EP2763243B1 - Connecting element and method of manufacturing a connecting element - Google Patents

Connecting element and method of manufacturing a connecting element Download PDFInfo

- Publication number

- EP2763243B1 EP2763243B1 EP13153250.9A EP13153250A EP2763243B1 EP 2763243 B1 EP2763243 B1 EP 2763243B1 EP 13153250 A EP13153250 A EP 13153250A EP 2763243 B1 EP2763243 B1 EP 2763243B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- connecting element

- layers

- grounding

- layer

- electrically conductive

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R4/00—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation

- H01R4/58—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation characterised by the form or material of the contacting members

- H01R4/62—Connections between conductors of different materials; Connections between or with aluminium or steel-core aluminium conductors

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/02—Contact members

- H01R13/03—Contact members characterised by the material, e.g. plating, or coating materials

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R35/00—Flexible or turnable line connectors, i.e. the rotation angle being limited

- H01R35/02—Flexible line connectors without frictional contact members

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R4/00—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation

- H01R4/58—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation characterised by the form or material of the contacting members

- H01R4/64—Connections between or with conductive parts having primarily a non-electric function, e.g. frame, casing, rail

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R4/00—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation

- H01R4/28—Clamped connections, spring connections

- H01R4/30—Clamped connections, spring connections utilising a screw or nut clamping member

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R4/00—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation

- H01R4/28—Clamped connections, spring connections

- H01R4/38—Clamped connections, spring connections utilising a clamping member acted on by screw or nut

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R4/00—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation

- H01R4/58—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation characterised by the form or material of the contacting members

- H01R4/66—Connections with the terrestrial mass, e.g. earth plate, earth pin

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R9/00—Structural associations of a plurality of mutually-insulated electrical connecting elements, e.g. terminal strips or terminal blocks; Terminals or binding posts mounted upon a base or in a case; Bases therefor

- H01R9/03—Connectors arranged to contact a plurality of the conductors of a multiconductor cable, e.g. tapping connections

- H01R9/05—Connectors arranged to contact a plurality of the conductors of a multiconductor cable, e.g. tapping connections for coaxial cables

- H01R9/0512—Connections to an additional grounding conductor

Definitions

- the present invention relates to a connecting element for establishing an electrically conductive connection between two further elements.

- the invention further relates to a method of manufacturing such connecting element.

- Connecting elements of the aforementioned type are used as part of grounding kits for connecting a coaxial cable or a cable of another type in outdoor applications to a ground potential.

- grounding kits may be used for grounding cables of cellular base stations and broadcast systems and the like. Such grounding is necessary to protect people and equipment from damages in case of lightning strikes and to prevent electrical potential differences to build up between the cable and other devices.

- grounding kits and their connection elements comprise crimp joints between different electrical conductors which are to be connected with each other.

- These crimp joints are comparatively complex to manufacture and do not provide for a reliable mechanical and electrical connection of elements under certain operational conditions.

- US 2011/0076861 A1 discloses a laminar electrical connector, wherein a stack of superimposed metal strips are joined into a unified body both structurally and electrically.

- US 6,422,900 B1 discloses a connector assembly for coupling a continuous length of coaxial cable to a bulkhead.

- WO 2007/049834 A1 discloses a grounding wire which is surrounded by a stainless steel covering pipe.

- this object is achieved by the feature combination according to claim 1.

- the three or more layers of the connecting element are arranged in a stacked configuration such that a sandwich-type assembly is obtained.

- At least one layer of the connecting element may comprise a plurality of materials.

- at least one layer of the connecting element is made of a specific material, i.e. does not comprise substantial portions of further materials.

- At least one layer is comprised of a portion of sheet metal made of the respective material.

- at least one layer may be made of material other than sheet metal, as long as sufficient electrical conductivity is ensured.

- At least one layer or the sheet metal which represents said layer, respectively comprises a substantially rectangular shape wherein a width and a length of said layer are large compared to a layer thickness of the respective layer.

- L defines a length

- W defines a width of the basically rectangular portion of sheet metal defining a specific layer

- the thickness d of said layer is defined by d ⁇ L/10 and/or d ⁇ W/5.

- length L and width W may comprise a ratio of L / W > 10.

- the stacked configuration of at least three layers of the connecting element according to an embodiment is mechanically flexible as opposed to monolithic connecting elements found in prior art, which facilitates mounting in the field and avoids additional machining for adapting the connecting element to different target systems.

- a particular advantage of the connecting element according to the embodiments is the fact that at least three layers comprise different material which enables to combine materials with different properties, preferably regarding mechanical stability, in particular tensile strength, and regarding electrical conductivity.

- connecting elements may be provided which comprise a very good (i.e., high) electrical conductivity and which are thus ideally suited for grounding purposes or for establishing other electrical connections (i.e., other than to ground potential).

- the connecting elements according to the embodiments comprise a comparatively high tensile strength contributing to a mechanically robust configuration.

- maximum tensile strengths for the connecting element may be attained which are much higher than the tensile strength of conventional connecting elements comprising crimp joints.

- At least one layer comprises copper and/or aluminium, whereby a low electric, i.e. Ohmic, resistance is attained.

- a whole, i.e. complete, layer of the connecting element may be made of a specific material such as e.g. copper or aluminium.

- a layer in the sense of the embodiments may also comprise different components such as sub-layers or the like, i.e. a layer in the sense of the embodiments is not restricted to a monolithic assembly as such.

- At least one layer comprises a material other than copper or aluminium, preferably a material with a higher tensile strength than that of copper or aluminium.

- at least one layer of the connecting element comprises stainless steel.

- stainless steel comprises a lower electrical conductivity in comparison to copper or aluminium, however it comprises an increased tensile strength.

- a combination of aluminium and stainless steel (or copper and stainless steel) is particularly preferred, because it offers both a good electrical conductivity and a good maximum tensile strength thus withstanding high tensile forces.

- a plurality of layers of the connecting element may be made of the same material or may comprise the same material. For example, it is possible to provide a connecting element which comprises a first number of layers made of aluminium, and at least one further layer which is made of a different material, for example stainless steel or the like.

- the connecting element in order to avoid contact corrosion between adjacent conductors such as the connecting element and e.g. a grounding element (for example a foundation earth electrode) the connecting element is to be connected to, it may be advantageous to place e.g. stainless steel material in the outer layers of the stack configuration of the connecting element, and to place less noble materials in the inner layers of the connecting element.

- the outer layers of the connecting element could be made of stainless steel, whereas the inner layers could be made of copper or aluminium.

- the outer layers may even comprise a noble metal or at least a thin (i.e. galvanized) layer of noble metal such as silver to prevent contact corrosion.

- At least two layers have a same layer thickness, which advantageously enables to provide a large number of identical components for assembling a connecting element according to the embodiments.

- at least two layers have different layer thickness which provides further degrees of freedom regarding the construction of the connecting element.

- each group comprises layers of identical thickness, and wherein different groups are associated with different layer thicknesses.

- At least one layer of the connecting element is at least partly surrounded by a jacket, which may e.g. be made of electrically isolating material.

- a jacket made of electrically isolating material which protects the layers of the connecting element from environmental influences.

- a jacket may also be configured to provide mechanical stability for the stacked configuration of the various layers of the connecting element.

- a common surrounding isolating jacket is the only means for keeping the various layers of the connecting element together in their stacked configuration.

- a non-isolating jacket or metallic clamps or the like are also possible.

- Such means may e.g. comprise soldering joints and/or welding joints and/or riveted bolts between one or more adjacent layers, clamps, screw connections comprising one or more adjacent layers and the like.

- said connecting element comprises a mounting section for connection to said further element.

- Said mounting section may e.g. be configured for mechanical and electrically conductive connection to a body unit of a grounding kit or a grounding element of a building such as an antenna tower and the like.

- said mounting section comprises at least one hole whereby a screw connection and/or fastening by means of a bolt and the like is enabled.

- a threaded bolt may also be provided at the mounting section.

- at least one component of said mounting section i.e. a threaded bolt, may form an integral part of one or more layers of the connecting element, whereby superior mechanical stability and a low Ohmic resistance is ensured.

- two groups of said layers of the connecting element are formed, wherein in an end portion of said connecting element both groups are arranged with a non-vanishing distance between each other to define a receiving section for receiving a component of said further element.

- a connecting element of a body unit of the grounding kit or the grounding element or the like may be arranged for connection with the connecting element.

- a cross-section of the connecting element is equal to or greater than about 10 mm 2 (square millimeter), which ensures a sufficient electric conductivity for handling electric currents, particularly surge currents during a lightning strike, without damage to the connecting element.

- the connecting element comprises a tensile strength (also referred to as “ultimate tensile strength", UTS) of about 2500 Newton or more.

- the tensile strength is also denoted as physical parameter "Rm” and defines the maximum stress that a material can withstand while being stretched before breaking.

- Rm physical parameter

- the connecting element is designed such that it can withstand tensile forces of about 2500 Newton or more without breaking.

- the connecting element comprises an electrical resistance R of about 2 mOhm/m (milliohm per meter) or less, which ensures a particularly low voltage drop in case of surge currents.

- grounding kit for connecting a cable to a grounding element.

- a grounding kit may e.g. be used for grounding a conductor of a cable or the like.

- the grounding kit may also be used to establish an electrically conductive connection between different conductors, wherein said conductors are not required to comprise ground potential or any kind of reference potential.

- the grounding kit comprises at least one connecting element according to the embodiments, and the grounding kit further comprises a body unit which is configured for establishing an electrically conductive connection with a component of said cable.

- said connecting element is detachably fixed to said body unit, particularly by means of one or more screws and/or a clamping mechanism, which facilitates easy installation of the grounding kit or the connecting element in the field.

- connecting elements of different lengths may be chosen to be connected with the body unit.

- said connecting element is non-detachably fixed to said body unit, particularly by means of welding, preferably ultrasonic welding.

- welding preferably ultrasonic welding.

- said body unit of the grounding kit enables to establish a watertight electrically conductive connection with the component of said cable.

- sealing means such us EPDM (ethylene propylene diene monomer) and/or other types of rubber and/or mastic.

- Figure 1a depicts a schematic side view of a connecting element 100 according to a first embodiment.

- the connecting element 100 serves for establishing an electrically conductive connection between two further elements, which are not depicted in figure 1a .

- the connecting element 100 comprises a first layer 102a of a first material, and a second layer 102b of a second material, which is different from the first material.

- the various layers 102a, 102b of the connecting element 100 are arranged in a stacked configuration as depicted by figure 1a , i.e. the first layer is arranged on top of the second layer in the depiction of figure 1a .

- Both layers 102a, 102b are preferably made of sheet metal, wherein the first layer 102a is for example made of stainless steel, and wherein the second layer 102b is made of aluminium.

- the material combination of stainless steel and aluminium offers a comparatively high mechanical robustness, particularly a high tensile strength, due to the stainless steel layer 102a. Moreover, a good electrical conductivity is ensured by using aluminium for the second layer 102b. Further, the layer configuration of a plurality of layers 102a, 102b, each of which may e.g. be comparatively thin such as e.g. 0.1 mm to e.g. 2.0 mm, advantageously results in a high mechanical flexibility so that the connecting element 100 can easily be bent for installation purposes. At least one mounting section 106 is provided, which enables to establish a mechanical and/or electrical contact between the connecting element 100 and further elements to be connected thereto.

- Figure 1b depicts a connecting element 100a.

- the first layer 102a comprises a layer thickness d2, whereas the second layer 102b comprises a layer thickness d1.

- the layer thickness d2 is larger than the layer thickness d1.

- Each layer 102a, 102b may comprise a substantially rectangular cross-section. However, different layers may also exhibit different cross-sections or cross-sectional shapes.

- the mounting section 106 may also comprise one or more holes arranged within said layers 102a, 102b.

- each of both opposing end sections 104a, 104b comprises one hole, which enables mounting of said connecting element 100a by means of a bolt or a threaded bolt/screw connection or the like.

- Figure 1c depicts a schematic side view of a further embodiment 100b, wherein the connecting element 100b comprises seven layers 102c, ..., 102d, which ensures a good electrical conductivity and a high mechanical flexibility.

- the embodiment 100b does not require any crimp joints, but may rather also be attached to other elements by means of screws or bolts, which ensures both a low contact resistance and a mechanical robust connection to these other elements.

- Figure 1d depicts a connecting element 100c according to a further embodiment.

- the outer layers 102a, 102c (i.e. in Fig. 1d the top and bottom layers) of the connecting element 100c according to figure 1d are preferably made of stainless steel, wherein an intermediate layer 102b that is arranged within said stacked configuration between the outer layers 102a, 102c is e.g. made of copper or aluminium.

- an intermediate layer 102b that is arranged within said stacked configuration between the outer layers 102a, 102c is e.g. made of copper or aluminium.

- stainless steel layers 102a, 102c reduce this undesired effect.

- the stainless steel layers 102a, 102c advantageously contribute to the tensile strength of the connecting element 100c, while the intermediate aluminium or copper layer 102b effects a good electrical conductivity.

- Figure 2a shows an end section 104b of a connecting element according to a further embodiment.

- a bolt or threaded bolt 106a may be provided integrally with said third layer 102c. This may e.g. be attained by providing a sheet metal for defining the layer 102c, by providing a threaded bolt 106a of the same or a different, but weldable, material, and by welding both components 102c, 106a to form one single monolithic component.

- layer 102a also is made of stainless steel to avoid contact corrosion

- layer 102b is again made of aluminium or copper.

- the end section 104b as depicted by figure 2a can e.g. be used for easy mounting of the connecting element to a further element which e.g. comprises a hole or nut portion that can cooperate with said threaded bolt 106a.

- Figure 2b depicts a schematic view of one single layer of a connecting element according to a further embodiment.

- the layer 102a has in its end section at least one hole 106b which enables mounting by means of a screw connection or the like.

- at least one further hole may also be provided in the end section.

- At least one layer presently e.g. layer 102a of figure 2b , or the sheet metal which represents said layer 102a, respectively, comprises a substantially rectangular shape wherein a width W and a length L of said layer 102a are large compared to a layer thickness d2 ( fig. 1b ) of the respective layer.

- L defines a length and W defines a width of the basically rectangular portion of sheet metal defining a specific layer 102a

- the thickness of said layer is defined by d ⁇ L/10 and/or d ⁇ W/5.

- the length L and width W may comprise a ratio of L / W > 10, which results in a rectangular strip-type shape.

- Figure 2c schematically depicts a side view of a connecting element 100d according to a further embodiment.

- the groups g1, g2 together comprise all six layers of the connecting element 100d.

- further layers may be provided which contribute to an aggregated cross-section area and thus to electrical conductivity, but which do not contribute to mounting the connecting element 100d.

- Such further layers may also comprise a reduced length L ( fig. 2b ) as compared to the layers forming part of the groups g1, g2 to prevent them from extending into the end section 104b.

- the end sections of the different groups g1, g2 are spaced apart by a non-vanishing distance d3 from each other, whereby a receiving section 106c is defined.

- the end sections 104b of the groups g1, g2 may also comprise through holes 106b for applying a screw connection to a further mounting element that can be introduced into the receiving section 106c.

- any of the end sections depicted by figure 2a, figure 2b , figure 2c may be applied to either one end portion 104a, 104b or to both end portions 104a, 104b of any connecting element described above.

- a connecting element may have similar or identical end portions or mounting sections 106 or different end portions or mounting sections.

- Figure 3a depicts connecting element 100d in a mounting position at a body unit 200, which is part of a grounding kit for a cable 400.

- the body unit 200 is of the clamp type and comprises a basically C-shaped cross section, also cf. figure 3b .

- the body unit 200 is mounted on the cable 400 such that a radially inner section of the body unit 200 (not shown) establishes electrically conductive contact with an outer conductor (not shown) of the cable 400. For this purpose, portions of an isolating jacket (not shown) of cable 400 must be removed to enable said contact.

- the connecting element 100d is connected to the body unit 200 by means of two screws 106d, which are received in respective holes 106b ( figure 2c ) of the connecting element 100d. Due to its plurality of single layers, the connecting element 100d is mechanically flexible and can thus easily be mounted at the body unit 200 and the cable 400. Nevertheless, due to the aggregated cross section of the multiple layers, a good electrical connectivity is achieved. Moreover, a good tensile strength is also attained, because one or more layers may be formed of material having a greater tensile strength than the good electrical conductors aluminium or copper.

- the screw connection 106d can easily be made in the field, whereby costs for installing the connecting element 100d and the body unit 200 are reduced.

- figure 3b depicts a partial cross-section of the arrangement of figure 3a . It can be seen that by means of the screws 106d ( figure 3a ) both the clamping mechanism of the body unit 200 is locked around the cable 400 and the electrical and mechanical connection between the body unit 200 and the connecting element 100d ( figure 3a ) is established by means of the screws 106d, which is advantageous since no further components are required for locking the connecting element 100d to the body unit 200 and for locking the body unit 200 to the cable 400.

- 3a has the further advantage of a very large contact surface between electrically conducting portions of the body unit 200 and the connecting element 100d, since surface portions of both groups g1, g2 of layers are used for establishing the contact, whereby a contact resistance is further reduced. Moreover, since both end sections of the C-shaped clamp element of the body unit 200 are contacted by a respective layer group g1, g2, the overall Ohmic resistance between the cable 400 and the connecting element 100d is even further reduced.

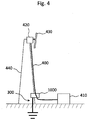

- Figure 4 depicts a schematic view of an operational scenario of a grounding kit 1000 according to an embodiment.

- the grounding kit 1000 comprises a body unit 200 as explained above with reference to figure 3a, 3b and a connecting element according to any of the above explained embodiments.

- FIG. 4 depicts an antenna tower 440 which carries a remote radio head 420 that is connected to a base station antenna system 430.

- a base station unit 410 is arranged on a ground floor, i.e. in a separate building arranged close to the antenna tower 440.

- the cable 400 establishes an electric and/or optic connection between the base station unit 410 and the remote radio head 420.

- the grounding kit 1000 for protecting the units 410, 420, 430 against lightning strikes, the grounding kit 1000 according to the embodiments is provided which establishes an electrically conductive connection between a radially outer conductor of the cable 400, which may for example comprise a hybrid cable or a coaxial cable, and a grounding element 300 of the antenna tower 440, which may e.g.

- the body unit 200 for example as a foundation earth electrode or which may be directly connected to a steel frame construction of the antenna tower 440 or the like.

- the body unit 200 For contacting the cable 400 or its outer conductor respectively, the body unit 200 as depicted by figure 3a, 3b is provided around the cable 400.

- An electrically conductive connection between the body unit 200 and the grounding element 300 of the antenna tower 440 is established by at least one connecting element according to the embodiments, which is not shown in figure 4 .

- connecting element 100d according to figure 3a may be used for establishing an electrically conductive connection between the body unit 200, the cable 400, and the grounding element 300 of the antenna tower 440.

- More than one grounding kit 1000 may be provided for a cable (i.e.

- a first grounding kit may e.g. be placed close to the antenna

- a second grounding kit may e.g. be placed as depicted by Fig. 4

- a third grounding kit may e.g. be placed close to the shelter 410, i.e. at a shelter entry, to provide further improved lightning protection for all components.

- both a good electrical conductivity, i.e. a low Ohmic resistance, and a large tensile strength is achieved for the connecting element 100, 100a, 100b, 100c, 100d, which is important since tensile forces resulting from electromagnetic field forces that may occur during a lightning strike may amount up to 2400 Newton and even more.

- the connecting element according to the embodiments can be attached to and locked at further elements 200, 300 by using screw connections or bolts or the like, which are more robust than the crimp connections.

- a particular advantage of the connecting element according to the embodiments is its high mechanical flexibility which facilitates installation on site, i.e. in the field.

- the highly conductive layers 102b ( figure 1d ) and the mechanical strong material layers (102a, 102c) are calculated such that on one hand the effective conductivity of the overall connecting element is equivalent to or higher than what is required by the relevant standards, which e.g. require a copper cross-section of 16 mm 2 or above for sufficient electrical conductivity.

- the connecting element may be connected to a ground bar 300 of a building such as an antenna tower 440 or the like, the ground bar 300 usually being made of copper or stainless steel. In many cases, the ground bar may also be implemented in the form of a galvanized steel bar with a zinc surface.

- the preferred embodiment proposes to use outer layers 102a, 102c ( figure 1d ) of stainless steel (or even noble metal or noble metal coating, i.e. silver coating), and one or more intermediate layers 102b of aluminium or copper, whereby contact corrosion is minimized and at the same time a low resistance is obtained.

- the connecting element according to the embodiments provides higher product reliability as compared to conventional systems. At the same time, the electrical contact resistance is reduced which leads to an improved lightning protection.

- a comparatively large outer surface is given for the connecting element, which improves heat dissipation thus further enabling larger maximum currents for the connecting element according to the embodiments.

- the layer construction according to the embodiments may even be configured in the field, i.e. by cutting respective preformed pieces of sheet metal.

- holes may e.g. be applied to the sheet metal by punching or drilling for enabling a screw connecting and the like.

- the layers of the connecting element according to an embodiment can be adapted with simple means or tools to different sizes of through holes and regarding the number of holes for the screw connections.

- one or more layers of the connecting element may e.g. be non-detachably attached to the body unit 200 of the grounding kit, i.e. by welding, wherein a cost-effective ultrasonic welding process may be employed.

- a cross-section of the connecting element 100 is equal to or greater than about 10 mm 2 (square millimeter), which ensures a sufficient electric conductivity for handling electric currents, particularly surge currents during a lightning strike, without damage to the connecting element 100.

- the connecting element 100 comprises a tensile strength (also referred to as “ultimate tensile strength", UTS) of about 2500 Newton or more.

- the tensile strength is also denoted as physical parameter "Rm” and defines the maximum stress that a material can withstand while being stretched before failing / breaking.

- Rm physical parameter

- the connecting element 100 is designed such that it can withstand tensile forces of about 2500 Newton or more without breaking.

- the connecting element 100 comprises an electrical resistance R of about 2 mOhm/m (milliohm per meter) or less.

- the layer construction of the connecting element advantageously enables different layers to contribute to an overall, i.e. aggregated, cross-section and/or electric conductivity and/or tensile strength, wherein contributions to one or more of these parameters of individual layers may differ from those contributions of another layer.

- at least one layer 102a may primarily contribute to an overall low electric resistance, while another layer 102b may primarily contribute to an overall high tensile strength.

Landscapes

- Cable Accessories (AREA)

Description

- The present invention relates to a connecting element for establishing an electrically conductive connection between two further elements. The invention further relates to a method of manufacturing such connecting element.

- Connecting elements of the aforementioned type are used as part of grounding kits for connecting a coaxial cable or a cable of another type in outdoor applications to a ground potential. Especially, such grounding kits may be used for grounding cables of cellular base stations and broadcast systems and the like. Such grounding is necessary to protect people and equipment from damages in case of lightning strikes and to prevent electrical potential differences to build up between the cable and other devices.

- Disadvantageously, conventional grounding kits and their connection elements comprise crimp joints between different electrical conductors which are to be connected with each other. These crimp joints are comparatively complex to manufacture and do not provide for a reliable mechanical and electrical connection of elements under certain operational conditions.

-

US 2011/0076861 A1 discloses a laminar electrical connector, wherein a stack of superimposed metal strips are joined into a unified body both structurally and electrically. -

US 6,422,900 B1 discloses a connector assembly for coupling a continuous length of coaxial cable to a bulkhead. -

WO 2007/049834 A1 discloses a grounding wire which is surrounded by a stainless steel covering pipe. - Thus, it is an object of the present invention to provide an improved connecting element and an improved method of manufacturing a connecting element which avoid the disadvantages of the prior art.

- According to the present invention, regarding a connecting element, this object is achieved by the feature combination according to

claim 1. - According to a preferred embodiment, the three or more layers of the connecting element are arranged in a stacked configuration such that a sandwich-type assembly is obtained.

- According to a further embodiment, at least one layer of the connecting element may comprise a plurality of materials. However, according to further preferred embodiments, at least one layer of the connecting element is made of a specific material, i.e. does not comprise substantial portions of further materials.

- According to an example, at least one layer, but preferably each layer, is comprised of a portion of sheet metal made of the respective material. According to a further embodiment, alternatively or in addition, at least one layer may be made of material other than sheet metal, as long as sufficient electrical conductivity is ensured.

- According to a further example, at least one layer or the sheet metal which represents said layer, respectively, comprises a substantially rectangular shape wherein a width and a length of said layer are large compared to a layer thickness of the respective layer. For example, if L defines a length and W defines a width of the basically rectangular portion of sheet metal defining a specific layer, the thickness d of said layer is defined by d < L/10 and/or d < W/5. Thus, it is ensured, that the respective layer may easily be bent, so that an increased flexibility for mounting the connecting element is given in contrast to conventional solutions which comprise massive metal bars for implementing a connecting element.

- According to a further example, length L and width W may comprise a ratio of L / W > 10. According to the invention, the stacked configuration of at least three layers of the connecting element according to an embodiment is mechanically flexible as opposed to monolithic connecting elements found in prior art, which facilitates mounting in the field and avoids additional machining for adapting the connecting element to different target systems. A particular advantage of the connecting element according to the embodiments is the fact that at least three layers comprise different material which enables to combine materials with different properties, preferably regarding mechanical stability, in particular tensile strength, and regarding electrical conductivity.

- For example, according to the principle of the embodiments, connecting elements may be provided which comprise a very good (i.e., high) electrical conductivity and which are thus ideally suited for grounding purposes or for establishing other electrical connections (i.e., other than to ground potential). At the same time, the connecting elements according to the embodiments comprise a comparatively high tensile strength contributing to a mechanically robust configuration. For example, according to some embodiments, maximum tensile strengths for the connecting element may be attained which are much higher than the tensile strength of conventional connecting elements comprising crimp joints.

- According to a further preferred embodiment, at least one layer comprises copper and/or aluminium, whereby a low electric, i.e. Ohmic, resistance is attained. According to a further embodiment, a whole, i.e. complete, layer of the connecting element may be made of a specific material such as e.g. copper or aluminium. However, it is also possible to provide other material for implementing the layer such as alloys of copper and/or aluminium and the like. According to a further embodiment, a layer in the sense of the embodiments may also comprise different components such as sub-layers or the like, i.e. a layer in the sense of the embodiments is not restricted to a monolithic assembly as such.

- According to a further preferred embodiment, at least one layer comprises a material other than copper or aluminium, preferably a material with a higher tensile strength than that of copper or aluminium. Particularly, it is preferred if at least one layer of the connecting element comprises stainless steel. As such, stainless steel comprises a lower electrical conductivity in comparison to copper or aluminium, however it comprises an increased tensile strength. Thus, a combination of aluminium and stainless steel (or copper and stainless steel) is particularly preferred, because it offers both a good electrical conductivity and a good maximum tensile strength thus withstanding high tensile forces. According to the invention, a plurality of layers of the connecting element may be made of the same material or may comprise the same material. For example, it is possible to provide a connecting element which comprises a first number of layers made of aluminium, and at least one further layer which is made of a different material, for example stainless steel or the like.

- According to a further embodiment, there is no restriction regarding the order of layers or materials within the stacked configuration of the plurality of layers defining the connecting element. However, according to one embodiment, in order to avoid contact corrosion between adjacent conductors such as the connecting element and e.g. a grounding element (for example a foundation earth electrode) the connecting element is to be connected to, it may be advantageous to place e.g. stainless steel material in the outer layers of the stack configuration of the connecting element, and to place less noble materials in the inner layers of the connecting element. For example, the outer layers of the connecting element could be made of stainless steel, whereas the inner layers could be made of copper or aluminium. Alternatively or in addition, the outer layers may even comprise a noble metal or at least a thin (i.e. galvanized) layer of noble metal such as silver to prevent contact corrosion.

- According to a further embodiment, at least two layers have a same layer thickness, which advantageously enables to provide a large number of identical components for assembling a connecting element according to the embodiments. Alternatively, it is also possible that at least two layers have different layer thickness which provides further degrees of freedom regarding the construction of the connecting element.

- Of course, it is also possible to provide different groups of layers, wherein each group comprises layers of identical thickness, and wherein different groups are associated with different layer thicknesses.

- According to a further embodiment, at least one layer of the connecting element is at least partly surrounded by a jacket, which may e.g. be made of electrically isolating material. According to a preferred embodiment, all layers of the connecting element are commonly surrounded by a jacket made of electrically isolating material which protects the layers of the connecting element from environmental influences. A common jacket of non-isolating, i.e. conductive material, such as a metallic mesh or the like, is also possible, which contributes to mechanical stability of the stack arrangement of the connecting element without affecting mechanical flexibility.

I.e., a jacket may also be configured to provide mechanical stability for the stacked configuration of the various layers of the connecting element. - For example, it is possible that a common surrounding isolating jacket is the only means for keeping the various layers of the connecting element together in their stacked configuration. Alternatively or in addition thereto, a non-isolating jacket or metallic clamps or the like are also possible.

- Of course, additional means for stabilizing the stacked configuration may also be provided. Such means may e.g. comprise soldering joints and/or welding joints and/or riveted bolts between one or more adjacent layers, clamps, screw connections comprising one or more adjacent layers and the like.

- According to a further preferred embodiment, said connecting element comprises a mounting section for connection to said further element. Said mounting section may e.g. be configured for mechanical and electrically conductive connection to a body unit of a grounding kit or a grounding element of a building such as an antenna tower and the like.

- According to a further embodiment, said mounting section comprises at least one hole whereby a screw connection and/or fastening by means of a bolt and the like is enabled. Alternatively or additionally, a threaded bolt may also be provided at the mounting section. Advantageously, according to a further embodiment, at least one component of said mounting section, i.e. a threaded bolt, may form an integral part of one or more layers of the connecting element, whereby superior mechanical stability and a low Ohmic resistance is ensured.

- According to a further embodiment, for defining said mounting section, two groups of said layers of the connecting element are formed, wherein in an end portion of said connecting element both groups are arranged with a non-vanishing distance between each other to define a receiving section for receiving a component of said further element. I.e., in the receiving section, which is located between the different groups of connecting elements, a connecting element of a body unit of the grounding kit or the grounding element or the like may be arranged for connection with the connecting element.

- According to a further embodiment, a cross-section of the connecting element, particularly an aggregated cross-section of all electrically conductive components or layers, respectively, is equal to or greater than about 10 mm2 (square millimeter), which ensures a sufficient electric conductivity for handling electric currents, particularly surge currents during a lightning strike, without damage to the connecting element.

- According to a further embodiment, the connecting element comprises a tensile strength (also referred to as "ultimate tensile strength", UTS) of about 2500 Newton or more. The tensile strength is also denoted as physical parameter "Rm" and defines the maximum stress that a material can withstand while being stretched before breaking. I.e., according to a preferred embodiment, the connecting element is designed such that it can withstand tensile forces of about 2500 Newton or more without breaking.

- According to a further embodiment, the connecting element comprises an electrical resistance R of about 2 mOhm/m (milliohm per meter) or less, which ensures a particularly low voltage drop in case of surge currents.

- A further solution to the object of the present invention is given by a grounding kit for connecting a cable to a grounding element. Such a grounding kit may e.g. be used for grounding a conductor of a cable or the like. Of course, instead of grounding (i.e. connecting to an electrical ground potential), generally, the grounding kit may also be used to establish an electrically conductive connection between different conductors, wherein said conductors are not required to comprise ground potential or any kind of reference potential.

- According to an embodiment, the grounding kit comprises at least one connecting element according to the embodiments, and the grounding kit further comprises a body unit which is configured for establishing an electrically conductive connection with a component of said cable.

- According to a further embodiment, said connecting element is detachably fixed to said body unit, particularly by means of one or more screws and/or a clamping mechanism, which facilitates easy installation of the grounding kit or the connecting element in the field. I.e., connecting elements of different lengths may be chosen to be connected with the body unit.

- Particularly, it is beneficial to avoid crimping joints, which are comparatively difficult to establish with high quality, at least in the field, and which do not exhibit the same high tensile strength as the screw or bolt connections proposed according to the embodiments.

- According to a further embodiment, said connecting element is non-detachably fixed to said body unit, particularly by means of welding, preferably ultrasonic welding. Thus, both the body unit and the connecting element of the grounding kit may form a monolithic conductor arrangement which is particularly robust.

- According to a further embodiment, said body unit of the grounding kit enables to establish a watertight electrically conductive connection with the component of said cable. This may e.g. be achieved by said body unit comprising sealing means such us EPDM (ethylene propylene diene monomer) and/or other types of rubber and/or mastic.

- A further solution to the object of the present invention is given by a method as defined in claim 15.

- Further features, aspects and advantages of the present invention are given in the following detailed description with reference to the drawings in which:

- Figure 1a

- depicts a side view of a connecting element according to a first embodiment,

- Figure 1b to 1d

- each depict a further embodiment of the connecting element,

- Figure 2a to 2c

- depict different embodiments of end sections of the connecting element,

- Figure 3a

- depicts a side view of an end portion of the connecting element according to an embodiment connected to a cable,

- Figure 3b

- depicts a partial cross-section of the configuration according to

Figure 3a , and - Figure 4

- depicts a schematic view of an operational scenario of a grounding kit according to an embodiment.

-

Figure 1a depicts a schematic side view of a connectingelement 100 according to a first embodiment. The connectingelement 100 serves for establishing an electrically conductive connection between two further elements, which are not depicted infigure 1a . - It is to be noted that the drawings comprise schematic depictions of the embodiments and that the various elements depicted in the figures are not necessarily drawn to scale. The connecting

element 100 according tofigure 1a comprises afirst layer 102a of a first material, and asecond layer 102b of a second material, which is different from the first material. Thevarious layers element 100 are arranged in a stacked configuration as depicted byfigure 1a , i.e. the first layer is arranged on top of the second layer in the depiction offigure 1a . Bothlayers first layer 102a is for example made of stainless steel, and wherein thesecond layer 102b is made of aluminium. - The material combination of stainless steel and aluminium offers a comparatively high mechanical robustness, particularly a high tensile strength, due to the

stainless steel layer 102a. Moreover, a good electrical conductivity is ensured by using aluminium for thesecond layer 102b. Further, the layer configuration of a plurality oflayers element 100 can easily be bent for installation purposes. At least one mountingsection 106 is provided, which enables to establish a mechanical and/or electrical contact between the connectingelement 100 and further elements to be connected thereto. -

Figure 1b depicts a connectingelement 100a. Thefirst layer 102a comprises a layer thickness d2, whereas thesecond layer 102b comprises a layer thickness d1. Presently, the layer thickness d2 is larger than the layer thickness d1. Eachlayer figure 1b , the mountingsection 106 may also comprise one or more holes arranged within saidlayers end sections element 100a by means of a bolt or a threaded bolt/screw connection or the like. -

Figure 1c depicts a schematic side view of afurther embodiment 100b, wherein the connectingelement 100b comprises sevenlayers 102c, ..., 102d, which ensures a good electrical conductivity and a high mechanical flexibility. In contrast to braided wires of conventional connecting elements, theembodiment 100b does not require any crimp joints, but may rather also be attached to other elements by means of screws or bolts, which ensures both a low contact resistance and a mechanical robust connection to these other elements. -

Figure 1d depicts a connectingelement 100c according to a further embodiment. - The

outer layers Fig. 1d the top and bottom layers) of the connectingelement 100c according tofigure 1d are preferably made of stainless steel, wherein anintermediate layer 102b that is arranged within said stacked configuration between theouter layers intermediate layer 102b may be contacted at an outer surface of the connectingelement 100c (with exception of the end sections of the connectingelement 100c). - This advantageously avoids contact corrosion effects since

stainless steel layers stainless steel layers element 100c, while the intermediate aluminium orcopper layer 102b effects a good electrical conductivity. -

Figure 2a shows anend section 104b of a connecting element according to a further embodiment. As can be seen fromfigure 2a , a bolt or threadedbolt 106a may be provided integrally with saidthird layer 102c. This may e.g. be attained by providing a sheet metal for defining thelayer 102c, by providing a threadedbolt 106a of the same or a different, but weldable, material, and by welding bothcomponents -

Further layers layer 102a also is made of stainless steel to avoid contact corrosion, and whereinlayer 102b is again made of aluminium or copper. - The

end section 104b as depicted byfigure 2a can e.g. be used for easy mounting of the connecting element to a further element which e.g. comprises a hole or nut portion that can cooperate with said threadedbolt 106a. -

Figure 2b depicts a schematic view of one single layer of a connecting element according to a further embodiment. Thelayer 102a has in its end section at least onehole 106b which enables mounting by means of a screw connection or the like. Optionally, at least one further hole may also be provided in the end section. At least one layer, presently e.g.layer 102a offigure 2b , or the sheet metal which represents saidlayer 102a, respectively, comprises a substantially rectangular shape wherein a width W and a length L of saidlayer 102a are large compared to a layer thickness d2 (fig. 1b ) of the respective layer. For example, if L defines a length and W defines a width of the basically rectangular portion of sheet metal defining aspecific layer 102a, the thickness of said layer is defined by d < L/10 and/or d < W/5. Thus, it is ensured, that therespective layer 102a may easily be bent, so that an increased flexibility for mounting the connecting element is given in contrast to conventional solutions which comprise massive metal bars for implementing a connecting element. The length L and width W may comprise a ratio of L / W > 10, which results in a rectangular strip-type shape.Figure 2c schematically depicts a side view of a connectingelement 100d according to a further embodiment. In itsend section 104b, three adjacent layers of the stack configuration of connectingelement 100d are combined to form a first group g1 of layers, and three further layers of the connectingelement 100d are combined to define a second group g2. Presently, the groups g1, g2 together comprise all six layers of the connectingelement 100d. However, according to further embodiments, it is not required that all layers of the connectingelement 100d are comprised of one of the groups g1, g2. For example, between groups g1, g2 or outside thereof (not shown) further layers may be provided which contribute to an aggregated cross-section area and thus to electrical conductivity, but which do not contribute to mounting the connectingelement 100d. Such further layers may also comprise a reduced length L (fig. 2b ) as compared to the layers forming part of the groups g1, g2 to prevent them from extending into theend section 104b. - As depicted by

figure 2c , the end sections of the different groups g1, g2 are spaced apart by a non-vanishing distance d3 from each other, whereby a receivingsection 106c is defined. Theend sections 104b of the groups g1, g2 may also comprise throughholes 106b for applying a screw connection to a further mounting element that can be introduced into the receivingsection 106c. - According to a further embodiment, any of the end sections depicted by

figure 2a, figure 2b ,figure 2c may be applied to either oneend portion end portions sections 106 or different end portions or mounting sections. -

Figure 3a depicts connectingelement 100d in a mounting position at abody unit 200, which is part of a grounding kit for acable 400. - As can be seen, the

body unit 200 is of the clamp type and comprises a basically C-shaped cross section, also cf.figure 3b . - The

body unit 200 is mounted on thecable 400 such that a radially inner section of the body unit 200 (not shown) establishes electrically conductive contact with an outer conductor (not shown) of thecable 400. For this purpose, portions of an isolating jacket (not shown) ofcable 400 must be removed to enable said contact. - The connecting

element 100d is connected to thebody unit 200 by means of twoscrews 106d, which are received inrespective holes 106b (figure 2c ) of the connectingelement 100d. Due to its plurality of single layers, the connectingelement 100d is mechanically flexible and can thus easily be mounted at thebody unit 200 and thecable 400. Nevertheless, due to the aggregated cross section of the multiple layers, a good electrical connectivity is achieved. Moreover, a good tensile strength is also attained, because one or more layers may be formed of material having a greater tensile strength than the good electrical conductors aluminium or copper. - Moreover, the

screw connection 106d can easily be made in the field, whereby costs for installing the connectingelement 100d and thebody unit 200 are reduced. - As already mentioned above,

figure 3b depicts a partial cross-section of the arrangement offigure 3a . It can be seen that by means of thescrews 106d (figure 3a ) both the clamping mechanism of thebody unit 200 is locked around thecable 400 and the electrical and mechanical connection between thebody unit 200 and the connectingelement 100d (figure 3a ) is established by means of thescrews 106d, which is advantageous since no further components are required for locking the connectingelement 100d to thebody unit 200 and for locking thebody unit 200 to thecable 400. The configuration offig. 3a has the further advantage of a very large contact surface between electrically conducting portions of thebody unit 200 and the connectingelement 100d, since surface portions of both groups g1, g2 of layers are used for establishing the contact, whereby a contact resistance is further reduced. Moreover, since both end sections of the C-shaped clamp element of thebody unit 200 are contacted by a respective layer group g1, g2, the overall Ohmic resistance between thecable 400 and the connectingelement 100d is even further reduced. -

Figure 4 depicts a schematic view of an operational scenario of agrounding kit 1000 according to an embodiment. - The

grounding kit 1000 comprises abody unit 200 as explained above with reference tofigure 3a, 3b and a connecting element according to any of the above explained embodiments. -

Figure 4 depicts anantenna tower 440 which carries aremote radio head 420 that is connected to a basestation antenna system 430. Abase station unit 410 is arranged on a ground floor, i.e. in a separate building arranged close to theantenna tower 440. Thecable 400 establishes an electric and/or optic connection between thebase station unit 410 and theremote radio head 420. For protecting theunits grounding kit 1000 according to the embodiments is provided which establishes an electrically conductive connection between a radially outer conductor of thecable 400, which may for example comprise a hybrid cable or a coaxial cable, and agrounding element 300 of theantenna tower 440, which may e.g. be integrated into a pedestal of the antenna tower 440 (for example as a foundation earth electrode) or which may be directly connected to a steel frame construction of theantenna tower 440 or the like. For contacting thecable 400 or its outer conductor respectively, thebody unit 200 as depicted byfigure 3a, 3b is provided around thecable 400. An electrically conductive connection between thebody unit 200 and thegrounding element 300 of theantenna tower 440 is established by at least one connecting element according to the embodiments, which is not shown infigure 4 . For example, connectingelement 100d according tofigure 3a may be used for establishing an electrically conductive connection between thebody unit 200, thecable 400, and thegrounding element 300 of theantenna tower 440. More than onegrounding kit 1000 may be provided for a cable (i.e. feeder cable 400) as depicted byFig. 4 . A first grounding kit may e.g. be placed close to the antenna, a second grounding kit may e.g. be placed as depicted byFig. 4 , and a third grounding kit may e.g. be placed close to theshelter 410, i.e. at a shelter entry, to provide further improved lightning protection for all components. - Due to its mechanical flexibility, which is enabled by the multi-layer construction according to the embodiments, an easy installation of the connecting

element 100d is enabled. - Moreover, due to the material combination over the various layers according to the embodiments, both a good electrical conductivity, i.e. a low Ohmic resistance, and a large tensile strength is achieved for the connecting

element - In contrast to conventional connecting elements, which require crimp connections, the connecting element according to the embodiments can be attached to and locked at

further elements - A particular advantage of the connecting element according to the embodiments is its high mechanical flexibility which facilitates installation on site, i.e. in the field.

- According to an embodiment, by using dissimilar metals the highly

conductive layers 102b (figure 1d ) and the mechanical strong material layers (102a, 102c) are calculated such that on one hand the effective conductivity of the overall connecting element is equivalent to or higher than what is required by the relevant standards, which e.g. require a copper cross-section of 16 mm2 or above for sufficient electrical conductivity. - On the other hand, the overall tensile strength of the connecting element should be high enough to survive the mechanical stress occurring during a lightning strike (tensile forces due to currents of up to 100 kilo Ampere flowing through the connecting element and their magnetic forces). The connecting element may be connected to a

ground bar 300 of a building such as anantenna tower 440 or the like, theground bar 300 usually being made of copper or stainless steel. In many cases, the ground bar may also be implemented in the form of a galvanized steel bar with a zinc surface. To avoid contact corrosion between theground bar 300 and the connecting element according to the embodiments, the preferred embodiment proposes to useouter layers figure 1d ) of stainless steel (or even noble metal or noble metal coating, i.e. silver coating), and one or moreintermediate layers 102b of aluminium or copper, whereby contact corrosion is minimized and at the same time a low resistance is obtained. - Due to avoiding crimp joints, the connecting element according to the embodiments provides higher product reliability as compared to conventional systems. At the same time, the electrical contact resistance is reduced which leads to an improved lightning protection.

- Also, due to the basically rectangular shape of the single layers and of the resulting stack of layers forming the connecting element according to some embodiments, a comparatively large outer surface is given for the connecting element, which improves heat dissipation thus further enabling larger maximum currents for the connecting element according to the embodiments.

- Advantageously, the layer construction according to the embodiments may even be configured in the field, i.e. by cutting respective preformed pieces of sheet metal. Moreover, holes may e.g. be applied to the sheet metal by punching or drilling for enabling a screw connecting and the like. Advantageously, the layers of the connecting element according to an embodiment can be adapted with simple means or tools to different sizes of through holes and regarding the number of holes for the screw connections. Alternatively or in addition to screw connections, one or more layers of the connecting element may e.g. be non-detachably attached to the

body unit 200 of the grounding kit, i.e. by welding, wherein a cost-effective ultrasonic welding process may be employed. - According to a further embodiment, a cross-section of the connecting

element 100, particularly an aggregated cross-section of all electrically conductive components orlayers element 100. - According to a further embodiment, the connecting

element 100 comprises a tensile strength (also referred to as "ultimate tensile strength", UTS) of about 2500 Newton or more. The tensile strength is also denoted as physical parameter "Rm" and defines the maximum stress that a material can withstand while being stretched before failing / breaking. I.e., according to a preferred embodiment, the connectingelement 100 is designed such that it can withstand tensile forces of about 2500 Newton or more without breaking. - According to a further embodiment, the connecting

element 100 comprises an electrical resistance R of about 2 mOhm/m (milliohm per meter) or less. - Any combinations of the aforementioned embodiments are also possible. Particularly, the layer construction of the connecting element advantageously enables different layers to contribute to an overall, i.e. aggregated, cross-section and/or electric conductivity and/or tensile strength, wherein contributions to one or more of these parameters of individual layers may differ from those contributions of another layer. E.g., at least one

layer 102a may primarily contribute to an overall low electric resistance, while anotherlayer 102b may primarily contribute to an overall high tensile strength. - The description and drawings merely illustrate the principles of the invention. The scope of the invention is defined by the appended claims.

Claims (15)

- Connecting element (100) for establishing an electrically conductive connection between two further elements (200, 300), namely for connecting a body unit (200) of a grounding kit (1000) with a grounding element (300), wherein said connecting element (100) comprises at least three layers (102a, 102b, 102c) of electrically conductive material, wherein at least two layers (102a, 102b) comprise different material, and wherein at least two layers comprise the same material,

characterized in that said connecting element is mechanically flexible. - Connecting element (100) according to claim 1, wherein at least one layer (102a) comprises copper and/or aluminium.

- Connecting element (100) according to one of the preceding claims, wherein at least one layer (102c) comprises a material other than copper or aluminium, preferably a material with a higher tensile strength than that of copper or aluminium, particularly stainless steel.

- Connecting element (100) according to one of the preceding claims, wherein outer layers (102a, 102c) of said connecting element (100) are made of stainless steel, and wherein at least one inner layer (102b) of said connecting element (100), which is arranged between said outer layers (102a, 102c), is made of aluminium or copper.

- Connecting element (100) according to one of the preceding claims, wherein at least two layers have a same or different layer thickness (d1, d2).

- Connecting element (100) according to one of the preceding claims, wherein at least one layer, preferably all layers, are at least partly surrounded by a jacket.

- Connecting element (100) according to one of the preceding claims, wherein said connecting element (100) comprises a mounting section (106) for connection to said further element (200, 300).

- Connecting element (100) according to claim 7, wherein said mounting section (106) comprises at least one hole (106b) and/or a, preferably threaded, bolt (106a).

- Connecting element (100) according to claim 7 or 8, wherein, for defining said mounting section (106), two groups (g1, g2) of said layers are formed, and wherein in an end portion (104b) of said connecting element (100) both groups (g1, g2) are arranged with a non-vanishing distance (d3) between each other to define a receiving section (106c) for receiving a component of said further elements (200, 300).

- Connecting element (100) according to one of the preceding claims, wherein at least one of the following criteria is met:a. a cross-section of the connecting element (100), particularly an aggregated cross-section of all electrically conductive components or layers (102a, 102b), respectively, is equal to or greater than about 10 square millimetre,b. the connecting element (100) comprises a tensile strength, preferably an ultimate tensile strength, of about 2500 Newton or more,c. the connecting element (100) comprises an electrical resistance of about 2 mOhm/m or less.

- Grounding kit (1000) for connecting a cable (400) to a grounding element (300), wherein said grounding kit (1000) comprises at least one connecting element (100, 100a, 100b, 100c, 100d) according to one of the preceding claims, and wherein said grounding kit (1000) further comprises a body unit (200) configured for establishing an electrically conductive connection with a component of said cable (400).

- Grounding kit (1000) according to claim 11, wherein said connecting element (100, 100a, 100b, 100c, 100d) is detachably fixed to said body unit (200), particularly by means of one or more screws (106d) and/or a clamping mechanism.

- Grounding kit (1000) according to claim 11, wherein said connecting element (100, 100a, 100b, 100c, 100d) is non-detachably fixed to said body unit (200), particularly by means of welding, preferably ultrasonic welding.

- Grounding kit (1000) according to one of the claims 11 to 13, wherein said body unit (200) enables to establish a watertight electrically conductive connection with a component of said cable (400).

- Method of manufacturing a connecting element (100) for establishing an electrically conductive connection between two further elements (200, 300), namely for connecting a body unit (200) of a grounding kit (1000) with a grounding element (300), wherein at least three layers (102a, 102b, 102c) of electrically conductive material are provided, wherein at least two of said layers (102a, 102b) comprise different material, wherein said at least two layers (102a, 102b) of electrically conductive material are provided such that said connecting element (100) is mechanically flexible, and wherein at least two layers comprise the same material.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP13153250.9A EP2763243B1 (en) | 2013-01-30 | 2013-01-30 | Connecting element and method of manufacturing a connecting element |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP13153250.9A EP2763243B1 (en) | 2013-01-30 | 2013-01-30 | Connecting element and method of manufacturing a connecting element |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2763243A1 EP2763243A1 (en) | 2014-08-06 |

| EP2763243B1 true EP2763243B1 (en) | 2017-06-07 |

Family

ID=47630194

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP13153250.9A Active EP2763243B1 (en) | 2013-01-30 | 2013-01-30 | Connecting element and method of manufacturing a connecting element |

Country Status (1)

| Country | Link |

|---|---|

| EP (1) | EP2763243B1 (en) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3490071A1 (en) * | 2017-11-22 | 2019-05-29 | Tyco Electronics Services GmbH | Electrical connection device |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2007049834A1 (en) * | 2005-10-25 | 2007-05-03 | Kui-Yeun Kim | The constitution and method making of the stainless covered wire |

| EP2398112A1 (en) * | 2010-06-16 | 2011-12-21 | Alcatel Lucent | Coaxial connector for terminating a coaxial cable, coaxial cable and base station thereof |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6422900B1 (en) * | 1999-09-15 | 2002-07-23 | Hh Tower Group | Coaxial cable coupling device |

| JP2005314749A (en) * | 2004-04-28 | 2005-11-10 | Shinei Hitec:Kk | Electronic component and surface treatment method thereof |

| DE102006025870A1 (en) * | 2006-06-02 | 2007-12-06 | Robert Bosch Gmbh | Bonding wire for connecting pad and pin of chip, has outer and inner layers, where inner layer has high conductivity, low bending stiffness, low breaking load and low tensile strength than that of outer layers and wire is designed as tape |

| ATE531103T1 (en) * | 2006-12-13 | 2011-11-15 | Panduit Corp | COMMUNICATION SOCKET WITH LAYER-SHAPED CONNECTOR CONTACTS |

| US7976333B2 (en) * | 2009-09-29 | 2011-07-12 | Flex-Cable | Laminar electrical connector |

-

2013

- 2013-01-30 EP EP13153250.9A patent/EP2763243B1/en active Active

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2007049834A1 (en) * | 2005-10-25 | 2007-05-03 | Kui-Yeun Kim | The constitution and method making of the stainless covered wire |

| EP2398112A1 (en) * | 2010-06-16 | 2011-12-21 | Alcatel Lucent | Coaxial connector for terminating a coaxial cable, coaxial cable and base station thereof |

Also Published As

| Publication number | Publication date |

|---|---|

| EP2763243A1 (en) | 2014-08-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US9985362B2 (en) | Arc resistant power terminal | |

| EP3130043B1 (en) | Adjustable bus bar for power distribution equipment | |

| US8410378B1 (en) | Grounding fitting | |

| JP2018531502A6 (en) | Arc resistant power terminal | |

| CA2965161C (en) | Pad extending member | |

| US10290986B2 (en) | Systems and methods for connecting power distribution devices | |

| CN109285633B (en) | Method for producing a busbar by means of a metal core and busbar | |

| JP6118823B2 (en) | Connection method of current return network in non-conductive structure, equipotential shunt connection, and equipotential bonding | |

| EP2763243B1 (en) | Connecting element and method of manufacturing a connecting element | |

| US7170459B1 (en) | Split lead antenna system | |

| US8581115B2 (en) | Grounding bar/hatchplate for use with lightning arrestors | |

| US9509068B2 (en) | Creepage design terminal strip | |

| US12080449B2 (en) | Power conductor and system | |

| KR20110054540A (en) | Booth Duct Connection Using Semi-Metal Gasket | |

| US20140292609A1 (en) | Device and Process for Reduction of Passive Intermodulation | |

| US20180090855A1 (en) | Connecting Element for Contacting a Shielding of a Power Cable | |

| KR101222871B1 (en) | Earth wire type surge discharge object | |

| US6888507B2 (en) | Split lead antenna system | |

| DE102005058029B4 (en) | Power supply for cryogenic electrical systems | |

| KR20120022102A (en) | High frequency wire connector | |

| CN216598058U (en) | Terminal structure and wind power generation equipment | |

| US20030037944A1 (en) | Flexible electrical coupling with conductive bonding jumper | |

| KR200458499Y1 (en) | Terminal for compressing cable | |

| EP2166621A1 (en) | Grounding device | |

| EP2882039A1 (en) | Coaxial cable to non-solderable material transition |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20140326 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| 17Q | First examination report despatched |

Effective date: 20150610 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: H01R 4/66 20060101ALN20160907BHEP Ipc: H01R 9/05 20060101ALN20160907BHEP Ipc: H01R 13/03 20060101ALI20160907BHEP Ipc: H01R 4/30 20060101ALN20160907BHEP Ipc: H01R 4/62 20060101AFI20160907BHEP Ipc: H01R 4/38 20060101ALN20160907BHEP Ipc: H01R 4/64 20060101ALI20160907BHEP |

|

| INTG | Intention to grant announced |

Effective date: 20160927 |

|

| GRAJ | Information related to disapproval of communication of intention to grant by the applicant or resumption of examination proceedings by the epo deleted |

Free format text: ORIGINAL CODE: EPIDOSDIGR1 |

|

| GRAJ | Information related to disapproval of communication of intention to grant by the applicant or resumption of examination proceedings by the epo deleted |

Free format text: ORIGINAL CODE: EPIDOSDIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTC | Intention to grant announced (deleted) | ||

| INTG | Intention to grant announced |

Effective date: 20170109 |

|

| RIC1 | Information provided on ipc code assigned before grant |