EP2733232A1 - Device for protecting external surfaces when aluminizing hollow components - Google Patents

Device for protecting external surfaces when aluminizing hollow components Download PDFInfo

- Publication number

- EP2733232A1 EP2733232A1 EP12193051.5A EP12193051A EP2733232A1 EP 2733232 A1 EP2733232 A1 EP 2733232A1 EP 12193051 A EP12193051 A EP 12193051A EP 2733232 A1 EP2733232 A1 EP 2733232A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- component

- container

- blade

- powder

- aluminizing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C8/00—Solid state diffusion of only non-metal elements into metallic material surfaces; Chemical surface treatment of metallic material by reaction of the surface with a reactive gas, leaving reaction products of surface material in the coating, e.g. conversion coatings, passivation of metals

- C23C8/04—Treatment of selected surface areas, e.g. using masks

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C10/00—Solid state diffusion of only metal elements or silicon into metallic material surfaces

- C23C10/04—Diffusion into selected surface areas, e.g. using masks

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C10/00—Solid state diffusion of only metal elements or silicon into metallic material surfaces

- C23C10/06—Solid state diffusion of only metal elements or silicon into metallic material surfaces using gases

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C10/00—Solid state diffusion of only metal elements or silicon into metallic material surfaces

- C23C10/06—Solid state diffusion of only metal elements or silicon into metallic material surfaces using gases

- C23C10/08—Solid state diffusion of only metal elements or silicon into metallic material surfaces using gases only one element being diffused

Definitions

- the invention relates to a protective device outer surfaces of a hollow component, which should not be coated during mecanical obstructive obstructive obstructive obstructive obstructive obstructive obstructive obstructive obstructive obstructive obstructive obstructive obstructive obstructive obstructive obstructive obstructive osene.

- the object is achieved by an apparatus of claim 1 and a method according to claim 5.

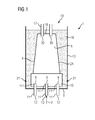

- FIG. 1 1 shows a hollow component 4, in particular a turbine blade 120, 130 as an exemplary component 4 in the interior preferably be alitiert.

- a coating material 12 is introduced into the cavity of the component 4, 120, 130 in the blade root 10 of the component 4, 120, 130.

- aluminum-containing gas 12 is used or generated.

- other materials can be applied and, if appropriate, used or introduced corresponding gases.

- the component 4, 120, 130 is surrounded by a ceramic powder 16.

- the powder 16 may be alumina, boron nitride or any other oxide or non-oxide ceramic material or any mixtures thereof.

- the component 4 or the turbine blade 120, 130 have at their end 10 or in the foot region 10 one or more openings 9 in the cavity.

- the device 1 has a container 13 which is open upwards on one side 19 and which has a plurality of corresponding tubes 11 at the bottom 8, the component 4 preferably being able to be placed on recesses 11 'which are formed at the end of the tubes 11.

- the component 4 is correspondingly with powder 16 in the container 13th surround.

- the container 13 is made higher than the length of the turbine blade 120, 130 or the component. 4

- the bottom 8 of the container 13 can be made modular, which is adapted to different types of the component 4 or turbine blade 120, 130.

- the floor 8 may be releasably secured at locations 21, 21 'and another floor (not shown) with other recesses for other types of components is attached thereto.

- the turbine blade 120, 130 introduced in the simplest manner and placed on recesses 11 '. There are appropriate gas outlets 17 at the top or the opposite end 18 of the bottom 10 is used and then only the cavity between the component 4, 120, 130 and the container 13 with the powder 16 must be filled. This is a simple and very cost effective approach.

- the recesses 11 ' are specially adapted to the openings 9 of the component 4, 120, 130 and are formed at the end of the tubes 11, which pass through the bottom 8.

- the gas 12 flows from the outside into or into the tubes 11 through the bottom 8 and out of outlet openings of the tubes 11 into the component 4, 120, 130, through the component 4, 120, 130 and back out through the gas outlets 17.

- the powder 16 can be used again and again.

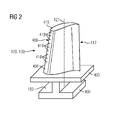

- FIG. 2 shows a perspective view of a blade 120 or guide vane 130 of a turbomachine, which extends along a longitudinal axis 121.

- the turbomachine may be a gas turbine of an aircraft or a power plant for power generation, a steam turbine or a compressor.

- the blade 120, 130 has along the longitudinal axis 121 consecutively a fastening region 400, a blade platform 403 adjacent thereto and an airfoil 406 and a blade tip 415.

- the blade 130 may have at its blade tip 415 another platform (not shown).

- a blade root 183 is formed, which serves for attachment of the blades 120, 130 to a shaft or a disc (not shown).

- the blade root 183 is designed, for example, as a hammer head. Other designs as Christmas tree or Schwalbenschwanzfuß are possible.

- the blade 120, 130 has a leading edge 409 and a trailing edge 412 for a medium flowing past the airfoil 406.

- Such superalloys are for example from EP 1 204 776 B1 .

- EP 1 306 454 .

- the blade 120, 130 can be made by a casting process, also by directional solidification, by a forging process, by a milling process or combinations thereof.

- Workpieces with a monocrystalline structure or structures are used as components for machines which are exposed to high mechanical, thermal and / or chemical stresses during operation.

- Such monocrystalline workpieces takes place e.g. by directed solidification from the melt.

- These are casting processes in which the liquid metallic alloy is transformed into a monocrystalline structure, i. to the single-crystal workpiece, or directionally solidified.

- dendritic crystals are aligned along the heat flow and form either a columnar grain structure (columnar, i.e., grains that run the full length of the workpiece and here, in common usage, are referred to as directionally solidified) or a monocrystalline structure, i. the whole workpiece consists of a single crystal.

- a columnar grain structure columnar, i.e., grains that run the full length of the workpiece and here, in common usage, are referred to as directionally solidified

- a monocrystalline structure i. the whole workpiece consists of a single crystal.

- directionally solidified microstructures which means both single crystals that have no grain boundaries or at most small angle grain boundaries, and stem crystal structures that have probably longitudinal grain boundaries but no transverse grain boundaries. These second-mentioned crystalline structures are also known as directionally solidified structures.

- the blades 120, 130 may have coatings against corrosion or oxidation, e.g. M is at least one element of the group iron (Fe), cobalt (Co), nickel (Ni), X is an active element and stands for yttrium (Y) and / or silicon and / or at least one element of the rare ones Earth, or hafnium (Hf)).

- M is at least one element of the group iron (Fe), cobalt (Co), nickel (Ni)

- X is an active element and stands for yttrium (Y) and / or silicon and / or at least one element of the rare ones Earth, or hafnium (Hf)).

- Such alloys are known from the EP 0 486 489 B1 .

- EP 0 412 397 B1 or EP 1 306 454 A1 are known from the EP 0 486 489 B1 .

- the density is preferably 95% of the theoretical density.

- the layer composition comprises Co-30Ni-28Cr-8Al-0.6Y-0.7Si or Co-28Ni-24Cr-10Al-0.6Y.

- nickel-based protective layers such as Ni-10Cr-12Al-0.6Y-3Re or Ni-12Co-21Cr-11Al-0.4Y-2Re or Ni-25Co-17Cr-10Al-0.4Y-1 are also preferably used , 5RE.

- thermal barrier coating which is preferably the outermost layer, and consists for example of ZrO 2 , Y 2 O 3 -ZrO 2 , ie it is not, partially or completely stabilized by yttria and / or calcium oxide and / or magnesium oxide.

- the thermal barrier coating covers the entire MCrAlX layer.

- suitable coating methods e.g. Electron beam evaporation (EB-PVD) produces stalk-shaped grains in the thermal barrier coating.

- the thermal barrier coating may have porous, micro- or macro-cracked grains for better thermal shock resistance.

- the thermal barrier coating is therefore preferably more porous than the MCrAlX layer.

- Refurbishment means that components 120, 130 may have to be freed of protective layers after use (eg by sandblasting). This is followed by removal of the corrosion and / or oxidation layers or products. Optionally, even cracks in the component 120, 130 are repaired. Thereafter, a recoating occurs of the component 120, 130 and a renewed use of the component 120, 130.

- the blade 120, 130 may be hollow or solid. If the blade 120, 130 is to be cooled, it is hollow and may still film cooling holes 418 (indicated by dashed lines) on.

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Turbine Rotor Nozzle Sealing (AREA)

Abstract

Description

Die Erfindung betrifft eine Schutzvorrichtung äußerer Oberflächen eines hohlen Bauteils, die beim Innenalitieren nicht beschichtet werden sollen.The invention relates to a protective device outer surfaces of a hollow component, which should not be coated during Innenalitieren.

Das Innenalitieren von hohlen Bauteilen, insbesondere von Turbinenschaufeln ist bekannt, wobei oftmals eine äußere Alitierung nicht erwünscht ist, da dort andere Schichten aufgebracht werden.Internal galling of hollow components, particularly turbine blades, is well known, often without external alitization because other layers are applied there.

Daher müssen die äußeren Oberflächen vor eventuell austretendem gasförmigem Beschichtungsmaterial, das zur Alitierung führt, geschützt werden.Therefore, the outer surfaces must be protected from any leaking gaseous coating material that leads to Alitierung.

Es ist daher Aufgabe der Erfindung eine Vorrichtung und ein Verfahren aufzuzeigen, mit dem eine Alitierung einfach durchgeführt werden kann.It is therefore an object of the invention to provide a device and a method with which a Alitierung can be easily performed.

Die Aufgabe wird gelöst durch eine Vorrichtung des Anspruchs 1 und ein Verfahren gemäß Anspruch 5.The object is achieved by an apparatus of claim 1 and a method according to

In den Unteransprüchen sind weitere vorteilhafte Maßnahmen aufgelistet, die beliebig miteinander kombiniert werden können, um weitere Vorteile zu erzielen. Es zeigen:

- Figur 1

- eine erfindungsgemäße Vorrichtung,

Figur 2- eine Turbinenschaufel,

Figur 3- eine Liste von Superlegierungen.

- FIG. 1

- a device according to the invention,

- FIG. 2

- a turbine blade,

- FIG. 3

- a list of superalloys.

Die Beschreibung und die Figur stellen nur Ausführungsbeispiele der Erfindung dar.The description and the figure represent only embodiments of the invention.

Die

Zum Schutz der äußeren Oberfläche 5 des Bauteils 4, 120, 130 wird das Bauteil 4, 120, 130 mit einem keramischen Pulver 16 umgeben.To protect the

Das Pulver 16 kann Aluminiumoxid, Bornitrid oder jedes weitere Oxid oder nicht-oxidisches keramisches Material oder jegliche Mischungen daraus sein.The

Das Bauteil 4 oder die Turbinenschaufel 120, 130 weisen an ihrem Ende 10 oder im Fußbereich 10 einen oder mehrere Öffnungen 9 in den Hohlraum auf.The

Dementsprechend weist die Vorrichtung 1 einen mit einer Seite 19 nach oben offenen Behälter 13 auf, der am Boden 8 mehrere entsprechende Rohre 11 aufweist, wobei das Bauteil 4 vorzugsweise auf Aufnehmungen 11' aufsetzbar ist, die am Ende der Rohre 11 ausgebildet sind.Accordingly, the device 1 has a

Ebenso kann das Bauteil 4 am anderen Ende 18, bei Turbinenschaufeln 120, 130 im Kronenboden an der Turbinenschaufelspitze Löcher 20 aufweisen, in die dann optional Gasauslässe 17 eingesteckt werden und aus denen das Beschichtungsmaterial 12, das durch die Rohre 11 in Richtung 7 eingeströmt war, wieder ausströmen kann.Likewise, the

Um zu verhindern, dass ausströmendes Gas aus anderen Löchern, bspw. hier im Bereich 24, bei Turbinenschaufel 120, 130 im Bereich der Austrittskante, zur Beschichtung der äußeren Oberfläche 5 des Bauteils 4 führt, wird das Bauteil 4 entsprechend mit Pulver 16 im Behälter 13 umgeben.In order to prevent escaping gas from other holes, for example here in the

Daher ist der Behälter 13 höher ausgeführt als die Länge der Turbinenschaufel 120, 130 oder des Bauteils 4.Therefore, the

Durch das Pulver 16, das im Bereich des Schaufelfußes 10 und Eintrittsöffnungen 9 bzw. an der Turbinenschaufelspitze 18 oder im Bereich der Austrittsöffnungen 24 vorhanden ist, wird verhindert, dass Gas austreten kann und es zur Beschichtung der äußeren Oberfläche 5 des Bauteils 4, 120, 130 kommen kann.The

Gegebenenfalls kann der Boden 8 des Behälters 13 modular ausgeführt werden, der an verschiedene Typen vom Bauteil 4 oder von Turbinenschaufel 120, 130 angepasst ist. So kann der Boden 8 an den Stellen 21, 21' lösbar befestigt sein und ein anderer Boden (nicht dargestellt) mit anderen Aufnehmungen für andere Bauteiltypen wird daran befestigt.Optionally, the bottom 8 of the

Ansonsten liegt hier eine sehr einfache Handhabung vor.Otherwise there is a very simple handling here.

In einen Behälter 13 wird die Turbinenschaufel 120, 130 in einfachster Art und Weise eingeführt und auf Aufnehmungen 11' aufgesetzt. Es werden entsprechende Gasauslässe 17 an der Spitze bzw. dem entgegengesetzten Ende 18 des Bodens 10 eingesetzt und dann muss nur noch der Hohlraum zwischen dem Bauteil 4, 120, 130 und dem Behälter 13 mit dem Pulver 16 aufgefüllt werden. Dies ist eine einfache und sehr kostengünstige Vorgehensweise.In a

Die Aufnehmungen 11' sind speziell den Öffnungen 9 des Bauteils 4, 120, 130 angepasst und sind am Ende der Rohre 11 ausgebildet, die durch den Boden 8 führen.The recesses 11 'are specially adapted to the

Das Gas 12 strömt von außen in das oder in die Rohre 11 durch den Boden 8 hindurch und aus Austrittsöffnungen der Rohre 11 in das Bauteil 4, 120, 130, durch das Bauteil 4, 120, 130 hindurch und durch die Gasauslässe 17 wieder hinaus.The

Das Pulver 16 kann immer wieder verwendet werden.The

Die

Die Strömungsmaschine kann eine Gasturbine eines Flugzeugs oder eines Kraftwerks zur Elektrizitätserzeugung, eine Dampfturbine oder ein Kompressor sein.The turbomachine may be a gas turbine of an aircraft or a power plant for power generation, a steam turbine or a compressor.

Die Schaufel 120, 130 weist entlang der Längsachse 121 aufeinander folgend einen Befestigungsbereich 400, eine daran angrenzende Schaufelplattform 403 sowie ein Schaufelblatt 406 und eine Schaufelspitze 415 auf.The blade 120, 130 has along the

Als Leitschaufel 130 kann die Schaufel 130 an ihrer Schaufelspitze 415 eine weitere Plattform aufweisen (nicht dargestellt).As a guide blade 130, the blade 130 may have at its

Im Befestigungsbereich 400 ist ein Schaufelfuß 183 gebildet, der zur Befestigung der Laufschaufeln 120, 130 an einer Welle oder einer Scheibe dient (nicht dargestellt).In the

Der Schaufelfuß 183 ist beispielsweise als Hammerkopf ausgestaltet. Andere Ausgestaltungen als Tannenbaum- oder Schwalbenschwanzfuß sind möglich.The

Die Schaufel 120, 130 weist für ein Medium, das an dem Schaufelblatt 406 vorbeiströmt, eine Anströmkante 409 und eine Abströmkante 412 auf.The blade 120, 130 has a leading

Bei herkömmlichen Schaufeln 120, 130 werden in allen Bereichen 400, 403, 406 der Schaufel 120, 130 beispielsweise massive metallische Werkstoffe, insbesondere Superlegierungen verwendet.In conventional blades 120, 130, for example, solid metallic materials, in particular superalloys, are used in all

Solche Superlegierungen sind beispielsweise aus der

Die Schaufel 120, 130 kann hierbei durch ein Gussverfahren, auch mittels gerichteter Erstarrung, durch ein Schmiedeverfahren, durch ein Fräsverfahren oder Kombinationen daraus gefertigt sein.The blade 120, 130 can be made by a casting process, also by directional solidification, by a forging process, by a milling process or combinations thereof.

Werkstücke mit einkristalliner Struktur oder Strukturen werden als Bauteile für Maschinen eingesetzt, die im Betrieb hohen mechanischen, thermischen und/oder chemischen Belastungen ausgesetzt sind.Workpieces with a monocrystalline structure or structures are used as components for machines which are exposed to high mechanical, thermal and / or chemical stresses during operation.

Die Fertigung von derartigen einkristallinen Werkstücken erfolgt z.B. durch gerichtetes Erstarren aus der Schmelze. Es handelt sich dabei um Gießverfahren, bei denen die flüssige metallische Legierung zur einkristallinen Struktur, d.h. zum einkristallinen Werkstück, oder gerichtet erstarrt.The production of such monocrystalline workpieces takes place e.g. by directed solidification from the melt. These are casting processes in which the liquid metallic alloy is transformed into a monocrystalline structure, i. to the single-crystal workpiece, or directionally solidified.

Dabei werden dendritische Kristalle entlang dem Wärmefluss ausgerichtet und bilden entweder eine stängelkristalline Kornstruktur (kolumnar, d.h. Körner, die über die ganze Länge des Werkstückes verlaufen und hier, dem allgemeinen Sprachgebrauch nach, als gerichtet erstarrt bezeichnet werden) oder eine einkristalline Struktur, d.h. das ganze Werkstück besteht aus einem einzigen Kristall. In diesen Verfahren muss man den Übergang zur globulitischen (polykristallinen) Erstarrung meiden, da sich durch ungerichtetes Wachstum notwendigerweise transversale und longitudinale Korngrenzen ausbilden, welche die guten Eigenschaften des gerichtet erstarrten oder einkristallinen Bauteiles zunichte machen.Here, dendritic crystals are aligned along the heat flow and form either a columnar grain structure (columnar, i.e., grains that run the full length of the workpiece and here, in common usage, are referred to as directionally solidified) or a monocrystalline structure, i. the whole workpiece consists of a single crystal. In these processes, it is necessary to avoid the transition to globulitic (polycrystalline) solidification, since non-directional growth necessarily produces transverse and longitudinal grain boundaries which negate the good properties of the directionally solidified or monocrystalline component.

Ist allgemein von gerichtet erstarrten Gefügen die Rede, so sind damit sowohl Einkristalle gemeint, die keine Korngrenzen oder höchstens Kleinwinkelkorngrenzen aufweisen, als auch Stängelkristallstrukturen, die wohl in longitudinaler Richtung verlaufende Korngrenzen, aber keine transversalen Korngrenzen aufweisen. Bei diesen zweitgenannten kristallinen Strukturen spricht man auch von gerichtet erstarrten Gefügen (directionally solidified structures).The term generally refers to directionally solidified microstructures, which means both single crystals that have no grain boundaries or at most small angle grain boundaries, and stem crystal structures that have probably longitudinal grain boundaries but no transverse grain boundaries. These second-mentioned crystalline structures are also known as directionally solidified structures.

Solche Verfahren sind aus der

Ebenso können die Schaufeln 120, 130 Beschichtungen gegen Korrosion oder Oxidation aufweisen, z. B. (MCrAlX; M ist zumindest ein Element der Gruppe Eisen (Fe), Kobalt (Co), Nickel (Ni), X ist ein Aktivelement und steht für Yttrium (Y) und/oder Silizium und/oder zumindest ein Element der Seltenen Erden, bzw. Hafnium (Hf)). Solche Legierungen sind bekannt aus der

Die Dichte liegt vorzugsweise bei 95% der theoretischen Dichte.The density is preferably 95% of the theoretical density.

Auf der MCrAlX-Schicht (als Zwischenschicht oder als äußerste Schicht) bildet sich eine schützende Aluminiumoxidschicht (TGO = thermal grown oxide layer).A protective aluminum oxide layer (TGO = thermal grown oxide layer) is formed on the MCrAlX layer (as an intermediate layer or as the outermost layer).

Vorzugsweise weist die Schichtzusammensetzung Co-30Ni-28Cr-8Al-0,6Y-0,7Si oder Co-28Ni-24Cr-10Al-0,6Y auf. Neben diesen kobaltbasierten Schutzbeschichtungen werden auch vorzugsweise nickelbasierte Schutzschichten verwendet wie Ni-10Cr-12Al-0,6Y-3Re oder Ni-12Co-21Cr-11Al-0,4Y-2Re oder Ni-25Co-17Cr-10Al-0,4Y-1,5Re.Preferably, the layer composition comprises Co-30Ni-28Cr-8Al-0.6Y-0.7Si or Co-28Ni-24Cr-10Al-0.6Y. In addition to these cobalt-based protective coatings, nickel-based protective layers such as Ni-10Cr-12Al-0.6Y-3Re or Ni-12Co-21Cr-11Al-0.4Y-2Re or Ni-25Co-17Cr-10Al-0.4Y-1 are also preferably used , 5RE.

Auf der MCrAlX kann noch eine Wärmedämmschicht vorhanden sein, die vorzugsweise die äußerste Schicht ist, und besteht beispielsweise aus ZrO2, Y2O3-ZrO2, d.h. sie ist nicht, teilweise oder vollständig stabilisiert durch Yttriumoxid und/oder Kalziumoxid und/oder Magnesiumoxid.On the MCrAlX may still be present a thermal barrier coating, which is preferably the outermost layer, and consists for example of ZrO 2 , Y 2 O 3 -ZrO 2 , ie it is not, partially or completely stabilized by yttria and / or calcium oxide and / or magnesium oxide.

Die Wärmedämmschicht bedeckt die gesamte MCrAlX-Schicht. Durch geeignete Beschichtungsverfahren wie z.B. Elektronenstrahlverdampfen (EB-PVD) werden stängelförmige Körner in der Wärmedämmschicht erzeugt.The thermal barrier coating covers the entire MCrAlX layer. By suitable coating methods, e.g. Electron beam evaporation (EB-PVD) produces stalk-shaped grains in the thermal barrier coating.

Andere Beschichtungsverfahren sind denkbar, z.B. atmosphärisches Plasmaspritzen (APS), LPPS, VPS oder CVD. Die Wärmedämmschicht kann poröse, mikro- oder makrorissbehaftete Körner zur besseren Thermoschockbeständigkeit aufweisen. Die Wärmedämmschicht ist also vorzugsweise poröser als die MCrAlX-Schicht.Other coating methods are conceivable, e.g. atmospheric plasma spraying (APS), LPPS, VPS or CVD. The thermal barrier coating may have porous, micro- or macro-cracked grains for better thermal shock resistance. The thermal barrier coating is therefore preferably more porous than the MCrAlX layer.

Wiederaufarbeitung (Refurbishment) bedeutet, dass Bauteile 120, 130 nach ihrem Einsatz gegebenenfalls von Schutzschichten befreit werden müssen (z.B. durch Sandstrahlen). Danach erfolgt eine Entfernung der Korrosions- und/oder Oxidationsschichten bzw. -produkte. Gegebenenfalls werden auch noch Risse im Bauteil 120, 130 repariert. Danach erfolgt eine Wiederbeschichtung des Bauteils 120, 130 und ein erneuter Einsatz des Bauteils 120, 130.Refurbishment means that components 120, 130 may have to be freed of protective layers after use (eg by sandblasting). This is followed by removal of the corrosion and / or oxidation layers or products. Optionally, even cracks in the component 120, 130 are repaired. Thereafter, a recoating occurs of the component 120, 130 and a renewed use of the component 120, 130.

Die Schaufel 120, 130 kann hohl oder massiv ausgeführt sein. Wenn die Schaufel 120, 130 gekühlt werden soll, ist sie hohl und weist ggf. noch Filmkühllöcher 418 (gestrichelt angedeutet) auf.The blade 120, 130 may be hollow or solid. If the blade 120, 130 is to be cooled, it is hollow and may still film cooling holes 418 (indicated by dashed lines) on.

Claims (5)

zum Schutz einer Außenfläche (5) eines hohlen Bauteils (4, 120, 130) gegen eine Alitierung während des Innenalitierens des hohlen Bauteils (4, 120, 130),

die (1) zumindest aufweist:

for protecting an outer surface (5) of a hollow component (4, 120, 130) against alitization during the inner galling of the hollow component (4, 120, 130),

which (1) has at least:

bei dem der Boden (8) des Behälters (13) modular (21, 21') ausgebildet ist,

um sich an verschiedene Typen von Bauteilen (4, 120, 130) anzupassen.Device according to claim 1,

in which the bottom (8) of the container (13) is modular (21, 21 '),

to adapt to different types of components (4, 120, 130).

in der keramisches Pulver, insbesondere Aluminiumoxidpulver als Pulver (16) vorhanden ist.Device according to one or both of claims 1 or 2,

in the ceramic powder, in particular alumina powder as a powder (16) is present.

insbesondere die in die Einlässe des Bauteils (4, 120, 130) hineinragen.Device according to one of the preceding claims, comprising tubes (11) on the bottom (8) of the container (13) on which (11) the component (4, 120, 130) can be placed and

in particular, which protrude into the inlets of the component (4, 120, 130).

bei dem eine Vorrichtung nach einem oder mehreren der Ansprüche 1, 2, 3 oder 4, verwendet wird und

ein Beschichtungsmaterial (12) in das Innere des Bauteils (4, 120, 130) eingeführt (7) wird.Method of interior alitation,

in which a device according to one or more of claims 1, 2, 3 or 4, is used and

a coating material (12) is introduced into the interior of the component (4, 120, 130) (7).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP12193051.5A EP2733232A1 (en) | 2012-11-16 | 2012-11-16 | Device for protecting external surfaces when aluminizing hollow components |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP12193051.5A EP2733232A1 (en) | 2012-11-16 | 2012-11-16 | Device for protecting external surfaces when aluminizing hollow components |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP2733232A1 true EP2733232A1 (en) | 2014-05-21 |

Family

ID=47191621

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP12193051.5A Withdrawn EP2733232A1 (en) | 2012-11-16 | 2012-11-16 | Device for protecting external surfaces when aluminizing hollow components |

Country Status (1)

| Country | Link |

|---|---|

| EP (1) | EP2733232A1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN106637068A (en) * | 2016-12-20 | 2017-05-10 | 四川成发航空科技股份有限公司 | Anti-percolator for tenons of guide blades of aeronautic engine |

Citations (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0486489B1 (en) | 1989-08-10 | 1994-11-02 | Siemens Aktiengesellschaft | High-temperature-resistant, corrosion-resistant coating, in particular for components of gas turbines |

| EP0412397B1 (en) | 1989-08-10 | 1998-03-25 | Siemens Aktiengesellschaft | Rhenium-containing protective coating with high corrosion and oxidation resistance |

| EP0892090A1 (en) | 1997-02-24 | 1999-01-20 | Sulzer Innotec Ag | Method for manufacturing single crystal structures |

| EP0786017B1 (en) | 1994-10-14 | 1999-03-24 | Siemens Aktiengesellschaft | Protective layer for protecting parts against corrosion, oxidation and excessive thermal stresses, as well as process for producing the same |

| WO1999067435A1 (en) | 1998-06-23 | 1999-12-29 | Siemens Aktiengesellschaft | Directionally solidified casting with improved transverse stress rupture strength |

| US6024792A (en) | 1997-02-24 | 2000-02-15 | Sulzer Innotec Ag | Method for producing monocrystalline structures |

| WO2000044949A1 (en) | 1999-01-28 | 2000-08-03 | Siemens Aktiengesellschaft | Nickel base superalloy with good machinability |

| EP1076111A2 (en) * | 1999-08-11 | 2001-02-14 | General Electric Company | Apparatus and method for selectively coating internal and external surfaces of an airfoil |

| EP1306454A1 (en) | 2001-10-24 | 2003-05-02 | Siemens Aktiengesellschaft | Rhenium containing protective coating protecting a product against corrosion and oxidation at high temperatures |

| EP1319729A1 (en) | 2001-12-13 | 2003-06-18 | Siemens Aktiengesellschaft | High temperature resistant part, made of single-crystal or polycrystalline nickel-base superalloy |

| EP1403395A1 (en) * | 2002-09-27 | 2004-03-31 | GE Aviation Services Operation (Pte) Ltd. | Method for vapor phase aluminiding of a gas turbine blade partially masked with a masking enclosure |

| EP1204776B1 (en) | 1999-07-29 | 2004-06-02 | Siemens Aktiengesellschaft | High-temperature part and method for producing the same |

| EP1772531A1 (en) * | 2005-10-07 | 2007-04-11 | Siemens Aktiengesellschaft | Method and apparatus for internal coating. |

| EP1788109A1 (en) * | 2005-11-22 | 2007-05-23 | United Technologies Corporation | Selective aluminide coating process |

-

2012

- 2012-11-16 EP EP12193051.5A patent/EP2733232A1/en not_active Withdrawn

Patent Citations (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0486489B1 (en) | 1989-08-10 | 1994-11-02 | Siemens Aktiengesellschaft | High-temperature-resistant, corrosion-resistant coating, in particular for components of gas turbines |

| EP0412397B1 (en) | 1989-08-10 | 1998-03-25 | Siemens Aktiengesellschaft | Rhenium-containing protective coating with high corrosion and oxidation resistance |

| EP0786017B1 (en) | 1994-10-14 | 1999-03-24 | Siemens Aktiengesellschaft | Protective layer for protecting parts against corrosion, oxidation and excessive thermal stresses, as well as process for producing the same |

| EP0892090A1 (en) | 1997-02-24 | 1999-01-20 | Sulzer Innotec Ag | Method for manufacturing single crystal structures |

| US6024792A (en) | 1997-02-24 | 2000-02-15 | Sulzer Innotec Ag | Method for producing monocrystalline structures |

| WO1999067435A1 (en) | 1998-06-23 | 1999-12-29 | Siemens Aktiengesellschaft | Directionally solidified casting with improved transverse stress rupture strength |

| WO2000044949A1 (en) | 1999-01-28 | 2000-08-03 | Siemens Aktiengesellschaft | Nickel base superalloy with good machinability |

| EP1204776B1 (en) | 1999-07-29 | 2004-06-02 | Siemens Aktiengesellschaft | High-temperature part and method for producing the same |

| EP1076111A2 (en) * | 1999-08-11 | 2001-02-14 | General Electric Company | Apparatus and method for selectively coating internal and external surfaces of an airfoil |

| EP1306454A1 (en) | 2001-10-24 | 2003-05-02 | Siemens Aktiengesellschaft | Rhenium containing protective coating protecting a product against corrosion and oxidation at high temperatures |

| EP1319729A1 (en) | 2001-12-13 | 2003-06-18 | Siemens Aktiengesellschaft | High temperature resistant part, made of single-crystal or polycrystalline nickel-base superalloy |

| EP1403395A1 (en) * | 2002-09-27 | 2004-03-31 | GE Aviation Services Operation (Pte) Ltd. | Method for vapor phase aluminiding of a gas turbine blade partially masked with a masking enclosure |

| EP1772531A1 (en) * | 2005-10-07 | 2007-04-11 | Siemens Aktiengesellschaft | Method and apparatus for internal coating. |

| EP1788109A1 (en) * | 2005-11-22 | 2007-05-23 | United Technologies Corporation | Selective aluminide coating process |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN106637068A (en) * | 2016-12-20 | 2017-05-10 | 四川成发航空科技股份有限公司 | Anti-percolator for tenons of guide blades of aeronautic engine |

| CN106637068B (en) * | 2016-12-20 | 2018-11-27 | 四川成发航空科技股份有限公司 | A kind of aero-engine guide vane tenon percolator |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2444590B1 (en) | Method for coating cooling holes | |

| EP2547488B1 (en) | Method for reconditioning a turbine blade with at least one platform | |

| EP2591872A1 (en) | Remelting method and subsequent filling and resulting component | |

| EP2865781A1 (en) | Two layer ceramic layer having different microstructures | |

| EP2386823A1 (en) | Surface analysis and device for detecting closed holes and device for opening them again | |

| EP2712700A1 (en) | Laser drills without burr formation | |

| EP2631321A1 (en) | Ceramic heat insulation layer system with external high aluminium layer and method | |

| EP2878697A1 (en) | Method for producing a chamfer, component with chamfer and device | |

| EP2712699A1 (en) | Method for protecting a component, method for laser boring and component | |

| EP2604377B1 (en) | Method for laser processing a laminated piece with ceramic coating | |

| EP2774710A1 (en) | Surface and crack repair by means of different soldering materials | |

| DE102013223202A1 (en) | Geometry-induced spray spot adaptation in coating processes | |

| EP2733232A1 (en) | Device for protecting external surfaces when aluminizing hollow components | |

| DE102014200114A1 (en) | Method for protecting a component, method for laser drilling and component | |

| EP2730364A1 (en) | Weld pool backing at the edge area | |

| EP2547179B1 (en) | Plasma spray nozzle with internal injection | |

| EP2340909A1 (en) | Sealing of circular and oval openings in crown bases of turbine rotor blades using conical plugs | |

| EP2591876A1 (en) | Process for build-up welding a single or directionally solidified metallic article | |

| DE102013224566A1 (en) | Tungsten alloy masking mask and a tungsten alloy | |

| EP2754528A1 (en) | Method of build up welding a substrate through laser remelting of a prefabricated mold | |

| EP2720033A1 (en) | Device and method for combined flow and thermography measurement | |

| EP2716779A1 (en) | Metal alloy with quasi-crystalline particles, powder, component, method and layer system | |

| EP2581563A1 (en) | Method and device for channel measurement | |

| WO2011141430A1 (en) | Surface analysis for detecting closed holes and method for reopening | |

| EP2756907A1 (en) | Built-up welding with an external thicker outline contour |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20121116 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20141122 |