EP2989641B1 - High-speed data cable - Google Patents

High-speed data cable Download PDFInfo

- Publication number

- EP2989641B1 EP2989641B1 EP14720520.7A EP14720520A EP2989641B1 EP 2989641 B1 EP2989641 B1 EP 2989641B1 EP 14720520 A EP14720520 A EP 14720520A EP 2989641 B1 EP2989641 B1 EP 2989641B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- speed data

- conductors

- data cable

- core

- cable according

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B7/00—Insulated conductors or cables characterised by their form

- H01B7/30—Insulated conductors or cables characterised by their form with arrangements for reducing conductor losses when carrying alternating current, e.g. due to skin effect

- H01B7/303—Conductors comprising interwire insulation

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B11/00—Communication cables or conductors

- H01B11/02—Cables with twisted pairs or quads

- H01B11/04—Cables with twisted pairs or quads with pairs or quads mutually positioned to reduce cross-talk

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B11/00—Communication cables or conductors

- H01B11/002—Pair constructions

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B11/00—Communication cables or conductors

- H01B11/18—Coaxial cables; Analogous cables having more than one inner conductor within a common outer conductor

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B3/00—Insulators or insulating bodies characterised by the insulating materials; Selection of materials for their insulating or dielectric properties

- H01B3/18—Insulators or insulating bodies characterised by the insulating materials; Selection of materials for their insulating or dielectric properties mainly consisting of organic substances

- H01B3/30—Insulators or insulating bodies characterised by the insulating materials; Selection of materials for their insulating or dielectric properties mainly consisting of organic substances plastics; resins; waxes

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B7/00—Insulated conductors or cables characterised by their form

- H01B7/02—Disposition of insulation

Definitions

- the present invention relates to a high-speed data cable.

- Typical data transmission cables are more or less rigid coaxial cables, in which an inner conductor is surrounded by a cylindrical outer conductor, and more flexible, differential (symmetrical) cables, in which positive and negative wires are laid parallel to one another.

- the wires can be a solid single conductor or strands of several conductors. The wires are separated from each other by an insulating material. In a strand, the conductors can be loosely next to each other or twisted.

- the differential pair may itself (sheathed) form a cable or form a cable with several other differential pairs in a bundle.

- the WO2009129028 describes a conductor comprising a central element having a length, a plurality of insulated strands disposed about the central element in at least a first and a second concentric layer, and a layer of dielectric material having a propagation velocity around the plurality of isolated strands is arranged around.

- Each of the plurality of insulated strands has a conductive element and a layer of insulating material disposed about the conductive element and a length approximately equal to an inverse of the propagation velocity of the associated dielectric materials multiplied by the product of the length of the central element and the number one hundred.

- the object of the present invention is to provide an improved high-speed data cable, which allows a high-rate (high-frequency) data transmission.

- the core idea of the present invention is to have realized that it is possible to more efficiently enable high-frequency data transmission in a high-speed data cable, resulting in lower attenuation, especially at high frequencies.

- the high-speed data cable comprises at least one pair of wires, with a conductive shield surrounding the wires.

- the conductive shielding results in an increased immunity to interference of the cable, which, inter alia, a faster data transmission is possible.

- An insulating cable sheath encloses the conductive shield and protects the cable from mechanical stress and corrosion, among other things.

- Each of the wires comprises at least three electrical conductors insulated from one another, wherein the conductors are arranged to extend in an equidistant manner to a longitudinal central axis of the respective core.

- the skin effect refers to the narrowing of the signal current in ever smaller space (near or at the conductor surface) at higher frequencies. Effectively, the conductor cross-section available for the current transport decreases or the ohmic resistance increases with increasing frequency. The skin effect thus leads to a high signal attenuation, especially at high frequencies.

- Fig. 1 shows a cross-section of an embodiment of a high-speed data cable 100, hereinafter also referred to as cable 100.

- the cable 100 includes at least one wire pair 102. It is exemplarily designed as a differential (symmetrical) cable in which the two wires 104a, 104b of the wire pair 102 are parallel to one another in an axial direction.

- the two wires 104a, 104b of the wire pair 102 have a differential push-pull impedance and a common mode impedance.

- the transmission of a useful signal takes place in that the difference between the two wires 104a, 104b represents the useful signal.

- a useful signal In contrast, in the case of asymmetrical cables, transmission takes place by means of a useful signal whose value changes with respect to a reference potential (ground).

- the useful signal may have a voltage potential and / or a current strength.

- the useful signal In symmetric signal transmission, the useful signal, especially in the high frequency range, less prone to interference on a transmission link. At high frequencies disturbances interfere more easily, because eg the screen attenuation decreases. Asymmetric cables can not compensate for this.

- the coupling of interference in practice is still reduced by the earth unbalance attenuation. Earth imbalance damping indicates the deviation from the theoretically ideal equality of the positive and negative wires.

- the disturbing influences for example due to capacitive or inductive couplings on the transmission path, are approximately equal in the case of the symmetrical signal transmission on both cores 104a, 104b, so that the disturbance almost disappears during the subtraction of the two signals of the cores 104a, 104b.

- a conductive shield 108 longitudinally surrounds the wires 104a, 104b and forms a Faraday cage around the wires 104a, 104b.

- the wires 104a, 104b may each be surrounded in pairs by a common conductive shield 108. Alternatively, an individual shield per vein or a plurality of veins would be possible together.

- the cores 104a, 104b are protected against external alternating electromagnetic fields by the Faraday cage. That capacitive or inductive couplings of interference to the cable 100 are prevented or at least reduced.

- the Faraday cage of the shield 108 prevents the cores 104a, 104b from transmitting AC electromagnetic fields, thereby further protecting the cores 104a, 104b of the cable 100 and the environment of the cable 100 from electromagnetic emission.

- the conductive shield 108 may be made of any conductive material.

- the conductive shield 108 is metal clad Plastic film or formed from non-insulated metal wires.

- the conductive shield 108 may each at least one wire pair 102 in any form, for example. Wrapped or braided surrounded.

- the conductive shield 108 is a wire mesh in which individual, mutually non-insulated metal wires are overlaid or a plastic-laminated metal foil which is wound around the wires 104a, 104b.

- the conductive shield 108 is fabricated depending on the desired mechanical flexibility and / or the required electrical shielding characteristic of the cable 100.

- the conductive screen 108 may be fabricated as a closed / solid shell or as a combination of the previously described elements.

- the wires 104a, 104b may be twisted together, i. the wires 104a, 104b are twisted in the longitudinal direction about a common axis.

- the twisting of the wires 104a, 104b favors the symmetrical properties of the cable 100. Interferences which act on the wires 104a, 104b from a certain direction, for example, are impressed identically on both wires 104a, 104b of the wire pair 102.

- the individual wire pairs 102 in the cable 100 can be twisted to different degrees with each other. As a result, coupling in of interference of the wire pairs 102 with one another is reduced.

- An insulating sheath 106 encloses the conductive shield 108 and forms the surface of the cable 100.

- the insulating sheath 106 may be made of, for example, polyvinyl chloride (PVC), polypropylene (PP), polyethylene (PE), or other insulating material.

- the insulating sheathing 106 completely encloses the conductive shield 108 and prevents electrical connection between the conductive shield 108 and the environment of the cable 100.

- the insulating sheath 106 protects the cable 100 from chemical or mechanical influences that may result in damage to the cable 100 , For example, the insulating sheath 106 may be extruded onto the conductive shield 108.

- Fig. 1 shows a first implementation form of a wire 104a, 104b, which comprises three electrical conductors 110.

- the conductors 110 may be made of any electrically conductive material.

- the electrical conductors 110 are made of metal, such as copper or aluminum or copper or aluminum alloys. Copper and aluminum have a low electrical resistivity, which makes them particularly suitable as electrical conductors.

- copper and aluminum have a low electrical resistivity, which makes them particularly suitable as electrical conductors.

- aluminum exhibits a low mass density and thus a low specific weight, whereby the weight of the cable 100 can be kept low.

- the conductors 110 are arranged equidistant (with the same distance) to a longitudinal central axis 118 of the respective wire 104a, 104b.

- a circular arrangement of the conductors 110 around a center of the wires 104a, 104b or the centers of the wires 110 are arranged on a circle around the longitudinal central axis 118.

- the conductors 110 are twisted in each strand 104a, 104b or arranged twisted around the longitudinal center axis 118. Twisting the conductors 110 increases the flexibility of the wires 104a, 104b, i.

- the more twisted the conductors 110 in the wire 104a, 104b the more flexible the wire 104a, 104b can bend, allowing smaller bend radii with the wire 104a, 104b without breaking the wires 110 in the wire 104a, 104b.

- the same electrical (environmental) conditions are achieved for all conductors. However, a stronger twisting leads at the same time to a greater effective conductor length with the same outer length of the cable.

- the individual conductors 110 of a wire are each short-circuited. This can e.g. done by soldering or crimping.

- a plurality of conductors 110 may be arranged equidistantly in the wire 104a, 104b.

- a wire comprises 3 to 18 conductors 110.

- Each conductor 110 adjoins on its outer surface at least one insulating material, in which the conductors 110 of the respective core 104a, 104b run separately from one another.

- the insulating material encloses the conductor 110 and prevents electrical currents between the conductors 110.

- the insulating material between the conductors 110 reduces the influence of the skin effect.

- the skin effect occurs when an electrical conductor with a higher-frequency alternating current flows through it.

- the current density inside the conductor is lower than at the surface.

- the displacement of the current to the surface increases with increasing frequency. This leads to unwanted attenuation of an electrical cable.

- the insulation of the individual conductors against each other increases the effective surface area while maintaining the same cross section. Instead of a single conductor are several small electrical conductors available, creating a larger surface. This leads to an effectively higher conductor cross section at high frequencies. This results in a lower damping in the respective wire 104a, 104b.

- the conductors 110 of the wires 104a, 104b may be adjacent to different insulating materials.

- the conductors 110 are at least partially embedded in insulating material.

- the insulating material forms a wire jacket 116 and may be made of, for example, polyvinyl chloride (PVC), polypropylene (PP), polyethylene (PE) or other insulating material.

- the materials may be present as solid or with a gas, eg air, foamed substances.

- the core jacket 116 keeps the wire 104a, 104b mechanically stable.

- the center of the wire 104a, 104b may be recessed from insulating material such that in the center, for example, air as an insulating material adjoins the outer surface of the conductors. Air isolates the conductors 110 from each other and keeps the weight of the wires 104a, 104b low.

- the conductors 110 of the wires 104a, 104b are arranged equidistant from the longitudinal central axis 118 of the wires 104a, 104b.

- all conductors 110 of the wires 104a, 104b have the same overall length.

- the insulating material which surrounds the conductors 110 an exchange of the useful signal between the conductors 110 is not possible.

- conductors can be twisted in multiple layers. This leads in particular to longer cables with insulated individual wires to runtime differences of the useful signal, whereby the maximum signal transmission of the desired signal and thus the maximum transmission rate is restricted.

- all conductors 110 are the same length regardless of the total length of the cable 100, whereby no delay differences of the useful signal in the individual conductor 110 arise.

- Fig. 2 shows a cross-section of a wire 204 of a high-speed data cable according to another embodiment of the present invention.

- wire 204 differs from the wires 104a, 104b in FIG. 1 inter alia, by an insulating coating 212, which encloses each conductor 210 of the wire 204 as an insulating material.

- the insulating coating 212 is designed to completely enclose each conductor 210 laterally, ie on the surface of the longitudinal side.

- the insulating coating 212 allows the conductors 210 and their insulating coating 212 to abut each other without short circuits occurring between the conductors 210. It is thereby a denser arrangement of the conductors 210 in the wire 204 possible, whereby a total of a larger conductor cross-section is ready for the useful signal.

- the adjoining conductors 210 increase the stability of the cable.

- the insulating coating 212 may be, for example, a lacquer layer or a plastic, as used, for example, for the core or the cable sheath.

- the advantage of a resist layer is that a thin-walled and inexpensive insulating coating 212 is possible, wherein the wall thickness of the insulating coating 212 may preferably be in a range of less than 10 ⁇ m to 80 ⁇ m.

- the ratio between the wall thickness of the insulating coating 212 and the radius of the conductor 210 is preferably in the range 0.015 to 0.42. Since the voltage potentials between the conductors 210 of the wires 202 are small, thin-walled insulation is sufficient.

- the Durscherfestmaschine the paint layer insulation is eg in the range of 2kV / mm.

- the potential difference may be 40V. All conductors 210 of a wire 202 carry the same signal, so that, for example due to local differences in transit time, the potential differences remain very small.

- the thin-walled insulation results in a smaller volume and weight of the conductors 210.

- the conductors 210 with the insulating coating 212 are enclosed by the core jacket 216.

- FIG. 2 shown wire 204 of the in FIG. 1 shown cores 104a, 104b by an insulator core 214, which along the longitudinal central axis 118 of the wire 204 is arranged and to which the conductors 210 of the wire 204 can abut.

- the conductors 210 are thus arranged in a circle around the insulator core 214.

- the insulator core 214 holds the conductors 210 and the conductors 210 with the insulated coating 212 at a certain distance from the longitudinal central axis 118 of the core 204, the distance corresponding to the radius of the insulator core 214.

- the conductor centers are at a distance, radius of the insulator core 214 + radius of the conductor 210 with insulating coating 212, away from the longitudinal central axis 118 of the wire 204.

- the insulator core 214 may be made of a more or less flexible material.

- the insulator core 214 in the center of the wire 204 and the insulated coating conductors 210 disposed therealong have the same diameter.

- the insulated coating conductors 210 are adjacent to each other as well as to the insulator core 214.

- Other ratios may be selected between insulative conductor diameter 212 and insulator core 214.

- the diameters of the conductors 210 and the insulator core 214 are selected so that the conductors 210 cover the surface of the insulator core 214 once. That is, the conductors 210 with the insulating coating 212 on the insulator core 214 and against each other. This feature keeps the arrangement mechanically stable.

- the diameter of the insulator core 214 can be selected to be slightly larger, so that when stranded (if necessary) the insulated conductors 210 press into the insulator core 214 and thus forms a closed arrangement of the conductors 210 around the insulator core 214.

- the material of the insulator core 214 is preferably softer than the material of the insulating coating 212.

- the situation may arise that the conductors 210 to one small insulator core 214 are pressed against each other and the insulating coating 212 is damaged.

- the insulator core 214 non-conductive core

- the laminar surface of the insulator core surface (core surface) with conductor 210 with insulated coating 212 ensures that all conductors 210 are the same length, thus eliminating tread differences in the useful signal.

- the insulator core 214 (non-conductor) inside the core 204 (assembly) and the insulating coating 212 also reduces the proximity effect.

- the proximity effect in electrical engineering refers to the effect of current confinement or current displacement between two closely adjacent conductors under the influence of alternating currents due to the stray magnetic flux between them caused by rectified currents in the conductors 210. Similar to the skin effect, the rectified current has in the neighboring ladder the "urge" to prevent the flow of current at the surface. The electricity is forced into a smaller cross section. By keeping the adjacent conductor at a distance, its influence can be reduced.

- the insulator core 214 is preferably made of an insulating material and thus the electrical current is not conductive. Suitable materials for the insulator core 214 are, for example, plastics or rubber. Particularly preferably, the insulator core 214 is made of polypropylene, polyamide or polyethylene. The material may e.g. solid, foamed or processed as a monofilament.

- the weight of the cable is reduced by the replacement of conductors 210 by non-conductors as the insulator core 214.

- the Indian FIG. 2 shown insulating coating 212 and the insulator core 214 are two independent features and can also individually on the in FIG. 1 shown embodiment or be transferred to other embodiments shown.

- FIG. 3A is a perspective view of a high-speed data cable 300 according to another embodiment of the present invention.

- the wires 304 may be just parallel to each other, twisted together or arranged as a star quad stranded or twisted.

- the star quad stranding represents a special arrangement of the wires 304 or of two differentiating wire pairs 302a, 302b.

- the star quad can in turn form a cable 300 together with other wire pairs and quads.

- 4 wires 304 are stranded together, after which the diagonally opposite wires 304 are operated as differential pairs 302a and 302b.

- a stabilizing film 309 surrounds and holds the two wire pairs 302a, 302b in position.

- the stabilizing film 309 may, for example, be made of elastic material which fits snugly against the wires or be formed as a shrink tube, which is shrunk onto the wires 304.

- the stabilizing film 309 can also have electrically conductive properties and thus form a conductive shield 308, for example as a metal-laminated plastic film, as described above.

- a conductive shield 308 which is formed, for example, as a wire mesh. Furthermore, the conductive shield 308 may be enclosed by a cable sheath.

- Fig. 3B 12 shows another embodiment of a high-speed data cable 300.

- the high-speed data cable 300 each includes four wires 304 surrounded by a conductive shield 308 are.

- the wires 304 can be like in FIG. 3B to be twisted.

- An insulating cable sheath 306 encloses the conductive shield 308.

- the individual electrical conductors of one of the wires 304 are due to the low resolution of FIG. 3B represented graphically as a surface.

- the wires 304 are each enclosed by a core jacket 316.

- the wires 304 each consist of six electrical conductors 310, which have on their outer surfaces an insulating coating 312 and embedded in a core jacket 316 consist.

- the conductors 310 are twisted about the insulator core 314 extending along the longitudinal central axis 118 such that each individual conductor 310 travels the same relative positions to the other other conductors 304 and to the conductive shield 308 along the length of the cable 300. Only then are the same electrical ratio and thus the same electrical parameters (especially signal propagation times) of each conductor 310 given.

- Embodiments of the high speed data cable 100, 300, 500, 600 may be used in any high data rate application. These include all Ethernet standard cables, LVDS cables, HDMI cables, TV transmission cables and also USB cables. Further fields of application are possible.

- the wave impedance of a wire pair 302a, 302b results from the inductance pad and the capacitance pad and lies in the range between 50 ⁇ to 300 ⁇ , preferably a wave impedance of the high-speed data cable 100, 300, 500, 600 is in the range between 75 ⁇ to 160 ⁇ (differential).

- the wave impedance can also be higher.

- FIG. 4 shows a cross-section of a wire 404 of a high-speed data cable according to another embodiment of the present invention.

- wire 404 differs from that in FIG. 2 shown vein 204 in that the eight at regular intervals around the insulator core 414 arranged conductors 410 have no insulating coating 212.

- the insulating material to which each conductor adjoins is formed by the insulator core 414 as well as the core jacket.

- the conductors 410 are embedded in the insulator core 414 and arranged equidistant from the longitudinal central axis 118 of the wire 404.

- the insulator core 414 has on its surface recesses, which are preferably formed according to the radius of the conductors 410. On the side facing away from the insulator core 414, the conductors 410 are cast in the core jacket 416 or extruded. There is thus no electrical connection between the conductors 410. Through the in FIG. 4 In the embodiment shown, costs and material for the insulating coating 212 can be saved.

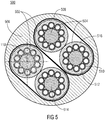

- FIG. 12 shows a cross section of a high-speed data cable 500 according to another embodiment of the present invention.

- the cores 504 are each enclosed in pairs by the conductive shield 508 and an insulating cable sheath 506 surrounds the conductive shield 508.

- each core pair 502 may be wrapped by a metal-laminated plastic film and in addition the entire bundle of wire pairs 502 of a conductive shield, for example.

- the two conductive shields 508 may have different shielding characteristics.

- the wire mesh can improve the mechanical properties, such as abrasion or bending strength of the cable.

- the wires 504 each have an insulator core 514, which is arranged along the longitudinal center axis 118 and around which ten conductors 510 with insulating coating 512 are arranged.

- the core jacket 516 in which the conductors 510 are embedded may also rest on the insulator core 514.

- Fig. 6A shows a first schematic representation of a star-four stranding.

- the conductors can be enclosed with an insulating coating. Furthermore, the conductors are surrounded by the wire jacket 616 and form a single wire 604. In the center of the wire 604, an insulating core may be arranged.

- the wires 604 may be twisted as a pair of wires 602 or star quad.

- the conductive shield 608 surrounds the cores 604 and is enclosed by the insulating sheathing 606.

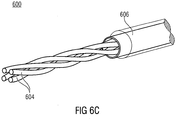

- FIG. 6B and 6C show more schematic representations of a star-four stranding.

- FIG. 6B and 6C There are four wires 604 without wire sheath. As a result, the course of the individual wires 604 in a star-quad stranding is clearly visible.

- the wires 604 are partially covered with an insulating cable sheath 606.

- the individual electrical conductors of one of the cores 604 are due to the low resolution of FIGS. 6A, 6B and 6C represented graphically as a surface.

- the embodiments shown in the figures show arrangement of electrically conductive and non-conductive elements in the cross-section of the wire 604 of the cable 600. This new arrangement reduces the attenuation down to the GHz range and also reduces the weight of the cable 600. Both will be re-used reached the usual materials.

- a wire 304 denotes the conductor or conductors 310 with insulation (insulating coating 312 and wire jacket 316).

- This disclosure describes a particular arrangement of the conductors 310 of a constant-loss attenuation-reducing core 304 with a focus on high-speed data transmission in which signal propagation times are involved. Furthermore, the structure of the high-speed data transmission cable 300 using this wire 304 will be described. The aim is a cable 300 with controlled impedance, low attenuation and small diameter.

- enamel-insulated solid conductors 310 are stranded around an insulator core 114 (nonconductive core).

- the cable 300 Due to the cable 300, with the same diameter and materials (except for the insulating coating 312 (additional paint layer) of the conductor 310 (individual wires)), a reduced damping is made possible. Also, the "top metal layer" of the conductors of a conventional wire can be replaced with paint, i. the diameter of the conductor 310 may be reduced so that the previous outer diameter of the wire 304 is obtained with the insulating coating 312. This reduces the weight per conductor. The entire outer diameter of the cable can remain the same.

- the cable 300 is particularly suitable for high-speed data transmission in the gigahertz range, where also runtime differences must be considered.

- Embodiments of the high-speed data cable can be used for symmetrical signal transmission.

- the high-speed data cable may be used, for example, in a system configured to transmit a balanced signal over the high-speed data cable.

- a system which comprises a high-speed data cable, may for example be a network with a plurality of computers or a communication network, for example for voice transmission.

- Computer here in the broadest sense includes active network nodes, at least contain a processor with memory and to which, for example, peripherals such as sensors, control units, monitors, cameras, etc. may be connected.

- aspects have been described in the context of a device, it will be understood that these aspects also constitute a description of the corresponding method, so that a block or a component of a device is also to be understood as a corresponding method step or as a feature of a method step. Similarly, aspects described in connection with or as a method step also represent a description of a corresponding block or detail or feature of a corresponding device.

- Some or all of the method steps may be performed by a hardware device (or using a hardware device). Apparatus), such as a microprocessor, a programmable computer or an electronic circuit. In some embodiments, some or more of the most important method steps may be performed by such an apparatus.

Landscapes

- Physics & Mathematics (AREA)

- Spectroscopy & Molecular Physics (AREA)

- Communication Cables (AREA)

Description

Die vorliegende Erfindung bezieht sich auf ein Hochgeschwindigkeitsdatenkabel.The present invention relates to a high-speed data cable.

Typische Kabel zur Datenübertragung sind zum einen mehr oder weniger steife Koaxialkabel, bei denen ein Innenleiter von einem zylindrischen Außenleiter umgeben ist, zum anderen flexiblere, differentielle (symmetrische) Kabel, bei denen positive und negative Adern parallel zueinander verlegt werden. Die Adern können dabei ein massiver Einzelleiter oder Litzen aus mehreren Leitern sein. Die Adern sind voneinander durch ein isolierendes Material getrennt. In einer Litze können die Leiter lose nebeneinander liegen oder verdrillt sein. Das differentielle Paar kann selbst (mit Mantel) ein Kabel bilden oder mit mehreren anderen differentiellen Paaren in einem Bündel ein Kabel bilden.Typical data transmission cables are more or less rigid coaxial cables, in which an inner conductor is surrounded by a cylindrical outer conductor, and more flexible, differential (symmetrical) cables, in which positive and negative wires are laid parallel to one another. The wires can be a solid single conductor or strands of several conductors. The wires are separated from each other by an insulating material. In a strand, the conductors can be loosely next to each other or twisted. The differential pair may itself (sheathed) form a cable or form a cable with several other differential pairs in a bundle.

Insbesondere bei hohen Datenraten treten Probleme auf, wie z.B. aufgrund von stärkeren ohmschen Leitungsverlusten bei höheren Frequenzen und Laufzeitunterschieden (der Signale im Zeitbereich) zwischen den Leitern einer Ader (Mehrwegeausbreitung). Diese resultieren in einer reduzierten Signalqualität und daraus folgend in einer schlechteren Übertragungseffizienz, d.h. geringere Datenrate, geringere Reichweite, höhere notwendige Sendleistung oder dergleichen.Especially at high data rates, problems such as e.g. due to higher resistive conduction losses at higher frequencies and skewed time differences (of the time domain signals) between the conductors of one wire (multipath propagation). These result in a reduced signal quality and consequent poorer transmission efficiency, i. lower data rate, shorter range, higher required transmission power or the like.

Die

Die Aufgabe der vorliegenden Erfindung besteht darin, ein verbessertes Hochgeschwindigkeitsdatenkabel zu schaffen, welches eine hochratige (hochfrequente) Datenübertragung zulässt.The object of the present invention is to provide an improved high-speed data cable, which allows a high-rate (high-frequency) data transmission.

Die Aufgabe wird durch den Gegenstand des unabhängigen Anspruchs gelöst.The object is solved by the subject matter of the independent claim.

Der Kerngedanke der vorliegenden Erfindung besteht darin, erkannt zu haben, dass es möglich ist, eine hochfrequente Datenübertragung in einem Hochgeschwindigkeitsdatenkabel effizienter zu ermöglichen, wobei insbesondere bei hohen Frequenzen eine geringere Dämpfung resultiert. Das Hochgeschwindigkeitsdatenkabel umfasst dabei zumindest ein Aderpaar, wobei eine leitende Abschirmung die Adern umgibt. Durch die leitende Abschirmung ergibt sich eine erhöhte Störfestigkeit des Kabels, wodurch unteranderem eine schnellere Datenübertragung möglich ist. Ein isolierender Kabelmantel umschließt die leitende Abschirmung und schützt das Kabel unter anderem vor mechanischen Belastungen und Korrosion. Jede der Adern umfasst mindestens drei voneinander isolierte elektrische Leiter, wobei die Leiter äquidistant zu einer Längsmittelachse der jeweiligen Ader verdrillt verlaufend angeordnet sind. Durch die äquidistante Anordnung der Leiter zu einer Längsmittelachse weisen alle Leiter einer jeweiligen Ader dieselbe Länge auf. Durch das Verdrillen durchläuft jeder Leiter mit einer gewissen Periodizität eine mögliche Störquelle bzw. ist innerhalb der Ader durch den Wechsel der Positionen der Leiter eine Angleichung der elektrischen Eigenschaften bzw. Umgebung der einzelnen Leiter in der Ader gegeben. Somit werden Signallaufzeitunterschiede innerhalb jeder Ader des Kabels aufgrund unterschiedlich langer Leiter verhindert. Die verschiedenen Wege bei dieser Mehrwegeausbreitung sind elektrisch gleich. Jeder der Leiter grenzt an seiner Außenfläche an mindestens einen isolierenden Stoff an. Die Leiter verlaufen in der jeweiligen Ader getrennt voneinander. Durch die elektrische Isolation der Leiter untereinander ergibt sich bei gleicher Materialmenge der elektrischen Leiter eine größere Oberfläche und somit eine größere effektive Querschnittsfläche der Ader bei hohen Frequenzen, da bei diesen der Strom vor allem nahe der Oberfläche geführt wird (Skin-Effekt). Der Skin-Effekt bezeichnet die Einengung des Signalstromes auf immer kleinerem Raum (nahe bzw. an der Leiteroberfläche) bei höheren Frequenzen. Effektiv sinkt damit der für den Stromtransport zur Verfügung stehende Leiterquerschnitt bzw. der ohmsche Widerstand steigt mit steigender Frequenz. Der Skin-Effekt führt damit insbesondere bei hohen Frequenzen zu einer hohen Signaldämpfung.The core idea of the present invention is to have realized that it is possible to more efficiently enable high-frequency data transmission in a high-speed data cable, resulting in lower attenuation, especially at high frequencies. The high-speed data cable comprises at least one pair of wires, with a conductive shield surrounding the wires. The conductive shielding results in an increased immunity to interference of the cable, which, inter alia, a faster data transmission is possible. An insulating cable sheath encloses the conductive shield and protects the cable from mechanical stress and corrosion, among other things. Each of the wires comprises at least three electrical conductors insulated from one another, wherein the conductors are arranged to extend in an equidistant manner to a longitudinal central axis of the respective core. Due to the equidistant arrangement of the conductors to a longitudinal center axis, all the conductors of a respective core on the same length. By twisting each conductor with a certain periodicity passes through a possible source of interference or is within the vein by changing the positions of the conductors given an approximation of the electrical properties or environment of the individual conductors in the vein. Thus, signal propagation time differences within each wire of the cable are prevented due to conductors of different lengths. The different ways in this multipath propagation are electrically the same. Each of the conductors adjoins on its outer surface at least one insulating material. The conductors run separately in the respective core. Due to the electrical insulation of the conductors with each other results in the same amount of material of the electrical conductor, a larger surface area and thus a greater effective cross-sectional area of the wire at high frequencies, since in these the current is mainly conducted near the surface (skin effect). The skin effect refers to the narrowing of the signal current in ever smaller space (near or at the conductor surface) at higher frequencies. Effectively, the conductor cross-section available for the current transport decreases or the ohmic resistance increases with increasing frequency. The skin effect thus leads to a high signal attenuation, especially at high frequencies.

Vorteilhafte Implementierungen der vorliegenden Erfindung sind Gegenstand der abhängigen Patentansprüche. Bevorzugte Ausführungsbeispiele der vorliegenden Erfindung werden nachfolgend Bezug nehmend auf die beiliegenden Zeichnungen näher erläutert. Es zeigen:

- Fig. 1

- einen Querschnitt eines Ausführungsbeispiels eines Hochgeschwindigkeitsdatenkabels;

- Fig. 2

- einen Querschnitt eines Ausführungsbeispiels einer Ader eines Hochgeschwindigkeitsdatenkabels;

- Fig. 3A

- eine perspektivische Ansicht eines Ausführungsbeispiels eines Hochgeschwindigkeitsdatenkabels;

- Fig. 3B

- eine weitere perspektivische Ansicht eines Ausführungsbeispiels eines Hochgeschwindigkeitsdatenkabels;

- Fig. 4

- einen Querschnitt eines weiteren Ausführungsbeispiels einer Ader eines Hochgeschwindigkeitsdatenkabels mit Isolatorkern;

- Fig. 5

- einen Querschnitt eines weiteren Ausführungsbeispiels eines Hochgeschwindigkeitsdatenkabels;

- Fig. 6A

- Eine erste schematische Darstellung einer Stern-Vierer Verseilung eines Hochgeschwindigkeitsdatenkabels;

- Fig. 6B

- Eine zweite schematische Darstellung einer Stern-Vierer Verseilung eines Hochgeschwindigkeitsdatenkabels.

- Fig. 6C

- Eine dritte schematische Darstellung einer Stern-Vierer Verseilung eines Hochgeschwindigkeitsdatenkabels.

- Fig. 1

- a cross section of an embodiment of a high-speed data cable;

- Fig. 2

- a cross-section of an embodiment of a wire of a high-speed data cable;

- Fig. 3A

- a perspective view of an embodiment of a high-speed data cable;

- Fig. 3B

- another perspective view of an embodiment of a high-speed data cable;

- Fig. 4

- a cross-section of another embodiment of a wire of a high-speed data cable with insulator core;

- Fig. 5

- a cross section of another embodiment of a high-speed data cable;

- Fig. 6A

- A first schematic representation of a star-quad strand of a high-speed data cable;

- Fig. 6B

- A second schematic representation of a star-quad stranding of a high-speed data cable.

- Fig. 6C

- A third schematic representation of a star-quad stranding of a high-speed data cable.

Eine leitende Abschirmung 108 umgibt die Adern 104a, 104b in Längsrichtung und bildet einen Faradayschen Käfig um die Adern 104a, 104b. Die Adern 104a, 104b können jeweils paarweise von einer gemeinsamen leitenden Abschirmung 108 umgeben sein. Alternativ wäre auch eine individuelle Abschirmung pro Ader oder einer Mehrzahl von Adern gemeinsam möglich. Durch den Faradayschen Käfig sind die Adern 104a, 104b gegen äußere elektromagnetische Wechselfelder geschützt. D.h. kapazitive oder induktive Einkopplungen von Störungen auf das Kabel 100 werden verhindert oder zumindest reduziert. Zusätzlich verhindert der Faradaysche Käfig der Abschirmung 108, dass die Adern 104a, 104b elektromagnetische Wechselfelder aussenden, wodurch weitere Adern 104a, 104b des Kabels 100 sowie die Umgebung des Kabels 100 vor elektromagnetischen Emission geschützt sind.A

Die leitende Abschirmung 108 kann aus einem beliebigen, leitenden Material gefertigt sein Beispielsweise ist die leitende Abschirmung 108 aus metallkaschierter Kunststofffolie oder aus nicht-isolierten Metalldrähten gebildet. Ferner kann die leitende Abschirmung 108 jeweils mindestens ein Aderpaar 102 in beliebiger Form bspw. gewickelt oder geflochten umgeben. Vorzugsweise ist die leitende Abschirmung 108 ein Drahtgeflecht, bei welchem einzelne, gegeneinander nicht-isolierte Metalldrähte übereinandergelegt werden oder eine kunststoffkaschierte Metallfolie welche um die Adern 104a, 104b gewickelt ist. Die leitende Abschirmung 108 wird abhängig von der gewünschten mechanischen Flexibilität bzw. Festigkeit und/oder der geforderten elektrischen Abschirmungscharakteristik des Kabels 100 gefertigt. Der leitende Schirm 108 kann als geschlossener/massiver Mantel oder als Kombination der vorgängig beschriebenen Elemente gefertigt sein.The

Die Adern 104a, 104b können miteinander verdrillt bzw. verseilt sein, d.h. die Adern 104a, 104b werden in Längsrichtung um eine gemeinsame Achse verdreht. Das Verdrillen der Adern 104a, 104b begünstigt die symmetrische Eigenschaften des Kabels 100. Störungen, welche beispielsweise aus einer bestimmten Richtung auf die Adern 104a, 104b einwirken, werden auf beide Adern 104a, 104b des Aderpaares 102 identisch aufgeprägt. Bei mehreren Aderpaaren 102 können die einzelnen Aderpaare 102 im Kabel 100 unterschiedlich stark miteinander verdrillt sein. Dadurch wird ein Einkoppeln von Störungen der Aderpaare 102 untereinander reduziert.The

Ein isolierender Kabelmantel 106 umschließt die leitende Abschirmung 108 und bildet die Oberfläche des Kabels 100. Der isolierende Kabelmantel 106 kann beispielsweise aus Polyvinylchlorid (PVC), Polypropylen (PP), Polyethylen (PE) oder einem anderen isolierenden Material bestehen. Der isolierende Kabelmantel 106 umschließt die leitende Abschirmung 108 vollständig und verhindert eine elektrische Verbindung zwischen der leitenden Abschirmung 108 und der Umgebung des Kabels 100. Zusätzlich schützt der isolierende Kabelmantel 106 das Kabel 100 vor chemischen oder mechanischen Einflüssen, welche zu Beschädigungen des Kabels 100 führen können. Der isolierende Kabelmantel 106 kann beispielsweise auf die leitende Abschirmung 108 extrudiert werden.An insulating

Die Leiter 110 sind äquidistant (mit gleichem Abstand) zu einer Längsmittelachse 118 der jeweiligen Ader 104a, 104b verlaufend angeordnet. Somit ergibt sich bei der Betrachtung des Aderquerschnitts eine kreisförmige Anordnung der Leiter 110 um ein Zentrum der Ader 104a, 104b bzw. die Mitten der Leiter 110 sind auf einem Kreis um die Längsmittelachse 118 angeordnet. Die Leiter 110 sind in jeder Ader 104a, 104b verdrillt bzw. verdreht um die Längsmittelachse 118 angeordnet. Durch das Verdrillen der Leiter 110 erhöht sich die Flexibilität der Ader 104a, 104b, d.h. je stärker die Leiter 110 in der Ader 104a, 104b verdrillt sind, desto flexibler lässt sich die Ader 104a, 104b biegen, wodurch kleinere Biegeradien mit der Ader 104a, 104b möglich sind, ohne dass die Leiter 110 in der Ader 104a, 104b brechen. Zusätzlich werden für alle Leiter die gleichen elektrischen (Umgebungs)Verhältnisse erreicht. Ein stärkeres Verdrillen führt aber gleichzeitig zu einer größeren effektiven Leiterlänge bei gleicher Außenlänge des Kabels. An den Enden des Kabels sind die einzelnen Leiter 110 einer Ader jeweils kurzgeschlossen. Dies kann z.B. durch Löten oder Crimpen geschehen.The

In weiteren Implementierungen der Ader 104a, 104b können eine Vielzahl von Leiter 110 in der Ader 104a, 104b äquidistant angeordnet sein. Vorzugsweise umfasst eine Ader 3 bis 18 Leiter 110.In further implementations of the

Jeder Leiter 110 grenzt an seiner Außenfläche an mindestens einen isolierenden Stoff an, in welchem die Leiter 110 der jeweiligen Ader 104a, 104b getrennt voneinander verlaufen. Der isolierende Stoff umschließt den Leiter 110 und verhindert elektrische Ströme zwischen den Leitern 110. Durch den isolierenden Stoff zwischen den Leitern 110 wird der Einfluß des Skin-Effekt reduziert. Der Skin-Effekt tritt auf, wenn ein elektrischer Leiter mit einem höherfrequenten Wechselstrom durchflossen wird. Dabei ist die Stromdichte im Inneren des Leiters niedriger als an dessen Oberfläche. Die Verdrängung des Stromes an die Oberfläche nimmt mit steigender Frequenz zu. Dies führt zu unerwünschten Dämpfungen eines elektrischen Kabels. Durch die Isolation der einzelnen Leiter gegeneinander wird die effektive Oberfläche bei gleichbleibendem Querschnitt erhöht. Anstelle eines einzelnen Leiters stehen mehrere kleine elektrische Leiter zur Verfügung, wodurch eine größere Oberfläche entsteht. Dies führt zu einem effektiv höheren Leiterquerschnitt bei hohen Frequenzen. Daraus resultiert eine geringere Dämpfung in der jeweiligen Ader 104a, 104b.Each

Wie in

Beim Ausführungsbeispiel von

Der isolierende Überzug 212 kann bspw. eine Lackschicht oder ein Kunststoff, wie er bspw. für den Ader- oder den Kabelmantel verwendet wird, sein. Der Vorteil einer Lackschicht ist, dass ein dünnwandiger und kostengünstiger isolierender Überzug 212 möglich ist, wobei die Wandstärke des isolierenden Überzugs 212 vorzugsweise in einem Bereich von weniger als 10µm bis 80µm liegen kann. Das Verhältnis zwischen Wandstärke des isolierenden Überzugs 212 und Radius des Leiters 210 liegt vorzugsweise im Bereich 0,015 bis 0,42. Da die Spannungspotentiale zwischen den Leitern 210 der Ader 202 klein sind, ist eine dünnwandige Isolation ausreichend. Die Durschlagfestigkeit der Lackschichtisolation liegt z.B. im Bereich von 2kV/mm. Damit lassen sich 10um dünne Lackschichten benutzen, wobei die Potential-Differenz 40V betragen darf. Alle Leiter 210 einer Ader 202 führen das gleiche Signal, so dass, z.B. durch lokale Laufzeitunterschiede, die Potentialdifferenzen sehr klein bleiben. Durch die dünnwandige Isolation ergibt sich ein geringeres Volumen und Gewicht der Leiter 210.The insulating

Die Leiter 210 mit dem isolierenden Überzug 212 werden vom Adermantel 216 umschlossen.The

Ferner unterscheidet sich die in

Bei der in

Durch den Isolatorkern 214 (nicht-leitenden Kern) und die flächige Abdeckung der Isolatorkernoberfläche (Kernoberfläche) mit Leiter 210 mit isoliertem Überzug 212 wird sichergestellt, dass alle Leiter 210 die gleiche Länge haben und somit Laufzeltunterschiede des Nutzsignales ausgeschlossen sind.The insulator core 214 (non-conductive core) and the laminar surface of the insulator core surface (core surface) with

Durch den Isolatorkern 214 (Nicht-Leiter) im Inneren der Ader 204 (Anordnung) und den isolierenden Überzug 212 wird außerdem der Proximity-Effekt reduziert. Der Proximity-Effekt bezeichnet in der Elektrotechnik die Wirkung der Stromeinschnürung oder Stromverdrängung zwischen zwei eng benachbarten Leitern unter dem Einfluss von Wechselströmen aufgrund des magnetischen Streuflusses zwischen ihnen, verursacht durch gleichgerichtete Ströme in den Leitern 210. Ähnlich wie beim Skin-Effekt hat der gleichgerichtete Strom im benachbarten Leiter den "Drang", den Stromfluß an der Oberfläche zu unterbinden. Die Strom wird in einen kleineren Querschnitt gezwungen. Indem der benachbarte Leiter auf Abstand gehalten wird, lässt sich dessen Einfluß verringern.The insulator core 214 (non-conductor) inside the core 204 (assembly) and the insulating

Der Isolatorkern 214 ist vorzugsweise aus einem isolierenden und damit den elektrischen Strom nicht leitenden Material, gefertigt. Geeignete Materialien für den Isolatorkern 214 sind beispielsweise Kunststoffe oder Gummi. Besonders bevorzugt ist der Isolatorkern 214 aus Polypropylen, Polyamid oder Polyethylen gefertigt. Das Material kann dabei z.B. massiv, geschäumt oder auch als Monofil verarbeitet werden.The

Gegenüber bekannten Kabel, bei welchem der Kern der Ader ebenfalls aus einem metallischen Leiter besteht, wird neben der Erhöhung der Datenrate das Gewicht des Kabels durch den Austausch von Leitern 210 durch Nicht-Leiter als Isolatorkern 214 reduziert.In contrast to known cables, in which the core of the core also consists of a metallic conductor, in addition to increasing the data rate, the weight of the cable is reduced by the replacement of

Der in der

Eine stabilisierende Folie 309 umgibt die zwei Aderpaare 302a, 302b, und hält diese in ihrer Position. Die stabilisierende Folie 309 kann bspw. aus elastischem Material gefertigt sein kann, welches eng an den Adern anliegt oder als ein Schrumpfschlauch ausgebildet sein, welcher auf die Adern 304 aufgeschrumpft wird. Die stabilisierende Folie 309 kann auch elektrisch leitende Eigenschaften aufweisen und damit eine, wie vorhergehend beschrieben, leitende Abschirmung 308 bspw. als metallkaschierter Kunststofffolie bilden.A stabilizing

Um die stabilisierende Folie 309 kann eine leitende Abschirmung 308 angeordnet sein, welche bspw. als Drahtgeflecht ausgebildet ist. Ferner kann die leitende Abschirmung 308 von einem Kabelmantel umschlossen sein.To the stabilizing

Die einzelnen elektrischen Leiter einer der Adern 304 sind aufgrund der geringen Auflösung der

Die Adern 304 können wie im Ausführungseispiel gezeigt, aus je sechs elektrischen Leitern 310, welche an ihren Außenflächen einen isolierenden Überzug 312 aufweisen und in einen Adermantel 316 eingebettet sind, bestehen. Die Leiter 310 sind um den Isolatorkern 314, welcher entlang der Längsmittelachse 118 verläuft, verdrillt sein, so dass jeder einzelne Leiter 310 über die Länge des Kabels 300 die gleichen relativen Positionen zu den weiteren anderen Adern 304 und zur leitenden Abschirmung 308 durchläuft. Nur so sind gleiche elektrische Verhältnis und damit gleiche elektrische Parameter (vor allem Signallaufzeiten) jedes Leiters 310 gegeben.The

Ausführungsbeispiele des Hochgeschwindigkeitsdatenkabel 100, 300, 500, 600 können in jeder Anwendung mit hohe Datenraten Einsatz finden. Dazu gehören unter anderem alle Kabel der Ethernet-Standards, LVDS-Kabel, HDMI-Kabel, Fernseh-Übertragungskabel und auch USB-Kabel. Weitere Einsatzgebiete sind möglich. Bei Übertragungen in der Hochfrequenztechnik ist es allgemein notwendig die Wellenimpedanz des Kabels 100, 300, 500, 600 an die Quellen- und Abschlussimpedanz der Übertragungsstrecke anzupassen. Die Wellenimpedanz eines Aderpaares 302a, 302b ergibt sich aus Induktivitätsbelag und Kapazitätsbelag und liegt im Bereich zwischen 50Ω bis 300Ω, bevorzugt ist eine Wellenimpedanz des Hochgeschwindigkeitsdatenkabels 100, 300, 500, 600 im Bereich zwischen 75Ω bis 160Ω (differentiell). Die Wellenimpedanz kann aber auch höher liegen.Embodiments of the high

Der Isolatorkern 414 weist an seiner Oberfläche Vertiefungen auf, welche vorzugsweise dem Radius der Leiter 410 entsprechend ausgebildet sind. Auf der vom Isolatorkern 414 abgewandten Seite, sind die Leiter 410 in den Adermantel 416 eingegossen bzw. einextrudiert. Zwischen den Leiter 410 besteht somit keine elektrische Verbindung. Durch das in

Die Ader 504 weisen je einen Isolatorkern 514 auf, welcher entlang der Längsmittelachse 118 angeordnet ist und um welchen je zehn Leiter 510 mit isolierendem Überzug 512 angeordnet sind.The

Durch die aneinander anliegenden Leiter 510 liegt der Adermantel 516, wie schon in

Die einzelnen elektrischen Leiter einer der Adern 604 sind aufgrund der geringen Auflösung der

Die in den Figuren gezeigten Ausführungsbeispiele zeigen Anordnung von elektrisch leitenden und nicht-leitenden Elementen im Querschnitt der Ader 604 des Kabels 600. Diese neue Anordnung reduziert die Dämpfung bis in den GHz-Bereich und verringert außerdem das Gewicht des Kabels 600. Beides wird unter Weiterverwendung der bisher üblichen Materialien erreicht.The embodiments shown in the figures show arrangement of electrically conductive and non-conductive elements in the cross-section of the

in anderen Worten ausgedrückt und dabei exemplarisch die Bezugszeichen von

Diese Offenbarung beschreibt eine spezielle Anordnung der Leiter 310 einer Ader 304 zur Reduzierung der Dämpfung bei gleichbleibendem Querschnitt mit Fokus auf hochratiger Datenübertragung, bei der Signallaufzeiten eine Rolle spielen. Des Weiteren wird der Aufbau des Kabels 300 für hochratige Datenübertragung, welches diese Ader 304 verwendet, beschrieben. Ziel ist ein Kabel 300 mit kontrolliertem Wellenwiderstand, niedriger Dämpfung und kleinem Durchmesser.This disclosure describes a particular arrangement of the

Bei der Ader 304 werden vorzugsweise 3 bis 18 lackisolierte massive Leiter 310 um einen Isolatorkern 114 (nichtleitenden Kern) verseilt.In the

Durch das Kabel 300 wird bei gleichbleibendem Durchmesser und Materialien (ausgenommen der isolierende Überzug 312 (zusätzliche Lackschicht) der Leiter 310 (Einzeldrähte)) eine reduzierte Dämpfung ermöglicht. Auch kann die "oberste Metallschicht" der Leiter einer konventionellen Ader durch Lack ersetzt werden, d.h. der Durchmesser des Leiters 310 kann so reduziert werden, dass mit dem isolierenden Überzug 312 der vorherige Außendurchmesser der Ader 304erhalten bleibt. Dadurch wird das Gewicht pro Leiter geringer. Der gesamte Außendurchmesser des Kabels kann gleich bleiben. Das Kabel 300 ist besonders für hochratige Datenübertragung im Gigahertz-Bereich geeignet, wo auch Laufzeitunterschiede beachtet werden müssen.Due to the

Ausführungsbeispiele des Hochgeschwindigkeitsdatenkabels können zur symmetrischen Signalübertragung verwendet werden. Dabei kann das Hochgeschwindigkeitsdatenkabel bspw. in einem System, welches ausgebildet ist, um ein symmetrisches Signal über das Hochgeschwindigkeitsdatenkabel zu übertragen, verwendet werden. Ein solches System, welches ein Hochgeschwindigkeitsdatenkabel umfasst, kann beispielsweise ein Netzwerk mit einer Mehrzahl von Computern oder ein Kommunikationsnetzwerk beispielsweise zur Sprachübertragung sein. Computer umfasst hier im weitesten Sinne aktive Netzwerkknoten, die zumindest einen Prozessor mit Speicher enthalten und an die auch beispielsweise Peripherie wie Sensoren, Steuergeräte, Monitore, Kameras, etc. angeschlossen sein kann.Embodiments of the high-speed data cable can be used for symmetrical signal transmission. Here, the high-speed data cable may be used, for example, in a system configured to transmit a balanced signal over the high-speed data cable. Such a system, which comprises a high-speed data cable, may for example be a network with a plurality of computers or a communication network, for example for voice transmission. Computer here in the broadest sense includes active network nodes, at least contain a processor with memory and to which, for example, peripherals such as sensors, control units, monitors, cameras, etc. may be connected.

Obwohl manche Aspekte im Zusammenhang mit einer Vorrichtung beschrieben wurden, versteht es sich, dass diese Aspekte auch eine Beschreibung des entsprechenden Verfahrens darstellen, sodass ein Block oder ein Bauelement einer Vorrichtung auch als ein entsprechender Verfahrensschritt oder als ein Merkmal eines Verfahrensschrittes zu verstehen ist. Analog dazu stellen Aspekte, die im Zusammenhang mit einem oder als ein Verfahrensschritt beschrieben wurden, auch eine Beschreibung eines entsprechenden Blocks oder Details oder Merkmals einer entsprechenden Vorrichtung dar. Einige oder alle der Verfahrensschritte können durch einen Hardware-Apparat (oder unter Verwendung eines Hardware-Apparats), wie zum Beispiel einen Mikroprozessor, einen programmierbaren Computer oder einer elektronischen Schaltung durchgeführt werden. Bei einigen Ausführungsbeispielen können einige oder mehrere der wichtigsten Verfahrensschritte durch einen solchen Apparat ausgeführt werden.Although some aspects have been described in the context of a device, it will be understood that these aspects also constitute a description of the corresponding method, so that a block or a component of a device is also to be understood as a corresponding method step or as a feature of a method step. Similarly, aspects described in connection with or as a method step also represent a description of a corresponding block or detail or feature of a corresponding device. Some or all of the method steps may be performed by a hardware device (or using a hardware device). Apparatus), such as a microprocessor, a programmable computer or an electronic circuit. In some embodiments, some or more of the most important method steps may be performed by such an apparatus.

Die oben beschriebenen Ausführungsbeispiele stellen lediglich eine Veranschaulichung der Prinzipien der vorliegenden Erfindung dar. Es versteht sich, dass Modifikationen und Variationen der hierin beschriebenen Anordnungen und Einzelheiten anderen Fachleuten einleuchten werden. Deshalb ist beabsichtigt, dass die Erfindung lediglich durch den Schutzumfang der nachstehenden Patentansprüche und nicht durch die spezifischen Einzelheiten, die anhand der Beschreibung und der Erläuterung der Ausführungsbeispiele hierin präsentiert wurden, beschränkt sei.The embodiments described above are merely illustrative of the principles of the present invention. It will be understood that modifications and variations of the arrangements and details described herein will be apparent to others of ordinary skill in the art. Therefore, it is intended that the invention be limited only by the scope of the appended claims and not by the specific details presented in the description and explanation of the embodiments herein.

Claims (15)

- High-speed data cable comprising:at least one core pair (102; 302a, 302b; 502), wherein- a conductive shielding (108; 308; 508) surrounds the cores (104a, 104b; 204; 304; 404; 504; 604);- an insulating cable cladding (106; 306; 506; 606) encloses the conductive shielding (108; 308; 508; 608); andeach of the cores (104a, 104b; 204; 304; 404; 504; 604) comprises at least three electric conductors (110; 210; 310; 410; 510; 610), wherein- each conductor (110; 210; 310; 410; 510; 610) abuts, on its outer surface, on at least one insulating material through which the conductors (110; 210; 310; 410; 510; 610) of the respective core (104a, 1040b; 204; 304; 404; 504; 604) run separately from one another,characterized in that- the conductors (110; 210; 310; 410; 510; 610) are arranged in a twisted manner equidistantly to a longitudinal center axis (118) of the respective core (104a, 104b; 204; 304; 404; 504; 604).

- High-speed data cable according to claim 1, wherein, in each core (204; 304; 504; 604), each conductor (210; 310; 510; 610) is enclosed on its outer surface by an insulating cover (212; 312; 512; 612) as insulating material.

- High-speed data cable according to claim 2, wherein the insulating cover (212; 312; 512; 612) is a resist layer.

- High-speed data cable according to claim 2 or 3, wherein, in each core (104a, 104b; 204; 304; 404; 504; 604), the conductors (110, 210, 310, 410, 510, 610) are at least partly embedded in insulating material.

- High-speed data cable according to any one of the preceding claims, wherein, in each core (204; 304; 404; 504; 604), an isolator core (214; 314; 414; 514; 614) is arranged along the longitudinal center axis (118) on which the conductors (210; 310; 410; 510; 610) of the respective core (204; 304; 404; 504; 604) abut.

- High-speed data cable according to claim 5, wherein the isolator core (214; 314; 414; 514; 614) is made from polypropylene, polyamide or polyethylene (each massive, foamed or as monofil).

- High-speed data cable according to claim 5 to 6, wherein, in each core (204; 304; 504; 604), the electric conductors (210; 310; 510; 610) with the insulating cover (212; 312; 512; 612) abut on the isolator core (214; 314; 514; 614) as well as on one another.

- High-speed data cable according to any one of the preceding claims, wherein the cores (104; 204; 304; 404; 504; 604) run in a twisted manner to one another.

- High-speed data cable according to any one of the preceding claims, wherein the conductive shielding (108; 308; 508; 608) is implemented of plastic-clad metal foil and/or wire mesh.

- High-speed data cable according to any one of the preceding claims, wherein the cores (104; 304; 504; 604) are respectively surrounded by the conductive shielding (108, 308, 508; 608) in pairs.

- High-speed data cable according to any one of the preceding claims, wherein four cores (304; 504; 604) are arranged as star quad in a twisted manner.

- High-speed data cable according to any one of the preceding claims, wherein each core (104; 204; 304; 404; 504; 604) comprises 3 to 18 electric conductors (110; 210; 310; 410; 510; 610).

- High-speed data cable according to any one of the preceding claims, wherein at least one core pair (102, 302, 502, 602) comprises differential wave impedance in the range of 50Ω to 300Ω.

- Usage of a high-speed data cable according to claim 1 for balanced signal transmission.

- System comprising:a high-speed data cable according to claim 1, wherein the system is implemented to transmit a balanced signal via the high-speed data cable.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102013207743 | 2013-04-26 | ||

| DE102013223584.4A DE102013223584A1 (en) | 2013-04-26 | 2013-11-19 | HIGH SPEED DATA CABLE |

| PCT/EP2014/057481 WO2014173711A1 (en) | 2013-04-26 | 2014-04-14 | High-speed data cable |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2989641A1 EP2989641A1 (en) | 2016-03-02 |

| EP2989641B1 true EP2989641B1 (en) | 2017-09-13 |

Family

ID=51685111

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP14720520.7A Not-in-force EP2989641B1 (en) | 2013-04-26 | 2014-04-14 | High-speed data cable |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US20160042840A1 (en) |

| EP (1) | EP2989641B1 (en) |

| DE (1) | DE102013223584A1 (en) |

| WO (1) | WO2014173711A1 (en) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102018114488A1 (en) * | 2018-06-18 | 2019-12-19 | Schaeffler Technologies AG & Co. KG | Actuator for actuating a motor vehicle clutch with a covered cable; and coupling system |

| JP7082102B2 (en) * | 2018-10-11 | 2022-06-07 | アプティブ・テクノロジーズ・リミテッド | Automotive communication cable |

| US12014847B2 (en) | 2021-12-03 | 2024-06-18 | Aptiv Technologies AG | Cable for connecting system components |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3150031A1 (en) * | 1981-12-17 | 1983-06-23 | H. Stoll Gmbh & Co, 7410 Reutlingen | HIGHLY FLEXIBLE INSULATED ELECTRIC CABLE |

| US4445321A (en) * | 1982-11-29 | 1984-05-01 | Hutchinson Raymond E | Tendon construction for posttensioning prestressed concrete and the method of making such tendons |

| GB9012062D0 (en) * | 1990-05-30 | 1990-07-18 | Phillips Cables Ltd | Moisture-impermeable stranded electric conductor |

| US6469251B1 (en) * | 2000-05-15 | 2002-10-22 | Tyco Electronics Corporation | Vapor proof high speed communications cable and method of manufacturing the same |

| FR2907256A1 (en) * | 2006-10-11 | 2008-04-18 | Nexans Sa | ELECTRICAL CONTROL CABLE AND METHOD OF MANUFACTURING THE SAME |

| US7674973B2 (en) * | 2008-04-18 | 2010-03-09 | George Cardas | Electrical conductor and cable utilizing same |

| TWI419178B (en) * | 2008-07-31 | 2013-12-11 | Sumitomo Electric Industries | Differential transmission signal cable and composite cable containing the same |

| JP5421565B2 (en) * | 2008-09-24 | 2014-02-19 | 住友電気工業株式会社 | coaxial cable |

| JP5487661B2 (en) * | 2009-03-19 | 2014-05-07 | ソニー株式会社 | Shielded cable |

| WO2013051096A1 (en) * | 2011-10-04 | 2013-04-11 | 東京特殊電線株式会社 | Hollow core body for signal transmission cable |

-

2013

- 2013-11-19 DE DE102013223584.4A patent/DE102013223584A1/en not_active Withdrawn

-

2014

- 2014-04-14 WO PCT/EP2014/057481 patent/WO2014173711A1/en active Application Filing

- 2014-04-14 EP EP14720520.7A patent/EP2989641B1/en not_active Not-in-force

-

2015

- 2015-10-26 US US14/923,285 patent/US20160042840A1/en not_active Abandoned

Non-Patent Citations (1)

| Title |

|---|

| None * |

Also Published As

| Publication number | Publication date |

|---|---|

| EP2989641A1 (en) | 2016-03-02 |

| WO2014173711A1 (en) | 2014-10-30 |

| US20160042840A1 (en) | 2016-02-11 |

| DE102013223584A1 (en) | 2014-10-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE875054C (en) | Electrical conductor | |

| EP3224838B1 (en) | Cable comprising braided pairs of strands | |

| EP3172741B1 (en) | Data cable for high-speed data transmissions | |

| EP2697804B1 (en) | Star-quad cable with shield | |

| EP3430633B1 (en) | Cable for transmitting electrical signals | |

| EP3132513B1 (en) | Cable arrangement | |

| EP3103122A1 (en) | Data cable | |

| EP3350813A1 (en) | Data cable for high-speed data transmissions | |

| DE69524866T2 (en) | HIGH LEAD COAXIAL CABLES FOR THE PRODUCTION OF CONNECTIONS WITH A HIGH PACKING DENSITY AND PRODUCTION METHOD | |

| EP2989641B1 (en) | High-speed data cable | |

| EP3285266B1 (en) | Cable with adapted stranding | |

| DE29719866U1 (en) | Data transmission cable | |

| WO2016075151A1 (en) | Data cable, and method for producing a data cable | |

| WO2017076984A1 (en) | Data cable and use of the data cable in a motor vehicle | |

| WO2021185983A1 (en) | Cable | |

| EP3367514A1 (en) | Plug-in connection for high frequency applications, for instance for ethernet use | |

| EP2697803B1 (en) | Star-quad cable having a shield | |

| EP0568048A2 (en) | Data transmission cable | |

| WO2017072265A1 (en) | Electric cable | |

| DE102014013558B4 (en) | Audio cable for signal transmission | |

| DE102018103607B4 (en) | Two-wire cable with nested insulation, and method and device for producing a two-wire cable | |

| DE102023103716A1 (en) | Data transmission cable and method for producing a shielded data transmission cable | |

| WO2025056253A1 (en) | Electrical cable having parallel conductors | |

| DE10057289A1 (en) | Data transmission cable comprises at least two data conductors twisted into a pair, two parallel voltage-carrying conductors, and two dielectric elements in specified zones within the cable cross section | |

| DE102020110370A1 (en) | Cable for electrical data transmission |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20151008 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| DAX | Request for extension of the european patent (deleted) | ||

| 17Q | First examination report despatched |

Effective date: 20161128 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20170323 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 928884 Country of ref document: AT Kind code of ref document: T Effective date: 20171015 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502014005444 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20170913 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170913 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171213 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170913 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170913 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170913 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170913 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171213 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170913 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171214 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170913 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170913 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 5 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170913 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170913 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170913 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170913 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170913 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180113 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170913 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170913 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502014005444 Country of ref document: DE |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170913 |

|

| 26N | No opposition filed |

Effective date: 20180614 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170913 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170913 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170913 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20180430 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180414 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180430 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180430 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180414 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170913 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170913 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20140414 Ref country code: MK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170913 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170913 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170913 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 928884 Country of ref document: AT Kind code of ref document: T Effective date: 20190414 |

|