EP2285508B1 - Production-optimized method for producing a multilayered tube - Google Patents

Production-optimized method for producing a multilayered tube Download PDFInfo

- Publication number

- EP2285508B1 EP2285508B1 EP09776794A EP09776794A EP2285508B1 EP 2285508 B1 EP2285508 B1 EP 2285508B1 EP 09776794 A EP09776794 A EP 09776794A EP 09776794 A EP09776794 A EP 09776794A EP 2285508 B1 EP2285508 B1 EP 2285508B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- pipe

- layer

- multilayer

- producing

- elements

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21C—MANUFACTURE OF METAL SHEETS, WIRE, RODS, TUBES OR PROFILES, OTHERWISE THAN BY ROLLING; AUXILIARY OPERATIONS USED IN CONNECTION WITH METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL

- B21C37/00—Manufacture of metal sheets, bars, wire, tubes or like semi-manufactured products, not otherwise provided for; Manufacture of tubes of special shape

- B21C37/06—Manufacture of metal sheets, bars, wire, tubes or like semi-manufactured products, not otherwise provided for; Manufacture of tubes of special shape of tubes or metal hoses; Combined procedures for making tubes, e.g. for making multi-wall tubes

- B21C37/15—Making tubes of special shape; Making tube fittings

- B21C37/154—Making multi-wall tubes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21C—MANUFACTURE OF METAL SHEETS, WIRE, RODS, TUBES OR PROFILES, OTHERWISE THAN BY ROLLING; AUXILIARY OPERATIONS USED IN CONNECTION WITH METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL

- B21C37/00—Manufacture of metal sheets, bars, wire, tubes or like semi-manufactured products, not otherwise provided for; Manufacture of tubes of special shape

- B21C37/06—Manufacture of metal sheets, bars, wire, tubes or like semi-manufactured products, not otherwise provided for; Manufacture of tubes of special shape of tubes or metal hoses; Combined procedures for making tubes, e.g. for making multi-wall tubes

- B21C37/08—Making tubes with welded or soldered seams

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21C—MANUFACTURE OF METAL SHEETS, WIRE, RODS, TUBES OR PROFILES, OTHERWISE THAN BY ROLLING; AUXILIARY OPERATIONS USED IN CONNECTION WITH METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL

- B21C37/00—Manufacture of metal sheets, bars, wire, tubes or like semi-manufactured products, not otherwise provided for; Manufacture of tubes of special shape

- B21C37/06—Manufacture of metal sheets, bars, wire, tubes or like semi-manufactured products, not otherwise provided for; Manufacture of tubes of special shape of tubes or metal hoses; Combined procedures for making tubes, e.g. for making multi-wall tubes

- B21C37/08—Making tubes with welded or soldered seams

- B21C37/09—Making tubes with welded or soldered seams of coated strip material ; Making multi-wall tubes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D5/00—Bending sheet metal along straight lines, e.g. to form simple curves

- B21D5/01—Bending sheet metal along straight lines, e.g. to form simple curves between rams and anvils or abutments

- B21D5/015—Bending sheet metal along straight lines, e.g. to form simple curves between rams and anvils or abutments for making tubes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D5/00—Bending sheet metal along straight lines, e.g. to form simple curves

- B21D5/06—Bending sheet metal along straight lines, e.g. to form simple curves by drawing procedure making use of dies or forming-rollers, e.g. making profiles

- B21D5/10—Bending sheet metal along straight lines, e.g. to form simple curves by drawing procedure making use of dies or forming-rollers, e.g. making profiles for making tubes

- B21D5/12—Bending sheet metal along straight lines, e.g. to form simple curves by drawing procedure making use of dies or forming-rollers, e.g. making profiles for making tubes making use of forming-rollers

Definitions

- the present invention relates to a production-optimized method for producing a multilayer pipe.

- Multilayer pipes are preferably used in case of high requirements against corrosion or abrasion.

- Corrosion-resistant pressure vessels or pressure lines can be produced more cost-effectively by using multilayer pipes than solid versions made of appropriate materials. This is achieved by the load sharing on a thin, corrosion-resistant inner layer (e.g., stainless and acid resistant steel) and a high strength, pressure resistant outer layer (eg, fine-block steel). As a result, overall steel consumption can be significantly reduced and much of the remaining steel consumption can be shifted to low-cost materials.

- a thin, corrosion-resistant inner layer e.g., stainless and acid resistant steel

- a high strength, pressure resistant outer layer eg, fine-block steel

- Abrasion-resistant pipes are made possible by the design as a multilayer pipe (such as mechanical bond, see below) in certain grades in the first place, because materials (eg high-strength steels with high hardness) can be used as an inner layer, which alone or only very difficult can be processed into tubes.

- steel sheets - is used as a starting semi-finished a clad composite sheet of two different (steel) materials use.

- the use of rolled and / or blast-plated semifinished product is avoided by first creating a first joint between the layers of material, such as a weld, and thereafter the respective layer of material acting as an inner tube during tube forming in the bending roll by attaching it after a certain deformation progress - Pressed further connection between the material layers frictionally in each functioning as an outer tube material layer and is frictionally held in the respective outer tube and without having to expand the multilayer tube and thus to address the above-mentioned expansion method disadvantages.

- this method has the technical production disadvantage that it is necessary to create a further connection between the material layers during the tube forming in the bending roll after a certain deformation progress, which is usually done by welding. For this connection, it is therefore necessary to interrupt the tube forming in order to connect the two material layers together at this further point.

- the still unfinished pipe must be removed from the bending roll and then created the connection, so in general, the weld can be applied.

- it can also be welded in the bending roll, which however blocks it during this time. Then, the tube blank (also called slot tube) can be re-introduced into the bending roll to continue the local manufacturing process.

- Such a procedure is extremely time-consuming and therefore represents a significant production cost disadvantage.

- the respective inner layer it is also possible to use materials such as particularly high-strength steels which are difficult or impossible to weld.

- the material layer acting as an inner tube is already pressed into the bending roll in the bending roll in a force-fitting manner into the respective material layer functioning as an outer tube and thus held frictionally in the respective outer tube without a connection, such as a weld to be created requirement. Therefore, a time- and cost-intensive interruption of the tube forming process in the bending roll is also not required here.

- this manufacturing process in turn has the disadvantage that in this case the pipe inner layer is not completely closed inwardly, since a part of the pipe inner circumference is formed by the on the respective base plate, so the respective outer material layer, attached stop edges, which leads to here the beneficial effects of the tube inner layer, such as corrosion or abrasion resistance can not occur.

- This disadvantage can not be solved easily by a build-up welding in this area, as a weld between the material of the stop edge and the inner layer in this process, which wants to avoid welding between outer and inner layer just out of the question.

- the interruption of the tube forming process in the sheet metal forming machine - ie in the bending roll - thereby avoided that at least two elements that later form the inner layer, initially, ie before the tube forming process, edge side with the later forming the outer layer Material layer connected, so usually welded to this, be.

- the free ends of these elements then move towards each other due to the different bending radii (or circumferential lengths, which means the same thing) of the inner and outer tubes and eventually hit one another.

- the edges of the abutting layers do not jump from each other, but remain abutting, but they - assuming a smooth edge shaped - a, with increasing deformation progress increasing strength exert on the material inner layer, with which this is pressed against the outer layer.

- the method according to the invention is designed so that it ensures that from the moment in which the initially still freely mutually displaceable edges of the inner layer sheets abut, the tube to be formed at each point, on the inner and outer layer on each other, already arched. That is, the tube to be formed at each point, on the inner and outer layer on each other has a finite radius (ie nowhere there has an infinite radius).

- This can be achieved, for example with respect to the majority of the tubular body, preferably by sufficient bending before abutting the displaceable edges of the inner layer elements, which can be done for example by suitable dimensioning and / or positioning of the elements of the inner layer. Also, this (possibly also in addition) - preferably in the edge region, so the area of the later to be closed pipe longitudinal seam comes close - means a previously made bending of the pipe to be formed material layers can be achieved.

- the first connection between the material layers is created by connecting them along approximately one of the longitudinal or transverse edges of the overlying material layer or approximately along a line parallel thereto, but along the future pipe longitudinal seam.

- the applied elements can thus lie with their longitudinal edge parallel to the longitudinal edge of the underlying material layer, but need not. So it is also possible that they come to rest with their longitudinal edge transverse thereto.

- the connection with the material layer below is always along or parallel to the future pipe longitudinal seam.

- connection along an edge or along a (preferably imaginary) line means any type of connection along the edge or line, whether or not it is Connection along the entire edge or line or only in sections along the edge or line or even in single points (such as spot welds), for instance at two points - preferably at the end points of the edge or line - or even at a single point at the point Edge or on the line.

- the material layer functioning as an inner tube can also form a partial circle in the finished multilayer tube, which can be achieved by covering the elements of the overlying material layer, which later form the inner tube layer, only a part of the surface of the material layer which later forms the outer layer. while it is nevertheless important to ensure that they still encounter each other in the course of the tube forming process with their then free ends and so the inner is pressed into the outer layer.

- the material layer functioning as an inner tube and forming a partial circle in cross-section in the finished multilayer tube forms a groove at the foot of the multilayer tube.

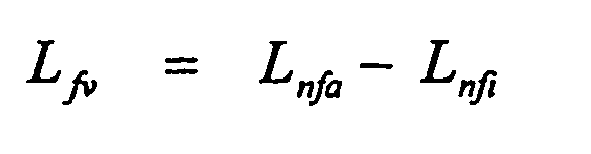

- L afa THERE - SA ⁇ ⁇

- the compression allowance takes into account the manufacturing inaccuracy in the fixation of at least one other material layer connection, and compensates for this so that the desired pressing force of the inner tube is at least achieved against the outer tube.

- the resting elements along first weld the longitudinal edges of the later forming the outer layer material layer and select these (the later inner layer forming) elements of their size and geometry forth so that between their free edges a gap remains, which closes in the course of the tube forming process and then the two then abutting Edges are encountered by the yet to be completed further tube forming process only insofar as it allows the compression limit of the material of the future inner layer.

- the multilayer pipe is closed by welding the outer pipe along the pipe seam and build-up welding of the inner pipe so as to complete the multilayer pipe body.

- the material layers can be connected to the front sides of the tube, such as there to prevent the ingress of moisture between the metallurgically yes not fully connected material layers.

- a preferred application of the method according to the present invention is the production of double-layer tubes according to the invention, however, the invention is not limited thereto, also three-, four- and more multi-layer pipes according to the invention are hereby basically produced.

- sheets preferably metal sheets and more preferably steel sheets, as a material layer or elements of the material layer use.

- At least one of the joints of the material layers is preferably used as a weld, which is particularly suitable for the aforementioned metal sheets, preferably steel sheets.

- Blechumformmaschine is about a bending roll, for example, a three-roll bending machine, but also a press / die assembly, such as in the context of known from the prior art UOE (U-shapes, O- forms, expand) -Rohrformungsvons (see UOE Method for example: Hiersig, Heinz M., Encyclopedia Mechanical Engineering, Heidelberg 1997, p. 704f , for keyword "Leksnabt-Großrohrher ein ”) or the so-called JCO-tube forming method is suitable.

- the tube is formed by first placing the sheet in a press by means of a sword in the shape of a horizontal J 'and then in that of a horizontal' C '. After that, it then - as in the case of the UOE method - bends into the ' O ' shape.

- the inventive method can now also be operated as a continuous production process in which the material layers to be combined or their elements (each unwound from a wound tape and then continuously superimposed, preferably continuously welded, wherein the subsequent tube forming process also takes place continuously by a Einform No, which forms a slit tube from the continuously superimposed layers of material, serves as Blechumformmaschine for tube forming are known from the prior art, as in the US 3,327,383 is described and which is hereby included in the disclosure of the present document.

- the present illustration is intended to clarify the process once more, however, by showing in its upper part the installation serving for this purpose from the side and in the lower part of the illustration at different stations marked by allocation arrows 11 in cross section and, in contrast, the feed direction 12 .

- the material layer elements 1 a, 1 b which are continuously fed from above as a strip , have a width which is suitable after carrying out the invention Manufacturing process to form the desired inner wall of the pipe to be produced and also in this case to be sufficiently upset by the resulting due to the tube forming pressing force.

- the supplied from below material layer 2 is later used as an outer layer and therefore has the width of the outer circumference of the tube to be produced 5 on.

- the two layers 1a, 1b, 2 are each welded at the edge by means of a welding system 10 , so that the elements 1a, 1b of the later inner layer are now each connected to the later outer layer 2 at the outer edge.

- the two elements 1a, 1b of the later pipe inner layer still loosely lie with their edges there.

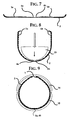

- Fig. 7 shows the starting situation of the inventive method, when the sheet metal forming is carried out by means of a UO (E) -Pressen- / Gesenkanaku.

- the later outer material layer 2 is down here and the two, the subsequent inner layer 1 forming elements 1a, 1b are outside. They were already welded to the lower layer 2 at the edge and there rounded together with the lower layer 2 . Possibly. can the marginal welding of the layers 1a, 1b, 2 but also after the rounding of the edge area done. In the middle of the two resting elements 1a, 1b are still spaced apart.

- Fig. 8 shows the forming step of a, U 'forms by means of a press (not shown here), which drives a correspondingly shaped punch 13 down, where the material layers 1a, 1b, 2 thereby together in a die (not here also not to be driven).

- a press not shown here

- the inner material layer elements 1a, 1b with their still freely movable sheet edges - due to the different radii of outer 2 and inner layer 1, 1a, 1b - to each other to move.

- Fig. 9 shows the forming step, which forms an ' O' , ie a slit tube by means of a press (not shown here), the two molded as a half round punch 14, 15 from below and above against the tubular body to be molded, where the material layers 1a , 1b, 2 thereby in turn together to one - seen in cross section - are formed round.

- the inner material layer elements 1a, 1b with their still movable sheet edges due to the different radii of outer and inner layer to each other moves and indeed until they abut and thus forms a continuous inner layer 1 , which now in the further tube forming in the Outer layer 2 is pressed, since the originally free edges of the inner layer elements 1a, 1b now can not move towards each other. As a result of the curvature they do not jump from each other, but lie down against the outer wall 2 .

- the method according to the invention can be carried out in a similar manner by means of a press / die arrangement designed for the so-called "JCO” method.

- JCO so-called "JCO” method.

- E modified UO

- the overlying elements 1a, 1b are welded on the edge side to the material layer 2 forming the later outer layer, and then a slot tube is formed by the JCO method.

- the desired effect according to the invention occurs, in which the initially free sheet edges of the inner layer elements 1a, 1b abut, thereby forming a continuous inner layer 1 and then pressed due to the different bending radii of outer and inner layer against the outer layer 2 .

- both the inventively modified RO (E) method, as with the inventively modified JCO process the initially freely movable abutting edges of the two inner sheet members 1a 1b may after their abutting each other and / or be welded to the outer sheet 2 , which can be done for example by the still open slot of the slot tube, preferably by means of a laser welding device.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Bending Of Plates, Rods, And Pipes (AREA)

- Rigid Pipes And Flexible Pipes (AREA)

- Metal Extraction Processes (AREA)

- Blow-Moulding Or Thermoforming Of Plastics Or The Like (AREA)

Abstract

Description

Die vorliegende Erfindung betrifft ein produktionsoptimiertes Verfahren zur Herstellung eines Mehrlagenrohres. Mehrlagen-Rohre werden vorzugsweise bei hohen Anforderungen gegen Korrosion oder Abrasion verwendet.The present invention relates to a production-optimized method for producing a multilayer pipe. Multilayer pipes are preferably used in case of high requirements against corrosion or abrasion.

Korrosionsbeständige Druckbehälter oder Druckleitungen können durch Anwendung von Mehrlagen-Rohren kostengünstiger hergestellt werden als Massivausführungen aus entsprechenden Werkstoffen. Dies wird erreicht durch die Lastenteilung auf eine dünne, korrosionsbeständige Innenlage (z.B. rost- und säurebeständiger Stahl) und eine hochfeste, druckbeständige Außenlage (z. B. Feinkombaustahl). Dadurch kann der Stahlverbrauch insgesamt erheblich gesenkt und ein Großteil des verbleibenden Stahlverbrauchs auf kostengünstige Werkstoffe verlagert werden.Corrosion-resistant pressure vessels or pressure lines can be produced more cost-effectively by using multilayer pipes than solid versions made of appropriate materials. This is achieved by the load sharing on a thin, corrosion-resistant inner layer (e.g., stainless and acid resistant steel) and a high strength, pressure resistant outer layer (eg, fine-block steel). As a result, overall steel consumption can be significantly reduced and much of the remaining steel consumption can be shifted to low-cost materials.

Abrasionsbeständige Rohrleitungen werden durch die Ausführung als Mehrlagen-Rohr (etwa mit mechanischer Bindung, s.u.) in bestimmten Güteklassen überhaupt erst ermöglicht, da Werkstoffe (z.B. hochfeste Stähle mit hohen Härten) als Innenlage eingesetzt werden können, die für sich alleine nicht oder nur sehr schwierig zu Rohren verarbeitet werden können.Abrasion-resistant pipes are made possible by the design as a multilayer pipe (such as mechanical bond, see below) in certain grades in the first place, because materials (eg high-strength steels with high hardness) can be used as an inner layer, which alone or only very difficult can be processed into tubes.

Andere Werkstoffkombinationen sind in großer Vielfalt möglich, prinzipiell begrenzt sich die Kombinierbarkeit von Werkstoffen dabei nur durch die jeweilig infrage kommenden Verarbeitungstechniken.Other material combinations are possible in a great variety, in principle, the combinability of materials is limited only by the applicable processing techniques.

Beim Aufbau des Rohrmantels wird unterschieden zwischen

- vollflächiger metallurgischer Bindung (diese erfordert plattiertes Blech als Ausgangshalbzeug), und

- rein mechanischer Bindung (etwa einer Reibbindung) zwischen Innen- und Außenrohr - vorzugsweise Innen- und Außenblech und ihrer Verschweißung an den Blechkanten -.

- full-surface metallurgical bond (this requires plated sheet metal as a starting semi-finished product), and

- purely mechanical bond (such as a friction bond) between inner and outer tube - preferably inner and outer sheet and their welding at the sheet edges -.

Bei Mehrlagenrohren mit metallurgischer Bindung zwischen den Lagen - etwa Mehrlagenrohren aus Metallblechen, vorzugsweise Stahlblechen - findet als Ausgangshalbzeug ein plattiertes Verbundblech aus zwei verschiedenen (Stahl-)Werkstoffen Verwendung.For multi-layer pipes with metallurgical bond between the layers - such as multi-layer pipes made of metal sheets, preferably steel sheets - is used as a starting semi-finished a clad composite sheet of two different (steel) materials use.

Der Nachteil dieses Verfahrens nach dem Stand der Technik liegt zum einen in den hohen Kosten des Ausgangshalbzeuges und damit auch des Endproduktes, zum anderen aber auch in einer mangelnden ausreichenden Verfügbarkeit dieses Ausgangshalbzeuges aufgrund äußerst beschränkter Produktionskapazitäten hierfür in der Welt. Weiterhin ist die Anzahl der Werkstoffe, die sich auf diese Weise verarbeiten lassen, begrenzt. So lassen sich etwa bestimmte abrasionsbeständige Stähle als Innenlage dann nicht verwenden, wenn sie sich aufgrund ihres hohen Kohlenstoffanteils nicht oder nur schlecht schweißen lassen.The disadvantage of this method according to the prior art is firstly the high cost of the starting semifinished product and thus also of the end product, but on the other hand also a lack of sufficient availability of this semifinished product due to extremely limited production capacity for this purpose in the world. Furthermore, the number of materials that can be processed in this way, limited. For example, certain abrasion-resistant steels can not be used as the inner layer if they are difficult or impossible to weld because of their high carbon content.

Bei Mehrlagenrohren mit mechanischer Bindung finden nach älterem Stand der Technik als Ausgangshalbzeug mehrere - vorzugsweise zwei - fertige Rohre Verwendung. Das Verfahren soll dabei im folgenden anhand des Beispiels zweier Rohre erläutert werden (im Falle weiterer Lagen sind die Ausführungen entsprechend zu verstehen):

- Zwei fertige Rohre werden aus den zu kombinierenden Werkstoffen passgenau gefertigt und ohne Reibung ineinander geschoben, wobei das äußere Rohr eine höhere Streckgrenze aufweisen muß als das innere.

- Durch Expandieren (mechanisch - etwa vermittels eines Expansionsstempels - oder durch Flüssigkeitsdruck, wobei im letzten Falle die ineinander liegenden Rohre in ein das Außenrohr umfassendes Gesenk gepreßt werden) wird das Innenrohr unter elastischer Aufweitung des Außenrohrs in das Außenrohr gedrückt. Nach Wegfallen der Expansionskräfte legt sich das Außenrohr wegen der höheren elastischen Rückfederung kraftschlüssig um das Innenrohr.

- Abschließend werden die beiden Werkstoffe an den Stirnseiten verschweißt. Der Nachteil dieses Verfahrens nach dem Stand der Technik liegt darin begründet, daß das äußere Rohr eine höhere Streckgrenze aufweisen muß als das innere, da ansonsten die den Kraftschluß mit dem Innenrohr hervorrufende und daher erforderliche elastische Rückfederung des Außenrohres fehlt. Dies ist insbesondere deshalb nachteilig, weil hochfeste Werkstoffe

- etwa besonders hochfeste Stähle -, wie sie vorzugsweise für abrasionsbeständige Rohrleitungen im Inneren des Rohres besonders vorteilhaft sind, hohe oder sogar sehr hohe Streckgrenzen aufweisen und sich damit für dieses Herstellungsverfahren nicht eignen.

- Two finished tubes are made of the materials to be combined accurately and pushed into each other without friction, the outer tube must have a higher yield strength than the inner.

- By expanding (mechanically - such as by means of an expansion punch - or by fluid pressure, in the latter case, the nested tubes are pressed into a die comprising the outer tube), the inner tube is pressed with elastic expansion of the outer tube into the outer tube. After elimination of the expansion forces, the outer tube sets because of the higher elastic resilience frictionally around the inner tube.

- Finally, the two materials are welded at the ends. The disadvantage of this method according to the prior art is due to the fact that the outer tube must have a higher yield strength than the inner, otherwise the lack of adhesion to the inner tube causing and therefore required elastic resilience of the outer tube. This is particularly disadvantageous because high-strength materials

- For example, particularly high-strength steels - as they are preferably particularly advantageous for abrasion-resistant piping inside the pipe, have high or even very high yield strengths and thus are not suitable for this manufacturing process.

Inzwischen sind aber auch weitere Verfahren aus der

- einzelne zum Mehrlagenrohr zu kombinierende Werkstofflagen aufeinandergelegt, und

- der so gebildete Mehrlagen-Werkstoff mit Hilfe der Biegewalze zu einem Mehrlagenrohr geformt, wobei in der Endphase der Rohrformung in der Biegewalze eine jeweilig als Innenrohr fungierende Werkstofflage kraftschlüssig in eine jeweilig als Außenrohr fungierende Werkstofflage gepresst wird.

- individual layers of material to be combined with the multi-layer pipe stacked on top of one another, and

- the multilayer material thus formed is formed into a multilayer pipe with the aid of the bending roll, wherein in the final phase of pipe forming in the bending roll, a respective material layer functioning as an inner pipe is pressed non-positively into a material layer acting as an outer pipe.

Mit Hilfe dieses Verfahrens können Mehrlagenrohre hergestellt werden, die ohne walzund/oder sprengplattiertes Halbzeug auskommen, andererseits aber auch nicht den Beschränkungen unterliegen, die die Herstellung mehrlagiger Rohre nach dem vorgenannten Stand der Technik mit reibschlüssiger mechanischer Bindung von Lagen untereinander mit sich bringt.With the aid of this method multilayer pipes can be produced which do not require rolled and / or blast-plated semi-finished products, but on the other hand are not subject to the restrictions which the production of multi-layer pipes according to the aforementioned prior art with frictional mechanical bonding of layers with each other.

Die Verwendung walz- und/oder sprengplattierten Halbzeugs wird dadurch vermieden, daß zunächst zwischen den Werkstofflagen eine erste Verbindung - etwa eine Schweißnaht - geschaffen wird und hiernach die jeweilige als Innenrohr fungierende Werkstofflage während der Rohrformung in der Biegewalze durch eine - nach einem bestimmten Verformungsfortschritt anzubringende - weitere Verbindung zwischen den Werkstofflagen kraftschlüssig in die jeweilig als Außenrohr fungierende Werkstofflage gepresst und auf diese Weise im jeweiligen Außenrohr reibschlüssig gehalten wird und zwar ohne das Mehrlagenrohr aufweiten zu müssen und damit die zum o.a. Expansionsverfahren angeführten Nachteile einzugehen.The use of rolled and / or blast-plated semifinished product is avoided by first creating a first joint between the layers of material, such as a weld, and thereafter the respective layer of material acting as an inner tube during tube forming in the bending roll by attaching it after a certain deformation progress - Pressed further connection between the material layers frictionally in each functioning as an outer tube material layer and is frictionally held in the respective outer tube and without having to expand the multilayer tube and thus to address the above-mentioned expansion method disadvantages.

Gleichwohl hat dieses Verfahren den produktionstechnischen Nachteil, daß es hierbei erforderlich ist, während der Rohrformung in der Biegewalze nach einem bestimmten Verformungsfortschritt eine weitere Verbindung zwischen den Werkstofflagen zu schaffen, was in der Regel durch ein Verschweißen geschieht. Für diese Verbindung ist es daher erforderlich, die Rohrformung zu unterbrechen, um die beiden Werkstofflagen an dieser weiteren Stelle miteinander zu verbinden. Hierzu muß das noch unfertige Rohr aus der Biegewalze entfernt und sodann die Verbindung geschaffen, in der Regel also die Schweißnaht aufgebracht werden. Alternativ dazu kannes auch in der Biegewalze geschweißt werden, was diese jedoch währenddessen blockiert. Sodann kann der Rohrrohling (auch Schlitzrohr genannt) wieder in die Biegewalze eingebracht werden, um den dortigen Fertigungsprozeß weiter zu führen. Eine solches Vorgehen ist äußerst zeitintensiv und stellt daher einen erheblichen Produktionskostennachteil dar.Nevertheless, this method has the technical production disadvantage that it is necessary to create a further connection between the material layers during the tube forming in the bending roll after a certain deformation progress, which is usually done by welding. For this connection, it is therefore necessary to interrupt the tube forming in order to connect the two material layers together at this further point. For this purpose, the still unfinished pipe must be removed from the bending roll and then created the connection, so in general, the weld can be applied. Alternatively, it can also be welded in the bending roll, which however blocks it during this time. Then, the tube blank (also called slot tube) can be re-introduced into the bending roll to continue the local manufacturing process. Such a procedure is extremely time-consuming and therefore represents a significant production cost disadvantage.

Die

- einzelne zum Mehrlagenrohr zu kombinierende Werkstofflagen aufeinandergelegt werden, wobei eine als jeweiliges Außenrohr fungierende Werkstofflage ein Grundblech bildet, das in etwa entlang seiner beiden Längskanten oder in etwa parallel hierzu jeweils eine, vorzugsweise aufgeschweißte, Anschlagkante aufweist und die aufliegende Werkstofflage lose zwischen diese Anschlagkanten zu liegen kommt, und

- der so gebildete Mehrlagen-Werkstoff mit Hilfe der Biegewalze zu einem Mehrlagenrohr geformt wird, wobei die jeweilige als Innenrohr fungierende Werkstofflage zwischen die Anschlagkanten geklemmt und in der Endphase der Rohrformung in der Biegewalze die jeweilige als Innenrohr fungierende Werkstofflage hierdurch kraftschlüssig in die jeweilig als Außenrohr fungierende Werkstofflage gepresst wird.

- individual material layers to be combined to form multilayer pipe are stacked, wherein a material layer acting as a respective outer tube forms a base plate, which has a stop edge preferably approximately along its two longitudinal edges or approximately parallel thereto, and the resting material layer lies loosely between these stop edges comes, and

- the multilayer material formed in this way is formed into a multilayer pipe with the aid of the bending roll, the respective material layer acting as inner pipe being clamped between the abutment edges and in the final phase of pipe forming in the bending roll the respective material layer functioning as inner pipe thereby frictionally engaging in the respective outer pipe Material layer is pressed.

Nach dieser Ausführungsform der

Es ist daher Aufgabe der vorliegenden Erfindung ausgehend vom Stand der Technik nach der

Diese Aufgabe wird erfindungsgemäß durch ein Verfahren mit den Merkmalen des Auspruchs 1 gelöst.This object is achieved by a method having the features of

Bei diesem Verfahren nach der vorliegenden Erfindung wird die Unterbrechung des Rohrformungsprozesses in der Blechumformmaschine - also etwa in der Biegewalze - dadurch vermieden, daß mindestens zwei Elemente, die später die Innenlage bilden, zunächst, d.h. vor dem Rohrformungsprozeß, randseitig mit der später die Außenlage bildenden Werkstofflage verbunden, also in der Regel mit dieser verschweißt, werden. Während des Rohrformungsprozesses, also z.B. in der Biegewalze, bewegen sich dann die freien Enden dieser Elemente aufgrund der unterschiedlichen Biegeradien (oder Umfangslängen, was das Gleiche bedeutet) von Innenund Außenrohr aufeinander zu und stoßen irgendwann aneinander. Da zu diesem Zeitpunkt auch bereits eine Wölbung des Bleches hin zu einem Rohr eingesetzt hat, springen die Kanten der aneinanderstoßenden Lagen nicht voneinander ab, sondern verbleiben aneinanderstoßend, wobei sie jedoch - eine glatt geformte Kante vorausgesetzt - eine, mit zunehmendem Verformungsfortschritt stärker werdende, Kraft auf die Werkstoffinnenlage ausüben, mit der diese gegen die Außenlage gepreßt wird. Zu beachten ist, daß das erfindungsgemäße Verfahren so ausgestaltet ist, daß es sicherstellt, daß ab dem Augenblick, in dem die zunächst noch frei gegeneinander verschieblichen Kanten der Innenlagenbleche aneinanderstoßen, das zu formende Rohr an jeder Stelle, an der Innen- und Außenlage aufeinanderliegen, bereits gewölbt ist. D.h., daß das zu formende Rohr an jeder Stelle, an der Innen- und Außenlage aufeinanderliegen einen endlichen Radius (also nirgends dort einen unendlichen Radius) aufweist. Dies kann - etwa hinsichtlich des Großteils des Rohrkörpers - vorzugsweise durch eine ausreichende Biegung vor Aneinanderstoßen der verschieblichen Kanten der Innenlagenelemente erreicht werden, was etwa durch eine geeignete Bemessung und/oder Positionierung der Elemente der Innenlage geschehen kann. Auch kann dies (möglicherweise auch zusätzlich) - vorzugsweise im Randbereich, also dem Bereich der der später zu schließenden Rohrlängsnaht nahe kommt - vermittels einer zuvor bereits erfolgten Anbiegung der zum Rohr zu formenden Werkstofflagen erreicht werden.In this method according to the present invention, the interruption of the tube forming process in the sheet metal forming machine - ie in the bending roll - thereby avoided that at least two elements that later form the inner layer, initially, ie before the tube forming process, edge side with the later forming the outer layer Material layer connected, so usually welded to this, be. During the tube forming process, eg in the bending roll, the free ends of these elements then move towards each other due to the different bending radii (or circumferential lengths, which means the same thing) of the inner and outer tubes and eventually hit one another. Since at this time already a curvature of the sheet has been used to a pipe, the edges of the abutting layers do not jump from each other, but remain abutting, but they - assuming a smooth edge shaped - a, with increasing deformation progress increasing strength exert on the material inner layer, with which this is pressed against the outer layer. It should be noted that the method according to the invention is designed so that it ensures that from the moment in which the initially still freely mutually displaceable edges of the inner layer sheets abut, the tube to be formed at each point, on the inner and outer layer on each other, already arched. That is, the tube to be formed at each point, on the inner and outer layer on each other has a finite radius (ie nowhere there has an infinite radius). This can be achieved, for example with respect to the majority of the tubular body, preferably by sufficient bending before abutting the displaceable edges of the inner layer elements, which can be done for example by suitable dimensioning and / or positioning of the elements of the inner layer. Also, this (possibly also in addition) - preferably in the edge region, so the area of the later to be closed pipe longitudinal seam comes close - means a previously made bending of the pipe to be formed material layers can be achieved.

Auf diese Weise ist eine Unterbrechung des Formungsprozesses - etwa zur weiteren Verschweißung der Werkstofflagen - zur Ausbildung einer vollflächigen Werkstoffinnenlage aus dem hierfür vorgesehenen Material im Rohrinneren nicht mehr erforderlich.In this way, an interruption of the molding process - for example, for further welding of the material layers - to form a full-surface material inner layer of the material provided for this purpose inside the pipe no longer required.

Die erste Verbindung zwischen den Werkstofflagen wird dadurch geschaffen , daß diese in etwa entlang einer der Längs- oder Querkanten der aufliegenden Werkstofflage oder in etwa entlang einer Linie parallel hierzu aber entlang der zukünftigen Rohrlängsnaht miteinander verbunden werden. Die aufgelegten Elemente können somit mit ihrer Längskante parallel zur Längskante der unterliegenden Werkstofflage liegen, müssen dies aber nicht. So ist es auch möglich, daß sie mit ihrer Längskante quer hierzu zu liegen kommen. Die Verbindung mit der unten liegenden Werkstofflage erfolgt aber immer entlang der oder parallel zu der zukünftigen Rohrlängsnaht.The first connection between the material layers is created by connecting them along approximately one of the longitudinal or transverse edges of the overlying material layer or approximately along a line parallel thereto, but along the future pipe longitudinal seam. The applied elements can thus lie with their longitudinal edge parallel to the longitudinal edge of the underlying material layer, but need not. So it is also possible that they come to rest with their longitudinal edge transverse thereto. However, the connection with the material layer below is always along or parallel to the future pipe longitudinal seam.

In diesem Zusammenhang sei angemerkt, daß dann, wenn in diesem Text hier von einer Verbindung entlang einer Kante oder entlang einer (vorzugsweise nur gedachten) Linie die Rede ist, damit jede Art von Verbindung entlang der Kante oder Linie gemeint ist, gleich, ob diese Verbindung entlang der gesamten Kante oder Linie oder nur abschnittsweise entlang der Kante oder Linie oder auch nur in einzelnen Punkten (wie etwa Punktschweißungen), etwa in zwei Punkten - vorzugsweise an den Endpunkten der Kante oder Linie - oder gar nur in einem einzelnen Punkt an der Kante oder auf der Linie besteht.In this connection, it should be noted that when this text is used herein to refer to a connection along an edge or along a (preferably imaginary) line only, it means any type of connection along the edge or line, whether or not it is Connection along the entire edge or line or only in sections along the edge or line or even in single points (such as spot welds), for instance at two points - preferably at the end points of the edge or line - or even at a single point at the point Edge or on the line.

Auch kann die als Innenrohr fungierende Werkstofflage beim fertigen Mehrlagenrohr im Querschnitt einen Teilkreis bilden, was man dadurch erreichen kann, daß die Elemente der aufliegenden Werkstofflage, die später die Rohrinnenlage bilden, nur einen Teil der Fläche der Werkstofflage abdecken, die später die Außenlage bildet, wobei gleichwohl darauf zu achten ist, daß sie dennoch im Verlaufe des Rohrformungsprozesses mit ihren dann noch freien Enden gegeneinander stoßen und so die Innen- in die Außenlage gepreßt wird.The material layer functioning as an inner tube can also form a partial circle in the finished multilayer tube, which can be achieved by covering the elements of the overlying material layer, which later form the inner tube layer, only a part of the surface of the material layer which later forms the outer layer. while it is nevertheless important to ensure that they still encounter each other in the course of the tube forming process with their then free ends and so the inner is pressed into the outer layer.

Vorzugsweise formt dabei die als Innenrohr fungierende und beim fertigen Mehrlagenrohr im Querschnitt einen Teilkreis bildende Werkstofflage eine Rinne am Fuß des Mehrlagenrohres.Preferably, the material layer functioning as an inner tube and forming a partial circle in cross-section in the finished multilayer tube forms a groove at the foot of the multilayer tube.

Nach Fertigstellung des Schlitzrohres, also nach Abschluß des wesentlichen Rohrformungsprozesses, etwa in der Biegewalze, kann dann eine weitere Verbindung, vorzugsweise Verschweißung zwischen den Werkstofflagen und/oder den aneinanderstoßenden Kanten der Elemente der aufliegenden Werkstofflage erfolgen, insbesondere um hier diese Stoßkante dicht zu schließen. Eine Unterbrechung des eigentlichen Formungsprozesses ist hierfür aber nicht erforderlich. Vielmehr erfolgt ein solcher Schritt erst nach Abschluß des eigentlichen Rohrformungsprozesses. Auch ist es nicht erforderlich hierfür einen weiteren Werkstoffinnenlagenstreifen einzuarbeiten. Vielmehr genügt hier eine einfache Schweißung. In Fällen, in denen es nicht auf die völlige Dichtigkeit der Stoßkante ankommt - etwa dann, wenn nur eine erhöhte Abrasionsbeständigkeit der Innenlage gefordert ist - kann von dieser Schweißung zur Abdichtung sogar ganz abgesehen werden.After completion of the slotted tube, so after completion of the essential tube forming process, such as in the bending roll, then another connection, preferably welding between the material layers and / or the abutting edges of the elements of the overlying material layer can be done, in particular to close this butt joint tight here. An interruption of the actual molding process is not required for this purpose. Rather, such a step takes place only after completion of the actual tube forming process. Nor is it necessary to incorporate a further material inner layer strip for this purpose. Rather, a simple weld is sufficient here. In cases where it does not depend on the total tightness of the abutting edge - for example, if only an increased abrasion resistance of the inner layer is required - can be even completely ignored by this weld for sealing.

Hinsichtlich der Kraft, mit der die Innenlage gegen die Außenlage gepreßt werden soll, sei auf die bereits aus der

- DA

- als Außendurchmesser des Außenrohres in mm,

- SA

- als Wanddicke des Außenrohres in mm,

- SI

- als Wanddicke des Innenrohres in mm,

- σI

- als Streckgrenze des Innenrohres in N/mm2,

- Zs

- als Stauchungszuschlag angegeben in Teilen von Hundert und

- E

- als Elastizitätsmodul (E-Modul) in N/mm2

- THERE

- as the outer diameter of the outer tube in mm,

- SA

- as the wall thickness of the outer tube in mm,

- SI

- as the wall thickness of the inner tube in mm,

- σ I

- as yield strength of the inner tube in N / mm2,

- Z s

- as a compression surcharge given in parts of hundred and

- e

- as elastic modulus (modulus of elasticity) in N / mm2

Verwendung findet. Entsprechend den bereits in der

Die Länge der neutralen Faser des Außenrohres - hier Lafa genannt - beträgt dabei:

Die Länge der neutralen Faser des Innenrohres - hier Lufi genannt - beträgt:

Die Verschiebung der freien Blechkanten der Elemente der aufliegenden Werkstofflage (der späteren Innenlage) beträgt dann bei 100 % Verformungsgrad des Rohres - hier Lfr genannt - :

Der Stauchungsgrad des Innenrohres zum Erreichen der Stauchgrenze - hier εSt genannt - ergibt sich zu:

und die entsprechende Stauchungslänge zum Erreichen der Stauchgrenze zu:

and the corresponding compression length to reach the compression limit to:

Der Verformungsfortschritt - hier Ffor genannt -, bei dem die freien Blechkanten der Elemente der aufliegenden Werkstofflage aneinanderstoßen sollen - so man eine maximale Preßkraft erreichen will -, beträgt dann (als Wert zwischen 0 und 1 angegeben) etwa:

und in Teilen von Hundert angegeben:

and in parts of a hundred:

Löst man diesen Ausdruck mit

- DA

- als Außendurchmesser des Außenrohres in mm,

- SA

- als Wanddicke des Außenrohres in mm,

- SI

- als Wanddicke des Innenrohres in mm,

- σI

- als Streckgrenze des Innenrohres in N/mm2,

- Zs

- als Stauchungszuschlag angegeben in Teilen von Hundert und

- E

- als Elastizitätsmodul (E-Modul) in N/mm2

- THERE

- as the outer diameter of the outer tube in mm,

- SA

- as the wall thickness of the outer tube in mm,

- SI

- as the wall thickness of the inner tube in mm,

- σ I

- as yield strength of the inner tube in N / mm 2 ,

- Z s

- as a compression surcharge given in parts of hundred and

- e

- as elastic modulus ( modulus of elasticity ) in N / mm 2

Der Stauchungszuschlag berücksichtigt dabei die Fertigungsungenauigkeit in der Fixierung der zumindest einen weiteren Werkstofflagenverbindung, und kompensiert dies so, daß die angestrebte Preßkraft des Innenrohres gegen das Außenrohr mindestens erreicht wird.The compression allowance takes into account the manufacturing inaccuracy in the fixation of at least one other material layer connection, and compensates for this so that the desired pressing force of the inner tube is at least achieved against the outer tube.

In der Praxis wird man also etwa dann, wenn man ein vollständiges Innenrohr aus der innen liegenden Werkstofflage bilden will und zugleich die mittels des erfindungsgemäßen Verfahrens maximal erreichbare Preßkraft anstrebt - bei zwei aufliegenden Elementen, die später die Innenlage bilden -, die aufliegenden Elemente zunächst entlang der Längskanten der später die Außenlage bildenden Werkstofflage verschweißen und diese (die spätere Innenlage bildenden) Elemente von ihrer Größe und ihrer Geometrie her so wählen, daß zwischen ihren freien Kanten ein Spalt verbleibt, der sich im Verlaufe des Rohrformungsprozesses schließt und sodann die beiden dann aneinanderstoßenden Kanten durch den noch zu absolvierenden weiteren Rohrformungsprozeß nur noch insoweit gegeneinander gestoßen werden, wie es die Stauchgrenze des Materials der zukünftigen Innenlage erlaubt.In practice, if you want to form a complete inner tube from the inner layer of material and at the same time strives for the maximum achievable pressing force by means of the method according to the invention - with two resting elements that later form the inner layer -, the resting elements along first weld the longitudinal edges of the later forming the outer layer material layer and select these (the later inner layer forming) elements of their size and geometry forth so that between their free edges a gap remains, which closes in the course of the tube forming process and then the two then abutting Edges are encountered by the yet to be completed further tube forming process only insofar as it allows the compression limit of the material of the future inner layer.

Vorzugsweise wird bei dem Verfahren zur Herstellung eines Mehrlagenrohres mit Hilfe des Verfahrens nach der hier vorliegenden Erfindung das Mehrlagenrohr durch eine Schweißung des Außenrohres entlang der Rohrnaht und eine Auftragsschweißung des Innenrohres geschlossen, um so den Mehrlagenrohrkörper fertigzustellen.Preferably, in the method for producing a multilayer pipe by means of the method according to the present invention, the multilayer pipe is closed by welding the outer pipe along the pipe seam and build-up welding of the inner pipe so as to complete the multilayer pipe body.

Auch können die Werkstofflagen an den Stirnseiten des Rohres verbunden werden, etwa um dort das Eindringen von Feuchtigkeit zwischen die metallurgisch ja nicht vollflächig verbundenen Werkstofflagen zu verhindern.Also, the material layers can be connected to the front sides of the tube, such as there to prevent the ingress of moisture between the metallurgically yes not fully connected material layers.

Einen bevorzugten Anwendungsfall des Verfahrens nach der vorliegenden Erfindung stellt die Herstellung von erfindungsgemäßen Doppellagenrohren dar, gleichwohl beschränkt sich die Erfindung nicht hierauf, auch drei-, vier- und noch mehrlagigere erfindungsgemäße Rohre sind hiermit grundsätzlich herstellbar.A preferred application of the method according to the present invention is the production of double-layer tubes according to the invention, however, the invention is not limited thereto, also three-, four- and more multi-layer pipes according to the invention are hereby basically produced.

In einer weiteren besonders bevorzugten Ausführungsform der vorliegenden Erfindung finden Bleche, vorzugsweise Metallbleche und besonders bevorzugterweise Stahlbleche, als Werkstofflage oder Elemente der Werkstofflage Verwendung.In a further particularly preferred embodiment of the present invention find sheets, preferably metal sheets and more preferably steel sheets, as a material layer or elements of the material layer use.

Auch erfolgt in dem Verfahren zur Herstellung eines Mehrlagenrohres nach der hier vorliegenden Erfindung vorzugsweise zumindest eine der Verbindungen der Werkstofflagen als Schweißung, was sich vor allem für die zuvor erwähnten Metallbleche, vorzugsweise Stahlbleche eignet.Also, in the method for producing a multilayer pipe according to the present invention, at least one of the joints of the material layers is preferably used as a weld, which is particularly suitable for the aforementioned metal sheets, preferably steel sheets.

Als Blechumformmaschine ist etwa eine Biegewalze, also z.B. eine DreiwalzenRundbiegemaschine, aber auch eine Pressen-/Gesenkanordnung, wie sie etwa im Rahmen des aus dem Stand der Technik bekannten UOE(U-Formen, O-Formen, Expandieren)-Rohrformungsverfahrens (siehe zum UOE-Verfahren beispielsweise: Hiersig,

Beim JCO-Verfahren wird das Rohr dadurch geformt, daß das Blech in einer Presse vermittels eines Schwertes zunächst in die Form eines liegenden J' und dann in die eines liegenden ,C' gebracht wird. Hiernach wid es dann - wie im Falle des UOE-Verfahrens auch - in die ,O'-Form gebogen.In the JCO process, the tube is formed by first placing the sheet in a press by means of a sword in the shape of a horizontal J 'and then in that of a horizontal' C '. After that, it then - as in the case of the UOE method - bends into the ' O ' shape.

Aufgrund des Umstandes, daß der eigentliche Rohrformungsprozeß bei dem Verfahren nach der vorliegenden Erfindung nicht mehr für die Schaffung einer weiteren Verbindung zwischen den Werkstofflagen unterbrochen werden muß, kann das erfindungsgemäße Verfahren nunmehr aber auch als kontinuierliches Produktionsverfahren betrieben werden, bei dem die zu kombinierenden Werkstofflagen oder deren Elemente (jeweils von einem aufgewickelten Band abgewickelt und hernach kontinuierlich übereinander gelegt und kontinuierlich verbunden, vorzugsweise verschweißt werden, wobei der nachfolgende Rohrformungsprozeß ebenfalls kontinuierlich erfolgt, indem eine Einformstraße, die aus den kontinuierlich übereinandergelegten Werkstofflagen ein Schlitzrohr formt, als Blechumformmaschine dient. Derartige Einformstraßen zur Rohrformung sind etwa aus dem Stand der Technik bekannt, wie er in der

Im folgenden werden nicht einschränkend zu verstehende Ausführungsbeispiele anhand der Zeichnung besprochen. In dieser zeigt:

- Fig. 1

- eine perspektivisch skizzierte Aufsicht auf zwei aufeinandergelegte zum Mehrlagen- rohr zu kombinierende Werkstofflagen,

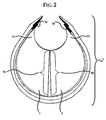

- Fig. 2

- eine perspektivisch skizzierte Sicht in ein - noch nicht fertiggestelltes -Mehrlagenrohr von einer Stirnseite her während des erfindungsgemäßen Herstellverfahrens, nämlich in dem Verfahrensschritt, wo der hierbei gebildete Mehrlagen-Werkstoff mit Hilfe der Blechumformmaschine zum Rohr geformt wird, die Kanten der beiden aufliegenden Elemente aber noch frei gegeneinander beweglich sind,

- Fig. 3

- eine perspektivisch skizzierte Sicht in ein - ebenfalls noch nicht fertiggestelltes - Mehrlagenrohr von einer Stirnseite her während des erfindungsgemäßen Herstellver- fahrens, nämlich in dem Verfahrensschritt, wo nach einem bestimmten Verformungs- fortschritt die beiden freien Stoßkanten der aufliegenden Elemente nun aneinander stoßen,

- Fig. 4

- einen perspektivischen Querschnitt durch ein fertiggestelltes Mehrlagenrohr mit In- nen- und Außenlage,

- Fig. 5

- einen perspektivischen Querschnitt durch ein Mehrlagenrohr mit Innen- und Außen- lage in Detailansicht im Bereich der Schweißnaht, und

- Fig. 6

- einen kontinuierlichen Rohrformungsprozeß nach der vorliegenden Erfindung in Prinzipdarstellung, bei dem die zu kombinierenden Werkstofflagen oder deren Ele- mente jeweils als aufgewickeltes Band (auch Coil genannt) vorliegen, von dem sie ab- gewickelt und hernach kontinuierlich übereinander gelegt werden,

- Fig. 7

- die Ausgangssituation des erfindungsgemäßen Verfahrens, wenn die Blechformung vermittels einer UO(E)-Pressen-/Gesenkanordnung ausgeführt wird,

- Fig. 8

- den Formungsschritt, der ein ,U' formt und zwar vermittels einer Presse (hier nicht dargestellt), die einen entsprechend ausgeformten Stempel nach unten treibt, wo die Werkstofflagen hierdurch gemeinsam in ein Gesenk (hier nicht ebenfalls nicht zu se- hen) getrieben werden, und

- Fig. 9

- den Formungsschritt der ein ,O', also ein Schlitzrohr ausformt und zwar vermittels einer Presse (hier nicht dargestellt), die zwei als Halbrund ausgeformte Stempel von unten und oben gegen den zu formenden Rohrkörper treibt, wo die Werkstofflagen hierdurch wiederum gemeinsam zu einem - im Querschnitt gesehen - Rund geformt werden.

-

Fig. 1 zeigt eine perspektivisch skizzierte Aufsicht auf zwei aufeinandergelegte zum Mehrlagenrohr zu kombinierende Werkstofflagen 1a, 1b, 2, wobei hier eine der Werkstofflagen, nämlich die aufgelegte Werkstofflage 1a,1b, welche später die Innenlage des Mehrlagenrohres bilden soll, aus zwei inRohrlängsrichtung aufgelegten Elementen -

Fig. 2 zeigt eine perspektivisch skizzierte Sicht in ein - noch nicht fertiggestelltes -Mehrlagenrohr 5 von einer Stirnseite her während des erfindungsgemäßen Herstellverfahrens, nämlich in dem Verfahrensschritt, wo der hierbei gebildete Mehrlagen-Werkstoff mit Hilfe der Blechumformmaschine, etwa einer Biegewalze (Die Blechumformmaschine selbst, also etwa die Biegewalze, ist hier ausgeblendet und daher nicht zu sehen!) zumRohr 5 geformt wird, wobei bei der Verformung die noch nicht mit der benachbarten Werkstofflage 2verbundenen Kanten Biegeradien von Innenrohr 1b und Außenrohr 2 sich entsprechend dem Verformungsfortschritt frei gegeneinander verschieben. Die erste Verbindung zwischen den beidenWerkstofflagen den Kanten 3b der Werkstofflagen und Außenlage Fig. 2 hier möglicherweise nicht so gut zu erkennen, so daß hier diese klarstellende Erläuterung erfolgt. -

Fig. 3 zeigt eine perspektivisch skizzierte Sicht in ein - ebenfalls noch nicht fertiggestelltes -Mehrlagenrohr 5 von einer Stirnseite her während des erfindungsgemäßen Herstellverfahrens, nämlich in dem Verfahrensschritt, wo nach einem bestimmten Verformungsfortschritt die beiden freien Stoßkanten 4a, 4b der aufliegenden Elemente 1a, 1b nun aneinander stoßen. Hierauf folgend kann sodanndas Mehrlagenrohr 5 mit Hilfe der Blechumformmaschine zu Ende geformt werden (nicht mehr zu sehen), wobei sich nun während dieser Endformung die Werkstofflagen aufgrund des Aneinanderstoßens derKanten 4a und 4b nun nicht mehr weiter gegeneinander verschieben, wodurch die jeweilige alsInnenrohr fungierende Werkstofflage Außenrohr fungierende Werkstofflage 2 gepresst wird. Auch hier ist ebenfalss, wie schon zuFig. 2 anzumerken, daß das Rohr auch im oberen Bereichder Darstellung (also in dem Bereich, der auf denn noch offenen Rohrschlitz zuläuft) und wo Innen-und Außenlage Fig. 3 hier möglicherweise nicht so gut zu erkennen, so daß hier diese klarstellende Erläuterung erfolgt. -

Fig. 4 zeigt sodann einen perspektivischen Querschnitt durchein fertiggestelltes Mehrlagenrohr 5 mit Innenlage (auch Innenrohr, Innenrohrleitung, Innenblech etc. genannt) 1, 1a, 1b und Außenlage (auch Außenrohr, Außenrohrleitung, Grundblech etc. genannt) 2,wobei das Mehrlagenrohr 5durch eine Schweißung 7 des Außenrohres 2 entlang einerRorhrnaht 8 und eine .Auftragsschweißung 9 desInnenrohres Die ersten Verbindungen den Lagen Kanten -

Fig. 5 zeigt einen perspektivischen Querschnitt durch ein Mehrlagenrohr nachFig. 4 mit Innenlage 1b und Außenlage 2 in Detailansicht im Bereich der beiden Schweißnähte 3a, 3b, 7, 9. -

Fig. 6 zeigt eine kontinuierliche Rohrformung nach der vorliegenden Erfindung, bei dem die zu kombinierenden Werkstofflagen 1a, 1b, 2 oder deren Elemente jeweils als aufgewickeltes Band (auch Coil genannt) vorliegen, von dem sie abgewickelt und hernach kontinuierlich übereinander gelegt werden. Hiernach erfolgt dann eine ebenfalls kontinuierliche Verschweißung der Lagen am äußeren Rand mittels einer jeweiligen Schweißanlage 10, etwa eines Lasers oder einer Rollennahtschweißmaschine oder einer Punktnahtschweißmaschine oder dergleichen. Auch ein Lichtbogenschweißen ist hier denkbar. Der sodann nachfolgende Rohrformungsprozeß erfolgt abermals kontinuierlich und zwar vermittels einer Einformstraße, die mittels Konturrollen 6 aus den kontinuierlich übereinanderliegenden und amRande 1b, 2verschweißten Werkstofflagen 1aein Schlitzrohr 5 formt und so als Blechumformmaschine dient. Derartige Einformstraßen zur Rohrformung sind etwa aus dem Stand der Technik bekannt, wie er in derUS 3 327 383 Konturrollen 6 hingegen korrekt zu sehen.)

- Fig. 1

- a perspectively outlined top view of two layers of material to be combined to form a multilayer pipe,

- Fig. 2

- a perspectively outlined view into a - not yet completed -Multlagen tube from one end face during the manufacturing process according to the invention, namely in the process step, where the resulting multilayer material is formed by means of Blechumformmaschine to the tube, but the edges of the two resting elements still are freely movable against each other,

- Fig. 3

- a perspectively sketched view into a - also not yet finished - multilayer pipe from one end side during the manufacturing process according to the invention, namely in the process step where after a certain deformation progress the two free abutting edges of the resting elements now abut each other,

- Fig. 4

- a perspective cross section through a finished multi-layer pipe with inner and outer layer,

- Fig. 5

- a perspective cross section through a multi-layer pipe with inner and outer layer in detail view in the region of the weld, and

- Fig. 6

- a continuous tube forming process according to the present invention in a schematic representation, in which the material layers to be combined or their elements are each in the form of a wound-up band (also called a coil), from which they are unwound and thereafter placed continuously over one another,

- Fig. 7

- the starting situation of the method according to the invention, when the sheet metal forming is carried out by means of a UO (E) press / die arrangement,

- Fig. 8

- the forming step which forms a 'U' by means of a press (not shown here) which drives a correspondingly shaped punch downwards, where the material layers are driven together into a die (not seen here likewise), and

- Fig. 9

- the forming step of an 'O', ie a slot tube ausformungt by means of a press (not shown here), which drives two shaped as a half round punch from below and above against the tubular body to be molded, where the material layers in turn together to a - im Cross-section seen - round shaped.

-

Fig. 1 shows a perspective outlined plan view of two superimposed multilayer pipe to be combinedmaterial layers material layer longitudinal direction elements longitudinal edges adjacent material layer 2 , which is to form the outer layer of the tube later, for the first time - preferably by a weld - are connected. -

Fig. 2 shows a perspective sketched perspective in a - not yet finished -multilayer tube 5 from one end side during the manufacturing process according to the invention, namely in the process step where the thus formed multilayer material using the sheet metal forming machine, such as a bending roll (The Blechumformmaschine itself, ie the bending roll, is hidden here and therefore not visible!) To thetube 5 is formed, wherein in the deformation not yet connected to theadjacent material layer 2edges elements inner tube outer tube 2 move freely against each other according to the deformation progress. The first connection between the twomaterial layers edges inner tube first connection outer layer Fig. 2 may not be so well recognized here, so here is this clarifying explanation. -

Fig. 3 shows a perspective sketched perspective in a - also not yet finished -multilayer pipe 5 from one end side during the manufacturing process according to the invention, namely in the process step, where after a certain deformation progress , the two free abuttingedges overlying elements multi-layer tube 5 can be formed using the Blechumformmaschine to the end (no longer visible), now no longer move due to the abutment of theedges material layer tube material layer 2 . Here too is just as good as it already isFig. 2 It should be noted that the tube is also already rounded in the upper area of the representation (ie in the region which tapers towards the still open tube slot) and where the inner andouter layers Fig. 3 may not be so well recognized here, so here is this clarifying explanation. -

Fig. 4 shows then a perspective cross-section through afinished multilayer pipe 5 with inner layer (also called inner tube, inner tube, inner plate, etc.) 1, 1a, 1b and Outer layer (also called outer tube, outer tube, base plate, etc.) 2, wherein themultilayer tube 5 by aweld 7 of theouter tube 2 along aRorhrnaht 8 and a.Hardfacing 9 of theinner tube first connections layers free edges inner layer elements -

Fig. 5 shows a perspective cross section through a multilayer pipe afterFig. 4 withinner layer outer layer 2 in a detailed view in the region of the twoweld seams -

Fig. 6 shows a continuous tube forming according to the present invention, in which the material layers to be combined 1a, 1b, 2 or their elements are each present as a wound band (also called coil), from which they are unwound and thereafter continuously superimposed. Thereafter, then also a continuous welding of the layers at the outer edge by means of arespective welding system 10, such as a laser or a roller seam welding machine or a Punktnahtschweißmaschine or the like. Arc welding is also conceivable here. The subsequent tube forming process then takes place continuously again by means of an injection molding line which forms aslot tube 5 by means ofcontour rollers 6 from the material layers1a US 3,327,383 contour rollers 6 are correctly seen.)

Die hiesige Darstellung soll den Prozeß aber noch einmal verdeutlichen, indem in ihrem oberen Teil die hierzu dienende Anlage von der Seite her und im unteren Teil der Darstellung an verschiedenen durch Zuordnungspfeile 11 gekennzeichneten Stationen im Querschnitt und zwar entgegegn der Vorschubrichtung 12 gesehen abgebildet ist.The present illustration is intended to clarify the process once more, however, by showing in its upper part the installation serving for this purpose from the side and in the lower part of the illustration at different stations marked by

Von oben laufen hier mithin zwei Werstofflagenelemente 1a, 1b und von unten eine Werkstofflage 2 zusammen. Die von oben kontinuierlich als Band zugeführten Werkstofflagenelemente 1a, 1b weisen dabei eine Breite auf, die geeignet ist, nach Durchführung des erfindungsgemäßen Herstellungsverfahrens die angestrebte Innenwandung des zu fertigenden Rohres zu bilden und zudem hierbei auch durch die infolge der durch die Rohrformung entstehenden Preßkraft noch ausreichend gestaucht zu werden. Die Details der Bemessung und Positionierung der Elemente der Werkstofflage, die innen zu liegen kommen soll, wurde dabei bereits vorstehend im allgemeinen Teil der Beschreibung hier diskutiert, worauf an dieser Stelle verwiesen sei. Die von unten her zugeführte Werkstofflage 2 dient später als Außenlage und weist daher als Breite den Außenumfang des zu fertigenden Rohres 5 auf.From above, two

Liegen die beiden Lagen 1a, 1b, 2 aufeinander, so werden sie jeweils randseitig mittels einer Schweißanlage 10 verschweißt, so daß die Elemente 1a, 1b der späteren Innenlage nun jeweils mit der späteren Außenlage 2 am Außenrand verbunden sind. In der Mitte der die spätere Außenwand bildenden Werkstofflage 2 hingegen liegen die beiden Elemente 1a,1b der späteren Rohrinnelage mit ihren dortigen Kanten noch lose auf.If the two

In der nachfolgenden Einformstraße, die nunmehr aus dem mehrlagigen Blech 1a, 1b, 2 kontinuierlich vermittels einer Anordnung von Konturrollen 6 (Zur Darstellung der Konturrollen beachte die Anmerkung oben!) ein Rohr 5 formt, werden die vorgenannten noch losen Kanten der innenliegenden Werkstofflagenelemente 1a, 1b nun infolge der unterschiedlichen Biegeradien von Außen- und Innenrohr gegeneinander geschoben und schließen sich dann infolge des Aneinanderstoßens dieser bis zu diesem Punkt noch frei verschieblichen Blechkanten zu einer Innenlage 1. Hiernach wirkt der Verformungsprozeß zum Rohr hin nun so, daß die beiden Innenlagenelemente 1a, 1b nun weiter gegeneinander geschoben werden, was nun aber zu einer Stauchung der Innenlage 1 und infolge dessen zu deren Pressung gegen die sich weiter formende Außenlage 2 führt, bis schließlich ein Schlitzrohr 5 entstanden ist, welches entlang des Schlitzes durch Schweißung geschlossen werden kann. Bei Bedarf können zuvor auch die Stoßkanten der beiden Innenlagenelemente 1a, 1b - etwa vermittels eines Lasers durch den noch offenen Schlitz hindurch - miteinander und/oder mit der äußeren Werkstofflage 2 verschweißt werden.In the following Einformstraße, now from the

Es sei angemerkt, daß das erfindungsgemäße Verfahren in ähnlicher Weise vermittels einer Pressen-/Gesenkanordnung, die für das sogenannte ,JCO'-Verfahren ausgelegt ist, durchgeführt werden kann. Hier wird dann entsprechend dem JCO-Verfahren vorgegangen, dies aber so modifiziert, daß wiederum zwei Werkstofflagen, wie beim erfindungsgemäß modifizierten UO(E)-Verfahren gebildet werden. Auch hier werden die aufliegenden Elemente 1a, 1b randseitig mit der die spätere Außenlage bildenden Werkstofflage 2 verschweißt und sodann ein Schlitzrohr nach dem JCO-Verfahren geformt. Auch hierbei tritt der gewünschte erfindungsgemäße Effekt ein, bei dem die zunächst freien Blechkanten der Innenlagenelemente 1a, 1b aneinanderstoßen, dadurch eine durchgehende Innenlage 1 bilden und sodann infolge der unterchiedlichen Biegeradien von Außen- und Innenlage gegen die Außenlage 2 gepreßt werden.It should be noted that the method according to the invention can be carried out in a similar manner by means of a press / die arrangement designed for the so-called "JCO" method. Here is then proceeded according to the JCO method, but this modified so that in turn two layers of material, as in the present invention modified UO (E) method are formed. Here, too, the

In allen Fällen, also sowohl beim erfindungsgemäß modifizierten UO(E)-Verfahren, wie auch bei dem erfindungsgemäß modifizierten JCO -Verfahren können die zunächst noch frei beweglichen Stoßkanten der beiden Innenlagenelemente 1a 1b nach ihrem Aneinanderstoßen miteinander und/oder mit der Außenlage 2 verschweißt werden, was etwa durch den noch offenen Schlitz des Schlitzrohres, vorzugsweise vermittels eines Laserschweißgerätes geschehen kann.In all cases, therefore, both the inventively modified RO (E) method, as with the inventively modified JCO process the initially freely movable abutting edges of the two

Claims (14)

- Process for producing a multilayer pipe (5) with the aid of a plate forming machine, wherein- individual layers of material (1, 2) to be combined to form the multilayer pipe (5) are laid one on top of the other, at least one of the layers of material (1) consisting of more than one laid-on element (1a 1b),- after that, a first connection (3a, 3b), respectively, is then created between the elements of the overlying layer of material (1a, 1b) and the adjacent layer of material (2) at the border along one of the longitudinal or transverse edges of the respective element of the overlying layer of material (1, 1a, 1b), or approximately along a line parallel thereto, but always along or parallel to the future longitudinal seam (8) of the pipe,- the multilayer material formed in this way is formed into the pipe (5) and, during the deformation, the edges (4a, 4b) of the elements (1a, 1b) of the overlying layer of material (1a, 1b) that are still freely displaceable with respect to one another can move freely toward one another in accordance with the extent to which deforming has progressed, on account of the different circumferential lengths of the inner pipe (1a, 1b) and the outer pipe (2),

characterized in that- then, after deforming has progressed to a certain extent, these edges (4a, 4b) of the elements (1a, 1b) of the overlying layer of material (1a, 1b) that are moving toward one another butt against one another, and- then the multilayer pipe (5) is formed to completion with the aid of the plate forming machine, the edges (4a, 4b) of the elements (1a, 1b) of the overlying layer of material (1a, 1b) then no longer being able to move freely toward one another during this final forming, as a result of which the layer of material (1a, 1b) respectively acting as the inner pipe is pressed with a force fit into the layer of material (2) respectively acting as the outer pipe. - Process for producing a multilayer pipe (5) according to Claim 1, characterized in that the forming of the multilayer material into the pipe is designed in such a way that, when deforming has progressed to the extent that the edges (4a, 4b) of the elements (1a, 1b) of the overlying layer of material (1a, 1b) that were previously moving toward one another butt against one another, the pipe to be formed has already been made to curve at every point at which the inner layer and the outer layer lie one on top of the other.

- Process for producing a multilayer pipe (5) according to Claim 1 or 2, characterized in that, in the finished multilayer pipe (5), the layer of material (1, 1a, 1b) acting as the inner pipe forms a pitch circle in cross section.

- Process for producing a multilayer pipe (5) according to one of Claims 1 to 3, characterized in that the layer of material (1, 1a, 1b) acting as the inner pipe and forming a pitch circle in cross section of the finished multilayer pipe (5) forms a channel at the foot of the multilayer pipe.

- Process for producing a multilayer pipe (5) according to one of Claims 1 to 4, characterized in that a connection, preferably welding, takes place between the edges (4a, 4b) of the elements of the overlying layer of material (1a, 1b) that butt against one another.

- Process for producing a multilayer pipe (5) according to one of Claims 1 to 5, characterized in that the multilayer pipe (5) is closed by a welding (7) of the outer pipe (2) along the pipe seam (8) and a build-up welding (9) of the inner pipe (1, 1a, 1b).

- Process for producing a multilayer pipe (5) according to one of Claims 1 to 6, characterized in that the layers of material (1, 1a, 1b, 2) are connected at the end faces of the pipe (5).

- Process for producing a multilayer pipe (5) according to one of Claims 1 to 7, characterized in that a double-layer pipe is produced as the multilayer pipe (5).

- Process for producing a multilayer pipe (5) according to one of Claims 1 to 8, characterized in that plates, preferably metal plates and particularly preferably steel plates, are used as the layer of material (1, 2) or elements (1a, 1b) of the layer of material (1).

- Process for producing a multilayer pipe (5) according to one of Claims 1 to 9, characterized in that at least one of the connections (3a, 3b, 4a, 4b) of the layers of material (1, 2) is performed as welding.

- Process for producing a multilayer pipe (5) according to one of Claims 1 to 10, characterized in that the process is designed as a continuous process in which the layers of material (1, 1a, 1b, 2) to be combined or elements (1a, 1b) thereof are respectively unwound from a wound-up strip and then continuously laid one on top of the other and continuously connected, preferably welded, the subsequent pipe forming process likewise taking place continuously, in that a forming line which forms an open-seam pipe (5) from the layers of material laid continuously one on top of the other serves as the plate forming machine.

- Process for producing a multilayer pipe (5) according to one of Claims 1 to 10, characterized in that a bending roll is used as the plate forming machine.

- Process for producing a multilayer pipe (5) according to one of Claims 1 to 10, characterized in that a UO(E) press/die arrangement (13, 14, 15) is used as the plate forming machine.

- Process for producing a multilayer pipe (5) according to one of Claims 1 to 10, characterized in that a JCO press/die arrangement is used as the plate forming machine.

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PCT/EP2009/004467 WO2010145680A1 (en) | 2009-06-19 | 2009-06-19 | Production-optimized method for producing a multilayered tube |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2285508A1 EP2285508A1 (en) | 2011-02-23 |

| EP2285508B1 true EP2285508B1 (en) | 2011-08-17 |

Family

ID=41528987

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP09776794A Not-in-force EP2285508B1 (en) | 2009-06-19 | 2009-06-19 | Production-optimized method for producing a multilayered tube |

Country Status (10)

| Country | Link |

|---|---|

| US (1) | US20110146366A1 (en) |

| EP (1) | EP2285508B1 (en) |

| JP (1) | JP2012529993A (en) |

| KR (1) | KR101205676B1 (en) |

| CN (1) | CN101983109A (en) |

| AT (1) | ATE520479T1 (en) |

| AU (1) | AU2009318922B2 (en) |

| BR (1) | BRPI0906446A2 (en) |

| CA (1) | CA2706347C (en) |

| WO (1) | WO2010145680A1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102013103811B3 (en) * | 2013-04-16 | 2014-03-20 | EISENBAU KRäMER GMBH | Method for producing a multi-layered large pipe |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102012019315A1 (en) | 2012-10-02 | 2014-04-03 | Bergrohr Gmbh Siegen | Process for the rapid production of a multilayer pipe |

| BR102013021664B1 (en) * | 2013-08-23 | 2020-11-10 | Vallourec Soluções Tubulares Do Brasil S.A | process for production of clad tube by drawing and clad tube |

| KR101657817B1 (en) * | 2014-12-23 | 2016-09-20 | 주식회사 포스코 | Manufacturing method of plate for cladding pipe and manufacturing apparatus for the same and clade pipe |

| CN106140922A (en) * | 2015-04-10 | 2016-11-23 | 上海丁柯机械有限公司 | A kind of drawing process of laminated multi-layer workpiece |

| CN115846791A (en) * | 2023-03-03 | 2023-03-28 | 无锡市源隆金属制品有限公司 | Welding device for automobile straight welded pipe |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE582387C (en) * | 1933-08-14 | Kurt Ruppin | Process for the production of double-walled tubes or similar hollow bodies | |

| US2489802A (en) * | 1945-04-02 | 1949-11-29 | Smith Corp A O | Method of constructing multilayer cylinders |

| US2585237A (en) * | 1946-04-03 | 1952-02-12 | Babcock & Wilcox Co | Method of making banded pressure vessels |

| US3327383A (en) | 1963-01-03 | 1967-06-27 | Walter C Reed | Method of making clad pipe |

| US3400449A (en) * | 1966-06-06 | 1968-09-10 | Continental Can Co | Method of preparing a surface for welding |

| US3857159A (en) * | 1973-09-27 | 1974-12-31 | Pacific Roller Die Co Inc | Pipe forming method |