EP3433427B2 - Verbessertes filterpapier für zigarettenfilter - Google Patents

Verbessertes filterpapier für zigarettenfilter Download PDFInfo

- Publication number

- EP3433427B2 EP3433427B2 EP17701315.8A EP17701315A EP3433427B2 EP 3433427 B2 EP3433427 B2 EP 3433427B2 EP 17701315 A EP17701315 A EP 17701315A EP 3433427 B2 EP3433427 B2 EP 3433427B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- filter

- filter paper

- fibers

- weight

- paper

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24D—CIGARS; CIGARETTES; TOBACCO SMOKE FILTERS; MOUTHPIECES FOR CIGARS OR CIGARETTES; MANUFACTURE OF TOBACCO SMOKE FILTERS OR MOUTHPIECES

- A24D3/00—Tobacco smoke filters, e.g. filter-tips, filtering inserts; Filters specially adapted for simulated smoking devices; Mouthpieces for cigars or cigarettes

- A24D3/06—Use of materials for tobacco smoke filters

- A24D3/08—Use of materials for tobacco smoke filters of organic materials as carrier or major constituent

- A24D3/10—Use of materials for tobacco smoke filters of organic materials as carrier or major constituent of cellulose or cellulose derivatives

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24D—CIGARS; CIGARETTES; TOBACCO SMOKE FILTERS; MOUTHPIECES FOR CIGARS OR CIGARETTES; MANUFACTURE OF TOBACCO SMOKE FILTERS OR MOUTHPIECES

- A24D3/00—Tobacco smoke filters, e.g. filter-tips, filtering inserts; Filters specially adapted for simulated smoking devices; Mouthpieces for cigars or cigarettes

- A24D3/06—Use of materials for tobacco smoke filters

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H11/00—Pulp or paper, comprising cellulose or lignocellulose fibres of natural origin only

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H15/00—Pulp or paper, comprising fibres or web-forming material characterised by features other than their chemical constitution

- D21H15/02—Pulp or paper, comprising fibres or web-forming material characterised by features other than their chemical constitution characterised by configuration

- D21H15/06—Long fibres, i.e. fibres exceeding the upper length limit of conventional paper-making fibres; Filaments

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H27/00—Special paper not otherwise provided for, e.g. made by multi-step processes

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H27/00—Special paper not otherwise provided for, e.g. made by multi-step processes

- D21H27/08—Filter paper

Definitions

- the present invention relates to a paper for producing a cigarette filter and a method for producing the filter paper.

- the invention further relates to an associated cigarette.

- a filter made from the filter paper according to the invention has retention properties similar to those of cellulose acetate filters and therefore improves the taste impression of a cigarette made from this filter paper compared to cigarettes with paper filters made from conventional filter papers.

- a conventionally manufactured filter cigarette generally consists of a cylindrical column of tobacco wrapped in a cigarette paper, and a filter made of a filter material wrapped in a filter wrapper paper.

- a common filter material is cellulose acetate.

- the tobacco column and the filter are connected by a tipping paper.

- paper is also known as a filter material for cigarettes.

- a cigarette filter can consist of several segments, each segment being made of a different material.

- filters consisting of two segments are known from the prior art, with one segment being a cellulose acetate filter and a second segment being a paper filter. It is also known to mix cellulose acetate fibers and pulp fibers in one segment or to arrange structures made of these fibers separately within a segment, for example, in a longitudinal or radial direction.

- Paper filters generally have the advantage that they degrade more quickly in the environment and are generally less expensive than cellulose acetate filters.

- a major disadvantage of a conventional paper filter is that it has different retention properties than a cellulose acetate filter.

- the draw resistance that is, the resistance the filter offers to the flow of smoke—is often considerably lower than that of a cellulose acetate filter.

- the hardness of a paper filter that is, its resistance to mechanical deformation—often does not meet the expectations of a smoker accustomed to a cellulose acetate filter.

- EP 2 761 085 For example, a particularly biodegradable paper for paper filters is described, but this cannot completely satisfactorily solve the problems regarding taste or filtration efficiency.

- the EP 10 98 036 A1 discloses a filter wrap paper comprising a paper layer having a first and a second surface.

- the filter wrap paper has a first overlap air permeability measured when a perforated paper is overlaid with the first surface, and a second overlap air permeability measured when a perforated tipping paper is overlaid with the second surface.

- the first overlap air permeability is higher than the second overlap air permeability.

- the present invention is therefore based on the object of providing a filter paper that can be produced easily and cost-effectively and simultaneously imparts a filtration efficiency similar to a filter made of cellulose acetate with comparable draw resistance.

- This object is achieved by a filter paper according to claim 1 and its production method according to claim 10.

- the invention further relates to a filter and a filter cigarette using this material.

- the inventors have determined that the amount of fines in the filter paper, i.e., fibers with a length of less than 0.2 mm, is significant in reducing the filtration efficiency of a filter made from the filter paper according to the invention, making it more similar to that of a cellulose acetate filter. This is surprising because the fines themselves have a large surface area, and their presence should therefore increase filtration efficiency. In fact, however, it is neither beneficial to have too many nor too few fines in the filter paper; rather, their proportion relative to the number of fibers in the filter paper should be in the narrow range between 2% and 10%.

- the inventors have determined that the air permeability of the filter paper is a key parameter for controlling the draw resistance of the paper filter and thus also its filtration efficiency over a wide range. This is surprising because cigarette smoke in a paper filter typically flows along the surface of the filter paper and not through it. Contrary to the expectations of the skilled person, a close relationship between air permeability, draw resistance, and filtration efficiency is evident.

- Air permeability is influenced by the intensity of fiber refining. Intensively refined fibers result in low air permeability, while less intensively refined fibers result in high air permeability. However, since not only air permeability but also the fines content is influenced by fiber refining, it is not self-evident that air permeability can be adjusted within the range described in the invention with an approximately constant fines content. In addition, the filter paper must also meet requirements regarding mechanical strength, which is also significantly influenced by fiber refining.

- the dimensions of the fibers in the filter paper influence their surface area and thus also the air permeability and filtration efficiency of the filter made from it. Therefore, it is beneficial if the average length and width of the fibers in the filter paper lie within a certain range.

- the length and width of the fibers in the filter paper can be measured according to ISO 16065 using the automated optical method described therein. However, in deviation from ISO 16065, fiber portions with a length of less than 0.2 mm are included in the measurement. Such a measurement is possible with the L&W Fiber Tester Plus - code 912 Plus from Lorentzen & Wettre, which can also determine the amount of fines.

- a sample of approximately 0.1 g of dry fibers is suspended in water and pumped through a thin gap between two plates by the measuring device.

- a camera monitors the fiber suspension flowing through the gap between the plates and takes images at short intervals. These images are analyzed to determine the geometry of the flowing fibers.

- the results of this measuring device include a number-related distribution of fiber lengths and fiber widths, from which the number-related mean length and mean width as well as the proportion of fines can be determined.

- the mean length of the fibres in the filter paper determined in this way, based on the number, should be more than 1 mm and less than 5 mm, and preferably more than 2 mm and less than 4 mm.

- the mean width of the fibers in the filter paper determined in this way, based on the number, is also between 10 ⁇ m and 50 ⁇ m, preferably between 20 ⁇ m and 40 ⁇ m, and most preferably between 25 ⁇ m and 35 ⁇ m.

- the filter paper according to the invention contains fibers, wherein the fibers in any case comprise cellulose fibers.

- Cellulose fibers are cellulose-based fibers of plant origin, for example, long-fiber cellulose fibers or short-fiber cellulose fibers.

- fibers made of plastics, fibers made of regenerated cellulose, and in particular cellulose acetate fibers are not considered cellulose fibers.

- the pulp fibers can basically be bleached or unbleached or a mixture of Bleached and unbleached pulp fibers are preferred. However, the pulp fibers are preferably bleached because the filter paper is then white, and this is the color expected by the smoker. The use of at least some unbleached pulp fibers results in a filter paper with a light brown to dark brown color and is less preferred.

- the proportion of long-fiber pulp fibers relative to the weight of the filter paper should therefore be at least 80 wt.%, preferably at least 90 wt.%, particularly preferably at least 95 wt.%, and most particularly preferably 100 wt.% of the filter paper.

- filter paper 100% by weight of the filter paper is made of long-fiber pulp is intended to mean that the filter paper contains essentially only long-fiber pulp fibers.

- This statement therefore also includes filter papers containing impurities from any other substances and materials, such as other fibers, short-fiber pulp fibers, fillers, pigments, additives, or processing aids, as may occur during paper production according to the state of the art.

- Long-fiber pulp can be obtained from coniferous wood, especially spruce or pine, but also from other plants such as hemp, flax, sisal, abaca, cotton, ramie, jute, kenaf, gampi, kozu, or matsumata.

- long-fiber pulp refers to the natural length of the fibers, not to the actual length in the milled state in the paper.

- the filter paper according to the invention must contain a certain proportion of fines. Fines include all fibers less than 0.2 mm long.

- the proportion of fines in the filter paper according to the invention is between 2% and 10% based on the number of fibers in the filter paper, preferably between 3% and 9%, and particularly preferably between 4% and 8%, each based on the number of fibers in the filter paper.

- the filter paper according to the invention must have an air permeability within a predetermined range, as this determines the filtration efficiency of the paper filter made from this filter paper.

- the air permeability of the filter paper according to the invention measured according to ISO 2965:2009 using a measuring head with an opening of 10 mm ⁇ 20 mm, is between 1000 cm min -1 kPa -1 and 9000 cm min -1 kPa -1 .

- the filter paper may comprise additional cellulose fibers, such as short-fiber cellulose fibers, or other fibers, such as fibers made from regenerated cellulose, such as viscose fibers, modal fibers, lyocell fibers, fibers made from cellulose esters such as cellulose acetate, or from plastics such as polyvinyl alcohol, polyethylene, polyester, or polypropylene, or even fibers made from polylactates.

- these fibers reduce the mechanical strength, and the total proportion of such fibers should therefore not exceed 10% by weight, preferably not more than 5% by weight, and particularly preferably not more than 2% by weight of the filter paper.

- viscose fibers, modal fibers, lyocell fibers, fibers made from cellulose acetate, polyvinyl alcohol, polyethylene, polyester, or polypropylene impair biodegradability increase the price of the filter paper, and, due to their low density, cause problems in the production of the filter paper, so that in a particularly preferred embodiment, the filter paper does not contain such fibers.

- Short-fiber pulp fibers can be obtained from hardwood, especially birch, beech or eucalyptus, but also from other plants, such as esparto grass.

- the filter paper may contain fillers to influence, for example, the whiteness, color, or opacity of the filter paper.

- the optical properties of the filter paper may be important, particularly if the filter made from the filter paper according to the invention extends all the way to the mouth of the cigarette so that the smoker can see it.

- the fillers reduce the strength of the filter paper and can undesirably affect the porous structure.

- the proportion of fillers should therefore not exceed 10% by weight, preferably not exceed 5% by weight, and most preferably not exceed 2% by weight of the filter paper.

- the filter paper is free of fillers.

- Fillers may be mineral fillers, in particular carbonates, sulfates, silicates or oxides, in particular, for example, calcium carbonate, magnesium oxide, magnesium hydroxide, magnesium carbonate, titanium dioxide, talc, kaolin or aluminum hydroxide, as well as mixtures thereof.

- the particle shape, particle size distribution and crystal structure of the fillers can vary within wide ranges and the person skilled in the art will select these parameters according to the state of the art and the purpose that the person skilled in the art wishes to achieve.

- the filter paper according to the invention can contain pigments or dyes to impart a specific color to the filter paper.

- a pigment is iron oxide, which is typically yellow, red, or black and can be used alone or in mixtures. Iron oxides or other pigments or dyes can change their color permanently or temporarily when heated, so these substances can also be added to achieve special optical effects during or after smoking.

- the filter paper according to the invention can further Contain additives to influence certain properties of the filter paper.

- additives include, for example, sizing agents such as alkyl ketene dimer (AKD), succinic anhydride (ASA), fatty acids, fatty alcohols, or other hydrophobic substances to make the filter paper water-repellent, or starch to increase the strength of the filter paper, or wet strength agents.

- sizing agents such as alkyl ketene dimer (AKD), succinic anhydride (ASA), fatty acids, fatty alcohols, or other hydrophobic substances to make the filter paper water-repellent, or starch to increase the strength of the filter paper, or wet strength agents.

- the filter paper can therefore contain substances that influence the carbon monoxide content, such as catalysts; zinc oxide or other metal oxides; nitrates of transition metals or of copper, iron, or silver; or platinum.

- Zinc oxide or sodium glycinate can be used to influence hydrogen cyanide (HCN), particularly its reduction.

- Ascorbic acid, tartaric acid, sodium carbonate, or polyethyleneimine can be used to influence formaldehyde. Additions of activated carbon, polyethylene glycol, triacetin, or triethyl citrate are also possible.

- the filter paper is at least free of pigments and dyes.

- the mechanical properties of the filter paper are important for the production of a filter from the filter paper according to the invention.

- the mechanical properties of the filter paper differ in the machine direction, i.e., the direction in which the filter paper runs through the paper machine, and the transverse direction, i.e., the direction orthogonal to the running direction in the paper machine.

- the filter paper may be creped in the machine direction or in the transverse direction. In this case, its elongation at break in the direction or directions in which the filter paper is creped is at most 25%, preferably at most 15%, and most preferably at most 10%.

- Short-fiber pulp fibers can be obtained from hardwood, especially birch, beech or eucalyptus, but also from other plants, such as esparto grass.

- the refining unit is a Papillon refiner.

- the inventors have found that such a Papillon refiner can refining the fiber material in such a way that the desired combination of properties, namely air permeability, fines content, and strength of the filter paper, can be achieved.

- Papillon refiners are offered by various machine manufacturers, for example by Andritz with the model designations CS380, CS450, CC380, and CC450. The following information applies to an Andritz Papillon Refiner CS380 as an example and can easily be transferred to other refining units with the knowledge of the specialist or through testing.

- the Papillon refiner settings must be adapted to the type and quantity of unrefined fiber material, the dimensions of the refining unit, and the refining set.

- a pulp density i.e., the mass-related proportion of dry fiber material in the suspension used for refining, of between 1 wt.% and 5 wt.% has proven effective.

- the flow rate can be between 300 l min -1 and 700 l min -1 .

- the specific refining edge load can be between 0.3 J m -1 and 1.0 J m -1 .

- the fiber material is refined with an energy input of 30 W h kg -1 to 100 W h kg -1 , based on the mass of the dry, unrefined fiber material.

- the speed and power input must also be determined.

- the speed is between 500 min -1 and 2000 min -1 , and preferably between 600 min -1 and 1600 min -1 .

- the power supplied to the Papillon refiner is between 50 kW and 200 kW, preferably between 60 kW and 150 kW.

- the air permeability of the filter paper can be adjusted. Generally, a high speed or Low power leads to higher air permeability. Conversely, low speed or high power leads to low air permeability.

- That part of the suspension of the unground fiber material which was previously diverted and not ground is then added back to the suspension of the ground fiber material.

- fillers such as fillers, additives, processing aids, pigments, or dyes

- processing aids such as processing aids, pigments, or dyes

- dyes can be added to the aqueous suspension of the milled fiber material.

- the type and quantity of fillers, additives, processing aids, pigments, and dyes the information provided above applies.

- fines i.e., fibers with a maximum length of 0.2 mm

- the proportion of fines in the finished aqueous suspension is between 2% and 10%, based on the number of fibers in the aqueous suspension, preferably between 3% and 9%, and particularly preferably between 4% and 8%, each based on the number of fibers in the aqueous suspension.

- finished suspension refers to the suspension in the state in which it is fed to a paper machine in a step (C) described below, i.e., after all additions of further unrefined long-fiber pulp, fiber material, or fines have taken place.

- the length and width of the fibers are important.

- the average length of the fibers in the finished aqueous fiber suspension should preferably be more than 1 mm and less than 5 mm, and particularly preferably more than 2 mm and less than 4 mm.

- the average width of the fibers in the finished aqueous fiber suspension is preferably between 10 ⁇ m and 50 ⁇ m, particularly preferably between 20 ⁇ m and 40 ⁇ m, and most particularly preferably between 25 ⁇ m and 35 ⁇ m.

- the finished aqueous suspension is fed to a paper machine, where a filter paper is produced using processes known per se in the prior art.

- the paper machine is preferably an inclined-wire machine, because these machines can produce papers with particularly high air permeability, whose filtration efficiency is well suited for filtering cigarette smoke. Less preferred alternatives are fourdrinier or cylinder-wire machines.

- the suspension On a paper machine suitable for the process, the suspension is first collected in a headbox and then pumped onto a screen so that a large portion of the water flows through the screen, while the fiber material and other components largely remain on the screen to form a fiber web.

- the fiber web then passes through a press section where the fiber web is further dewatered by mechanical pressure, for example against a felt, and then through a drying section where the fiber web is dried by heat, microwave radiation, or infrared radiation, preferably by contact with steam-heated drying cylinders and most preferably by hot air, in particular by impingement air drying or through-air drying, until it has a moisture content of 3% to 10% by weight based on the mass of the filter paper.

- the filter paper is rolled up and optionally cut into narrower rolls with a width of at least 100 mm and a maximum of 400 m, which can then be used for the production of cigarette filters.

- a filter paper web with a width of at least 100 mm and a maximum of 400 mm, for example, approximately 300 mm is usually embossed or creped, sometimes at elevated temperatures or humidity. Creping can be done in the machine direction, the cross direction, or both directions; it can also be done diagonally, in any direction, or in patterns.

- the filter paper is then formed into a continuous strand, as with conventional cellulose acetate filters, which is wrapped in a filter wrapping paper. Filter rods are then cut from this continuous strand.

- any filter wrapping paper known from the state of the art can be used as the filter wrapping paper, in particular a filter wrapping paper with little porosity or a filter wrapping paper with an air permeability measured according to ISO 2965:2009 between 1000 cm ⁇ min -1 ⁇ kPa -1 and 30000 cm ⁇ min -1 ⁇ kPa -1 .

- the invention further relates to a paper filter comprising the filter paper according to the invention.

- a paper filter according to the invention can be in the form of a filter rod with a length of 60 mm to 200 mm, preferably with a length of 80 mm to 180 mm.

- the length of the filter rod is an integer multiple, preferably four to six times, of the length of the filter plug, which then serves as a filter on the cigarette.

- the paper filter according to the invention can therefore also be provided as a filter plug with a length of 10 mm to 50 mm, preferably with a length of 15 mm to 30 mm.

- the paper filter according to the invention can also be present as a segment of a cigarette filter. This is the case, for example, if the cigarette filter consists of a segment of cellulose acetate and a segment of filter paper, or if, for example, the cigarette filter contains a cavity containing activated carbon particles, which is delimited by two segments that may contain filter paper.

- the paper filter according to the invention can therefore also have a length of 3 mm to 10 mm, preferably 4 mm to 8 mm.

- the paper filter i.e. the filter rod, filter plug, or paper filter segment

- the paper filter has a diameter between 3 mm and 10 mm, preferably between 4 mm and 9 mm, and especially preferably between 7 mm and 9 mm.

- the diameter depends on the diameter of the cigarette that will contain the paper filter.

- CORESTA Guide No. 10 can be used to measure the diameter of a paper filter.

- the tensile resistance of the paper filter depends essentially on the diameter, the filter material and the length of the paper filter and can be measured according to ISO 6565:2011 at a volume flow of 17.5 cm 3 s -1 .

- the tensile resistance of a paper filter is given in Pa and is, to a very good approximation, proportional to the length of the paper filter, provided that the paper filter is approximately homogeneous over its length. Therefore, the length-specific tensile resistance can be expressed as a pressure difference per mm of length of the paper filter if the information is to be independent of the actual length of the paper filter.

- the paper filter according to the invention has a length-specific tensile resistance between 10 Pa mm -1 and 40 Pa mm -1 , preferably between 15 Pa mm -1 and 35 Pa mm -1 .

- a key feature of a paper filter is its filtration efficiency for the particulate phase of cigarette smoke. More specifically, the particulate phase is nicotine-free dry particulate matter (NFDPM), colloquially referred to as "tar,” whose content in cigarette smoke is sometimes indicated on the package in mg per cigarette.

- the filtration efficiency for NFDPM describes the mass ratio of the particulate phase of the smoke retained in the filter to the total particulate phase of the smoke flowing into the filter.

- the filtration efficiency is expressed in %.

- the filter comprising the filter paper according to the invention has a filtration efficiency for NFPDM of between 20% and 80%, preferably between 30% and 70%.

- the filtration efficiency of the filter is influenced, as is known from the prior art, by the diameter, length, and draw resistance of the paper filter.

- the filtration efficiency of a filter is determined by first smoking a sufficient number of cigarettes, for example, 20 cigarettes, on a smoking machine according to ISO 3308:2012.

- the resulting NFDPM content is determined in mg per cigarette, denoted by X, according to ISO 4387:2000.

- the filter of each smoked cigarette is separated and analyzed to determine the amount of NFDPM contained in the filter in mg per cigarette, denoted by Y.

- the amount of NFDPM contained in each filter segment denoted by Y i in mg per cigarette, can be determined.

- the invention also relates to a filter cigarette comprising a paper filter.

- the paper filter can be the only filter on the filter cigarette or, preferably, can be a segment in a segmented cigarette filter.

- a filter cigarette is particularly preferred in which the filter segment closest to the mouth end is formed from cellulose acetate and at least one further segment closer to the tobacco rod contains the filter paper according to the invention, because then the visual appearance of the mouth end corresponds to that of a filter cigarette with a cellulose acetate filter and thus meets the smoker's expectations.

- a filter cigarette comprising a paper filter according to the invention

- the production of a filter cigarette comprising a paper filter according to the invention can be carried out according to the methods known from the prior art.

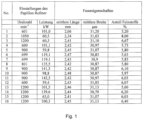

- the fiber material used was exclusively bleached, unrefined long-fiber pulp fibers, which were refined in a Papillon refiner at various speeds between 600 rpm and 1200 rpm and powers between approximately 60 kW and 140 kW. A total of 16 different power and speed combinations were selected. The specific values are given in Table 1 ("Papillon refiner settings"), which is available in Fig. 1 is shown. Unrefined long-fiber pulp fibers were added to the refined long-fiber pulp fibers so that the total suspension of long-fiber pulp fibers contained approximately 60 wt% refined and approximately 40 wt% unrefined long-fiber pulp fibers.

- the properties of the fibers in the suspension were determined in accordance with ISO 16065 using an L&W Fiber Tester Plus - code 912 Plus, taking into account also the fines, i.e. fibers with a length of less than 0.2 mm.

- the mean fiber length, the mean fiber width and the percentage of fines in relation to the number of fibers are shown in the corresponding columns of Table 1.

- Fig. 1 The average fiber length for the exemplary filter papers according to the invention is approximately between 2 mm and 2.5 mm, the average fiber width between 30.5 ⁇ m and 31.5 ⁇ m, and the proportion of fines is between 5% and 8% based on the number of fibers in the fiber material.

- the inventors assume that only a Papillon Refiner can achieve such constant fiber properties despite the variable air permeability of the filter paper and that these fiber properties contribute significantly to the filtration efficiency of the filters made from these filter papers.

- filter papers were produced on an inclined screen machine.

- the filter papers are numbered 1 to 16 according to the "No.” column in the Fig. 1 to 3 shown in Tables 1 to 3, whereby in all tables a number designates the same filter paper or the filter made from it.

- the basis weight according to ISO 536:2012, the thickness according to ISO 534:2011 and the air permeability according to ISO 2965:2009 were determined for each filter paper and are shown in the corresponding columns in Table 2 ( Fig. 2 ).

- the basis weight is between 34.9 g m -2 and 36.6 g m -2 , which is a very narrow range; the thickness also varies only between 83 ⁇ m and 101 ⁇ m.

- the air permeability of the filter papers however, varies depending on the grinding of the fiber material and lies between 1099 CU and 8364 CU.

- the tensile strength and elongation at break were determined according to ISO 1924-2:2008 for the uncreped filter paper in the machine direction (MD) and in the cross direction (CD). These values are also shown in the corresponding columns of Table 2 ( Fig. 2 ). The tensile strength values all exceed the technically necessary minimum for producing filters from the filter papers. Likewise, the elongation at break is within a favorable range for further processing of the filter paper.

- the tensile strength of each paper filter rod was determined according to ISO 6565:2011 and is converted to a length of 22 mm and given as specific tensile strength in the corresponding columns of Table 3 ( Fig. 3 ) is specified.

- Each paper filter rod was divided into six equal-length paper filter plugs, each 22 mm long, and used to produce cigarettes with a length of 83 mm, a circumference of 24.5 mm, a tobacco rod length of 61 mm, and a tobacco weight of 600 mg.

- the tobacco was formed into a tobacco rod using conventional cigarette paper with an air permeability of 50 cm min -1 kPa -1 .

- the paper filter was wrapped with a 27 mm long tipping paper, so that the tipping paper overlapped the tobacco rod by 5 mm, thus bonding the paper filter to the tobacco rod.

- the tobacco blend and all geometric data of the cigarettes were identical, differing only in the paper filter. Using these cigarettes, the filtration efficiency of the paper filters was determined using the method described above.

- the filtration efficiency for nicotine-free dry condensate (NFDPM) is shown for each of the 16 filter plugs (22 mm) in Table 3 ( Fig. 3 ). It results in A filtration efficiency of between 36.2% and 55.2% is obtained for NFPDM.

- a conventional paper filter has a draw resistance of approximately 300 Pa

- a conventional cellulose acetate filter has a draw resistance of approximately 600 Pa.

- the draw resistance of an unventilated filter cigarette is essentially determined by the draw resistance of the filter and that of the tobacco rod. For a king-size cigarette with a circumference of 24 mm to 25 mm, the smoker expects a draw resistance of approximately 1000 Pa. If one replaces the conventional cellulose acetate filter with a draw resistance of 600 Pa in an existing cigarette design with a conventional paper filter with 300 Pa, the draw resistance of the filter cigarette drops to 700 Pa, i.e. by 30%. This difference is clearly noticeable and undesirable for the smoker.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Paper (AREA)

- Cigarettes, Filters, And Manufacturing Of Filters (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL17701315.8T PL3433427T5 (pl) | 2016-03-21 | 2017-01-24 | Ulepszona bibuła filtracyjna do filtrów papierosowych |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102016105235.3A DE102016105235B4 (de) | 2016-03-21 | 2016-03-21 | Verbessertes Filterpapier für Zigarettenfilter, dessen Herstellung und Filterzigarette |

| PCT/EP2017/051368 WO2017162347A1 (de) | 2016-03-21 | 2017-01-24 | Verbessertes filterpapier für zigarettenfilter |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP3433427A1 EP3433427A1 (de) | 2019-01-30 |

| EP3433427B1 EP3433427B1 (de) | 2020-09-09 |

| EP3433427B2 true EP3433427B2 (de) | 2025-06-25 |

Family

ID=57882080

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP17701315.8A Active EP3433427B2 (de) | 2016-03-21 | 2017-01-24 | Verbessertes filterpapier für zigarettenfilter |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US11083217B2 (pl) |

| EP (1) | EP3433427B2 (pl) |

| CN (1) | CN108779609B (pl) |

| BR (1) | BR112018068607A2 (pl) |

| DE (1) | DE102016105235B4 (pl) |

| ES (1) | ES2836530T5 (pl) |

| PH (1) | PH12018501973A1 (pl) |

| PL (1) | PL3433427T5 (pl) |

| WO (1) | WO2017162347A1 (pl) |

Families Citing this family (44)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CA3086981C (en) * | 2017-12-26 | 2022-11-29 | Japan Tobacco Inc. | Filtered smoking article |

| DE102018107944B3 (de) | 2018-04-04 | 2019-06-19 | Delfortgroup Ag | Verbessertes filterpapier, herstellungsverfahren und daraus gefertigter beutel |

| US11414818B2 (en) | 2018-08-23 | 2022-08-16 | Eastman Chemical Company | Dewatering in paper making process |

| US11492757B2 (en) | 2018-08-23 | 2022-11-08 | Eastman Chemical Company | Composition of matter in a post-refiner blend zone |

| US11332888B2 (en) | 2018-08-23 | 2022-05-17 | Eastman Chemical Company | Paper composition cellulose and cellulose ester for improved texturing |

| US11306433B2 (en) * | 2018-08-23 | 2022-04-19 | Eastman Chemical Company | Composition of matter effluent from refiner of a wet laid process |

| US11525215B2 (en) | 2018-08-23 | 2022-12-13 | Eastman Chemical Company | Cellulose and cellulose ester film |

| US11492756B2 (en) | 2018-08-23 | 2022-11-08 | Eastman Chemical Company | Paper press process with high hydrolic pressure |

| US11479919B2 (en) | 2018-08-23 | 2022-10-25 | Eastman Chemical Company | Molded articles from a fiber slurry |

| US11420784B2 (en) | 2018-08-23 | 2022-08-23 | Eastman Chemical Company | Food packaging articles |

| US11466408B2 (en) | 2018-08-23 | 2022-10-11 | Eastman Chemical Company | Highly absorbent articles |

| US11414791B2 (en) | 2018-08-23 | 2022-08-16 | Eastman Chemical Company | Recycled deinked sheet articles |

| US11441267B2 (en) | 2018-08-23 | 2022-09-13 | Eastman Chemical Company | Refining to a desirable freeness |

| US11299854B2 (en) | 2018-08-23 | 2022-04-12 | Eastman Chemical Company | Paper product articles |

| US11512433B2 (en) | 2018-08-23 | 2022-11-29 | Eastman Chemical Company | Composition of matter feed to a head box |

| US11519132B2 (en) | 2018-08-23 | 2022-12-06 | Eastman Chemical Company | Composition of matter in stock preparation zone of wet laid process |

| US11401659B2 (en) | 2018-08-23 | 2022-08-02 | Eastman Chemical Company | Process to produce a paper article comprising cellulose fibers and a staple fiber |

| US11421385B2 (en) | 2018-08-23 | 2022-08-23 | Eastman Chemical Company | Soft wipe comprising cellulose acetate |

| US11230811B2 (en) | 2018-08-23 | 2022-01-25 | Eastman Chemical Company | Recycle bale comprising cellulose ester |

| US11408128B2 (en) | 2018-08-23 | 2022-08-09 | Eastman Chemical Company | Sheet with high sizing acceptance |

| US11639579B2 (en) | 2018-08-23 | 2023-05-02 | Eastman Chemical Company | Recycle pulp comprising cellulose acetate |

| US11339537B2 (en) | 2018-08-23 | 2022-05-24 | Eastman Chemical Company | Paper bag |

| US11390991B2 (en) | 2018-08-23 | 2022-07-19 | Eastman Chemical Company | Addition of cellulose esters to a paper mill without substantial modifications |

| US11286619B2 (en) | 2018-08-23 | 2022-03-29 | Eastman Chemical Company | Bale of virgin cellulose and cellulose ester |

| US11313081B2 (en) | 2018-08-23 | 2022-04-26 | Eastman Chemical Company | Beverage filtration article |

| US11421387B2 (en) | 2018-08-23 | 2022-08-23 | Eastman Chemical Company | Tissue product comprising cellulose acetate |

| US11332885B2 (en) | 2018-08-23 | 2022-05-17 | Eastman Chemical Company | Water removal between wire and wet press of a paper mill process |

| US11390996B2 (en) | 2018-08-23 | 2022-07-19 | Eastman Chemical Company | Elongated tubular articles from wet-laid webs |

| US11492755B2 (en) | 2018-08-23 | 2022-11-08 | Eastman Chemical Company | Waste recycle composition |

| US11401660B2 (en) | 2018-08-23 | 2022-08-02 | Eastman Chemical Company | Broke composition of matter |

| CN109588769B (zh) * | 2018-12-26 | 2021-05-14 | 湖南中烟工业有限责任公司 | 一种降温嘴棒及卷烟 |

| DE102019100112B4 (de) * | 2019-01-04 | 2020-09-10 | Delfortgroup Ag | Biologisch abbaubares Segment eines Rauchartikels |

| KR20220018476A (ko) * | 2019-06-10 | 2022-02-15 | 필립모리스 프로덕츠 에스.에이. | 에어로졸 발생 물품용 안정적 래퍼 |

| CN114765995B (zh) * | 2019-12-13 | 2024-02-23 | 德尔福特集团有限公司 | 用于吸烟制品的水力缠结的过滤材料 |

| FI3839138T3 (fi) * | 2019-12-20 | 2023-01-13 | Vesihöyryä läpäisevä ja kuumaa vettä kestävä paperi | |

| DE102020131672A1 (de) * | 2020-07-01 | 2022-01-05 | Delfortgroup Ag | Hitzebeständiges umhüllungspapier für aerosolerzeugende artikel |

| DK4314406T3 (da) * | 2021-03-31 | 2025-05-05 | Glatfelter Gernsbach Gmbh | Filtermateriale til fødevareemballage |

| DE102021115450A1 (de) * | 2021-06-15 | 2022-12-15 | Delfortgroup Ag | Filtermaterial für rauchartikel mit verbessertem dehnungsverhalten |

| DE102021115456A1 (de) * | 2021-06-15 | 2022-12-15 | Delfortgroup Ag | Filtermaterial für segmente für rauchartikel mit reduzierter kriechneigung |

| GB202118180D0 (en) * | 2021-12-15 | 2022-01-26 | Nicoventures Trading Ltd | A component for an article for use in or as an aerosol provision system |

| ES2958821B2 (es) | 2022-07-19 | 2025-12-01 | Miquel Y Costas & Miquel Sa | Papel para filtro de cigarrillos y filtro que lo comprende |

| CN115094674A (zh) * | 2022-07-20 | 2022-09-23 | 胡菊生 | 一种双层结构液体过滤用滤纸及其制备方法 |

| ES3015074A1 (es) * | 2023-10-26 | 2025-04-29 | Miquel Y Costas & Miquel Sa | Filtro para articulos de fumar y papel filtrante que lo conforma constituido por fibras de plantas |

| CN119663680A (zh) * | 2024-12-18 | 2025-03-21 | 湖北中烟工业有限责任公司 | 一种全植物纤维纸质滤棒滤芯原纸及其制备方法和纸质滤嘴棒 |

Family Cites Families (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2075328B (en) | 1980-04-21 | 1984-05-02 | Filtrona Ltd | Tobacco-smoke filter |

| DE3624661A1 (de) | 1986-07-22 | 1988-02-04 | Rhodia Ag | Ventilierte zigarette |

| JP3194580B2 (ja) * | 1991-03-11 | 2001-07-30 | 日本たばこ産業株式会社 | シガレット |

| JP3420359B2 (ja) | 1994-10-21 | 2003-06-23 | ダイセル化学工業株式会社 | たばこ煙用フィルター素材、繊維状セルロースエステル及びその製造方法 |

| JP2883298B2 (ja) | 1995-08-09 | 1999-04-19 | 三島製紙株式会社 | たばこ用水分散性シート並びにこれを用いたたばこ |

| US6103294A (en) | 1997-02-28 | 2000-08-15 | Preservation Products, Inc. | Preservative for digestible food and beverage products |

| DE19753195A1 (de) * | 1997-11-21 | 1999-05-27 | Reemtsma H F & Ph | Biologisch abbaubarer Filter für Cigaretten |

| AU3630599A (en) * | 1998-05-12 | 1999-11-29 | Japan Tobacco Inc. | Cigarette filter roll paper, cigarette filter, and filter cigarette |

| JP3779945B2 (ja) | 2002-08-08 | 2006-05-31 | ダイセル化学工業株式会社 | たばこ煙用フィルター素材、繊維状セルロースエステル短繊維及びその製造方法 |

| WO2009031246A1 (ja) | 2007-09-05 | 2009-03-12 | Daicel Chemical Industries, Ltd. | たばこフィルター用素材及びたばこフィルター |

| GB0910373D0 (en) | 2009-06-16 | 2009-07-29 | Filtrona Int Ltd | Tabacco smoke filter |

| US9149070B2 (en) | 2011-07-14 | 2015-10-06 | R.J. Reynolds Tobacco Company | Segmented cigarette filter for selective smoke filtration |

| ES2421621T3 (es) | 2011-07-28 | 2013-09-04 | Delfortgroup Ag | Papel de envoltura de filtro resistente al aceite |

| WO2014009498A1 (en) * | 2012-07-13 | 2014-01-16 | Philip Morris Products S.A. | Degradable filter for smoking articles |

| DE102012106801A1 (de) | 2012-07-26 | 2014-01-30 | Delfortgroup Ag | In Wasser rasch zerfallendes Filterpapier |

| KR102339129B1 (ko) | 2013-06-26 | 2021-12-14 | 에스더블유엠 서비스 에스.에이.에스. | 필터 매질 |

| ES2778099T3 (es) | 2013-09-05 | 2020-08-07 | Schweitzer-Mauduit International Inc | Envoltura del tapón revestida para un artículo para fumar |

| US10076135B2 (en) | 2014-05-23 | 2018-09-18 | Greenbutts Llc | Biodegradable cigarette filter tow and method of manufacture |

-

2016

- 2016-03-21 DE DE102016105235.3A patent/DE102016105235B4/de active Active

-

2017

- 2017-01-24 ES ES17701315T patent/ES2836530T5/es active Active

- 2017-01-24 US US16/087,172 patent/US11083217B2/en active Active

- 2017-01-24 WO PCT/EP2017/051368 patent/WO2017162347A1/de not_active Ceased

- 2017-01-24 CN CN201780018157.9A patent/CN108779609B/zh active Active

- 2017-01-24 EP EP17701315.8A patent/EP3433427B2/de active Active

- 2017-01-24 PL PL17701315.8T patent/PL3433427T5/pl unknown

- 2017-01-24 BR BR112018068607A patent/BR112018068607A2/pt not_active Application Discontinuation

-

2018

- 2018-09-13 PH PH12018501973A patent/PH12018501973A1/en unknown

Also Published As

| Publication number | Publication date |

|---|---|

| US11083217B2 (en) | 2021-08-10 |

| CN108779609A (zh) | 2018-11-09 |

| EP3433427A1 (de) | 2019-01-30 |

| PL3433427T3 (pl) | 2021-03-08 |

| PL3433427T5 (pl) | 2025-11-03 |

| BR112018068607A2 (pt) | 2019-02-05 |

| US20190059443A1 (en) | 2019-02-28 |

| CN108779609B (zh) | 2021-11-16 |

| DE102016105235B4 (de) | 2019-02-14 |

| PH12018501973A1 (en) | 2019-06-17 |

| ES2836530T3 (es) | 2021-06-25 |

| WO2017162347A1 (de) | 2017-09-28 |

| DE102016105235A1 (de) | 2017-09-21 |

| ES2836530T5 (en) | 2025-11-18 |

| EP3433427B1 (de) | 2020-09-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3433427B2 (de) | Verbessertes filterpapier für zigarettenfilter | |

| EP3283686B2 (de) | Zigarettenpapier mit hohem kurzfaseranteil | |

| EP2761085B1 (de) | In wasser rasch zerfallendes filterpapier | |

| EP3861159B1 (de) | Wasserstrahlverfestigtes filtermaterial für rauchartikel | |

| DE69414938T2 (de) | Tabakrauchfiltermaterials und Verfahren zu dessen Herstellung | |

| EP2804497B1 (de) | Mit tabakpartikeln gefülltes papier | |

| DE102015107829B4 (de) | Umhüllungspapier, Verfahren zu dessen Herstellung und Zigarette mit einem Umhüllungspapier | |

| EP3568523B1 (de) | Verbessertes filterpapier | |

| DE102021115456A1 (de) | Filtermaterial für segmente für rauchartikel mit reduzierter kriechneigung | |

| WO2015028276A1 (de) | Effizient herstellbares zigarettenpapier für selbstverlöschende zigaretten | |

| AT524998B1 (de) | Bedruckbares, mehrlagiges Papier für Verpackungen und Verfahren zu dessen Herstellung | |

| EP4124200A1 (de) | Filtermaterial für rauchartikel mit verbessertem dehnungsverhalten | |

| EP3839138B1 (de) | Wasserdampfdurchlässiges und heisswasserbeständiges papier | |

| DE102022102066B4 (de) | Segment für rauchartikel mit kalandrierter faserbahn | |

| DE102009036551A1 (de) | Faserstoffhaltiges Material auf Cellulosebasis |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: UNKNOWN |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE INTERNATIONAL PUBLICATION HAS BEEN MADE |

|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20180724 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| DAV | Request for validation of the european patent (deleted) | ||

| DAX | Request for extension of the european patent (deleted) | ||

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| 17Q | First examination report despatched |

Effective date: 20191031 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20200616 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R108 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 1311715 Country of ref document: AT Kind code of ref document: T Effective date: 20200915 Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: RO Ref legal event code: EPE |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200909 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200909 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200909 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201209 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201209 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200909 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20200909 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200909 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200909 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200909 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210111 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200909 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200909 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200909 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210109 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2836530 Country of ref document: ES Kind code of ref document: T3 Effective date: 20210625 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200909 |

|

| 26 | Opposition filed |

Opponent name: MIQUEL Y COSTAS & MIQUEL S.A. Effective date: 20210609 Opponent name: SCHWEITZER-MAUDUIT INTERNATIONAL INC. Effective date: 20210608 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200909 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200909 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200909 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210124 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20210131 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210131 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210124 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210131 |

|

| APBM | Appeal reference recorded |

Free format text: ORIGINAL CODE: EPIDOSNREFNO |

|

| APBP | Date of receipt of notice of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA2O |

|

| APAH | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOSCREFNO |

|

| APAW | Appeal reference deleted |

Free format text: ORIGINAL CODE: EPIDOSDREFNO |

|

| APBM | Appeal reference recorded |

Free format text: ORIGINAL CODE: EPIDOSNREFNO |

|

| APBP | Date of receipt of notice of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA2O |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230313 |

|

| APBQ | Date of receipt of statement of grounds of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA3O |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200923 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200909 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20170124 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200909 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200909 |

|

| APBU | Appeal procedure closed |

Free format text: ORIGINAL CODE: EPIDOSNNOA9O |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: RO Payment date: 20250114 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20250210 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GR Payment date: 20250121 Year of fee payment: 9 Ref country code: AT Payment date: 20250120 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20250127 Year of fee payment: 9 Ref country code: PL Payment date: 20250107 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20250121 Year of fee payment: 9 Ref country code: IT Payment date: 20250122 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: TR Payment date: 20250114 Year of fee payment: 9 |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 20250625 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AL AT BE BG CH CY CZ DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: DC2A Ref document number: 2836530 Country of ref document: ES Kind code of ref document: T5 Effective date: 20251118 |