die cutter fixing plate and drive the left die pressing plate and the right die pressing plate respectively to press the die cutter closely against the lower surface of the die cutter fixing plate. The limiting assembly includes front limiting components and rear limiting components located at front and rear side surfaces of the die cutter fixing plate. At least one of the front limiting component and the rear limiting component is a movable limiting component and the other is a fixed limiting component or movable limiting component. The movable limiting components perform limiting for the front and rear side surfaces of the die cutter in linkage with the left die pressing plate or the right die pressing plate.

- Furthermore, the pressing cylinder includes a cylindrical hole, a valve core shaft, an upper piston, a lower piston, an upper air chamber and a lower air chamber, where the cylindrical hole is disposed inside the die cutter fixing plate and the valve core shaft, the upper piston, the lower piston, the upper air chamber and the lower air chamber are disposed inside the cylindrical hole. The upper piston and the lower piston are disposed on the valve core shaft respectively. The upper air chamber is disposed between the upper piston and the top wall of the cylindrical hole. The lower air chamber is disposed between the upper piston and the lower piston. An upper air pipe connector and a lower air pipe connector are disposed on the die cutter fixing plate respectively. The upper air pipe connector and the lower air pipe connector are in communication with the upper air chamber and the lower air chamber through an upper channel and a lower channel disposed in the die cutter fixing plate. A stop washer is disposed on an inner wall of the cylindrical hole to limit a movement position of the lower piston.

- Furthermore, the movable limiting component includes a first connection bar, a second connection bar, a first rotary shaft, a second rotary shaft, and a third rotary shaft. The first rotary shaft is fixed on the die cutter fixing plate, and the third rotary shaft is fixed on the left die pressing plate or the right die pressing plate. The first rotary shaft is movable disposed in the middle of the first connection bar, and the second rotary shaft movably connects an end of the first connection bar to an end of the second connection bar. A blocking portion is disposed on the other end of the first connection bar to limit the die cutter, and the other end of the second connection bar is movably connected with the third rotary shaft.

- Furthermore, the fixed limiting component includes a limiting block and a fastening bolt. The limiting block limits the movement position of the die cutter, and the fastening bolt fixes the limiting block on a side surface of the die cutter fixing plate.

- Furthermore, limiting screws are disposed between the left die pressing plate/the right die pressing plate and the die cutter fixing plate. The limiting screws are used to limit a maximum distance between the left die pressing plate/the right die pressing plate and the die cutter fixing plate respectively.

- The present invention is achieved by providing a method of changing a die cutter, which is used on the above high-speed smart cutting and processing center. The method includes the following steps.

- At

step 1, the rotary cutting head is moved from a working region in the middle of the working table to be over the die cutter circulation table; the movable limiting components of the clamping and limiting device is moved close to the die cutter magazine; the rotary cutting head drives the die cutter to descend to a position for changing the die cutter; the pressing cylinders drive the left die pressing plate and the right die pressing plate to move down respectively to enable the movable limiting components to be in an unlocked state through linkage; the clamping assembly is in a released state, and the old die cutter waits for being changed. - At

step 2, the primary thrust cylinder drives the secondary thrust cylinder and the hook plate to move from an initial position toward the rotary cutting head; at the same time, the secondary thrust cylinder also drives the hook plate toward the rotary cutting head until the hook plate is located below the old die cutter to be changed; two lifting cylinders drive the secondary thrust cylinder and the hook plate to move upward through the cylinder connection plate at the same time until the pull hook of the hook plate is inserted upward into the hook hole of the old die cutter. - At

step 3, the secondary thrust cylinder and the primary thrust cylinder move toward the die cutter magazine at the same time; the old die cutter is pulled out of the clamping and limiting device in a released state instep 1 and moved to a set position in the die cutter magazine; next, two lifting cylinders drive the hook plate to move down and then the secondary thrust cylinder retreats to enable the hook plate to leave the die cutter magazine. - At

step 4, the lifting device in the die cutter magazine acts to move a new die cutter to a proper position; the secondary thrust cylinder moves again toward the die cutter magazine, and the two lifting cylinders lift the hook plate again until the pull hook of the hook plate is inserted upward into the hook hole of the new die cutter. - At

step 5, the primary thrust cylinder drives the secondary thrust cylinder and the hook plate toward the rotary cutting head; at the same time, the secondary thrust cylinder also drives the hook plate toward the rotary cutting head until the hook plate moves the new die cutter into the clamping and limiting device in a released state; the new die cutter is stopped by the fixed limiting component at the other side, and the clamping assembly acts reversely to clamp the new die cutter; the pressing cylinders drive the left die pressing plate and the right die pressing plate to move upward to enable the movable limiting components to be in a limiting state through linkage; thus, the new die cutter is clamped and limited; then, two lifting cylinders drive the hook plate to move down, and then the primary thrust cylinder and the second thrust cylinder retreat to their initial positions; the rotary cutting head is lifted up and returned to the working region in the middle of the working table, thereby completing the cycle of changing the die cutter. - Compared with the prior arts, the high-speed smart cutting and processing center and the method of changing a die cutter in the present invention have the following advantages.

- 1. The present invention can automatically and quickly change a die cutter, shortening the time for changing a die cutter and improving working efficiency.

- 2. The die cutter magazine is disposed at an end of the cutting machine such that the die cutter will move a shorter distance for change, achieving more accurate positioning, more reasonable structure and higher changing efficiency.

- 3. The machine can run stably with low failure rate.

-

-

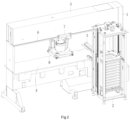

FIG. 1 is a stereoscopic schematic diagram illustrating a preferred embodiment of a high-speed smart cutting and processing center according to the present invention. -

FIG. 2 is a stereoscopic schematic diagram ofFIG. 1 from another perspective. -

FIG. 3 is a partially-enlarged view of M part inFIG. 1 . -

FIG. 4 is a front view of the die cutter magazine inFIG. 1 . -

FIG. 5 is a stereoscopic schematic diagram ofFIG. 4 . -

FIG. 6 is a stereoscopic schematic diagram ofFIG. 5 from another perspective. -

FIG. 7 is an enlarged view of part P inFIG. 5 . -

FIG. 8 is a stereoscopic schematic diagram of the die cutter inFIG. 5 . -

FIG. 9 is a stereoscopic schematic diagram of the locking rod inFIG. 5 . -

FIG. 10 is a stereoscopic schematic diagram of the rotary cutting head according to the present invention inFIG. 1 . -

FIG. 11 is a stereoscopic schematic diagram of the die cutter fixing plate and the die cutter clamping and limiting device in an assembled state inFIG. 10 . -

FIG. 12 is a stereoscopic schematic diagram ofFIG. 11 from another perspective, showing N-N section. -

FIG. 13 is a stereoscopic schematic diagram of the first connection bar inFIG. 11 . - In order to make the technical problems, the technical solutions and the beneficial effects of the present invention clearer and more intelligible, the present invention will be further elaborated in combination with accompanying drawings and specific embodiments. It should be understood that the specific embodiments described herein are used only to explain the present invention rather than limit the present invention.

- By referring to

FIGS.1 ,2 and3 at the same time, a preferred embodiment of a high-speed smart cutting and processing center of the present invention includes a cuttingmachine 1, adie cutter magazine 2 and a die cutter circulation table 3. - The cutting

machine 1 includes a machine base, a working table 4 and across beam 5, where the working table 4 and thecross beam 5 are disposed on the machine base. Thecross beam 5 is located above the working table 4. Apunch slide rail 6 is disposed at the front and rear sides of thecross beam 5 respectively. A matchingpunch slide seat 7 is disposed on the twopunch slide rails 6 respectively. Arotary cutting head 8 is disposed under the punch slide seats 7. A diecutter fixing plate 10 is disposed at the bottom of therotary cutting head 8. A die cutter A for cutting and a die cutter clamping and limiting device 9 are disposed on the diecutter fixing plate 10. The clamping and limiting device 9 is used to achieve limiting and clamping on an imported die cutter A or achieve unlocking and release on a die cutter to be exported. - The die cutter circulation table 3 is located at the left side of the working table 4. One end of the die cutter circulation table 3 is connected with the

die cutter magazine 2 and the other end is connected with the working table 4. Therotary cutting head 8 may move to be above the die cutter circulation table 3. The die cutter circulation table 3 is used to pull out a die cutter A from thedie cutter magazine 2 and mount it into the clamping and limiting device 9 of therotary cutting head 8 or pull out and return the die cutter A in the clamping and limiting device 9 of therotary cutting head 8 to thedie cutter magazine 2. - By referring to

FIGS. 4 to 9 at the same time, thedie cutter magazine 2 includes aframe 21, a diecutter storage rack 22 and alifting device 23, where the diecutter storage rack 22 and thelifting device 23 are disposed within theframe 21. An exit-entry portion 24 for the die cutter A to enter and exit the diecutter storage rack 22 is disposed at the front and rear sides of theframe 21 respectively. The exit-entry portion 24 at the front side is connected with the cuttingmachine 1 to provide a desired die cutter A to the cuttingmachine 1. The exit-entry portion 24 at the rear side is used to change and sequentially configure the die cutters A in theframe 21. A plurality of die cutters A are stacked up and down in different layers in the diecutter storage rack 22.Guide columns 25 are disposed at four corners of theframe 21, and guidesleeves 26 slidably cooperating with theguide columns 25 are disposed on the diecutter storage rack 22. The liftingdevice 23 drives the diecutter storage rack 22 to move up and down along theguide columns 25. - The lifting

device 23 includes amotor gear box 231 provided with a dual-output shaft, drivingbelt wheels 232, a drivenshaft 233, drivenbearings 234, drivenbelt wheels 235 andsynchronous belts 236. Themotor gear box 231 is disposed on the top of theframe 21. Two drivingbelt wheels 232 are respectively disposed on both ends of the output shaft. Two drivenbearings 234 are fixed at a lower portion of theframe 21 and located below the diecutter storage rack 22. The drivenshaft 233 is penetrated through the two drivenbearings 234, and the drivenbelt wheels 235 are disposed on both ends of the drivenshaft 233. The drivingbelt wheels 232 drive the drivenbelt wheels 235 to rotate by thesynchronous belts 236. Asynchronous belt 236 is disposed on left and right sides of theframe 21 respectively, and eachsynchronous belt 236 is provided with a cutterrack fixing plate 237. One end of the cutterrack fixing plate 237 is fixed on thesynchronous belt 236, and the other end is fixed on thestorage rack 22 at this side. The twosynchronous belts 236 drive the diecutter storage rack 22 to move up and down along theguide columns 25 through respective cutterrack fixing plates 237 at the same time. With the synchronous belt technology, the structure of thelifting device 23 is simplified and the repeatability of the up and down moving position of the diecutter storage rack 22 is improved, thereby increasing the running stability. - A plurality of

slideways 27 for placing the die cutters A are disposed at the left and right sides of the diecutter storage rack 22 respectively and a diecutter locking device 28 for positioning the die cutters A in theslideways 27 is disposed at the right side of the diecutter storage rack 22. - The die

cutter locking device 28 includes alocking cylinder 281, a lockingoperation rod 282, lockingbearings 283, drivingrods 284, lockingrods 285, lockingrod rotary shafts 286, and a rotaryshaft fixing rod 287. Thelocking cylinder 281, the lockingbearings 283, and the rotaryshaft fixing rod 287 are respectively fixed to the diecutter storage rack 22. - The

locking cylinder 281 is fixed on an upper portion of the diecutter storage rack 22, and the lockingoperation rod 282 is fixedly connected with an output shaft of thelocking cylinder 281. The lockingoperation rod 282 is penetrated through two lockingbearings 283 which are fixed on the diecutter storage rack 22 and respectively located both ends of the lockingoperation rod 282. The lockingoperation rod 282 is slid up and down along the lockingbearings 283 under the drive of thelocking cylinder 281. The rotaryshaft fixing rod 287 is fixed at a side of the diecutter storage rack 22, and the rotaryshaft fixing rod 287 is provided with a plurality of avoidingholes 2871 each corresponding to a placement position of the each layer of die cutter A. - The driving

rods 284, the lockingrods 285 and the lockingrod rotary shafts 286 are disposed at a side of the placement position of each layer of die cutter A respectively by sets. As shown inFIG. 9 , the lockingrod 285 is provided with a waist-shapedhole 2851, arotary shaft hole 2852 and an arc-shapedportion 2853 respectively, where the waist-shapedhole 2851 and the arc-shapedportion 2853 are located at both sides of therotary shaft hole 2852. The lockingrod rotary shafts 286 are penetrated through the rotaryshaft fixing rod 287 and therotary shaft holes 2852 of the lockingrods 285 to movably connect the lockingrods 285 in the lockingrod avoiding holes 2871 such that the lockingrods 285 can rotate around the lockingrod rotary shafts 286. One end of the drivingrods 284 is fixed on the locking rods 85, and the other end is movable inserted into the waist-shapedholes 2851 of the lockingrods 285. The arc-shapedportions 2853 of the lockingrods 285 are fitted into limiting grooves B of side edges of the die cutters A, as shown inFIG. 8 . - The locking

operation rod 282 slides up and down and thus drives the lockingrods 285 to rotate around the lockingrod rotary shafts 286 through the driving rods 84, such that the arc-shapedportions 2853 of the lockingrods 285 are fitted into the limiting grooves B of the die cutters A so as to lock up the die cutters A, or the arc-shapedportions 2853 of the lockingrods 285 are released from the limiting grooves B of the die cutters A so as to unlock the die cutters A. - The locking

operation rod 282 is provided with acontact block 288, and an upper travel switch 210 and alower travel switch 211 cooperating with thecontact block 288 are respectively disposed on theframe 21. Thecontact block 288 moves up and down along with the lockingoperation rod 282 to trigger the upper travel switch 210 and thelower travel switch 211 respectively so as to limit the upper and lower positions for the movement of the lockingoperation rod 282, thereby improving the operation safety of the diecutter locking device 28. - With the

locking cylinder 281 as power, the response time of the diecutter locking device 28 can be shortened and the working efficiency of the die cutter supply system can be improved. - A

roller 29 is disposed at a sidewall of eachslideway 27. Therollers 29 are located above the die cutters A and close to the exit-entry portion 24 at the back of theframe 21, so as to achieve limiting and guiding effect when the die cutters A are guided into or out of the diecutter storage rack 22. A cutterrack support column 212 is disposed at the bottom of the diecutter storage rack 22 and fixed on theframe 21. A cutterrack limiting column 213 is disposed on the top of theframe 21. In this embodiment, four cutterrack support columns 212 are disposed correspondingly at four corners of the bottom of the diecutter storage rack 22, and four cutterrack limiting columns 213 are disposed correspondingly at four corners of the top of theframe 21. In this way, the safety and stability of the diecutter storage rack 22 can be improved. - A

stop switch 214 triggered by the diecutter storage rack 22 is disposed on theframe 21. Thestop switch 214 is used to limit a descending position of the diecutter storage rack 22, thereby improving the movement safety and stability of the diecutter storage rack 22. - By referring to

FIGS. 1 and3 at the same time, the die cutter circulation table 3 includes tworaceway plates 31, acylinder mounting plate 32, aprimary thrust cylinder 33, athrust slide rail 34, athrust block 35, two liftingcylinders 36, acylinder connection plate 37, asecondary thrust cylinder 38, and a hook plate 39 with apull hook 310. One end of the tworaceway plates 31 is connected to thedie cutter magazine 2, and the other end is connected with the working table 4. The tworaceway plates 31 are separated left and right to form a channel for the die cutter A to enter or exit thedie cutter magazine 2. Thecylinder mounting plate 32 is fixed on the working table 4, and theprimary thrust cylinder 33 and thethrust slide rail 34 are fixed on thecylinder mounting plate 32. Theprimary thrust cylinder 33 is a rodless cylinder which drives thethrust block 35 to reciprocate along thethrust slide rail 34. - The

primary thrust cylinder 33 and thesecondary thrust cylinder 38 are disposed, which not only shortens the length of theprimary thrust cylinder 33 but also avoids excess length of theprimary thrust cylinder 33, thereby saving costs and improving the movement stability of thethrust block 35. Furthermore, when the two stages of cylinders thrust or retreat, they can thrust or retreat at the same time, shortening the thrust or retreat time and achieving fast movement of thethrust block 35. Further, the die cutters A can be stably and quickly changed, thereby improving working efficiency. The disposal of thethrust slide rail 34 increases the stability of thethrust block 35 in quick thrust or retreat process. - The two lifting

cylinders 36 are respectively fixed at the left and right sides of thethrust block 35. Thecylinder connection plate 37 is linked to cylinder rods of the two liftingcylinders 36 respectively. Thesecondary thrust cylinder 38 is fixed on thecylinder connection plate 37, and the hook plate 39 is disposed on a cylinder rod of thesecondary thrust cylinder 38. Theprimary thrust cylinder 33 drives, by thethrust block 35, the two liftingcylinders 36, thecylinder connection plate 37, thesecondary thrust cylinder 38 and the hook plate 39 to reciprocate along thethrust slide rail 34 at the same time. Thepull hook 310 on the hook plate 39 is inserted into a hook hole C on the die cutter A as shown inFIG. 8 , such that the die cutter A is pushed into the released clamping and limiting device 9 or pulled out from the released clamping and limiting device 9. - By referring to

FIGS. 10 to 13 at the same time, the clamping and limiting device 9 includes a clampingassembly 91 and a limiting assembly and is mounted on the diecutter fixing plate 10 located at the bottom of the cuttingmachine 1. The clampingassembly 91 includes a leftdie pressing plate 94, a rightdie pressing plate 95, andpressing cylinders 96. The left die pressingplate 94 and the rightdie pressing plate 95 are disposed on the left and right side edges of a lower surface of the diecutter fixing plate 10 respectively. Thepressing cylinders 96 are disposed inside the diecutter fixing plate 10 and located at four corners of the diecutter fixing plate 10 in a manner of left-right and back-front symmetry. Thepressing cylinders 96 drive the leftdie pressing plate 94 and the rightdie pressing plate 95 respectively to press the die cutter A closely against the lower surface of the diecutter fixing plate 10. - The limiting assembly includes front limiting components and rear limiting components located at front and rear side surfaces of the die

cutter fixing plate 10. At least one of the front limiting component and the rear limiting component is a movable limitingcomponent 97 and the other is a fixed limiting component or movable limitingcomponent 97. The movable limitingcomponents 97 perform limiting or unlocking for the front and rear side surfaces of the die cutter A in linkage with the leftdie pressing plate 94 or the rightdie pressing plate 95. As shown inFIGS. 10 ,11, and 12 , movable limitingcomponents 97 are disposed at the front and rear side surfaces of the diecutter fixing plate 10. - When the die cutter A is in a clamped state, the left die pressing

plate 94 and the rightdie pressing plate 95 press the die cutter A closely against the lower surface of the diecutter fixing plate 10 along an up-down direction under the drive of thepressing cylinders 6. At this time, the limiting assembly performs limiting for the front and rear side surfaces of the die cutter A. In this way, the position repeatability and positioning accuracy of the die cutter is improved and the size accuracy of the cut products is also improved. - The limiting assembly acts in the following process: when the left

die pressing plate 94 and the rightdie pressing plate 95 of the clampingassembly 91 press the die cutter A closely against the lower surface of the diecutter fixing plate 10, the movable limitingcomponents 97 perform limiting for the front side surface and/or rear side surface of the die cutter A immediately. On the contrary, when the leftdie pressing plate 94 and the rightdie pressing plate 95 of the clampingassembly 91 release the up-down press on the die cutter A, the movable limitingcomponents 97 release limitation for the front side surface and/or the rear side surface of the die cutter A immediately. - Two

pressing cylinders 96 are disposed at the right and left sides of the diecutter fixing plate 10 respectively. The twopressing cylinders 96 act simultaneously to press or release the die cutter A. - The