EP1968355B1 - Induction coil and device for inductive heating of workpieces - Google Patents

Induction coil and device for inductive heating of workpieces Download PDFInfo

- Publication number

- EP1968355B1 EP1968355B1 EP20070004759 EP07004759A EP1968355B1 EP 1968355 B1 EP1968355 B1 EP 1968355B1 EP 20070004759 EP20070004759 EP 20070004759 EP 07004759 A EP07004759 A EP 07004759A EP 1968355 B1 EP1968355 B1 EP 1968355B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- induction coil

- turns

- flat

- turn

- coil

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 230000006698 induction Effects 0.000 title claims description 85

- 238000010438 heat treatment Methods 0.000 title claims description 17

- 230000001939 inductive effect Effects 0.000 title claims description 15

- 229910052802 copper Inorganic materials 0.000 claims description 7

- 239000010949 copper Substances 0.000 claims description 7

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 claims description 6

- 239000002826 coolant Substances 0.000 claims description 5

- 239000004809 Teflon Substances 0.000 claims description 4

- 229920006362 Teflon® Polymers 0.000 claims description 4

- 239000000463 material Substances 0.000 claims description 3

- 229910000859 α-Fe Inorganic materials 0.000 claims description 3

- 238000010276 construction Methods 0.000 claims 1

- 230000011664 signaling Effects 0.000 claims 1

- 238000004804 winding Methods 0.000 description 50

- 239000004020 conductor Substances 0.000 description 14

- 230000015572 biosynthetic process Effects 0.000 description 9

- 238000005755 formation reaction Methods 0.000 description 9

- 230000000694 effects Effects 0.000 description 6

- 238000007789 sealing Methods 0.000 description 6

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 6

- 238000001816 cooling Methods 0.000 description 5

- 238000011161 development Methods 0.000 description 5

- 230000018109 developmental process Effects 0.000 description 5

- 238000003754 machining Methods 0.000 description 5

- 239000012141 concentrate Substances 0.000 description 4

- 230000005672 electromagnetic field Effects 0.000 description 3

- 230000003321 amplification Effects 0.000 description 2

- 239000011888 foil Substances 0.000 description 2

- 238000000465 moulding Methods 0.000 description 2

- 238000003199 nucleic acid amplification method Methods 0.000 description 2

- 238000004026 adhesive bonding Methods 0.000 description 1

- 239000003990 capacitor Substances 0.000 description 1

- 238000005253 cladding Methods 0.000 description 1

- 150000001879 copper Chemical class 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 238000002955 isolation Methods 0.000 description 1

- 238000005304 joining Methods 0.000 description 1

- 238000007493 shaping process Methods 0.000 description 1

- 229910000679 solder Inorganic materials 0.000 description 1

- 238000005476 soldering Methods 0.000 description 1

- 239000006228 supernatant Substances 0.000 description 1

- 238000010792 warming Methods 0.000 description 1

- 238000003466 welding Methods 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05B—ELECTRIC HEATING; ELECTRIC LIGHT SOURCES NOT OTHERWISE PROVIDED FOR; CIRCUIT ARRANGEMENTS FOR ELECTRIC LIGHT SOURCES, IN GENERAL

- H05B6/00—Heating by electric, magnetic or electromagnetic fields

- H05B6/02—Induction heating

- H05B6/36—Coil arrangements

- H05B6/362—Coil arrangements with flat coil conductors

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05B—ELECTRIC HEATING; ELECTRIC LIGHT SOURCES NOT OTHERWISE PROVIDED FOR; CIRCUIT ARRANGEMENTS FOR ELECTRIC LIGHT SOURCES, IN GENERAL

- H05B6/00—Heating by electric, magnetic or electromagnetic fields

- H05B6/02—Induction heating

- H05B6/36—Coil arrangements

- H05B6/44—Coil arrangements having more than one coil or coil segment

Definitions

- the present invention relates to an induction coil for inductive heating of workpieces, which has a plurality of turns, wherein at least one of the turns is at least partially flat, according to the preamble of patent claim 1.

- the invention relates to a device for inductive heating of workpieces, comprising a high-frequency generator (HF generator) in signal-operative connection with at least one induction coil, according to the preamble of patent claim 11.

- a high-frequency generator HF generator

- Such devices are used for inductive heating of workpieces containing electrically conductive components, and are used for example for the hardening of workpieces, for joining (welding, gluing) of workpieces or for sealing containers.

- Devices for inductive heating basically consist of a high-frequency generator and an induction coil (or in short: coil), which is usually arranged in a processing head.

- the coil is either flat in a plane or three-dimensional, in particular helical or tunnel-shaped, wound. It usually consists either of copper pipe, which is flowed through with water for cooling, or of stranded wire. Coils made of stranded wire can be cooled by air. It is also known to surround the coil with a Ferrritumhüllung that focuses the electromagnetic field in the direction of application.

- the coil is typically incorporated in a series or parallel resonant circuit that is driven near the resonant frequency to produce current spikes in the coil. Due to the electromagnetic field of the induction coil eddy currents are generated in the electrically conductive components of the workpieces, which lead to a warming.

- the machining head which contains the induction coil, is often arranged above a conveying device, with the aid of which the workpieces to be heated under the coil or through it. It is also possible to immerse the workpieces in the coil or coil in the workpieces.

- An induction coil for inductive heating of workpieces having a plurality of turns is known from US 5,156,237 DE 23 31 004 known.

- a planar winding is surrounded in a radially inner region by a single, radially outer winding, wherein both windings are arranged concentrically in a common plane.

- the two windings are also arranged concentrically in a common plane, wherein the outer winding is arranged in a groove of the inner winding.

- the invention has for its object to further develop an induction coil or a device of the type mentioned in each case that a high concentration and gain effect on the magnetic field generated and thus the heating effect and energy efficiency can be improved.

- Efindungsfer is an induction coil for inductive heating of workpieces, which has a plurality of turns, characterized in that the planar winding extends at least over a covered area of the other turns, wherein either the induction coil flat and with a substantially annular, flat Winding under the other, spirally extending turns is formed, wherein the flat winding is parallel to the coil plane of the remaining turns; or the induction coil has helically extending turns, wherein the two-dimensional turn is substantially cylindrical and arranged within the helically extending turns.

- a device for the inductive heating of workpieces, comprising a high-frequency generator in operative signal connection with at least one induction coil, characterized in that the induction coil is designed as an induction coil according to the invention.

- the effect of a concentrator can be increased many times when the concentrator is designed as an additional, at least partially or sectionally planar winding of the induction coil, that is, connected in series with a number of the remaining coil turns.

- the induction coil consists of several turns, wherein at least one of the turns is at least partially flat, and wherein this planar turn or partial turn of at least a portion of the remaining turns inductively, ie by the electromagnetic field of the other turns being affected.

- the inductive influencing is preferably carried out in that at least a portion of the remaining turns is arranged directly adjacent, parallel or enveloping to the flat (partial) winding, ie, characterized in that the flat winding at least one of the supernatant turns covered area extends.

- the at least one planar (partial) winding is referred to as a "planar winding" in places, without expressing that this winding is completely, in accordance with the invention. must be formed flat in a whole.

- the concentration of the magnetic field of an induction coil according to the invention is preferably further improved by the fact that the flat winding of the coil has a shape, e.g. has a recess or bulge with smaller dimensions than the flat turn itself, which extends in the direction of the workpiece.

- the effect of the magnetic field is focused in this way in the area of the molding on the workpiece.

- Induction coils with such integrated concentrator, which forms one of the coil turns, can have different geometric embodiments:

- the induction coil is planar and formed with a substantially annular, flat winding under the other, spirally extending turns, wherein the planar winding is parallel to the coil plane of the other turns.

- the induction coil is designed as a helical coil with a cylindrical concentrator winding, ie, the planar winding is substantially cylindrical and formed within the arranged helically extending turns, wherein the two-dimensional turn inside for concentration purposes may have a rectangular or conical shape in cross-section.

- the two-dimensional turn extends inwards beyond the remaining turns, so that only a relatively small-scale recess in the form of a small hole for receiving a workpiece remains inside the flat turn. This causes a strong concentration of energy input at this point in the workpiece.

- the induction coil is designed as a tunnel coil, each having a flat partial turn on the two parallel sides of the coil (coil halves), wherein the planar winding for concentrating the field without limiting the generality has a rectangular in cross section molding inward.

- an induction coil in development of the invention is either designed so that one of the remaining turns is soldered to the flat winding, so that these two windings act as a common turn, so are effective, in particular electrically connected.

- the flat winding is contacted only at its two ends by one of the remaining turns and thus acts as an additional turn of the coil, which is connected in series with all other windings.

- an insulating layer can be arranged in a further development of the invention, preferably in the form of a Teflon foil.

- At least the flat winding and particularly preferably all turns of the induction coil according to the invention consist of copper.

- the formations of the flat winding can be flowed through in the invention as well as the other windings for cooling with water or another cooling medium.

- Fig. 1 shows a basic schematic representation of an inventive device 1 for inductive heating of workpieces, For example, for sealing containers or containers 2.

- the device 1 has a high-frequency generator (HF generator) 3 in conjunction with a resonant circuit 4.

- the oscillating circuit 4 comprises a capacitor 5 which is connected in series with an induction coil (inductance) 6 in order to achieve a current increase.

- the capacitance can also be arranged parallel to the inductance and then together with this form a parallel resonant circuit.

- At least the induction coil 6 is arranged in a movable or fixed machining head 1a of the device 1.

- the movable machining head 1a is movable as a whole in the direction of the double arrows A, A 'in order to adapt the device 1 to different dimensions of the workpieces to be heated, in this case the container 2 to be sealed. It is alternatively also possible that the workpiece 2 moves and the machining head 1 is fixed.

- the induction coil 6 In the current-carrying state, the induction coil 6 generates an (electro) magnetic field H, in the region of which a container 2 to be sealed is arranged with a container opening or a sealing film 7 present on the container opening.

- the container 2 is typically moved by means of a conveyor 8, such as a conveyor belt, through the area of the magnetic field H. Thereby, the sealing film 7 is heated and fused with the material of the container 2, so that it is sealed.

- the scope of the device 1 is by no means limited to the sealing of containers or containers, but can be extended to any type of induction heating of workpieces.

- Fig. 2a shows an overall perspective view of a first embodiment of the inventive induction coil 6.

- the induction coil 6 has connection jaws 6a, 6b, which are connected to a conductor 6c in the form of a copper tube.

- the conductor 6c or the copper tube are in the operation of the induction coil 6 for cooling purposes by a cooling medium, in particular water, flows through.

- the conductor 6c Starting from the connecting jaw 6a, the conductor 6c initially has a straight course, is then angled downwards and then arranged in the form of a planar spiral, that is to say in the form of helical spiral windings 6c ', 6c "with decreasing diameter or winding radius 6c 'of the conductor 6c is then returned to the connection jaw 6b essentially parallel to the initial course of the conductor 6c from the connection jaw 6a.

- a further turn of the induction coil 6 is arranged, which is referred to as a planar winding 6d is formed with a relative to the other conductor 6c enlarged (top) surface is formed.

- the flat winding 6d is formed in the form of an open ring made of copper and has corresponding at 6e a slot and an inner space 6f (recess), the Recording of workpieces to be heated (not shown here) serve

- a considerable concentration and amplification of the magnetic field generated by the induction coil 6 takes place in the region of the free space 6f and below the coil turns.

- the workpieces to be heated are arranged either below the induction coil 6 or within the free space 6f. Further details of the induction coil 6 according to Fig. 2a are in Fig. 2b shown.

- Fig. 2b shows a sectional view of the induction coil 6 according to Fig. 2a along the line II in Fig. 2a ,

- a Teflon film may be arranged.

- the inner spiral turn 6c 'does not contact the two-dimensional turn 6d over the slit 6e, so that the two-dimensional turn 6d effectively cooperates with the inner spiral turn 6c' as one turn of the induction coil 6.

- it functions as a concentrator, through which the magnetic field of the induction coil 6 concentrates on the region below the spiral turns as well as within the free space 6f and noticeably strengthened in this area.

- the inner spiral turn 6c ' also serves to cool the flat turn 6d, which itself is not flowed through by water.

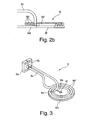

- Fig. 3 shows an overall perspective view of another embodiment of the induction coil 6 according to the invention substantially corresponds to the embodiment according to the FIGS. 2a . b , so that in this case only on relevant differences will be discussed in more detail. While the flat turn 6d in the embodiment according to the FIGS. 2a . b is formed limited by one of the remaining (spiral) turns 6c ', 6c "covered area, the embodiment according to Fig. 3 In that the planar winding 6d extends beyond an area covered by the remaining (spiral) windings 6c ', 6c " Fig.

- the flat winding 6d extends inwardly over the course of the inner spiral turn 6c ', so that at an inner end of the slit 6e only one opposite to the embodiment of FIGS. 2a . b in its dimensions greatly reduced space 6f remains in the form of a hole. This serves to accommodate workpieces of smaller dimensions, with a correspondingly increased concentration of the magnetic field of the induction coil 6 takes place in this area.

- Fig. 4a shows a perspective view of a further embodiment of the induction coil 6 according to the invention.

- this has an angle-shaped holding part 6g, on which the conductor 6c is guided in isolation.

- the windings 6c ', 6c "of the induction coil 6 extend in a helical manner, the two-dimensional turn 6d being substantially cylindrical and arranged within the helically extending remaining windings 6c', 6c" of the induction coil 6.

- the annular planar winding of the embodiments according to the FIGS. 2a . b and 3 also indicates the two-dimensional turn 6d of the embodiment Fig. 4a a slot 6e.

- the two-dimensional turn 6d is electrically insulated by an insulating layer 6h in the form of a Teflon foil, the latter having openings at 6i and 6j at which the two inner of the remaining coil turns 6c 'are electrically conductive with the flat turn 6d connected to both sides of the slot 6 e, preferably soldered, are, so that the flat winding 6 d effectively acts as an additional turn of the induction coil 6.

- Fig. 4b shows the induction coil 6 according to Fig. 4a according to a section along the line II-II in Fig. 4a

- the planar winding 6d has an encircling hollow formation 6k that extends inwards, that is to say in the region of the free space 6f, with respect to the remaining windings 6c ', 6c ", which is rectangular in cross section

- Formations 6k is thus again provided with an area of lesser dimension (smaller diameter) so that a magnetic field generated by the induction coil 6 is concentrated and amplified in the free space 6f, in particular between the formations 6k of the planar coil 6d Fig. 4a and Fig.

- the inner, hollow coil turns 6c ' connected to the openings 6i and 6j with the hollow shape 6k, so that during operation of the induction coil 6, the cooling medium, preferably water, both the coil turns 6', 6c "and the formation 6k and the conductor 6c flows through in a common cooling circuit.

- the cooling medium preferably water

- Fig. 5 shows by means of a representation, the perspective of those in Fig. 4b corresponds to a further embodiment of the induction coil 6 according to the invention.

- the flat winding 6d of the induction coil 6 has an inwardly extending hollow formation 6k, which is cone-shaped in cross-section. This way is opposite to in Fig. 4b shown embodiment of the induction coil 6 reaches a reinforced cooling effect on the flat turn 6d.

- a cylindrical Ferrritumhüllung 9 is shown with a U-shaped inner profile, which surrounds the induction coil 6 and additionally focuses the magnetic field of the coil on the coil interior.

- Analogously designed ferrite cladding can also be used in all other induction coils according to the invention shown.

- the internal formation of the flat turn 6d or its shape 6k is not based on the embodiments according to FIGS FIGS. 4b and 5 limited.

- Various further shaping geometries for generating correspondingly concentrated magnetic fields in the free space 6f of the induction coil 6 are possible without departing from the scope of the present invention.

- Fig. 6 shows an induction coil 6, which is formed as a tunnel coil with two substantially parallel coil halves 6 ', 6 ".

- (Coil) conductor 6c consists of stranded wire and forms in the region of the two coil halves 6', 6" in each case a number of parallel conductor sections which are connected to coil windings via conductor loops 6I, 6I '.

- a planar partial turn 6d, 6d' is arranged, which is contacted at points 6i 'and 6j' (and analogously for the coil half 6", not visible here) through the conductor 6c (eg screwed or soldered to it) so as to act as an additional partial turn of the corresponding coil half 6 ', 6 ".

- the two planar partial turns 6d, 6d' have on their inner side, that is to say, their side facing the respective other coil half hollow shape 6k, 6k ', which according to the present example is rectangular in cross-section, deviating configurations of the formations 6k, 6k' are of course possible, in particular a conical configuration according to FIG Fig. 5 What the expert readily recognizes.

- the formation 6k, 6k ' is in the operation of the induction coil 6 by a cooling medium, preferably of water, flows through.

Landscapes

- Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- General Induction Heating (AREA)

Description

Die vorliegende Erfindung betrifft eine Induktionsspule zum induktiven Erwärmen von Werkstücken, die eine Mehrzahl von Windungen aufweist, wobei wenigstens eine der Windungen zumindest teilweise flächig ausgebildet ist, gemäß dem Oberbegriff des Patentanspruchs 1.The present invention relates to an induction coil for inductive heating of workpieces, which has a plurality of turns, wherein at least one of the turns is at least partially flat, according to the preamble of patent claim 1.

Weiterhin betrifft die Erfindung eine Vorrichtung zum induktiven Erwärmen von Werkstücken, aufweisend einen Hochfrequenzgenerator (HF-Generator) in signaltechnischer Wirkverbindung mit wenigstens einer Induktionsspule, gemäß dem Oberbegriff des Patentanspruchs 11.Furthermore, the invention relates to a device for inductive heating of workpieces, comprising a high-frequency generator (HF generator) in signal-operative connection with at least one induction coil, according to the preamble of patent claim 11.

Derartige Vorrichtungen dienen zum induktiven Erwärmen von Werkstücken, die elektrisch leitfähige Komponenten enthalten, und werden beispielsweise zum Härten von Werkstücken, zum Verbinden (Schweißen, Kleben) von Werkstücken oder zum Versiegeln von Behältern eingesetzt.Such devices are used for inductive heating of workpieces containing electrically conductive components, and are used for example for the hardening of workpieces, for joining (welding, gluing) of workpieces or for sealing containers.

Vorrichtungen zum induktiven Erwärmen bestehen grundsätzlich aus einem Hochfrequenzgenerator und einer Induktionsspule (oder kurz: Spule), die meistens in einem Bearbeitungskopf angeordnet ist. Die Spule ist dabei entweder flach in einer Ebene oder auch dreidimensional, insbesondere helix- oder tunnelförmig, gewickelt. Sie besteht normalerweise entweder aus Kupferrohr, das zur Kühlung mit Wasser durchströmt wird, oder aus Litzendraht. Bei Spulen aus Litzendraht kann die Kühlung durch Luft erfolgen. Außerdem ist bekannt, die Spule mit einer Ferritumhüllung zu umgeben, die das elektromagnetische Feld in die Anwendungsrichtung fokussiert. Die Spule ist in der Regel in einen seriellen oder parallelen Schwingkreis eingebunden, der nahe der Resonanzfrequenz angesteuert wird, um Stromüberhöhungen in der Spule zu erzeugen. Durch das elektromagnetische Feld der Induktionsspule werden in den elektrisch leitfähigen Komponenten der Werkstücke gezielt Wirbelströme erzeugt, die zu einer Erwärmung führen.Devices for inductive heating basically consist of a high-frequency generator and an induction coil (or in short: coil), which is usually arranged in a processing head. The coil is either flat in a plane or three-dimensional, in particular helical or tunnel-shaped, wound. It usually consists either of copper pipe, which is flowed through with water for cooling, or of stranded wire. Coils made of stranded wire can be cooled by air. It is also known to surround the coil with a Ferrritumhüllung that focuses the electromagnetic field in the direction of application. The coil is typically incorporated in a series or parallel resonant circuit that is driven near the resonant frequency to produce current spikes in the coil. Due to the electromagnetic field of the induction coil eddy currents are generated in the electrically conductive components of the workpieces, which lead to a warming.

Der Bearbeitungskopf, der die Induktionsspule enthält, ist häufig über einer Fördervorrichtung angeordnet, mit deren Hilfe die zu erwärmenden Werkstücke unter der Spule oder durch sie hindurch befördert werden. Es ist ebenso möglich, die Werkstücke in die Spule oder die Spule in die Werkstücke einzutauchen.The machining head, which contains the induction coil, is often arranged above a conveying device, with the aid of which the workpieces to be heated under the coil or through it. It is also possible to immerse the workpieces in the coil or coil in the workpieces.

Aus der

Aus der

Eine Induktionsspule zum induktiven Erwärmen von Werkstücken, die eine Mehrzahl von Windungen aufweist, ist aus der

In der

Der Erfindung liegt die Aufgabe zugrunde, eine Induktionsspule bzw. eine Vorrichtung der jeweils eingangs genannten Art dahingehend weiter zu entwickeln, dass eine hohe Konzentrations- und Verstärkungswirkung auf das erzeugte Magnetfeld erreicht und damit die Heizwirkung und die Energieeffizienz verbessert werden.The invention has for its object to further develop an induction coil or a device of the type mentioned in each case that a high concentration and gain effect on the magnetic field generated and thus the heating effect and energy efficiency can be improved.

Die Aufgabe wird durch eine Induktionsspule mit den Merkmalen des Patentanspruchs 1 und durch eine Vorrichtung mit den Merkmalen des Patentanspruchs 11 gelöst.The object is achieved by an induction coil having the features of patent claim 1 and by a device having the features of patent claim 11.

Efindungsgemäß ist eine Induktionsspule zum induktiven Erwärmen von Werkstücken, die eine Mehrzahl von Windungen aufweist, dadurch gekennzeichnet, dass die flächige Windung sich zumindest über einen von den übrigen Windungen überdeckten Bereich erstreckt, wobei entweder die Induktionsspule eben und mit einer im Wesentlichen ringförmig ausgebildeten, flächigen Windung unter den übrigen, spiralförmig verlaufenden Windungen ausgebildet ist, wobei die flächige Windung parallel zur Spulenebene der übrigen Windungen verläuft; oder die Induktionsspule helixförmig verlaufende Windungen aufweist, wobei die flächige Windung im Wesentlichen zylinderförmig ausgebildet und innerhalb der helixförmig verlaufenden Windungen angeordnet ist.Efindungsgemäß is an induction coil for inductive heating of workpieces, which has a plurality of turns, characterized in that the planar winding extends at least over a covered area of the other turns, wherein either the induction coil flat and with a substantially annular, flat Winding under the other, spirally extending turns is formed, wherein the flat winding is parallel to the coil plane of the remaining turns; or the induction coil has helically extending turns, wherein the two-dimensional turn is substantially cylindrical and arranged within the helically extending turns.

Darüber hinaus ist eine erfindungsgemäße Vorrichtung zum induktiven Erwärmen von Werkstücken, aufweisend einen Hochfrequenzgenerator in signaltechnischer Wirkverbindung mit wenigstens einer Induktionsspule, dadurch gekennzeichnet, dass die Induktionsspule als eine erfindungsgemäße Induktionsspule ausgebildet ist.In addition, a device according to the invention for the inductive heating of workpieces, comprising a high-frequency generator in operative signal connection with at least one induction coil, characterized in that the induction coil is designed as an induction coil according to the invention.

Vorteilhafte Weiterbildungen der Erfindung sind jeweils Gegenstand von Unteransprüchen, deren Wortlaut hiermit durch ausdrückliche Bezugnahme in die vorliegende Beschreibung aufgenommen wird, um unnötige Textwiederholungen zu vermeiden.Advantageous developments of the invention are the subject matter of subclaims, the wording of which is hereby incorporated by express reference into the present description in order to avoid unnecessary text repetitions.

Es ist überraschender Weise erkannt worden, dass sich die Wirkung eines Konzentrators um ein Vielfaches steigern lässt, wenn der Konzentrator als zusätzliche, wenigstens teil- oder abschnittweise flächige Wicklung der Induktionsspule ausgeführt wird, d.h. mit einer Anzahl der übrigen Spulenwindungen in Reihe geschaltet ist. In einer erfindungsgemäßen Vorrichtung zur Induktionserwärmung besteht also die Induktionsspule aus mehreren Windungen, wobei mindestens eine der Windungen wenigstens teilweise flächig ausgeführt ist, und wobei diese flächige Windung bzw. Teilwindung von zumindest einem Teil der übrigen Windungen induktiv, d.h. durch das elektromagnetische Feld der übrigen Windungen beeinflusst wird. Die induktive Beeinflussung erfolgt dabei vorzugsweise dadurch, dass zumindest ein Teil der übrigen Windungen direkt benachbart, parallel oder umhüllend zu der flächigen (Teil-)Windung angeordnet ist, d.h. dadurch, dass die flächige Windung sich zumindest über einen von den überigen Windungen überdeckten Bereich erstreckt. Mit einer solchen erfindungsgemäßen Spulenform lässt sich mit deutlich geringerer Ausgangsleistung des HF-Generators ein besserer Energieeintrag in die Werkstücke erreichen als mit den im Stand der Technik beschriebenen Induktionsspulen. Es wird nicht nur eine Konzentration, sondern auch eine deutliche Verstärkung des Magnetfelds der Induktionsspule am Ort des Werkstücks erreicht.It has surprisingly been recognized that the effect of a concentrator can be increased many times when the concentrator is designed as an additional, at least partially or sectionally planar winding of the induction coil, that is, connected in series with a number of the remaining coil turns. In an apparatus according to the invention for induction heating, therefore, the induction coil consists of several turns, wherein at least one of the turns is at least partially flat, and wherein this planar turn or partial turn of at least a portion of the remaining turns inductively, ie by the electromagnetic field of the other turns being affected. The inductive influencing is preferably carried out in that at least a portion of the remaining turns is arranged directly adjacent, parallel or enveloping to the flat (partial) winding, ie, characterized in that the flat winding at least one of the supernatant turns covered area extends. With such a coil form according to the invention, a significantly better energy input into the workpieces can be achieved with significantly lower output power of the HF generator than with the induction coils described in the prior art. Not only a concentration, but also a significant amplification of the magnetic field of the induction coil at the location of the workpiece is achieved.

Im Folgenden wird die wenigstens eine flächige (Teil-)Windung stellenweise vereinfachend nur als "flächige Windung" bezeichnet, ohne dass hierdurch ausgedrückt werden soll, dass diese Windung erfindungsgemäß vollständig, d.h. in einer Gesamtheit flächig ausgebildet sein muss.In the following, the at least one planar (partial) winding is referred to as a "planar winding" in places, without expressing that this winding is completely, in accordance with the invention. must be formed flat in a whole.

Die Konzentration des magnetischen Feldes einer erfindungsgemäßen Induktionsspule wird vorzugsweise noch weiter dadurch verbessert, dass die flächig ausgeführte Windung der Spule eine Ausformung, z.B. eine Ausnehmung oder Auswölbung mit geringeren Abmessungen als die flächige Windung selbst aufweist, die sich in Richtung auf das Werkstück erstreckt. Die Wirkung des magnetischen Feldes wird auf diese Weise im Bereich der Ausformung auf das Werkstück fokussiert.The concentration of the magnetic field of an induction coil according to the invention is preferably further improved by the fact that the flat winding of the coil has a shape, e.g. has a recess or bulge with smaller dimensions than the flat turn itself, which extends in the direction of the workpiece. The effect of the magnetic field is focused in this way in the area of the molding on the workpiece.

Induktionsspulen mit derart integriertem Konzentrator, welcher eine der Spulenwindungen bildet, können verschiedene geometrischen Ausführungsformen aufweisen:Induction coils with such integrated concentrator, which forms one of the coil turns, can have different geometric embodiments:

Gemäß einer ersten Ausführungsform ist die Induktionsspule eben und mit einer im Wesentlichen ringförmig ausgebildeten, flächigen Windung unter den übrigen, spiralförmig verlaufenden Windungen ausgebildet, wobei die flächige Windung parallel zur Spulenebene der übrigen Windungen verläuft. Dadurch wird das magnetische Feld unter den Windungen und im Bereich einer ggf. vorhandenen Ausnehmung der flächigen Windung verstärkt und homogenisiert.According to a first embodiment, the induction coil is planar and formed with a substantially annular, flat winding under the other, spirally extending turns, wherein the planar winding is parallel to the coil plane of the other turns. As a result, the magnetic field is amplified and homogenized under the turns and in the region of a possibly existing recess of the flat turn.

Gemäß einer zweiten, alternativen Ausführungsform ist die Induktionsspule als helixförmige Spule mit zylinderförmiger Konzentrator-Wicklung ausgebildet, d.h. die flächige Windung ist im Wesentlichen zylinderförmig ausgebildet und innerhalb der helixförmig verlaufenden Windungen angeordnet, wobei die flächige Windung nach innen zu Konzentrierungszwecken eine im Querschnitt rechteckige oder konusförmige Ausformung aufweisen kann.According to a second alternative embodiment, the induction coil is designed as a helical coil with a cylindrical concentrator winding, ie, the planar winding is substantially cylindrical and formed within the arranged helically extending turns, wherein the two-dimensional turn inside for concentration purposes may have a rectangular or conical shape in cross-section.

Gemäß einer Weiterbildung erstreckt sich die flächige Windung über die übrigen Windungen hinaus nach innen, so dass im Inneren der flächigen Windung nur eine relativ kleinskalige Ausnehmung in Form eines kleinen Lochs für die Aufnahme eines Werkstücks verbleibt. Dies bewirkt eine starke Konzentration des Energieeintrags an dieser Stelle in das Werkstück.According to a further development, the two-dimensional turn extends inwards beyond the remaining turns, so that only a relatively small-scale recess in the form of a small hole for receiving a workpiece remains inside the flat turn. This causes a strong concentration of energy input at this point in the workpiece.

Bei einer nicht erfindungsgemäßen Ausgestaltung ist die Induktionsspule als Tunnelspule mit jeweils einer flächigen Teilwindung auf den beiden Parallelseiten der Spule (Spulenhälften) ausgebildet, wobei die flächige Windung zur Konzentrierung des Feldes ohne Beschränkung der Allgemeinheit eine im Querschnitt rechteckige Ausformung nach innen aufweist.In an embodiment not according to the invention, the induction coil is designed as a tunnel coil, each having a flat partial turn on the two parallel sides of the coil (coil halves), wherein the planar winding for concentrating the field without limiting the generality has a rectangular in cross section molding inward.

Allgemein ist der Aufbau einer Induktionsspule in Weiterbildung der Erfindung entweder so gestaltet, dass eine der übrigen Windungen mit der flächigen Windung verlötet ist, so dass diese beiden Windungen als gemeinsame Windung fungieren, also wirkungsmäßig, insbesondere elektrisch leitend verbunden sind. Alternativ ist die flächige Windung nur an ihren beiden Enden durch jeweils eine der übrigen Windungen kontaktiert und fungiert so als zusätzliche Windung der Spule, die in Reihe zu allen übrigen Windungen geschaltet ist. Zwischen den weiteren Windungen und der flächigen Windung kann in Weiterbildung der Erfindung eine Isolierschicht angeordnet sein, vorzugsweise in Form einer Teflonfolie.Generally, the structure of an induction coil in development of the invention is either designed so that one of the remaining turns is soldered to the flat winding, so that these two windings act as a common turn, so are effective, in particular electrically connected. Alternatively, the flat winding is contacted only at its two ends by one of the remaining turns and thus acts as an additional turn of the coil, which is connected in series with all other windings. Between the further turns and the flat turn, an insulating layer can be arranged in a further development of the invention, preferably in the form of a Teflon foil.

Vorzugsweise bestehen zumindest die flächige Windung und besonders bevorzugt alle Windungen der erfindungsgemäßen Induktionsspule aus Kupfer.Preferably, at least the flat winding and particularly preferably all turns of the induction coil according to the invention consist of copper.

Die Ausformungen der flächigen Windung können in Weiterbildung der Erfindung ebenso wie die übrigen Windungen zur Kühlung mit Wasser oder einem anderen Kühlmedium durchströmt sein.The formations of the flat winding can be flowed through in the invention as well as the other windings for cooling with water or another cooling medium.

Um die Wirkung des magnetischen Spulenfeldes noch stärker am Ort des Werkstücks zu konzentrieren, kann die Spule auf ihrer dem Werkstück abgewandten Seite mit einer Umhüllung aus magnetisch gut und elektrisch schlecht leitendem Material, vorzugsweise aus Ferrit, umgeben sein, die das Magnetfeld der Spule begrenzt und in Anwendungsrichtung fokussiert.To concentrate the effect of the magnetic coil field even more at the location of the workpiece, the coil on its side facing away from the workpiece with a sheath of magnetically good and electrically poorly conductive material, preferably ferrite, be surrounded, which limits the magnetic field of the coil and focused in application direction.

Weitere Vorteile und Eigenschaften der vorliegenden Erfindung ergeben sich aus der nachfolgenden Beschreibung von Ausführungsbeispielen anhand der Zeichnung. Aus den einzelnen Ausführungsbeispielen zu entnehmende Merkmale können einzeln oder in Kombination bei Ausgestaltungen der vorliegenden Erfindung verwirklicht sein. Es zeigt/zeigen:

- Fig. 1

- eine grundlegende schematische Darstellung einer erfindungsgemäßen Vorrichtung zum induktiven Erwärmen von Werkstücken;

- Fig. 2a, b

- verschiedene Ansichten einer ersten Ausführungsform der erfindungsgemäßen Induktionsspule;

- Fig. 3

- eine zweite Ausführungsform der erfindungsgemäßen Induktionsspule;

- Fig. 4a, b

- verschiedene Ansichten einer dritten Ausführungsform der erfindungsgemäßen Induktionsspule;

- Fig. 5

- eine vierte Ausführungsform der erfindungsgemäßen Induktionsspule; und

- Fig. 6

- eine Ausgestaltung einer Induktionsspule als Tunnelspule.

- Fig. 1

- a basic schematic representation of an inventive device for inductive heating of workpieces;

- Fig. 2a, b

- different views of a first embodiment of the induction coil according to the invention;

- Fig. 3

- a second embodiment of the induction coil according to the invention;

- Fig. 4a, b

- different views of a third embodiment of the induction coil according to the invention;

- Fig. 5

- a fourth embodiment of the induction coil according to the invention; and

- Fig. 6

- an embodiment of an induction coil as a tunnel coil.

Wie der Fachmann erkennt, ist der Anwendungsbereich der Vorrichtung 1 keineswegs auf das Versiegeln von Behältern oder Gebinden beschränkt, sondern kann auf jede Art der induktiven Erwärmung von Werkstücken ausgedehnt werden.As those skilled in the art will appreciate, the scope of the device 1 is by no means limited to the sealing of containers or containers, but can be extended to any type of induction heating of workpieces.

Alternativ zu der exemplarisch gezeigten Ausführungsform ist es je nach Anwendungsgebiet auch möglich, die Werkstücke 2 mittels einer hierfür geeigneten Einrichtung, z.B. durch geeignete Ausgestaltung der Fördereinrichtung 8 bzw. des Bearbeitungskopfes 1a, in die Induktionsspule 6 oder die Induktionsspule 6 selbst in die Werkstücke 2 einzutauchen.As an alternative to the embodiment shown by way of example, it is also possible, depending on the field of application, to place the

Ausgehend von der Anschlussbacke 6a weist der Leiter 6c zunächst einen geraden Verlauf auf, ist dann nach unten abgewinkelt und anschließend in Form einer ebenen Spirale, das heißt in Form von schneckenförmigen Spiralwindungen 6c', 6c" mit abnehmendem Durchmesser oder Windungsradius angeordnet. Die innerste Spiralwindung 6c' des Leiters 6c ist anschließend im Wesentlichen parallel zu dem anfänglichen Verlauf des Leiters 6c ausgehend von der Anschlussbacke 6a zu der Anschlussbacke 6b zurückgeführt. Unterhalb der Spiralwindungen des Leiters 6c ist eine weitere Windung der Induktionsspule 6 angeordnet, die als flächige Windung 6d, das heißt mit einer relativ zu dem übrigen Leiter 6c vergrößerten (Ober-)Fläche ausgebildet ist. Die flächige Windung 6d ist in Form eines offenen Rings aus Kupfer ausgebildet und weist entsprechend bei 6e einen Schlitz sowie einen inneren Freiraum 6f (Ausnehmung) auf, der zum Aufnehmen von zu erwärmenden Werkstücken (hier nicht gezeigt) dienen kann. Erfindungsgemäß findet bei Stromfluss durch die Induktionsspule 6 eine erhebliche Konzentration und Verstärkung des durch die Induktionsspule 6 erzeugten Magnetfelds in dem Bereich des Freiraums 6f sowie unterhalb der Spulenwindungen statt. Die zu erwärmenden Werkstücke werden abhängig von ihrer Geometrie entweder unterhalb der Induktionsspule 6 oder innerhalb des Freiraums 6f angeordnet. Weitere Einzelheiten der Induktionsspule 6 gemäß

Wie der Fachmann erkennt, ist die innere Ausbildung der flächigen Windung 6d beziehungsweise deren Ausformung 6k nicht auf die Ausgestaltungen gemäß den

Claims (12)

- An induction coil (6) for inductive heating of workpieces (2), which comprises a plurality of turns (6c', 6c", 6d), wherein at least one of the turns (6d) has an at least partially flat configuration,

characterised in that

the flat turn extends at least over a region overlapped by the remaining turns (6c', 6c"), wherein

either the induction coil (6) has a planar configuration with a substantially annularly configured flat turn (6d) under the remaining spirally running turns (6c', 6c"), wherein the flat turn (6d) runs parallel to the coil plane of the remaining turns (6c', 6c"),

or the induction coil (6) comprises helically running turns (6c', 6c"), wherein the flat turn (6d) has a substantially cylindrical configuration and is arranged inside the helically running turns (6c', 6c"). - An induction coil (6) according to the preceding claim, characterised in that for the inductive effect at least a part of the remaining turns (6c', 6c") is arranged directly adjacent to, parallel to and/or enclosing the flat turn (6d, 6d').

- An induction coil (6) according to the claim 1 or 2, characterised in that the flat turn (6d, 6d') comprises a region (6f) having smaller dimensions than an overall dimension of the flat turn, said region being designed for receiving a workpiece to be heated.

- An induction coil (6) according to any one of the preceding claims, characterised in that the annular flat turn (6d) is opened by means of a slot (6e).

- An induction coil (6) according to any one of the preceding claims, characterised in that the flat turn (6d) is configured so as to be restricted substantially to a region overlapped by the remaining turns (6c', 6c").

- An induction coil (6) according to any one of claims 1 to 4, characterised in that the flat turn (6d) is of configured to extend beyond a region overlapped by the remaining turns (6c', 6c").

- An induction coil (6) according to any one of the preceding claims, characterised in that one of the remaining turns (6c') is operatively connected, in particular soldered, to the flat (partial) turn (6d).

- An induction coil (6) according to any one of the preceding claims, characterised in that an insulating layer, in particular in the form of a Teflon film, is arranged between the flat (partial) turn (6d) and the remaining turns (6c', 6c").

- An induction coil (6) according to any one of the preceding claims, characterised in that at least the flat (partial) turn (6d) and in particular all turns (6c', 6c"; 6d) consist of copper.

- An induction coil (6) according to any one of the preceding claims, characterised in that the remaining turns (6c', 6c") are of hollow, in particular tubular, construction and during operation a coolant flows therethrough.

- A device (1) for inductive heating ofworkpieces (2), comprising a high frequency generator (3) operatively connected in terms of signalling to at least one induction coil (6), characterised in that the induction coil (6) is configured according to one of the preceding claims.

- A device (1) for inductive heating of workpieces (2) according to the preceding claim, characterised in that the induction coil (6), on the face thereof facing away from the workpiece (2), is enclosed with a covering (9) made of material, in particular of ferrite, that is magnetically highly conductive and electrically poorly conductive.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP20070004759 EP1968355B1 (en) | 2007-03-08 | 2007-03-08 | Induction coil and device for inductive heating of workpieces |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP20070004759 EP1968355B1 (en) | 2007-03-08 | 2007-03-08 | Induction coil and device for inductive heating of workpieces |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1968355A1 EP1968355A1 (en) | 2008-09-10 |

| EP1968355B1 true EP1968355B1 (en) | 2013-02-27 |

Family

ID=38294109

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP20070004759 Active EP1968355B1 (en) | 2007-03-08 | 2007-03-08 | Induction coil and device for inductive heating of workpieces |

Country Status (1)

| Country | Link |

|---|---|

| EP (1) | EP1968355B1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102018208400A1 (en) * | 2018-05-28 | 2019-11-28 | Siemens Aktiengesellschaft | Apparatus for heating a component material, additive manufacturing equipment, and additive manufacturing method |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102011004530A1 (en) | 2010-12-15 | 2012-06-21 | Mahle International Gmbh | heater |

| JP6886685B2 (en) * | 2017-02-27 | 2021-06-16 | トクデン株式会社 | A superheated steam generator and a method for manufacturing a conductor tube used in the device. |

| US10917946B2 (en) * | 2017-05-26 | 2021-02-09 | Illinois Tool Works Inc. | Induction heating methods and apparatus |

| DE102018201452A1 (en) * | 2018-01-31 | 2019-08-01 | MTU Aero Engines AG | Device for the additive production of at least one component region of a component, induction heating device for such a device, method for operating a device and component for a turbomachine |

| DE102018203273A1 (en) | 2018-03-06 | 2019-09-12 | MTU Aero Engines AG | Induction heating device, apparatus for the additive production of at least one component region of a component with such an induction heating device, method for inductive heating of a component region and component for a turbomachine |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE918158C (en) | 1943-11-18 | 1954-09-20 | Siemens Ag | Device for inductive heating of flat workpieces |

| US3017485A (en) * | 1957-11-19 | 1962-01-16 | Asea Ab | Means for electric vacuum furnaces |

| DE1132671B (en) | 1960-11-24 | 1962-07-05 | Telefunken Patent | Device for heating an electrically conductive body in a high-frequency magnetic field |

| DE1802524B1 (en) * | 1968-10-11 | 1970-06-04 | Siemens Ag | Device for crucible-free zone melting of a crystalline rod, in particular a semiconductor rod |

| DE2331004C3 (en) | 1973-06-18 | 1982-02-04 | Siemens AG, 1000 Berlin und 8000 München | Induction heating coil for crucible-free zone melting |

| DE2357688C2 (en) | 1973-11-19 | 1982-11-18 | Siemens AG, 1000 Berlin und 8000 München | Induction heating coil for crucible-free zone melting |

| US5048260A (en) | 1989-10-17 | 1991-09-17 | Wm. Wrigley, Jr. Company | Induction sealing machine and package wrapper useful therewith |

| FR2792158B1 (en) * | 1999-04-09 | 2001-05-18 | Jaeger Regulation | MODULAR INDUCTION COOKING FIREPLACE WITH REDUCED RADIATION AND METHOD OF MAKING |

-

2007

- 2007-03-08 EP EP20070004759 patent/EP1968355B1/en active Active

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102018208400A1 (en) * | 2018-05-28 | 2019-11-28 | Siemens Aktiengesellschaft | Apparatus for heating a component material, additive manufacturing equipment, and additive manufacturing method |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1968355A1 (en) | 2008-09-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1968355B1 (en) | Induction coil and device for inductive heating of workpieces | |

| DE69603325T2 (en) | Container coating and preparation method with concentrated induction heating using a thinly laminated core | |

| DE102005061670B4 (en) | Method for inductive heating of a workpiece | |

| DE10046275A1 (en) | Magnetic coil with interwoven spiral of two conductors with one hollow conductor carrying a coolant, so that a high magnetic field can be generated at a relatively low temperature, for use in nerve stimulation | |

| DE3032118C2 (en) | Die welding coil | |

| DE102010053284A1 (en) | Method and induction heater for heating a billet | |

| EP3924985A1 (en) | Coil and method for producing a coil | |

| EP3876669B1 (en) | Method for manufacturing an electric heating device and electric heating device | |

| EP3329739B1 (en) | Inductor and inductor arrangement | |

| DE102013112325B4 (en) | Toroidal coil and manufacturing process for a toroidal coil | |

| EP3529054B1 (en) | Inductive welding of plastic tubes by means of a coil arrangement with multiple individual coils | |

| WO2008011907A1 (en) | Welding device for arc welding by means of drawn arc ignition | |

| EP3724360B1 (en) | Inductor and method for hardening rack gears | |

| DE3843728C2 (en) | ||

| EP1614783B1 (en) | Inductor core for a heatable galette | |

| EP2497333A1 (en) | Device for inductively heating workpieces made of electrically conductive material | |

| DE102019216194A1 (en) | Method for welding square bars made of a copper material | |

| DE29601328U1 (en) | Electromagnetic induction coil | |

| DE3418173A1 (en) | Device for the electro-inductive heating of metallic workpieces | |

| WO2000018190A2 (en) | Inductor for generating an electromagnetic alternating field | |

| DE2153179C3 (en) | Device for continuous inductive longitudinal or spiral seam welding of metal pipes | |

| DE1145728B (en) | Low temperature heating device for inductive heating | |

| DE2609217A1 (en) | Inductance coil magnetic impulse metal forming - has windings connected in series to reduce thermal losses | |

| EP2830392A1 (en) | Device for inductive heating and combination of such a device with a workpiece | |

| DE10152867A1 (en) | Continuously adjustable inductance, e.g. for fine tuning of resonant circuits, is formed between connecting terminals of main winding sections that are connected together |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC MT NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK RS |

|

| 17P | Request for examination filed |

Effective date: 20090303 |

|

| 17Q | First examination report despatched |

Effective date: 20090414 |

|

| AKX | Designation fees paid |

Designated state(s): DE FR GB |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FR GB |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502007011349 Country of ref document: DE Effective date: 20130425 |

|

| RAP2 | Party data changed (patent owner data changed or rights of a patent transferred) |

Owner name: TRUMPF HUETTINGER GMBH + CO. KG |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502007011349 Country of ref document: DE Representative=s name: KOHLER SCHMID MOEBUS PATENTANWAELTE, DE Effective date: 20130801 Ref country code: DE Ref legal event code: R081 Ref document number: 502007011349 Country of ref document: DE Owner name: TRUMPF HUETTINGER GMBH + CO. KG, DE Free format text: FORMER OWNER: HUETTINGER ELEKTRONIK GMBH + CO. KG, 79111 FREIBURG, DE Effective date: 20130801 Ref country code: DE Ref legal event code: R082 Ref document number: 502007011349 Country of ref document: DE Representative=s name: KOHLER SCHMID MOEBUS PATENTANWAELTE PARTNERSCH, DE Effective date: 20130801 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20131128 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502007011349 Country of ref document: DE Effective date: 20131128 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 11 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20220321 Year of fee payment: 16 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20230308 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230308 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230308 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20240320 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20240321 Year of fee payment: 18 |