EP1982948A2 - Sliding pad for a jib - Google Patents

Sliding pad for a jib Download PDFInfo

- Publication number

- EP1982948A2 EP1982948A2 EP08152244A EP08152244A EP1982948A2 EP 1982948 A2 EP1982948 A2 EP 1982948A2 EP 08152244 A EP08152244 A EP 08152244A EP 08152244 A EP08152244 A EP 08152244A EP 1982948 A2 EP1982948 A2 EP 1982948A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- jib

- pad

- jib structure

- supporting member

- sliding

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B66—HOISTING; LIFTING; HAULING

- B66C—CRANES; LOAD-ENGAGING ELEMENTS OR DEVICES FOR CRANES, CAPSTANS, WINCHES, OR TACKLES

- B66C23/00—Cranes comprising essentially a beam, boom, or triangular structure acting as a cantilever and mounted for translatory of swinging movements in vertical or horizontal planes or a combination of such movements, e.g. jib-cranes, derricks, tower cranes

- B66C23/62—Constructional features or details

- B66C23/64—Jibs

- B66C23/70—Jibs constructed of sections adapted to be assembled to form jibs or various lengths

- B66C23/701—Jibs constructed of sections adapted to be assembled to form jibs or various lengths telescopic

- B66C23/707—Jibs constructed of sections adapted to be assembled to form jibs or various lengths telescopic guiding devices for telescopic jibs

Definitions

- the present invention relates to an extendable and stowable jib of a working machine such as a crane. Particularly, the present invention relates to a structure of a sliding pad to be attached to the above jib.

- An example of a working machine to which the present invention is applied includes a crane and an elevating work vehicle.

- An extendable and stowable jib provided in the above working machine has a plurality of jib structures which are telescopically inserted into each other.

- a sliding pad is provided between an inner jib structure and an outer jib structure arranged on the outside of the inner jib structure. This kind of sliding pad is installed to an outer surface in the base end portion of the inner jib structure and an inner surface on the front end portion of the outer jib structure so as to stably support the jib structures when a base end portion of the inner jib structure is located anywhere inside the inner jib structure.

- an inner boom is extendably and stowably inserted into an outer boom in a square cylindrical shape, and to the both sides of a base end portion of the inner boom, side pads sliding on an inner surface of the outer boom are attached.

- the side pad is screwed into a side surface of the inner boom by a screw.

- a shearable pin stretching from the side pad to the inner boom is provided.

- a shim having a cutout portion in a U shape is disposed. In the side pad, by adjusting a thickness of the shim, it is possible to adjust a clearance between the side pad and the outer boom.

- a side pad disclosed in Japanese Utility Model Laid-Open No. Hei7-35484 .

- fitting holes are provided in the base end portions of the boom structures to be inserted, and the pads are fitted into the fitting holes in a state of protruding from surfaces of the booms.

- a stopper portion for resisting against suppress strength worked on the pad from the outside.

- the stopper portion an example in which the pad fitted into the fitting hole of the boom base end portion is fixed by a bolt from the inside of the boom is disclosed.

- the jib according to the present invention is an extendable and stowable jib comprises a plurality of jib structures which are telescopically inserted into each other.

- the jib according to the present invention is provided with an inner jib structure, an outer jib structure arranged on the outside of the inner jib structure, and a sliding pad arranged between the inner jib structure and the outer jib structure.

- the sliding pad is attached on the base end portion of the inner jib structure slidably on an inner surface of the outer jib structure.

- the first aspect of the present invention is that a supporting member protruding towards the inner surface of the outer jib structure is provided in the inner jib structure, and the sliding pad is connected to the supporting member so as to restrict movement in the perpendicular direction to the protruding direction of the supporting member.

- the sliding pad is attached in a state of being sandwiched by the outer jib structure and the supporting member in the protruding direction of the supporting member, and the movement of them in the protruding direction is restricted by the outer jib structure. In the perpendicular direction to the protruding direction, the movement is restricted by the supporting member. Thereby, it is possible to surely prevent the sliding pad from dropping off.

- the supporting member is installed in the jib structure so that the sliding pad can be attached to the jib structure through the supporting member. Therefore, there is no need for forming a hole which lowers the strength of the jib structure in the jib structure. Consequently, it is possible to prevent the lowering of the strength of the jib structure.

- the jib includes a main jib capable of raising and lowering mounted in an upper rotating body of a crane or the like, for example, and an auxiliary jib connected to a front end of the main jib. That is, there is a case where the main jib and constituent components thereof are called the "boom". In such a case, the auxiliary jib is sometimes simply called the "jib". However, the term "jib" in the present specification includes not only the main jib but also the auxiliary jib.

- the sliding pad has a pad head portion having a sliding surface sliding on the inner surface of the outer jib structure, and a pad body portion formed in a hollow shape and extending from an end on the opposite side of the sliding surface of the pad head portion.

- the pad body portion is connected to an end of the supporting member.

- a protruding length of the supporting member is adjustable from the inner jib structure.

- the supporting member is formed in an axial shape, and a male screw is threaded on at least a part of the axial portion of the supporting member.

- the supporting member is screwed into a screw hole formed in the inner jib structure.

- the supporting member by rotating the supporting member, the supporting member is inserted into or out of the screw hole so that the protruding length of the supporting member from the inner jib structure can be continuously adjusted.

- the clearance between the sliding surface of the sliding pad and the inner surface of the outer jib structure with a simple mechanism, and adjustment is also easily and precisely performed.

- the protruding length of the supporting member is adjustable from the inside of the inner jib structure.

- the supporting member is formed in an axial shape, and a male screw is threaded on at least a part of the axial portion of the supporting member.

- the supporting member is screwed into a screw hole formed in the inner jib structure in a state that an end of the supporting member protrudes towards the inside of the inner jib structure.

- An engaging portion is provided in the end and the supporting member can be rotated around an axis by the engaging portion.

- the end of the supporting member protrudes towards the inside of the jib, and the engaging portion is provided in the end. Therefore, it is possible to rotate the supporting member by engaging a tool or the like with the engaging portion. Thereby, since operation of rotating and moving the supporting member to the jib is easily performed, it is possible to efficiently adjust the clearance between the sliding surface of the sliding pad and the inner surface of the outer jib structure.

- the supporting member extends towards the inner surface of the outer jib structure and is formed in a hollow shape.

- the sliding pad is fitted into the inside of the supporting member so as to outwardly protrude one end serving as a sliding surface.

- the sliding pad by inserting the sliding pad into the supporting member, it is possible to mount the sliding pad to the jib structure. Therefore, the mounting operation is easily performed. Since the sliding pad is formed in a simple shape, forming the sliding pad is easily performed.

- a positioning member for supporting an end surface on the opposite side of the sliding surface in the sliding pad is provided therewith.

- a male screw is threaded on at least a part of the axial portion of the positioning member, and the positioning member is screwed into a screw hole formed in the inner jib structure.

- opening portions are formed on wall surfaces of a plurality of the jib structures constituting the jib.

- the opening portions are formed at a position where the outside of the jib are linearly communicated to the supporting member through the opening portions in a state that the jib is stowed.

- the mounting and positioning adjustment of the sliding pad are easily performed. Maintenance of the sliding pad or the like is also easily performed.

- the inner jib structure is provided with a bracket extending from an end surface of a base end portion of the inner jib structure in the stowing direction.

- the bracket has a pair of supporting walls extending opposing to each other in a clearance narrower than a width of the inner jib structure, and the supporting member is fixed to the supporting walls.

- a pair of the supporting walls are arranged in the clearance narrower than the width of the inner jib structure. Therefore, it is possible to widen the clearance between the supporting walls and the inner surface of the outer jib structure. In such a case, it is possible to further increase the length of the supporting member protruding from the supporting walls, and it is also possible to increase the length of the sliding pad to be fitted into the supporting member in the protruding direction. Therefore, it is possible to further increase the depth for fitting the sliding pad into the supporting member, and it is possible to surely fix the sliding pad by the supporting member.

- Fig. 1 is an entire view showing a wheel crane provided with a sliding pad for a jib according to the first embodiment of the present invention.

- a wheel crane 1 is provided with a lower traveling body 2 having wheels 2a and 2b, and an upper rotating body 4 mounted on the lower traveling body 2 rotatably around a vertical shaft through a rotation bearing 3.

- a cab 5 serving as an operator cab at the time of traveling and a control cab at the time of performing a crane work.

- a main jib 6 extending towards the front side of the cab 5 and an auxiliary jib 7 connected to a front end portion of the main jib 6 in the extending direction.

- the main jib 6 is formed into a box structure, and it comprises a basic jib structure 6a and a plurality of movable jib structures 6b which are telescopically, extendably and stowably inserted into each other.

- a base end portion of the most outer basic jib structure 6a is pivoted by a jib foot pin (not shown) on the upper rotating body 4. It is possible to raise and lower the main jib 6.

- the jib foot pin functions as a supporting point.

- the auxiliary jib 7 is also formed into a box structure, and it comprises a first jib structure 71, a second jib structure 72 and a third jib structure 73 which are telescopically and extendably inserted into each other. It should be noted that Fig. 1 shows an intermediate projecting state in which the second jib structure 72 housing the third jib structure 73 extends forward from the first jib structure 71.

- a base end portion of the first jib structure 71 located at the most outer part of the auxiliary jib 7 is axially supported by a supporting axis 8 located on the lower side of the front end portion of the main jib 6.

- a front end portion of the first jib structure 71 and the front end portion of the main jib 6 are coupled with each other through a jib suspension rod 9 serving as a coupling member in a rod shape.

- both ends of the first jib structure 71 of the auxiliary jib 7 are coupled with the main jib 6 and the auxiliary jib 7 is raised and lowered in accordance with raising and lowering of the main jib 6.

- the sliding pad for a jib according to the embodiment of the present invention is applicable to the main jib 6 and the auxiliary jib 7 serving as working attachment of the wheel crane 1 mentioned above.

- the case where the sliding pad according to the present invention is applied to the auxiliary jib 7 will be mentioned as an example.

- the sliding pad according to the present embodiment is applied to a sliding pad 10 disposed between the second jib structure 72 and the third jib structure 73 of the auxiliary jib 7.

- Fig. 2 is a partially sectional view showing the auxiliary jib 7 in Fig. 1 , and a view schematically showing a state that the auxiliary jib 7 is completely stowed. That is, the second jib structure 72 and the third jib structure 73 are drawn to the side of the first jib structure 71.

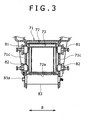

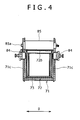

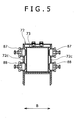

- Figs. 3 to 6 are sectional arrow views by lines S1-S1, S2-S2, S3-S3 and S4-S4 respectively in Fig. 2 .

- the first jib structure 71, the second jib structure 72 and the third jib structure 73 are telescopically fitted in order from outside.

- vertical cross sections of the jib structures 71 to 73 in the longitudinal direction are substantially formed into rectangular shape.

- the first jib structure 71 is a square cylindrical jib structure located on the outermost side in the auxiliary jib 7.

- the second jib structure 72 can slide along an inner surface of a peripheral wall of the first jib structure 71.

- the second jib structure 72 is a square cylindrical jib structure located adjacent to and inside the first jib structure 71.

- the second jib structure 72 is movable in the extending direction of the jib structure or in the stowing direction which is the opposite direction to the extending direction in a state that movement thereof in the width direction is restricted within a predetermined range by sliding pads 81 and 82 installed on side walls 71c of the first jib structure 71.

- the width direction indicates a direction shown by an arrow B in Figs. 3 to 6 .

- the stowing direction indicates a direction shown by an arrow A2 in Fig. 2 .

- a lower portion 72a of the second jib structure 72 is supported by a lower roller 83 having a rotation axis 83a extending in the width direction which is installed in the front end of the first jib structure 71.

- the movement of the second jib structure 72 in the width direction is restricted from the front end of the first jib structure 71 within a predetermined range by sliding pads 84 installed in side walls 71c of the first jib structure 71.

- the second jib structure 72 is provided with an inclined wall portion 72t inclined so as to come apart from a lower portion 71a of the first jib structure 71 as coming close to the base end side, in the vicinity of a base end portion thereof.

- a roller 86 having a rotation axis extending in the width direction of the second jib structure 72.

- the base end portion of the second jib structure 72 is supported by the lower portion 71a of the first jib structure 71 by the roller 86.

- the third jib structure 73 is a square cylinder jib structure disposed adjacent to and inside the second jib structure 72, and has a main body formed in a square cylinder and a bracket 20 installed in the base end portion of the main body.

- the third jib structure 73 is slidable in the extending direction or the stowing direction in a state that movement thereof in the width direction is restricted within a predetermined range by sliding pads 87 and 88 installed in a pair of side walls 72c of the second jib structure 72.

- the front end portion in the extending direction as shown in Fig.

- the lower portion 73a of the third jib structure 73 is supported by a lower roller 89 having a rotation axis 89a extending in the width direction which is installed in the front end of the second jib structure 72.

- the sliding pads 87 and 88 of the second jib structure 72 and the lower roller 89 are installed in the vicinity of the front end portion of the second jib structure 72 extending towards the outside of the first jib structure 71 in a state that the auxiliary jib 7 is completely stowed.

- Fig. 7 is an enlarged partially sectional view of the second jib structure 72 and the third jib structure 73 in the base end portion of the auxiliary jib 7 shown in Fig. 2 .

- Fig. 8 is a partially sectional arrow view by the line S5-S5 in Fig. 7 , showing a cross section of the second jib structure 72 and the sliding pad 10.

- Fig. 9 is a partially sectional arrow view by the line S6-S6 in Fig. 7 , showing a cross section of the second jib structure 72.

- the third jib structure 73 is provided with an inclined wall portion 73t inclined so as to come apart from a lower portion 72a of the second jib structure 72 as closer to the base end side, in the vicinity of a base end portion.

- a roller 90 having a rotation axis extending in the width direction of the third jib structure 73.

- the base end portion of the third jib structure 73 is supported by the lower portion 72a of the second jib structure 72 by the roller 90.

- sliding pads 91 substantially formed into a rectangular shape extending in parallel with the longitudinal direction of the third jib structure 73.

- the sliding pads 91 are formed so as to slide on the upper portion 72b of the second jib structure 72. It should be noted that the sliding pad 91 is fixed to the upper portion 73b of the third jib structure 73 at two points in the longitudinal direction.

- the bracket 20 extending from the end surface 73e in the stowing direction is integrally formed.

- the bracket 20 is formed of a steel plate substantially curved in a U shape and it is provided with a pair of supporting walls 21 extending in parallel from the end surface 73e of the base end portion of the third jib structure 73 in the width direction with leaving a predetermined clearance, and a coupling wall 22 for linking front ends of a pair of the supporting walls to each other.

- the bracket 20 is fixed to the end surface 73e of the base end portion of the third jib structure 73 by welding, for example.

- a pair of the supporting walls 21 are formed so as to oppose to each other in a clearance narrower than a width of the third jib structure 73.

- the supporting walls 21 are formed so that the clearance is approximately one half of the width of the third jib structure 73.

- an opening portion 72h In the inclined wall portion 72t of the second jib structure 72 is formed an opening portion 72h.

- the opening portion 72h is an opening with a diameter of approximately 100mm, and formed at a position where the outside of the second jib structure 72 are linearly communicated to the bracket 20 through the opening portion 72h.

- the opening portion 72h is formed so as to include at least a part of a position where the bracket 20 is orthographically projected to the inclined wall portion 72t.

- the lower portion 71a of the first jib structure 71 has an opening portion 71h at a position in the vicinity of the opening portion 72h of the second jib structure 72.

- the outside of the auxiliary jib 7 is linearly communicated to the bracket 20 and the sliding pad 10 installed in the bracket 20 through the opening portions 71h and 72h.

- a screw hole 21a passing through the supporting wall 21 in the width direction.

- a pad supporting bolt 23 (supporting member) having a head portion 23a and an axis portion 23b.

- the pad supporting bolt 23 is screwed so that the head portion 23a protrudes towards an inner surface 72i of the second jib structure 72 from a surface of the supporting wall 21 opposing to the inner surface 72i of the second jib structure 72.

- a nut 24 is fastened for fixing a position of the pad supporting bolt 23.

- a position of the sliding pad 10 installed and fitted so as to house the head portion 23a described later is properly adjusted. That is, a clearance between a sliding surface 11a of the sliding pad 10 and the inner surface 72i of the second jib structure 72 is adjusted.

- the sliding pad 10 formed into a cap shape is fitted into the pad supporting bolt 23 so as to cover the head portion 23a.

- the sliding pad 10 has a pad head portion 11 having the sliding surface 11a sliding on the inner surface 72i of the second jib structure 72, and a pad body portion 12 formed in a hollow shape and extending from an end on the opposite side of the sliding surface 11a in the pad head portion 11.

- An edge portion of the sliding surface 11a in the pad head portion 11 is formed into a curved surface.

- An inner diameter of the pad body portion 12 is formed larger than an outer diameter of the head portion 23a so as to make predetermined clearance between the pad body portion 12 and the head portion23a when the pad body portion 12 is fitted into the head portion 23a of the pad supporting bolt 23.

- the outer diameter of the head portion 23a is approximately 24mm, while the inner diameter of the pad body portion 12 is formed to be approximately 25mm. That is, the inner diameter of the pad body portion 12 is formed approximately 1mm larger than the outer diameter of the head portion 23a.

- the positions of the head portions 23a are adjusted so that a clearance between the sliding surfaces 11a located on the both sides of the third jib structure 73 is wider than a clearance in the width direction between outer surfaces 73i of the third jib structure 73, and so that the clearance is approximately 2mm to 3mm narrower than a clearance in the width direction between the inner surfaces 72i of the second jib structure 72 (approximately 200mm).

- the adjustment is desirably performed so that a pair of the sliding pads 10 are located substantially symmetrically about a central surface in the width direction of the third jib structure 73.

- the sliding pad 10 and the inner surface 72i of the second jib structure 72 are brought into abutment with each other. Thereby, movement of the third jib structure 73 in the width direction is within a predetermined range, and it is possible to reduce sliding resistance of the third jib structure 73 and the second jib structure 72.

- the first jib structure 71 is a jib structure located on the outermost side in the auxiliary jib 7. Therefore, a supporting member of the sliding pads 81, 82 and 84 and a positioning member such as a bolt can protrude outwards.

- the sliding pads 87 and 88 provided in the second jib structure 72 are always provided in the second jib structure 72 extending towards the outside of the first jib structure 71 in order to guide sliding movement of the third jib structure 73 inside the second jib structure 72.

- the sliding pad 10 is attached to the third jib structure 73 and the third jib structure 73 can slide on the inner surface 72i of the second jib structure 72.

- the sliding pad 10 in an extendable and stowable jib having at least three jib structures telescopically inserted into each other, is particularly effective in the case where the sliding pad is mounted to the base end portions of the jib structure which at least two jib structures are arranged in the outer sides thereof.

- the sliding pad for a jib according to the first embodiment is applied to the extendable and stowable auxiliary jib 7 having the three jib structures 71, 72 and 73 which are telescopically inserted into each other.

- the above sliding pad for a jib is disposed between the third jib structure 73 and the second jib structure 72, and movable with sliding on the inner surface 72i of the second jib structure 72.

- the pad supporting bolt 23 protruding towards the inner surface 72i of the second jib structure 72.

- the sliding pad 10 is fitted into the pad supporting bolt 23 so as to restrict movement of them in the perpendicular direction to the protruding direction of the pad supporting bolt 23. That is, when the third jib structure 73 is moved in the extending direction or the stowing direction, the sliding pad 10 is moved together with the pad supporting bolt 23 installed in the third jib structure 73.

- the sliding pad 10 is attached in a state of being sandwiched by the second jib structure 72 and the pad supporting bolt 23 in the protruding direction of the pad supporting bolt 23, and their movement in the protruding direction is restricted by the second jib structure 72.

- the movement of the sliding pad 10 is restricted by bringing the inner surface of the pad body portion 12 into abutment with the pad supporting bolt 23. Thereby, it is possible to surely prevent dropping-off of the sliding pad 10.

- the pad supporting bolt 23 is installed in the third jib structure 73, and it is possible to mount the sliding pad 10 to the third jib structure 73 through the pad supporting bolt 23. Therefore, there is no need for forming an excessively large hole which lowers strength of the third jib structure 73 in the third jib structure 73. Thereby, by the mounting of the sliding pad 10, it is possible to prevent the lowering of the strength of the third jib structure 73.

- the sliding pad 10 is formed as a cap-shaped pad having an opening end provided with the pad head portion 11 having the sliding surface 11a sliding on the inner surface 72i of the second jib structure 72, and having the pad body portion 12 formed in a hollow shape, the pad body portion 12 extending from the end on the opposite side of the sliding surface 11a in the pad head portion 11.

- the pad body portion 12 is fitted onto a front end of the pad supporting bolt 23.

- the protruding length of the pad supporting bolt 23 from the bracket 20 towards the inner surface 72i of the second jib structure 72 is adjustable. Therefore, by adjusting the protruding length of the pad supporting bolt 23, it is possible to adjust a clearance between the sliding surface 11a of the sliding pad 10 covered on the pad supporting bolt 23 and the inner surface 72i of the second jib structure 72.

- the pad supporting bolt 23 in which a male screw is threaded on the axis portion 23b is formed as an axial shape member.

- the pad supporting bolt 23 is screwed into the screw hole 21a formed in the bracket 20 provided in an end of the third jib structure 73. Therefore, by rotating the pad supporting bolt 23, the pad supporting bolt 23 is inserted into or out of the screw hole 21a so that the protruding length of the pad supporting bolt 23 from the bracket 20 can be continuously adjusted. Thereby, it is possible to continuously adjust the clearance between the sliding surface 11a of the sliding pad 10 by which the pad supporting bolt 23 is covered and the inner surface 72i of the second jib structure 72 with a simple mechanism, and adjustment is also easily and precisely performed.

- the clearance adjusting mechanism can be simply formed, it is possible to reduce the number of parts required for constituting the sliding pad, and it is possible to reduce manufacturing the cost. In comparison with the case where the clearance is adjusted by a shim or the like, a clearance adjustment operation can be more easily and rapidly performed.

- the opening portions 71h and 72h are formed on the wall surfaces of the first jib structure 71 on the outermost side in the auxiliary jib 7 and the second jib structure 72 disposed adjacent to and inside the first jib structure 71.

- the opening portions 71h and 72h are formed at a position where the outside of the auxiliary jib 7 are linearly communicated to the pad supporting bolt 23 through the opening portions 71h and 72h in a state that the auxiliary jib 7 is stowed.

- the third jib structure 73 is provided with the bracket 20 extending from the end surface 73e of the base end portion in the stowing direction.

- the bracket 20 has a pair of the supporting walls 21 opposing to each other in a clearance narrower than a width of the third jib structure 73 and extending in substantially parallel with the extending direction of the auxiliary jib 7.

- the pad supporting bolt 23 is screwed into the screw hole 21a formed in the supporting walls 21.

- a pair of the supporting walls 21 are arranged in the clearance narrower than the width of the third jib structure 73, and it is possible to widen the clearance between the supporting wall 21 and the inner surface 72i of the second jib structure 72.

- the sliding pad 10 and the head portion 23a of the pad supporting bolt 23 are fitted to each other so as to have a predetermined clearance in the radial direction. Therefore, within the pad body portion 12, inclination of the pad supporting bolt 23 is allowable to a predetermined extent.

- the above inclination indicates inclination of the axis portion 23b to a cylindrical axis of the pad body portion 12.

- the clearance between the sliding surfaces 11a of the sliding pad 10 is formed wider than the clearance in the width direction between the outer surfaces 73i of the third jib structure 73. Therefore, it is possible to prevent that the outer surface 73i of the third jib structure 73 is brought into abutment with the inner surface 72i of the second jib structure 72.

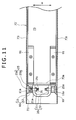

- Figs. 11 and 12 are partially sectional views showing an attachment structure of a sliding pad for a jib according to the second embodiment.

- Figs. 11 and 12 respectively correspond to Fig. 8 of the sectional arrow view by the line S5-S5 and Fig. 9 of the sectional arrow view by the line S6-S6 in Fig. 7 used in the description of the first embodiment.

- the sliding pad for a jib according to the second embodiment is different from the sliding pad according to the first embodiment in terms of a configuration of the pad supporting bolt 23 for supporting the sliding pad 10 in the first embodiment.

- Other configurations of the auxiliary jib 7 are the same as in the first embodiment.

- the same members are given the same reference numerals as the first embodiment and an explanation thereof will be omitted.

- a pad supporting bolt 25 has a head portion 25a and an axis portion 25b, and screwed into the screw hole 21a formed in the supporting wall 21 of the bracket 20.

- the pad supporting bolt 25 is screwed into the screw hole 21a so that an end of on the opposite side of the head portion 25a in the axis portion 25b extends from the supporting wall 21 to the central portion in width of the third jib structure 73.

- a plan portion 25c (engaging portion) chamfered symmetrically about the axis is partially formed.

- the axis portion 25b arranged on the opposite side of the head portion 25a sandwiching the supporting wall 21 is fastened by a nut 26 for fixing a position of the pad supporting bolt 25. It should be noted , as well as the first embodiment, that the pad supporting bolt 25 is screwed so that the head portion 25a protrudes from the surface of the supporting wall 21 opposing to the inner surface 72i of the second jib structure 72 towards the inner surface 72i of the second jib structure 72.

- the pad supporting bolt 25 is attached so that the protruding length thereof towards the inner surface 72i of the second jib structure 72 is adjustable from the inside of the bracket 20. That is, by loosening the nut 26 installed in the axis portion 25b extending to the central portion in width of the third jib structure 73, engaging a tool such as a spanner with the plan portion 25c formed in an end of the axis portion 25b and rotating the pad supporting bolt 25 to the screw hole, the protruding length of the head portion 25a is adjustable from the inside of the bracket 20.

- the protruding length of the head portion 25a is adjustable from the inside of the bracket 20 to which the pad supporting bolt 25 is attached in a state that the sliding pad 10 is attached to the pad supporting bolt 25.

- the protruding length of the head portion 25a is adjustable from the surface side opposite to the surface on the side opposing to the second jib structure 72 in the supporting wall 21, the protruding length of the head portion 25a is adjustable. Thereby, the adjustment of the clearance between the sliding surface 11a of the sliding pad 10 and the inner surface 72i of the second jib structure 72 is easily performed.

- a male screw is threaded over the substantially entire area of the axis portion 25b, and the pad supporting bolt 25 is formed as an axial shape member as a whole.

- the pad supporting bolt 25 is screwed into the screw hole 21a formed in the bracket 20 provided in the third jib structure 73 in a state that one end of the axis portion 25b protrudes towards the inside of the bracket 20.

- the plan portion 25c which is used when the pad supporting bolt 25 is rotated around the axis. It should be noted that the axis portion 25b has at least two plan portions 25c in parallel with each other.

- the end of the axis portion 25b of the pad supporting bolt 25 protrudes towards the central portion in width of the third jib structure 73, and the plan portion 25c is provided in the end. Therefore, it is possible to easily give a rotation force to the pad supporting bolt 25 by engaging the tool such as a spanner with the chamfered plan portion 25c. Thereby, since an operation of rotating and moving the pad supporting bolt 25 to the third jib structure 73 is easily performed, it is possible to efficiently adjust the clearance between the sliding surface 11a of the sliding pad 10 and the inner surface 72i of the second jib structure 72.

- the present invention is not limited to the case where the plan portion 25c is formed by cutting out the end of the axis portion 25b, but an engaging member which is used when the pad supporting bolt 25 is rotated around the axis may be fixed to the end of the axis portion 25b.

- the pad supporting bolt 25 has a function of the supporting member for supporting the sliding pad 10, as well as a function of the positioning member for adjusting the position of the sliding pad 10. Thereby, it is possible to reduce the number of parts of the sliding pad capable of adjusting the position of the sliding pad 10.

- the opening portions 71h and 72h are formed in the first jib structure 71 and the second jib structure 72 located on the outside of the third jib structure 73. Therefore, in a state that the auxiliary jib 7 is stowed, it is possible to rotate the pad supporting bolt 25 by the tool or the like through the opening portions 71h and 72h. Thereby, it is possible to further improve workability of adjusting the clearance.

- the size of the opening portions 71h and 72h are formed so that the tool is insertable.

- a lid for covering the opening portions 71h and 72h can be provided so as to make them closed except for while adjusting the clearance and performing the maintenance. Thereby, it is possible to prevent sand, water and the like from penetrating into the inside of the jib structure through the opening portions 71h and 72h.

- the present invention is not limited to a configuration that the bracket is provided in the base end portion of the jib structure and the supporting member for supporting the sliding pad such as the pad supporting bolt is attached to the bracket as in the present embodiment.

- a screw hole may be formed on a pair of left and right side walls forming a main body of a jib structure extending in the longitudinal direction so that the supporting member is attached.

- the axis portion of the pad supporting bolt extending towards the inside of the jib structure that is, the space sandwiched by a pair of the left and right side walls, is installed and the rotation force is added to the extending axis portion, then it is possible to easily adjust the position of the sliding pad fitted into the head portion of the pad supporting bolt from the inside of the jib structure.

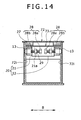

- Figs. 13 and 14 are partially sectional views showing a sliding pad for a jib according to the third embodiment.

- Figs. 13 and 14 respectively correspond to Fig. 8 of the sectional arrow view by the line S5-S5 and Fig. 9 of the sectional arrow view by the line S6-S6 in Fig. 7 used in the description of the first embodiment.

- the sliding pad for a jib according to the third embodiment is different from the sliding pad according to the first embodiment in terms of a configuration of the sliding pad 10 and the pad supporting bolt 23 in the first embodiment.

- Other configurations of the auxiliary jib 7 are the same as in the first embodiment.

- the same members are given the same reference numerals as the first embodiment and an explanation thereof will be omitted.

- a hollow supporting member 27 in a cylindrical shape is joined to a surface on the side opposing to the inner surface 72i of the second jib structure 72.

- the hollow supporting member 27 is installed so that a cylindrical center axis is substantially coaxial to a center axis of the screw hole 21a. It should be noted that the hollow supporting member 27 is joined to the bracket 20 by welding, for example.

- a bolt 28 (positioning member) is screwed into the screw hole 21a.

- the bolt 28 is screwed into the screw hole 21a so that a head portion 28a is located on the central portion in width of the third jib structure 73.

- An end of an axis portion 28b can protrude from the supporting wall 21 towards the side of the inner surface 72i of the second jib structure 72.

- a sliding pad 13 is formed into a substantially columnar shape whose outer diameter is approximately 1mm smaller than an inner diameter of the hollow supporting member 27.

- the sliding pad 13 is fitted into the inside of the hollow supporting member 27 in a state that a sliding surface 13a serving as an end surface substantially orthogonal to the columnar axial direction faces to the inner surface 72i of the second jib structure 72.

- An edge portion of the sliding surface 13a is formed into a curved surface.

- An end surface 13b on the opposite side of the sliding surface 13a is brought into abutment with the end of the axis portion 28b of the bolt 28 screwed into the screw hole 21a so that movement of the sliding pad 13 to the side of the supporting wall 21 is restricted.

- the supporting member for supporting the sliding pad 13 is formed as the hollow supporting member 27 extending towards the inner surface 72i of the second jib structure 72.

- the sliding pad 13 is formed into a columnar shape with one end serving as the sliding surface 13a, and fitted into the inside of the hollow supporting member 27 so that the sliding surface 13a protrudes outwards.

- the sliding pad 13 is formed so that a columnar height of the sliding pad 13 formed into a columnar shape is substantially the same as a columnar height of the hollow supporting member 27 formed into a cylindrical shape.

- the axis portion 28b of the bolt 28 protrudes from the supporting wall 21 towards the inside of the hollow supporting member 27 so that the sliding surface 13a of the sliding pad 13 is in a state of protruding outwards from the hollow supporting member 27. Therefore, it is possible to prevent that the hollow supporting member 27 is brought into abutment with the inner surface 72i of the second jib structure 72.

- the bolt 28 serving as the positioning member for supporting the end surface 13b on the opposite side of the sliding surface 13a in the sliding pad 13 is provided.

- the bolt 28 is formed as an axial shape member in which a male screw is threaded on the axis portion 28b thereof, and the bolt 28 is screwed into the screw hole 21a formed in the bracket 20 provided in the third jib structure 73 so as to move coaxially to the hollow supporting member 27.

- An extendable and stowable jib (7) comprises a plurality of jib structures (71, 72 and 73) telescopically inserted into each other.

- a sliding pad (10) sliding on an inner surface (72i) of an outer jib structure (72) is attached to the base end portion of an inner jib structure (73).

- the inner jib structure (73) is provided with a supporting member (23) protruding towards the inner surface (72i) of the outer jib structure (72).

- the sliding pad (10) is connected to the supporting member (23) so as to restrict movement in the perpendicular direction to the protruding direction of the supporting member (23).

- the present invention can prevent from damaging the jib structure due to a screw and drop-off of the sliding pad.

- the present invention does not lower strength of the jib structure.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Jib Cranes (AREA)

Abstract

Description

- The present invention relates to an extendable and stowable jib of a working machine such as a crane. Particularly, the present invention relates to a structure of a sliding pad to be attached to the above jib.

- An example of a working machine to which the present invention is applied includes a crane and an elevating work vehicle. An extendable and stowable jib provided in the above working machine has a plurality of jib structures which are telescopically inserted into each other. Between an inner jib structure and an outer jib structure arranged on the outside of the inner jib structure, a sliding pad is provided. This kind of sliding pad is installed to an outer surface in the base end portion of the inner jib structure and an inner surface on the front end portion of the outer jib structure so as to stably support the jib structures when a base end portion of the inner jib structure is located anywhere inside the inner jib structure.

- As examples of patent documents showing the sliding pad arranged in the base end portion of the inner jib structure, Japanese Examined Utility Model No.

Sho 61-16306 Hei 7-35484 - Firstly, a description will be given to a side pad disclosed in Japanese Examined Utility Model No.

Sho61-16306 - Next, a description will be given to a side pad disclosed in Japanese Utility Model Laid-Open No.

Hei7-35484 - However, in the case of the sliding pad for a jib disclosed in Japanese Examined Utility Model No.

Sho61-16306 Hei7-35484 - It is an object of the present invention to provide a jib capable of preventing dropping-off of a sliding pad and damage of a jib structure due to a dropped screw. Further, it is another object of the present invention to provide a jib capable of attaching the sliding pad to the jib structure without lowering strength of the jib structure.

- The jib according to the present invention is an extendable and stowable jib comprises a plurality of jib structures which are telescopically inserted into each other. The jib according to the present invention is provided with an inner jib structure, an outer jib structure arranged on the outside of the inner jib structure, and a sliding pad arranged between the inner jib structure and the outer jib structure. The sliding pad is attached on the base end portion of the inner jib structure slidably on an inner surface of the outer jib structure.

- The first aspect of the present invention is that a supporting member protruding towards the inner surface of the outer jib structure is provided in the inner jib structure, and the sliding pad is connected to the supporting member so as to restrict movement in the perpendicular direction to the protruding direction of the supporting member.

- According to the above configuration, by connecting to the supporting member, it is possible to attach the sliding pad, and there is no need for a screw or the like in the attachment of the sliding pad. Therefore, it is possible to prevent the screw or the like from damaging the inner surface of the outer jib structure.

- The sliding pad is attached in a state of being sandwiched by the outer jib structure and the supporting member in the protruding direction of the supporting member, and the movement of them in the protruding direction is restricted by the outer jib structure. In the perpendicular direction to the protruding direction, the movement is restricted by the supporting member. Thereby, it is possible to surely prevent the sliding pad from dropping off.

- Further, the supporting member is installed in the jib structure so that the sliding pad can be attached to the jib structure through the supporting member. Therefore, there is no need for forming a hole which lowers the strength of the jib structure in the jib structure. Consequently, it is possible to prevent the lowering of the strength of the jib structure.

- It should be noted that the jib includes a main jib capable of raising and lowering mounted in an upper rotating body of a crane or the like, for example, and an auxiliary jib connected to a front end of the main jib. That is, there is a case where the main jib and constituent components thereof are called the "boom". In such a case, the auxiliary jib is sometimes simply called the "jib". However, the term "jib" in the present specification includes not only the main jib but also the auxiliary jib.

- As the second aspect of the jib according to the present invention, the sliding pad has a pad head portion having a sliding surface sliding on the inner surface of the outer jib structure, and a pad body portion formed in a hollow shape and extending from an end on the opposite side of the sliding surface of the pad head portion. The pad body portion is connected to an end of the supporting member.

- According to the above configuration, by connecting the pad body portion to the end of the supporting member in substantially parallel with the protruding direction of the supporting member, it is possible to mount the sliding pad. Therefore, mounting operation is easily performed. Since it is possible to make the supporting member simple, forming the supporting member is easily performed.

- As the third aspect of the jib according to the present invention, a protruding length of the supporting member is adjustable from the inner jib structure.

- According to the above configuration, by adjusting the protruding length of the supporting member, it is possible to adjust a clearance between the sliding surface of the sliding pad and the inner surface of the outer jib structure.

- As the fourth aspect of the jib according to the present invention, the supporting member is formed in an axial shape, and a male screw is threaded on at least a part of the axial portion of the supporting member. The supporting member is screwed into a screw hole formed in the inner jib structure.

- According to the above configuration, by rotating the supporting member, the supporting member is inserted into or out of the screw hole so that the protruding length of the supporting member from the inner jib structure can be continuously adjusted. Thereby, it is possible to continuously adjust the clearance between the sliding surface of the sliding pad and the inner surface of the outer jib structure with a simple mechanism, and adjustment is also easily and precisely performed. It is possible to reduce the number of parts for constituting the clearance adjusting mechanism due to the simple configuration, and it is possible to reduce manufacturing cost. In comparison with the case where the clearance is adjusted by a shim or the like, it is possible to more easily and rapidly perform a clearance adjustment operation.

- As the fifth aspect of the jib according to the present invention, the protruding length of the supporting member is adjustable from the inside of the inner jib structure.

- According to the above configuration, in a state that the sliding pad is mounted to the supporting member, it is possible to adjust the protruding length of the supporting member from the inside of the jib structure to which the supporting member is mounted. Therefore, the adjustment of the clearance between the sliding surface of the sliding pad and the inner surface of the outer jib structure is easily performed.

- As the sixth aspect of the jib according to the present invention, the supporting member is formed in an axial shape, and a male screw is threaded on at least a part of the axial portion of the supporting member. The supporting member is screwed into a screw hole formed in the inner jib structure in a state that an end of the supporting member protrudes towards the inside of the inner jib structure. An engaging portion is provided in the end and the supporting member can be rotated around an axis by the engaging portion.

- According to the above configuration, the end of the supporting member protrudes towards the inside of the jib, and the engaging portion is provided in the end. Therefore, it is possible to rotate the supporting member by engaging a tool or the like with the engaging portion. Thereby, since operation of rotating and moving the supporting member to the jib is easily performed, it is possible to efficiently adjust the clearance between the sliding surface of the sliding pad and the inner surface of the outer jib structure.

- As the seventh aspect of the jib according to the present invention, the supporting member extends towards the inner surface of the outer jib structure and is formed in a hollow shape. The sliding pad is fitted into the inside of the supporting member so as to outwardly protrude one end serving as a sliding surface.

- According to the above configuration, by inserting the sliding pad into the supporting member, it is possible to mount the sliding pad to the jib structure. Therefore, the mounting operation is easily performed. Since the sliding pad is formed in a simple shape, forming the sliding pad is easily performed.

- As the eighth aspect of the jib according to the present invention, a positioning member for supporting an end surface on the opposite side of the sliding surface in the sliding pad is provided therewith. A male screw is threaded on at least a part of the axial portion of the positioning member, and the positioning member is screwed into a screw hole formed in the inner jib structure.

- According to the above configuration, by adjusting a position of the positioning member, it is possible to adjust a position where the sliding pad is supported. Thereby, it is possible to adjust the clearance between the sliding surface of the sliding pad and the inner surface of the outer jib structure.

- As the ninth aspect of the jib according to the present invention, opening portions are formed on wall surfaces of a plurality of the jib structures constituting the jib. The opening portions are formed at a position where the outside of the jib are linearly communicated to the supporting member through the opening portions in a state that the jib is stowed.

- According to the above configuration, through the opening portions formed on the wall surfaces of the jib structures in a state that the jib is stowed, the mounting and positioning adjustment of the sliding pad are easily performed. Maintenance of the sliding pad or the like is also easily performed.

- As the tenth aspect of the jib according to the present invention, the inner jib structure is provided with a bracket extending from an end surface of a base end portion of the inner jib structure in the stowing direction. The bracket has a pair of supporting walls extending opposing to each other in a clearance narrower than a width of the inner jib structure, and the supporting member is fixed to the supporting walls.

- According to the above configuration, a pair of the supporting walls are arranged in the clearance narrower than the width of the inner jib structure. Therefore, it is possible to widen the clearance between the supporting walls and the inner surface of the outer jib structure. In such a case, it is possible to further increase the length of the supporting member protruding from the supporting walls, and it is also possible to increase the length of the sliding pad to be fitted into the supporting member in the protruding direction. Therefore, it is possible to further increase the depth for fitting the sliding pad into the supporting member, and it is possible to surely fix the sliding pad by the supporting member.

-

-

Fig. 1 is an entire view showing a wheel crane provided with a sliding pad for a jib according to the first embodiment of the present invention; -

Fig. 2 is a partially sectional view showing a state that an auxiliary jib inFig. 1 is completely stowed; -

Fig. 3 is a sectional arrow view by line S1-S1 inFig. 2 ; -

Fig. 4 is a sectional arrow view by line S2-S2 inFig. 2 ; -

Fig. 5 is a sectional arrow view by line S3-S3 inFig. 2 ; -

Fig. 6 is a sectional arrow view by line S4-S4 inFig. 2 ; -

Fig. 7 is an enlarged partially sectional view of the base end portion of the auxiliary jib shown inFig. 2 ; -

Fig. 8 is a partially sectional arrow view by line S5-S5 inFig. 7 ; -

Fig. 9 is a partially sectional arrow view by line S6-S6 inFig. 7 ; -

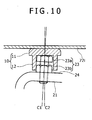

Fig. 10 is an enlarged view of a portion in the vicinity of the sliding pad; -

Fig. 11 is a partially sectional view showing a sliding pad for a jib according to the second embodiment; -

Fig. 12 is another partially sectional view according to the second embodiment; -

Fig. 13 is a partially sectional view showing a sliding pad for a jib according to the third embodiment; and -

Fig. 14 is another partially sectional view according to the third embodiment. - Hereinafter, a description will be given to a best mode for carrying out the present invention with reference to the drawings.

-

Fig. 1 is an entire view showing a wheel crane provided with a sliding pad for a jib according to the first embodiment of the present invention. - A

wheel crane 1 is provided with a lower traveling body 2 havingwheels rotation bearing 3. In the upper rotating body 4 is provided acab 5 serving as an operator cab at the time of traveling and a control cab at the time of performing a crane work. In the upper rotating body 4 are also provided amain jib 6 extending towards the front side of thecab 5 and anauxiliary jib 7 connected to a front end portion of themain jib 6 in the extending direction. - The

main jib 6 is formed into a box structure, and it comprises abasic jib structure 6a and a plurality ofmovable jib structures 6b which are telescopically, extendably and stowably inserted into each other. A base end portion of the most outerbasic jib structure 6a is pivoted by a jib foot pin (not shown) on the upper rotating body 4. It is possible to raise and lower themain jib 6. The jib foot pin functions as a supporting point. - The

auxiliary jib 7 is also formed into a box structure, and it comprises afirst jib structure 71, asecond jib structure 72 and athird jib structure 73 which are telescopically and extendably inserted into each other. It should be noted thatFig. 1 shows an intermediate projecting state in which thesecond jib structure 72 housing thethird jib structure 73 extends forward from thefirst jib structure 71. - A base end portion of the

first jib structure 71 located at the most outer part of theauxiliary jib 7 is axially supported by a supportingaxis 8 located on the lower side of the front end portion of themain jib 6. A front end portion of thefirst jib structure 71 and the front end portion of themain jib 6 are coupled with each other through ajib suspension rod 9 serving as a coupling member in a rod shape. As mentioned above, both ends of thefirst jib structure 71 of theauxiliary jib 7 are coupled with themain jib 6 and theauxiliary jib 7 is raised and lowered in accordance with raising and lowering of themain jib 6. - The sliding pad for a jib according to the embodiment of the present invention is applicable to the

main jib 6 and theauxiliary jib 7 serving as working attachment of thewheel crane 1 mentioned above. In the present embodiment, the case where the sliding pad according to the present invention is applied to theauxiliary jib 7 will be mentioned as an example. It should be noted that the sliding pad according to the present embodiment is applied to a slidingpad 10 disposed between thesecond jib structure 72 and thethird jib structure 73 of theauxiliary jib 7. -

Fig. 2 is a partially sectional view showing theauxiliary jib 7 inFig. 1 , and a view schematically showing a state that theauxiliary jib 7 is completely stowed. That is, thesecond jib structure 72 and thethird jib structure 73 are drawn to the side of thefirst jib structure 71.Figs. 3 to 6 are sectional arrow views by lines S1-S1, S2-S2, S3-S3 and S4-S4 respectively inFig. 2 . - As shown in

Fig. 2 , in theauxiliary jib 7, thefirst jib structure 71, thesecond jib structure 72 and thethird jib structure 73 are telescopically fitted in order from outside. As shown inFigs. 3 to 6 , vertical cross sections of thejib structures 71 to 73 in the longitudinal direction are substantially formed into rectangular shape. - The

first jib structure 71 is a square cylindrical jib structure located on the outermost side in theauxiliary jib 7. Thesecond jib structure 72 can slide along an inner surface of a peripheral wall of thefirst jib structure 71. - The

second jib structure 72 is a square cylindrical jib structure located adjacent to and inside thefirst jib structure 71. In the front end portion in the extending direction shown by an arrow A1 inFigs. 2 and7 , as shown inFig. 3 , thesecond jib structure 72 is movable in the extending direction of the jib structure or in the stowing direction which is the opposite direction to the extending direction in a state that movement thereof in the width direction is restricted within a predetermined range by slidingpads side walls 71c of thefirst jib structure 71. Here, the width direction indicates a direction shown by an arrow B inFigs. 3 to 6 . The stowing direction indicates a direction shown by an arrow A2 inFig. 2 . In the front end portion in the extending direction, alower portion 72a of thesecond jib structure 72 is supported by alower roller 83 having arotation axis 83a extending in the width direction which is installed in the front end of thefirst jib structure 71. - At a position which is in approximately one fourth of the overall length of the

second jib structure 72 and is closer to the base end side, as shown inFig. 4 , the movement of thesecond jib structure 72 in the width direction is restricted from the front end of thefirst jib structure 71 within a predetermined range by slidingpads 84 installed inside walls 71c of thefirst jib structure 71. On the base end portion side from a position where the slidingpad 84 is installed in thefirst jib structure 71, is installed anupper roller 85 having arotation axis 85a extending in the width direction. By theupper roller 85, anupper portion 72b of thesecond jib structure 72 is guided. - As shown in

Fig. 2 , thesecond jib structure 72 is provided with aninclined wall portion 72t inclined so as to come apart from alower portion 71a of thefirst jib structure 71 as coming close to the base end side, in the vicinity of a base end portion thereof. In theinclined wall portion 72t is installed aroller 86 having a rotation axis extending in the width direction of thesecond jib structure 72. The base end portion of thesecond jib structure 72 is supported by thelower portion 71a of thefirst jib structure 71 by theroller 86. - The

third jib structure 73 is a square cylinder jib structure disposed adjacent to and inside thesecond jib structure 72, and has a main body formed in a square cylinder and abracket 20 installed in the base end portion of the main body. In the front end portion in the extending direction, as shown inFig. 5 , thethird jib structure 73 is slidable in the extending direction or the stowing direction in a state that movement thereof in the width direction is restricted within a predetermined range by slidingpads side walls 72c of thesecond jib structure 72. In the front end portion in the extending direction, as shown inFig. 6 , thelower portion 73a of thethird jib structure 73 is supported by alower roller 89 having arotation axis 89a extending in the width direction which is installed in the front end of thesecond jib structure 72. It should be noted that the slidingpads second jib structure 72 and thelower roller 89 are installed in the vicinity of the front end portion of thesecond jib structure 72 extending towards the outside of thefirst jib structure 71 in a state that theauxiliary jib 7 is completely stowed. - Next, a detailed description will be given to a structure in the base end portion of the

auxiliary jib 7 to which the sliding pad according to the present invention is applied.Fig. 7 is an enlarged partially sectional view of thesecond jib structure 72 and thethird jib structure 73 in the base end portion of theauxiliary jib 7 shown inFig. 2 .Fig. 8 is a partially sectional arrow view by the line S5-S5 inFig. 7 , showing a cross section of thesecond jib structure 72 and the slidingpad 10.Fig. 9 is a partially sectional arrow view by the line S6-S6 inFig. 7 , showing a cross section of thesecond jib structure 72. - As shown in

Fig. 7 , thethird jib structure 73 is provided with aninclined wall portion 73t inclined so as to come apart from alower portion 72a of thesecond jib structure 72 as closer to the base end side, in the vicinity of a base end portion. In theinclined wall portion 73t is installed aroller 90 having a rotation axis extending in the width direction of thethird jib structure 73. The base end portion of thethird jib structure 73 is supported by thelower portion 72a of thesecond jib structure 72 by theroller 90. - As shown in

Figs. 7 and8 , in anupper portion 73b of the base end portion of thethird jib structure 73, in line in the width direction thereof, are installed slidingpads 91 substantially formed into a rectangular shape extending in parallel with the longitudinal direction of thethird jib structure 73. The slidingpads 91 are formed so as to slide on theupper portion 72b of thesecond jib structure 72. It should be noted that the slidingpad 91 is fixed to theupper portion 73b of thethird jib structure 73 at two points in the longitudinal direction. - In an

end surface 73e of the base end portion of thethird jib structure 73, thebracket 20 extending from theend surface 73e in the stowing direction is integrally formed. Thebracket 20 is formed of a steel plate substantially curved in a U shape and it is provided with a pair of supportingwalls 21 extending in parallel from theend surface 73e of the base end portion of thethird jib structure 73 in the width direction with leaving a predetermined clearance, and acoupling wall 22 for linking front ends of a pair of the supporting walls to each other. Thebracket 20 is fixed to theend surface 73e of the base end portion of thethird jib structure 73 by welding, for example. A pair of the supportingwalls 21 are formed so as to oppose to each other in a clearance narrower than a width of thethird jib structure 73. For example, the supportingwalls 21 are formed so that the clearance is approximately one half of the width of thethird jib structure 73. - In the

inclined wall portion 72t of thesecond jib structure 72 is formed anopening portion 72h. Theopening portion 72h is an opening with a diameter of approximately 100mm, and formed at a position where the outside of thesecond jib structure 72 are linearly communicated to thebracket 20 through theopening portion 72h. Specifically, theopening portion 72h is formed so as to include at least a part of a position where thebracket 20 is orthographically projected to theinclined wall portion 72t. It should be noted , as shown inFig. 2 , that thelower portion 71a of thefirst jib structure 71 has anopening portion 71h at a position in the vicinity of theopening portion 72h of thesecond jib structure 72. Thereby, the outside of theauxiliary jib 7 is linearly communicated to thebracket 20 and the slidingpad 10 installed in thebracket 20 through the openingportions - As shown in

Figs. 8 and9 , in the supportingwall 21 is formed ascrew hole 21a passing through the supportingwall 21 in the width direction. Into thescrew hole 21a, is screwed a pad supporting bolt 23 (supporting member) having ahead portion 23a and anaxis portion 23b. Thepad supporting bolt 23 is screwed so that thehead portion 23a protrudes towards aninner surface 72i of thesecond jib structure 72 from a surface of the supportingwall 21 opposing to theinner surface 72i of thesecond jib structure 72. In theaxis portion 23b between thehead portion 23a and the surface of the supportingwall 21, anut 24 is fastened for fixing a position of thepad supporting bolt 23. By adjusting a protruding length of thehead portion 23a of thepad supporting bolt 23, a position of the slidingpad 10 installed and fitted so as to house thehead portion 23a described later is properly adjusted. That is, a clearance between a slidingsurface 11a of the slidingpad 10 and theinner surface 72i of thesecond jib structure 72 is adjusted. - The sliding

pad 10 formed into a cap shape is fitted into thepad supporting bolt 23 so as to cover thehead portion 23a. The slidingpad 10 has apad head portion 11 having the slidingsurface 11a sliding on theinner surface 72i of thesecond jib structure 72, and apad body portion 12 formed in a hollow shape and extending from an end on the opposite side of the slidingsurface 11a in thepad head portion 11. An edge portion of the slidingsurface 11a in thepad head portion 11 is formed into a curved surface. - An inner diameter of the

pad body portion 12 is formed larger than an outer diameter of thehead portion 23a so as to make predetermined clearance between thepad body portion 12 and the head portion23a when thepad body portion 12 is fitted into thehead portion 23a of thepad supporting bolt 23. For example, the outer diameter of thehead portion 23a is approximately 24mm, while the inner diameter of thepad body portion 12 is formed to be approximately 25mm. That is, the inner diameter of thepad body portion 12 is formed approximately 1mm larger than the outer diameter of thehead portion 23a. - When a pair of the sliding

pads 10 are fitted into thehead portions 23a, the positions of thehead portions 23a are adjusted so that a clearance between the slidingsurfaces 11a located on the both sides of thethird jib structure 73 is wider than a clearance in the width direction betweenouter surfaces 73i of thethird jib structure 73, and so that the clearance is approximately 2mm to 3mm narrower than a clearance in the width direction between theinner surfaces 72i of the second jib structure 72 (approximately 200mm). It should be noted that the adjustment is desirably performed so that a pair of the slidingpads 10 are located substantially symmetrically about a central surface in the width direction of thethird jib structure 73. - As mentioned above, by mounting the sliding

pads 10 on the both ends in the width direction of the base end portion of thethird jib structure 73, the slidingpad 10 and theinner surface 72i of thesecond jib structure 72 are brought into abutment with each other. Thereby, movement of thethird jib structure 73 in the width direction is within a predetermined range, and it is possible to reduce sliding resistance of thethird jib structure 73 and thesecond jib structure 72. - Here, as shown in

Figs. 3 and4 , with regard to the slidingpads second jib structure 72 inside thefirst jib structure 71, thefirst jib structure 71 is a jib structure located on the outermost side in theauxiliary jib 7. Therefore, a supporting member of the slidingpads pads second jib structure 72 are always provided in thesecond jib structure 72 extending towards the outside of thefirst jib structure 71 in order to guide sliding movement of thethird jib structure 73 inside thesecond jib structure 72. Therefore, a supporting member of the slidingpads second jib structure 72 comes inside of thefirst jib structure 71 in the stowed state of theauxiliary jib 7, there is a fear that the pad might contact with thefirst jib structure 71. Therefore, it is difficult to adopt a sliding pad protruding towards the outside of thesecond jib structure 72. In the sliding pad according to the present embodiment, the slidingpad 10 is attached to thethird jib structure 73 and thethird jib structure 73 can slide on theinner surface 72i of thesecond jib structure 72. Therefore, an attachment member of the slidingpad 10 does not protrude from thesecond jib structure 72 and it does not contact with thefirst jib structure 71. Consequently, the sliding pad according to the present invention, in an extendable and stowable jib having at least three jib structures telescopically inserted into each other, is particularly effective in the case where the sliding pad is mounted to the base end portions of the jib structure which at least two jib structures are arranged in the outer sides thereof. - As mentioned above, the sliding pad for a jib according to the first embodiment is applied to the extendable and stowable

auxiliary jib 7 having the threejib structures third jib structure 73 and thesecond jib structure 72, and movable with sliding on theinner surface 72i of thesecond jib structure 72. - In the

third jib structure 73, is installed thepad supporting bolt 23 protruding towards theinner surface 72i of thesecond jib structure 72. The slidingpad 10 is fitted into thepad supporting bolt 23 so as to restrict movement of them in the perpendicular direction to the protruding direction of thepad supporting bolt 23. That is, when thethird jib structure 73 is moved in the extending direction or the stowing direction, the slidingpad 10 is moved together with thepad supporting bolt 23 installed in thethird jib structure 73. - According to the above configuration, by fitting into the

pad supporting bolt 23, it is possible to attach the slidingpad 10, and there is no need for a screw or the like in the attachment of the slidingpad 10. Therefore, it is possible to prevent from damaging theinner surface 72i of thesecond jib structure 72 by the screw or the like. - The sliding

pad 10 is attached in a state of being sandwiched by thesecond jib structure 72 and thepad supporting bolt 23 in the protruding direction of thepad supporting bolt 23, and their movement in the protruding direction is restricted by thesecond jib structure 72. In the perpendicular direction to the protruding direction, the movement of the slidingpad 10 is restricted by bringing the inner surface of thepad body portion 12 into abutment with thepad supporting bolt 23. Thereby, it is possible to surely prevent dropping-off of the slidingpad 10. - Further, in the present embodiment, the

pad supporting bolt 23 is installed in thethird jib structure 73, and it is possible to mount the slidingpad 10 to thethird jib structure 73 through thepad supporting bolt 23. Therefore, there is no need for forming an excessively large hole which lowers strength of thethird jib structure 73 in thethird jib structure 73. Thereby, by the mounting of the slidingpad 10, it is possible to prevent the lowering of the strength of thethird jib structure 73. - The sliding

pad 10 is formed as a cap-shaped pad having an opening end provided with thepad head portion 11 having the slidingsurface 11a sliding on theinner surface 72i of thesecond jib structure 72, and having thepad body portion 12 formed in a hollow shape, thepad body portion 12 extending from the end on the opposite side of the slidingsurface 11a in thepad head portion 11. In the slidingpad 10, thepad body portion 12 is fitted onto a front end of thepad supporting bolt 23. - According to the above configuration, by fitting the

pad body portion 12 into the front end of thepad supporting bolt 23 in substantially parallel with the protruding direction of thepad supporting bolt 23, it is possible to mount the slidingpad 10. Therefore, mounting operation is easily performed. Since it is possible to make the shape of thepad supporting bolt 23 simple, there is no need for performing a complicated treatment to thepad supporting bolt 23, and it is possible to reduce the cost. - The protruding length of the

pad supporting bolt 23 from thebracket 20 towards theinner surface 72i of thesecond jib structure 72 is adjustable. Therefore, by adjusting the protruding length of thepad supporting bolt 23, it is possible to adjust a clearance between the slidingsurface 11a of the slidingpad 10 covered on thepad supporting bolt 23 and theinner surface 72i of thesecond jib structure 72. - The

pad supporting bolt 23 in which a male screw is threaded on theaxis portion 23b is formed as an axial shape member. Thepad supporting bolt 23 is screwed into thescrew hole 21a formed in thebracket 20 provided in an end of thethird jib structure 73. Therefore, by rotating thepad supporting bolt 23, thepad supporting bolt 23 is inserted into or out of thescrew hole 21a so that the protruding length of thepad supporting bolt 23 from thebracket 20 can be continuously adjusted. Thereby, it is possible to continuously adjust the clearance between the slidingsurface 11a of the slidingpad 10 by which thepad supporting bolt 23 is covered and theinner surface 72i of thesecond jib structure 72 with a simple mechanism, and adjustment is also easily and precisely performed. In such a case, since the clearance adjusting mechanism can be simply formed, it is possible to reduce the number of parts required for constituting the sliding pad, and it is possible to reduce manufacturing the cost. In comparison with the case where the clearance is adjusted by a shim or the like, a clearance adjustment operation can be more easily and rapidly performed. - On the wall surfaces of the

first jib structure 71 on the outermost side in theauxiliary jib 7 and thesecond jib structure 72 disposed adjacent to and inside thefirst jib structure 71, are formed the openingportions portions auxiliary jib 7 are linearly communicated to thepad supporting bolt 23 through the openingportions auxiliary jib 7 is stowed. - According to the above configuration, in a state that the

auxiliary jib 7 is stowed, maintenance of the slidingpad 10 is easily performed through the openingportions first jib structure 71 and thesecond jib structure 72. - The

third jib structure 73 is provided with thebracket 20 extending from theend surface 73e of the base end portion in the stowing direction. Thebracket 20 has a pair of the supportingwalls 21 opposing to each other in a clearance narrower than a width of thethird jib structure 73 and extending in substantially parallel with the extending direction of theauxiliary jib 7. Into thescrew hole 21a formed in the supportingwalls 21 is screwed thepad supporting bolt 23. - According to the above configuration, a pair of the supporting

walls 21 are arranged in the clearance narrower than the width of thethird jib structure 73, and it is possible to widen the clearance between the supportingwall 21 and theinner surface 72i of thesecond jib structure 72. In such a case, it is possible to further increase a length of thepad supporting bolt 23 protruding from the supportingwall 21, and it is also possible to increase a length of the slidingpad 10 fitted into thepad supporting bolt 23 in the protruding direction. Therefore, it is possible to further increase a depth for fitting the slidingpad 10 into thepad supporting bolt 23, and it is possible to surely fix the slidingpad 10 by thepad supporting bolt 23. - The sliding

pad 10 and thehead portion 23a of thepad supporting bolt 23 are fitted to each other so as to have a predetermined clearance in the radial direction. Therefore, within thepad body portion 12, inclination of thepad supporting bolt 23 is allowable to a predetermined extent. The above inclination indicates inclination of theaxis portion 23b to a cylindrical axis of thepad body portion 12. Thereby, for example, as shown in an enlarged view of a part in the vicinity of the slidingpad 10 inFig. 10 , even in the case where thethird jib structure 73 is inclined during the stowing action of theauxiliary jib 7, and an axis C1 of thepad supporting bolt 23 is moved in a state where the axis is not orthogonal to theinner surface 72i of thesecond jib structure 72, the slidingsurface 11a of the slidingpad 10 and theinner surface 72i of thesecond jib structure 72 are maintained in parallel with each other. That is, a cylindrical axis C2 of the slidingpad 10 is maintained in an orthogonal state to theinner surface 72i. Thereby, it is possible to prevent unbalanced abrasion of the slidingpad 10, and it is possible to improve durability. - It is also possible to prevent that the sliding

pad 10 is partly brought into contact with theinner surface 72i of thesecond jib structure 72 and thereby large bending moment is imposed on thepad supporting bolt 23. Thereby, there is no need for increasing girth of theaxis portion 23b of thepad supporting bolt 23 in order to ensure the strength. That is, there is no need for increasing size of the supporting member, and it is possible to reduce the size of the supporting member of the sliding pad. - The clearance between the sliding

surfaces 11a of the slidingpad 10 is formed wider than the clearance in the width direction between theouter surfaces 73i of thethird jib structure 73. Therefore, it is possible to prevent that theouter surface 73i of thethird jib structure 73 is brought into abutment with theinner surface 72i of thesecond jib structure 72. -

Figs. 11 and12 are partially sectional views showing an attachment structure of a sliding pad for a jib according to the second embodiment.Figs. 11 and12 respectively correspond toFig. 8 of the sectional arrow view by the line S5-S5 andFig. 9 of the sectional arrow view by the line S6-S6 inFig. 7 used in the description of the first embodiment. - The sliding pad for a jib according to the second embodiment is different from the sliding pad according to the first embodiment in terms of a configuration of the