EP2014850B1 - Connecting structure for a traffic-safe pole - Google Patents

Connecting structure for a traffic-safe pole Download PDFInfo

- Publication number

- EP2014850B1 EP2014850B1 EP08160183.3A EP08160183A EP2014850B1 EP 2014850 B1 EP2014850 B1 EP 2014850B1 EP 08160183 A EP08160183 A EP 08160183A EP 2014850 B1 EP2014850 B1 EP 2014850B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- connecting structure

- pole

- mounting

- recesses

- another

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 230000002093 peripheral effect Effects 0.000 claims description 6

- 239000000853 adhesive Substances 0.000 claims description 3

- 230000001070 adhesive effect Effects 0.000 claims description 3

- 230000000694 effects Effects 0.000 description 7

- 238000010008 shearing Methods 0.000 description 7

- 230000003014 reinforcing effect Effects 0.000 description 5

- 208000027418 Wounds and injury Diseases 0.000 description 1

- 230000001133 acceleration Effects 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- 239000004411 aluminium Substances 0.000 description 1

- 230000033228 biological regulation Effects 0.000 description 1

- 238000005266 casting Methods 0.000 description 1

- 230000007797 corrosion Effects 0.000 description 1

- 238000005260 corrosion Methods 0.000 description 1

- 230000006378 damage Effects 0.000 description 1

- 208000014674 injury Diseases 0.000 description 1

- 230000005923 long-lasting effect Effects 0.000 description 1

- 230000007774 longterm Effects 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 230000035945 sensitivity Effects 0.000 description 1

- 230000006641 stabilisation Effects 0.000 description 1

- 238000011105 stabilization Methods 0.000 description 1

- 238000003466 welding Methods 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04H—BUILDINGS OR LIKE STRUCTURES FOR PARTICULAR PURPOSES; SWIMMING OR SPLASH BATHS OR POOLS; MASTS; FENCING; TENTS OR CANOPIES, IN GENERAL

- E04H12/00—Towers; Masts or poles; Chimney stacks; Water-towers; Methods of erecting such structures

- E04H12/02—Structures made of specified materials

- E04H12/08—Structures made of specified materials of metal

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01F—ADDITIONAL WORK, SUCH AS EQUIPPING ROADS OR THE CONSTRUCTION OF PLATFORMS, HELICOPTER LANDING STAGES, SIGNS, SNOW FENCES, OR THE LIKE

- E01F9/00—Arrangement of road signs or traffic signals; Arrangements for enforcing caution

- E01F9/60—Upright bodies, e.g. marker posts or bollards; Supports for road signs

- E01F9/623—Upright bodies, e.g. marker posts or bollards; Supports for road signs characterised by form or by structural features, e.g. for enabling displacement or deflection

- E01F9/631—Upright bodies, e.g. marker posts or bollards; Supports for road signs characterised by form or by structural features, e.g. for enabling displacement or deflection specially adapted for breaking, disengaging, collapsing or permanently deforming when deflected or displaced, e.g. by vehicle impact

- E01F9/635—Upright bodies, e.g. marker posts or bollards; Supports for road signs characterised by form or by structural features, e.g. for enabling displacement or deflection specially adapted for breaking, disengaging, collapsing or permanently deforming when deflected or displaced, e.g. by vehicle impact by shearing or tearing, e.g. having weakened zones

Definitions

- the invention relates to a connecting structure for a traffic pole, such as a lamp post, composed of two pole parts, comprising connecting pieces which can each be connected to a pole part in such a manner that the connecting pieces and pole parts are in line with one another, which connecting pieces are each provided with an end face and a connecting part which can be connected to a pole part, a mounting flange having recesses opening into a periphery thereof and a mounting face, which mounting face is turned away from the associated end face, as well as clamping members which are accommodated in recesses which are aligned with respect to one another and which are supported on mounting faces which are turned away from one another in such a manner that the end faces of the connecting pieces are pushed together.

- a connecting structure of this type is known from GB-A-1,087,073 and US2005/0284999 .

- both pole parts have external, more or less square or triangular flanges, respectively. Cutouts are provided on the four and three corners, respectively, of these flanges, in which bolt connections are accommodated.

- the bolt connections clamp the flanges together at a predetermined force. This clamping force is such that the pole remains intact under normal circumstances, but can shear under the effect of collision forces.

- the upper section of the pole is thus able to yield and can then fall over.

- the aim of such a procedure is to limit the collision forces to which a vehicle colliding with the pole is subjected. The passengers in the vehicle are thus subjected to accelerations which are less high, thereby reducing the risk of injuries.

- the drawback of this known pole is that the attachment means which are provided externally may be dangerous. They form projections which may penetrate into a colliding vehicle, so that the vehicle may be decelerated considerably as a result of hook effects. As a result, passengers run the risk of still being injured. In addition, due to the fact that they are arranged externally, the attachment means are exposed to weather conditions, as a result of which the reliability thereof in the long term cannot be reliably ensured.

- a further drawback is the fact that the presence of the flanges on the exterior of the pole may form an obstacle when providing a so-called ground-level protection and/or an obligatory base-part protection and/or the protection for that part of the pole which extends into the ground, which protection, according to the regulations, has to extend approximately 25 cm above ground level.

- Another drawback is also the fact that the directional sensitivity of the known connecting structure is relatively high, depending on the direction of mounting between the connecting pieces. It is therefore an object of the invention to provide a connecting structure for a traffic-safe pole which does not result in additional risks and the correct action of which can be ensured for a relatively long time. This object is achieved by the fact that the recesses open into the inner periphery of the mounting faces, said inner periphery situated inside the connecting structure.

- Providing the recesses on the inner periphery of the mounting flanges has the advantage that the exterior of the connecting structure does not have any irregularities or sharp edges, so that the danger of a cutting action or hook action is significantly reduced.

- the parts which are critical to the correct functioning of the connecting structure can be more readily protected against outside influences.

- the base-part protection which extends across the connecting structure ensures that the respective parts are invisible from the outside.

- the advantage thereof is also that poles provided with such a connecting structure are less susceptible to vandalism.

- the recesses flare out, for example in accordance with a V shape.

- washer discs are preferably provided between each mounting face and clamping member. These washer discs may also be designed in such a manner that they flare out, viewed in the direction of the inner periphery of the mounting faces. The effect of these flaring shapes is that, viewed in the peripheral direction, it becomes less critical where a vehicle collides with the pole. This effect is reinforced by the use of a relatively large number of clamping members, for example 8, 10 or 12.

- the connecting pieces each have holders which project with respect to the mounting faces of the mounting flanges, between which holders the washer discs are accommodated.

- two adjacent holders can then determine a holder space for the associated washer disc, which holder space flares out in the direction of the inner periphery of the mounting flanges.

- the washer discs which shear off under the effect of collision forces can readily be guided.

- the holder space in which the washer disc is enclosed provides greater stability to the connecting structure during normal use, so that the pole is able to withstand normal loads, such as those caused by the wind and the like.

- the mounting faces at adjacent recesses form steps.

- adjacent washer discs of a connecting piece can be at different levels.

- a friction means such as one or more friction rings, may be provided between the mounting faces, which results in a low, controlled friction.

- two rings lying on top of one another are provided which cause a reliable and long-lasting nominal shearing force between them.

- the connecting pieces may each have a reinforcing flange at a distance from the end face.

- the connecting pieces, at their ends which face one another, may each comprise a collar which projects with respect to the sleeve and which determines a stop for a pole part which can be placed over the sleeve.

- the connecting pieces may comprise a sleeve, in which case the mounting flanges are situated on the inside of the sleeve.

- the connecting pieces may be rotationally symmetrical and are preferably made of aluminium castings.

- a connecting piece may be provided with a reinforcing flange at a distance from the end face. Said reinforcing flange is preferably at the level of impact, in such a manner that the collision forces can reliably be passed on to the end faces without the connecting pieces breaking prematurely.

- the connecting pieces may be rotationally symmetrical.

- alignment means may be provided for aligning the connecting pieces and the recesses with respect to one another.

- a friction means such as one or more friction rings, may be provided between the end faces. At least one of the friction rings may have recesses which open into the inner periphery thereof, in which recesses a bolt is accommodated in each case.

- a connecting piece may have a reinforcing flange at a distance from the end face.

- the connecting pieces may be identical.

- the pole parts may be connected to the connecting pieces by an adhesive connection.

- the area of the pole parts adjacent to the connecting structure and the connecting structure may be covered by a base-part protection.

- the invention also relates to a traffic pole having pole parts which are in line with one another and which are connected to one another by a connecting structure as described above.

- the pole parts are connected to the connecting pieces by an adhesive connection. This prevents local weakened sections being formed by, for example, welding, which may give cause corrosion and fatigue phenomena.

- One of the pole parts or the so-called base part is designed to be installed on or in a foundation, in such a manner that the connecting structure is situated at a slight distance above the ground level of the area in which the foundation is situated, which is preferably approximately 5 cm.

- the connecting structure Since the flanges and the clamping members are situated inside the connecting structure, the latter may be designed in such a manner that the peripheral contour thereof is identical to the peripheral contour of the pole parts. This results in a very uniform appearance, which is not susceptible to soiling and does not have any dangerous protruding parts.

- the lamp post 1 illustrated in Fig. 1 comprises a lower pole part 3 and an upper pole part 2, which are connected to one another by the connecting structure 4 according to the invention.

- the lower pole part 3 has its foundation in the ground 5, the upper pole part 2 carries a lighting fixture 6. Nevertheless, the connecting structure 4 can also be used with other poles, which are at risk of vehicles colliding with them.

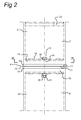

- Fig. 2 shows the connecting structure 4 on an enlarged scale.

- the connecting structure 4 comprises two connecting pieces 7, 8 which are identical in the illustrated exemplary embodiment.

- Each connecting piece 7, 8 has a connecting part 9 which can be attached to a respective pole part 2, 3.

- each connecting piece has a collar 10 and end faces 11 which are turned towards one another at the collar 10. Between the end faces 11, a friction ring or a couple of friction rings 12 may be provided which may produce a certain shearing force.

- each bolt connection 13 comprises a bolt 14, a nut 15 and washer discs 16 under the head of the bolt and under the nut 15.

- These bolt connections 13 are accommodated in the V-shaped recesses 17 which expand towards the inside and which are provided in each connecting piece 7, 8, namely in the inner mounting flange 18 thereof.

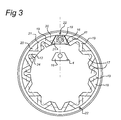

- At least one of the friction rings 12 is provided with undercut recesses 24 on the inner periphery.

- the shank of a bolt 14 can be inserted or pushed into these recesses 24, and subsequently held therein. This results in a certain stabilization of the bolt connections 16 which prevents the bolt connections from being displaced as a result of, for example, vibrations.

- the recesses 24 are designed in such a manner that the bolt connections 16 can be forced out of the recesses under the effect of a collision.

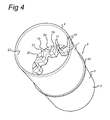

- Each mounting flange 18 has a series of mounting faces 19 for the bolt connections 13, in particular for the washer discs 16 thereof. As can be seen in Figs. 3 and 4 , the washer discs 16 are also designed to flare out. Furthermore, the flanges 18 are provided with so-called holders 20, which protrude relative to the mounting faces 19. The mounting faces 19 which are adjacent to one another are situated at different levels, viewed in the axial direction of the connecting structure 4, as can be seen in the perspective view of Fig. 4 and the side view of Fig. 2 .

- two adjacent holders 20 determine a holder space 21, the bottom of which is formed by a mounting face 19.

- a correspondingly shaped washer disc 16 fits into this holder space 21 and on the mounting face 19 in a tight-fitting manner.

- the flared shape of the holder space 19 and of the recesses 17 in this case ensures that, in relative terms, it is not critical where a vehicle hits the connecting structure 4, viewed in the peripheral direction, with regard to the shearing direction. As has been discussed above, the relatively large number of bolt connections 16 is important in this connection.

- the connecting pieces 7, 8, and in particular the recesses 17 thereof, may be aligned with respect to one another by means of alignment means 22, such as a tenon-mortise joint.

- alignment means 22 such as a tenon-mortise joint.

- a reinforcing flange 23 may be provided on the upper end of the upper connecting piece 7, by means of which the collision energy can be withstood in such a manner that correct shearing can be achieved.

- the connecting structure 4 and the adjacent sections of the pole parts 2, 3 may be covered with a so-called base-part protection 26.

- the latter can be provided without any problems as the connecting structure 4 does not have any parts which protrude outside the contours of the pole 1.

- the connecting structure 4 is hidden from view, so that the risk of vandalism is reduced to a minimum.

- the connecting structure 4, in particular the end faces 11 thereof are at a height of approximately 5 cm above the ground.

- a very low stump 3 remains in the ground after the upper pole part 2 has sheared off, which stump presents only a very low-risk danger to the colliding vehicle.

- a height of 5 cm is so small that the vehicle cannot be decelerated thereby and cannot become caught behind such a low stump.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- Chemical & Material Sciences (AREA)

- Materials Engineering (AREA)

- Wood Science & Technology (AREA)

- Refuge Islands, Traffic Blockers, Or Guard Fence (AREA)

- Road Signs Or Road Markings (AREA)

Description

- The invention relates to a connecting structure for a traffic pole, such as a lamp post, composed of two pole parts, comprising connecting pieces which can each be connected to a pole part in such a manner that the connecting pieces and pole parts are in line with one another, which connecting pieces are each provided with an end face and a connecting part which can be connected to a pole part, a mounting flange having recesses opening into a periphery thereof and a mounting face, which mounting face is turned away from the associated end face, as well as clamping members which are accommodated in recesses which are aligned with respect to one another and which are supported on mounting faces which are turned away from one another in such a manner that the end faces of the connecting pieces are pushed together.

- A connecting structure of this type is known from

GB-A-1,087,073 US2005/0284999 . With these known connecting structures, both pole parts have external, more or less square or triangular flanges, respectively. Cutouts are provided on the four and three corners, respectively, of these flanges, in which bolt connections are accommodated. The bolt connections clamp the flanges together at a predetermined force. This clamping force is such that the pole remains intact under normal circumstances, but can shear under the effect of collision forces. The upper section of the pole is thus able to yield and can then fall over. The aim of such a procedure is to limit the collision forces to which a vehicle colliding with the pole is subjected. The passengers in the vehicle are thus subjected to accelerations which are less high, thereby reducing the risk of injuries. - However, the drawback of this known pole is that the attachment means which are provided externally may be dangerous. They form projections which may penetrate into a colliding vehicle, so that the vehicle may be decelerated considerably as a result of hook effects. As a result, passengers run the risk of still being injured. In addition, due to the fact that they are arranged externally, the attachment means are exposed to weather conditions, as a result of which the reliability thereof in the long term cannot be reliably ensured. A further drawback is the fact that the presence of the flanges on the exterior of the pole may form an obstacle when providing a so-called ground-level protection and/or an obligatory base-part protection and/or the protection for that part of the pole which extends into the ground, which protection, according to the regulations, has to extend approximately 25 cm above ground level. Another drawback is also the fact that the directional sensitivity of the known connecting structure is relatively high, depending on the direction of mounting between the connecting pieces. It is therefore an object of the invention to provide a connecting structure for a traffic-safe pole which does not result in additional risks and the correct action of which can be ensured for a relatively long time. This object is achieved by the fact that the recesses open into the inner periphery of the mounting faces, said inner periphery situated inside the connecting structure.

- Providing the recesses on the inner periphery of the mounting flanges has the advantage that the exterior of the connecting structure does not have any irregularities or sharp edges, so that the danger of a cutting action or hook action is significantly reduced. In addition, the parts which are critical to the correct functioning of the connecting structure can be more readily protected against outside influences. The base-part protection which extends across the connecting structure ensures that the respective parts are invisible from the outside. The advantage thereof is also that poles provided with such a connecting structure are less susceptible to vandalism.

- Preferably, the recesses flare out, for example in accordance with a V shape. In order to achieve a reliable shearing action, washer discs are preferably provided between each mounting face and clamping member. These washer discs may also be designed in such a manner that they flare out, viewed in the direction of the inner periphery of the mounting faces. The effect of these flaring shapes is that, viewed in the peripheral direction, it becomes less critical where a vehicle collides with the pole. This effect is reinforced by the use of a relatively large number of clamping members, for example 8, 10 or 12.

- The effect can be further improved if the connecting pieces each have holders which project with respect to the mounting faces of the mounting flanges, between which holders the washer discs are accommodated. In each case two adjacent holders can then determine a holder space for the associated washer disc, which holder space flares out in the direction of the inner periphery of the mounting flanges. In such a flaring holder space, the washer discs which shear off under the effect of collision forces can readily be guided. In addition, the holder space in which the washer disc is enclosed provides greater stability to the connecting structure during normal use, so that the pole is able to withstand normal loads, such as those caused by the wind and the like.

- In another preferred embodiment, it is provided that the mounting faces at adjacent recesses form steps. As a result thereof, adjacent washer discs of a connecting piece can be at different levels. When the pole shears off on account of a collision, the washer discs which are relatively close to one another and which move even closer together during the shearing can then slide over one another and thus do not become locked.

- A friction means, such as one or more friction rings, may be provided between the mounting faces, which results in a low, controlled friction. Preferably, two rings lying on top of one another are provided which cause a reliable and long-lasting nominal shearing force between them. Furthermore, the connecting pieces may each have a reinforcing flange at a distance from the end face. The connecting pieces, at their ends which face one another, may each comprise a collar which projects with respect to the sleeve and which determines a stop for a pole part which can be placed over the sleeve.

- In a preferred embodiment, the connecting pieces may comprise a sleeve, in which case the mounting flanges are situated on the inside of the sleeve. The connecting pieces may be rotationally symmetrical and are preferably made of aluminium castings. In addition, a connecting piece may be provided with a reinforcing flange at a distance from the end face. Said reinforcing flange is preferably at the level of impact, in such a manner that the collision forces can reliably be passed on to the end faces without the connecting pieces breaking prematurely.

- The connecting pieces may be rotationally symmetrical. In addition, alignment means may be provided for aligning the connecting pieces and the recesses with respect to one another. Between the end faces, a friction means, such as one or more friction rings, may be provided. At least one of the friction rings may have recesses which open into the inner periphery thereof, in which recesses a bolt is accommodated in each case.

- These recesses in the friction ring may have an undercut shape. Furthermore, a connecting piece may have a reinforcing flange at a distance from the end face. The connecting pieces may be identical. The pole parts may be connected to the connecting pieces by an adhesive connection. The area of the pole parts adjacent to the connecting structure and the connecting structure may be covered by a base-part protection.

- The invention also relates to a traffic pole having pole parts which are in line with one another and which are connected to one another by a connecting structure as described above. Preferably, the pole parts are connected to the connecting pieces by an adhesive connection. This prevents local weakened sections being formed by, for example, welding, which may give cause corrosion and fatigue phenomena.

- One of the pole parts or the so-called base part is designed to be installed on or in a foundation, in such a manner that the connecting structure is situated at a slight distance above the ground level of the area in which the foundation is situated, which is preferably approximately 5 cm.

- Since the flanges and the clamping members are situated inside the connecting structure, the latter may be designed in such a manner that the peripheral contour thereof is identical to the peripheral contour of the pole parts. This results in a very uniform appearance, which is not susceptible to soiling and does not have any dangerous protruding parts.

- The invention will be explained in more detail below with reference to an exemplary embodiment illustrated in the figures, in which:

-

Fig. 1 shows a lamp post comprising a connecting structure according to the invention; -

Fig. 2 shows a connecting structure as used with the lamp post fromFig. 1 ; -

Fig. 3 shows a view of a connecting piece of the connecting structure; -

Fig. 4 shows a perspective view of the connecting pieces. - The lamp post 1 illustrated in

Fig. 1 comprises alower pole part 3 and anupper pole part 2, which are connected to one another by the connectingstructure 4 according to the invention. Thelower pole part 3 has its foundation in theground 5, theupper pole part 2 carries alighting fixture 6. Nevertheless, the connectingstructure 4 can also be used with other poles, which are at risk of vehicles colliding with them. -

Fig. 2 shows the connectingstructure 4 on an enlarged scale. The connectingstructure 4 comprises two connectingpieces 7, 8 which are identical in the illustrated exemplary embodiment. Each connectingpiece 7, 8 has a connectingpart 9 which can be attached to arespective pole part collar 10 and end faces 11 which are turned towards one another at thecollar 10. Between the end faces 11, a friction ring or a couple of friction rings 12 may be provided which may produce a certain shearing force. - As regards achieving the desired shearing forces, the end faces 11 and the friction rings 12 have to be pressed together at a specific pretensioning force. This is achieved by means of a series of

bolt connections 13, which are evenly distributed on the inner periphery of the connectingstructure 4.Fig. 2 shows one of thesebolt connections 13. Eachbolt connection 13 comprises abolt 14, anut 15 andwasher discs 16 under the head of the bolt and under thenut 15. Thesebolt connections 13 are accommodated in the V-shapedrecesses 17 which expand towards the inside and which are provided in each connectingpiece 7, 8, namely in the inner mountingflange 18 thereof. - As is illustrated in

Fig. 3 , at least one of the friction rings 12 is provided with undercutrecesses 24 on the inner periphery. The shank of abolt 14 can be inserted or pushed into theserecesses 24, and subsequently held therein. This results in a certain stabilization of thebolt connections 16 which prevents the bolt connections from being displaced as a result of, for example, vibrations. However, therecesses 24 are designed in such a manner that thebolt connections 16 can be forced out of the recesses under the effect of a collision. - Each mounting

flange 18 has a series of mounting faces 19 for thebolt connections 13, in particular for thewasher discs 16 thereof. As can be seen inFigs. 3 and4 , thewasher discs 16 are also designed to flare out. Furthermore, theflanges 18 are provided with so-calledholders 20, which protrude relative to the mounting faces 19. The mounting faces 19 which are adjacent to one another are situated at different levels, viewed in the axial direction of the connectingstructure 4, as can be seen in the perspective view ofFig. 4 and the side view ofFig. 2 . - As can also be seen in

Fig. 4 , twoadjacent holders 20 determine aholder space 21, the bottom of which is formed by a mountingface 19. A correspondingly shapedwasher disc 16, as illustrated inFig. 3 , fits into thisholder space 21 and on the mountingface 19 in a tight-fitting manner. The fact that theadjacent washer discs 16 are situated at different levels as the mounting faces 19 on which they are supported are likewise on different levels, offers the advantage that thewasher discs 16 cannot touch one another when they shear off the mounting faces 19 in the event of a collision. The flared shape of theholder space 19 and of therecesses 17 in this case ensures that, in relative terms, it is not critical where a vehicle hits the connectingstructure 4, viewed in the peripheral direction, with regard to the shearing direction. As has been discussed above, the relatively large number ofbolt connections 16 is important in this connection. - The connecting

pieces 7, 8, and in particular therecesses 17 thereof, may be aligned with respect to one another by means of alignment means 22, such as a tenon-mortise joint. In addition, a reinforcingflange 23 may be provided on the upper end of the upper connecting piece 7, by means of which the collision energy can be withstood in such a manner that correct shearing can be achieved. - As is diagrammatically illustrated in

Fig. 1 , the connectingstructure 4 and the adjacent sections of thepole parts part protection 26. The latter can be provided without any problems as the connectingstructure 4 does not have any parts which protrude outside the contours of the pole 1. In addition, the connectingstructure 4 is hidden from view, so that the risk of vandalism is reduced to a minimum. Incidentally, the connectingstructure 4, in particular the end faces 11 thereof, are at a height of approximately 5 cm above the ground. Thus, only a verylow stump 3 remains in the ground after theupper pole part 2 has sheared off, which stump presents only a very low-risk danger to the colliding vehicle. In any case, a height of 5 cm is so small that the vehicle cannot be decelerated thereby and cannot become caught behind such a low stump.

Claims (15)

- Connecting structure (4) for a traffic pole, such as a lamp post (1), composed of two pole parts (2, 3), comprising connecting pieces (7, 8) which can each be connected to a pole part in such a manner that the connecting pieces and pole parts are in line with one another, which connecting pieces (7, 8) are each provided with an end face (11) and a connecting part (9) which can be connected to a pole part (2,3), a mounting face (19) having recesses (17) opening into a periphery thereof, which mounting face (19) is turned away from the associated end face (11), as well as clamping members (13) which are accommodated in said recesses (17) which are aligned with respect to one another and which are supported on said mounting faces (19) which are turned away from one another in such a manner that the end faces (11) of the connecting pieces (7, 8) are pushed together, characterized in that the recesses (17) open into the inner periphery of the mounting faces (19), said inner periphery situated inside the connecting structure.

- Connecting structure (4) according to Claim 1, in which washer discs (16) are provided between each mounting face (19) and clamping member (13).

- Connecting structure (4) according to Claim 2, in which the washer discs (16) are designed in such a manner that they flare out, viewed in the direction of the inner periphery of the mounting faces (19).

- Connecting structure (4) according to Claim 3, in which the connecting pieces (7, 8) each have holders (20) which project with respect to the mounting faces (19), between which holders (20) the washer discs (16) are accommodated.

- Connecting structure (4) according to Claim 4, in which adjacent holders (20) determine a holder space (21) for the associated washer disc (16), which holder space flares out in the direction of the inner periphery of the mounting faces (19).

- Connecting structure (4) according to Claim 5, in which the form of the holder space (21) corresponds to that of the washer disc (16).

- Connecting structure (4) according to one of Claims 2-6, in which the clamping members comprise bolt connections (13) and the head of each bolt (14) and each nut (15) rest on a washer disc (16).

- Connecting structure (4) according to one of the preceding claims, in which the mounting faces (19) at adjacent recesses (17) form steps.

- Connecting structure (4) according to one of the preceding claims, in which the connecting pieces (7, 8) comprise a sleeve (9) and the mounting faces (19) are situated on the inside of the sleeve (9).

- Connecting structure (4) according to one of the preceding claims, in which the connecting pieces (7, 8) , at their ends which face one another, each comprise a collar (10) which projects with respect to the sleeve and which determines a stop for a pole part (2, 3) which can be placed over the sleeve (9).

- Connecting structure (4) according to one of the preceding claims, in which at least five recesses (17) are evenly distributed in the peripheral direction in order to provide directional independence in the peripheral direction.

- Traffic pole (1), comprising pole parts (2, 3) which are in line with one another and are connected to one another by a connecting structure (4), characterized by a connecting structure (4) according to one of the preceding claims.

- Traffic pole (1) according to Claim 12, in which one of the pole parts (2, 3) is designed to be installed on or in a foundation, and the connecting structure (4) is situated at a distance above the ground level (5) of the area in which the foundation is situated.

- Traffic pole (1) according to Claim 13, in which the pole parts (2, 3) are connected to the connecting pieces (7, 8) by an adhesive connection.

- Traffic pole (1) according to one of Claims 12-14, in which the area of the pole parts adjacent to the connecting structure and the connecting structure (4) are covered by a base-part protection (26).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL08160183T PL2014850T3 (en) | 2007-07-11 | 2008-07-11 | Connecting structure for a traffic-safe pole |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| NL2000744A NL2000744C2 (en) | 2007-07-11 | 2007-07-11 | Connection construction for traffic-safe mast. |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2014850A1 EP2014850A1 (en) | 2009-01-14 |

| EP2014850B1 true EP2014850B1 (en) | 2015-09-02 |

Family

ID=39171392

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP08160183.3A Active EP2014850B1 (en) | 2007-07-11 | 2008-07-11 | Connecting structure for a traffic-safe pole |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP2014850B1 (en) |

| NL (1) | NL2000744C2 (en) |

| PL (1) | PL2014850T3 (en) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2400060A1 (en) | 2010-06-24 | 2011-12-28 | Hunter Douglas Industries B.V. | Utility Pole with frangible tube section |

| ES2396900B1 (en) * | 2011-02-15 | 2013-10-09 | Ecotécnica Integral S.L. | PASSIVE SAFETY DEVICE IN ROAD EQUIPMENT SUPPORT STRUCTURES. |

| NL1041270B1 (en) | 2015-04-13 | 2017-01-27 | Hunter Douglas Ind Bv | Utility pole with shear off coupling assembly. |

| US10435911B2 (en) | 2017-08-25 | 2019-10-08 | Pepco Holdings LLC | Utility pole with energy absorbing layer |

| PL440761A1 (en) * | 2022-03-25 | 2023-10-02 | Elektromontaż Rzeszów Spółka Akcyjna | Steel street lighting pole absorbing the impact energy of a motor vehicle |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1087073A (en) | 1963-09-11 | 1967-10-11 | Turner Philip Wilson | Lamp and other roadside standards |

| US7195222B2 (en) * | 2004-04-23 | 2007-03-27 | Dent Clifford M | Flanged base and breakaway system connector for road accessory posts |

-

2007

- 2007-07-11 NL NL2000744A patent/NL2000744C2/en not_active IP Right Cessation

-

2008

- 2008-07-11 PL PL08160183T patent/PL2014850T3/en unknown

- 2008-07-11 EP EP08160183.3A patent/EP2014850B1/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| NL2000744C2 (en) | 2009-01-13 |

| EP2014850A1 (en) | 2009-01-14 |

| PL2014850T3 (en) | 2016-01-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2014850B1 (en) | Connecting structure for a traffic-safe pole | |

| US6398192B1 (en) | Breakaway support post for highway guardrail end treatments | |

| US4759161A (en) | Breakaway support structure with replaceable shear connector | |

| US6308927B1 (en) | Breakaway sign post connector | |

| AU2011275601B2 (en) | Road safety barrier | |

| EP2317029A2 (en) | Anchorage device for fall protection | |

| US5088683A (en) | Breakaway pole assembly | |

| US20170247894A1 (en) | Tip-over post | |

| WO2014194377A1 (en) | Flexible coupling | |

| US20070063179A1 (en) | A weakened guardrail mounting connection | |

| US7384225B2 (en) | Fixing cover | |

| US20070063178A1 (en) | Guardrail flange protector | |

| US8960647B2 (en) | Barrier system | |

| WO2007084009A1 (en) | Yielding connector for poles and posts | |

| AU2015100857A4 (en) | A Frangible Pole Assembly | |

| AU2021100131A4 (en) | Frangible Pole | |

| EP3081695B1 (en) | Utility pole with shear off coupling assembly | |

| JP2005201020A (en) | Deformable protection fence | |

| KR100942674B1 (en) | crash barrier | |

| KR102673763B1 (en) | guardrail assembly | |

| AU2012101052A4 (en) | A Frangible Pole with Transition Shoe | |

| EP4158107A1 (en) | Safety mast | |

| AU2012207010B2 (en) | A Frangible Pole with Wear Shoe | |

| AU2021100100A4 (en) | Frangible Pole | |

| AU2019216603A1 (en) | A frangible pole |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA MK RS |

|

| 17P | Request for examination filed |

Effective date: 20090714 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| 17Q | First examination report despatched |

Effective date: 20090915 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20150324 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 746734 Country of ref document: AT Kind code of ref document: T Effective date: 20150915 Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602008039903 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: FP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 746734 Country of ref document: AT Kind code of ref document: T Effective date: 20150902 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151203 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150902 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150902 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150902 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151202 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150902 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150902 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150902 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150902 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150902 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150902 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160102 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150902 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160104 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602008039903 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 9 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20160603 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150902 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150902 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20160613 Year of fee payment: 9 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150902 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160731 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160731 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 10 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160711 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150902 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20080711 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: FP Effective date: 20151028 Ref country code: BE Ref legal event code: MM Effective date: 20170731 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 11 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150902 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150902 Ref country code: MT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150902 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170731 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 602008039903 Country of ref document: DE Representative=s name: KILBURN & STRODE LLP, NL |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230526 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IE Payment date: 20240621 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20240527 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20240528 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20240618 Year of fee payment: 17 Ref country code: FR Payment date: 20240604 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20240620 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PL Payment date: 20240711 Year of fee payment: 17 |