EP2228811A2 - Switch insert of an electrical installation device - Google Patents

Switch insert of an electrical installation device Download PDFInfo

- Publication number

- EP2228811A2 EP2228811A2 EP10001702A EP10001702A EP2228811A2 EP 2228811 A2 EP2228811 A2 EP 2228811A2 EP 10001702 A EP10001702 A EP 10001702A EP 10001702 A EP10001702 A EP 10001702A EP 2228811 A2 EP2228811 A2 EP 2228811A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- rocker

- switch

- actuator

- switching

- transverse actuator

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H13/00—Switches having rectilinearly-movable operating part or parts adapted for pushing or pulling in one direction only, e.g. push-button switch

- H01H13/50—Switches having rectilinearly-movable operating part or parts adapted for pushing or pulling in one direction only, e.g. push-button switch having a single operating member

- H01H13/56—Switches having rectilinearly-movable operating part or parts adapted for pushing or pulling in one direction only, e.g. push-button switch having a single operating member the contact returning to its original state upon the next application of operating force

- H01H13/60—Switches having rectilinearly-movable operating part or parts adapted for pushing or pulling in one direction only, e.g. push-button switch having a single operating member the contact returning to its original state upon the next application of operating force with contact-driving member moved alternately in opposite directions

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H11/00—Apparatus or processes specially adapted for the manufacture of electric switches

- H01H11/0006—Apparatus or processes specially adapted for the manufacture of electric switches for converting electric switches

- H01H11/0018—Apparatus or processes specially adapted for the manufacture of electric switches for converting electric switches for allowing different operating parts

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H23/00—Tumbler or rocker switches, i.e. switches characterised by being operated by rocking an operating member in the form of a rocker button

- H01H23/02—Details

- H01H23/12—Movable parts; Contacts mounted thereon

- H01H23/16—Driving mechanisms

Definitions

- the invention relates to a switch insert of an electrical installation device having a housing lower part, which has at least one switching chamber, wherein at least one pivotally mounted on the housing lower part rocker acting on an associated contact rocker of the switching chamber.

- an electrical switching device in particular parallel stroke button or switch, with a manual control element and acted upon by this, pivotally mounted rocker switch for actuating switch contacts and with a clutch, which is arranged between the manual control element and the rocker switch to their application and of a Shift gate and one with the shift gate engaged lever assembly is formed.

- the shift gate has two against each other at an angle hired sliding surfaces on which alternately a lever of the lever assembly slides along and thereby causes a change in length of the rocker switch.

- the lever assembly is formed by two levers arranged in a U-shape, which are integrally connected to one another by a web and held by at least one Anformung, which is attached to the manual operating element or on the rocker switch.

- the invention has for its object to provide a switch insert of an electrical installation device, the housing base with the switching chamber is universally complete for both a acted upon by a rocker switch rocker switch / rocker switch as well as for a can be acted upon via a manual operation button Druckfoleschalter / pressure follower.

- a connectable to the lower housing part housing upper part is provided, in which a in an actuating direction to the lower housing part towards slidable longitudinal actuator is guided and in that the rocker switch is guided at a right angle to the direction of actuation transverse actuator, wherein the transverse actuator has at least one inclined surface on which acts on movement in the actuation direction at least one actuating arm of the longitudinal actuator, thereby initially a lateral displacement of the transverse actuator and then a pivoting of the rocker switch and thus a pivoting of the contact rocker can be triggered.

- the achievable with the present invention consist in particular in that reduce the manufacturing costs for the switch insert, since the housing base including the connections for the electrical wiring, the contact rocker, the switch contacts and the pivot engagement for the pivot of the rocker both can be used for the rocker switch / rocker switch as well as for the print sequence switch / print follower.

- a rocker switch / rocker switch a rocker is inserted without inserted cross-actuator, while a cross-actuator is inserted into the rocker switch to implement a Druckfolschalter / pressure follower.

- single-switch / single-push buttons for a single circuit as well as double-switch / double-push buttons for two separate circuits can be realized.

- the lower housing part 3 has on its underside or on its side surfaces two terminals 4, 5 (screw terminals or plug-in connections) for electrical lines. At its top, at least two pivot-engagements 8 are provided, which cooperate with pivot 13 of the rocker switch 10, whereby a pivotal movement of the rocker switch 10 within predetermined limits relative to the housing base 3 is made possible.

- the rocker switch 10 has on its underside a switch plunger 14 which dips into the housing lower part 2 and there acts on a contact rocker 6, to effect such switching operations (ON-switching / OFF-switching, Tast-voltage pulse), as described in the FIGS. 6 to 9 is explained in more detail.

- a switch plunger 14 which dips into the housing lower part 2 and there acts on a contact rocker 6, to effect such switching operations (ON-switching / OFF-switching, Tast-voltage pulse), as described in the FIGS. 6 to 9 is explained in more detail.

- At the top of the rocker switch 10 is at least one receiving space 16 for the transverse actuator 20th

- the transverse actuator 20 has a first inclined surface 21, a second inclined surface 22, a first recess 23 and a second recess 24, wherein for further explanation of the operation of these embodiments on the FIGS. 6 to 9 is referenced. Of importance is also held within the transverse actuator 20 spring 26 which allows a resilient, translational movement of the transverse actuator 20 within the receiving space 16 of the rocker 10 and at rest, a return of the transverse actuator 20 in a central position (central position ) causes.

- the upper housing part 28 can be latched to the lower housing part 3 via a plurality of latching means 29 and, in its upper region, has a guide 30 for guiding the longitudinal actuating member 33 which dips into the housing upper part 28.

- 33 springs 38 are inserted between spring receptacles 31 of the housing upper part 28 and the underside of the longitudinal actuator, which effect a resilient return of a pressed toward the housing lower part 2 longitudinal actuator 33 back into a rest position.

- locking means 39 provided on the lower side of the longitudinal actuating member 33 prevent the longitudinal actuating member 33 from sliding out / falling out of the guide 30 of the housing upper part 28.

- Of importance are two provided on the underside of the longitudinal actuating member 33, with the transverse Actuator 20 cooperating actuating arms 36, 37 (see also the FIGS. 6 to 9 ).

- FIG. 2 an electrical installation device 46 is shown in the form of a single-switch / single-button, consisting of the switch insert 1, which by a central disk 41, a centrally disposed within the central disk 41 and cooperating with the longitudinal actuator 33 hand operation button 42nd for single switch / single pushbutton and a cover frame 45 is completed.

- a switch insert for a single switch / single pushbutton is shown in which the lower housing part 3 is connected to the upper housing part 28. It is the springs and movable mounted in the switch insert 1 longitudinal actuator 33 to recognize.

- FIGS. 4 and 5 are a view of one and a perspective view of a rocker switch for a single switch / single button shown.

- the rocker switch 10 has two receiving spaces 16, but in only one receiving space, a transverse actuator 20 springs and is movably guided / held.

- a transverse actuator 20 springs and is movably guided / held.

- a plurality of guide / retaining ribs 17 are provided.

- the formed in the form of a coil spring spring 26 on the transverse actuator 20 the latter is provided with two opposing rod-shaped spring holders 25.

- the transverse actuator 20 is deflected from its rest position - see the two possible lateral directions of movement indicative double arrow - the spring 26 is pressed against one of these spring-stop surfaces 18 and the spring 26 is compressed. Consequently, the spring 26 has the tendency / task, the transverse actuator 20 always returned to its rest position, as soon as possible.

- transverse actuator 20 Essential components of the transverse actuator 20 are the two inclined surfaces 21, 22 and the two recesses 23, 24th

- FIGS. 4, 5 the two required to pivot the rocker switch 10, engaging in trunnion engagement 8 pivot 13.

- Fig. 5 Furthermore, the switch plunger 14 can be seen.

- FIGS. 6, 7, 8, 9 Side sections are shown by a switch insert to explain the operation of the switch insert 1 on the basis of a switching operation.

- Fig. 6 shows as a starting position a through-connected (closed) switch, ie there is a closed circuit from the terminal 4 with its located in the switching chamber switching contact 4, which contacts the switching contact of the contact pad 6, further on the rocker bearing of the contact rocker 6 (rocker mount), which leads to connection 5.

- the rocker switch 10 is inclined to the left, consequently, the switch plunger 14 is right of the rocker bearing. It is indicated by means of a spring 15, that the switching plunger 14 is resiliently guided / locked within the switching rocker 10.

- the transverse actuator 20 is in its rest position in a central position in relation to the switching rocker 10, which is effected by the spring 26. It can be seen the two engaging in the spring 26 spring mounts 25 of the transverse actuator 20.

- the switch should now be opened during the subsequent switching operation (OFF switching).

- an electrical installation device 47 is shown in the form of a double-switch / double-button, consisting of the switch insert 1, which by a central disk 41, two arranged within the central disk 41 and with the longitudinal actuators 34, 35 cooperating manual operation knobs 43, 44 for double switch / double push button and a cover 45 is completed.

- a switch insert for a double-switch / double-push button is shown, in which the housing lower part 3 is connected to the housing upper part 28 is. There are two spring-mounted and movable mounted in the switch insert 1 longitudinal actuators 34, 35 can be seen.

- FIGS. 13 and 14 are a view of the two and a perspective view of both paddles for a double-switch / double-button shown.

- Each of the two shift paddles 11, 12 has a receiving space 16, in each of which a transverse actuator 20 springs and is movably guided / held.

- a transverse actuator 20 springs For the leadership / support of the transverse actuators 20 each have a plurality of guide / retaining ribs 17 are provided.

- For the fixation of the formed in the form of a coil spring springs 26 on each transverse actuator 20 latter are each provided with two opposing rod-shaped spring holders 25.

- each switching rocker 11, 12 has two pivot pins 13.

- the contact rocker 6 is able to take two stable switching positions, so as to enable a permanent ON / OFF switching.

- the contact rocker 6 springs after being acted upon by the longitudinal actuator 33 always back to its rest position, which z. B. the position "OFF-switching" corresponds.

- the "ON" position is always taken only for a short period of time during the actuation of the longitudinal actuator 33 so as to effect a strobe voltage pulse.

- the transverse actuator 20 need only have an inclined surface 21 and only one recess 24.

- the transverse actuator 20 required for the bistable switching device can also be used in the monostable switching device (push button), which advantageously results in a reduction of the required structural components.

Landscapes

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Tumbler Switches (AREA)

- Push-Button Switches (AREA)

- Switches With Compound Operations (AREA)

- Rotary Switch, Piano Key Switch, And Lever Switch (AREA)

- Switch Cases, Indication, And Locking (AREA)

- Mechanisms For Operating Contacts (AREA)

Abstract

Es wird ein Schaltereinsatz (1) eines elektrischen Installationsgerätes (46, 47) mit einem Gehäuse-Unterteil (3) vorgeschlagen, welches mindestens eine Schaltkammer aufweist, wobei mindestens eine schwenkbar am Gehäuse-Unterteil (3) gelagerte Schaltwippe (10, 11, 12) auf eine zugeordnete Kontaktwippe (6) der Schaltkammer einwirkt. Es ist ein mit dem Gehäuse-Unterteil (3) verbindbares Gehäuse-Oberteil (28) vorgesehen, in welchem ein in einer Betätigungsrichtung (A) zum Gehäuse-Unterteil (3) hin verschiebbares Längs-Betätigungsglied (33, 34, 35) geführt ist. In der Schaltwippe (10, 11, 12) ist ein rechtwinklig zur Betätigungsrichtung (A) verschiebbares Quer-Betätigungsglied (20) geführt, wobei das Quer-Betätigungsglied (20) mindestens eine Schrägfläche (21, 22) aufweist, auf welche bei Bewegung in der Betätigungsrichtung (A) mindestens ein Betätigungsarm (36, 37) des Längs-Betätigungsgliedes (33, 34, 35) einwirkt, wodurch zunächst ein seitliches Verschieben des Quer-Betätigungsgliedes (20) und anschließend ein Schwenken der Schaltwippe (10, 11, 12) und damit ein Schwenken der Kontaktwippe (6) auslösbar sind.It is a switch insert (1) of an electrical installation device (46, 47) proposed with a housing lower part (3) having at least one switching chamber, wherein at least one pivotally mounted on the housing lower part (3) rocker (10, 11, 12 ) acts on an associated contact rocker (6) of the switching chamber. It is provided with the housing lower part (3) connectable housing upper part (28) in which in a direction of actuation (A) to the housing lower part (3) towards slidable longitudinal actuator (33, 34, 35) is guided , In the switching rocker (10, 11, 12) a perpendicular to the actuation direction (A) displaceable transverse actuator (20) is guided, wherein the transverse actuator (20) has at least one inclined surface (21, 22), which upon movement in the actuating direction (A) at least one actuating arm (36, 37) of the longitudinal actuating member (33, 34, 35) acts, thereby initially a lateral displacement of the transverse actuator (20) and then pivoting the rocker (10, 11, 12 ) and thus a pivoting of the contact rocker (6) are triggered.

Description

Die Erfindung betrifft einen Schaltereinsatz eines elektrischen Installationsgerätes mit einem Gehäuse-Unterteil, welches mindestens eine Schaltkammer aufweist, wobei mindestens eine schwenkbar am Gehäuse-Unterteil gelagerte Schaltwippe auf eine zugeordnete Kontaktwippe der Schaltkammer einwirkt.The invention relates to a switch insert of an electrical installation device having a housing lower part, which has at least one switching chamber, wherein at least one pivotally mounted on the housing lower part rocker acting on an associated contact rocker of the switching chamber.

Aus der

Der Erfindung liegt die Aufgabe zugrunde, einen Schaltereinsatz eines elektrischen Installationsgerätes anzugeben, dessen Gehäuse-Unterteil mit der Schaltkammer universell sowohl für einen über eine Hand-Betätigungswippe beaufschlagbaren Wippenschalter/ Wippentaster als auch für einen über einen Hand-Betätigungsknopf beaufschlagbaren Druckfolgeschalter / Druckfolgetaster komplettierbar ist.The invention has for its object to provide a switch insert of an electrical installation device, the housing base with the switching chamber is universally complete for both a acted upon by a rocker switch rocker switch / rocker switch as well as for a can be acted upon via a manual operation button Druckfoleschalter / pressure follower.

Diese Aufgabe wird in Verbindung mit den Merkmalen des Oberbegriffes des Anspruchs 1 dadurch gelöst, dass ein mit dem Gehäuse-Unterteil verbindbares Gehäuse-Oberteil vorgesehen ist, in welchem ein in einer Betätigungsrichtung zum Gehäuse-Unterteil hin verschiebbares Längs-Betätigungsglied geführt ist und dass in der Schaltwippe ein rechtwinklig zur Betätigungsrichtung verschiebbares Quer-Betätigungsglied geführt ist, wobei das Quer-Betätigungsglied mindestens eine Schrägfläche aufweist, auf welche bei Bewegung in der Betätigungsrichtung mindestens ein Betätigungsarm des Längs-Betätigungsgliedes einwirkt, wodurch zunächst ein seitliches Verschieben des Quer-Betätigungsgliedes und anschließend ein Schwenken der Schaltwippe und damit ein Schwenken der Kontaktwippe auslösbar sind.This object is achieved in conjunction with the features of the preamble of

Die mit der Erfindung erzielbaren Vorteile bestehen insbesondere darin, dass sich die Herstellkosten für den Schalter-Einsatz reduzieren, da das Gehäuse-Unterteil inklusive der Anschlüsse für die elektrischen Leitungen, der Kontaktwippe, der Schaltkontakte und der Drehzapfen-Eingriffe für die Drehzapfen der Schaltwippe sowohl für den Wippenschalter / Wippentaster als auch für den Druckfolgeschalter / Druckfolgetaster verwendbar ist. Zur Realisierung eines Wippenschalters / Wippentasters wird eine Schaltwippe ohne eingelegtes Quer-Betätigungsglied verwendet, während zur Realisierung eines Druckfolgeschalters /Druckfolgetasters ein Quer-Betätigungsglied in die Schaltwippe eingelegt wird. Des Weiteren sind sowohl Einfach-Schalter / Einfach-Taster für einen einzigen Schaltkreis als auch Zweifach-Schalter / Zweifach-Taster für zwei separate Schaltkreise realisierbar.The achievable with the present invention consist in particular in that reduce the manufacturing costs for the switch insert, since the housing base including the connections for the electrical wiring, the contact rocker, the switch contacts and the pivot engagement for the pivot of the rocker both can be used for the rocker switch / rocker switch as well as for the print sequence switch / print follower. To realize a rocker switch / rocker switch a rocker is inserted without inserted cross-actuator, while a cross-actuator is inserted into the rocker switch to implement a Druckfolschalter / pressure follower. Furthermore, single-switch / single-push buttons for a single circuit as well as double-switch / double-push buttons for two separate circuits can be realized.

Vorteilhafte Ausgestaltungen der Erfindung sind in den Unteransprüchen gekennzeichnet.Advantageous embodiments of the invention are characterized in the subclaims.

Die Erfindung wird nachstehend an Hand der in der Zeichnung dargestellten Ausführungsbeispiele erläutert. Es zeigen:

- Fig. 1

- eine perspektivische Ansicht eines Schaltereinsatzes für einen Einfach-Schalter / Einfach-Taster in Form einer Explosionszeichnung,

- Fig. 2

- ein elektrisches Installationsgerät in Form eines Einfach-Schalters / Einfach-Tasters,

- Fig. 3

- einen Schalter-Einsatz für einen Einfach-Schalter / Einfach-Taster,

- Fig. 4, 5

- eine Sicht auf eine und eine perspektivische Ansicht einer Schaltwippe für einen Einfach-Schalter / Einfach-Taster,

- Fig. 6, 7, 8, 9

- seitliche Schnitte durch einen Schalter-Einsatz zur Erläuterung der Funktionsweise des Schalter-Einsatzes an Hand einer Schalthandlung (eines Schaltvorganges),

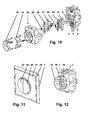

- Fig. 10

- eine perspektivische Ansicht eines Schaltereinsatzes für einen Zweifach-Schalter / Zweifach-Taster in Form einer Explosionszeichnung,

- Fig. 11

- ein elektrisches Installationsgerät in Form eines Zweifach-Schalters / Zweifach-Tasters,

- Fig. 12

- einen Schalter-Einsatz für einen Zweifach-Schalter / Zweifach-Taster,

- Fig. 13, 14

- eine Sicht auf die beiden und eine perspektivische Ansicht beider Schaltwippen für einen Zweifach-Schalter / Zweifach-Taster.

- Fig. 1

- a perspective view of a switch insert for a single switch / single button in the form of an exploded view,

- Fig. 2

- an electrical installation device in the form of a single-switch / single-button,

- Fig. 3

- a switch insert for a single switch / single pushbutton,

- Fig. 4, 5

- a view of one and a perspective view of a rocker switch for a single switch / single button,

- 6, 7, 8, 9

- lateral sections through a switch insert to explain the operation of the switch insert on the basis of a switching operation (a switching operation),

- Fig. 10

- a perspective view of a switch insert for a double switch / double button in the form of an exploded view,

- Fig. 11

- an electrical installation device in the form of a double switch / double pushbutton,

- Fig. 12

- a switch insert for a double switch / double button,

- Fig. 13, 14th

- a view of the two and a perspective view of both paddles for a double switch / double button.

In

- einem Gehäuse-

Unterteil 3 mit einer Schaltkammer (respektive mit zwei Schaltkammern bei einem Zweifach-Schalter / Zweifach-Taster, sieheFig. 10 ), - einer

Schaltwippe 10 für einen Einfach-Schalter / Einfach-Taster, - einem Quer-

Betätigungsglied 20, welches verschiebbar in derSchaltwippe 10 gelagert ist, - einem Gehäuse-

Oberteil 28, - einem Längs-

Betätigungsglied 33 für einen Einfach-Schalter / Einfach-Taster.

- a housing

lower part 3 with a switching chamber (respectively with two switching chambers in a double-switch / double-button, seeFig. 10 ) - a rocker switch 10 for a single switch / single pushbutton,

- a

transverse actuator 20 which is slidably mounted in therocker switch 10, - a

housing top 28, - a

longitudinal actuator 33 for a single switch / single pushbutton.

Das Gehäuse-Unterteil 3 weist an seiner Unterseite oder an seinen Seitenflächen zwei Anschlüsse 4, 5 (Schraubanschlüsse oder Steckanschlüsse) für elektrische Leitungen auf. An seiner Oberseite sind mindestens zwei Drehzapfen-Eingriffe 8 vorgesehen, welche mit Drehzapfen 13 der Schaltwippe 10 zusammenarbeiten, wodurch eine Schwenkbewegung der Schaltwippe 10 innerhalb vorgegebener Grenzen relativ zum Gehäuse-Unterteil 3 ermöglicht wird.The

Die Schaltwippe 10 besitzt an ihrer Unterseite einen Schaltstößel 14, welcher in das Gehäuse-Unterteil 2 eintaucht und dort auf eine Kontaktwippe 6 einwirkt, um derart Schalthandlungen (EIN-Schalten / AUS-Schalten, Tast-Spannungsimpuls) zu bewirken, wie dies unter den

Das Quer-Betätigungsglied 20 weist eine erste Schrägfläche 21, eine zweite Schrägfläche 22, eine erste Ausnehmung 23 sowie eine zweite Ausnehmung 24 auf, wobei zur näheren Erläuterung der Funktionsweise dieser Ausbildungen auf die

Das Gehäuse-Oberteil 28 ist über mehrere Rastmittel 29 mit dem Gehäuse-Unterteil 3 verrastbar und weist in seinem oberen Bereich eine Führung 30 für die Führung des in das Gehäuse-Oberteil 28 eintauchenden Längs-Betätigungsgliedes 33 auf. Dabei sind zwischen Feder-Aufnahmen 31 des Gehäuse-Oberteils 28 und der Unterseite des Längs-Betätigungsgliedes 33 Federn 38 eingelegt, welche eine federnde Rückführung eines in Richtung Gehäuse-Unterteil 2 gedrückten Längs-Betätigungsgliedes 33 zurück in eine Ruheposition bewirken. Dabei verhindern an der Unterseite des Längs-Betätigungsgliedes 33 vorgesehene Arretiermittel 39 ein Herausgleiten / Herausfallen des Längs-Betätigungsgliedes 33 aus der Führung 30 des Gehäuse-Oberteils 28. Von Wichtigkeit sind zwei an der Unterseite des Längs-Betätigungsgliedes 33 vorgesehene, mit dem Quer-Betätigungsglied 20 zusammenwirkende Betätigungsarme 36, 37 (siehe hierzu auch die

In

In

In den

Innerhalb des Aufnahmeraumes 16 der Schaltwippe sind Feder-Anschlagflächen 18 angeordnet, zwischen denen sich die Feder 26 bewegen kann. Sobald das Quer-Betätigungsglied 20 aus seiner Ruheposition ausgelenkt wird - siehe den die beiden möglichen seitlichen Bewegungsrichtungen bezeichnenden Doppelpfeil - wird die Feder 26 gegen eine dieser Feder-Anschlagflächen 18 gepresst und die Feder 26 wird komprimiert. Folglich hat die Feder 26 die Tendenz / Aufgabe, das Quer-Betätigungsglied 20 stets in seine Ruheposition zurückzuführen, sobald dies möglich ist.Within the receiving

Wesentliche Komponenten des Quer-Betätigungsgliedes 20 sind die beiden Schrägflächen 21, 22 sowie die beiden Ausnehmungen 23, 24.Essential components of the

Des Weiteren zeigen die

In den

Das im Gehäuse-Oberteil 28 federnd geführte Längs-Betätigungsglied 33 befindet sich in seiner Ruheposition mit entspannter Feder 38. Folglich sind die beiden Betätigungsarme 36, 37 entkoppelt von den Schrägflächen 21, 22 und den Ausnehmungen 23, 24 des Quer-Betätigungsgliedes 20.The spring-guided in the housing

Der Schalter soll nun bei der nachfolgenden Schalthandlung geöffnet werden (AUS-Schalten). Hierzu wird gegen die Federkraft der Feder 38 Druck auf das Längs-Betätigungsglied 33 in einer Betätigungsrichtung A zum Gehäuse-Unterteil 3 hin ausgeübt, was mittels Betätigung des Hand-Betätigungsknopfes 42 erfolgt. Zunächst stellt sich die in

Weiterhin wird gegen die Federkraft der Feder 38 Druck auf das Längs-Betätigungsglied 33 in der Betätigungsrichtung A zum Gehäuse-Unterteil 3 hin ausgeübt. Folglich wird die Feder 38 weiterhin komprimiert und der Betätigungsarm 37 greift nun in die Ausnehmung 24 ein, wie dies in

Hierdurch gleitet der Schaltstößel 14 nach links über die Wippenlagerung hinaus, wodurch die Kontaktwippe 6 eine Drehbewegung nach links (gegen den Uhrzeigersinn) ausführt, welche zum Öffnen des Schaltkontaktes, d. h. Abheben der Kontaktwippe 6 vom Schaltkontakt 7 führt. Das Quer-Betätigungsglied 20 verharrt in seiner nach links ausgelenkten Position, blockiert durch den in die Ausnehmung 24 greifenden Betätigungsarm 37. Der Stromkreis vom Anschluss 4 über die Kontaktwippe 6 zum Anschluss 5 ist nun unterbrochen.As a result, the

Nachdem keinerlei Druck mehr auf das Längs-Betätigungsglied 33 ausgeübt wird, stellt sich die in

Sobald wiederum gegen die Federkraft der Feder 38 Druck auf das Längs-Betätigungsglied 33 in einer Betätigungsrichtung A zum Gehäuse-Unterteil 3 hin ausgeübt wird, wird der Schalter bei der nächsten Schalthandlung geschlossen (EIN-Schalten).As soon as pressure is exerted against the spring force of the

In

- das Gehäuse-

Unterteil 3 weist zwei Schaltkammern mit separatenKontaktwippen 6 und die erforderlichen Anschlüsse für elektrische Leitungen auf, - das Gehäuse-

Unterteil 3 weist insgesamt vier Drehachsen-Eingriffe 8 für die Lagerung von zwei separaten Schaltwippen 11, 12 auf, jede Schaltwippe Betätigungsglied 20inklusive Feder 26 ausgerüstet,- im Gehäuse-

Oberteil 28 sind zwei separate Längs-Betätigungsglieder

- the

lower housing part 3 has two switching chambers withseparate contact paddles 6 and the necessary connections for electrical lines, - the

lower housing part 3 has a total of four axes ofrotation interventions 8 for the storage of two separate shift paddles 11, 12, - each

rocker transverse actuator 20 includingspring 26, - in the housing

upper part 28, two separatelongitudinal actuators

In

In

In den

In den vorstehenden Erläuterungen zur Funktionsweise wird von einem bistabilen Schaltgerät ausgegangen, d. h. die Kontaktwippe 6 ist in der Lage, zwei stabile Schaltstellungen einzunehmen, um derart ein permanentes EIN-Schalten / AUS-Schalten zu ermöglichen. In alternativer Weiterbildung ist darüber hinaus ein als Taster einsetzbares monostabiles Schaltgerät in gleicher Art und Weise realisierbar, d. h. bei dieser Ausführungsform federt die Kontaktwippe 6 nach erfolgter Beaufschlagung mittels des Längs-Betätigungsgliedes 33 stets wieder zurück in ihre Ruheposition, welche z. B. der Position "AUS-Schalten" entspricht. Die Position "EIN-Schalten" wird stets nur für eine kurze Zeitspanne während der Betätigung des Längs-Betätigungsgliedes 33 eingenommen, um derart einen Tast-Spannungsimpuls zu bewirken. Bei einer solchen Ausführungsform muss das Quer-Betätigungsglied 20 lediglich eine Schrägfläche 21 und lediglich eine Ausnehmung 24 besitzen. Allerdings kann das für das bistabile Schaltgerät erforderliche Quer-Betätigungsglied 20 auch beim monostabilen Schaltgerät (Taster) eingesetzt werden, was vorteilhaft eine Reduzierung der erforderlichen Baukomponenten zur Folge hat.In the above explanations on the operation of a bistable switching device is assumed, ie the

- 11

- Schalter-EinsatzSwitch Insert

- 22

- ------

- 33

- Gehäuse-Unterteil mit mindestens einer SchaltkammerHousing lower part with at least one switching chamber

- 44

- Anschluss für elektrische LeitungConnection for electric cable

- 55

- Anschluss für elektrische LeitungConnection for electric cable

- 66

- Kontaktwippecontact rocker

- 77

- Schaltkontaktswitching contact

- 88th

- Drehzapfen-EingriffeTrunnion interventions

- 99

- ------

- 1010

- Schaltwippe für Einfach-Schalter / Einfach-TasterRocker switch for single switch / single pushbutton

- 1111

- erste Schaltwippe für Zweifach-Schalter / Zweifach-Tasterfirst rocker switch for double switch / double push button

- 1212

- zweite Schaltwippe für Zweifach-Schalter Zweifach-Tastersecond rocker switch for double switch double button

- 1313

- Drehzapfenpivot

- 1414

- Schaltstößelswitching plunger

- 1515

- Federfeather

- 1616

- Aufnahmeraum für Quer-BetätigungsgliedReceiving space for transverse actuator

- 1717

- Führungs-/HalterippenGuide / retaining ribs

- 1818

- Feder-AnschlagflächeSpring-stop surface

- 1919

- ------

- 2020

- Quer-BetätigungsgliedCross-actuator

- 2121

- erste Schrägflächefirst inclined surface

- 2222

- zweite Schrägflächesecond inclined surface

- 2323

- erste Ausnehmungfirst recess

- 2424

- zweite Ausnehmungsecond recess

- 2525

- Federhalterungspring retainer

- 2626

- Federfeather

- 2727

- ------

- 2828

- Gehäuse-OberteilHousing upper part

- 2929

- Rastmittel zur Verrastung mit dem Gehäuse-UnterteilLocking means for locking with the housing lower part

- 3030

- Führung für mindestens ein Längs-BetätigungsgliedGuide for at least one longitudinal actuator

- 3131

- Feder-AufnahmeSpring receiving

- 3232

- ------

- 3333

- Längs-Betätigungsglied für Einfach-Schalter / Einfach-TasterLongitudinal actuator for single switch / single pushbutton

- 3434

- erstes Längs-Betätigungsglied für Zweifach-Schalter / Zweifach-Tasterfirst longitudinal actuator for double switch / double push button

- 3535

- zweites Längs-Betätigungsglied für Zweifach-Schalter / Zweifach-Tastersecond longitudinal actuator for double switch / double push button

- 3636

- erster Betätigungsarmfirst actuating arm

- 3737

- zweiter Betätigungsarmsecond actuating arm

- 3838

- Federfeather

- 3939

- Arretiermittellocking

- 4040

- ------

- 4141

- ZentralscheibeCover plate

- 4242

- Hand-Betätigungsknopf für Einfach-Schalter / Einfach-TasterHand control knob for single switch / single push button

- 4343

- erster Hand-Betätigungsknopf für Zweifach-Schalter / Zweifach-Tasterfirst hand control knob for double switch / double push button

- 4444

- zweiter Hand-Betätigungsknopf für Zweifach-Schalter / Zweifach-Tastersecond hand control knob for double switch / double push button

- 4545

- AbdeckrahmenCover

- 4646

- elektrisches Installationsgerät in Form eines Einfach-Schalters / Einfach-TastersElectrical installation device in the form of a single switch / single pushbutton

- 4747

- elektrisches Installationsgerät in Form eines Zweifach-Schalters / Zweifach-Tasterselectrical installation device in the form of a double-switch / double-push button

Claims (4)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL10001702T PL2228811T3 (en) | 2009-03-12 | 2010-02-19 | Switch insert of an electrical installation device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102009012937A DE102009012937B4 (en) | 2009-03-12 | 2009-03-12 | Switch insert of an electrical installation device |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP2228811A2 true EP2228811A2 (en) | 2010-09-15 |

| EP2228811A3 EP2228811A3 (en) | 2013-01-09 |

| EP2228811B1 EP2228811B1 (en) | 2017-04-26 |

Family

ID=42077250

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP10001702.9A Not-in-force EP2228811B1 (en) | 2009-03-12 | 2010-02-19 | Switch insert of an electrical installation device |

Country Status (7)

| Country | Link |

|---|---|

| EP (1) | EP2228811B1 (en) |

| CN (1) | CN101840807B (en) |

| DE (1) | DE102009012937B4 (en) |

| ES (1) | ES2632399T3 (en) |

| PL (1) | PL2228811T3 (en) |

| RU (1) | RU2513860C2 (en) |

| UA (1) | UA103752C2 (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR3032303A1 (en) * | 2015-02-03 | 2016-08-05 | Legrand France | TRAINER FOR AN ELECTRIC SWITCH AND ELECTRIC SWITCH COMPRISING SUCH A TRAINER |

| CN110442184A (en) * | 2019-08-30 | 2019-11-12 | 福建工程学院 | Can remote control rocking rod controller device |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR3078819B1 (en) * | 2018-03-08 | 2020-03-20 | Legrand France | SYNCHRONIZED OPERATION OF A BISTABLE DEVICE FROM A MULTITUDE OF MONOSTABLE CONTROLLERS |

| EP3726551B1 (en) * | 2019-04-15 | 2024-07-17 | Honeywell International Inc. | Flat wall switch assembly |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4239707C2 (en) | 1992-11-26 | 2003-07-31 | Abb Patent Gmbh | Electrical switching device |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE7401879U (en) * | 1974-01-21 | 1974-07-18 | Gebr Vedder Gmbh | counter |

| IT1028463B (en) * | 1975-01-20 | 1979-01-30 | Bassani Spa | MECHANISM FOR ELECTRIC SWITCH THAT CAN BE USED BOTH WITH SWINGING LEVER CONTROL AND WITH BUTTON CONTROL |

| DE3912798A1 (en) * | 1989-04-19 | 1990-10-25 | Jung Gmbh Albrecht | SWITCHING MECHANISM FOR A KEY SWITCH |

| DE19520239A1 (en) * | 1995-06-02 | 1996-12-05 | Abb Patent Gmbh | Electrical switching device |

| DE19640714C2 (en) * | 1996-10-02 | 2001-05-23 | Siegfried Baer | Electrical switch |

| ITMI20012002A1 (en) * | 2001-09-27 | 2003-03-27 | Vimar Spa | COMPRESSION DRIVE MECHANISM USING TILTING BUTTON SWITCHES SWITCH SWITCHES AND SIMILAR |

| DE20117514U1 (en) * | 2001-10-26 | 2002-01-17 | DREEFS GmbH Schaltgeräte und Systeme, 96364 Marktrodach | rocker switch |

-

2009

- 2009-03-12 DE DE102009012937A patent/DE102009012937B4/en not_active Expired - Fee Related

-

2010

- 2010-02-19 EP EP10001702.9A patent/EP2228811B1/en not_active Not-in-force

- 2010-02-19 PL PL10001702T patent/PL2228811T3/en unknown

- 2010-02-19 ES ES10001702.9T patent/ES2632399T3/en active Active

- 2010-03-11 UA UAA201002745A patent/UA103752C2/en unknown

- 2010-03-11 CN CN201010136869.0A patent/CN101840807B/en not_active Expired - Fee Related

- 2010-03-11 RU RU2010109077/07A patent/RU2513860C2/en not_active IP Right Cessation

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4239707C2 (en) | 1992-11-26 | 2003-07-31 | Abb Patent Gmbh | Electrical switching device |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR3032303A1 (en) * | 2015-02-03 | 2016-08-05 | Legrand France | TRAINER FOR AN ELECTRIC SWITCH AND ELECTRIC SWITCH COMPRISING SUCH A TRAINER |

| EP3054470A1 (en) * | 2015-02-03 | 2016-08-10 | Legrand France | Driver for an electric switch and electric switch comprising such a driver |

| CN110442184A (en) * | 2019-08-30 | 2019-11-12 | 福建工程学院 | Can remote control rocking rod controller device |

Also Published As

| Publication number | Publication date |

|---|---|

| HK1147594A1 (en) | 2011-08-12 |

| EP2228811B1 (en) | 2017-04-26 |

| EP2228811A3 (en) | 2013-01-09 |

| DE102009012937B4 (en) | 2012-01-19 |

| PL2228811T3 (en) | 2017-10-31 |

| RU2513860C2 (en) | 2014-04-20 |

| UA103752C2 (en) | 2013-11-25 |

| CN101840807B (en) | 2014-03-26 |

| RU2010109077A (en) | 2011-09-20 |

| DE102009012937A1 (en) | 2010-09-16 |

| ES2632399T3 (en) | 2017-09-12 |

| CN101840807A (en) | 2010-09-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE3719839C1 (en) | Push button setup | |

| DE102007051466A1 (en) | switching device | |

| EP2184754B1 (en) | Switch | |

| DE2028499B2 (en) | Electrical switching device | |

| DE112016005641T5 (en) | RELAY | |

| EP2228811B1 (en) | Switch insert of an electrical installation device | |

| DE102007014745B4 (en) | Electrical switching device for a motor vehicle | |

| DE102010029742B4 (en) | Electric switch | |

| DE3219294C2 (en) | ||

| DE3818810A1 (en) | ELECTRIC KEY SWITCH | |

| DE202016105826U1 (en) | Conductor terminal with at least one spring terminal connection | |

| DE102012011983A1 (en) | Electrical switch for operating electrically movable windows or sunroofs in vehicles, has spring-loaded actuating rams that are arranged on two parallel latching cams integrated in operating element | |

| EP1440455A2 (en) | Electric switch | |

| DE102020120623B3 (en) | VEHICLE COMPARTMENT WITH LOCKABLE MOVABLE COVER | |

| DE2551858C2 (en) | Limit switch | |

| DE1242735B (en) | Electrical snap-action switch actuated by a plunger | |

| DE4239707C2 (en) | Electrical switching device | |

| EP0450319B1 (en) | Push-button switch | |

| DE20117514U1 (en) | rocker switch | |

| DE102013003575A1 (en) | Pressure and rotary operated operating element for motor vehicle, particularly steering control element, has roller-shaped input element mounted on bearing block and rotational sensor for detecting rotational actuation of input element | |

| DE2107804C3 (en) | Electric control switch | |

| EP3871243B1 (en) | Sliding switch for a motor vehicle | |

| DE19704611B4 (en) | Tactile switch with long overtravel | |

| EP1744335B1 (en) | Switchgear for electrical home installation | |

| DE19603921C1 (en) | Electric pushbutton switch design |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA RS |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA RS |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: H01H 23/16 20060101ALI20121203BHEP Ipc: H01H 13/60 20060101AFI20121203BHEP Ipc: H01H 11/00 20060101ALI20121203BHEP |

|

| 17P | Request for examination filed |

Effective date: 20130507 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20161215 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 888514 Country of ref document: AT Kind code of ref document: T Effective date: 20170515 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502010013508 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: FP |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2632399 Country of ref document: ES Kind code of ref document: T3 Effective date: 20170912 |

|

| REG | Reference to a national code |

Ref country code: NO Ref legal event code: T2 Effective date: 20170426 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170426 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170426 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170727 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170426 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170826 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170726 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170426 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502010013508 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170426 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170426 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170426 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170426 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170426 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20180129 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170426 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170426 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170426 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20180228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180228 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180219 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180228 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20181031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180219 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180228 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180228 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20190218 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20190321 Year of fee payment: 10 Ref country code: IT Payment date: 20190225 Year of fee payment: 10 Ref country code: FI Payment date: 20190219 Year of fee payment: 10 Ref country code: GB Payment date: 20190218 Year of fee payment: 10 Ref country code: PL Payment date: 20190213 Year of fee payment: 10 Ref country code: NO Payment date: 20190220 Year of fee payment: 10 Ref country code: DE Payment date: 20190219 Year of fee payment: 10 Ref country code: CZ Payment date: 20190218 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20190219 Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: PC2A Owner name: ABB SCHWEIZ AG Effective date: 20190529 |

|

| REG | Reference to a national code |

Ref country code: NO Ref legal event code: CHAD Owner name: ABB SCHWEIZ AG, CH |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 732E Free format text: REGISTERED BETWEEN 20190718 AND 20190724 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: PD Owner name: ABB SCHWEIZ AG; CH Free format text: DETAILS ASSIGNMENT: CHANGE OF OWNER(S), ASSIGNMENT; FORMER OWNER NAME: ABB AG Effective date: 20190926 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: PC Ref document number: 888514 Country of ref document: AT Kind code of ref document: T Owner name: ABB SCHWEIZ AG, CH Effective date: 20190829 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R081 Ref document number: 502010013508 Country of ref document: DE Owner name: ABB SCHWEIZ AG, CH Free format text: FORMER OWNER: ABB AG, 68165 MANNHEIM, DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170426 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170426 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20100219 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170426 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170426 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502010013508 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: FI Ref legal event code: MAE |

|

| REG | Reference to a national code |

Ref country code: NO Ref legal event code: MMEP |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20200301 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 888514 Country of ref document: AT Kind code of ref document: T Effective date: 20200219 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20200219 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200219 Ref country code: NO Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200229 Ref country code: CZ Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200219 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200219 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200301 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200219 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200901 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20210708 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200219 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200220 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200219 |