EP2269738B1 - Device for thermo-dependent chain reaction amplification of target nucleic acid sequences - Google Patents

Device for thermo-dependent chain reaction amplification of target nucleic acid sequences Download PDFInfo

- Publication number

- EP2269738B1 EP2269738B1 EP10177401A EP10177401A EP2269738B1 EP 2269738 B1 EP2269738 B1 EP 2269738B1 EP 10177401 A EP10177401 A EP 10177401A EP 10177401 A EP10177401 A EP 10177401A EP 2269738 B1 EP2269738 B1 EP 2269738B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- cartridge

- reaction chambers

- reaction

- amplification

- reservoir

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01L—CHEMICAL OR PHYSICAL LABORATORY APPARATUS FOR GENERAL USE

- B01L3/00—Containers or dishes for laboratory use, e.g. laboratory glassware; Droppers

- B01L3/50—Containers for the purpose of retaining a material to be analysed, e.g. test tubes

- B01L3/502—Containers for the purpose of retaining a material to be analysed, e.g. test tubes with fluid transport, e.g. in multi-compartment structures

- B01L3/5027—Containers for the purpose of retaining a material to be analysed, e.g. test tubes with fluid transport, e.g. in multi-compartment structures by integrated microfluidic structures, i.e. dimensions of channels and chambers are such that surface tension forces are important, e.g. lab-on-a-chip

- B01L3/50273—Containers for the purpose of retaining a material to be analysed, e.g. test tubes with fluid transport, e.g. in multi-compartment structures by integrated microfluidic structures, i.e. dimensions of channels and chambers are such that surface tension forces are important, e.g. lab-on-a-chip characterised by the means or forces applied to move the fluids

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01L—CHEMICAL OR PHYSICAL LABORATORY APPARATUS FOR GENERAL USE

- B01L3/00—Containers or dishes for laboratory use, e.g. laboratory glassware; Droppers

- B01L3/50—Containers for the purpose of retaining a material to be analysed, e.g. test tubes

- B01L3/502—Containers for the purpose of retaining a material to be analysed, e.g. test tubes with fluid transport, e.g. in multi-compartment structures

- B01L3/5025—Containers for the purpose of retaining a material to be analysed, e.g. test tubes with fluid transport, e.g. in multi-compartment structures for parallel transport of multiple samples

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01L—CHEMICAL OR PHYSICAL LABORATORY APPARATUS FOR GENERAL USE

- B01L3/00—Containers or dishes for laboratory use, e.g. laboratory glassware; Droppers

- B01L3/50—Containers for the purpose of retaining a material to be analysed, e.g. test tubes

- B01L3/502—Containers for the purpose of retaining a material to be analysed, e.g. test tubes with fluid transport, e.g. in multi-compartment structures

- B01L3/5027—Containers for the purpose of retaining a material to be analysed, e.g. test tubes with fluid transport, e.g. in multi-compartment structures by integrated microfluidic structures, i.e. dimensions of channels and chambers are such that surface tension forces are important, e.g. lab-on-a-chip

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01L—CHEMICAL OR PHYSICAL LABORATORY APPARATUS FOR GENERAL USE

- B01L3/00—Containers or dishes for laboratory use, e.g. laboratory glassware; Droppers

- B01L3/50—Containers for the purpose of retaining a material to be analysed, e.g. test tubes

- B01L3/502—Containers for the purpose of retaining a material to be analysed, e.g. test tubes with fluid transport, e.g. in multi-compartment structures

- B01L3/5027—Containers for the purpose of retaining a material to be analysed, e.g. test tubes with fluid transport, e.g. in multi-compartment structures by integrated microfluidic structures, i.e. dimensions of channels and chambers are such that surface tension forces are important, e.g. lab-on-a-chip

- B01L3/502715—Containers for the purpose of retaining a material to be analysed, e.g. test tubes with fluid transport, e.g. in multi-compartment structures by integrated microfluidic structures, i.e. dimensions of channels and chambers are such that surface tension forces are important, e.g. lab-on-a-chip characterised by interfacing components, e.g. fluidic, electrical, optical or mechanical interfaces

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01L—CHEMICAL OR PHYSICAL LABORATORY APPARATUS FOR GENERAL USE

- B01L7/00—Heating or cooling apparatus; Heat insulating devices

- B01L7/52—Heating or cooling apparatus; Heat insulating devices with provision for submitting samples to a predetermined sequence of different temperatures, e.g. for treating nucleic acid samples

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01L—CHEMICAL OR PHYSICAL LABORATORY APPARATUS FOR GENERAL USE

- B01L2300/00—Additional constructional details

- B01L2300/08—Geometry, shape and general structure

- B01L2300/0803—Disc shape

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01L—CHEMICAL OR PHYSICAL LABORATORY APPARATUS FOR GENERAL USE

- B01L2300/00—Additional constructional details

- B01L2300/08—Geometry, shape and general structure

- B01L2300/0809—Geometry, shape and general structure rectangular shaped

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01L—CHEMICAL OR PHYSICAL LABORATORY APPARATUS FOR GENERAL USE

- B01L2300/00—Additional constructional details

- B01L2300/08—Geometry, shape and general structure

- B01L2300/0861—Configuration of multiple channels and/or chambers in a single devices

- B01L2300/0864—Configuration of multiple channels and/or chambers in a single devices comprising only one inlet and multiple receiving wells, e.g. for separation, splitting

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01L—CHEMICAL OR PHYSICAL LABORATORY APPARATUS FOR GENERAL USE

- B01L2300/00—Additional constructional details

- B01L2300/18—Means for temperature control

- B01L2300/1805—Conductive heating, heat from thermostatted solids is conducted to receptacles, e.g. heating plates, blocks

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01L—CHEMICAL OR PHYSICAL LABORATORY APPARATUS FOR GENERAL USE

- B01L2400/00—Moving or stopping fluids

- B01L2400/04—Moving fluids with specific forces or mechanical means

- B01L2400/0403—Moving fluids with specific forces or mechanical means specific forces

- B01L2400/0406—Moving fluids with specific forces or mechanical means specific forces capillary forces

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01L—CHEMICAL OR PHYSICAL LABORATORY APPARATUS FOR GENERAL USE

- B01L2400/00—Moving or stopping fluids

- B01L2400/04—Moving fluids with specific forces or mechanical means

- B01L2400/0475—Moving fluids with specific forces or mechanical means specific mechanical means and fluid pressure

- B01L2400/0487—Moving fluids with specific forces or mechanical means specific mechanical means and fluid pressure fluid pressure, pneumatics

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01L—CHEMICAL OR PHYSICAL LABORATORY APPARATUS FOR GENERAL USE

- B01L2400/00—Moving or stopping fluids

- B01L2400/04—Moving fluids with specific forces or mechanical means

- B01L2400/0475—Moving fluids with specific forces or mechanical means specific mechanical means and fluid pressure

- B01L2400/0487—Moving fluids with specific forces or mechanical means specific mechanical means and fluid pressure fluid pressure, pneumatics

- B01L2400/049—Moving fluids with specific forces or mechanical means specific mechanical means and fluid pressure fluid pressure, pneumatics vacuum

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01L—CHEMICAL OR PHYSICAL LABORATORY APPARATUS FOR GENERAL USE

- B01L7/00—Heating or cooling apparatus; Heat insulating devices

- B01L7/52—Heating or cooling apparatus; Heat insulating devices with provision for submitting samples to a predetermined sequence of different temperatures, e.g. for treating nucleic acid samples

- B01L7/525—Heating or cooling apparatus; Heat insulating devices with provision for submitting samples to a predetermined sequence of different temperatures, e.g. for treating nucleic acid samples with physical movement of samples between temperature zones

- B01L7/5255—Heating or cooling apparatus; Heat insulating devices with provision for submitting samples to a predetermined sequence of different temperatures, e.g. for treating nucleic acid samples with physical movement of samples between temperature zones by moving sample containers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01L—CHEMICAL OR PHYSICAL LABORATORY APPARATUS FOR GENERAL USE

- B01L7/00—Heating or cooling apparatus; Heat insulating devices

- B01L7/54—Heating or cooling apparatus; Heat insulating devices using spatial temperature gradients

Definitions

- the present invention relates to the field of genetics.

- the present invention relates to a device for the amplification of target nucleic sequences, and modes of use of this device.

- the object of the present invention is in particular to enable the detection and, where appropriate, the quantification in real time of target nucleic acid sequences in one or more samples.

- Detection of target nucleic acid sequences is an increasingly popular technique in many fields, and the range of applications of this technique is expected to expand as it becomes more reliable, cost-effective and more reliable. fast.

- the detection of certain nucleic acid sequences in certain cases allows a reliable and rapid diagnosis of viral or bacterial infections.

- the detection of certain genetic peculiarities can make it possible to identify susceptibilities to certain diseases, or to establish an early diagnosis of genetic or neoplastic diseases.

- the detection of target nucleic sequences is also used in the food industry, in particular to ensure the traceability of products, to detect the presence of genetically modified organisms and to identify them, or to carry out a health control of food.

- Nucleic acid-based detection methods almost invariably involve a molecular hybridization reaction between a target nucleic acid sequence and one or more sequences nucleic acid complementary to said target sequence.

- These methods have numerous variants such as the techniques known to those skilled in the art under the terms "transfer techniques” ( blot, dot block, Southern blot, Restriction Fragment Length Polymorphism, etc.), or else the miniaturized systems on which the complementary sequences of the target sequences ("biochips”) are prefixed.

- transfer techniques blot, dot block, Southern blot, Restriction Fragment Length Polymorphism, etc.

- biochips the complementary nucleic sequences are generally called probes.

- Another variant which may constitute in itself the basis of a diagnostic method or be only an additional step in one of the techniques mentioned above (in particular to increase the concentration of the target sequence and therefore the sensitivity of the diagnosis), consists in amplifying the targeted nucleic acid sequence.

- PCR Polymerase Chain Reaction

- PCR Polymerase Chain Rection

- primers complementary nucleic sequences of the target sequences

- the PCR reactions involve a repetition of cycles, the number of which generally ranges from 20 to 50, and which are each composed of three successive phases, namely: denaturation, hybridization, elongation.

- the first phase corresponds to the transformation of the double-stranded nucleic acids into single-stranded nucleic acids

- the second phase to the molecular hybridization between the target sequence and the complementary primers of said sequence

- the third phase to the elongation of the hybridized complementary primers. to the target sequence, by a DNA polymerase.

- phase are carried out at specific temperatures: generally 95 ° C for denaturation, 72 ° C for elongation, and between 30 ° C and 65 ° C for hybridization, depending on the hybridization temperature (Tm) of the primers used. It is also possible to perform the hybridization and elongation steps at the same temperature (generally 60 ° C).

- a PCR reaction therefore consists of a series of repetitive thermal cycles in which the number of target DNA molecules serving as template is theoretically doubled at each cycle.

- the yield r decreases during the PCR reaction, because of several factors, such as an amount mimicking at least one of the reagents necessary for the amplification, the inactivation of the polymerase by repeated passages. at 95 ° C, or its inhibition by the pyrophosphates produced by the reaction.

- the curve presenting the quantity of product, in logarithmic scale, as a function of the number of cycles, and a slope line (1 + r) and which intersects the y-axis with a value equal to the logarithm of the initial concentration.

- the real-time measurement of the quantity of product obtained can therefore make it possible to know the initial matrix concentration, which is particularly useful in a large number of applications, for example for measuring the viral load of a patient, or again to know the variability of a transcriptome.

- the PCRs involve reaction volumes ranging from 2 to 50 ⁇ l and are carried out in tubes, microtubes, capillaries or systems known to those skilled in the art under the term "microplates" (in fact sets of micro tubes secured).

- microplates in fact sets of micro tubes secured.

- Each batch of tubes or equivalent containers must be successively brought to the three temperatures corresponding to the different phases of the PCR, and as many times as desired cycles.

- oligonucleotides complementary to said sequence are based on oligonucleotides complementary to said sequence, and linked to couples of fluorophore or fluorophore / quencher moieties, such that hybridization of the probe to its target and subsequent amplification cycles result, depending on the case an increase or decrease in the total fluorescence of the mixture, in proportion to the amplification of the target sequence.

- Examples of useful probes for performing kinetic PCR include the TaqMan TM system (ABI ®), the AmpliSensor TM system (InGen) and the Sunrise TM system (Oncor ®, ® Appligene).

- the most used system today is the Taq Man TM system .

- This method combines the DNA polymerase and 5 ' ⁇ 3' nuclease activities of Taq polymerase during PCR. Its principle is as follows: in addition to the two primers of sequence complementary to that of the target to be quantified, a probe, called probe reporter, is added in the reaction medium. It has the ability to hybridize to the target in the body of the amplified sequence, but can not be amplified itself. Indeed, a phosphoryl group added to the 3 'end of the probe prevents its extension by Taq polymerase. A fluorescein derivative and a rhodamine derivative are incorporated into the probe at the 5 'and 3' ends, respectively. The probe is small, so the rhodamine derivative, located near the fluorescein, absorbs the energy emitted by the fluorescein subjected to a source of excitation ( quenching phenomenon).

- the Taq DNA polymerase attacks the probe by its 5 'activity. nuclease, releasing the quencher group and thereby restoring the fluorescence emission.

- the intensity of the fluorescence emitted is then proportional to the quantity of PCR products formed, which makes it possible to obtain a quantitative result.

- the fluorescence emitted is proportional to the number of starting target molecules. The kinetics of fluorescence development can be monitored in real time during the amplification reaction.

- This technique has the advantage of being easily automatable.

- An apparatus for carrying out this technique the ABI Prism 7700 TM , is marketed by Perkin-Elmer.

- This device combines a thermocycler and a fluorimeter. It is able to detect the increase in fluorescence generated during a quantification test according to the TaqMan TM process, thanks to optical fibers located below each tube and connected to a CCD camera that detects, in real time , the signal emitted by the fluorescent groups released during the PCR.

- the quantitative data are derived from the determination of the cycle at which the signal of the amplification product reaches a certain threshold determined by the user.

- this number of cycles is proportional to the amount of initial material (Gibson, Heid et al., 1996, Heid, Stevens et al., 1996, Williams, Giles et al., 1998).

- the objective of the present invention is to propose such a system which makes it possible to considerably reduce the number of manipulations required to implement an amplification method on a plurality of target sequences and, consequently, to reduce the time required. necessary for this operation.

- Another object of the present invention is to provide such a system which minimizes the risk of contamination from one container to another.

- Another objective of the present invention is to propose such a system which reduces the volumes of reagents involved and therefore the costs.

- Another objective of the present invention is to propose such a system which optimizes a homogeneous distribution in volume and in concentration of the reagents necessary for the PCR in the containers.

- Another objective is to provide all potential users, including hospitals, medical laboratories, agribusiness and health control laboratories, an easy-to-use and easy-to-use device to routine quantified nucleic acid amplifications in real time.

- the invention relates firstly to any device according to one of claims 1 to 16.

- the temperature of each zone of the platen can be homogeneous or, where appropriate, this temperature can vary according to a gradient.

- reaction mixture Several types of molecular biology reactions require placing the reaction mixture at different temperatures as a function of time. This is the case, for example, when it is desired to inactivate an enzyme after using it (for example, a restriction nuclease), or to test the stability of a complex. In the latter case, it is conceivable to place a complex (for example, an antigen / antibody complex, or receptor / ligand), one of which is coupled to a fluorophore and the other to a quencher of fluorescence, one of the reaction chambers of the device. The stage is then programmed to present several temperatures in increasing order, possibly in the form of a gradient.

- a complex for example, an antigen / antibody complex, or receptor / ligand

- the stability of the complex is then tested by moving the cartridge on the plate, so that the temperature of the reaction chamber rises gradually, and observing the increase in fluorescence, using excitation means measurement of the fluorescence placed opposite the reaction chamber.

- the increase in fluorescence then reflects the dissociation of the complex.

- the device of the invention is particularly suitable for reactions requiring a cyclic variation in the temperature of the reaction chambers, which is the case for certain nucleic acid amplification reactions, for example for polymerase chain reaction (PCR ), or for the ligase chain reaction (LCR).

- PCR polymerase chain reaction

- LCR ligase chain reaction

- the invention therefore relates in particular to a device for the thermo-dependent chain amplification of target nucleic acid sequences according to one of claims 1 to 16.

- Such a system according to the invention is less complex than the systems of the prior art, insofar as the temperatures required for the cycles of the chain amplification are provided by distinct zones of constant temperatures and not by a plate of which one must vary the temperature.

- thermo-dependent chain amplification reactions require the passage of samples at at least two temperatures.

- the CSF requires at each cycle a phase at about 95 ° C to denature the target DNA, then a phase between 55 and 65 ° C (depending on the Tm probes) to give rise to hybridization / ligation .

- each cycle generally breaks down into three phases, namely denaturation at about 95 ° C, hybridization whose temperature depends on the Tm of the probes, and elongation, usually performed at 72 ° C. .

- nucleic acids to be amplified it is possible to dispense, from a reservoir, a fluid containing a sample of nucleic acids to be analyzed and the reagents necessary for the PCR in a plurality of reaction chambers containing specific primers of target sequences. nucleic acids to be amplified, and to allow the amplification process by subjecting the contents of the chambers successively to different temperatures (namely those necessary for denaturation, hybridization and elongation) a multitude of times through a movement relative between the cartridge including said reaction chambers and said heating platen having two or three distinct zones that can be brought to different temperatures.

- the reaction chambers (13) may contain reagents necessary for a real-time PCR reaction other than the primers mentioned above.

- the reaction chambers also comprise, in addition to the primers, one or more specific probe (s) of the sequence to be amplified.

- the distribution of the probes in the reaction chambers may also be such that some chambers contain probes specific for the sequences to be amplified and other chambers comprise control probes, not recognizing a priori the sequence to be amplified. These probes may be labeled and, if several probes are present in the same reaction chamber (for example a probe specific for the sequence to be amplified and a control probe), these probes will preferably be labeled with different fluorophores.

- additional reagents such as dNTPs or salts, are initially deposited in the reaction chambers. These reagents will then be absent, or present in a smaller amount, in the fluid deposited in the reservoir (11). In the extreme case, all the reagents necessary for the PCR reaction, with the exception of the matrix, are deposited in the reaction chambers (13), and the fluid deposited in the reservoir (11) will then comprise only the sample. DNA (or RNA) to amplify.

- the variants described above assume that several reactions are carried out in parallel, with different primers and / or probes, on the same sample. It is therefore the characterization of a single sample (or a few samples if the reservoir is divided into a few sub-reservoirs) according to several criteria. In some applications, on the contrary, it is desired to characterize a multitude of samples according to a single criterion or a small number of criteria. This is the case for example in research, when it is desired to screen a library of phages or bacteria for the presence of a given gene. In this case, it is necessary to carry out a PCR on a large number of samples, from a given pair of primers.

- the device of the invention is also suitable for this type of manipulation.

- the samples are deposited in the reaction chambers (13).

- the primers can be introduced into the fluid deposited in the reservoir (11), along with the other reagents necessary for the PCR.

- this configuration does not exclude that certain reagents other than the sample to be analyzed are pre-deposited in the reaction chambers (13).

- each reagent deposited in the reaction chambers (13) can be advantageously deposited there by a simple liquid deposit, followed by drying.

- the arrival of the fluid from the reservoir (11) then allows the re-solution of these reagents.

- the amount of each reagent deposited is calculated as a function of the volume of fluid that will penetrate into each reaction chamber (13), so that the reactivation of the reagents will result in the desired final concentration for each of them.

- Cartridges as described above, in which at least a portion of the reaction chambers (13) comprise reagents which have been loaded therein by a liquid deposit, followed by drying, so that these reagents are returned to solution by the arrival of a fluid in these reaction chambers, are also an integral part of the invention.

- the device described above has the advantage of allowing a concomitant filling of all the reaction chambers, which reduces the preparation time and the risks of contamination from one chamber to another.

- This device also has the advantage of being able to be miniaturized and to involve the use of smaller volumes of reagents than in the state of the art.

- the invention makes it possible to accelerate PCR cycles, since it is not necessary to perform the various phases (denaturation, hybridization, elongation). to vary the temperature of the heating stage or of the atmosphere as in the state of the art, the relative movement between the cartridge and the plate making it possible to quickly and successively submit the contents of each of the chambers reaction at three distinct temperatures dedicated to each of these phases.

- the use of small reaction volumes, and a thin floor for the cartridge (1), also limit the thermal inertia at the reaction chambers, and therefore contribute to the speed of the reaction.

- the invention also relates to a device for thermo-dependent chain amplification of target nucleic acid sequences, measured in real time, characterized in that it comprises the same elements as any of the devices described above. above, and further comprising optical means (5) for excitation / measurement of fluorescence, arranged to excite and measure at each cycle the fluorescence of the contents of the reaction chambers.

- the diameter of the channels will preferably be chosen small enough not to allow a gravity distribution of the fluid present in the tank in the reaction chambers, so as to avoid non-reproducible filling of these chambers. This diameter will thus preferably be less than or equal to approximately 0.2 mm. With regard to this diameter, it will be noted that the section of the channels will preferably be circular but that it may also be of any other shape and in particular polygonal, the "diameter" of the channels then aiming at their greatest width in section.

- the reservoir intended to receive the sample of nucleic acids and the reagents necessary for the PCR may have a variable capacity, for example between about 0.1 ml and about 1 ml.

- the cartridge preferably comprises between about 20 and about 500 reaction chambers and, more preferably, between 60 and 100 reaction chambers.

- these rooms may also vary according to the embodiments.

- these chambers have a volume of between approximately 0.2 and 50 ⁇ l, preferably between 1 ⁇ l and 10 ⁇ l.

- the junction between the channels (12) and the reservoir (11) is at the periphery of the reservoir, and the bottom of said reservoir is inclined and / or convex, so as to ensure the distribution of a fluid contained in the tank at the entrance of the channels.

- a cartridge used according to the invention may have multiple forms. However, according to a preferred variant of the invention, this cartridge has a circular shape.

- the reservoir is provided substantially in the center of the cartridge, the reaction chambers being distributed in a circle around the reservoir, and the channels connecting the reservoir to the chambers being provided essentially radially.

- Such an architecture allows to optimize the filling of the reaction chambers from the central tank.

- the bottom of the tank (11) is conical.

- reaction chambers are provided relative to the periphery of said cartridge.

- said reaction chambers are provided relative to the periphery of said cartridge.

- such a cartridge comprises as many channels as there are reaction chambers.

- the cartridge preferably has a diameter of between about 1 and 10 cm.

- a variant of the cartridges of the invention described above whatever their geometry, consists in dividing the reservoir (11) into 2 to 20, preferably 2 to 8 sub-reservoirs, making it possible to simultaneously analyze several samples on a same cartridge.

- each of the reaction chambers (13) is connected to only one of these sub-tanks by a channel (12).

- the depth of the reaction chambers may also vary depending on the embodiments of the invention. According to a preferred variant, these chambers have a depth of between approximately 0.5 mm and 1.5 mm.

- this cartridge depends on several factors including the material constituting it.

- this cartridge is preferably made of plastic material, preferably polycarbonate, whose physical, optical and thermal properties are suitable for carrying out the present invention.

- the thickness of the cartridges of the invention is preferably between 0.5 and 5 mm.

- the thickness of the "floor” thereof will preferably be as low as possible. This thickness depends on the material used to make the cartridge. Preferably, it is between 0.05 and 0.5 mm, for example about 0.25 mm.

- reaction chambers of the cartridges of the invention are preferably closed by a transparent upper wall (17), for example of transparent plastic, in order to allow the excitation and the measurement of the fluorescence of the reaction fluid, in good conditions.

- the chambers are provided with vents (open system), allowing the air they contain to escape during their filling by the fluid from the tank.

- the channels (12) preferably consist of at least two parts of different diameters (121 and 122), the diameter of the second part (122) being smaller than that of the first part (121), so as to create a pressure drop in the channel (12).

- the pressure drop phenomenon stops the progression of the fluid in the channel or channels whose first portion (121) is filled, until all the channels are filled in the same way. This allows to "pre-calibrate” the volumes for each channel, to ensure a homogeneous filling of the different reaction chambers.

- the second portion of the channel (122) may consist for example of a glass capillary, much smaller in diameter than the first portion (121), said capillary being included in a plastic cartridge.

- the cartridges described above provided for use in an open system or for use in a closed system, preferably comprise an opening that can be adapted to means (4) for modulating the pressure in the reservoir (11), making it possible to moving the fluid present in the reservoir to the reaction chambers.

- each channel (12) is equipped with an anti-reflux cavity (123) at its junction with the reservoir (11), said anti-reflux cavity consisting of a substantially vertical channel portion of a diameter greater than or equal to that of the channel (12).

- This variant has two main advantages. On the one hand, these anti-reflux cavities make it possible to prevent cross-contamination in the event of an inadvertent return of fluid to the reservoir (11), or in the case where all the fluid has not been engaged in the channels. On the other hand, these cavities make it possible to provide, in the devices of the invention, a plug whose serrations come to marry these vertical inlets, in order to plug the channels after the addressing of the editorial fluid but before the amplification reaction.

- each of the reaction chambers (13) comprises oligonucleotides. More preferably, each of the reaction chambers (13) comprises two primers specific for a nucleic acid sequence to be amplified and, optionally, one or more labeled probe (s) specific for said sequence.

- a probe may be labeled so that its signal is increased when it hybridizes to its target sequence (Sunrise TM system), or so that elongation from a strand on which it is hybridized causes a decrease or increase in the signal (AmpliSensor TM system or TaqMan TM system, respectively).

- probes in the reaction chambers makes it possible to carry out quantized amplifications in real time, with a device of the invention having means (5) for excitation / measurement of the fluorescence, as described above.

- Control probes nonspecific of the sequence to be amplified, and labeled in a different way from the specific probes, can also be used to detect possible contaminations.

- these different probes and primers will preferably be chosen such that their melting temperatures (Tm) respective ones are close.

- Tm melting temperatures

- the Tm of the different primers will preferably be in the same range of about 5 ° C.

- the different probes will preferably have a Tm within the same range of 5 ° C, which may be different from the range of Tm primers.

- the probes will be chosen so that their Tm is greater than that of the primers, the difference between Tm of the different categories of oligonucleotides then being preferably of the order of 5 ° C.

- the hybridization temperature chosen to carry out the amplification then corresponds to the lowest of the melting temperatures of the primers.

- the reaction chambers (13) of the cartridges of the invention may also comprise, in addition to the primers and any probes, one or more other reagents necessary for the PCR reaction or measurement of the amplification. It may be, for example, salts, dNTPs, or a fluorescent interlayer of double-stranded DNA, SybrGreen type (trademark). As mentioned above, all these reagents are advantageously deposited at the level of the reaction chambers (13) by the deposition of a liquid solution, followed by drying.

- the cartridges are intended for screening a large number of samples according to a small number of criteria. This implies that the user of these cartridges can easily deposit his samples in each of the reaction chambers (13).

- the cartridge can for example have a removable cover which, when removed, gives direct access to the reaction chambers.

- Such cartridges may also be pre-charged and comprise, in the reaction chambers (13), one or more reagents necessary for amplification and / or detection.

- the devices of the invention mentioned above may comprise one or more cartridges corresponding to any of the cartridges described above.

- the distinct heating zones of the heating plate (2) are preferentially distributed according to disk portions ( Figure 2A ) or crown ( Figure 2B ). Each portion may be heated to a different temperature to successively bring the contents of the reaction chambers to the desired different temperatures, by means of relative displacement means (3) between the cartridge (1) and the heating stage (2).

- the thermoblocks are preferably sufficiently wide to heat also part of the channels, as represented for example in FIG. figure 11 , as part of a rectangular cartridge.

- the number of separate heating zones can be two, three, or more.

- platinum may have a 95 ° C zone for denaturation of double-stranded nucleic acids, and a 60 ° C region for primer hybridization and elongation.

- the platinum will have an area at 95 ° C (denaturation), a region between 40 and 70 ° C (primer hybridization), and an area at 72 ° C (elongation).

- the plate may have a number of zones greater than three, for example to temporarily block the reaction at a given moment in each cycle.

- the platen can also have a number of zones that is a multiple of two or three, so that one revolution of the cartridge corresponds to several PCR cycles.

- the relative size of the different heating zones is advantageously chosen proportionally to the desired incubation time for the reaction fluid at the temperature of said zone.

- the thermoblock 21, dedicated to the denaturation step has a surface twice as small as that of the thermoblocks for the hybridization and elongation steps (blocks 22 and 23, respectively).

- the plate (2) is fixed and the cartridge (1) is moved by means of displacement (3).

- the displacement means (3) allow the rotation of said cartridge and / or said platen.

- a conductive element can be provided between the cartridge and the heating plate.

- said cartridge is in direct contact with said heating stage.

- said plate is advantageously provided with a coating promoting displacement between said cartridge and said plate.

- a coating may for example be made of Teflon (registered trademark).

- the system heating plate may have at least two or three zones that can be raised to different temperatures.

- this plate consists of two or three independent thermal blocks ("thermoblocks") connected to separate means for programming their temperature.

- thermoblocks independent thermal blocks

- the first of these thermoblocks (21) is heated to the denaturation temperature, the second (22) to the hybridization temperature, the third (23) to the elongation temperature.

- the use of such thermoblocks constant temperature simple realization of the heating stage.

- the relative displacement means of the cartridge relative to the platen can be realized in multiple forms.

- the cartridge (1) has on the underside a central projection (181) having a notch (182), so that the projecting portion (181) fits into the heating stage (2) and connects the cartridge (1).

- the displacement means (3) at a cleat or shaft (32) set in motion by a micromotor (31).

- the protruding part (181) thus makes it possible, on the one hand, to position the cartridge with respect to a plate (2) such as that represented in FIG. Figure 2B and, secondly, to ensure its connection with the moving means (3).

- the cartridge has at least one lug (183) and the displacement means (3) include at least one axis (32) cooperating with said lug to instill in said cartridge a rotary movement.

- the relative mode of movement between the plate and the cartridge may vary according to the embodiments. It may be a movement at continuous speed or in jerks. The speed of movement may be constant or vary over time.

- the system according to the invention also comprises optical means of excitation / fluorescence measurement, provided for example above or on the side of said cartridge.

- these means will constitute a single and fixed system.

- An advantage of a preferred variant of the invention according to which the cartridge is circular and moved in a rotary displacement is to be able to successively bring each reaction chamber under said optical system, thus reducing its complexity.

- a tracking system located for example on the cartridge (1), makes it possible to determine at each instant which reaction chamber is located opposite the optical system.

- the means for supplying the fluid present in said reservoir to said reaction chambers can be made in different forms. As has been described above, two categories of modes of addressing the fluid towards the reaction chambers can be distinguished: open system addressing, which assumes an increase in pressure at the reservoir and the presence of vents (14). ) at the level of the reaction chambers, and the addressing in closed system, which begins on the contrary by the establishment of a vacuum in the cartridge (1), followed by a recovery of this pressure.

- the means (4) for supplying the fluid into the reaction chambers differ according to the embodiment chosen.

- the fluid contained in the reservoir is distributed under pressure in the reaction chambers so as to allow uniform filling of these chambers.

- the feed means (4) preferably include a piston device (41) whose penetration rate in the tank will be calculated-to promote the proper filling of the reaction chambers, alternatively, these supply means include a pump connected to increase the pressure in the tank (11).

- another preferred variant of the invention involves working in a closed system.

- the fluid contained in the reservoir is then distributed in the reaction chambers as follows: in a first step, a vacuum is created inside the cartridge, where appropriate by a piston device or a pump (42), connected this time to reduce the pressure in the cartridge (1).

- the pressure is then restored, allowing the fluid to engage the channels and fill the peripheral reaction chambers.

- reagents necessary for the amplification reaction and / or the detection of the products of the amplification, and distinct from the primers and probes are pre-distributed in the reaction chambers (13). of the cartridge (1).

- the fluid introduced into the reservoir (11) does not then contain these reagents.

- the fluid distribution step in the reaction chambers (13) is carried out either by applying a vacuum inside the cartridge, then by restoring the pressure (closed system), or by increasing the pressure at the reservoir (11). ), provided that the reaction chambers are provided with vents (open system).

- the system for detecting and quantifying target nucleic sequences represented in figure 1 comprises a circular plastic cartridge 2 mm thick having a diameter of 5 cm.

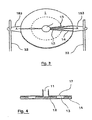

- This cartridge (1) is provided with a central reservoir (11) and will be described in more detail with reference hereinafter to Figures 3 and 4 .

- the capacity of the reservoir is, in the context of the present embodiment, 400 .mu.l. Its floor is flat but it will be noted that in other embodiments it may be curved to facilitate the passage of fluid to the chambers without the formation of air bubbles, especially at the end of addressing when the reservoir is almost empty.

- the system further comprises a heating plate (2) in direct contact with the underside of the cartridge (1) and means (3) for moving the cartridge (1) relative to the heating plate (2).

- These displacement means include a micromotor (31) connected to two axes (32) which cooperate with two lugs (183) of the cartridge (1) to inculcate in it a rotary movement on the heating plate (2), the latter while remaining fixed.

- the described system also comprises a piston (41) intended to cooperate with said reservoir (11) as well as an optical device (5) for excitation / fluorescence measurement (emitting source allowing excitation at a given, programmable wavelength). and fluorescence receiver emitted) fixed and placed above the cartridge (1) and the heating plate (2).

- the heating plate (2) consists of three metal blocks (21, 22 and 23) (hereinafter referred to as thermoblocks) in the form of disk portions. Note that in this embodiment, these thermoblocks have substantially the same size but that, in other embodiments, they may have a different size, the size being understood as the occupied angular surface in top view.

- thermoblock (21, 22 and 23) is designed to be brought to a constant and programmable temperature, corresponding to one of the phases (denaturation, hybridization or elongation) amplification cycles (PCR), generally respectively 94 ° C for denaturation, 72 ° C for elongation, and between 30-40 and 65-70 ° C for hybridization according to the Tm (hybridization temperature) of the primers used, the temperatures of the thermoblocks can be controlled by all means known to those skilled in the art.

- phases denaturation, hybridization or elongation amplification cycles (PCR)

- Tm hybridization temperature

- the cartridge (1) is provided with a central tank (11) of capacity 400 ⁇ l connected to 36 reaction chambers (13) by as many channels (12), distributed uniformly over the entire periphery of the cartridge (on the figure 3 , we did not represent all the channels and rooms but only some of them).

- These reaction chambers (13) are further provided with vents (14) abutting on the edge of the cartridge (1).

- the channels have a diameter of 0.2 mm and the volume of the reaction chambers is 2.5 microliters. In other embodiments, this diameter and this volume may of course be different.

- this cartridge (1) is also provided with two lugs (183) each pierced with an orifice for passing an axis (32) connected to the micromotor (31).

- the reaction chambers have a depth of 1 mm. Their floor has a thickness of about 0.2 mm. This thickness is sufficiently small to facilitate good heat exchange between the chambers (13) and the thermoblocks (21, 22 and 23).

- the reaction chambers (13) are closed in their upper part by a wall (17) transparent, also forming the wall of the tank (11).

- Each chamber 10 except a few for negative control purposes, contains two primers specific for a target sequence to be amplified, and optionally one or more labeled probes, allowing a subsequent specific measurement of fluorescence.

- 10 ng of each primer were distributed in each chamber except for those serving as a negative control.

- the piston (41) After partially filling the reservoir (11) with the fluid whose volume is equal to the sum of the volumes of the chambers (the volume of a chamber is defined as being the product of its "floor” surface by its depth), the piston (41) is actuated to dispense this fluid into the plurality of reaction chambers (13).

- This piston increases the pressure within the reservoir (11) and allows the passage of fluid in the channels to the chambers.

- the speed of movement of the piston in the reservoir is about 1 mm per second and said displacement is stopped at a level that depends on the volume of fluid to be addressed in the chambers.

- the small diameter of the channels (12) makes it possible to prevent the diffusion of the fluid from the reservoir (11) to the channels (12) and the chambers (13) under the effect of gravity (at this scale, the processes are usually negligible as the capillary forces become pregnant, and in this case are enough to keep the fluid in the tank). Thanks to the vents (14), the air present in the chambers (13) is evacuated, which ensures the filling thereof.

- thermoblocks (21, 22, 23) are brought to the three temperatures corresponding to the three temperatures of the PCR phases (or at slightly higher temperatures given the possible heat losses between the heating stage (2) and the cartridge 1) and the displacement means (3) are implemented so as to animate the cartridge (1) by a gyratory movement in order to pass each reaction chamber successively and as many times as desired over the three thermoblocks.

- the block (21) is brought to the temperature corresponding to the denaturation phase (94 ° C.)

- the thermoblock (22) is brought to the temperature corresponding to the hybridization phase (36 ° C.)

- the thermoblock (23) is brought to the temperature corresponding to the phase of elongation (72 ° C).

- the micromotor (31) of the displacement means (3) is adapted to inculcate a rotation of 10 degrees every 2.5 seconds to the cartridge (1) (ie a 1.5 PCR cycle). min).

- this movement may have a different speed and be continuous instead of jerky.

- the optical device (5) is provided above the corresponding block 23 raised to a temperature corresponding to the elongation temperature, and more particularly to a location corresponding to the end of the elongation phase.

- the optical device (5) can be placed at a different location, chosen in particular according to the chemistry used. For example, using TaqMan TM chemistry or nonspecific fluorescence, it makes sense to perform the measurement at the end of the elongation phase, as described above.

- the use of a Molecular Beacons TM type chemistry implies that the measurement is done rather at the time of the hybridization.

- the system presented makes it possible to rapidly and reproducibly fill a large quantity of reaction chambers and to carry out PCR and fluorescence measurements on each PCR cycle.

- FIGS. 5 to 10 represent an example of a circular cartridge exhibiting certain modifications with respect to the cartridge of example 1.

- This cartridge is intended for use in a closed system, that is to say that the reaction chambers (13) have no other opening than the arrival of the channel (12).

- the cartridge consists of two elements that fit into each other: the lower part, or base, is represented in Figures 5 and 6 , and the upper part, or cover, is represented in Figures 7 and 8 . The assembly of the two is illustrated in figures 9 and 10 .

- This cartridge is loaded as follows:

- the fluid is no longer addressed by an increase in pressure but by depression, which presents the advantage of not requiring a vent and therefore working in a closed system.

- the bottom of the tank has a conical shape allowing the fluid to be distributed at its periphery, that is to say near the entrance of the channels.

- an anti-reflux system consisting of a vertical channel portion (123), which, on the one hand, prevents cross contamination in the event of inadvertent return of fluid to the central part or in the case where all the fluid would not be engaged in the channel and, on the other hand, allows once the addressing done but before the PCR, to come to plug the channels by means of a plug whose serrations come to marry these vertical entries, to work in closed system (no contamination, no evaporation).

- the cartridge is made of plastic, preferably polycarbonate because this polymer has interesting physical, optical and thermal behavior characteristics.

- the size of the channels is for example 0.4 x 0.2 mm (half-moon) in section.

- the size of the consumable is for example 100 mm (diameter), the number of chambers is 80, the number of sub-tanks is between 1 and 8.

- the cartridge (1) has on the underside a central projection (181) having a notch (182), so that the projecting portion (181) fits into the heating stage (2) and connects the cartridge (1). ) with the moving means (3) at a cleat or shaft (32) moved by a micromotor (31).

- the protruding part (181) thus makes it possible, on the one hand, to position the cartridge with respect to a plate (2) such as that represented in FIG. Figure 2B and, secondly, to ensure its connection with the moving means (3).

- the reaction chambers are loaded with primers specific for target sequences and, where appropriate, with TaqMan TM or other probes specific for said targets.

- the targets will be viral or bacterial genes, junctions between a transgene and the genome of a plant to detect and / or identify certain GMOs, etc.

Landscapes

- Chemical & Material Sciences (AREA)

- Health & Medical Sciences (AREA)

- General Health & Medical Sciences (AREA)

- Clinical Laboratory Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Analytical Chemistry (AREA)

- Hematology (AREA)

- Dispersion Chemistry (AREA)

- Molecular Biology (AREA)

- Biochemistry (AREA)

- Life Sciences & Earth Sciences (AREA)

- Measuring Or Testing Involving Enzymes Or Micro-Organisms (AREA)

- Apparatus Associated With Microorganisms And Enzymes (AREA)

- Automatic Analysis And Handling Materials Therefor (AREA)

- Feeding, Discharge, Calcimining, Fusing, And Gas-Generation Devices (AREA)

- Physical Or Chemical Processes And Apparatus (AREA)

- Investigating Or Analysing Materials By The Use Of Chemical Reactions (AREA)

- Saccharide Compounds (AREA)

- Preparation Of Compounds By Using Micro-Organisms (AREA)

- Compounds Of Unknown Constitution (AREA)

- Polymers With Sulfur, Phosphorus Or Metals In The Main Chain (AREA)

Abstract

Description

La présente invention concerne le domaine de la génétique.The present invention relates to the field of genetics.

Plus précisément, la présente invention concerne un dispositif pour l'amplification de séquences nucléiques cibles, et des modes d'utilisation de ce dispositif.More specifically, the present invention relates to a device for the amplification of target nucleic sequences, and modes of use of this device.

La présente invention a notamment pour objectif de permettre la détection et, le cas échéant, la quantification en temps réel, de séquences d'acide nucléique cibles dans un ou plusieurs échantillons.The object of the present invention is in particular to enable the detection and, where appropriate, the quantification in real time of target nucleic acid sequences in one or more samples.

La détection de séquences nucléiques cibles est une technique de plus en plus utilisée dans de nombreux domaines, et l'éventail des applications de cette technique est appelé à s'étendre au fur et à mesure qu'elle deviendra plus fiable, plus économique et plus rapide. Ainsi, en santé humaine, la détection de certaines séquences d'acide nucléique permet dans certains cas un diagnostic fiable et rapide d'infections virales ou bactériennes. De même, la détection de certaines particularités génétiques peut permettre d'identifier des susceptibilités à certaines maladies, ou d'établir un diagnostic précoce de maladies génétiques ou néoplasiques. La détection de séquences nucléiques cibles est aussi utilisée dans l'industrie agroalimentaire, notamment pour assurer la traçabilité des produits, pour détecter la présence d'organismes génétiquement modifiés et les identifier, ou pour effectuer un contrôle sanitaire des aliments.Detection of target nucleic acid sequences is an increasingly popular technique in many fields, and the range of applications of this technique is expected to expand as it becomes more reliable, cost-effective and more reliable. fast. Thus, in human health, the detection of certain nucleic acid sequences in certain cases allows a reliable and rapid diagnosis of viral or bacterial infections. Similarly, the detection of certain genetic peculiarities can make it possible to identify susceptibilities to certain diseases, or to establish an early diagnosis of genetic or neoplastic diseases. The detection of target nucleic sequences is also used in the food industry, in particular to ensure the traceability of products, to detect the presence of genetically modified organisms and to identify them, or to carry out a health control of food.

Les procédés de détection basés sur les acides nucléiques font quasi systématiquement intervenir une réaction d'hybridation moléculaire entre une séquence nucléique cible et une ou plusieurs séquences nucléiques complémentaires de ladite séquence cible. Ces procédés présentent de nombreuses variantes comme les techniques connues de l'homme de métier sous les expressions "techniques de transfert" (blot, dot bloc, Southern blot, Restriction Fragment Length Polymorphism, etc.), ou encore comme les systèmes miniaturisés sur lesquels sont préfixées les séquences complémentaires des séquences cibles ("biopuces"). Dans le cadre de ces techniques, les séquences nucléiques complémentaires sont généralement appelées sondes. Une autre variante, qui peut constituer en soi la base d'un procédé de diagnostic ou n'être qu'une étape supplémentaire dans une des techniques mentionnées ci-dessus (afin notamment d'augmenter la concentration de la séquence cible et donc la sensibilité du diagnostic), consiste à amplifier la séquence d'acide nucléique ciblée. Plusieurs techniques permettant l'amplification spécifique d'une séquence d'acide nucléique ont été décrites, dont la plus utilisée est l'Amplification en Chaîne par Polymérase (ACP), ou Polymerase Chain Rection (PCR). Dans le cadre de cette dernière technique, des séquences nucléiques complémentaires des séquences cibles, appelées amorces, sont utilisées pour amplifier lesdites séquences cibles.Nucleic acid-based detection methods almost invariably involve a molecular hybridization reaction between a target nucleic acid sequence and one or more sequences nucleic acid complementary to said target sequence. These methods have numerous variants such as the techniques known to those skilled in the art under the terms "transfer techniques" ( blot, dot block, Southern blot, Restriction Fragment Length Polymorphism, etc.), or else the miniaturized systems on which the complementary sequences of the target sequences ("biochips") are prefixed. In the context of these techniques, the complementary nucleic sequences are generally called probes. Another variant, which may constitute in itself the basis of a diagnostic method or be only an additional step in one of the techniques mentioned above (in particular to increase the concentration of the target sequence and therefore the sensitivity of the diagnosis), consists in amplifying the targeted nucleic acid sequence. Several techniques for the specific amplification of a nucleic acid sequence have been described, the most commonly used of which is Polymerase Chain Reaction (PCR) or Polymerase Chain Rection (PCR). In the context of this latter technique, complementary nucleic sequences of the target sequences, called primers, are used to amplify said target sequences.

Les réactions de PCR impliquent une répétition de cycles, dont le nombre varie généralement de 20 à 50, et qui sont composés chacun de trois phases successives, à savoir : dénaturation, hybridation, élongation. Respectivement, la première phase correspond à la transformation des acides nucléiques bicaténaires en acides nucléiques monocaténaires, la seconde phase à l'hybridation moléculaire entre la séquence cible et les amorces complémentaires de ladite séquence, et la troisième phase à l'élongation des amorces complémentaires hybridées à la séquence cible, par une ADN polymérase. Ces phases sont menées à des températures spécifiques : généralement 95°C pour la dénaturation, 72°C pour l'élongation, et entre 30°C et 65°C pour l'hybridation, selon la température d'hybridation (Tm) des amorces utilisées. Il est aussi possible d'effectuer les étapes d'hybridation et d'élongation à la même température (généralement 60 °C).The PCR reactions involve a repetition of cycles, the number of which generally ranges from 20 to 50, and which are each composed of three successive phases, namely: denaturation, hybridization, elongation. Respectively, the first phase corresponds to the transformation of the double-stranded nucleic acids into single-stranded nucleic acids, the second phase to the molecular hybridization between the target sequence and the complementary primers of said sequence, and the third phase to the elongation of the hybridized complementary primers. to the target sequence, by a DNA polymerase. These phases are carried out at specific temperatures: generally 95 ° C for denaturation, 72 ° C for elongation, and between 30 ° C and 65 ° C for hybridization, depending on the hybridization temperature (Tm) of the primers used. It is also possible to perform the hybridization and elongation steps at the same temperature (generally 60 ° C).

Une réaction de PCR consiste donc en un enchaînement de cycles thermiques répétitifs au cours duquel le nombre de molécules d'ADN cible servant de matrice est théoriquement doublé à chaque cycle. En réalité, le rendement de la PCR est inférieur à 100%, si bien que la quantité de produit Xn obtenu après n cycles est :

Xn-1 est la quantité de produit obtenu au cycle précédent, et rn le rendement de la PCR au cycle n (0 < rn ≤ 1).A PCR reaction therefore consists of a series of repetitive thermal cycles in which the number of target DNA molecules serving as template is theoretically doubled at each cycle. In fact, the yield of the PCR is less than 100%, so that the amount of product X n obtained after n cycles is:

X n-1 is the amount of product obtained in the previous cycle, and n the yield of the PCR at cycle n (0 <r n ≤ 1).

En considérant le rendement constant, c'est-à-dire identique pour chaque cycle, la quantité de produit Xn obtenu après n cycles à partir d'une quantité initiale X0 est alors :

En réalité, le rendement r diminue au cours de la réaction de PCR, du fait de plusieurs facteurs, tel qu'une quantité imitant d'au moins un des réactifs nécessaires à l'amplification, l'inactivation de la polymérase par ses passages répétés à 95°C, ou son inhibition par les pyrophosphates produits par la réaction.In reality, the yield r decreases during the PCR reaction, because of several factors, such as an amount mimicking at least one of the reagents necessary for the amplification, the inactivation of the polymerase by repeated passages. at 95 ° C, or its inhibition by the pyrophosphates produced by the reaction.

Du fait de cette diminution du rendement, la cinétique d'une réaction de PCR présente d'abord une phase exponentielle (tant que r est constant), qui évolue ensuite vers une phase de plateau lorsque r diminue.Because of this decrease in yield, the kinetics of a PCR reaction first exhibit an exponential phase (as long as r is constant), which then progresses to a plateau phase as r decreases.

Au cours de la phase exponentielle, l'équation (A) ci-dessus est valable, et peut aussi s'écrire :

Ainsi, dans la phase exponentielle de la PCR, la courbe présentant la quantité de produit, en échelle logarithmique, en fonction du nombre de cycles, et une droite de pente (1 + r) et qui coupe l'axe des ordonnées à une valeur égale au logarithme de la concentration initiale.Thus, in the exponential phase of the PCR, the curve presenting the quantity of product, in logarithmic scale, as a function of the number of cycles, and a slope line (1 + r) and which intersects the y-axis with a value equal to the logarithm of the initial concentration.

La mesure en temps réel, de la quantité de produit obtenu, peut donc permettre de connaître la concentration initiale de matrice, ce qui est particulièrement utile dans un grand nombre d'applications, par exemple pour mesurer la charge virale d'un malade, ou encore pour connaître la variabilité d'un transcriptome.The real-time measurement of the quantity of product obtained can therefore make it possible to know the initial matrix concentration, which is particularly useful in a large number of applications, for example for measuring the viral load of a patient, or again to know the variability of a transcriptome.

Généralement, les PCR impliquent des volumes réactionnels allant de 2 à 50 µl et sont effectuées dans des tubes, des microtubes, des capillaires ou des systèmes connus de l'homme de l'art sous le terme "microplaques" (en fait des ensembles de micro tubes solidarisés). Chaque lot de tubes ou de contenants équivalents doit donc être successivement porté aux trois températures correspondant aux différentes phases de la PCR, et ce autant de fois que de cycles désirés.Generally, the PCRs involve reaction volumes ranging from 2 to 50 μl and are carried out in tubes, microtubes, capillaries or systems known to those skilled in the art under the term "microplates" (in fact sets of micro tubes secured). Each batch of tubes or equivalent containers must be successively brought to the three temperatures corresponding to the different phases of the PCR, and as many times as desired cycles.

L'utilisation de tubes ou de systèmes s'y approchant oblige l'utilisateur à effectuer de multiples manipulations pour préparer autant de tubes et de solutions (connues de l'homme de l'art sous l'expression "mix PCR") que de séquences cibles qu'il souhaite amplifier même à partir d'un échantillon unique d'acides nucléiques, à l'exception des procédés d'amplification "multiplex", qui permettent l'amplification de plusieurs séquences cibles simultanément dans le même contenant, soit par l'utilisation d'amorces dites peu spécifiques qui peuvent s'hybrider avec plusieurs séquences cibles comme par exemple la technique RAPD - Random Amplified Polymorphism DNA, soit par l'utilisation d'amorces spécifiques mais en nombre plus important, chaque couple d'amorces utilisé permettant l'amplification d'une séquence cible. Ces amplifications multiplex correspondent à des cas particuliers et ne sont pas la norme. De surcroît, elles ne garantissent pas l'absence d'interactions d'une réaction d'amplification sur une autre, et pour des raisons notamment de possibles hybridations entre les amorces, ne peuvent qu'être très limitées dans le nombre de séquences cibles amplifiées par contenant.The use of tubes or systems approaching it requires the user to perform multiple manipulations to prepare as many tubes and solutions (known to those skilled in the art as "PCR mix") that target sequences that it wishes to amplify even from a single sample of nucleic acids, with the exception of "multiplex" amplification methods, which allow the amplification of several target sequences simultaneously in the same container, either by the use of so-called unspecific primers which can hybridize with several target sequences, for example the RAPD- Random Amplified Polymorphism DNA technique , or by the use of specific primers but in larger numbers, each pair of primers used to amplify a target sequence. These multiplex amplifications correspond to particular cases and are not the norm. Of moreover, they do not guarantee the absence of interactions of one amplification reaction on another, and for reasons including possible hybridizations between the primers, can only be very limited in the number of target sequences amplified by container.

Ces différentes manipulations impliquent de nombreux inconvénients.These different manipulations involve many disadvantages.

En premier lieu, elles sont consommatrices de temps. En second lieu, elles ne sont pas sans risques du point de vue des éventuelles contaminations d'un tube à l'autre ou depuis l'environnement extérieur (poussière, bactérie, aérosol ou tout autre contaminant susceptible de contenir des molécules d'acides nucléiques ou des molécules susceptibles d'influer sur l'efficacité de la réaction d'amplification). De plus, elles n'assurent pas une homogénéité de volume et de concentration en réactifs d'un tube à l'autre. Enfin, elles imposent l'utilisation de volumes manipulables manuellement, généralement supérieurs à 1µl, ce qui a une incidence sur les coûts liés à la réalisation des PCR, les réactifs utilisés étant chers.In the first place, they are time consuming. Second, they are not without risk from the point of view of possible contamination from one tube to another or from the external environment (dust, bacteria, aerosol or any other contaminant likely to contain nucleic acid molecules or molecules likely to influence the efficiency of the amplification reaction). In addition, they do not ensure homogeneity of volume and concentration of reagents from one tube to another. Finally, they require the use of manually manipulable volumes, generally greater than 1 .mu., which has an impact on the costs associated with carrying out the PCRs, the reagents used being expensive.

L'utilisation de dispositifs conçus pour automatiser au moins partiellement de telles manipulations permet de pallier certains de ces inconvénients. Toutefois, de tels automates sont relativement chers et leur utilisation ne se trouve donc généralement économiquement justifiée que dans le cas des PCR en grandes séries, par exemple pour le séquençage des génomes.The use of devices designed to automate at least partially such manipulations overcomes some of these disadvantages. However, such automata are relatively expensive and their use is therefore generally economically justified only in the case of large-scale PCRs, for example for the sequencing of genomes.

Il existe aussi certains automates permettant de réaliser des réactions de PCR cinétiques. Comme il a été vu plus haut, la réalisation d'une PCR cinétique nécessite de quantifier en temps réel, et de façon spécifique, la séquence cible amplifiée. L'utilisation d'un intercalant fluorescent dans le mélange réactionnel permet de mesurer l'augmentation de la quantité totale d'ADN double brin dans ledit mélange. Toutefois, cette méthode ne permet pas de discriminer l'amplification de la séquence cible par rapport au bruit de fond ou à une éventuelle amplification non spécifique. Plusieurs systèmes de sondes ont été décrits récemment pour permettre de mesurer spécifiquement l'amplification d'une séquence cible déterminée. Ils sont basés sur des oligonucléotides complémentaires de ladite séquence, et liés à des couples de groupements de fluorophores ou fluorophores/quenchers, de telle sorte que l'hybridation de la sonde à sa cible et les cycles d'amplification successifs entraînent, suivant les cas, une augmentation ou une diminution de la fluorescence totale du mélange, proportionnellement à l'amplification de la séquence cible.There are also some automata for performing kinetic PCR reactions. As has been seen above, carrying out a kinetic PCR requires quantifying in real time, and specifically, the amplified target sequence. The use of a fluorescent intercalant in the reaction mixture makes it possible to measure the increase in the total amount of double-stranded DNA in said mixture. However, this method does not discriminate amplification of the target sequence with respect to background noise or a possible non-specific amplification. Several probe systems have recently been described to specifically measure the amplification of a specific target sequence. They are based on oligonucleotides complementary to said sequence, and linked to couples of fluorophore or fluorophore / quencher moieties, such that hybridization of the probe to its target and subsequent amplification cycles result, depending on the case an increase or decrease in the total fluorescence of the mixture, in proportion to the amplification of the target sequence.

A titre d'exemples de sondes utilisables pour réaliser des PCR cinétiques, on peut citer le système TaqMan™ (ABI®), le système AmpliSensor™ (InGen), et le système Sunrise™ (Oncor®, Appligène®).Examples of useful probes for performing kinetic PCR include the TaqMan ™ system (ABI ®), the AmpliSensor ™ system (InGen) and the Sunrise ™ system (Oncor ®, ® Appligene).

Le système le plus utilisé actuellement est le système Taq Man™.The most used system today is the Taq Man ™ system .

Ce procédé associe les activités ADN polymérase et 5'→3' nucléase de la Taq polymérase au cours de la PCR. Son principe en est le suivant : en sus des deux amorces de séquence complémentaire de celle de la cible à quantifier, une sonde, appelée sonde reporter, est ajoutée dans le milieu réactionnel. Elle a la capacité de s'hybrider à la cible dans le corps de la séquence amplifiée, mais ne peut être amplifiée elle-même. En effet, un groupe phosphoryle ajouté à l'extrémité 3' de la sonde empêche son extension par la Taq polymérase. Un dérivé de la fluorescéine et un dérivé de la rhodamine sont incorporés dans la sonde, respectivement aux extrémités 5' et 3'. La sonde est de petite taille, aussi le dérivé de la rhodamine, situé à proximité de la fluorescéine, absorbe-t-il l'énergie émise par la fluorescéine soumise à une source d'excitation (phénomène de quenching).This method combines the DNA polymerase and 5 '→ 3' nuclease activities of Taq polymerase during PCR. Its principle is as follows: in addition to the two primers of sequence complementary to that of the target to be quantified, a probe, called probe reporter, is added in the reaction medium. It has the ability to hybridize to the target in the body of the amplified sequence, but can not be amplified itself. Indeed, a phosphoryl group added to the 3 'end of the probe prevents its extension by Taq polymerase. A fluorescein derivative and a rhodamine derivative are incorporated into the probe at the 5 'and 3' ends, respectively. The probe is small, so the rhodamine derivative, located near the fluorescein, absorbs the energy emitted by the fluorescein subjected to a source of excitation ( quenching phenomenon).

Une fois les amorces hybridées à la cible, au cours de la réaction d'extension, la Taq ADN polymérase attaque la sonde par son activité 5' nucléase, libérant le groupement quencher et rétablissant ainsi l'émission de fluorescence. L'intensité de la fluorescence émise est alors proportionnelle à la quantité de produits de PCR formés, ce qui permet d'obtenir un résultat quantitatif. La fluorescence émise est proportionnelle au nombre de molécules cibles de départ. La cinétique de développement de la fluorescence peut être suivie en temps réel au cours de la réaction d'amplification.Once the primers hybridized to the target, during the extension reaction, the Taq DNA polymerase attacks the probe by its 5 'activity. nuclease, releasing the quencher group and thereby restoring the fluorescence emission. The intensity of the fluorescence emitted is then proportional to the quantity of PCR products formed, which makes it possible to obtain a quantitative result. The fluorescence emitted is proportional to the number of starting target molecules. The kinetics of fluorescence development can be monitored in real time during the amplification reaction.

Cette technique présente l'avantage d'être facilement automatisable. Un appareil permettant de réaliser cette technique, l'ABI Prism 7700™, est commercialisé par la société Perkin-Elmer. Cet appareil combine un thermocycleur et un fluorimètre. Il est capable de détecter l'augmentation de fluorescence générée au cours d'un test de quantification selon le procédé TaqMan™, ceci grâce à des fibres optiques situées au-dessous de chaque tube et reliées à une caméra CCD qui détecte, en temps réel, le signal émis par les groupes fluorescents libérés au cours de la PCR. Les données quantitatives sont déduites à partir de la détermination du cycle auquel le signal du produit d'amplification atteint un certain seuil déterminé par l'utilisateur. Plusieurs études ont en effet montré que ce nombre de cycles était proportionnel à la quantité de matériel initial (Gibson, Heid et al. 1996; Heid, Stevens et al. 1996; Williams, Giles et al. 1998).This technique has the advantage of being easily automatable. An apparatus for carrying out this technique, the ABI Prism 7700 ™ , is marketed by Perkin-Elmer. This device combines a thermocycler and a fluorimeter. It is able to detect the increase in fluorescence generated during a quantification test according to the TaqMan ™ process, thanks to optical fibers located below each tube and connected to a CCD camera that detects, in real time , the signal emitted by the fluorescent groups released during the PCR. The quantitative data are derived from the determination of the cycle at which the signal of the amplification product reaches a certain threshold determined by the user. Several studies have shown that this number of cycles is proportional to the amount of initial material (Gibson, Heid et al., 1996, Heid, Stevens et al., 1996, Williams, Giles et al., 1998).

Le nombre d'applications potentielles d'un tel appareil est considérable, tant en santé humaine qu'en agroalimentaire et en contrôle qualité. Malheureusement, l'ABI Prism 7700™ et les quelques autres appareils concurrents commercialisés actuellement sont extrêmement chers, De plus, ils ne peuvent être utilisés que par un manipulateur qualifié. En pratique, de tels appareils ne sont donc utilisés que dans certaines structures très spécialisées.The number of potential applications of such a device is considerable, both in human health, agri-food and quality control. Unfortunately, the ABI Prism 7700 ™ and the few other competing devices currently on the market are extremely expensive, and they can only be used by a skilled manipulator. In practice, such devices are therefore used only in some very specialized structures.

Il existe donc aujourd'hui un réel besoin pour un système d'amplification d'acides nucléiques, le cas échéant mesurée en temps réel, et qui ne présente pas les inconvénients cités ci-dessus de l'état de la technique.There is therefore today a real need for a nucleic acid amplification system, if necessary measured in real time, and which does not have the drawbacks mentioned above of the state of the art.

L'objectif de la présente invention est de proposer un tel système qui permette de diminuer considérablement le nombre de manipulations nécessaires à la mise en oeuvre d'une méthode d'amplification sur une pluralité de séquences cibles et, en conséquence, de diminuer le temps nécessaire à cette opération.The objective of the present invention is to propose such a system which makes it possible to considerably reduce the number of manipulations required to implement an amplification method on a plurality of target sequences and, consequently, to reduce the time required. necessary for this operation.

Un autre objectif de la présente invention est de proposer un tel système qui minimise les risques de contamination d'un contenant à l'autre.Another object of the present invention is to provide such a system which minimizes the risk of contamination from one container to another.

Un autre objectif de la présente invention est de proposer un tel système qui réduise les volumes de réactifs mis en jeu et donc les coûts.Another objective of the present invention is to propose such a system which reduces the volumes of reagents involved and therefore the costs.

Un autre objectif de la présente invention est de proposer un tel système qui optimise une répartition homogène en volume et en concentration des réactifs nécessaires à la PCR dans les contenants.Another objective of the present invention is to propose such a system which optimizes a homogeneous distribution in volume and in concentration of the reagents necessary for the PCR in the containers.