EP3070019B2 - Stackable wooden box - Google Patents

Stackable wooden box Download PDFInfo

- Publication number

- EP3070019B2 EP3070019B2 EP14828489.6A EP14828489A EP3070019B2 EP 3070019 B2 EP3070019 B2 EP 3070019B2 EP 14828489 A EP14828489 A EP 14828489A EP 3070019 B2 EP3070019 B2 EP 3070019B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- box

- walls

- base

- box according

- boxes

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000005304 joining Methods 0.000 claims description 26

- 239000000853 adhesive Substances 0.000 claims description 9

- 230000001070 adhesive effect Effects 0.000 claims description 9

- 239000011324 bead Substances 0.000 claims description 8

- 239000000463 material Substances 0.000 claims description 8

- 230000000295 complement effect Effects 0.000 claims description 7

- 239000002023 wood Substances 0.000 description 9

- 235000012055 fruits and vegetables Nutrition 0.000 description 8

- 241000220223 Fragaria Species 0.000 description 6

- 238000004519 manufacturing process Methods 0.000 description 5

- 238000004806 packaging method and process Methods 0.000 description 4

- 235000013399 edible fruits Nutrition 0.000 description 3

- 239000003292 glue Substances 0.000 description 3

- 235000021012 strawberries Nutrition 0.000 description 3

- 238000005520 cutting process Methods 0.000 description 2

- 238000006073 displacement reaction Methods 0.000 description 2

- 230000003014 reinforcing effect Effects 0.000 description 2

- 241000251468 Actinopterygii Species 0.000 description 1

- -1 carton Substances 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 230000001934 delay Effects 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 230000008030 elimination Effects 0.000 description 1

- 238000003379 elimination reaction Methods 0.000 description 1

- 230000005802 health problem Effects 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 238000007254 oxidation reaction Methods 0.000 description 1

- 239000011120 plywood Substances 0.000 description 1

- 230000002787 reinforcement Effects 0.000 description 1

- 238000009877 rendering Methods 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D21/00—Nestable, stackable or joinable containers; Containers of variable capacity

- B65D21/02—Containers specially shaped, or provided with fittings or attachments, to facilitate nesting, stacking, or joining together

- B65D21/0209—Containers specially shaped, or provided with fittings or attachments, to facilitate nesting, stacking, or joining together stackable or joined together one-upon-the-other in the upright or upside-down position

- B65D21/0215—Containers with stacking feet or corner elements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D85/00—Containers, packaging elements or packages, specially adapted for particular articles or materials

- B65D85/30—Containers, packaging elements or packages, specially adapted for particular articles or materials for articles particularly sensitive to damage by shock or pressure

- B65D85/34—Containers, packaging elements or packages, specially adapted for particular articles or materials for articles particularly sensitive to damage by shock or pressure for fruit, e.g. apples, oranges or tomatoes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D9/00—Containers having bodies formed by interconnecting or uniting two or more rigid, or substantially rigid, components made wholly or mainly of wood or substitutes therefor

- B65D9/06—Boxes or crates of polygonal cross-section

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D9/00—Containers having bodies formed by interconnecting or uniting two or more rigid, or substantially rigid, components made wholly or mainly of wood or substitutes therefor

- B65D9/32—Details of wooden walls; Connections between walls

- B65D9/34—Joints; Local reinforcements

Definitions

- the present invention a stackable box, relates to a box for transporting products, preferably fruit and vegetable products, which comprises at least one base and four lateral walls as well as joining means between said base and lateral walls, such that said joining is carried out without contact with the products which must be located in the interior of the box. Likewise, it comprises means for facilitating the stacking of boxes, one on top of the other.

- the field of application of the invention is the container sector for storing and transporting products, wooden boxes for storing and transporting fruit and vegetable products.

- boxes are known in the prior art, made from different materials such as carton, wood, plastic etc., used for transporting different items such as for example, fruit and vegetable products, fish, flowers, etc.

- the most common boxes are those which are formed by a flat base and four lateral walls, including in the area of the corners, corner pieces in the form of rectangular prisms used as a reinforcing element.

- the box which is the object of the present invention, comprises at least five independent components (one base and four lateral walls) if no stacking means is present, and nine components (four corner pieces must be added to the aforementioned components) if stacking means are present, all of which are preferably made of wood. It must be added to the foregoing that in order for the product to be profitable, and taking into account its low selling price, the manufacture of the boxes must be carried out in series which means the joining between the components must be carried out quickly and using economic joining means which are usually not very precise.

- Said joining means are traditionally staples arranged between the lateral walls and the corner pieces and the bottom or base. Therefore these joinings, made in an inaccurate and quick manner, prevent the positioning of the different components being accurate in each box, differences may thus exist with respect to the positions of the same components in different boxes. Said differences, derived from the fact that the stapling or sticking of the components does not provide the concrete precision which facilitates stacking, make quick and simple stacking difficult for the boxes since the upper part of the corner piece does not usually fit with the first in the cavity arranged in the lower part of the corresponding corner piece of the other box, which delays the packaging of the product with the consequent, mainly economic, results. Likewise, and due to the materials of the boxes, preferably wood or derivative products, which are not particularly resistant, if the stacking of one box on another is forced, it is possible to damage the same with consequent loss, since products may spill out from boxes already stacked.

- some boxes from the prior art comprise a rectangular bottom or base such that the four corners of said base coincide with the right angles formed by the walls, completely closing the housing or receptacle for the products, said housing being formed by the walls and the base.

- These boxes comprise four corner pieces for stacking the same.

- the corner pieces of a lower box are placed into contact with the base of an upper box which means that the height of the column of stacked boxes depends on three factors which directly affect the correct stacking and therefore the verticality of the column which leads to inclinations and falling of the columns which is worsened when the boxes are full with products.

- Other boxes comprise four walls, a base and four corner pieces, all of which are joined together by means of staples, the base remaining below the walls as has been mentioned previously.

- corner pieces with their flat upper and lower ends, without mechanization, are located with their lower end coinciding with the lower side of the wall, such that when different boxes are stacked, the upper ends of the corner piece of one lower box contact and are supported on the lower ends of the corner piece of an upper box.

- the horizontal displacement of the upper box with respect to the lower box is prevented exclusively by the thickness of the base of the box which protrudes underneath with respect to the walls, and taking into account that the thickness of said base does not usually exceed 3 mm and that small defects may exist in the manufacture and/or fitting of the components, the risk of displacement of one box with respect to another is high, which thus may affect the stacking of various boxes, with or without products.

- the present invention aims to resolve the aforementioned problems existing in the wooden boxes of the prior art the base of which is joined to the walls and/or corner pieces by means of staples and/or adhesives.

- the stackable box which the present invention proposes, has as its object a box according to Claim 1, made of wood, for storing and transporting products, preferably fruit and vegetables and more preferably strawberries and/or strawberry plants, which comprises at least one base and four lateral walls, having joining means between said base and the lateral walls, together forming a housing, and said joining means consisting of a bead of adhesive material, in the manner of a ledge which extends on the lateral walls and through the exterior part of the housing, said bead constituting the support of the base which is displace, in terms of height, a distance with respect to the lower side of the lateral walls and remains incorporated between the walls, such that the contact between the joining means and contents of the box is prevented.

- the walls of the box may be formed by more than one panel, for example, two, one located on top of another, as a function of the dimensions of the box and if the conditions so require.

- Said base remains incorporated between the four walls, supported on the bead of adhesive and displaced, in terms of height, a specified distance with respect to the lower side of the lateral walls, said distance preferably being approximately 3 mm.

- the same includes four corner pieces, blocks or columns with triangular section, each one with an upper and lower end, and arranged in the interior of the housing in each of the corners formed by each pair of walls.

- Said corner pieces are formed by prisms with triangular base made of wood with a greater length than that of the walls of the box.

- the corner pieces are joined to the lateral walls by means of joining means which are preferably mechanical, and more preferably staples which remain pressed into the interior of the corner piece, without reaching the interior of the box and saving the contents of the box from contact with said staples.

- the base of the box which is a general rectangular form, has, when the box comprises the mentioned corner pieces, its four corners cut into chamfers, allowing the passage of the corner pieces which pass through the bottom or base of the box since the cut in the base is slightly greater than the section of the corner pieces.

- this cut in the base it is possible for the boxes to be stacked thanks to the direct contact between the corner pieces of one box with the corner pieces of the upper box or the lower box, that is to say, the lower end of the corner pieces of one box is directly supported on the upper end of the corner pieces of the box located immediately below. In this way, there only exists one factor of variability when stacking the different boxes, exclusively the length of the mentioned corner pieces, which may affect the stability of a column of stacked boxes.

- Said corner pieces may have, at their upper end, a mount or projection laterally reduced with respect to the section of the corner piece which may be semicircular or triangular, directly machined onto the corner piece, which is preferably complementary with respect to a recess or cavity formed at the lower end of the corner piece, thus facilitating the stacking of boxes and making it difficult for the upper boxes to fall due to poor positioning.

- the lower end of the corner piece may also lack a cavity and be flat.

- the mount or the cavity may be inverted, such that the upper end comprises a cavity and the lower end comprises a mount or similar complemented by the upper end of the corner piece.

- the mount has a complementary form with respect to a free space formed at the lower end of the corner piece.

- Said corner pieces may be located, either at the same height as the lower side of the walls, that is to say, flush with the latter or on the contrary, may be located slightly displaced in height towards the top, that is to say, the lower end of the corner piece approximating the upper side of the wall, with respect to said lower side of the walls.

- the mounts and recesses at the ends of the corner pieces allow small constructive errors in the boxes due to the inaccuracies in the manufacturing of the same to be avoided, facilitating, thanks to these recesses, the introduction of the corner pieces through the cuts made in the bases as well as avoiding contact with the walls during stacking.

- the present invention has been developed with the purpose of providing a structurally-resistant stackable box and without the risk of breakage.

- the figures of the invention thus show a box mainly comprising a base (1) formed by a substantially rectangular laminate body having the chamfered corners and four lateral walls (2), forming a housing, and reinforced by corner pieces (3) arranged in each one of the corners of the interior area formed by the box or housing, having joining means between the base (1) and the lateral walls (2).

- Said joining means preferably consisting of a bead of adhesive material (4) such as a type of glue commonly used in the foodstuffs sector which passes through the exterior area of the box and of the housing (see Figure 3 ) such that it is not in direct contact with the stored products (not shown) which may be located in the housing of the box for transport and handling.

- Said bead remains hidden below the base (1) which is incorporated between the four lateral walls (2).

- the dimensions of the box may vary in the ranges of 185-600 mm in length, 165-400 mm in width and 50-300 mm in height, as a function of the purpose or use envisaged.

- figures 1, 2 , 4 and 5 show a box having corner pieces (3) which have, at their upper end, a semi-circular mount (30) which projects vertically and which has a complementary form with respect to a recess (31) formed at the lower end of the corner piece (see figures 1 and 2 ), the lower end of each corner piece (3) being aligned or flush with the lower side of the walls (2).

- the figures 4 and 5 show an example of stacking of two boxes which exhibit the lower end of the corner pieces (3) aligned with the lower side of the walls (2) and showing a cavity (31) in said lower end such that the boxes are stacked by way of the dovetail of the mounts with the complementary cavities.

- the corner pieces (3) are displaced, for example 5 mm in a vertically upwards direction, towards the interior of the housing of the box such that the lower end of the corner piece (3) approximates the upper side of the wall (2) in order to thus facilitate the stacking of the boxes, leaving an empty space between the lower end of the corner piece and the lower side of the wall to introduce the corner pieces of the following box into said hole.

- This stacking may be observed in Figure 6 and in the detail of the same, where the corner pieces (3) are displaced and the upper ends have lateral recesses, triangular protrusion or projection (300) with respect to the section of the corner piece and the lower ends do not have cavities as in the previously described embodiment.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- Wood Science & Technology (AREA)

- Stackable Containers (AREA)

- Cartons (AREA)

Description

- The present invention, a stackable box, relates to a box for transporting products, preferably fruit and vegetable products, which comprises at least one base and four lateral walls as well as joining means between said base and lateral walls, such that said joining is carried out without contact with the products which must be located in the interior of the box. Likewise, it comprises means for facilitating the stacking of boxes, one on top of the other.

- The field of application of the invention is the container sector for storing and transporting products, wooden boxes for storing and transporting fruit and vegetable products.

- A wide variety of boxes are known in the prior art, made from different materials such as carton, wood, plastic etc., used for transporting different items such as for example, fruit and vegetable products, fish, flowers, etc.

- The most common boxes are those which are formed by a flat base and four lateral walls, including in the area of the corners, corner pieces in the form of rectangular prisms used as a reinforcing element.

- To carry out the joining between such lateral walls and the base, the use of metallic staples is common (see

FR 1199102 A - Alternative joining means between the base and the walls of the box are adhesive means (see

EP 1609727 A1 ). The problem with these adhesive means is that, in addition to contacting the contents of the box, they are not reliable enough which is why there is the risk that they release when the box is being handled. Going into greater detail on the above, a box comprising its base adhered to the walls or corners pieces, poses the problem that, as already mentioned, the base may release from the walls or corner pieces due to incorrect handling of the box or also, that the base is released due to the weight exerted by the products stored in the same, which would push the base downwards causing the ripping of the box, unless reinforcing lower slats are used which in turn must also be joined to some of the components of the box. Likewise, it must be pointed out that due to the heterogeneities of the wood and the inaccuracies which are produced in the cuttings of the boards, it is frequently the case that the dimensions of the boards which are used in the wooden packaging have considerable intolerances. If these imperfections are mainly produced in the base, the same cannot, in any case, be joined by means of the edge to the lateral walls in those areas in which the dimension of the bottom is lower than the nominal amount. Therefore, in those boxes which use adhesive as joining means, there is a high risk of the ripping of the box when the base releases from the lateral walls or from the columns of the corners. Furthermore, in order to solve this problem derived from the heterogeneities of the base either an inversion in the cutting processes of the different pieces comprising the box could take place, or a greater supply of glue to preserve said heterogeneities is provided, either of these two measures making the product more expensive and the second measure increasing the risk of a greater quantity of glue entering into contact with the contents of the box. - Likewise, another existing problem is related to the stacking of the boxes, which stacking may take place, for example, when they are manufactured, when the product is stored in their interior, when they have to be transported or when they have to be stored for their subsequent distribution or sale, and it is due to said boxes not having effective positioning means which facilitate and help the user to handle the boxes in order to place one box on top of another in a completely stable manner, effectively and quickly. The wooden boxes require the stacking thereof to be quick and effective since time is an important factor when the boxes are being filled, such that they must be filled and they must be stacked with great speed, which is why it is necessary to improve and facilitate the stacking of said boxes. It must be taken into account that the wooden boxes for transporting and storing fruit and vegetable products are formed from different components joined together by means of different joining means and in particular, the box, which is the object of the present invention, comprises at least five independent components (one base and four lateral walls) if no stacking means is present, and nine components (four corner pieces must be added to the aforementioned components) if stacking means are present, all of which are preferably made of wood. It must be added to the foregoing that in order for the product to be profitable, and taking into account its low selling price, the manufacture of the boxes must be carried out in series which means the joining between the components must be carried out quickly and using economic joining means which are usually not very precise. Said joining means are traditionally staples arranged between the lateral walls and the corner pieces and the bottom or base. Therefore these joinings, made in an inaccurate and quick manner, prevent the positioning of the different components being accurate in each box, differences may thus exist with respect to the positions of the same components in different boxes. Said differences, derived from the fact that the stapling or sticking of the components does not provide the concrete precision which facilitates stacking, make quick and simple stacking difficult for the boxes since the upper part of the corner piece does not usually fit with the first in the cavity arranged in the lower part of the corresponding corner piece of the other box, which delays the packaging of the product with the consequent, mainly economic, results. Likewise, and due to the materials of the boxes, preferably wood or derivative products, which are not particularly resistant, if the stacking of one box on another is forced, it is possible to damage the same with consequent loss, since products may spill out from boxes already stacked.

- In relation to stacking, some boxes from the prior art comprise a rectangular bottom or base such that the four corners of said base coincide with the right angles formed by the walls, completely closing the housing or receptacle for the products, said housing being formed by the walls and the base. These boxes comprise four corner pieces for stacking the same. In this way, in order to stack these boxes, the corner pieces of a lower box are placed into contact with the base of an upper box which means that the height of the column of stacked boxes depends on three factors which directly affect the correct stacking and therefore the verticality of the column which leads to inclinations and falling of the columns which is worsened when the boxes are full with products.

- Other boxes comprise four walls, a base and four corner pieces, all of which are joined together by means of staples, the base remaining below the walls as has been mentioned previously. In addition to this is the fact that the corner pieces, with their flat upper and lower ends, without mechanization, are located with their lower end coinciding with the lower side of the wall, such that when different boxes are stacked, the upper ends of the corner piece of one lower box contact and are supported on the lower ends of the corner piece of an upper box. By means of this arrangement, the horizontal displacement of the upper box with respect to the lower box is prevented exclusively by the thickness of the base of the box which protrudes underneath with respect to the walls, and taking into account that the thickness of said base does not usually exceed 3 mm and that small defects may exist in the manufacture and/or fitting of the components, the risk of displacement of one box with respect to another is high, which thus may affect the stacking of various boxes, with or without products.

- It is normal that the stacking may exceed 15 boxes, which is why small errors in each box add up and may reach a point whereby the stability of the column of boxes is in danger.

- Said factors are:

- Length of the corner piece, block or prisms with triangular base, since when a material such as wood is involved combined with the manufacturing procedure, inaccuracies in the measurement of the length of said corner piece are frequent,

- Thickness of the bottom or base, since when a material such as wood is involved, said thickness is not always constant, in addition to the fact that during the positioning of the bottom or base for fitting the box, it cannot always be achieved for the box to not be slightly inclined, and

- Separation of the corner piece and base joining, which is not always constant depending on the manufacturing procedure.

- The present invention aims to resolve the aforementioned problems existing in the wooden boxes of the prior art the base of which is joined to the walls and/or corner pieces by means of staples and/or adhesives.

- The stackable box, which the present invention proposes, has as its object a box according to

Claim 1, made of wood, for storing and transporting products, preferably fruit and vegetables and more preferably strawberries and/or strawberry plants, which comprises at least one base and four lateral walls, having joining means between said base and the lateral walls, together forming a housing, and said joining means consisting of a bead of adhesive material, in the manner of a ledge which extends on the lateral walls and through the exterior part of the housing, said bead constituting the support of the base which is displace, in terms of height, a distance with respect to the lower side of the lateral walls and remains incorporated between the walls, such that the contact between the joining means and contents of the box is prevented. The walls of the box may be formed by more than one panel, for example, two, one located on top of another, as a function of the dimensions of the box and if the conditions so require. - Thanks to these characteristics, the use of angular staples between the base and the lateral walls used in wooden boxes of the prior art is eliminated, such that direct contact between the joining means and the product stored in the housing of the box formed by the walls and base is prevented. This property may be relevant, in particular when fruit and vegetable products are being transported such as soft fruits, for example strawberries and/or strawberry plants since this avoid such products becoming marked by the presence of the joining elements, as happens in the prior art. Likewise, the bead of adhesive through the exterior of the box and below the housing causes said bead to act as a perimeter ledge, supporting both the handling of the box as well as the weight of the products, rendering the use of additional reinforcement means unnecessary, which prevent the box ripping if the base falls.

- Said base remains incorporated between the four walls, supported on the bead of adhesive and displaced, in terms of height, a specified distance with respect to the lower side of the lateral walls, said distance preferably being approximately 3 mm. With the base remaining incorporated between the walls, this provides the box with improved torsion resistance and consequently this packaging being more suitable for transporting and distributing products, whose integrity must be preserved.

- The elimination of the angular staples which join the base and lateral walls in the boxes of the prior art, also prevents obstruction of the marked area which serves as commercial projection for the companies which use this type of packaging, achieving clear and cleaner surfaces.

- In order to provide the box with greater resistance and to enable the stacking thereof, the same includes four corner pieces, blocks or columns with triangular section, each one with an upper and lower end, and arranged in the interior of the housing in each of the corners formed by each pair of walls. Said corner pieces are formed by prisms with triangular base made of wood with a greater length than that of the walls of the box. The corner pieces are joined to the lateral walls by means of joining means which are preferably mechanical, and more preferably staples which remain pressed into the interior of the corner piece, without reaching the interior of the box and saving the contents of the box from contact with said staples.

- The base of the box which is a general rectangular form, has, when the box comprises the mentioned corner pieces, its four corners cut into chamfers, allowing the passage of the corner pieces which pass through the bottom or base of the box since the cut in the base is slightly greater than the section of the corner pieces. By means of this cut in the base, it is possible for the boxes to be stacked thanks to the direct contact between the corner pieces of one box with the corner pieces of the upper box or the lower box, that is to say, the lower end of the corner pieces of one box is directly supported on the upper end of the corner pieces of the box located immediately below. In this way, there only exists one factor of variability when stacking the different boxes, exclusively the length of the mentioned corner pieces, which may affect the stability of a column of stacked boxes.

- Said corner pieces may have, at their upper end, a mount or projection laterally reduced with respect to the section of the corner piece which may be semicircular or triangular, directly machined onto the corner piece, which is preferably complementary with respect to a recess or cavity formed at the lower end of the corner piece, thus facilitating the stacking of boxes and making it difficult for the upper boxes to fall due to poor positioning. The lower end of the corner piece may also lack a cavity and be flat. Likewise, the mount or the cavity may be inverted, such that the upper end comprises a cavity and the lower end comprises a mount or similar complemented by the upper end of the corner piece. In one alternative embodiment, there is the possibility that the mount has a complementary form with respect to a free space formed at the lower end of the corner piece.

- Said corner pieces may be located, either at the same height as the lower side of the walls, that is to say, flush with the latter or on the contrary, may be located slightly displaced in height towards the top, that is to say, the lower end of the corner piece approximating the upper side of the wall, with respect to said lower side of the walls.

- Proceeding from the foregoing, two types of boxes may preferably be constructed:

- A first type of box or dovetail box which comprises corner pieces having an upper end provided with a semi-circular mount, protrusion or projection and a lower end having a cavity or recess with a form complementary to the mount of the upper end, and said lower end being at the level of the lower side of the wall. In this way, when stacking two boxes with this configuration, the mount of the upper end of the corner piece of the first box or lower box, is introduced through the dovetail in the cavity of the lower end of the corner piece of the second box or upper box when the mount and the cavity are complementary.

- A second type of box or box with projections, which comprises corner pieces having an upper end provided with a projection slightly reduced with respect to the section of the corner piece and a lower end which is not machined, thus being flat and this lower end of the corner piece being slightly displaced with respect to the lower side of the wall, towards the interior of the housing. In this way, when stacking two boxes with this configuration, the recess at the upper end of the corner piece of the first box or lower box, contacts the flat lower end of the corner piece of the second box or upper box which is supported on the first.

- The mounts and recesses at the ends of the corner pieces allow small constructive errors in the boxes due to the inaccuracies in the manufacturing of the same to be avoided, facilitating, thanks to these recesses, the introduction of the corner pieces through the cuts made in the bases as well as avoiding contact with the walls during stacking.

- Due to these corner pieces and their characteristics, the stacking of this type of box is made possible, avoiding the risk of them being placed in an incorrect manner when being stacked in columns with the consequent risk of damaging the product to be transported, and this situation being particularly sensitive when the products are fruit and vegetables where the falling of the boxes may damage the exterior of the pieces of fruit.

- The present invention has been developed with the purpose of providing a structurally-resistant stackable box and without the risk of breakage.

-

-

Figure 1 is a top perspective view of a box according to the present invention. -

Figure 2 is a lower perspective view of the box represented inFigure 1 . -

Figure 3 is an elevated sectioned view of a lateral section of the box according to the invention. -

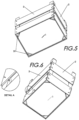

Figure 4 is a perspective view from above of two stacked boxes, one with respect to the other where the corner pieces include mounts. -

Figure 5 is a perspective view from below of two stacked boxes, one with respect to the other. -

Figure 6 is a perspective view of another alternative embodiment of two stacked boxes with the corner pieces provided with projections. -

Figure 7 is a perspective view of a box according to the invention provided with projections as opposed to mounts as inFigures 1 and 2 . - Below follows a description of preferred exemplary embodiments, based on the attached figures and on the adopted numeration of the same, of two stackable boxes made of wood for transporting and storing fruit and vegetable products, such as strawberries and/or strawberry plants.

- The figures of the invention thus show a box mainly comprising a base (1) formed by a substantially rectangular laminate body having the chamfered corners and four lateral walls (2), forming a housing, and reinforced by corner pieces (3) arranged in each one of the corners of the interior area formed by the box or housing, having joining means between the base (1) and the lateral walls (2). Said joining means preferably consisting of a bead of adhesive material (4) such as a type of glue commonly used in the foodstuffs sector which passes through the exterior area of the box and of the housing (see

Figure 3 ) such that it is not in direct contact with the stored products (not shown) which may be located in the housing of the box for transport and handling. Said bead remains hidden below the base (1) which is incorporated between the four lateral walls (2). - It must be mentioned that the fixing of the corner pieces (3) and the associated lateral walls is carried out by means of mechanical joining means, such as staples (5), preferably metallic, the placement of which is carried out by means of the use of conventional means which it is not necessary to specify.

- The dimensions of the box may vary in the ranges of 185-600 mm in length, 165-400 mm in width and 50-300 mm in height, as a function of the purpose or use envisaged.

- In one particularly preferred embodiment,

figures 1, 2 ,4 and5 show a box having corner pieces (3) which have, at their upper end, a semi-circular mount (30) which projects vertically and which has a complementary form with respect to a recess (31) formed at the lower end of the corner piece (seefigures 1 and 2 ), the lower end of each corner piece (3) being aligned or flush with the lower side of the walls (2). Thefigures 4 and5 show an example of stacking of two boxes which exhibit the lower end of the corner pieces (3) aligned with the lower side of the walls (2) and showing a cavity (31) in said lower end such that the boxes are stacked by way of the dovetail of the mounts with the complementary cavities. - In an alternative embodiment, shown in

figures 6 and7 , the corner pieces (3) are displaced, for example 5 mm in a vertically upwards direction, towards the interior of the housing of the box such that the lower end of the corner piece (3) approximates the upper side of the wall (2) in order to thus facilitate the stacking of the boxes, leaving an empty space between the lower end of the corner piece and the lower side of the wall to introduce the corner pieces of the following box into said hole. One example of this stacking may be observed inFigure 6 and in the detail of the same, where the corner pieces (3) are displaced and the upper ends have lateral recesses, triangular protrusion or projection (300) with respect to the section of the corner piece and the lower ends do not have cavities as in the previously described embodiment.

Claims (12)

- Stackable wooden box for storing and transporting products, which comprises at least one base (1) and four lateral walls (2), having joining means between said base (1) and lateral walls (2), forming a housing between said walls (2) and the base (1), characterized in that said joining means consists of a bead of adhesive material (4) in the manner of a ledge, which extends on the lateral walls (2) and through the exterior part of the housing, displaced, in terms of height, a distance with respect to the lower side of the lateral walls (2), constituting the support of the base (1) which remains incorporated between the walls (2) and preventing the contact between the joining means (4) and contents of the box.

- Box according to Claim 1, characterized in that said distance is approximately 3 mm.

- Box according to Claim 1, characterized in that it comprises four corner pieces (3) with triangular section, each one having an upper end and a lower end, arranged in the interior of the housing in each one of the corners formed by each pair of walls (2).

- Box according to Claim 3, characterized in that the corner pieces (3) are joined to the walls by means of mechanical joining means.

- Box according to Claim 4, characterized in that the mechanical joining means are staples (5).

- Box according to Claim 3, characterized in that the upper end has a mount (30, 300) or similar.

- Box according to Claim 6, characterized in that the lower end has a cavity or recess (31) with a form complementary to that of the mount (30, 300) of the upper end of the corner piece (3) for housing the mount (30, 300) of another box when they are stacked.

- Box according to Claims 6 and 7, characterized in that the mount (30) and the cavity (31) are semi-circular.

- Box according to Claims 6 and 7, characterized in that the mount (300) and the cavity are triangular.

- Box according to Claim 3, characterized in that the lower end of the corner piece (3) is located at the same height as the lower side of the walls (2).

- Box according to Claim 3, characterized in that the lower end of the corner piece (3) is located displaced in height with respect to the lower side of the walls (2).

- Box according to Claim 1, characterized in that the base (1) is rectangular having four corners cut into chamfers.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| ES201331428U ES1111083U (en) | 2013-12-12 | 2013-12-12 | Stackable box for the transportation of products (Machine-translation by Google Translate, not legally binding) |

| ES201331429U ES1101556U (en) | 2013-12-12 | 2013-12-12 | Stackable box for the transportation of products (Machine-translation by Google Translate, not legally binding) |

| PCT/ES2014/070915 WO2015086884A1 (en) | 2013-12-12 | 2014-12-12 | Stackable wooden box |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP3070019A1 EP3070019A1 (en) | 2016-09-21 |

| EP3070019B1 EP3070019B1 (en) | 2017-07-05 |

| EP3070019B2 true EP3070019B2 (en) | 2023-11-01 |

Family

ID=53370662

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP14828489.6A Active EP3070019B2 (en) | 2013-12-12 | 2014-12-12 | Stackable wooden box |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP3070019B2 (en) |

| ES (1) | ES2641868T5 (en) |

| PT (1) | PT3070019T (en) |

| WO (1) | WO2015086884A1 (en) |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB201205243D0 (en) | 2012-03-26 | 2012-05-09 | Kraft Foods R & D Inc | Packaging and method of opening |

| GB2511559B (en) | 2013-03-07 | 2018-11-14 | Mondelez Uk R&D Ltd | Improved Packaging and Method of Forming Packaging |

| GB2511560B (en) | 2013-03-07 | 2018-11-14 | Mondelez Uk R&D Ltd | Improved Packaging and Method of Forming Packaging |

| RS59715B1 (en) | 2017-05-19 | 2020-01-31 | Erkic Ivan | Multipurpose modular box with counterconical slide-track connecting system |

| ES2717667B2 (en) * | 2017-12-22 | 2020-07-28 | Fruit Packaging Innovations S L | MANUFACTURING PROCESS OF A REMOVABLE AND STACKABLE BOX |

| CN113044409B (en) * | 2021-04-25 | 2022-05-03 | 福建省农通科技发展有限公司 | Nanometer fresh-keeping dampproofing calcium-plastic case |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ES2285957A1 (en) † | 2007-03-23 | 2007-11-16 | Industrias Monzon Xii, S.L. | Box for storage and transportation of vegetables and fruits, has base in superior plane formed by interior part of lateral wall, which allows inserting columns of other boxes in space during stacking |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1199102A (en) * | 1958-06-12 | 1959-12-11 | Recoverable crate | |

| FR2617129B1 (en) * | 1987-06-29 | 1990-02-02 | Alazard Sarl Emballages | STACKABLE CONTAINER FOR THE TRANSPORT OF FRUIT |

| FR2870831A1 (en) | 2004-09-10 | 2005-12-02 | Roland Jean Marc Noilhan | One-way wooden container for e.g. fruits, has two side boards and two head boards connected to base by four foldable material strips, and semi cleat divided into two half semi cleats when assembling strip is torn or cut |

-

2014

- 2014-12-12 PT PT148284896T patent/PT3070019T/en unknown

- 2014-12-12 ES ES14828489T patent/ES2641868T5/en active Active

- 2014-12-12 EP EP14828489.6A patent/EP3070019B2/en active Active

- 2014-12-12 WO PCT/ES2014/070915 patent/WO2015086884A1/en active Application Filing

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ES2285957A1 (en) † | 2007-03-23 | 2007-11-16 | Industrias Monzon Xii, S.L. | Box for storage and transportation of vegetables and fruits, has base in superior plane formed by interior part of lateral wall, which allows inserting columns of other boxes in space during stacking |

Also Published As

| Publication number | Publication date |

|---|---|

| EP3070019B1 (en) | 2017-07-05 |

| ES2641868T3 (en) | 2017-11-14 |

| WO2015086884A1 (en) | 2015-06-18 |

| ES2641868T5 (en) | 2024-03-27 |

| EP3070019A1 (en) | 2016-09-21 |

| PT3070019T (en) | 2017-10-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3070019B2 (en) | Stackable wooden box | |

| ES2665557T3 (en) | Pallet room | |

| US3323674A (en) | Collapsible container | |

| US6889893B2 (en) | Stackable container with stack-tabs | |

| US3434648A (en) | Reinforced container structure | |

| US20090188411A1 (en) | Structural cardboard runner, pallet, shipping article | |

| RU2627000C2 (en) | Bendable box workpiece | |

| JPS58501321A (en) | shipping pallet | |

| US8418854B2 (en) | Tray and hood package | |

| WO2000071428A1 (en) | Package, comprising a series of subpackages | |

| US7959007B1 (en) | Shipping and display container with article support | |

| US3203612A (en) | Partition member | |

| WO2012088297A1 (en) | Hybrid shipping container | |

| US20160194107A1 (en) | Reconfigurable container partitions and their assembly | |

| BR112012017329B1 (en) | shipping container system and presentation and use | |

| US4211358A (en) | Lug box having cored-out plastic end walls | |

| US20110011312A1 (en) | Pallet for containing and transporting objects | |

| US9701462B2 (en) | Nestable carton for wheelbarrow kit | |

| US10264900B2 (en) | Foodstuff support device | |

| JP5441664B2 (en) | chopping board | |

| GB2123794A (en) | Box pallets | |

| CN209291012U (en) | Carton with pallet | |

| JPH0335716Y2 (en) | ||

| US20140124403A1 (en) | Front-To-Front Low Position Tray | |

| ES1304421U (en) | Cardboard packaging for fruit and vegetable products (Machine-translation by Google Translate, not legally binding) |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20160606 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| DAX | Request for extension of the european patent (deleted) | ||

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| INTG | Intention to grant announced |

Effective date: 20170503 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 906416 Country of ref document: AT Kind code of ref document: T Effective date: 20170715 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602014011598 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: SC4A Ref document number: 3070019 Country of ref document: PT Date of ref document: 20171004 Kind code of ref document: T Free format text: AVAILABILITY OF NATIONAL TRANSLATION Effective date: 20170926 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20170705 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2641868 Country of ref document: ES Kind code of ref document: T3 Effective date: 20171114 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 906416 Country of ref document: AT Kind code of ref document: T Effective date: 20170705 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 4 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170705 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170705 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171005 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170705 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170705 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170705 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170705 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170705 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170705 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171005 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171006 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170705 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171105 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R026 Ref document number: 602014011598 Country of ref document: DE |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170705 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170705 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170705 |

|

| 26 | Opposition filed |

Opponent name: FEDERACION ESPANOLA DEL ENVASE DE MADERA Y SUS COM Effective date: 20180405 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170705 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170705 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170705 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 602014011598 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170705 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171212 Ref country code: MT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171212 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20171231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180703 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171212 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171231 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171231 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170705 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20141212 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20181212 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170705 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170705 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181212 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170705 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170705 |

|

| APBM | Appeal reference recorded |

Free format text: ORIGINAL CODE: EPIDOSNREFNO |

|

| APBP | Date of receipt of notice of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA2O |

|

| APAH | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOSCREFNO |

|

| APBQ | Date of receipt of statement of grounds of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA3O |

|

| APBY | Invitation to file observations in appeal sent |

Free format text: ORIGINAL CODE: EPIDOSNOBA2O |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| R26 | Opposition filed (corrected) |

Opponent name: FEDERACION ESPANOLA DEL ENVASE DE MADERA Y SUS COMPONENTES - FEDEMCO Effective date: 20180405 |

|

| APBU | Appeal procedure closed |

Free format text: ORIGINAL CODE: EPIDOSNNOA9O |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230619 |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 20231101 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R102 Ref document number: 602014011598 Country of ref document: DE |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PT Payment date: 20231129 Year of fee payment: 10 Ref country code: IT Payment date: 20231220 Year of fee payment: 10 Ref country code: FR Payment date: 20231227 Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: DC2A Ref document number: 2641868 Country of ref document: ES Kind code of ref document: T5 Effective date: 20240327 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20240110 Year of fee payment: 10 |