EP2688741B1 - Presse mit verbesserter stütze - Google Patents

Presse mit verbesserter stütze Download PDFInfo

- Publication number

- EP2688741B1 EP2688741B1 EP12711140.9A EP12711140A EP2688741B1 EP 2688741 B1 EP2688741 B1 EP 2688741B1 EP 12711140 A EP12711140 A EP 12711140A EP 2688741 B1 EP2688741 B1 EP 2688741B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- compensator

- retaining nut

- guide bushing

- radial

- nut

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000003758 nuclear fuel Substances 0.000 claims description 8

- 238000004519 manufacturing process Methods 0.000 claims description 7

- 239000008188 pellet Substances 0.000 claims description 7

- 238000000465 moulding Methods 0.000 claims description 4

- 239000012530 fluid Substances 0.000 claims description 3

- 230000000712 assembly Effects 0.000 claims 1

- 238000000429 assembly Methods 0.000 claims 1

- 238000005553 drilling Methods 0.000 claims 1

- 238000007373 indentation Methods 0.000 description 6

- 238000012423 maintenance Methods 0.000 description 6

- 238000007789 sealing Methods 0.000 description 5

- 239000000843 powder Substances 0.000 description 4

- 230000006866 deterioration Effects 0.000 description 2

- 230000000149 penetrating effect Effects 0.000 description 2

- 238000010079 rubber tapping Methods 0.000 description 2

- WZECUPJJEIXUKY-UHFFFAOYSA-N [O-2].[O-2].[O-2].[U+6] Chemical compound [O-2].[O-2].[O-2].[U+6] WZECUPJJEIXUKY-UHFFFAOYSA-N 0.000 description 1

- SHZGCJCMOBCMKK-KGJVWPDLSA-N beta-L-fucose Chemical compound C[C@@H]1O[C@H](O)[C@@H](O)[C@H](O)[C@@H]1O SHZGCJCMOBCMKK-KGJVWPDLSA-N 0.000 description 1

- 230000003749 cleanliness Effects 0.000 description 1

- 238000011109 contamination Methods 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 230000001939 inductive effect Effects 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 235000010603 pastilles Nutrition 0.000 description 1

- 239000012207 thread-locking agent Substances 0.000 description 1

- 229910000439 uranium oxide Inorganic materials 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B30—PRESSES

- B30B—PRESSES IN GENERAL

- B30B15/00—Details of, or accessories for, presses; Auxiliary measures in connection with pressing

- B30B15/06—Platens or press rams

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B30—PRESSES

- B30B—PRESSES IN GENERAL

- B30B11/00—Presses specially adapted for forming shaped articles from material in particulate or plastic state, e.g. briquetting presses, tabletting presses

- B30B11/02—Presses specially adapted for forming shaped articles from material in particulate or plastic state, e.g. briquetting presses, tabletting presses using a ram exerting pressure on the material in a moulding space

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B30—PRESSES

- B30B—PRESSES IN GENERAL

- B30B15/00—Details of, or accessories for, presses; Auxiliary measures in connection with pressing

- B30B15/06—Platens or press rams

- B30B15/065—Press rams

- B30B15/067—Press rams with means for equalizing the pressure exerted by a plurality of press rams

Definitions

- the present invention relates to a press providing improved maintenance, for example a press for the manufacture of nuclear fuel pellets.

- a press for the manufacture of nuclear fuel pellets comprises a table in which molding dies are made for pressing the nuclear fuel powder between two punches, a lower punch and an upper punch.

- the upper punch moves in the die during pressing while the lower punch remains stationary.

- the powder is for example formed from a mixture of plutonium oxide and uranium oxide.

- the table has a plurality of dies etched simultaneously by a plurality of punches.

- Each upper punch is carried by a compensator, itself mounted in a common support which is moved relative to the table by means of a jack.

- the support is called "compensator housing”.

- a compensator forms a piston, sealingly movable in a bore formed in the compensator housing. Pressurized oil is injected between the bottom of the piston and the bottom of the bore so as to urge the piston bearing the punch outwardly of the compensator housing.

- the bores are interconnected, and the compensators are used to balance the oil pressure on the different punches.

- Each compensator has a large diameter portion on which the oil pressure is applied, and a small diameter portion of which a free end carries the punch.

- the large diameter portion has on its periphery seals.

- the compensator is guided in the bore by a bushing surrounding the small diameter part.

- the sleeve is itself held in the bore by a nut which is screwed into the bore of the compensator.

- the bushing also, has seals on its outer periphery and on its inner periphery.

- Reliable sealing of the compensator assembly is required to prevent contamination of the dies and the nuclear fuel powder. It is recalled that, for security reasons, the press is in a glove box; therefore, any intervention on it is long and tedious. In addition, a pollution of the powder causes discarding of the pellets.

- the seals are then monitored regularly, which requires disassembly of the compensators. For this, the retaining nut is unscrewed, then the guide sleeve is removed and finally the compensator is extracted from its bore. It may happen that the guide sleeve remains stuck in the bore, it is then necessary to exert a tensile force on the sleeve, which can damage the bushing and the inside of the bore.

- a guide bushing and holding nut assembly secured to one another axially, while ensuring axial play and radial clearance between the guide sleeve and the retaining nut so that to allow a self-centering of the sleeve in the bore and around the compensator, during the assembly, to avoid deterioration of the joints.

- the sleeve is free to rotate relative to the nut. Thus during tightening or loosening of the nut, the sleeve does not rotate on itself which reduces the risk of deterioration of the seals it carries.

- the guide sleeve is surrounded by the retaining nut over part of its length

- the securing means comprise at least two radial fingers housed in radial bores (made in the retaining nut and one of which radially inner end opens into an annular groove formed in the outer periphery of the guide sleeve, a radial clearance being provided between the radially inner end of the radial fingers and a radial bottom of the groove and an axial play being provided between side edges the radially inner end of the radial fingers and the lateral edges of the groove.

- the radial fingers are held in position in the radial housings by means of pressure screws.

- the pressure screws can be immobilized axially for example by means of a needle punch or a threadlock.

- the end radially inner fingers advantageously has a reduced diameter.

- the radial fingers are preferably three in number arranged at 120 ° from each other.

- the guide sleeve may comprise in its inner periphery a guide segment of the compensator.

- the retaining nut comprises, in a transverse face opposite to that in contact with the guiding bush, indentations intended to cooperate with indentations carried by a tool for exerting a tightening or loosening force on the holding nut.

- the press forms, for example, a press for manufacturing nuclear fuel pellets.

- a tool for mounting and dismounting the press compensator guiding and holding assembly according to the present invention, for clamping and loosening the compensator retaining nuts may have a longitudinal axis and has a central cavity open to a first end for receiving the second end of the compensator, said open end being bordered by an annular surface provided with indentations or protrusions corresponding to recesses protruding or recessed respectively to the housing of the nut, and a second end means for exerting a rotational force on the tool about its longitudinal axis.

- the tool may have protruding indentations and the nut may have indentations.

- the means for exerting a rotational force to the tool are formed for example by a fingerprint for the mounting and the angular immobilization of a lever on the tool, for example an imprint of polygonal shape recessed or protruding.

- the side wall of the central housing is perforated.

- the depth of the housing corresponds substantially to the length of the portion of the compensator projecting from the nut, or the length of the assembly formed by the portion of the compensator projecting from the nut and the punch.

- the present invention applies to any type of hydraulic press and is not limited to the nuclear field. It is particularly advantageous in the areas where cleanliness is an important criterion, but also in all areas using presses, because of its simplified maintenance.

- the press of the figure 1 is housed in a confined chamber 2, type glove box. It comprises a table 4 carrying the molding dies 6, mounted mobile along guide columns 8, a lower jack Vi to move the table 4, a fixed support 12 of lower punches 14 and a movable support 15 of upper punches 16 and displaceable by an upper cylinder Vs.

- the support 15 forms the compensator housing and carries the compensators (not shown) and the upper punches 16.

- the cylinders pass tightly through the walls of the enclosure 2.

- the compensator housing 15 is formed by a plate in which are machined bores 18, of longitudinal axis X, each of them receiving a compensator 20.

- the bores 18 are through and are closed at one end, opposite to that by which the compensator leaves, by a plug 22.

- Each bore 18 has a first portion of smaller diameter 18.1 and a second portion of larger diameter 18.2 connecting to the portion of smaller diameter 18.1 by an annular bearing surface 18.3.

- the compensator 20 has a first portion of larger diameter 20.1 and a second portion of smaller diameter 20.2 connecting to the larger diameter portion by a shoulder 20.3.

- the larger diameter portion 20.1 is received in the smaller diameter portion 18.1 of the bore 18.

- the larger diameter portion 20.1 of the compensator 20 has a groove 24 receiving a seal 26 and two grooves 28 located on either side of the groove 24 and receiving guide rings 30.

- the bottom of the larger diameter portion 20.1 of the compensator 20 comprises two bores 29 receiving two anti-rotation rods 31 fixed in the bottom of the bore 18.

- each bore defines with the bottom of the compensator that it contains a chamber 19 to be filled with oil under pressure.

- the chambers 19 of all the bores are in fluid communication with each other to allow the flow of oil between the chambers 19 and ensure the balancing of the pressures on the punches during the pressing step.

- a guide sleeve 32 is mounted in the larger diameter portion 18.2 of the bore 18 and abuts against the annular bearing surface 18.3.

- the bushing 32 surrounds the smaller diameter portion 20.2 of the compensator 20.

- the bushing has a large outer diameter portion 32.1 and a small outer diameter portion 32.2 connected by a shoulder 32.3.

- the guide sleeve 32 has on its outer periphery two seals 34 and on its inner periphery two axially offset sealing means 35 and a guide segment 36 of the compensator.

- the guide segment is mounted in the small outer diameter portion 32.2.

- the sealing means 35 each comprise an O-ring mounted radially at the bottom of the groove and a sealing ring at the outlet of the groove and rubbing on the compensator. The ring is then pressed onto the compensator by the O-ring and the pressurized oil.

- a retaining nut 38 is mounted in the larger diameter portion 18.2 of the bore 18 and bears against the shoulder 32.3 of the guide sleeve 32.

- the retaining nut 38 has a large inner diameter portion 38.1 and a small inner diameter portion 38.2.

- the retaining nut 38 is mounted around the sleeve 32 so that its large-diameter inner portion 38.1 surrounds the small outer diameter portion 32.2 of the guide sleeve 32.

- the retaining nut 38 has a thread 40 on its outer periphery cooperating with a tapping of the portion of larger diameter 18.2.

- the retaining nut carries on its inner periphery a seal 42, for example of the lip seal type rubbing on the smaller diameter portion 20.2 of the compensator.

- a clearance is provided between the inner diameter of the large diameter portion 38.1 of the nut and the outer diameter of the small diameter portion of the bushing 32, so that the bushing is not forced into the nut.

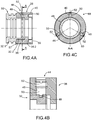

- FIG. 4A a sectional view of the guide sleeve assembly 32 and the retaining nut 38 can be seen, shown alone along a different section plane from that of the figure 3 .

- the bushing 32 and the nut are secured axially and radially to one another, while leaving an axial and radial clearance between the parts.

- Fixing means 44 with clearance are then provided between the sleeve 32 and the nut 38.

- the securing means 44 comprise three radial bores 46 arranged at 120 ° from each other formed in the nut, made in the part of small inside diameter and opening into a groove 48 made in the periphery of small outer diameter portion 32.2 of the sleeve 32 and fingers 50, housed in the housing 46 and penetrating the groove 48.

- the outer dimensions of the fingers and the dimensions of the groove 48 are chosen so that a radial clearance and axial play are assured.

- the fingers 50 are slidably mounted in the housings 46.

- the securing means could comprise two fingers, however the implementation of three fingers reduces the risk of biasing the nut relative to the sleeve.

- the groove 48 avoids the need to angularly orient the nut relative to the sleeve.

- the sleeve is not integral in rotation with the nut. Thus, during tightening and loosening of the nut, the sleeve 32 does not rotate with the nut, which avoids soliciting the seals.

- the transverse position of the fingers and thus the radial clearance are adjusted by pressure screws 52 screwed into the radial bores 46 after introduction of fingers.

- the rotation of the pressure screws 52 is blocked in order to ensure a fixed position of the fingers over time, for example by means of the threadlocker or by means of a needle punch at the level tapping.

- This definitive fixation makes it possible to fix the games permanently and in a very simple manner. This is made possible because during the life of the press, the bushing and the nut do not need to be separated.

- the end of the fingers 50 penetrating into the annular groove 48 has an end having a reduced diameter section, which makes it possible to limit the size of the annular groove 48 and avoids inducing weak spots in the bushing 32.

- This end With reduced diameter section provides non-binding guidance for the seals of the sleeve 32 during the introduction of the sleeve assembly 32 and nut 38 in the bore of the compensator housing. In the locked position, the clamping force is taken up by the surfaces in contact with the parts 32 and 38 at the level of the bearing surface 57 on the Figure 4A .

- an axial clearance between the sleeve 38 and the nut 37 is between 0.045 mm and 0.355 mm is provided.

- the clamping is adjusted to keep a radial clearance between 0.05 mm and 0.139 mm.

- the tool 54 is adapted to the tightening / loosening of the retaining nut 38 when the punch is not mounted on the compensator 20.

- the tool 54 comprises means for rotating the nut in a tightening direction. or loosening.

- the tool 54 comprises, at a first longitudinal end, an annular face 56 provided with three fingers 58 projecting and extending longitudinally.

- the fingers 58 are intended to penetrate into three corresponding housings 59 formed in one face of the retaining nut 38 oriented towards the outside of the bore 18.

- the fingers 58 are for example formed by pins mounted in bores made in the transverse face 56.

- the tool comprises at least two fingers and preferably at least three.

- the tool 54 also comprises a central cavity 60 bordered by the annular face 56; the cavity 60 is intended to receive the projecting end of the compensator 20.

- the tool 54 comprises, at a longitudinal end opposite to that carrying the fingers, a recess 62 for mounting a lever forming tool capable of exerting a torque on the tool about the longitudinal axis.

- the cavity is projecting 62 and has a hexagonal shape and the tool is of the ratchet type.

- the recess is recessed and has a hexagonal, square section ..., the lever is then immobilized angularly on the tool 54 and the application of a torque on it causes the rotation of the tool.

- the side wall of the central cavity 60 is perforated to reduce the mass of the tool 54. Indeed, this tool is held at arm's length during assembly and disassembly operations.

- the retaining nut has protruding pins and that the tool has corresponding indentations.

- the tool 54 ' is similar to the tool 54; however, it is adapted to the tightening / loosening of the retaining nut 38 when the punch is mounted on the compensator 20.

- the central cavity 60 has a greater depth to accommodate the compensator and the punch.

- the tool 54 is mounted around the punch and is oriented so that the fingers 58 are opposite the housing of the nut. The tool is then moved axially close to the nut and the fingers penetrate into the housing. A torque is exerted on the tool 54 in the loosening direction of the nut 38. The nut 38 turns on itself and unscrews itself. Almost simultaneously, the sleeve 32 is driven in rotation and axially by the nut 38, the displacement of the sleeve 32 has a slight delay due to axial and radial play.

- the nut 38 and the sleeve 32 are removed. Then, the compensator 20 is extracted from the bore 18 by exerting a tensile force thereon.

- the seals are checked and replaced if necessary.

- the compensator 20 is introduced into the bore 18, preferably by means of a jacket (not shown).

- the compensator is oriented so that the anti-rotation rod mounted in the bottom of the bore enters the bore of the compensator.

- the sleeve assembly 32 and nut 38 is introduced into the bore 18 and mounted around the compensator.

- the mounting of the sleeve 32 is made with particular care not to damage the seals.

- the nut 38 is then screwed into the bore, which moves the sleeve 32 axially until it abuts against the annular bearing surface of the bore. Because of the radial clearance and the axial play, the sleeve 38 can be positioned on the compensator 20 and in the bore 18 without damaging the seals.

- the present invention simplifies the maintenance of the presses, more particularly the maintenance of the compensators by providing a simplified disassembly of the guide sleeve and a mounting of the sleeve protecting the seals.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Automatic Assembly (AREA)

- Presses And Accessory Devices Thereof (AREA)

- Press Drives And Press Lines (AREA)

Claims (9)

- Presse, umfassend:- einen Tisch (4), der mit wenigstens zwei Formmatrizen (6) ausgestattet ist,- Stempel (16) mit longitudinaler Achse, die dazu ausgelegt sind, in die Matrizen einzudringen,- einen Träger (15) der Stempel (16), der dazu ausgelegt ist, durch einen Zylinder (Vs) verlagert zu werden, um die Stempel (16) an die Formmatrizen (6) in einer longitudinalen Richtung anzunähern,- Kompensatoren (20), die jedem der Stempel (16) zugeordnet sind, wobei jeder Kompensator (20) eine longitudinale Achse aufweist und dicht in einer Bohrung (18) des Trägers (20) montiert ist, und ein erstes longitudinales Ende umfasst, das dazu ausgelegt ist, einem Druck von hydraulischen Fluid ausgesetzt zu sein, und ein zweites longitudinales Ende, das den Stempel (16) trägt, wobei die Bohrungen (18) in Fluidkommunikation miteinander sind, und- Gruppen zur Führung und zum Halten jedes der Kompensatoren, wobei die Presse dadurch gekennzeichnet ist, dass jede Führungs- und Haltegruppe Folgendes umfasst:- eine Hülse (32) zur Führung des Kompensators (20) in seiner Bohrung, wobei die Führungshülse um den Kompensator (20) herum montiert ist,- eine Haltemutter (38), die in die Bohrung (18) geschraubt ist, wobei die Führungshülse (32) sich zwischen einer Schulter (20.3) des Kompensators (20) und der Haltemutter (38) befindet, und- Mittel (44), die axial die Führungshülse (32) und die Haltemutter (38) verbinden, wobei sie ein axiales und transversales Spiel zwischen der Führungshülse (32) und der Haltemutter (38) sicherstellen, wobei die Mittel (44) derart sind, dass die Führungshülse (32) bezüglich der Haltemutter (38) frei drehbar ist.

- Presse nach Anspruch 1, bei der die Führungshülse (32) über einen Teil ihrer Länge von der Haltemutter (38) umgeben ist, und die Verbindungsmittel (44) wenigstens zwei radiale Finger (50) umfassen, die in radialen Bohrungen (46) aufgenommen sind, welche in der Haltemutter (38) realisiert sind, und von denen ein radial inneres Ende in eine ringförmige Kehle (48) mündet, die im Außenumfang der Führungshülse (32) realisiert ist, wobei ein radiales Spiel vorgesehen ist zwischen dem radial inneren Ende der radialen Finger (50) und einem radialen Boden der Kehle (48), und ein axiales Spiel vorgesehen ist zwischen den lateralen Rändern des radial inneren Endes der radialen Finger (50) und den lateralen Rändern der Kehle (48).

- Presse nach Anspruch 2, bei der die radialen Finger (50) mit Hilfe von Druckschrauben (52) in Position in den radialen Aufnahmen gehalten sind.

- Presse nach Anspruch 3, bei der die Schrauben axial beispielsweise durch einen Körnerpunkt oder durch eine Schraubenbremse immobilisiert sind.

- Presse nach einem der Ansprüche 2, 3 oder 4, bei der das radial innere Ende der Finger einen reduzierten Durchmesser aufweist.

- Presse nach einem der Ansprüche 2 bis 5, bei der drei radiale Finger (50) vorgesehen und unter 120° zueinander angeordnet sind.

- Presse nach einem der Ansprüche 1 bis 6, bei der die Führungshülse (32) in ihrem Innenumfang ein Segment zur Führung des Kompensators umfasst.

- Presse nach einem der Ansprüche 1 bis 7, bei der die Haltemutter (38) in einer transversalen Fläche entgegengesetzt zu jener, die in Kontakt mit der Führungshülse (32) ist, Vertiefungen (59) umfasst, die dazu ausgelegt sind, mit Vertiefungen (58) zusammenzuwirken, die durch ein Werkzeug (54, 54') getragen werden, um eine Spann- oder Lösekraft auf die Haltemutter (38) auszuüben.

- Presse nach einem der Ansprüche 1 bis 8, die eine Presse zur Herstellung von Kernbrennstoffpastillen bildet.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR1152412A FR2972957B1 (fr) | 2011-03-23 | 2011-03-23 | Presse a maintenance amelioree |

| PCT/EP2012/054954 WO2012126930A1 (fr) | 2011-03-23 | 2012-03-21 | Presse a maintenance amelioree |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2688741A1 EP2688741A1 (de) | 2014-01-29 |

| EP2688741B1 true EP2688741B1 (de) | 2019-04-10 |

Family

ID=45908031

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP12711140.9A Active EP2688741B1 (de) | 2011-03-23 | 2012-03-21 | Presse mit verbesserter stütze |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US9114584B2 (de) |

| EP (1) | EP2688741B1 (de) |

| JP (1) | JP5950134B2 (de) |

| CN (1) | CN103442885B (de) |

| FR (1) | FR2972957B1 (de) |

| RU (1) | RU2591921C2 (de) |

| WO (1) | WO2012126930A1 (de) |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR3021805B1 (fr) * | 2014-05-27 | 2019-05-03 | Commissariat A L'energie Atomique Et Aux Energies Alternatives | Presse pour mettre en forme des pastilles dans un environnement restreint et hostile et procede d'assemblage de la presse |

| US10303438B2 (en) | 2017-01-16 | 2019-05-28 | International Business Machines Corporation | Fused-multiply-add floating-point operations on 128 bit wide operands |

| DE102018112476B4 (de) | 2017-06-02 | 2022-01-27 | Ulrich Lang | Verfahren und Fertigungsanlage zum Herstellen eines Foliensubstrats |

| US10241756B2 (en) | 2017-07-11 | 2019-03-26 | International Business Machines Corporation | Tiny detection in a floating-point unit |

| NL2019767B1 (en) * | 2017-10-20 | 2019-04-29 | Besi Netherlands Bv | Press part for supporting a mould part for encapsulating electronic components mounted on a carrier and a press comprising the press part |

| WO2019224364A1 (de) | 2018-05-24 | 2019-11-28 | Ulrich Lang | Verfahren und fertigungsanlage zum herstellen eines foliensubstrats |

| US11221279B2 (en) * | 2019-01-16 | 2022-01-11 | Indrio Technologies, Inc | Laser-based in-situ exhaust gas sensor |

| CN113954413A (zh) * | 2021-09-30 | 2022-01-21 | 中国原子能科学研究院 | 一种用于密封屏蔽手套箱内的压机 |

Family Cites Families (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| SU50474A1 (ru) * | 1936-06-23 | 1936-11-30 | П.С. Лапшин | Гидравлический компенсатор к прессам |

| US2569226A (en) * | 1946-01-11 | 1951-09-25 | Denison Eng Co | Method of producing articles from powdered material |

| FR1206366A (fr) * | 1958-08-13 | 1960-02-09 | Hydrel | Procédé pour le montage des organes divers notamment des chapeaux de vérin en bout des cylindres et tubes |

| GB1385028A (en) * | 1971-11-23 | 1975-02-26 | Coopers Metals Ltd | Briquetting presses |

| US3890413A (en) * | 1974-08-15 | 1975-06-17 | Hydramet American Inc | Apparatus and method for compacting particulate materials |

| SU667416A1 (ru) * | 1977-11-10 | 1979-06-15 | Zenchenko Vladimir P | Устройство дл прессовани |

| WO1980001050A1 (en) | 1978-11-27 | 1980-05-29 | Loepfe Automation | Press comprising at least one reciprocating tool |

| US4323003A (en) * | 1980-03-24 | 1982-04-06 | Clippard Instrument Laboratory, Inc. | Fluid cylinder with replaceable rod seal and guide |

| US5934165A (en) * | 1997-03-19 | 1999-08-10 | Strippit, Inc. | Adjustable punch assembly |

| JP2000094196A (ja) * | 1998-09-18 | 2000-04-04 | Daidoo Denshi:Kk | 粉末の圧縮成形装置 |

| US6276247B1 (en) * | 2000-03-03 | 2001-08-21 | Strippit, Inc. | Adjustable punch assembly with releasable locking |

| US6755110B2 (en) * | 2001-06-19 | 2004-06-29 | Wilson Tool International, Inc. | Adjustable length punch assembly |

| JP2005262239A (ja) * | 2004-03-16 | 2005-09-29 | Toyota Motor Corp | 粉末成形用金型 |

| US8714065B2 (en) * | 2004-11-19 | 2014-05-06 | Amada Company, Limited | Punching die |

| US7658134B2 (en) * | 2005-09-29 | 2010-02-09 | Mate Precision Tooling, Inc. | Punch with self-contained punch recess adjustment indexing |

| JP2007098460A (ja) * | 2005-10-07 | 2007-04-19 | Sumitomo Denko Shoketsu Gokin Kk | 粉末成形用プレス金型 |

| US8348249B2 (en) | 2008-10-07 | 2013-01-08 | Dadco, Inc. | Reaction device for forming equipment |

-

2011

- 2011-03-23 FR FR1152412A patent/FR2972957B1/fr not_active Expired - Fee Related

-

2012

- 2012-03-21 RU RU2013147167/02A patent/RU2591921C2/ru not_active IP Right Cessation

- 2012-03-21 CN CN201280014732.5A patent/CN103442885B/zh active Active

- 2012-03-21 WO PCT/EP2012/054954 patent/WO2012126930A1/fr active Application Filing

- 2012-03-21 JP JP2014500361A patent/JP5950134B2/ja active Active

- 2012-03-21 EP EP12711140.9A patent/EP2688741B1/de active Active

- 2012-03-21 US US14/006,382 patent/US9114584B2/en not_active Expired - Fee Related

Non-Patent Citations (1)

| Title |

|---|

| None * |

Also Published As

| Publication number | Publication date |

|---|---|

| WO2012126930A1 (fr) | 2012-09-27 |

| US20140004220A1 (en) | 2014-01-02 |

| FR2972957A1 (fr) | 2012-09-28 |

| RU2591921C2 (ru) | 2016-07-20 |

| RU2013147167A (ru) | 2015-04-27 |

| EP2688741A1 (de) | 2014-01-29 |

| CN103442885B (zh) | 2015-08-12 |

| US9114584B2 (en) | 2015-08-25 |

| CN103442885A (zh) | 2013-12-11 |

| JP5950134B2 (ja) | 2016-07-13 |

| FR2972957B1 (fr) | 2014-02-21 |

| JP2014514160A (ja) | 2014-06-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2688741B1 (de) | Presse mit verbesserter stütze | |

| CA1221477A (fr) | Dispositif de fixation de deux pieces par vis imperdable et procede de fixation correspondant | |

| EP2259901B1 (de) | Wiederverwendbare vorübergehende befestigungsvorrichtung zur vormontage von mindestens zwei vorab durchlochten bauteilen | |

| CH648635A5 (fr) | Obturateur a machoires. | |

| FR2601732A1 (fr) | Dispositif de liaison a separation rapide et application d'un tel dispositif a la realisation de connecteurs a deverrouillage rapide | |

| EP1498579B1 (de) | Rotorscheibe mit einem ringförmigen Flansch | |

| FR2979646A1 (fr) | Systeme mecanique comprenant un dispositif de liaison entre une piece d'usure et son support, godet d'engin de travaux publics et procede de mise en oeuvre d'un tel systeme | |

| WO2024052238A1 (fr) | Obturateur en ligne de grand diametre comportant une plaque d'obturation | |

| EP1618324B1 (de) | Fluidstromregelventilvorrichtung | |

| EP0052543B1 (de) | Scheibenbremse | |

| EP0869279B1 (de) | Federkraftbremse mit mechanischer Bremslösevorrichtung | |

| FR2615914A1 (fr) | Verin hydraulique ou pneumatique equipe d'un coussinet d'etancheite a demontage rapide | |

| EP0263042B1 (de) | Dichtungsvorrichtung zwischen Spindel und Ventilgehäuse und damit übereinstimmende, herausziehbare Hülse | |

| EP3017210B1 (de) | Bremsvorrichtung mit einem kolben mit vollständiger rückstossfunktion | |

| EP4176196B1 (de) | Dichtungsvorrichtung zum abdichten eines lecks in der wand eines rohrs oder eines tanks mit einem teil zum bohren und teil zum anbohren und dichtungsverfahren | |

| FR2806762A1 (fr) | Dispositif de fixation du type vis-ecrou a desserrage rapide | |

| FR3122461A1 (fr) | Assemblage boulonné comprenant une tige filetée et un capuchon d’étanchéité | |

| FR2595427A1 (fr) | Bouchon de tube demontable et etanche | |

| FR2933023A1 (fr) | Matrice pour une presse de filage | |

| FR2905426A1 (fr) | Dispositif hydraulique comprenant des moyens de fixation aptes a transmettre un couple eleve | |

| FR2924479A1 (fr) | Dispositif de limitation de course morte d'un actionneur de frein commande par un fluide, et actionneur mettant en oeuvre un tel dispositif | |

| EP3490787A1 (de) | Vulkanisationsform für reifen | |

| FR2939391A1 (fr) | Maitre-cylinde de frein | |

| WO2004097375A2 (fr) | Procede et dispositif de soutirage de liquide et en particulier d’huile de transformateur | |

| BE629284A (de) |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20130924 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| DAX | Request for extension of the european patent (deleted) | ||

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| 17Q | First examination report despatched |

Effective date: 20180131 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: ORANO CYCLE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R079 Ref document number: 602012058806 Country of ref document: DE Free format text: PREVIOUS MAIN CLASS: B30B0015060000 Ipc: B30B0011020000 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: B30B 15/00 20060101ALI20180906BHEP Ipc: B30B 15/06 20060101ALI20180906BHEP Ipc: B30B 11/02 20060101AFI20180906BHEP Ipc: F15B 15/14 20060101ALI20180906BHEP |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20181019 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: AT Ref legal event code: REF Ref document number: 1118085 Country of ref document: AT Kind code of ref document: T Effective date: 20190415 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: FRENCH |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602012058806 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20190410 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 1118085 Country of ref document: AT Kind code of ref document: T Effective date: 20190410 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190710 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190910 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190711 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190710 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190810 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602012058806 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 |

|

| 26N | No opposition filed |

Effective date: 20200113 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 602012058806 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20200331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200321 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200331 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200331 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201001 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200321 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200331 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 732E Free format text: REGISTERED BETWEEN 20220217 AND 20220223 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20240318 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20240320 Year of fee payment: 13 |