EP3402678B1 - Unlocking a coupling of a double gearwheel - Google Patents

Unlocking a coupling of a double gearwheel Download PDFInfo

- Publication number

- EP3402678B1 EP3402678B1 EP17702301.7A EP17702301A EP3402678B1 EP 3402678 B1 EP3402678 B1 EP 3402678B1 EP 17702301 A EP17702301 A EP 17702301A EP 3402678 B1 EP3402678 B1 EP 3402678B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- cylinder

- annular

- ring

- gear

- clamping

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41F—PRINTING MACHINES OR PRESSES

- B41F13/00—Common details of rotary presses or machines

- B41F13/008—Mechanical features of drives, e.g. gears, clutches

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41P—INDEXING SCHEME RELATING TO PRINTING, LINING MACHINES, TYPEWRITERS, AND TO STAMPS

- B41P2213/00—Arrangements for actuating or driving printing presses; Auxiliary devices or processes

- B41P2213/10—Constitutive elements of driving devices

- B41P2213/25—Couplings; Clutches

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41P—INDEXING SCHEME RELATING TO PRINTING, LINING MACHINES, TYPEWRITERS, AND TO STAMPS

- B41P2213/00—Arrangements for actuating or driving printing presses; Auxiliary devices or processes

- B41P2213/10—Constitutive elements of driving devices

- B41P2213/25—Couplings; Clutches

- B41P2213/254—Devices allowing two gears to engage with each other

Definitions

- the invention relates to a device for releasing a frictional connection according to the preamble of patent claim 1.

- a so-called sheet turning device is arranged in the transport path of the printed sheet for the purpose of accomplishing the use of the sheet. Normally, the sheet is transported with its leading edge through the entire machine, in which case only the top of the sheet is printed. If the sheet is to be printed from both sides, the sheet turning device is switched between two printing units, as a result of which there is the trailing edge of the sheet to the leading edge.

- the relative position of the adjacent printing units is to change so that at this point instead of the leading edge of the sheet now the trailing edge can be passed.

- To change the relative position of the gear train is in such a printing machine by means of a double-coupled double gear (on a main gear a ring gear is rotatably arranged) equipped with clamping devices.

- the clamping devices may include a clamping ring and are stretched and unlocked via curves or spring sets.

- a device of this type describes the DE-PS 35 34 488 ,

- the clamping force is applied by a spring which can be charged to cancel the clamping of a pneumatic piston or bellows.

- the clamping is done by means of one-armed cranked levers, which are connected via bolts with the clamps for clamping the gear ring.

- the one-armed, cranked levers are mounted on ball elements and generate at the point of articulation of the bolt in their Movement an axial displacement with respect to the clamping claws. As a result, a clamping force is applied to the clamping claws with the pivotal movement of the lever.

- the pivotal movement of the lever is generated by a guide body in which engage the ends of the lever.

- the guide body sits on a rod centric to the main gear.

- the rod is axially slidably connected to the drive pin of the gear and is loaded by a compression spring to the outside.

- the outer end of the guide rod around.

- the power transmission is very complicated solved.

- Another problem can be seen that the bellows is supported against the force of the compression spring between the housing wall and the cylinder.

- an axial force is applied to the cylinder bearings which can lead to a displacement of the entire cylinder and thus the gears.

- a coupling device for effecting a temporary decoupling of the sections of a gear train of a printing press is known.

- the coupling device for carrying out a change of the phase position of the respective gear portions serving each other adjustment process should be characterized by a robust construction and a reliable high torque transfer.

- the coupling device is coaxially provided with a first and second spur gear.

- a clamping device serves to generate one of the frictional transmission of a torque between the first and the second spur gear.

- a chamber device is used for applying a clamping force bringing the clamping device in a release state.

- a clamping plate is arranged, which is resiliently biased in a basic position and generates the necessary clamping force for the clutch engagement.

- a coupling device for effecting a temporary decoupling of the sections of a gear train of a printing press according to the preamble of claim 1 is known.

- the coupling device is used for the temporary separation of a gear train of a printing machine for processing a change in the phase position of portions of the gear train.

- a first and a second spur gear are clamped by a clamping device for the frictional transmission of torque.

- a force is applied by a pressure medium via a chamber device, wherein the chamber device is formed by a first ring member and a second, with respect to the first ring member axially displaceable ring member.

- the first ring element has a disengaging contact section which is set against a resiliently supported component in order to move the clamping device into a release state.

- the second ring element has a support abutment portion which is seated in the release state on a coupled with the first spur support shoulder.

- DE 36 11 324 A1 DE 197 18 140 C1 and DE 35 34 488 A1 described.

- the device aligns itself on the gear and has no contact with the double gear during normal operation.

- the unlocking mechanism consists of a rectangular in cross-section and formed by two concentric rings circular Hubkanal in which a lifting ring is displaced by means of a fluidically generated drive energy against the rings of the Hubkanals. During the displacement, the rings are supported on elements of the double gear so that the clamping of the gear ring is canceled.

- the described variants use hydraulic or pneumatic energy.

- the force applied to unlock the clamping of the gear ring on the main gear is diverted within the double gear and thereby a rigid axial bearing of the printing cylinder can act supported. This also results in no shifts z. B. could lead to a rotational displacement of the drive in a helical gearing.

- the unlocking system is not in the normal machine operation with the double gear in touch. At the double gear itself no additional elements are required, so that the mass of the double gear is not increased. The double gear itself is so completely maintenance-free and the clutch to cancel the clamping of the double gear is to be maintained without changes to this or built and removed.

- the second spur gear is clamped by loaded by spring tension tie rods on the first spur gear.

- the device is arranged symmetrically to the axis of the double gear and has for releasing at least one annular fluid-operated lifting arrangement. This is coupled to the machine frame and at least partially displaceable in the direction of an axis of the double gear.

- the lifting arrangement connects in the release position a part of the double gear to the machine frame.

- the cylinder pin is received in a cylinder bearing, in which an axial bearing arranged separately from a radial bearing is provided.

- the annular fluid operated lift assembly is disposed directly adjacent and concentric with the axial support on the machine frame of the sheet-fed rotary printing machine.

- a pressure element of the lifting arrangement is assigned to a respective pressure element transmitting the spring force to a respective tie rod.

- the annular lifting arrangement is formed from a ring cylinder and an annular piston arranged in this ring opening.

- the ring cylinder is arranged coaxially with the axis of the double gear and directly adjacent parallel to an outer periphery of a guide ring of the axial bearing of the cylinder bearing on the machine frame.

- the annular piston is arranged to be movable parallel to the axis in the direction of and to the machine frame to the double gear.

- annular piston is formed as insertable into a front side of the machine frame facing away open piston chamber insert with sealing inserts on the inner and the outer edge.

- the annular piston is assigned a retaining device which is arranged within the piston chamber and which does not influence the annular piston in its lifting movement but which is secured in its peripheral position relative to the annular cylinder.

- the ring cylinder is arranged fixedly connected to the machine frame.

- a support ring is provided in mechanical connection with the ring cylinder and the directly adjacent region of the double gear as Kraftleitelement.

- the support ring is preferably coupled with the ring cylinder and engages behind a further arranged on the double gear retaining ring.

- each tie rod is assigned a respective pressure piece at a head end, which is opposite to a clamping screw at the other end of the tie rod.

- the pressure piece is used to apply force to a respectively associated with the tie rod spring assembly.

- the thrust pieces of all tie rods are arranged so that they touch the ring piston in its stroke position.

- a spring plate between a clamping ring and a cylinder-fixed element of the double gear is arranged.

- the spring plate dissolves the clamping ring when canceling the clamping of the clamping ring against a cylinder-fixed part of the double gear and is designed as an annular spring element.

- one or more return springs are arranged on the annular piston in such a manner that the annular piston is pushed into the piston chamber when the annular cylinder is relieved of pressure under the force of the return springs.

- the annular lifting element is formed from a plurality of lifting cylinders and in each case one lifting piston arranged in these.

- the lifting cylinders are arranged concentrically with respect to the cylindrical pin annular.

- FIG. 1 schematically a section of a sheet-fed rotary printing machine is shown.

- Two printing units 1A and 1B are by printing cylinders 2, 3 and sheet transport drums 4, 5 interconnected.

- the drive of the printing units is carried by gears which are coaxial with the printing cylinders 2, 3 and sheet transport drums 4, 5 are arranged.

- the sheet transport drum 5 is formed as a so-called turning drum. For the turning operation, the relative position of the two printing units 1A, 1B to each other in the circumferential direction by the amount of the length of the sheet to be printed to change, so that the sheet end can be transferred instead of the beginning of the sheet.

- the double gear 6 consists of a main gear 8 and a gear ring 9.

- the main gear 8 is connected to a cylinder pin 10.

- a clamping connection via a clamping ring 11 is produced between the fixed to the main gear 8 clamping ring 11 and the gear ring 9 clamping elements 12 under the force of spring assemblies 13 from. If the spring assemblies 13 are unloaded from the outside, they clamp the clamping element 12 against the clamping ring 11 and connect the ring gear 9 frictionally connected to the main gear 8.

- the drive torque is transmitted from a gear 14 via the ring gear 9 to the main gear 8 and from there on in Gear train downstream drive elements passed.

- the sheet transport elements are adjusted relative to each other after releasing the clamping of the gear ring 9, wherein the clamping force of the clamping elements 12 between clamping ring 11 and Gear ring 9 is canceled.

- This is effected with the double-wheel clutch 7, which consists of an inner ring 15 and an outer ring 16.

- the rings 15, 16 form a hydraulic or pneumatic system with a pressure chamber 28, which is sealed with seals 25 and to which a fluid is supplied through a pressure medium connection 27.

- the unlocking system is loaded by springs 18 engaging in the ring 15 engaging retaining pin 17 axially displaceable against a fixed support 20 as a rest position.

- the outer ring 16 abuts with a stop surface 21 under load of compression springs 19 on the inner ring 15.

- the outer end face 22 of the inner ring 15 and a bent annular face 23 of the outer ring 16 are used as effective surfaces of the system.

- an unlocking element 24 which is connected to the gear ring 9.

- the Doppelradkupplung 7 is positioned on the carrier 20 which is rigidly connected to a part of the machine frame 26.

- the release system In the unlocked state, the release system is free from fixed supports to small spring forces. Upon further supply of pressure medium, the clamping of the gear parts is canceled, without axial forces in the main gear 8 and its storage are introduced. The main gear 8 can be rotated relative to the gear ring 9, while the gear ring 9 and coupled to him gear parts are held.

- the unlocking system is depressurized and is by means of the springs 18, 19 back to its original position.

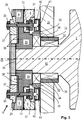

- FIG. 3 an embodiment of an unlocking device is shown on a double gear 6, which is not covered by the claims.

- the impression cylinder 2 is received with its cylindrical pin 10 via a radial bearing 32 guided in a bearing sleeve 33 and via a thrust bearing 34 guided in the machine side wall 26 on a guide ring 35.

- the guide ring 35 of the thrust bearing 34 is in this case attached from the outside to the machine side wall 26 and defines the entire bearing unit of the cylinder pin 10 immovably in this position.

- a gear main body 39 is fixed by means of a mounting plate 36.

- a first spur gear 8 is mounted rotationally.

- a second spur gear 9 is mounted as a gear ring on the gear main body 39 in parallel and coaxial with the first spur gear 8.

- a clamping ring 37 is arranged on the side facing away from the machine side wall 26 side. The clamping ring 37 is pressed by a tie rod 29 or more distributed over the circumference of the double gear 6 tie rods 29 against the first spur gear 8.

- each of the tie rods 29 passes through the first spur gear 8, the gear main body 39 and the clamping ring 37 and is supported, each with its own head-mounted pressure piece 31 against a respective spring assembly 13 (such as disc springs).

- a respective spring assembly 13 such as disc springs.

- Each of the spring assemblies 13 is received in corresponding devices on the first spur gear 8.

- Each tie rod 29 is further supported against the force of the spring pact 13 by a clamping nut 30, which is supported on the clamping ring 39, adjustable.

- annular spring plate 38 is arranged, which is shaped plate-shaped in the manner of a washer and is therefore biased during clamping between the clamping ring 37 and the gear main body 39. Therefore, the spring plate 38 when reducing or canceling the bias of the tie rods 29, the clamping ring 37 lift by a bulge of the gear ring of the second spur gear 9, so that it is movable relative to the first spur gear 8.

- This device consists of an annular cylinder (ring cylinder 40) which is arranged coaxially with the cylinder pin 10 in the immediate vicinity of the thrust bearing 34 on the machine side wall 26.

- ring cylinder 40 In the ring cylinder 40 is a Ring piston 41 under fluid supply or removal axially parallel to the cylinder pin 10 arranged displaceably.

- the annular piston 41 With fluid supply to the annular cylinder 40, the annular piston 41 is moved parallel to the axis of the cylinder pin 10 away from the machine side wall 26 and displaced against the plungers 31 of the tie rods 29. With appropriate pressure build-up, the annular piston 41 then presses together the spring assemblies 13 via the pressure pieces 31, so that the preload load that has been applied to the clamping ring 37 via the clamping nuts 30 is reduced or eliminated. Thereby, and by the return action of the spring plate 38, the second annular spur gear 9 is free and can be adjusted relative to the first spur gear 8.

- FIG. 4 A corresponding representation of the annular cylinder 40 in association with the cylinder pin 10 and its axial bearing 34 (dash-dot line) is in FIG. 4 shown, wherein the annular piston 41 is shown hatched for better visibility.

- each of these lifting cylinders 42 with their reciprocating piston 43 is such that they are each a respective tie rod 29 and its pressure piece 31 are positioned opposite to the machine side wall 26.

- a device for exact positioning of the double gear 6 must be provided in its rotational position.

- a precisely aligned action of each of the reciprocating piston 43 to the respective associated tie rod 29 and its respective pressure piece 31 is required.

- annular piston 43 arranged around the cylinder pin 10 and its storage also by an all reciprocating 43 overlapping and the tie rods 29 and the pressure pieces 31 opposite arranged intermediate ring are synchronized in their effect to unlock the Zahnradklemmung.

- FIG. 6 is a structurally simple embodiment of the device according to the invention FIG. 3 in conjunction with a bearing arrangement with separate axial and radial guidance for the drivable by means of the double gear 6 pressure cylinder 2, in which the unlocking device 7 is assigned directly to a thrust bearing 34 on the cylinder pin 10.

- the cylindrical pin 10 is received in the machine side wall 26 via the radial bearing 32 guided in the bearing sleeve 33 and the axial bearing 34 guided on the guide ring 35, whereby the guide ring 35 secures the axial bearing 34 on the outside of the machine side wall 26 and the cylinder pin 10 in this position in the axial direction fixed immovably.

- a gear base body 39 is fixed with a mounting plate 36.

- gear main body 39 On gear main body 39, a first spur gear 8 is mounted rotationally. Parallel and coaxial with the first spur gear 8, the second spur gear 9 is mounted as a gear ring on the gear main body 39.

- the annular spur gear 9 is fixed to the first spur gear 8 by a clamping ring 37 is disposed on the gear base body 39 on the side remote from the machine side wall 26, which is distributed by tie rods 29 on the circumference of the double gear 6 against the first spur gear 8 pressed.

- Each tie rod 29 passes through the first spur gear 8, the gear main body 39 and the clamping ring 37 and is supported with a stepped head 29A in each one of the support load distributing pressure piece 31 against a spring assembly 13, which is received in the first spur gear 8.

- Each tie rod 29 is biased on the head 29A opposite side of a clamping nut 30, which is supported on the clamping ring 39, adjustable against the force of the spring pact 13 to the clamping ring 39 with the annular spur gear 9 and the annular spur gear 9 with the fixed To connect spur 8 frictionally.

- an annular spring plate 38 is arranged.

- annular cylinder (ring cylinder 40) is arranged coaxially with the cylinder pin 10 in the immediate vicinity of the thrust bearing 34 on the machine side wall 26.

- the ring cylinder 40 is fixedly connected to the machine side wall 26 and surrounds the guide ring 35 of the thrust bearing 34 in the radial direction without spacing.

- annular piston 41 is arranged under fluid supply or - removal axially parallel to the cylinder pin 10 displaced. With fluid supply to the annular cylinder 40 of the annular piston 41 is moved parallel to the axis 44 of the cylinder pin 10 away from the machine side wall 26 and displaced against the plungers 31 of the tie rods 29.

- a support of the introduction of force on the double gear 6 is provided.

- a support ring 45 is attached to the ring cylinder 40, which preferably engages behind the ring cylinder 40 at its base and is bent on the side of the annular piston 41.

- the support ring 45 protrudes into a recess on the spur gear 8, which is covered by a retaining ring 46.

- the second annular spur gear 9 is released with high positional accuracy in its clamping position and can then adjusted in its recording on the gear base 39 and relative to the first spur gear 8 with equally high accuracy become.

- annular cylinder 40 is fixedly connected to the frame side wall 26.

- the annular cylinder 40 is fixedly connected to the frame side wall 26.

- a safe and well-supported force is given by the integrative proximity between the thrust bearing 34 of the cylinder bearing and the ring cylinder 40 of the unlocking mechanism.

- the ring cylinder 40 in conjunction with the annular piston 41 is very simple and easy to install and also designed as an extremely compact arrangement.

- the annular piston 41 is an insert element with an overlapping edge as a stop and a sealing system 41A in the axial direction to the cylinder pin 10 in an annular piston chamber 40A inside the annular cylinder 40 inserted pushed. This ensures a very simple operation and easy maintenance of the machine.

- the annular piston 41 can be loaded at the abovementioned overlapping edge with a few return springs 46 in the direction of the machine frame 26, so that it safely returns to the basic position in the ring cylinder 40 when pressure is released.

- FIG. 6A the basic position of the annular piston 41 is shown with minimum distance to the pressure piece 31 on the tie rod 29 under load by the return springs 46.

- the return springs 46 may be arranged in any free access position to the annular piston 41 and must be secured to the machine frame 26 connected.

- the annular piston 41 can for securing against unintentional displacement in the circumferential direction with a loosely engaging in a recess 41 C in the piston crown locking pin 41 B (see FIG. 6A ).

- the annular piston 41 is not obstructed by the securing pin 41B with respect to the function to be performed for unlocking in the form of a lifting movement.

- tie rods 29 are charged themselves, but that the force for unlocking via a this at the remote head 29A associated pressure piece 31 is introduced to a respective associated spring assembly 13.

- the tie rods 29 are therefore not overstressed and can not be moved under a direct action of the annular piston 41, which could lead to unintentional displacements.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Rotary Presses (AREA)

- Gear Transmission (AREA)

- Supply, Installation And Extraction Of Printed Sheets Or Plates (AREA)

Description

Die Erfindung betrifft eine Vorrichtung zum Lösen einer kraftschlüssig erzeugten Verbindung nach dem Oberbegriff von Patentanspruch 1.The invention relates to a device for releasing a frictional connection according to the preamble of

In Bogenrotationsdruckmaschinen wird zur Bewerkstelligung der Bogenwendung eine so genannte Bogenwendeeinrichtung im Transportweg der Druckbogen angeordnet. Im Normalfall wird der Bogen mit seiner Vorderkante voran durch die ganze Maschine transportiert, wobei dann nur die Oberseite des Druckbogens bedruckt wird. Wenn der Bogen von beiden Seiten bedruckt werden soll, wird die Bogenwendeeinrichtung zwischen zwei Druckwerken umgestellt, infolge dessen dort die Hinterkante des Bogens zur Vorderkante wird.In sheet-fed rotary printing presses, a so-called sheet turning device is arranged in the transport path of the printed sheet for the purpose of accomplishing the use of the sheet. Normally, the sheet is transported with its leading edge through the entire machine, in which case only the top of the sheet is printed. If the sheet is to be printed from both sides, the sheet turning device is switched between two printing units, as a result of which there is the trailing edge of the sheet to the leading edge.

Zur Bogenwendung ist also die Relativlage der benachbarten Druckwerke so zu verändern, dass an dieser Stelle anstatt der Vorderkante des Druckbogens nun die Hinterkante übergeben werden kann. Zur Veränderung der Relativlage wird der Getriebezug in einer solchen Druckmaschine mittels eines koppelbaren Doppelzahnrads (auf einem Hauptzahnrad ist ein Zahnradring verdrehbar angeordnet) mit Klemmeinrichtungen ausgerüstet. Die Klemmeinrichtungen können einen Klemmring enthalten und werden über Kurven oder Federsätze gespannt und entriegelt.For bowing, so the relative position of the adjacent printing units is to change so that at this point instead of the leading edge of the sheet now the trailing edge can be passed. To change the relative position of the gear train is in such a printing machine by means of a double-coupled double gear (on a main gear a ring gear is rotatably arranged) equipped with clamping devices. The clamping devices may include a clamping ring and are stretched and unlocked via curves or spring sets.

Eine Vorrichtung dieser Art beschreibt die

gelöst. Als weiteres Problem ist zu sehen, dass der Balgen sich gegen die Kraft der Druckfeder zwischen der Gehäusewand und dem Zylinder abstützt. Damit wird beim Entriegeln der Klemmung eine Axialkraft auf die Zylinderlager aufgebracht die zu einer Verlagerung des gesamten Zylinders und damit auch der Zahnräder führen kann.A device of this type describes the

solved. Another problem can be seen that the bellows is supported against the force of the compression spring between the housing wall and the cylinder. Thus, when unlocking the clamp, an axial force is applied to the cylinder bearings which can lead to a displacement of the entire cylinder and thus the gears.

In weiteren bekannten Vorrichtungen sind sowohl alle für die Verriegelung bzw. Entriegelung der Klemmung notwendigen Elemente als auch die dazu vorhandenen Antriebselemente auf dem Zahnrad untergebracht. Die ganze Einheit dieses Doppelzahnrades kann einige Nachteile aufweisen. Vor allen Dingen sind die Elemente zur Erzeugung der Klemmung relativ aufwendig und zylinderfest montiert. Damit laufen sie während des kompletten Betriebes mit zwar relativ kompakt gestaltet sein, sie wird aber sehr kompliziert und schwer. Zum größten Teil ist dabei nicht an die Automatisierbarkeit gedacht.In other known devices both all necessary for the locking and unlocking of the clamping elements and the existing drive elements are housed on the gear. The whole unit of this double gear can have some disadvantages. Above all, the elements for generating the clamping are relatively expensive and cylinder-mounted. Thus, they run during the entire operation with relatively compact, but it is very complicated and difficult. For the most part, this is not intended for automation.

Aus der

Aus der

Aus der

Weitere Vorrichtungen ähnlicher Art sind in

In allen Ausführungsformen ist eine raumfordernde Ausführung der gefundenen Entriegelungsmechanismen zu bemängeln. Des Weiteren ist keine Zuordnung zu als für den sensiblen Bereich der Antriebsgenauigkeit relevanten Lagerungsbereichen des jeweiligen Druckmaschinenzylinders aufgeführt. Eine leistungsfähige und einfach gestaltete, sowie kompakte Entriegelungsvorrichtung, die die Zahnrad- und Lagerungsanordnung bei den Klemm- und Entriegelungsvorgängen schont, ist aus dem Stand der Technik nicht bekannt.In all embodiments, a space-consuming design of the unlocking mechanisms found is to complain. Furthermore, no assignment to as relevant for the sensitive area of the drive accuracy storage areas of the respective printing press cylinder is listed. A powerful and simply designed, as well as compact unlocking device, which protects the gear and bearing assembly in the clamping and unlocking operations, is not known from the prior art.

Es stellt sich daher die Aufgabe, eine Vorrichtung nach dem Oberbegriff des Patentanspruchs 1 zu schaffen, die bei minimaler Veränderung am Antriebszahnrad eine sicher und schonend ausführbare und mit geringem Aufwand verbundene Entriegelung der Klemmung am Doppelzahnrad möglich macht, so dass die Wirckräfte keinen negativen Einfluss auf die betroffenen Komponenten haben.It is therefore an object to provide a device according to the preamble of

Diese Aufgabe wird nach dem Kennzeichen des Patentanspruchs 1 gelöst.This object is achieved according to the characterizing part of

Als besonders vorteilhaft ist darin zu sehen, dass die Vorrichtung sich selbst am Zahnrad ausrichtet und während des Normalbetriebes keinerlei Berührung mit dem Doppelzahnrad aufweist. Das wird dadurch erreicht, dass der Entriegelungsmechanismus aus einem im Querschnitt rechteckigen und durch zwei konzentrische Ringe gebildeten kreisförmigen Hubkanal besteht, in dem ein Hubring mit Hilfe einer fluidisch erzeugten Antriebsenergie gegenüber den Ringen des Hubkanals verschoben wird. Bei der Verschiebung stützen die Ringe sich an Elementen des Doppelzahnrades so ab, dass die Klemmung des Zahnradringes aufgehoben wird. Die Ausgestaltung verschiedener Varianten dieses Lösungsprinzips ist in den Unteransprüchen erläutert.To be particularly advantageous is to see that the device aligns itself on the gear and has no contact with the double gear during normal operation. This is achieved in that the unlocking mechanism consists of a rectangular in cross-section and formed by two concentric rings circular Hubkanal in which a lifting ring is displaced by means of a fluidically generated drive energy against the rings of the Hubkanals. During the displacement, the rings are supported on elements of the double gear so that the clamping of the gear ring is canceled. The embodiment of different variants of this solution principle is explained in the subclaims.

Die geschilderten Varianten benutzen hydraulische oder pneumatische Energie. Bei allen Varianten ist gleich, dass die zum Entriegeln der Klemmung vom Zahnradring auf dem Hauptzahnrad aufzubringende Kraft innerhalb des Doppelzahnrades umgeleitet wird und dabei über eine steife Axial-Lagerung des Druckzylinders abgestützt wirken kann. Damit ergeben sich auch keine Verschiebungen, die z. B. bei einer Schrägverzahnung zu einer Drehverlagerung des Antriebes führen könnten. Weiterhin steht das Entriegelungssystem im normalen Maschinenbetrieb nicht mit dem Doppelzahnrad in Berührung. Am Doppelzahnrad selbst sind keinerlei Zusatzelemente erforderlich, so dass die Masse des Doppelzahnrades nicht erhöht wird. Das Doppelzahnrad selbst ist also vollkommen wartungsfrei und die Kupplung zum Aufheben der Klemmung des Doppelzahnrades ist ohne Änderungen an diesem zu warten bzw. ein- und ausbaubar.The described variants use hydraulic or pneumatic energy. In all variants it is the same that the force applied to unlock the clamping of the gear ring on the main gear is diverted within the double gear and thereby a rigid axial bearing of the printing cylinder can act supported. This also results in no shifts z. B. could lead to a rotational displacement of the drive in a helical gearing. Furthermore, the unlocking system is not in the normal machine operation with the double gear in touch. At the double gear itself no additional elements are required, so that the mass of the double gear is not increased. The double gear itself is so completely maintenance-free and the clutch to cancel the clamping of the double gear is to be maintained without changes to this or built and removed.

Es ist eine Vorrichtung zum Lösen der kraftschlüssig erzeugten Verbindung eines aus einem auf einem Zylinderzapfen angeordneten ersten Stirnrad und einem diesem ersten Stirnrad zugeordneten als Zahnradring ausgebildeten zweiten Stirnrad bestehenden Doppelzahnrades vorgesehen, die in einer von Schön- auf Schön· und Widerdruck umstellbaren Bogenrotationsdruckmaschine angeordnet ist. Das zweite Stirnrad wird über durch Federkraft belastete Zuganker am ersten Stirnrad geklemmt wird. Die Vorrichtung ist symmetrisch zur Achse des Doppelzahnrades angeordnet ist und weist zum Lösen wenigstens eine ringförmige fluidbetriebene Hubanordnung auf. Diese ist mit dem Maschinengestell gekoppelt und wenigstens teilweise in Richtung einer Achse des Doppelzahnrades verschiebbar. Die Hubanordnung verbindet in Lösestellung einen Teil des Doppelzahnrades mit dem Maschinengestell.It is a device for releasing the frictionally generated connection of a arranged on a cylinder pin first spur gear and a first spur gear associated with this formed as a gear ring second spur existing double gear provided, which is arranged in a convertible from Schön- on perfecting sheet-fed rotary printing press. The second spur gear is clamped by loaded by spring tension tie rods on the first spur gear. The device is arranged symmetrically to the axis of the double gear and has for releasing at least one annular fluid-operated lifting arrangement. This is coupled to the machine frame and at least partially displaceable in the direction of an axis of the double gear. The lifting arrangement connects in the release position a part of the double gear to the machine frame.

Erfindungsgemäß ist der Zylinderzapfen in einem Zylinderlager aufgenommen, in dem eine von einer Radiallagerung getrennt angeordnete Axiallagerung vorgesehen ist. Die ringförmige fluidbetriebene Hubanordnung ist direkt benachbart und konzentrisch zur Axiallagerung am Maschinengestell der Bogenrotationsdruckmaschine angeordnet. Ein Druckelement der Hubanordnung ist je einem die Federkraft auf einen jeweiligen Zuganker übertragenden Druckstück zugeordnet. Dadurch werden die auf den oder die Zuganker wirkenden Federkräfte unter Belastung durch das Druckelement reduziert oder aufgehoben.According to the invention, the cylinder pin is received in a cylinder bearing, in which an axial bearing arranged separately from a radial bearing is provided. The annular fluid operated lift assembly is disposed directly adjacent and concentric with the axial support on the machine frame of the sheet-fed rotary printing machine. A pressure element of the lifting arrangement is assigned to a respective pressure element transmitting the spring force to a respective tie rod. As a result, the forces acting on the tie rod or the spring forces are reduced or removed under load by the pressure element.

Erfindungsgemäß ist die ringförmige Hubanordnung aus einem Ringzylinder und einem in diesem in einer Ringöffnung angeordneten Ringkolben gebildet. Der Ringzylinder ist koaxial zur Achse des Doppelzahnrads und direkt benachbart parallel zu einem äußeren Umfang eines Führungsringes der Axiallagerung des Zylinderlagers am Maschinengestell angeordnet. Der Ringkolben ist parallel zur Achse in Richtung von und zu dem Maschinengestell zum Doppelzahnrad bewegbar angeordnet.According to the invention, the annular lifting arrangement is formed from a ring cylinder and an annular piston arranged in this ring opening. The ring cylinder is arranged coaxially with the axis of the double gear and directly adjacent parallel to an outer periphery of a guide ring of the axial bearing of the cylinder bearing on the machine frame. The annular piston is arranged to be movable parallel to the axis in the direction of and to the machine frame to the double gear.

In Weiterbildung ist vorgesehen, dass der Ringkolben als in einen stirnseitig vom Maschinengestell weg weisend offenen Kolbenraum einführbarer Einsatz mit Dichtungseinsätzen an der Innen- und der Außenflanke ausgebildet ist.In a further development it is provided that the annular piston is formed as insertable into a front side of the machine frame facing away open piston chamber insert with sealing inserts on the inner and the outer edge.

In Weiterbildung ist vorgesehen, dass dem Ringkolben eine innerhalb des Kolbenraums angeordnete und den Ringkolben in seiner Hubbewegung nicht beeinflussenden aber in seiner Umfangslage relativ zum Ringzylinder sichernden Halteeinrichtung zugeordnet ist.In a further development, it is provided that the annular piston is assigned a retaining device which is arranged within the piston chamber and which does not influence the annular piston in its lifting movement but which is secured in its peripheral position relative to the annular cylinder.

In Weiterbildung ist vorgesehen, dass der Ringzylinder fest mit dem Maschinengestell verbunden angeordnet ist.In a further development it is provided that the ring cylinder is arranged fixedly connected to the machine frame.

Erfindungsgemäß ist vorgesehen, dass in mechanischer Verbindung mit dem Ringzylinder und dem direkt benachbarten Bereich des Doppelzahnrads als Kraftleitelement ein Stützring vorgesehen ist. Der Stützring ist mit dem Ringzylinder vorzugsweise diesen hintergreifend gekoppelt und hintergreift weiterhin einen an dem Doppelzahnrad angeordneten Haltering.According to the invention, it is provided that a support ring is provided in mechanical connection with the ring cylinder and the directly adjacent region of the double gear as Kraftleitelement. The support ring is preferably coupled with the ring cylinder and engages behind a further arranged on the double gear retaining ring.

In Weiterbildung ist vorgesehen, dass jedem Zuganker je ein Druckstück an einem Kopfende zugeordnet ist, das einer Spannschraube am anderen Ende des Zugankers gegenüberliegt. Das Druckstück dient zur Krafteinleitung auf ein jeweils dem Zuganker zugeordnetes Federpaket. Die Druckstücke aller Zuganker sind so angeordnet, dass sie den Ringkolben in dessen Hubstellung berühren.In a further development it is provided that each tie rod is assigned a respective pressure piece at a head end, which is opposite to a clamping screw at the other end of the tie rod. The pressure piece is used to apply force to a respectively associated with the tie rod spring assembly. The thrust pieces of all tie rods are arranged so that they touch the ring piston in its stroke position.

In Weiterbildung ist vorgesehen, dass eine Federplatte zwischen einem Klemmring und einem zylinderfesten Element des Doppelzahnrades angeordnet ist. Die Federplatte löst den Klemmring bei Aufhebung der Klemmung des Klemmrings gegen ein zylinderfestes Teil des Doppelzahnrads und ist als kreisringförmiges Federelement ausgebildet.In a further development it is provided that a spring plate between a clamping ring and a cylinder-fixed element of the double gear is arranged. The spring plate dissolves the clamping ring when canceling the clamping of the clamping ring against a cylinder-fixed part of the double gear and is designed as an annular spring element.

In Weiterbildung ist vorgesehen, dass an dem Ringkolben angreifend eine oder mehrere Rückstellfedern derart angeordnet sind, dass der Ringkolben bei Druckentlastung des Ringzylinders unter der Kraft der Rückstellfedern in den Kolbenraum hineingeschoben wird.In a further development, it is provided that one or more return springs are arranged on the annular piston in such a manner that the annular piston is pushed into the piston chamber when the annular cylinder is relieved of pressure under the force of the return springs.

In Weiterbildung ist vorgesehen, dass das ringförmige Hubelement aus mehreren Hubzylindern und jeweils einem in diesen angeordneten Hubkolben gebildet ist. Die Hubzylinder sind ringförmig konzentrisch zum Zylinderzapfen angeordnet.In a further development, it is provided that the annular lifting element is formed from a plurality of lifting cylinders and in each case one lifting piston arranged in these. The lifting cylinders are arranged concentrically with respect to the cylindrical pin annular.

Aus den Ausgestaltungen der verschiedenen Varianten ergeben sich weitere spezifische Vorteile, die im Folgenden in der Beschreibung der Ausführungsbeispiele erwähnt werden.From the embodiments of the various variants, there are further specific advantages which are mentioned below in the description of the exemplary embodiments.

Im Folgenden werden anhand von bildlichen Darstellungen einige Ausführungsformen der Erfindung näher beschrieben.In the following, some embodiments of the invention will be described in detail with reference to pictorial representations.

Im Einzelnen zeigen

-

Figur 1 - eine Teilansicht einer Bogenrotationsdruckmaschine,

-

Figur 2 - einen Teilschnitt einer Vorrichtung nach Stand der Technik,

- Figur 3

- eine Ausgestaltung der Entriegelungsvorrichtung, die nicht von den Ansprüchen gedeckt ist,

- Figur 4

- eine andere Ansicht dieser Vorrichtung und

-

Figur 5 - eine Variante dieser Vorrichtung und

-

Figur 6/6A - die erfindungsgemäße Vorrichtung.

- FIG. 1

- a partial view of a sheet-fed rotary printing press,

- FIG. 2

- a partial section of a device according to the prior art,

- FIG. 3

- an embodiment of the unlocking device, which is not covered by the claims,

- FIG. 4

- another view of this device and

- FIG. 5

- a variant of this device and

- Figure 6 / 6A

- the device according to the invention.

In

Das Prinzip einer solchen Doppelradkupplung 7 nach Stand der Technik ist in Figur 2 dargestellt. Das Doppelzahnrad 6 besteht aus einem Hauptzahnrad 8 und einem Zahnradring 9. Das Hauptzahnrad 8 ist mit einem Zylinderzapfen 10 verbunden. Zwischen Zahnradring 9 und Hauptzahnrad 8 wird eine Klemmverbindung über einen Klemmring 11 hergestellt. Dazu stützen sich zwischen dem am Hauptzahnrad 8 befestigten Klemmring 11 und dem Zahnradring 9 Klemmelemente 12 unter der Kraft von Federpaketen 13 ab. Wenn die Federpakete 13 von außen unbelastet sind, verspannen sie das Klemmelement 12 gegen den Klemmring 11 und verbinden den Zahnradring 9 reibschlüssig mit dem Hauptzahnrad 8. Die Antriebsmomente werden von einem Zahnrad 14 über den Zahnradring 9 auf das Hauptzahnrad 8 übertragen und von dort an im Räderzug nachgelagerte Antriebselemente weitergegeben.The principle of such a dual-

Zur Einstellung des Betriebs mit Bogenwendung werden die Bogentransportelemente relativ zueinander nach Lösen der Klemmung des Zahnradringes 9 verstellt, wobei die Klemmkraft der Klemmelemente 12 zwischen Klemmring 11 und Zahnradring 9 aufgehoben wird. Dies wird mit der Doppelradkupplung 7 bewirkt, die aus einem inneren Ring 15 und einem äußeren Ring 16 besteht. Die Ringe 15, 16 bilden ein Hydraulik- oder Pneumatiksystem mit einem Druckraum 28, der mit Dichtungen 25 abgedichtet ist und dem ein Fluid durch einen Druckmittelanschluss 27 zugeführt wird. Das Entriegelungssystem ist über in den Ring 15 eingreifende Haltebolzen 17 axial verschiebbar von Federn 18 belastet gegen einen festen Träger 20 als Ruheposition belastet. Der äußere Ring 16 liegt mit einer Anschlagfläche 21 unter Last von Druckfedern 19 am inneren Ring 15 an.To set the operation with perfecting the sheet transport elements are adjusted relative to each other after releasing the clamping of the

Zum Entriegeln der Klemmung werden als Wirkflächen des Systems die äußere Stirnfläche 22 des inneren Ringes 15 und eine abgekröpfte Ringfläche 23 des äußeren Ringes 16 benutzt. Als Kraftangriff für die Stirnfläche 22 des inneren Ringes 15 dienen die Klemmelemente 12 und als Kraftangriff für die Ringfläche 23 des äußeren Ringes 16 dient ein Entriegelungselement 24, das mit dem Zahnradring 9 verbunden ist. Die Doppelradkupplung 7 ist am Träger 20 positioniert, der mit einem Teil des Maschinenrahmens 26 starr verbunden ist.To unlock the clamp, the outer end face 22 of the

Im Entriegelungszustand ist das Entriegelungssystem von gestellfesten Halterungen bis auf geringe Federkräfte frei. Bei weiterer Druckmittelzufuhr wird die Klemmung der Zahnradteile aufgehoben, ohne dass Axialkräfte in das Hauptzahnrad 8 bzw. dessen Lagerung eingebracht werden. Das Hauptzahnrad 8 kann gegenüber dem Zahnradring 9 verdreht werden, während der Zahnradring 9 und die an ihn gekoppelten Getriebeteile festgehalten werden.In the unlocked state, the release system is free from fixed supports to small spring forces. Upon further supply of pressure medium, the clamping of the gear parts is canceled, without axial forces in the

Nach Relativeinstellung der Antriebsräder wird das Entriegelungssystem drucklos geschaltet und stellt sich mittels der Federn 18, 19 in seine Ausgangslage zurück.After Relativeinstellung the drive wheels, the unlocking system is depressurized and is by means of the

In

Auf dem Zylinderzapfen 10 ist ein Zahnradgrundkörper 39 mittels einer Befestigungsplatte 36 festgelegt. An dem Zahnradgrundkörper 39 ist ein erstes Stirnrad 8 verdrehfest montiert. Weiterhin ist parallel und koaxial zu dem ersten Stirnrad 8 ein zweites Stirnrad 9 als Zahnradring auf dem Zahnradgrundkörper 39 aufgesetzt. Zur Festlegung des ringförmigen Stirnrades 9 gegenüber dem ersten Stirnrad 8 auf dem Zahnradgrundkörper 39 ist auf der von der Maschinenseitenwand 26 abgewandten Seite ein Klemmring 37 angeordnet. Der Klemmring 37 wird von einem Zuganker 29 oder mehreren über den Umfang des Doppelzahnrades 6 verteilten Zugankern 29 gegen das erste Stirnrad 8 gepresst. Dazu durchgreift jeder der Zuganker 29 das erste Stirnrad 8, den Zahnradgrundkörper 39 und den Klemmring 37 und stützt sich mit je einem eigenen kopfseitig angebrachten Druckstück 31 gegen ein jeweiliges Federpaket 13 (etwa aus Tellerfedern) ab. Jedes der Federpakete 13 wird hierbei in entsprechenden Vorrichtungen an dem ersten Stirnrad 8 aufgenommen. Jeder Zuganker 29 wird weiterhin jeweils gegen die Kraft des Federpaktes 13 von einer Spannmutter 30, die sich auf dem Klemmring 39 abstützt, einstellbar gehaltert.On the

Zur Verbesserung der Handhabung ist zwischen dem Klemmring 37 und dem Zahnradgrundkörper 39 ist eine ringförmige Federplatte 38 angeordnet, die in der Art einer Unterlegscheibe tellerförmig verformt ist und daher beim Einklemmen zwischen dem Klemmring 37 und dem Zahnradgrundkörper 39 vorgespannt wird. Daher kann die Federplatte 38 beim Reduzieren oder Aufheben der Vorspannung der Zuganker 29 den Klemmring 37 durch ein Aufwölben von dem Zahnradring des zweiten Stirnrades 9 abheben, so dass dieses gegenüber dem ersten Stirnrad 8 bewegbar wird.To improve the handling between the clamping

Zur Aufhebung der reibschlüssigen Verbindung, die unter der Belastung durch die Federpakete 13 zwischen den gegeneinander verspannten Elementen Klemmring 37, zweites Stirnrad 9 und erstes Stirnrad 8 erzeugt wird, ist eine fluidtechnische Hubeinrichtung vorgesehen.To cancel the frictional connection, which is generated under the load by the

Diese Einrichtung besteht aus einem ringförmigen Zylinder (Ringzylinder 40), der koaxial zu dem Zylinderzapfen 10 in direkter Nachbarschaft zu dem Axiallager 34 an der Maschinenseitenwand 26 angeordnet ist. In dem Ringzylinder 40 ist ein Ringkolben 41 unter Fluidzufuhr oder -abfuhr achsparallel zum Zylinderzapfen 10 verlagerbar angeordnet. Bei Fluidzufuhr zu dem Ringzylinder 40 wird der Ringkolben 41 parallel zu Achse des Zylinderzapfens 10 von der Maschinenseitenwand 26 weg bewegt und gegen die Druckstücke 31 der Zuganker 29 verlagert. Unter entsprechendem Druckaufbau presst dann der Ringkolben 41 über die Druckstücke 31 die Federpakete 13 zusammen, so dass die Vorspannlast, die über die Spannmuttern 30 auf den Klemmring 37 aufgebracht wurde, reduziert oder aufgehoben wird. Dadurch, und durch die Rückstellwirkung der Federplatte 38, wird das zweite ringförmige Stirnrad 9 frei und kann relativ zum ersten Stirnrad 8 verstellt werden.This device consists of an annular cylinder (ring cylinder 40) which is arranged coaxially with the

Infolge des großen Durchmessers des Doppelzahnrades 6 sind hier auch ein Ringzylinder 40 mit einem angemessen großen Durchmesser und ein entsprechend groß dimensionierter Ringkolben 41 erforderlich. Eine entsprechende Darstellung des Ringzylinders 40 in Zuordnung zum Zylinderzapfen 10 und dessen Axiallagerung 34 (Strich-Punkt-Linierung) ist in

Daher kann alternativ eine ringförmig gleichmäßig um den Zylinderzapfen 10 verteilte Anordnung von kleineren Hubzylindern 42 mit einem jeweiligen Hubkolben 43 vorgesehen werden, wie dies in

Die Zuordnung jedes dieser Hubzylinder 42 mit ihrem Hubkolben 43 erfolgt so, dass diese jeweils einem jeweiligen Zuganker 29 bzw. dessen Druckstück 31 gegenüberliegend an der Maschinenseitenwand 26 positioniert werden. In diesem Fall muss eine Vorrichtung zur exakten Positionierung des Doppelzahnrades 6 in seiner Drehlage vorgesehen werden. Für eine einwandfrei gleichmäßige Aufhebung der Klemmung innerhalb des Doppelzahnrades 6 ist eine exakt ausgerichtete Einwirkung jedes der Hubkolben 43 auf den jeweils zugeordneten Zuganker 29 bzw. dessen jeweiligem Druckstück 31 erforderlich.The assignment of each of these lifting

Alternativ könnten die gemäß

In

Am Zylinderzapfen 10 ist ein Zahnradgrundkörper 39 mit einer Befestigungsplatte 36 festgelegt. Am Zahnradgrundkörper 39 ist ein erstes Stirnrad 8 verdrehfest montiert. Parallel und koaxial zum ersten Stirnrad 8 ist das zweite Stirnrad 9 als Zahnradring auf dem Zahnradgrundkörper 39 aufgesetzt. Das ringförmige Stirnrad 9 wird am ersten Stirnrad 8 festgelegt, indem auf dem Zahnradgrundkörper 39 auf der von der Maschinenseitenwand 26 abgewandten Seite ein Klemmring 37 angeordnet ist, der von Zugankern 29 am Umfang des Doppelzahnrades 6 verteilt gegen das erste Stirnrad 8 gepresst wird. Jeder Zuganker 29 durchgreift das erste Stirnrad 8, den Zahnradgrundkörper 39 und den Klemmring 37 und stützt sich mit einem abgesetzten Kopf 29A in je einem die Auflagelast verteilenden Druckstück 31 gegen ein Federpaket 13 ab, das im ersten Stirnrad 8 aufgenommen ist. Jeder Zuganker 29 wird auf der dem Kopf 29A gegenüberliegenden Seite von einer Spannmutter 30, die sich auf dem Klemmring 39 abstützt, gegen die Kraft des Federpaktes 13 einstellbar vorgespannt, um den Klemmring 39 mit dem ringförmigen Stirnrad 9 und das ringförmige Stirnrad 9 mit dem festen Stirnrad 8 reibschlüssig zu verbinden. Zur Verbesserung der Handhabung beim Lösen der reibschlüssigen Verbindungen ist entsprechend

Zur Aufhebung der reibschlüssigen Verbindung auf Basis Klemmung durch Federpakete 13 zwischen Klemmring 37, zweitem Stirnrad 9 und erstem Stirnrad 8 ist ein ringförmiger Zylinder (Ringzylinder 40) koaxial zu dem Zylinderzapfen 10 in direkter Nachbarschaft zu dem Axiallager 34 an der Maschinenseitenwand 26 angeordnet. Der Ringzylinder 40 ist fest mit der Maschinenseitenwand 26 verbunden und umschließt in radialer Richtung den Führungsring 35 des Axiallagers 34 abstandsfrei. In dem Ringzylinder 40 ist ein Ringkolben 41 unter Fluidzu- oder - abfuhr achsparallel zum Zylinderzapfen 10 verlagerbar angeordnet. Bei Fluidzufuhr zu dem Ringzylinder 40 wird der Ringkolben 41 parallel zu Achse 44 des Zylinderzapfens 10 von der Maschinenseitenwand 26 weg bewegt und gegen die Druckstücke 31 der Zuganker 29 verlagert.To cancel the frictional connection based on clamping by

Der Kraftaufbau ausgehend vom Ringzylinder 40 bzw. dem Ringkolben 41 gegen die Maschinenseitenwand 26 und gegen das Doppelzahnrad 6 findet dabei in dem geringst möglichem Abstand zur Befestigung des Axiallagers 34 der Zylinderlagerung an der Maschinenseitenwand 26 und am Zylinderzapfen 10 statt. Gleichwohl ist zu berücksichtigen, dass von der Druckkraft an Ringzylinder 40 und Ringkolben 41 Elastizitäten und Spieleffekte im Bereich des Doppelzahnrads 6 und der Zylinderlagerung ausgestellt werden, so dass eine ungewollte Verlagerung des Doppelzahnrads 6 erfolgen kann.The force build-up starting from the

Daher wird gemäß der Erfindung, zusätzlich zu der kompakten Krafteinleitung, eine Abstützung der Krafteinleitung am Doppelzahnrad 6 vorgesehen. Dazu ist an dem Ringzylinder 40 ein Stützring 45 angebracht, der bevorzugt den Ringzylinder 40 an seiner Basis hintergreift und an der Seite des Ringkolbens 41 abgekröpft ist. Hier ragt der Stützring 45 in eine Ausnehmung am Stirnrad 8, die von einem Haltering 46 abgedeckt wird. Damit ist eine axiale Verlagerung des Doppelzahnrads 6 gegenüber dem Ringzylinder 40 bzw. der Maschinenseitenwand 26 nur in einem sehr begrenzten und auf minimale Werte einstellbaren Maß möglich.Therefore, according to the invention, in addition to the compact introduction of force, a support of the introduction of force on the

Unter entsprechendem Druckaufbau mittels Fluidzufuhr in den Ringzylinder 40 presst dann der Ringkolben 41 über die Druckstücke 31 die Federpakete 13 zusammen, wobei sich der Stützring 45 über den Haltering 46 an dem fest auf dem Zylinderzapfen 10 montierten Stirnrad 8 abstützt.Under appropriate pressure build-up by means of fluid supply into the

Dadurch wird die von den Federpaketen 13 erzeugte Vorspannlast, die über die Spannmuttern 30 auf den Klemmring 37 wirkt, reduziert oder aufgehoben. Hierbei findet durch die Wirkung des Stützrings 45, der sich über den Haltering 41 am Stirnrad 8 abstützt, keine unbeabsichtigte Verlagerung von Lagerelementen oder anderen Teilen des Doppelzahnrads 6 statt. Die Krafteinleitung auf die verschiedenen Druckstücke 31 der Zuganker 29 verteilt sich gleichmäßig über den Umfang des Doppelzahnrades 6, da der Fluiddruck sich gleichmäßig über den Umfang des Ringzylinders 40 aufbaut.As a result, the biasing load generated by the

Durch die Entlastung der Vorspannung der Zuganker 29 und durch die Rückstellwirkung der Federplatte 38, wird das zweite ringförmige Stirnrad 9 mit hoher Lagegenauigkeit in seiner Klemmposition freigestellt und kann danach in seiner Aufnahme auf dem Zahnradgrundkörper 39 und relativ zum ersten Stirnrad 8 mit ebenso hoher Genauigkeit verstellt werden.By relieving the bias of the

Besonders vorteilhaft an der erfindungsgemäßen Ausführungsform ist, dass der Ringzylinder 40 fest mit der Gestellseitenwand 26 verbunden ist. Im Gegensatz zum Stand der Technik kann so keine unbeabsichtigte Berührung zwischen dem Doppelzahnrad 6 und dem Entriegelungsmechanismus im Laufbetrieb der Maschine vorkommen. Weiterhin ist eine sichere und gut abgestützte Krafteinleitung durch die integrative Nähe zwischen dem Axiallager 34 des Zylinderlagers und dem Ringzylinder 40 des Entriegelungsmechanismus gegeben.Particularly advantageous in the embodiment according to the invention is that the

In der vergrößerten Auszugsdarstellung nach

Im Betrieb kann der Ringkolben 41 an dem oben genannten übergreifenden Rand mit wenigen Rückstellfedern 46 in Richtung zum Maschinengestell 26 belastet werden, so dass er bei Druckentlastung sicher in die Grundstellung im Ringzylinder 40 zurückkehrt. In

Der Ringkolben 41 kann zur Sicherung gegen eine unbeabsichtigte Verlagerung in Umfangsrichtung mit einem lose in eine Ausnehmung 41C in den Kolbenboden eingreifenden Sicherungsstift 41B (siehe

Dabei wird der Ringkolben 41 durch den Sicherungsstift 41B nicht bezüglich der zur Entriegelung auszuführenden Funktion in Form einer Hubbewegung behindert. Bei Drehbewegungen am Doppelzahnrad 6, die für die Einstellung der Bogenrotationsdruckmaschine auf die Betriebsart Schön- und Widerdruck und zurück auszuführen sind, wird eine Bewegung des Ringkolbens 41 gegenüber dem Ringzylinder 40 in Umfangsrichtung des Doppelzahnrads 6 aber durch den Sicherungsstift 41B verhindert. Damit kann auch keine unbeabsichtigte Verdrehung des Doppelzahnrades 6 während der Funktionsumstellung erfolgen.In this case, the

Schließlich ist vorteilhaft, dass zur Entriegelung nicht die Zuganker 29 selbst belastet werden, sondern dass die Kraft zur Entriegelung über ein diesen an deren abgesetztem Kopf 29A zugeordnetes Druckstück 31 auf ein jeweils zugeordnetes Federpaket 13 eingeleitet wird. Die Zuganker 29 werden daher nicht überbeansprucht und können auch nicht unter einer direkten Einwirkung des Ringkolbens 41 verschoben werden, was zu unbeabsichtigten Verschiebungen führen könnte.Finally, it is advantageous that for unlocking not the

- 11

- Druckwerke (1A / 1B)Printing units (1A / 1B)

- 22

- Druckzylinderpressure cylinder

- 33

- Druckzylinderpressure cylinder

- 44

- BogentransporttrommelSheet transport drum

- 55

- BogentransporttrommelSheet transport drum

- 66

- Doppelzahnraddouble gear

- 77

- Kupplungclutch

- 88th

- Hauptzahnradmain gear

- 99

- Zahnradringgear ring

- 1010

- Zylinderzapfencylinder journal

- 1111

- Klemmringclamping ring

- 1212

- Klemmelementclamping element

- 1313

- Federpaketspring assembly

- 1414

- Zahnradgear

- 1515

- innerer Ringinner ring

- 1616

- äußerer Ringouter ring

- 1717

- Haltebolzenretaining bolt

- 1818

- Federfeather

- 1919

- Druckfedercompression spring

- 2020

- Trägercarrier

- 2121

- Anschlagflächestop surface

- 2222

- Stirnflächeface

- 2323

- Ringflächering surface

- 2424

- Entriegelungselementunlocking

- 2525

- Dichtungpoetry

- 2626

- Maschinenrahmen / MaschinenseitenwandMachine frame / machine side wall

- 2727

- DruckmittelanschlussPressure medium connection

- 2828

- Druckraumpressure chamber

- 2929

- Zugankertie rods

- 3030

- Spannmutterlocknut

- 3131

- DruckstückPressure piece

- 3232

- Radiallagerradial bearings

- 3333

- Lagerhülsebearing sleeve

- 3434

- Axiallagerthrust

- 3535

- Führungsringguide ring

- 3636

- Befestigungsplattemounting plate

- 3737

- Klemmringclamping ring

- 3838

- Federplattespring plate

- 3939

- ZahnradgrundkörperGear body

- 4040

- Ringzylinderring cylinder

- 4141

- Ringkolbenannular piston

- 4242

- Einzelzylinder / HubzylinderSingle cylinder / lifting cylinder

- 4343

- Einzelkolben / HubkolbenSingle piston / reciprocating piston

- 4444

- Achse des DruckzylindersAxis of the printing cylinder

- 4545

- Stützringsupport ring

- 4646

- Halteringretaining ring

- 4747

- RückstellfederReturn spring

- 7A7A

- Entriegelungsantriebunlock drive

- 29A29A

- Kopf des ZugankersHead of the tie rod

- 40A40A

- Kolbenraum im RingzylinderPiston space in the ring cylinder

- 41A41A

- Dichtungen für RingkolbenSeals for ring pistons

- 41B41B

- Verdrehsicherung für RingkolbenAnti-rotation device for ring pistons

- 41C41C

- Ausnehmung im Kolbenboden des RingkolbensRecess in the piston head of the annular piston

Claims (9)

- A device for unlocking a connection generated in a non-positive manner, of a double gearwheel (6) consisting of a first spur gear (8) arranged on a cylinder journal (10) of a printing press cylinder (2), and a second spur wheel (9) assigned to said first spur wheel (8) and being embodied as gear ring, in a sheet-fed rotary printing press, which can be switched from face printing to face and reverse printing, wherein the second spur gear (9) is clamped on the first spur gear (8) via tie rods (29), which are loaded by spring force, and the device for unlocking is arranged symmetrically to the axis (44) of the double gearwheel (6), wherein the device has at least one annular fluid-operated lift assembly (40, 41), which has a connection to a machine frame (26) and which is fastened in an at least partially displaceable manner in the direction of an axis (44) of the double gearwheel (6; 8, 9), wherein the lift assembly (40, 41) connects a portion of the double gearwheel (6; 8, 9) to the machine frame (26) in a rotationally fixed manner in an unlocked position, wherein the cylinder journal (10) is received in a cylinder bearing, in which an axial bearing (34) is provided, which is arranged so as to be separated from a radial bearing (32), wherein the annular fluid-operated lift assembly (40, 41) is arranged directly adjacent and concentrically to the axial bearing (34) on the machine frame (26) of the sheet-fed rotary printing press,

wherein a pressure element of the lift assembly (40, 41) is assigned to a respective pressure piece (31), which transfers the spring force to a respective tie rod (29) and which is arranged coaxially to the tie rod (29) in such a way that the spring forces acting on the tie rod/rods (29) are reduced or eliminated by putting pressure on the pressure element,

wherein die annular lift assembly is formed of an annular cylinder (40) and an annular piston (41) arranged in an annular opening of the annular cylinder (40),

wherein the annular cylinder (40) is arranged on the machine frame (26) coaxially to the axis (44) of the double gearwheel (6) and directly adjacent parallel to an outer circumference of a guide ring (35) of the axial bearing (34) of the cylinder bearing, and

wherein the annular piston (41) parallel to the axis (44) can be moved to the double gearwheel (6) in the direction from and to the machine frame (26),

wherein, in mechanical connection to the annular cylinder (40) and the directly adjacent region of the double gearwheel (6), a support ring (45) is provided as force transmission,

characterized in that the support ring (45) is coupled to the annular cylinder (40), preferably engaging behind the latter, and that the support ring (45) is further arranged so as to engage behind a holding ring (46), which is arranged on the double gearwheel (6). - The device according to claim 1, characterized in that the annular piston (41) is embodied as an insert, which can be inserted into an open annular piston chamber (40A) of the annular cylinder (40), which faces away from the machine frame (26) on the front side, comprising seals (41B) on the inner and the outer shoulder.

- The device according to one or a plurality of claims 1 to 2, characterized in that a holding device (41A), which is arranged within the piston chamber (40A) so as to be connected to the annular cylinder (40) and which does not influence the annular piston (41) in its lift movement, but secures it in its circumferential position relative to the annular cylinder (40), is assigned to the annular piston (41) .

- The device according to one or a plurality of claims 1 to 3,

characterized in

that the annular cylinder (40) is arranged so as to be fixedly connected to the machine frame (26). - The device according to one or a plurality of claims 1 to 4,

characterized in

that a respective pressure piece (31), which is arranged so as to be located opposite a clamping screw (30) on the other end of the tie rod (29), is provided on each tie rod (29) on a top end, for the force transmission to a spring assembly (13), which is in each case assigned to the tie rod (29). - The device according to one or a plurality of claims 1 to 5,

characterized in

that the pressure pieces (31) of all tie rods (29) are assigned to the annular piston (41) in the lift position thereof in the function for unlocking the clamping of the spur gears (8, 9) by means of the pressure element of the lift assembly and that the pressure pieces (31) of all tie rods (29) of the annular piston (41) in the rest position thereof in the function for releasing the clamping of the spur gears (8, 9) are assigned to the lift assembly in a non-contacting manner by the pressure element. - The device according to one or a plurality of claims 1 to 6,

characterized in

that a spring plate (38) is arranged between a clamping ring (37) and an element of the double gearwheel (6) fixed to the cylinder as circular ring-shaped spring element, which releases the clamping ring (37) when eliminating the clamping of the clamping ring (37) against a part of the double gearwheel (6), which is fixed to the cylinder. - The device according to one or a plurality of claims 1 to 7,

characterized in

that one or a plurality of return springs are arranged so as to engage with the annular piston (41) in such a manner that the annular piston (41) is pushed into the piston chamber (40A) all the way against a stop under the force of the return spring in response to the pressure relief of the annular cylinder (40). - The device according to one or a plurality of claims 1 to 8,

characterized in

that the annular lift assembly is of a plurality of lift cylinders (42) and of a respective lift piston (43) arranged therein is formed in that the lift cylinders (42) are arranged annularly concentrically to the cylinder journal (10) and to the axis (44) of the double gearwheel (6), wherein each lift cylinder (42) is arranged on the machine frame (26) so as to be fixed to the frame, and the respective annular piston (43) is arranged so as to be movable parallel to the axis (44) in the direction from the machine frame (26) to the double gearwheel (6).

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102016100532 | 2016-01-14 | ||

| DE102017100661.3A DE102017100661A1 (en) | 2016-01-14 | 2017-01-13 | Unlocking a coupling of a double gear |

| PCT/EP2017/050737 WO2017121889A2 (en) | 2016-01-14 | 2017-01-14 | Unlocking a coupling of a double gearwheel |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP3402678A2 EP3402678A2 (en) | 2018-11-21 |

| EP3402678B1 true EP3402678B1 (en) | 2019-10-30 |

Family

ID=59256348

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP17702301.7A Active EP3402678B1 (en) | 2016-01-14 | 2017-01-14 | Unlocking a coupling of a double gearwheel |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP3402678B1 (en) |

| CN (1) | CN108472945A (en) |

| DE (1) | DE102017100661A1 (en) |

| WO (1) | WO2017121889A2 (en) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113874216B (en) * | 2019-05-23 | 2023-01-06 | 博斯特比勒费尔德有限公司 | Clamping shaft, printing cylinder unit and method of operating the clamping shaft |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5871163A (en) * | 1981-10-24 | 1983-04-27 | Komori Printing Mach Co Ltd | Phase adjustment device for sheet-fed rotary printing press with reversing mechanism |

| DE3534488A1 (en) | 1985-09-27 | 1987-04-16 | Koenig & Bauer Ag | CLUTCH IN AN ARC ROTATION PRINTING MACHINE |

| DE3611324A1 (en) | 1986-04-04 | 1987-10-08 | Heidelberger Druckmasch Ag | DEVICE FOR ADJUSTING THE RELATIVE ROTATION BETWEEN A GEAR WHEEL AND A GEAR WHEEL BEARING WITH THIS SIMULTANEOUSLY |

| JPS63173644A (en) * | 1987-01-13 | 1988-07-18 | Sumitomo Heavy Ind Ltd | Phase switching device for reversing cylinder in sheet-fed press for both one-side printing and perfecting |

| DE4141817C2 (en) | 1991-12-18 | 1993-10-07 | Roland Man Druckmasch | Gear train separation device |

| DE19718140C1 (en) | 1997-04-30 | 1998-10-01 | Roland Man Druckmasch | Device for releasably connecting a gear ring to the main gear |

| US7484610B2 (en) * | 2004-03-10 | 2009-02-03 | Heidelberger Druckmaschinen | Apparatus for the actuation of clamping elements that can be controlled remotely |

| DE102005039918A1 (en) | 2005-08-24 | 2007-03-08 | Man Roland Druckmaschinen Ag | Coupling device for disconnecting gear trains of e.g. sheet printing machine, has clamping unit to provide clamping forces that are directed transverse to friction surfaces for friction-conclusive torque transmission between spur gear units |

| DE102005041696A1 (en) | 2005-09-02 | 2007-03-15 | Man Roland Druckmaschinen Ag | Coupling device for effecting a temporary decoupling of the sections of a gear train of a printing press |

| DE102005045098B4 (en) | 2005-09-21 | 2008-02-28 | Pierburg Gmbh | Cooling device for an internal combustion engine |

-

2017

- 2017-01-13 DE DE102017100661.3A patent/DE102017100661A1/en not_active Withdrawn

- 2017-01-14 EP EP17702301.7A patent/EP3402678B1/en active Active

- 2017-01-14 CN CN201780006751.6A patent/CN108472945A/en active Pending

- 2017-01-14 WO PCT/EP2017/050737 patent/WO2017121889A2/en not_active Ceased

Non-Patent Citations (1)

| Title |

|---|

| None * |

Also Published As

| Publication number | Publication date |

|---|---|

| CN108472945A (en) | 2018-08-31 |

| DE102017100661A1 (en) | 2017-07-20 |

| EP3402678A2 (en) | 2018-11-21 |

| WO2017121889A3 (en) | 2017-09-08 |

| WO2017121889A2 (en) | 2017-07-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE2823038C2 (en) | ||

| EP0549884B1 (en) | Device for gear train separation | |

| DE2462270A1 (en) | PRESS DRIVE | |

| EP0239830A2 (en) | Device for adjusting the relative rotational position between a toothed wheel and a coaxal toothed crown | |

| DE3534486C2 (en) | ||

| EP2939773A1 (en) | Clamping device | |

| DE4012965C1 (en) | Device for the on, off and setting of application rollers | |

| EP0442265B1 (en) | Clamping device for an axial movable actuator for the reversal of the gripper with a sheet-fed rotary letterpress | |

| EP3402678B1 (en) | Unlocking a coupling of a double gearwheel | |

| DE2829026C2 (en) | Device for driving or synchronizing cylinders in offset printing machines | |

| EP1370417B1 (en) | Fixing device | |

| DE4307535A1 (en) | Stroke adjustment device for an eccentric drive, in particular for an eccentric press | |

| DE2802153C2 (en) | Bearer ring arrangement | |

| DE4401684C2 (en) | Adjustment device for a printing press | |

| DE2713994A1 (en) | SHEET HOLDING DEVICE OF A SHEET ROTARY PRINTING MACHINE, WHICH IS ABLE TO SLIGHTLY DEFORM THE PRINTED SHEET | |

| DE2901236A1 (en) | Drive adjusting unit for rotary sheet printing machine - reduces adjusting time for selective first and back-up printing | |

| DE19540573C1 (en) | Device for compensating play in rotary printing machines | |

| DE2740382C2 (en) | Device for adjusting the stroke of an eccentric press | |

| DE2708478C3 (en) | Transfer and turning drum for a sheet-fed rotary printing press | |

| EP1984181B1 (en) | Printing cylinder coupling | |

| EP3008354B1 (en) | Bearing arrangement | |

| DE60005496T2 (en) | DIFFERENTIAL LOCK | |

| DE3702884C1 (en) | Friction clutch with actuating device | |

| DE2323132C2 (en) | Controllable standstill seal | |

| EP0875375B1 (en) | Device for detachably coupling a double toothed wheel |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: UNKNOWN |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE INTERNATIONAL PUBLICATION HAS BEEN MADE |

|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20180814 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| DAV | Request for validation of the european patent (deleted) | ||

| DAX | Request for extension of the european patent (deleted) | ||

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20190612 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 1195699 Country of ref document: AT Kind code of ref document: T Effective date: 20191115 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502017002740 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191030 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191030 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191030 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191030 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200130 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200131 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200130 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191030 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191030 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200302 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20191030 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191030 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200229 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191030 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191030 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191030 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191030 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191030 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191030 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191030 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502017002740 Country of ref document: DE |

|