EP1982950A1 - Braking system for lifts - Google Patents

Braking system for lifts Download PDFInfo

- Publication number

- EP1982950A1 EP1982950A1 EP07381034A EP07381034A EP1982950A1 EP 1982950 A1 EP1982950 A1 EP 1982950A1 EP 07381034 A EP07381034 A EP 07381034A EP 07381034 A EP07381034 A EP 07381034A EP 1982950 A1 EP1982950 A1 EP 1982950A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- pulley

- brake

- braking system

- lifts

- complementary

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 230000000295 complement effect Effects 0.000 claims abstract description 16

- 239000000725 suspension Substances 0.000 claims description 4

- 230000000903 blocking effect Effects 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 230000001105 regulatory effect Effects 0.000 description 2

- 230000006978 adaptation Effects 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

- 239000000463 material Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B66—HOISTING; LIFTING; HAULING

- B66D—CAPSTANS; WINCHES; TACKLES, e.g. PULLEY BLOCKS; HOISTS

- B66D5/00—Braking or detent devices characterised by application to lifting or hoisting gear, e.g. for controlling the lowering of loads

- B66D5/02—Crane, lift hoist, or winch brakes operating on drums, barrels, or ropes

- B66D5/06—Crane, lift hoist, or winch brakes operating on drums, barrels, or ropes with radial effect

- B66D5/08—Crane, lift hoist, or winch brakes operating on drums, barrels, or ropes with radial effect embodying blocks or shoes

Definitions

- the object of the present invention is a braking system for lifts and elevation systems in general where the braking system is of the transversal type and situated in the extension of the axis of the drum or braking cone.

- the present braking system is characterised by the fact that it makes use of the space in one of the sides of the suspension pulley, using it to increase the braking force generated by the springs through a system of levers.

- the braking system may be applied both on the free surface of the pulley and by means of a brake drum rigidly attached to the pulley axis.

- the present invention is characterised by the increased braking force due to the transmission of the force by means of articulated arms which act as a lever.

- Braking systems used for lifts are based on various systems such as disc shoes or brakes of the drum type where the shoes and arms are on the same plane as the drum.

- the braking force is directly applied without there being any means which would enable the force generated for braking to be increased by the means of application used, which would result in a reduction of the braking force required.

- the object of the present invention is to develop a braking system with transversal application which may be applied on the possible free surface of the pulley as well as on the brake drum, which implies a reduction in the force which needs to be generated in order to obtain the braking torque, as well as making use of the space on one side of the pulley.

- the braking system which is the object of the invention makes use of the space on one side of the pulley and uses it to increase the braking force generated by the springs through a system of levers. On one end of the lever there is an electromagnetic coil which releases the brake.

- the braking system of a pulley for a lift or elevation system in general may either be applied on part of the free surface of the suspension pulley or by means of a brake drum rigidly attached to the pulley axis.

- the braking system comprises brake shoes fitted on an articulated arm which acts as a lever.

- the articulated arm is articulated on one of its ends on an axis and the other end is activated by a pre-stressed spring. Due to the tension of the spring, the lever tightens the brake shoe against the brake drum, preventing rotation of the drum, if there is one. In turn, the blocking of the drum rotation prevents the rotation of the pulley.

- an electromagnetic coil acts on the end of the lever in the opposite direction to the force of the springs.

- the coil acts through the effect of an electric current, this pushes the lever with a force greater than that exercised on the springs, transmitting movement to the brake shoes, so that these separate from the drum.

- the mechanical system is duplicated, two levers are used, two springs and two brake shoes in order to comply with the regulatory requirements for lifts.

- the braking force may be applied on part of the free surface of the elevation pulley or either on the brake drum.

- the brake shoes should be provided with a geometric form which is complementary to the surface on which they act, so that the contact surface between the shoe and the braking surface is as extensive as possible.

- the geometry which both the braking surface of either the pulley or the brake drum, like the shoes themselves, may be varied, with the only requirement being that both geometries should be complementary so that the braking surface or friction is optimum.

- a possible embodiment would be that the brake drum or pulleys were to be provided with a perimeter "V" shaped groove while the brake shoe would have a "V” shaped transversal section which could be coupled on the previous groove.

- Figure 1 shows the pulley (1) in which on part of the external surface there is a free surface (2) on which transversally arranged brake shoes (3) act.

- the brake shoes (3) are fitted on an articulated arm (4).

- Each articulated arm (4) functions as a lever.

- One end of each arm (4) is articulated on its respective axis (5) and the other end is activated by a pre-stressed spring (6).

- One end of each of the springs (6) rests on the base (8) and the other end of the springs (6) pulls a mobile part (7) associated with each spring (6).

- each spring (6) is transmitted through the mobile part (7) to the associated articulated arm (4), the articulated arm (4) tightens the brake shoe (3) against the free surface (2) part of the pulley or against a brake drum (11) ( figures 10 and 11 ), and due to the force of friction between the brake shoe and the free surface (2) or the drum (11),0 rotation of the pulley (1) or the drum (11) is prevented.

- an electromagnetic coil (9) which acts on one of the ends of the two articulated arms (4)in the opposite direction of the force of the springs (6).

- the coil (9) acts through the effect of an electric current, this pushes the levers (4) by means of push screws (10) joined to each of the articulated arms (4) with a force greater than and contrary to that exercised by the springs (6), transmitting the opening movement to the brake shoes (3) causing them to separate either from the free surface part (2) of the pulley (1) or the drum (11).

- the drum (11) is able to rotate freely and the support pulley (1).

- the mechanical system is duplicated, two levers are used, two springs and two brake shoes in order to comply with the regulatory requirements for lifts.

- Figures 2 , 3 and 4 show the elements described above in order to provide details of the relation and interaction between the various elements of the braking system.

- Figure 5 shows a section of the pulley together with the braking system, which shows how the shoes (3) and the free surface (2) of the pulley (1) remain in contact throughout their surface indicating a complementary geometry which in this case is smooth.

- Figures 6 , 7 , 8 and 9 show a form of alternative embodiment to the geometry of the free surface of the pulley (2) and the geometry of the brake shoes (3) where now the free surface (2) of the pulley _(1) shows a "V" shaped groove (13) into which a shoe (4) fits having a part of the external free surface of the pulley which should have a "V” shaped geometry complementary to the "V” shaped groove (13) so that surface contact is optimum, as may be seen in figure 9 .

- Figure 10 shows a perspective representation of a pulley together with an associated braking system where the braking force is applied on a brake drum (11) which is rigidly joined to the pulley axis (12).

- Figures 11 and 12 show the sections obtained by cutting the unit of figure 10 through planes XI-XI and XII-XII respectively.

- the surface of the brake drum (11) and that of the shoes (3) should be complementary, in this case smooth, so that they contact throughout their surface, which encourages the braking action for which purpose both geometries that of the external surface of the brake drum and the section of the brake shoe, should be complementary.

- a form of alternative embodiment in respect of the geometries which may be presented by the brake drum surface and the brake shoe surface should be in a "V" shape, so that the brake drum would present a groove whereas the brake shoes would have complementary "V" shaped sections.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Braking Arrangements (AREA)

Abstract

Braking system which makes use of the space on one side of the pulley and uses it to increase the braking force by means of a system of levers, applying the braking force directly on the system pulley on part of the free surface, or on a brake drum rigidly joined to the pulley by means of an axis, provided for this purpose with two brake shoes with geometries complementary to the surfaces on which they act, and which are articulated arms which articulate on one of their ends in an axis while the other end is activated by springs pre-compressed by means of mobile parts joined to the spring, with the braking action being released by means of an electromagnetic coil which when activated displaces push screws from the ends of the articulated arms with a force greater and contrary to that of the springs.

Description

- The object of the present invention is a braking system for lifts and elevation systems in general where the braking system is of the transversal type and situated in the extension of the axis of the drum or braking cone.

- The present braking system is characterised by the fact that it makes use of the space in one of the sides of the suspension pulley, using it to increase the braking force generated by the springs through a system of levers.

- The braking system may be applied both on the free surface of the pulley and by means of a brake drum rigidly attached to the pulley axis.

- The present invention is characterised by the increased braking force due to the transmission of the force by means of articulated arms which act as a lever.

- Therefore, the present invention is circumscribed within the scope of lift braking systems or similar elevation apparatus.

- Braking systems used for lifts are based on various systems such as disc shoes or brakes of the drum type where the shoes and arms are on the same plane as the drum.

- However, among the known braking systems none has a transversal application which permits its adaptation both on the free surface of the pulley and on the brake drum rigidly joined to the axis of the pulley, and which makes use of the lift shaft at one side of the pulley.

- It is also the case that the braking force is directly applied without there being any means which would enable the force generated for braking to be increased by the means of application used, which would result in a reduction of the braking force required.

- Therefore, the object of the present invention is to develop a braking system with transversal application which may be applied on the possible free surface of the pulley as well as on the brake drum, which implies a reduction in the force which needs to be generated in order to obtain the braking torque, as well as making use of the space on one side of the pulley.

- The braking system which is the object of the invention makes use of the space on one side of the pulley and uses it to increase the braking force generated by the springs through a system of levers. On one end of the lever there is an electromagnetic coil which releases the brake.

- The braking system of a pulley for a lift or elevation system in general, which is the subject of this invention, may either be applied on part of the free surface of the suspension pulley or by means of a brake drum rigidly attached to the pulley axis. In both cases the braking system comprises brake shoes fitted on an articulated arm which acts as a lever. The articulated arm is articulated on one of its ends on an axis and the other end is activated by a pre-stressed spring. Due to the tension of the spring, the lever tightens the brake shoe against the brake drum, preventing rotation of the drum, if there is one. In turn, the blocking of the drum rotation prevents the rotation of the pulley.

- In order to release the brake and enable rotation of the pulley, an electromagnetic coil is used which acts on the end of the lever in the opposite direction to the force of the springs. When the coil acts through the effect of an electric current, this pushes the lever with a force greater than that exercised on the springs, transmitting movement to the brake shoes, so that these separate from the drum. Thus the drum is able to rotate freely and also the support pulley. The mechanical system is duplicated, two levers are used, two springs and two brake shoes in order to comply with the regulatory requirements for lifts.

- The braking force, as we have indicated previously, may be applied on part of the free surface of the elevation pulley or either on the brake drum. For this purpose the brake shoes should be provided with a geometric form which is complementary to the surface on which they act, so that the contact surface between the shoe and the braking surface is as extensive as possible. However, the geometry which both the braking surface of either the pulley or the brake drum, like the shoes themselves, may be varied, with the only requirement being that both geometries should be complementary so that the braking surface or friction is optimum.

- Thus, a possible embodiment would be that the brake drum or pulleys were to be provided with a perimeter "V" shaped groove while the brake shoe would have a "V" shaped transversal section which could be coupled on the previous groove.

- In order to complement the description which follows and to provide a better understanding of the characteristics of the invention, the present descriptive report is accompanied by a set of drawings which are illustrative and not restrictive any way, representing the most significant details of the invention.

-

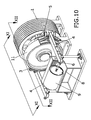

Figure 1 shows a perspective view of a pulley on which the braking system which is the subject of this invention has been arranged, applied on part of the external free surface of the pulley. -

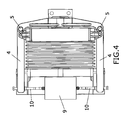

Figures 2 ,3 and4 show a representation of the front, back and ground view of the pulley, together with the braking system represented infigure 1 . -

Figure 5 shows a representation of the section made to the pulley together with the braking system infigure 1 on a V-V horizontal plane. -

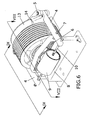

Figure 6 shows a perspective view of a pulley on which the braking system which is the subject of this invention has been arranged, applied on part of the free external surface of the pulley with the pulley and the brake shoes presenting a complementary "V" shaped geometry. -

Figure 7 shows the elevation view offigure 6 . -

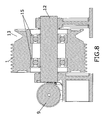

Figures 8 and9 show the sections obtained by sectioning the pulley together with the braking system represented infigure 6 through planes VIII-VIII and IX-IX respectively. -

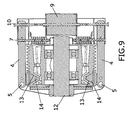

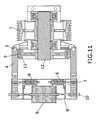

Figure 10 , shows a perspective representation of an alternative embodiment of a group formed by a pulley, brake drum and braking system, where it is joined rigidly to the brake drum and on which the braking system which is the object of the invention is applied. -

Figure 11 shows a section of an alternative embodiment of a group formed by a pulley, a brake drum and a braking system sectioned by a XI-XI horizontal plane. -

Figure 12 shows a section of the group infigure 10 sectioned by a XII-XII vertical plane. - In the light of the figures a preferred embodiment of the invention proposed is described below.

-

Figure 1 shows the pulley (1) in which on part of the external surface there is a free surface (2) on which transversally arranged brake shoes (3) act. - The brake shoes (3) are fitted on an articulated arm (4). Each articulated arm (4) functions as a lever. One end of each arm (4) is articulated on its respective axis (5) and the other end is activated by a pre-stressed spring (6). One end of each of the springs (6) rests on the base (8) and the other end of the springs (6) pulls a mobile part (7) associated with each spring (6).

- The force of each spring (6) is transmitted through the mobile part (7) to the associated articulated arm (4), the articulated arm (4) tightens the brake shoe (3) against the free surface (2) part of the pulley or against a brake drum (11) (

figures 10 and11 ), and due to the force of friction between the brake shoe and the free surface (2) or the drum (11),0 rotation of the pulley (1) or the drum (11) is prevented. - In the event that the braking force is applied on the brake drum (11) as shown in

figure 10 , the blocking of the drum (11) rotation prevents rotation of the pulley (1) as both form part of the same rigidly joined unit. - In order to release the brake and permit rotation of the pulley (1) an electromagnetic coil (9) is used which acts on one of the ends of the two articulated arms (4)in the opposite direction of the force of the springs (6). When the coil (9) acts through the effect of an electric current, this pushes the levers (4) by means of push screws (10) joined to each of the articulated arms (4) with a force greater than and contrary to that exercised by the springs (6), transmitting the opening movement to the brake shoes (3) causing them to separate either from the free surface part (2) of the pulley (1) or the drum (11). Thus the drum (11) is able to rotate freely and the support pulley (1).

- As may be seen, the mechanical system is duplicated, two levers are used, two springs and two brake shoes in order to comply with the regulatory requirements for lifts.

-

Figures 2 ,3 and4 show the elements described above in order to provide details of the relation and interaction between the various elements of the braking system. -

Figure 5 shows a section of the pulley together with the braking system, which shows how the shoes (3) and the free surface (2) of the pulley (1) remain in contact throughout their surface indicating a complementary geometry which in this case is smooth. -

Figures 6 ,7 ,8 and9 show a form of alternative embodiment to the geometry of the free surface of the pulley (2) and the geometry of the brake shoes (3) where now the free surface (2) of the pulley _(1) shows a "V" shaped groove (13) into which a shoe (4) fits having a part of the external free surface of the pulley which should have a "V" shaped geometry complementary to the "V" shaped groove (13) so that surface contact is optimum, as may be seen infigure 9 . -

Figure 10 shows a perspective representation of a pulley together with an associated braking system where the braking force is applied on a brake drum (11) which is rigidly joined to the pulley axis (12).Figures 11 and12 show the sections obtained by cutting the unit offigure 10 through planes XI-XI and XII-XII respectively. - Once again the surface of the brake drum (11) and that of the shoes (3) should be complementary, in this case smooth, so that they contact throughout their surface, which encourages the braking action for which purpose both geometries that of the external surface of the brake drum and the section of the brake shoe, should be complementary.

Thus, a form of alternative embodiment in respect of the geometries which may be presented by the brake drum surface and the brake shoe surface should be in a "V" shape, so that the brake drum would present a groove whereas the brake shoes would have complementary "V" shaped sections. - The essential nature of this invention is not altered in any way by variations in materials, form, shape and arrangement of the component elements, which are described in a manner which is in no way restrictive but which is sufficient for an expert to proceed to its reproduction.

Claims (8)

- Braking system for lifts characterised in that it consists of:Two brake shoesTwo articulated arms on which the shoes are arranged where one end of each arm articulates on an axis, whereas the other is activated by a pre-stressed spring.Mobile parts which transmit the force of each spring to one of the ends of each articulated arm.Means for releasing the brake and enabling rotation of the pulley

- Braking system for lifts according to claim one, characterised in that the means for releasing the brake consist of an electromagnetic coil which acts on each articulated arm one of its ends in the direction opposite the force of the springs, by means of push screws of the articulated arm.

- Braking system for lifts according to claims 1 or 2, characterised in that the brake shoes apply their force on the part of the free surface which remains on the suspension and traction pulley.

- Braking system for lifts, according to claim 3 characterised in that both the part of the free surface which remains on the pulley and the brake shoes have a complementary smooth surface.

- Braking system for lifts according to claim 3, characterised in that both the part of the free surface remaining on the pulley and the brake shoes presents a complementary "V" shaped surface and the part of the free surface of the pulley presents a "V" shaped groove in which a brake shoe having a complementary "V" shape fits.

- Braking system for lifts, according to claim 1 or 2 characterised in that the brake shoes apply their force on a brake drum joined rigidly to the suspension and traction pulley by means of an axis.

- Braking system for lifts according to claim 6, characterised in that both brake drum and the brake shoes present a complementary smooth surface.

- Braking system for lifts according to claim 3, characterised in that both brake drum and the brake shoes present a complementary "V" shaped surface, and the brake drum presents a "V" shaped groove in which a brake shoes fits having a complementary "V" shaped section.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP07381034A EP1982950A1 (en) | 2007-04-17 | 2007-04-17 | Braking system for lifts |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP07381034A EP1982950A1 (en) | 2007-04-17 | 2007-04-17 | Braking system for lifts |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP1982950A1 true EP1982950A1 (en) | 2008-10-22 |

Family

ID=38480098

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP07381034A Withdrawn EP1982950A1 (en) | 2007-04-17 | 2007-04-17 | Braking system for lifts |

Country Status (1)

| Country | Link |

|---|---|

| EP (1) | EP1982950A1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3326953A1 (en) * | 2016-11-18 | 2018-05-30 | Otis Elevator Company | Retrofitting an elevator machine with primary and secondary braking |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4875558A (en) * | 1989-03-16 | 1989-10-24 | Otis Elevator Company | Safety brake for escalators |

| US6146303A (en) * | 1994-10-10 | 2000-11-14 | Wittur Ag | Drive unit for a hoist |

| EP1298084A2 (en) * | 2001-09-28 | 2003-04-02 | Kabushiki Kaisha Meidensha | Hoisting machine for elevator |

| DE10246588A1 (en) * | 2002-10-05 | 2004-04-22 | System Antriebstechnik Dresden Gmbh | Emergency braking system for lifts comprises three brake units acting on independent disks notably first and second double brake units ensuring cabin arrest without injury. |

-

2007

- 2007-04-17 EP EP07381034A patent/EP1982950A1/en not_active Withdrawn

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4875558A (en) * | 1989-03-16 | 1989-10-24 | Otis Elevator Company | Safety brake for escalators |

| US6146303A (en) * | 1994-10-10 | 2000-11-14 | Wittur Ag | Drive unit for a hoist |

| EP1298084A2 (en) * | 2001-09-28 | 2003-04-02 | Kabushiki Kaisha Meidensha | Hoisting machine for elevator |

| DE10246588A1 (en) * | 2002-10-05 | 2004-04-22 | System Antriebstechnik Dresden Gmbh | Emergency braking system for lifts comprises three brake units acting on independent disks notably first and second double brake units ensuring cabin arrest without injury. |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3326953A1 (en) * | 2016-11-18 | 2018-05-30 | Otis Elevator Company | Retrofitting an elevator machine with primary and secondary braking |

| US10618775B2 (en) | 2016-11-18 | 2020-04-14 | Otis Elevator Company | Retrofitting an elevator machine with primary and secondary braking |

| US11377323B2 (en) | 2016-11-18 | 2022-07-05 | Otis Elevator Company | Retrofitting an elevator machine with primary and secondary braking |

| EP4234474A3 (en) * | 2016-11-18 | 2023-09-20 | Otis Elevator Company | Retrofitting an elevator machine with primary and secondary braking |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0416760A1 (en) | Brake assembly | |

| JP3551382B2 (en) | Mechanically driven drum brake | |

| EP0046432A3 (en) | Disc brake | |

| MY108647A (en) | Safety anchorages for controlling pay-out of a safety line | |

| US8469159B2 (en) | Brake assembly | |

| KR20060045942A (en) | Interlocking brake device of the vehicle | |

| JPH0233892B2 (en) | ||

| US4193481A (en) | Drag free sliding caliper disc brake bushing | |

| EP0015178B1 (en) | Drum brake assembly | |

| US3664469A (en) | Mechanically-operated disc-brake | |

| CN103717276B (en) | Brakes for roller skates, skateboards or the like | |

| CA1111356A (en) | Pin slider disc brake | |

| JPS5926810B2 (en) | Sliding caliper type disc brake | |

| EP0063513A1 (en) | Drum brake having duo mode | |

| EP1982950A1 (en) | Braking system for lifts | |

| US6286631B1 (en) | Actuating lever for a wheelbarrow brake | |

| US20040149524A1 (en) | Cable brake at a speed limiter for lifts | |

| EP0800015A3 (en) | Drum brake device with single shoe extension device | |

| EP0299929B1 (en) | Resilient device for connection between two structural elements | |

| US3708040A (en) | Disk brake with servo action | |

| US3315769A (en) | Self-energizing caliper type disc brake | |

| TWI901312B (en) | Brake mechanism and baby carrier | |

| KR920006218A (en) | Elevator | |

| SE434986B (en) | BRAKE POWER SUPPLY BOLT CONTROL FOR A FLAT BRAKE WITH FLOATING BOWL | |

| BR0211133A (en) | Disc brake |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC MT NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK RS |

|

| AKX | Designation fees paid | ||

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: 8566 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20090423 |