EP3023031A1 - Paint brush - Google Patents

Paint brush Download PDFInfo

- Publication number

- EP3023031A1 EP3023031A1 EP14194160.9A EP14194160A EP3023031A1 EP 3023031 A1 EP3023031 A1 EP 3023031A1 EP 14194160 A EP14194160 A EP 14194160A EP 3023031 A1 EP3023031 A1 EP 3023031A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- bristles

- paint brush

- paint

- range

- length

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46B—BRUSHES

- A46B9/00—Arrangements of the bristles in the brush body

- A46B9/02—Position or arrangement of bristles in relation to surface of the brush body, e.g. inclined, in rows, in groups

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46B—BRUSHES

- A46B2200/00—Brushes characterized by their functions, uses or applications

- A46B2200/20—Brushes for applying products to surfaces in general

- A46B2200/202—Applicator paint brush

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46B—BRUSHES

- A46B3/00—Brushes characterised by the way in which the bristles are fixed or joined in or on the brush body or carrier

- A46B3/08—Brushes characterised by the way in which the bristles are fixed or joined in or on the brush body or carrier by clamping

- A46B3/10—Brushes characterised by the way in which the bristles are fixed or joined in or on the brush body or carrier by clamping into rings or the like

- A46B3/12—Brushes characterised by the way in which the bristles are fixed or joined in or on the brush body or carrier by clamping into rings or the like specially adapted for paint-brushes

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46D—MANUFACTURE OF BRUSHES

- A46D1/00—Bristles; Selection of materials for bristles

- A46D1/02—Bristles details

- A46D1/0207—Bristles characterised by the choice of material, e.g. metal

Definitions

- the present invention is directed to a paint brush in accordance with the preamble of claim 1.

- paint brushes In the prior art there are generally known paint brushes. Within the brushes there are distinguished paint brushes and brushes for cleaning purposes, e.g. tooth brushes and the like.

- Brushes for cleaning purposes differ from paint brushes in that their bristles have a high stiffness making it possible to scratch away particles which adhere at a surface to be cleaned.

- the bristles are usually fixed at a bristle carrier such that a clearance is formed in between the bristles, e.g. the bristles are not in contact with each other. It is also possible that there are formed groups of bristles and that between the groups of the bristles there is formed the clearance for discharging the particles.

- Paint brushes are usually made of bristles having a smaller stiffness than the bristles used for brushes for cleaning purposes. Essentially, all adjacent bristles of a paint brush are in contact with each other. The bristles form a bristle pack or brush head, respectively, which is able to hold therein a paint by adhesion as well as capillary forces. When painting the brush head is pressed onto the surface to be painted by the hand of the operator. Thereby, the bristles are bent and the paint being held between the bristles is forced to flow out of the brush head as it is moved along the surface to be painted.

- Common paint brushes have a bristle head made of bristles having a length of 4 to 11 cm.

- the bristles are usually natural bristles, e.g. a root diameter in a root section of the bristles is typically between 0,17 and 0,35 mm, whereas a tip diameter in a tip section is in the range of 0,11 to 0,13 mm.

- a paint brush in accordance with the preamble of claim 1 is known from US 5,220,702 .

- the known paint brush is composed of a core of short thick hairs with long fine hairs surrounding said core and substantially longer stiff bristles dispersed throughout said core of thick hairs.

- the known paint brush is used to draw very fine lines. It has the capability to store a large amount of paint within the brush head.

- US 2005/0229346 A1 discloses a paint brush having a brush head containing a continuum of bristles configured from a plurality of primary short bristles and secondary longer bristles with split and smaller diameter distal extremities.

- a coating made of a modern paint and being applied by a conventional paint brush has a poorer surface quality than a coating made of a conventional paint.

- Fig. 1 shows a schematically cross section through a first coating C1 made of a conventional paint by use of a conventional paint brush and Fig. 2 showing a cross section through a second coating C2 made by a modern paint by use the same conventional paint brush.

- Reference sign S designates an substrate upon which the respective coating is provided.

- bristle an elongated flexible body having just one first end and just one second end.

- the first end is part of a root section where the bristle is fastened in a bristle carrier.

- Said root section may have a length of 5 to 10 mm.

- root diameter there is understood an average diameter of the bristle in the root section.

- a second end of the bristle forms a free tip which usually contacts a surface to be coated with paint.

- the second end is part of the tip section of the bristle.

- the tip section has a length of 5 to 10 mm.

- tip diameter there is understood an average diameter of the bristle in the tip section.

- essentially all bristles there is understood that at least 80%, preferably at least 90%, and most preferably at least 95% of the adjacent bristles are in direct contact with each other.

- a plurality of bristles is fastened to said bristle carrier such that essentially all adjacent bristles are in contact with each other.

- the bristles form a pack or bristle head, respectively.

- the pack is a continuum where essentially all bristles are in contact.

- the first bristles surround at least partly the second bristles and thereby laterally support the second bristles in order to keep them upright.

- the "stiffness" or bending stiffness, respectively, can be measured e.g. with a bending stiffness measurement apparatus which is e.g. provided by the company Lorentzen & Wettre GmbH. 10 pieces of bristles are measured in analogy to DIN 53121 which describes the determination of the bending stiffness measured in accordance with the beam method (see also ISO 2493). The bending stiffness is measured in centinewton (cN).

- a 50 mm long bristle is clamped in jaws of the measurement apparatus at a distance of 1,0 mm to a load sensor.

- the bristle is then bent up to an angle of 30° and again back to 0° while a maximum force is measured in cN.

- Such modern paint is also called "low-VOC paint” and may be e.g. an acrylic paint, an acrylic lacquer, a water-based lacquer and the like.

- d is in the range of 5 to 15 mm, preferably in the range of 6 to 9 mm.

- the first bristles may have a first tip diameter in the range of 0,1 to 0,2 mm.

- the second bristles may have a second tip diameter in the range of 0,04 to 0,08 mm.

- first and the second bristles may be made of the same material. This allows a cheap and easy production of the paint brush.

- the first and the second bristles have a uniform physico-chemical behavior with respect to the paint or a solvent.

- the first and the second bristles may be made of a natural or a synthetic material.

- the natural material can be e.g. hog or goat bristles or bristles of other animal.

- the synthetic material may be selected from the following group: PE, PA, PET, PBT.

- the synthetic material may be mixture of the aforementioned materials.

- the bristles may have a conical or cylindrical shape.

- bristles made of a synthetic material may have the following cross sections: solid, hollow, trilocular, quadrilocular.

- the material may be provided with small holes, the total volume of which may be in the range of 10 to 30 Vol.%.

- the tip section of the bristles may be treated mechanically or chemically. The tip section may be tipped or flagged.

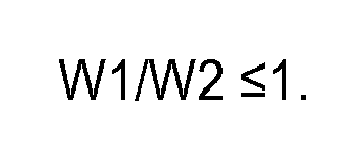

- a weight ratio between a first weight W1 of the first bristles and a second weight W2 of the second bristles may satisfy the following relation: W 1 / W 2 ⁇ 1.

- first weight W1 there is understood the total weight of all first bristles contained in the bristle head

- second weight W2 there is understood the total weight of all second bristles contained in the bristle head

- the weight ratio W1M/2 may be in the range of 0,4 to 0,8, preferably in the range of 0,5 to 0,7.

- the first weight W1 of all first bristles may be 30 to 50% of the total weight of the bristles.

- the second weight W2 of all second bristles may be 50 to 70% of the total weight of the bristles.

- Figs. 3 to 5 are views of paint brushes in accordance with the present invention.

- the paint brush is of "T"-form. It incorporates a handle 1 with as bristle carrier e.g. a ferrule 2 attached to one end of the handle 1 and a brush head 3 secured in the ferrule 2. Paint brush handles 1, ferrules 2 and methods of securing the paint brush head 3 in the ferrule 2 are known in the art.

- the brush head 3 is composed of first bristles 4 and second bristles 5. As can be seen in particular from Fig. 4 the first bristles 4 have a first length L1 and the second bristles 5 have a second length L2.

- RS indicates a root section of the bristles 4, 5.

- the root section RS comprises the end section of the bristles 4, 5 which is fixed by the ferrule 2 and a glue 2a at the handle 1.

- Reference sign TS1 indicates a first tip section of the first bristles 4, and reference sign TS2 indicates a second tip section of the second bristles 5.

- a first tip diameter of the first bristles 4, being an average diameter in the first tip section TS1 may be in the range of 0,1 to 0,2 mm.

- a second tip diameter of the second bristles 5, being an average diameter in the second tip section TS2 may be in the range of 0,06 to 0,08 mm.

- a second length L2 of the second bristles 5 is greater than a first length L1 of the first bristles 4.

- the difference d L2 - L1 is advantageously in the range of 6 to 9 mm.

- the second bristles 5 are in contact along an essential part of their second length L2 with the first bristles 4.

- the first bristles 4 having a higher stiffness and a greater diameter than the second bristles 5 laterally support the first bristles 5 and keep them in an essentially upright position.

- the second bristles 5 can be dispersed uniformly within a pack formed by the first bristles 4.

- a pack being formed of first 4 and second bristles 5 forms a core 6 which is surrounded by a wrap 7 consisting just of first bristles 4.

- a weight ratio in the mixture of first 4 and second bristles 5 is preferably in the range of 0,5 to 0,7.

- a first weight W1 of the first bristles 4 is preferably in the range of 35 to 45 wt%.

- a second weight W2 of the second bristles 5 is preferably in the range of 55 to 65 wt%.

Abstract

a handle (1) having at its one end a bristle carrier (2),

and a plurality of bristles fastened to said bristle carrier (2) such that essentially all adjacent bristles are in contact with each other,

said plurality of said bristles comprising first bristles (4) having a first length L1 and second bristles (5) having a second length L2,

characterized in that

said first length L1 and said second length L2 satisfies the following relation:

said first bristles (4) having a first stiffness being higher than a second stiffness of said second bristles (5).

Description

- The present invention is directed to a paint brush in accordance with the preamble of

claim 1. - In the prior art there are generally known paint brushes. Within the brushes there are distinguished paint brushes and brushes for cleaning purposes, e.g. tooth brushes and the like.

- Brushes for cleaning purposes differ from paint brushes in that their bristles have a high stiffness making it possible to scratch away particles which adhere at a surface to be cleaned. In order to effectively discharge the removed particles the bristles are usually fixed at a bristle carrier such that a clearance is formed in between the bristles, e.g. the bristles are not in contact with each other. It is also possible that there are formed groups of bristles and that between the groups of the bristles there is formed the clearance for discharging the particles.

- Paint brushes are usually made of bristles having a smaller stiffness than the bristles used for brushes for cleaning purposes. Essentially, all adjacent bristles of a paint brush are in contact with each other. The bristles form a bristle pack or brush head, respectively, which is able to hold therein a paint by adhesion as well as capillary forces. When painting the brush head is pressed onto the surface to be painted by the hand of the operator. Thereby, the bristles are bent and the paint being held between the bristles is forced to flow out of the brush head as it is moved along the surface to be painted.

- Common paint brushes have a bristle head made of bristles having a length of 4 to 11 cm. The bristles are usually natural bristles, e.g. a root diameter in a root section of the bristles is typically between 0,17 and 0,35 mm, whereas a tip diameter in a tip section is in the range of 0,11 to 0,13 mm.

- A paint brush in accordance with the preamble of

claim 1 is known fromUS 5,220,702 . The known paint brush is composed of a core of short thick hairs with long fine hairs surrounding said core and substantially longer stiff bristles dispersed throughout said core of thick hairs. The known paint brush is used to draw very fine lines. It has the capability to store a large amount of paint within the brush head. -

US 2005/0229346 A1 discloses a paint brush having a brush head containing a continuum of bristles configured from a plurality of primary short bristles and secondary longer bristles with split and smaller diameter distal extremities. - Conventional paints having a high content of volatile organic components are recently more and more replaced due to legal restrictions by modern paints having just a small content of volatile organic components or even no volatile organic components. In practice it has turned out that a coating made of a modern paint and being applied by a conventional paint brush has a poorer surface quality than a coating made of a conventional paint. Reference is made to

Fig. 1 which shows a schematically cross section through a first coating C1 made of a conventional paint by use of a conventional paint brush andFig. 2 showing a cross section through a second coating C2 made by a modern paint by use the same conventional paint brush. Reference sign S designates an substrate upon which the respective coating is provided. - It is a primary object of the present invention to overcome the problems in the art. According to a further object of the present invention there shall be provided a paint brush by which a coating made of a modern paint can be manufactured with a higher surface quality.

- This object is solved by the features of

claim 1. Embodiments of the invention result from the features ofclaim 2 to 9. -

- In the context of the present invention under the term "bristle" there is understood an elongated flexible body having just one first end and just one second end. The first end is part of a root section where the bristle is fastened in a bristle carrier. Said root section may have a length of 5 to 10 mm. Under the term "root diameter" there is understood an average diameter of the bristle in the root section. A second end of the bristle forms a free tip which usually contacts a surface to be coated with paint. The second end is part of the tip section of the bristle. The tip section has a length of 5 to 10 mm. Under the term "tip diameter" there is understood an average diameter of the bristle in the tip section.

- Further, in the context of the present invention under the term "essentially all bristles" there is understood that at least 80%, preferably at least 90%, and most preferably at least 95% of the adjacent bristles are in direct contact with each other. According to a further aspect of the invention a plurality of bristles is fastened to said bristle carrier such that essentially all adjacent bristles are in contact with each other. I.e. the bristles form a pack or bristle head, respectively. The pack is a continuum where essentially all bristles are in contact. In particular, the first bristles surround at least partly the second bristles and thereby laterally support the second bristles in order to keep them upright. Within the pack formed of the first bristles having dispersed therein the second bristles, in at least in a tip section of the first bristles, there are no free intersections surrounding the bristles, i.e. essentially all adjacent bristles contact each other.

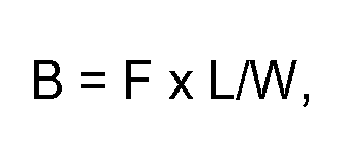

- The "stiffness" or bending stiffness, respectively, can be measured e.g. with a bending stiffness measurement apparatus which is e.g. provided by the company Lorentzen & Wettre GmbH. 10 pieces of bristles are measured in analogy to DIN 53121 which describes the determination of the bending stiffness measured in accordance with the beam method (see also ISO 2493). The bending stiffness is measured in centinewton (cN).

- For this purpose a 50 mm long bristle is clamped in jaws of the measurement apparatus at a distance of 1,0 mm to a load sensor. The bristle is then bent up to an angle of 30° and again back to 0° while a maximum force is measured in cN.

-

- B

- bending stiffness [N/mm2],

- F

- bending strength at a bending angle of 30° [N],

- L

- distance to the load sensor [mm], here 1,0 mm,

- W

- modulus [mm3].

-

- By the proposed paint brush it is advantageously possible to manufacture a coating with an excellent surface quality when using a modern paint having a small amount of volatile organic components or even no volatile organic components. Such modern paint is also called "low-VOC paint" and may be e.g. an acrylic paint, an acrylic lacquer, a water-based lacquer and the like.

- According to an embodiment of the invention d is in the range of 5 to 15 mm, preferably in the range of 6 to 9 mm. The first bristles may have a first tip diameter in the range of 0,1 to 0,2 mm. The second bristles may have a second tip diameter in the range of 0,04 to 0,08 mm. The selection of the value for d as well as the relation of the first tip diameter to the second tip diameter result in a further improved surface quality of a coating being manufactured by the paint brush according to the present invention.

- According to a further embodiment the first and the second bristles may be made of the same material. This allows a cheap and easy production of the paint brush. In this case the first and the second bristles have a uniform physico-chemical behavior with respect to the paint or a solvent.

- According to a further embodiment of the invention the first and the second bristles may be made of a natural or a synthetic material. The natural material can be e.g. hog or goat bristles or bristles of other animal. The synthetic material may be selected from the following group: PE, PA, PET, PBT. The synthetic material may be mixture of the aforementioned materials.

- The bristles may have a conical or cylindrical shape. In particular, bristles made of a synthetic material may have the following cross sections: solid, hollow, trilocular, quadrilocular. The material may be provided with small holes, the total volume of which may be in the range of 10 to 30 Vol.%. The tip section of the bristles may be treated mechanically or chemically. The tip section may be tipped or flagged.

-

- Under the term "first weight W1" there is understood the total weight of all first bristles contained in the bristle head, and under the term "second weight W2" there is understood the total weight of all second bristles contained in the bristle head.

- In particular, the weight ratio W1M/2 may be in the range of 0,4 to 0,8, preferably in the range of 0,5 to 0,7. E.g. the first weight W1 of all first bristles may be 30 to 50% of the total weight of the bristles. The second weight W2 of all second bristles may be 50 to 70% of the total weight of the bristles. It has turned out that by a paint brush having first and second bristles in the aforementioned weight ratio there can be manufactured a coating with an excellent surface quality when using modern paints.

- Further objects and advantages of the invention will become more apparent and more radially appreciated from the following detailed description, taken in conjunction with the accompanying drawings, of which:

- Fig. 1

- is a sectional view through a coating manufactured with a conventional paint and a conventional paint brush,

- Fig. 2

- is a sectional view of a coating manufactured with a modern paint and a conventional paint brush,

- Fig. 3

- is a side view of a paint brush in accordance with the present invention,

- Fig. 4

- is a sectional view through a part of the bristle head according to

Fig. 3 and - Fig. 5

- is a top plan view upon a further paint brush.

- The preferred embodiments of the paint brush of the present invention will hereinafter be described in detail with reference to the accompanying drawings.

-

Figs. 3 to 5 are views of paint brushes in accordance with the present invention. The paint brush is of "T"-form. It incorporates ahandle 1 with as bristle carrier e.g. aferrule 2 attached to one end of thehandle 1 and abrush head 3 secured in theferrule 2. Paint brush handles 1,ferrules 2 and methods of securing thepaint brush head 3 in theferrule 2 are known in the art. - The

brush head 3 is composed offirst bristles 4 andsecond bristles 5. As can be seen in particular fromFig. 4 thefirst bristles 4 have a first length L1 and thesecond bristles 5 have a second length L2. RS indicates a root section of thebristles bristles ferrule 2 and aglue 2a at thehandle 1. Reference sign TS1 indicates a first tip section of thefirst bristles 4, and reference sign TS2 indicates a second tip section of thesecond bristles 5. A first tip diameter of thefirst bristles 4, being an average diameter in the first tip section TS1, may be in the range of 0,1 to 0,2 mm. A second tip diameter of thesecond bristles 5, being an average diameter in the second tip section TS2, may be in the range of 0,06 to 0,08 mm. - As can be seen from

Figs. 3 and4 a second length L2 of thesecond bristles 5 is greater than a first length L1 of thefirst bristles 4. The difference d = L2 - L1 is advantageously in the range of 6 to 9 mm. - As can be seen in particular from

Fig. 4 thesecond bristles 5 are in contact along an essential part of their second length L2 with thefirst bristles 4. The first bristles 4 having a higher stiffness and a greater diameter than thesecond bristles 5 laterally support thefirst bristles 5 and keep them in an essentially upright position. The second bristles 5 can be dispersed uniformly within a pack formed by thefirst bristles 4. - According to a further embodiment - shown in

Fig. 5 - it may also be possible that a pack being formed of first 4 andsecond bristles 5 forms a core 6 which is surrounded by awrap 7 consisting just offirst bristles 4. - A weight ratio in the mixture of first 4 and

second bristles 5 is preferably in the range of 0,5 to 0,7. I.e. a first weight W1 of thefirst bristles 4 is preferably in the range of 35 to 45 wt%. A second weight W2 of thesecond bristles 5 is preferably in the range of 55 to 65 wt%. - While only a few exemplary embodiments of this invention have been described in detail those skilled in the art will radially appreciate that many modifications are possible in the preferred embodiments without materially departing from the teachings and advantages of the present invention. Accordingly, all such variations and modifications are intended to be within the spirit and the valid scope of the invention as defined by the following claims.

-

- 1

- handle

- 2

- ferrule

- 2a

- glue

- 3

- brush head

- 4

- first bristle

- 5

- second bristle

- 6

- core

- 7

- wrap

- C1

- first coating

- C2

- second coating

- L1

- first length

- L2

- second length

- RS

- root section

- S

- substrate

- TS1

- first tip section

- TS2

- second tip section

- W1

- first weight

- W2

- second weight

Claims (9)

- A paint brush, comprising:a handle (1) having at its one end a bristle carrier (2),and a plurality of bristles fastened to said bristle carrier (2) such that essentially all adjacent bristles are in contact with each other,said plurality of said bristles comprising first bristles (4) having a first length L1 and second bristles (5) having a second length L2,characterized in thatsaid first length L1 and said second length L2 satisfies the following relation:

where d is a value between 4 and 18 mm, andsaid first bristles (4) having a first stiffness being higher than a second stiffness of said second bristles (5). - The paint brush according to claim, wherein d is in the range of 5 to 15 mm, preferably in the range of 6 to 9 mm.

- The paint brush according to one of the previous claims, wherein said first bristles having a first tip diameter in the range 0,1 to 0,2 mm, said second bristles having a second tip diameter in the range of 0,04 to 0,08 mm.

- The paint brush according to one of the previous claims, wherein said first (4) and said second bristles (5) are made of the same material.

- The paint brush according to one of the previous claims, wherein said first (4) and said second bristles (5) are made of a natural or a synthetic material.

- The paint brush according to one of the previous claims, wherein said synthetic material is selected from the following group: PE, PA, PET, PBT or a mixture thereof.

- The paint brush according to one of the previous claims, wherein W1M/2 is in the range of 0,4 to 0,8, preferably in the range of 0,5 to 0,7.

- The paint brush according to one of the previous claims, wherein in a cross section through a pack formed of all bristles (4, 5) there is formed a core (6) comprising said second bristles (5) being dispersed within the first bristles (4), said core (6) being surrounded by a wrap (7) consisting of said first bristles (4).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP14194160.9A EP3023031B1 (en) | 2014-11-20 | 2014-11-20 | Paint brush |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP14194160.9A EP3023031B1 (en) | 2014-11-20 | 2014-11-20 | Paint brush |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP3023031A1 true EP3023031A1 (en) | 2016-05-25 |

| EP3023031B1 EP3023031B1 (en) | 2018-01-10 |

Family

ID=51932260

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP14194160.9A Active EP3023031B1 (en) | 2014-11-20 | 2014-11-20 | Paint brush |

Country Status (1)

| Country | Link |

|---|---|

| EP (1) | EP3023031B1 (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| RU170521U1 (en) * | 2016-12-13 | 2017-04-26 | Андрей Леонидович Бяков | Paintbrushing element of flat brushes used for nail design, drawing and creativity when working with liquid paints |

| RU174655U1 (en) * | 2017-03-24 | 2017-10-24 | Общество с ограниченной ответственностью "ВАЛЕРИ-Д" | BRUSH |

| EP3576571A4 (en) * | 2017-03-07 | 2020-11-25 | Orkla House Care AB | Paint brush comprising a monofilament blend of three different types of bristles |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5220702A (en) | 1988-10-19 | 1993-06-22 | Howell Marian N | Paint brushes with multiple stiffness bristles |

| US20050229346A1 (en) | 2004-04-16 | 2005-10-20 | Learned Addison W Iii | Isokinetic bristle bundle brushes |

| WO2007034156A1 (en) * | 2005-09-24 | 2007-03-29 | L G Harris & Co Limited | Improvements in or relating to brushes |

| DE102012105477A1 (en) * | 2011-06-27 | 2012-12-27 | General Electric Co. | brush seal |

-

2014

- 2014-11-20 EP EP14194160.9A patent/EP3023031B1/en active Active

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5220702A (en) | 1988-10-19 | 1993-06-22 | Howell Marian N | Paint brushes with multiple stiffness bristles |

| US20050229346A1 (en) | 2004-04-16 | 2005-10-20 | Learned Addison W Iii | Isokinetic bristle bundle brushes |

| WO2007034156A1 (en) * | 2005-09-24 | 2007-03-29 | L G Harris & Co Limited | Improvements in or relating to brushes |

| DE102012105477A1 (en) * | 2011-06-27 | 2012-12-27 | General Electric Co. | brush seal |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| RU170521U1 (en) * | 2016-12-13 | 2017-04-26 | Андрей Леонидович Бяков | Paintbrushing element of flat brushes used for nail design, drawing and creativity when working with liquid paints |

| EP3576571A4 (en) * | 2017-03-07 | 2020-11-25 | Orkla House Care AB | Paint brush comprising a monofilament blend of three different types of bristles |

| EP3884808A1 (en) | 2017-03-07 | 2021-09-29 | Orkla House Care AB | Paint brush comprising a monofilament blend |

| EP4018880A1 (en) | 2017-03-07 | 2022-06-29 | Orkla House Care AB | Paint brush comprising a bristle blend of three different types of bristles |

| EP3884808B1 (en) | 2017-03-07 | 2022-11-23 | Orkla House Care AB | Paint brush comprising a monofilament blend |

| EP4018880B1 (en) | 2017-03-07 | 2022-11-23 | Orkla House Care AB | Paint brush comprising a bristle blend of three different types of bristles |

| EP4154764A1 (en) | 2017-03-07 | 2023-03-29 | Orkla House Care AB | Paint brush comprising a bristle blend of three different types of bristles |

| RU174655U1 (en) * | 2017-03-24 | 2017-10-24 | Общество с ограниченной ответственностью "ВАЛЕРИ-Д" | BRUSH |

Also Published As

| Publication number | Publication date |

|---|---|

| EP3023031B1 (en) | 2018-01-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US11445810B2 (en) | Oral care implement and filament for the same | |

| EP3023031B1 (en) | Paint brush | |

| US6367114B1 (en) | Paint brush having crinkle filaments and natural bristles | |

| US6241411B1 (en) | Mascara brush, container, and method | |

| EP1736073B1 (en) | Hair treatment applicator | |

| US11344109B2 (en) | Makeup brush for cosmetic application with a concave profile | |

| JPWO2006038408A1 (en) | Brush for painting | |

| US7913348B2 (en) | Paint brush with increased ferrule paint reservoir | |

| US7266858B2 (en) | Three in one paintbrush cleaner and conditioner | |

| EP3576571B1 (en) | Paint brush comprising a monofilament blend of three different types of bristles | |

| US20050229346A1 (en) | Isokinetic bristle bundle brushes | |

| JP2012110801A (en) | Brush structure for adhesive application | |

| EP2064969B1 (en) | Brush for transferring fluid or paste-like media | |

| JPH11313716A (en) | Synthetic fibers for brush and synthetic fiber bundle for brush | |

| US20160007724A1 (en) | Multicolored filament loading guide brush | |

| US20140366298A1 (en) | Paint Brush with Reinforced Ferrule Construction | |

| US20190061417A1 (en) | Device for Cleaning a Paint Roller Cover | |

| US20190328123A1 (en) | Applicator for cosmetic product, and associated applicator assembly | |

| SE541005C2 (en) | Paint brush comprising a monofilament blend of three different types of bristles | |

| AU2005100668A4 (en) | Excess paint remover | |

| JP2020171569A (en) | Coating film removing tool | |

| SE541177C2 (en) | Paint brush comprising a monofilament blend of three different types of bristles | |

| AU2006201107A1 (en) | An angle oval cutter brush | |

| DE202011106620U1 (en) | Hand tools, in particular drumsticks | |

| DE102016113674A1 (en) | cleaning device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20161019 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| 17Q | First examination report despatched |

Effective date: 20170105 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20170725 |

|

| GRAJ | Information related to disapproval of communication of intention to grant by the applicant or resumption of examination proceedings by the epo deleted |

Free format text: ORIGINAL CODE: EPIDOSDIGR1 |

|

| GRAR | Information related to intention to grant a patent recorded |

Free format text: ORIGINAL CODE: EPIDOSNIGR71 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| INTC | Intention to grant announced (deleted) | ||

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| INTG | Intention to grant announced |

Effective date: 20171201 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: AT Ref legal event code: REF Ref document number: 961466 Country of ref document: AT Kind code of ref document: T Effective date: 20180115 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602014019800 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20180110 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 961466 Country of ref document: AT Kind code of ref document: T Effective date: 20180110 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180410 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180410 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180411 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180510 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602014019800 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 |

|

| 26N | No opposition filed |

Effective date: 20181011 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20181120 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181120 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20181130 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181130 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181120 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181120 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181120 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180110 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20141120 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20221118 Year of fee payment: 9 Ref country code: DE Payment date: 20221012 Year of fee payment: 9 |