EP2314520A1 - Verschluss - Google Patents

Verschluss Download PDFInfo

- Publication number

- EP2314520A1 EP2314520A1 EP09173868A EP09173868A EP2314520A1 EP 2314520 A1 EP2314520 A1 EP 2314520A1 EP 09173868 A EP09173868 A EP 09173868A EP 09173868 A EP09173868 A EP 09173868A EP 2314520 A1 EP2314520 A1 EP 2314520A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- closure

- container

- attachment means

- packaging

- groove

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D47/00—Closures with filling and discharging, or with discharging, devices

- B65D47/04—Closures with discharging devices other than pumps

- B65D47/06—Closures with discharging devices other than pumps with pouring spouts or tubes; with discharge nozzles or passages

- B65D47/08—Closures with discharging devices other than pumps with pouring spouts or tubes; with discharge nozzles or passages having articulated or hinged closures

- B65D47/0804—Closures with discharging devices other than pumps with pouring spouts or tubes; with discharge nozzles or passages having articulated or hinged closures integrally formed with the base element provided with the spout or discharge passage

Definitions

- the present invention concerns a packaging comprising at least two parts which are assembled by deforming one portion of the plastic material - preferably polyethylene terephtalate (PET) or polyethylene naphtalate (PEN) of at least one of these parts.

- PET polyethylene terephtalate

- PEN polyethylene naphtalate

- a packaging generally comprises a container with a container opening that is closed by a closure element.

- closure element (cap) The assembly process of the closure element (cap) to the container requires to have cooperating screw threads on these two parts of the packaging, or an equivalent means such as clipping cooperating elements.

- a packaging comprising a container with a container body, and a container opening having an upper edge, and a closure for closing said container, the container and the closure being made out of polyethylene terephtalate (PET), polyethylene naphtalate (PEN), or a combination thereof, said container and said closure comprising respectively first and second attachment means

- PET polyethylene terephtalate

- PEN polyethylene naphtalate

- the packaging is characterized in that:

- the permanent deformation that is applied to the groove wall was found to be possible under certain constraints, and only with PET or PEN. This deformation is permanent and the deformed part is sufficiently strong to prevent the attached part to detach from the other, even when high mechanical constraints are applied to the assembly. Basically, the type of link that is achieved with such an assembly method, is as strong as heat sealing between the two parts.

- the first attachment means is a groove having one of its walls which is deformable by punching or rolling

- the second attachment means is an extending ridge adapted in shape and size to be inserted into the groove, and in that the closure is attached to the container in a water-tight arrangement by inserting the closure ridge into the container groove and permanently deforming at least one wall of the groove so as to unremovably catch the ridge into the groove.

- the closure can comprise a spout and an overcap attached to the spout, in which case the closure's ridge extends from the lower edge of the spout.

- the closure element can comprise a ring-shaped base and an overcap attached to the base, in which case the closure's ridge extends from the lower edge of the ring-shaped base.

- the ring-shaped base is less than 10 mm, preferably less than 3 mm in height.

- the overcap mentioned above is preferably made out of polypropylene (PP), and also preferably, said spout and said overcap are manufactured as one single piece.

- PP polypropylene

- the closure element can also be attached to the container ultrasonic sealing.

- the packaging according to the present invention further comprises tamper-evident means, said means preferably comprising a detachable tamper-evident band that is formed together with the closure, so that it catches one part of the container, thus preventing removal of the closure from said container, unless the said tamper-evident band is torn from the rest of the closure.

- tamper-evident means said means preferably comprising a detachable tamper-evident band that is formed together with the closure, so that it catches one part of the container, thus preventing removal of the closure from said container, unless the said tamper-evident band is torn from the rest of the closure.

- the invention concerns a packaging 1 comprising a bottle 2 made from blow-moulding of a preform 3, the bottle 2 being closed by a closure 4, and both the bottle 2 and the closure 4 being made of polyethyleneterephtalate (PET).

- PET polyethyleneterephtalate

- figure 1 represents a not yet blown bottle, so what is represented in figure 1 is the PET preform 3 that will later be blown into a full size bottle.

- the container 2 comprises a container body 5 and a container opening having an upper edge. Said container 2 and said closure 4 comprising first 8 and second 9 corresponding attachment means.

- the second attachment means 9 are adapted in shape and size to cooperate with the first attachment means 8, and both attachment means 8, 9 are made of PET and integrally part of the rest of the pieces they are linked to - they could however be added to existing parts, by any means of linking, such as heat sealing, ultrasonic welding for instance -. More than that, both attachment means 8, 9 are adapted in shape and size to deform permanently by rolling to create a fluid-tight permanent arrangement between said container 2 and said closure 4.

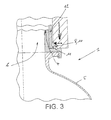

- the first attachment means is a groove 8 having one of its walls 10 which is deformable by rolling, as illustrated in figure 2 .

- the second attachment means is an extending ridge 9 that is adapted in shape and size to be inserted into the groove 8, such that the closure can be attached to the container in a water-tight arrangement by inserting the closure ridge into the container groove and permanently deforming the wall 10 of the groove 8 so as to unremovably catch the ridge 9 into said groove 8.

- first attachment means of the closure could be a groove

- second attachment means of the container could be a corresponding ridge (inverted positioning of the attachment means relative to the constitutive parts of the packaging.

- the deformable groove wall 10 is about 1.5 mm thin so as to be more easily deformable during the rolling operation, and so as to avoid possible problems of cracking or whitening of the plastic material when the deformation is applied.

- the flexibility and permanent deformation of the material is made possible when the piece to be deformed is sufficiently thin so as to bend, up its point of permanent deformation, without stressing too much the plastic material.

- the closure element comprises a ring-shaped base and an overcap attached to the base.

- the closure's ridge extends from the lower edge of the ring-shaped base.

- the overcap is pivotably attached to the spout or, respectively, to the ring-shaped base, by a pivot hinge.

- the ring-shaped base is about 3 mm in height.

- the ridge 9 of the closure is disposed into the groove 8 of the preform (or bottle) neck, and the latter is permanently deformed after the rolling operation, in a position that locks the ridge 9 into the groove 8, so that the closure 4 is permanently attached to the neck of the bottle 2.

- This attachment is a fluid tight attachment.

- the groove is a U-shaped groove with a height of at least 2, preferably at least 3 mm, and a width sufficient to accommodate the ridge of the closure.

- the permanent deformation can be performed by punching, rolling, cold forming, hot forming, or a combination thereof.

- the permanent deformation technique cited before can also be used in combination with ultrasonic welding, so that when the second attachment means is deformed to catch the first attachment means, in order to create a fluid-tight connection between said container and said closure, an additional ultrasonic welding step is performed to create a permanent seal between the container 2 and the closure 4.

- the plastic material is melted, and then colds back to its initial solid state, in such a way that the closure and the container form one single integral piece.

- Such a ultrasonic welding operation is performed in this case with a sonotrode, which also plays the role of a puncher that deforms the attachment means of the container, before (or at the same time) transmitting ultrasonic waves to seal the closure and the container together.

- the permanent deformation of the PET or PEN is performed at a temperature comprised between 0°C and the glass transition temperature of the plastic material.

- This temperature of glass transition is well defined for both thermoplastics used in the present invention.

- Tg 69°C.

- Tg 122°C.

- the permanent deformation is applied at a temperature which is comprised in a more restricted range, and a range which is closer to ambient temperature, that is to say a temperature comprised between 18°C and 40°C, more preferably at a temperature comprised between 20°C and 30°C.

- the attachment means of the bottle 2 is a circular ridge 9, that is deformed inwardly towards the centre of the bottle, and catches the attachment means of the closure, which is a horizontal extension 11 of the closure skirt 12.

- attachment means of the container and/or the closure could be not entirely circular (i.e. all around the periphery), but rather on a portion of the circumference of the container and/or closure, or even at very specific points of the said container and/or closure.

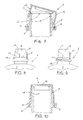

- the closure 4 can be a hinged closure, comprising a base ring 13 and an overcap 14 that is pivotably attached to the ring 13 by a hinge 15.

- the lower part of the ring 13 is disposed into a groove 8 of the bottle neck, before a wall 10 of said groove is deformed to permanently catch the ring 13, as described before.

- the overcap 14 is moulded as one integral piece with the ring 13, but these two parts are linked via breakable bridges 16, which are broken by tearing when the used first lifts the overcap 14 to open the closure 4. This systems constitutes a tamper-evident means.

- the closure front wall 17 is preferably equipped with a detachable front wall portion 19 as illustrated in figure 8 , that can be torn off before lifting the overcap 14 in open position of the closure, as shown in figure 9 .

- This detachable portion 19 is moulded as an integral portion of the rest of the closure 4, but linked to the latter by breakable bridges 16 of plastic material.

- This detachable front wall portion 19 of the closure can be also integral to the ring 13 of the closure (embodiment not shown in the drawing), or alternatively it can be also detachable from the ring 13, as illustrated in figure 9 .

- a detachable front wall portion 19 of the closure 4 makes it possible for a very tall neck 18 of the closure which will still be closed with a hinged closure.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Closures For Containers (AREA)

Priority Applications (10)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP09173868A EP2314520A1 (de) | 2009-10-23 | 2009-10-23 | Verschluss |

| PCT/EP2010/065494 WO2011048017A1 (en) | 2009-10-23 | 2010-10-15 | A closure |

| EP10771709A EP2490958A1 (de) | 2009-10-23 | 2010-10-21 | Verschluss |

| CA2774914A CA2774914C (en) | 2009-10-23 | 2010-10-21 | A closure |

| CN201080047767.XA CN102574613B (zh) | 2009-10-23 | 2010-10-21 | 封闭件 |

| US13/503,517 US8875918B2 (en) | 2009-10-23 | 2010-10-21 | Closure |

| MX2012003934A MX2012003934A (es) | 2009-10-23 | 2010-10-21 | Una tapa de cierre. |

| PCT/EP2010/065839 WO2011048166A1 (en) | 2009-10-23 | 2010-10-21 | A closure |

| BR112012011329A BR112012011329A2 (pt) | 2009-10-23 | 2010-10-21 | oclusão |

| CL2012001001A CL2012001001A1 (es) | 2009-10-23 | 2012-04-19 | Envase que comprende un contenedor y tapa de cierre de pen, pet o combinacion y comprende respectivamente un primer y segundo medios de union, adaptados en forma y tamaño para cooperar entre si donde al menos uno es de pet o pen y es adaptado para reformarse permanentemente por perforacion o enrollamiento para union hermetica. |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP09173868A EP2314520A1 (de) | 2009-10-23 | 2009-10-23 | Verschluss |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP2314520A1 true EP2314520A1 (de) | 2011-04-27 |

Family

ID=41402071

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP09173868A Withdrawn EP2314520A1 (de) | 2009-10-23 | 2009-10-23 | Verschluss |

Country Status (1)

| Country | Link |

|---|---|

| EP (1) | EP2314520A1 (de) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2014057054A1 (de) * | 2012-10-11 | 2014-04-17 | Capartis Ag | Verschlusskappe, behälterhals, garantieverschluss sowie verfahren zur herstellung eines garantieverschlusses |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1123000A (en) * | 1965-11-19 | 1968-08-07 | Metal Box Co Ltd | Improvements in or relating to closure members for bottles or like containers |

| US3927805A (en) * | 1973-10-15 | 1975-12-23 | Morton B Stull | Tilt/lift safety closure |

| WO2002042174A1 (de) * | 2000-11-27 | 2002-05-30 | Alpla Werke Alwin Lehner Gmbh & Co. Kg | Verschluss aus biegsamem kunststoff für behälter, insbesondere für flaschen |

-

2009

- 2009-10-23 EP EP09173868A patent/EP2314520A1/de not_active Withdrawn

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1123000A (en) * | 1965-11-19 | 1968-08-07 | Metal Box Co Ltd | Improvements in or relating to closure members for bottles or like containers |

| US3927805A (en) * | 1973-10-15 | 1975-12-23 | Morton B Stull | Tilt/lift safety closure |

| WO2002042174A1 (de) * | 2000-11-27 | 2002-05-30 | Alpla Werke Alwin Lehner Gmbh & Co. Kg | Verschluss aus biegsamem kunststoff für behälter, insbesondere für flaschen |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2014057054A1 (de) * | 2012-10-11 | 2014-04-17 | Capartis Ag | Verschlusskappe, behälterhals, garantieverschluss sowie verfahren zur herstellung eines garantieverschlusses |

| US9475618B2 (en) | 2012-10-11 | 2016-10-25 | Capartis Ag | Closing cap, container neck, tamper-evident closure, and method for producing a tamper-evident closure |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN102933468B (zh) | 拆封警示瓶盖 | |

| US5379908A (en) | Plastic closure cap, in particular for glass containers | |

| AU2008351695B2 (en) | Closures for plastic containers adapted for automated insert molding | |

| US7810663B2 (en) | Tamper-evident closure | |

| PL195915B1 (pl) | Butelka cienkościenna z tworzywa sztucznego, zamknięcie do butelki i sposób butelkowania płynów | |

| WO2011048017A1 (en) | A closure | |

| US20090184082A1 (en) | Stopper Device for a Container, a Container Fitted with Such a Device, and a Method of Fabricating Such a Device | |

| CN104364163A (zh) | 容器闭合组件 | |

| EP1966059B1 (de) | Trinkausgiesstülle | |

| US20220388741A1 (en) | A package closure and a method for producing a package closure | |

| EP2314444A1 (de) | Verschluss | |

| EP2314520A1 (de) | Verschluss | |

| HK1155705A (en) | A closure | |

| CN102482007A (zh) | 包括容器和封闭件的单件式包装 | |

| HK1155693A (en) | A closure | |

| PL210146B1 (pl) | Sposób montowania wylotu z tworzywa sztucznego na szyjce pojemnika, wylot z tworzywa sztucznego oraz pojemnik | |

| US20090050596A1 (en) | Sealing Cap | |

| EP1600395B1 (de) | Trinkverschluss für Getränkebehälter | |

| US20250051060A1 (en) | Package closures and methods and devices for producing package closures | |

| JP2745876B2 (ja) | 不正開封防止キャップ付容器 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN WITHDRAWN |

|

| 18W | Application withdrawn |

Effective date: 20111027 |

|

| REG | Reference to a national code |

Ref country code: HK Ref legal event code: DE Ref document number: 1155705 Country of ref document: HK |

|

| REG | Reference to a national code |

Ref country code: HK Ref legal event code: WD Ref document number: 1155705 Country of ref document: HK |