EP1801034A2 - Coussin de forme relâc - Google Patents

Coussin de forme relâc Download PDFInfo

- Publication number

- EP1801034A2 EP1801034A2 EP06126633A EP06126633A EP1801034A2 EP 1801034 A2 EP1801034 A2 EP 1801034A2 EP 06126633 A EP06126633 A EP 06126633A EP 06126633 A EP06126633 A EP 06126633A EP 1801034 A2 EP1801034 A2 EP 1801034A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- filter

- filter pad

- pad according

- pad

- subspaces

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D85/00—Containers, packaging elements or packages, specially adapted for particular articles or materials

- B65D85/70—Containers, packaging elements or packages, specially adapted for particular articles or materials for materials not otherwise provided for

- B65D85/804—Disposable containers or packages with contents which are mixed, infused or dissolved in situ, i.e. without having been previously removed from the package

- B65D85/8043—Packages adapted to allow liquid to pass through the contents

- B65D85/8046—Pods, i.e. closed containers made only of filter paper or similar material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D85/00—Containers, packaging elements or packages, specially adapted for particular articles or materials

- B65D85/70—Containers, packaging elements or packages, specially adapted for particular articles or materials for materials not otherwise provided for

- B65D85/804—Disposable containers or packages with contents which are mixed, infused or dissolved in situ, i.e. without having been previously removed from the package

- B65D85/8043—Packages adapted to allow liquid to pass through the contents

- B65D85/8061—Filters

Definitions

- the invention relates to a filter pad comprising an upper filter sheet and a lower filter sheet and an intermediate receiving space for receiving leachable and / or at least partially soluble substances, which is subdivided into subspaces.

- substances coffee or tea powder, coffee whitener, flavorings or the like can be filled.

- the pad is placed in a brewing chamber of a pad machine to prepare a hot drink and charged with hot water.

- Typical hot drinks that are made in this way are coffee, tea, cocoa or drinkable soups.

- the DE 203 19 191 U1 describes a dimensionally stable pad provided with at least a first shell into which a substance, such as milk powder, frother or similar additives, which are soluble in a liquid such as water, is enclosed.

- the shell comprises an upper and a lower sheet of a filter material.

- the pad is further provided with a forming stiffening body disposed between the upper and lower sheets.

- the stiffening body has a dividing wall assembly which, from an upper side to a lower side, constitutes a liquid-permeable mesh structure. In this structure, which forms individual compartments, there is at least a part of the soluble substance.

- This dimensionally stable pad is due to the porous filter material, in which the stiffening body is wrapped, consuming and complicated to manufacture. It is therefore characterized by a high reject rate.

- the object of the invention is therefore to provide a pad whose interior is also divided, but that is easier to manufacture and less prone to damage.

- a filter pad of the type mentioned, but which is form-weak By dispensing with a stiff or stiffening Body within the pad simplifies its manufacture, because it can be dispensed with the complex connection between dimensionally stable and shapeless body. Instead, recourse can be had to connection methods known from the production of conventional pads. Avoiding a stiff body also eliminates the risk that it destroys the porous filter bag by acting on him forces in handling.

- the subspaces are arranged one above the other with respect to an extension plane of the filter pad.

- the superimposed subspaces or chambers of the pad are flowed through in an order with respect to the flow direction from top to bottom.

- the solution or the eluate of the first through-flow chamber thus also flows through the chambers downstream of it, resulting in a particularly good mixing of the solutions or eluates of the individual chambers or subspaces. Since the lower chamber is already acted upon by a solution or an eluate, it can be assumed that the substances contained therein are dissolved or leached differently than by fresh water.

- the filter pad consists of at least three filter layers which are connected to one another only at their peripheral edges.

- a plurality of subspaces can be produced in a very simple manner, which are arranged parallel to one another or in the throughflow direction with respect to the plane of extent of the filter pad.

- the connection of the filter layers at their edges corresponds to the usual production methods of known pads, with which the manufacture of the pads according to the invention can be carried out essentially as known.

- filter layers do not necessarily have to be connected to one another only at their edges.

- filter layers of different sizes can also be connected to one another by attaching a smaller filter layer at its edge to a larger one.

- Another, corresponding in size to the larger of the first two filter layers position can then be connected at its edge with the existing pad to form two different sized subspaces.

- the subspaces can also be arranged parallel to one another with respect to the plane of extent of the filter pad, that is to say that they are therefore arranged parallel in the direction of flow.

- This division of the subspaces has the consequence that the subspaces are traversed during the flow of water substantially independently of each other. As a result, thorough mixing of the solution or of the eluate already in the pad or unequal elution or solution of the substances introduced can be avoided.

- the subspaces within the pad are formed exclusively in that the upper and lower filter layers are connected to one another at joints.

- the originally continuous receiving space of a pad is thus divided according to the invention by joints, for example in the form of a quilt, into several subspaces.

- joints for example in the form of a quilt

- a single linear joint may divide the pad into two equal or different subspaces.

- the course of the joints may be interrupted.

- the two filter layers are not interconnected.

- two adjacent subspaces are connected to each other.

- an exchange of the substances of adjacent subspaces can take place.

- the user can mechanically correct, for example, a transport-related unequal distribution of the substances within the subspaces, if necessary.

- the interruptions are so small that no exchange of substances can take place, they at least provide the water with an additional flow path.

- the Quer barnströmhus the pad can be increased. In a partial accumulation within the pad can be counteracted by the formation of an undesirable overpressure in the brewing chamber.

- the subspaces may also be formed by at least one separate partition wall.

- the insertion of a separate dividing wall into the receiving space of the pad represents a greater outlay in the production, but in each case causes more compact subspaces with an otherwise unchanged shape or outer contour of the pad.

- partition walls With one or more partition walls, both an arrangement of the subspaces next to each other as well as one above the other or even combinations thereof can be accomplished.

- the partition wall As a material for the partition wall almost any, preferably flexible, and - depending on the orientation of the partition wall parallel or transverse to the flow direction - permeable material can be used.

- the partition wall consists of a material comparable to the upper and / or the lower filter sheet. In superimposed subspaces, this is required because otherwise the flow through the pad is obstructed. In contrast, with adjacent subspaces, this material also permits cross-flow of the pad, which may result in good mixing of the solution or of the eluate, but also in a bypass flow, if an area of reduced or disturbed flow forms in the pad. Same materials for The two filter sheets and the partition walls can also simplify the production of the pad. On the other hand, if a cross-flow should be avoided, for. B. because mixing is not desirable, the partition may be formed impermeable.

- the dividing walls it is not necessary for the dividing walls to be stationarily located within the pad, they can be held exclusively by the filling with substances. According to a further advantageous embodiment of the invention, however, they are connected by joints on the upper and / or lower filter sheet. This advantageously results in a form fidelity of the subspaces and excludes mixing of the different substances contained in the pad.

- the joints are formed by pressing, embossing, deformation or gluing using the least possible amounts of adhesive. These joining processes ensure that they have as little flavor as possible on the beverage.

- the filter pads described so far have in common the design principle that their subspaces are formed by walls which are more or less precisely determinable with respect to their position.

- An alternative design principle of the inventive pad turns away from this concept. Its receiving space or at least one of its subspaces is filled with particles of very different spatial extent. Subspaces are thus created no longer by walls, but by the surfaces of several non-contiguous bodies of greater spatial extent, which form spaces through their generally irregular arrangement within the pad. They represent subspaces in which particles with a smaller spatial extent can stay. Thus, between the particles of larger spatial extent, a large number of relatively equally distributed subspaces are formed, in which smaller particles are absorbed. The plurality of subspaces may be desirable or necessary if the most even distribution of a fine-grained substance is necessary.

- the particles of different sizes also have a different dissolution behavior with respect to speed. Among them is the whole range of an immediate dissolution of water contact to the insolubility to understand. In the case of insolubility, the larger particles merely serve to produce finely distributed subspaces without participating in the overall flavor of the solution or eluate. Thus, a form-slack pad can be produced which nevertheless has a uniform distribution of sub-compartments of calculable sizes and calculable circumference.

- the particles of larger extent preferably exhibit the slower dissolution behavior. Then they essentially form the subspaces for the finely divided substances. These subspaces are to be maintained for as long as possible for the purpose of uniform distribution of the finer substances during the dissolution or leaching process and / or avoiding agglomeration of the finer substances.

- the different dissolution behavior can also create an order of processing of the substances within a pad. Influencing the chronological order in which different constituents of the same pad as solution or eluate leave the coffee machine makes it possible to produce layered coffee drinks.

- An advantageous embodiment of the previously described embodiment is that the larger particles of roasted coffee and the smaller consist of flavoring and / or additives.

- the size of the coffee particles can be adjusted by the degree of grinding of the coffee.

- the coffee particles remain in the pad anyway, because they are not completely dissolved, but leached.

- the flavoring and / or additives should generally dissolve completely and out of the pad be rinsed out. They are therefore advantageous anyway in greater fineness, ie as smaller particles.

- the larger particles have a substantially regular geometric shape, for example a spherical shape on.

- the gaps created between the balls can be determined relatively accurately because both the interior of the pad and the sum of the volumes of the balls can be calculated.

- spherical particles have a diameter which corresponds approximately to the thickness of the pad in the direction of flow. This creates the largest possible partial spaces between the balls.

- FIG. 1 shows a first, simple form of a pad 1 in a plan view (FIG. 1 a) and in a sectional view (FIG. 1 b).

- the pad 1 is formed of an upper filter sheet 2 and a lower filter sheet 4.

- As with known pads it also includes a receiving space 5 between the two filter sheets 2, 4, which - in contrast to known pads - is subdivided by a linear joint 8 into two equal subspaces 10, 12.

- the upper filter sheet 2 and the lower filter sheet 4 are both circular and disc-shaped and secured along its circumference 6 in a known manner by a circumferential joint 7 with each other.

- Both the peripheral joint 7 and the linear joint 8 are in a conventional manner, formed by embossing, gluing or pressing, for example, to a pressure water resistant compound.

- the semi-circular in plan view subspaces 10, 12 take on different substances, eg. B. ground coffee of different varieties to produce a blend. Since the subspaces 10, 12 are arranged next to one another, they are in principle treated equally with water and flows through it at the same time. The content of each subspace 10, 12 is thus eluted separately. Essentially, the eluate mixes only below the lower filter sheet 4 in the brewing chamber of the machine. This ensures that both substances are eluted evenly and provide the same contribution to the flavor of the prepared beverage.

- the linear course and the position of the joint 8 are only to be understood as examples. It may of course also be curved or circular, for example, as shown in FIG.

- the pad 1 in Figure 1 is thus formed from only two conventional filter sheets 2, 4. It thus essentially has the shape property according to the invention, i. H. it is form-limbed.

- the joint 8 gives the pad 1 an additional softness in that it can be folded along the joint 8. Another reason for a curved course of a joint 8 can therefore be the avoidance of the kink possibility of the pad 1.

- the invention not only offers the possibility of subdividing a receiving space into two juxtaposed subspaces, but also into those which are arranged one above the other.

- Such an embodiment is shown in a plan view in FIG. 2a and in a sectional view in FIG. 2b.

- the pad 20 is formed of three substantially conventional circular filter sheets 22, 24, 26, of which the upper filter sheet 22 and the lower filter sheet 26 include a receiving space 28 in a known manner.

- the middle filter sheet 24 divides the receiving space 28 by a linear joint 38 in the juxtaposed subspaces 30 and 32 on the one hand and in the two spanning subspace 34.

- the two subspaces 30 and 32 are arranged in the same manner as the subspaces 10 and 12 in Figure 1.

- the subspace 34 is above or in the direction of flow A of the pad 20 in front of it.

- the three filter sheets 22, 24, 26 are along in a conventional manner their periphery 36 connected to each other, so that the particles contained in them can not escape.

- the subspaces 30, 32 continue to flow through more or less simultaneously. However, in the direction of flow A from top to bottom, the water now first flows through the subspace 34, elutes or dissolves the substances contained therein and then flows through the subspaces 30, 32. Thus, this results in a fürströmungs Herbertn surprise, after which first the subspace 34 and only then the subspaces 30 and 32 are flowed through. This also means that the subspaces 30, 32 are not reached by fresh water, but by eluate that has already formed in the subspace 34. This may result in the subsequent flow through the subspaces 30, 32, a different elution or dissolution behavior, as if these subspaces 30, 32 would be acted upon by fresh water. In any case, a thorough mixing of the eluate from the subspaces 34 and 30 or 32 already takes place above the lower filter sheet 26 - in contrast to the pad 1 according to FIG. 1.

- the arrangement of the central filter sheet 24 is to be understood by way of example.

- the joint 38, the middle filter sheet 24 of course also connect to the upper filter sheet 22 or completely eliminated.

- the middle filter sheet 24 also need not necessarily be connected to the common periphery 36 with the upper filter sheet 22 and the lower filter sheet 26. Rather, it may also have a smaller diameter than this and be attached only to the upper filter sheet 22 or the lower filter sheet 26.

- a criterion for such a configuration may consist in the requirement to apply one of them at least partially with fresh water even in subregions arranged one above the other.

- the pad 40 according to FIG. 3 represents one of the many alternative embodiments to the pad 1. It has three joints 42, 44, 46 which are arranged as concentric circles around the geometric center M of the circular pad 40. They divide the pad 40 into two subspaces 50, 52. The curved course of the joints 42, 44, 46th causes the pad 40 does not lose stability despite the relatively large number of joints, in particular can not easily bend.

- the joints 42, 46 are formed continuously, so they connect the filter blades 41 along their entire length with each other.

- the joint 44 has a discontinuous course: at joints 54 where the two filter sheets are firmly connected to each other, follow interruptions 56.

- the subspace 50 is composed of two annular spaces 58, 59 together, which are interconnected via the interruptions 56.

- the subspace 52 is thus completely separated from its adjacent subspace 50.

- a limited exchange of water and / or particles can take place between the annular spaces 58, 59. It gives the pad 40 in the region of the subspace 50 better Quer barnströmbarkeit.

- the water or eluate can seek an alternative route via the interruption 56, so that it is not possible to build up an undesired overpressure.

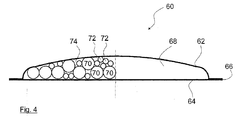

- FIG. 4 A quite different principle of the creation of partial spaces in a receiving space of a pad is shown in FIG. 4.

- the pad 60 consists in a known manner of an upper filter sheet 62 and a lower filter sheet 64, which are connected along their circumference 66 so as to form a receiving space 68 include.

- the receiving space 68 is filled with different substrates 70, 72.

- the shape of the substrates 70, 72 are quite different from each other:

- the substrate 70 has a more or less regular spherical shape, whose diameter is substantially larger than that of the substrate 72.

- the spherical particles 70 completely fill the receiving space 68 of the pad 60. Even with closest possible storage remain between the balls 70 unfilled areas that form spaces 74 of the receiving space 68.

- the substrate 72 can be recorded with its much finer particles. This results in a fine distribution of spaces 74 within the receiving space 68, which are arranged both side by side and one above the other. In this way, a plurality of gaps 74 can be formed within the receiving space 68.

- the substrates 70, 72 differ not only in size but also in their dissolution behavior. That can have physical-chemical reasons or simply result from the different size of the particles 70, 72.

- the finer particles 72 dissolve faster, so that when an impingement of the pad 60 with water they are first dissolved or eluted and get into the outlet of the beverage machine.

- the solution or elution of the larger particles 70 starts. Their ingredients are released but later in the hot water. In this way, an order of dissolution or elution of the substrates 70, 72 within the pad 60 can thus be created.

- the slower dissolution of the larger particles 70 also has the purpose of maintaining the interstices 74 within the receiving space 68 at least until the finer particles 72 have completely dissolved or are eluted.

- the fine distribution of the intermediate spaces 74 is required for the finer particles do not clump together during their elution or dissolution process under water access. They can be, for example, coffee whitener, cocoa or other flavorings.

- the large particles 70 as described above, can in turn contribute to the formation of the coffee beverage by their solution or elution, e.g. B. consist of particles of roasted coffee.

- the particles 70 may also be those which merely serve to form gaps 74 within the receiving space 68. They are then insoluble.

- This way of creating spaces 74 also provides the ability to uniquely determine the gaps 74 in size. For the larger the diameter of the spherical particles 70, the greater is the space remaining therebetween or the gaps 74, and the smaller is their number. Conversely, the total volume of the interstices 74 can be reduced or the number of subspaces increased and their respective volumes reduced by making the diameter of the particles 70 smaller. Finally, the particles 70 are not limited to a spherical shape, but may take any regular or irregular shape with the respective consequences for the formation of the gaps 74.

- the pads described in detail are embodiments, they may be modified in a conventional manner to a wide extent by those skilled in the art without departing from the scope of the invention.

- the pads may also have other peripheral shapes than the circular ones.

- the use of the indefinite article "on” or “one” does not exclude that the characteristics in question may also be present multiple times.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Apparatus For Making Beverages (AREA)

- Packages (AREA)

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102005061927A DE102005061927A1 (de) | 2005-12-23 | 2005-12-23 | Formschlaffes Pad |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1801034A2 true EP1801034A2 (fr) | 2007-06-27 |

| EP1801034A3 EP1801034A3 (fr) | 2008-07-02 |

| EP1801034B1 EP1801034B1 (fr) | 2013-05-22 |

Family

ID=37963599

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP06126633.4A Not-in-force EP1801034B1 (fr) | 2005-12-23 | 2006-12-20 | Dosette flexible |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP1801034B1 (fr) |

| DE (1) | DE102005061927A1 (fr) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ITBO20100234A1 (it) * | 2010-04-15 | 2011-10-16 | Aroma System Srl | Cialda multipla contenente due o piu prodotti separati tra loro e processo per realizzarla |

| WO2014057094A1 (fr) * | 2012-10-12 | 2014-04-17 | Nestec S.A. | Capsule d'aliments ayant de multiples compartiments |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1277826A (en) | 1968-12-30 | 1972-06-14 | Procter & Gamble | Divisible coffee packet |

| US5958478A (en) | 1995-11-09 | 1999-09-28 | Lehrer; Robert | Filtration device for preparation of foods from food concentrates and liquids |

| US20010053399A1 (en) | 2000-05-31 | 2001-12-20 | Walter Herod | Coffee filter pack apparatus & method |

| DE20319191U1 (de) | 2003-12-11 | 2004-06-09 | Lee, Sara | Formstabiles Pad zu Bereitung eines für den Verzehr geeigneten Getränks |

| WO2004078009A2 (fr) | 2003-03-03 | 2004-09-16 | The Procter & Gamble Company | Doses pour infusion contenant des materiaux insolubles |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB9316717D0 (en) * | 1993-08-11 | 1993-09-29 | Gen Foods Ltd | Cartridge and method for the preparation fo whipped beverages |

| US5895672A (en) * | 1998-01-13 | 1999-04-20 | Cooper; Barry Patrick Wesley | Product and process for preparing a tea extract |

| CN1681425A (zh) * | 2002-09-20 | 2005-10-12 | 雀巢技术公司 | 制备起泡的流质食品的方法、装置和胶囊 |

| EP1510159A1 (fr) * | 2003-08-25 | 2005-03-02 | Nestec S.A. | Procédé de préparation d'un produit alimentaire |

-

2005

- 2005-12-23 DE DE102005061927A patent/DE102005061927A1/de not_active Ceased

-

2006

- 2006-12-20 EP EP06126633.4A patent/EP1801034B1/fr not_active Not-in-force

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1277826A (en) | 1968-12-30 | 1972-06-14 | Procter & Gamble | Divisible coffee packet |

| US5958478A (en) | 1995-11-09 | 1999-09-28 | Lehrer; Robert | Filtration device for preparation of foods from food concentrates and liquids |

| US20010053399A1 (en) | 2000-05-31 | 2001-12-20 | Walter Herod | Coffee filter pack apparatus & method |

| WO2004078009A2 (fr) | 2003-03-03 | 2004-09-16 | The Procter & Gamble Company | Doses pour infusion contenant des materiaux insolubles |

| DE20319191U1 (de) | 2003-12-11 | 2004-06-09 | Lee, Sara | Formstabiles Pad zu Bereitung eines für den Verzehr geeigneten Getränks |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ITBO20100234A1 (it) * | 2010-04-15 | 2011-10-16 | Aroma System Srl | Cialda multipla contenente due o piu prodotti separati tra loro e processo per realizzarla |

| WO2014057094A1 (fr) * | 2012-10-12 | 2014-04-17 | Nestec S.A. | Capsule d'aliments ayant de multiples compartiments |

| EP2906086A1 (fr) * | 2012-10-12 | 2015-08-19 | Nestec S.A. | Capsule d'aliments ayant de multiples compartiments |

| US9776789B2 (en) | 2012-10-12 | 2017-10-03 | Nestec S.A. | Food capsule with multiple compartments |

| US10343839B2 (en) | 2012-10-12 | 2019-07-09 | Nestec S.A. | Food capsule with multiple compartments |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1801034B1 (fr) | 2013-05-22 |

| EP1801034A3 (fr) | 2008-07-02 |

| DE102005061927A1 (de) | 2007-06-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0824033B1 (fr) | Cartouche filtrant avec tamis dans un orifice de sortie | |

| DE3803886C2 (fr) | ||

| EP2067420B1 (fr) | Utilisation de filtre fabriqué à partir d'un papier filtre, de type sac | |

| EP0640385B1 (fr) | Garnissage avec des matériaux catalytiques ou adsorbants | |

| EP1344722A1 (fr) | Cartouche mono-dose pour la préparation d'une boisson | |

| CH670573A5 (fr) | ||

| DE1436279A1 (de) | Selbsttaetige Hochleistungsfilterpresse | |

| DE2211832C3 (de) | Auftriebskörper | |

| DE2435945A1 (de) | Behaelter zum auffangen von fluessigkeiten oder gasen | |

| EP0018511B1 (fr) | Substance réactive de remplissage ayant des propriétés d'échange | |

| DE3940334A1 (de) | Sieb fuer drucksortierer fuer fasersuspensionen | |

| DD296606A5 (de) | Filtervorrichtung | |

| EP1380332B1 (fr) | Bougie de filtration pour filtre à pré-couche, Filtre à pré-couche et utilisation d' une bougie de filtration | |

| EP1801034B1 (fr) | Dosette flexible | |

| EP2353690A1 (fr) | Filtre pour la préparation d'eau | |

| EP4008688A1 (fr) | Cartouche filtrante et dispositif filtrant | |

| DE19516800C2 (de) | Filterpapiereinsatz zur Herstellung von Aromaauszügen aus Kaffee oder Tee | |

| DE1667202C3 (de) | Vorrichtung zum Erzeugen ultrahoher Drücke | |

| DE2904417A1 (de) | Kombinationsfilter | |

| DE2802240C2 (de) | Kaffeefilter für Kaffeemaschinen mit gleichmäßiger Brühwasserzufuhr | |

| CH705525A2 (de) | Wiederbefüllbare Kapsel für eine Zubereitungsmaschine. | |

| DE1611086C3 (de) | Mehrstoff-Filter | |

| DE19958647A1 (de) | Wasserfilter mit Filtermaterialtrennelement | |

| EP1186332A1 (fr) | Elément de filtration tubulaire à rincage par contre-courant | |

| DE9101876U1 (de) | Filtereinsatz für das Entfernen von Nitraten und Pestiziden aus Trinkwasser |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK YU |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK RS |

|

| 17P | Request for examination filed |

Effective date: 20090105 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| 17Q | First examination report despatched |

Effective date: 20090220 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 613090 Country of ref document: AT Kind code of ref document: T Effective date: 20130615 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502006012872 Country of ref document: DE Effective date: 20130718 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130522 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130902 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130522 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130922 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130522 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130823 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130923 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130522 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20130522 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130522 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130822 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130522 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130522 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130522 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130522 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130522 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130522 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130522 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130522 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20140225 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502006012872 Country of ref document: DE Effective date: 20140225 |

|

| BERE | Be: lapsed |

Owner name: BSH BOSCH UND SIEMENS HAUSGERATE G.M.B.H. Effective date: 20131231 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131220 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130522 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20131231 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20131231 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20131220 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20131231 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 613090 Country of ref document: AT Kind code of ref document: T Effective date: 20131220 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R081 Ref document number: 502006012872 Country of ref document: DE Owner name: BSH HAUSGERAETE GMBH, DE Free format text: FORMER OWNER: BSH BOSCH UND SIEMENS HAUSGERAETE GMBH, 81739 MUENCHEN, DE Effective date: 20130523 Ref country code: DE Ref legal event code: R081 Ref document number: 502006012872 Country of ref document: DE Owner name: BSH HAUSGERAETE GMBH, DE Free format text: FORMER OWNER: BSH BOSCH UND SIEMENS HAUSGERAETE GMBH, 81739 MUENCHEN, DE Effective date: 20150407 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20131220 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130522 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130522 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20061220 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: CD Owner name: BSH HAUSGERATE GMBH, DE Effective date: 20151022 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 11 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20181219 Year of fee payment: 13 Ref country code: FR Payment date: 20181218 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20181231 Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502006012872 Country of ref document: DE |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20191220 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20191220 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20191231 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200701 |