EP1777458B1 - Leistungsverbesserung einer Brennkammer durch vielfache Perforierung der Wände - Google Patents

Leistungsverbesserung einer Brennkammer durch vielfache Perforierung der Wände Download PDFInfo

- Publication number

- EP1777458B1 EP1777458B1 EP06120816.1A EP06120816A EP1777458B1 EP 1777458 B1 EP1777458 B1 EP 1777458B1 EP 06120816 A EP06120816 A EP 06120816A EP 1777458 B1 EP1777458 B1 EP 1777458B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- holes

- wall

- combustion chamber

- bores

- cooling

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23R—GENERATING COMBUSTION PRODUCTS OF HIGH PRESSURE OR HIGH VELOCITY, e.g. GAS-TURBINE COMBUSTION CHAMBERS

- F23R3/00—Continuous combustion chambers using liquid or gaseous fuel

- F23R3/002—Wall structures

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23R—GENERATING COMBUSTION PRODUCTS OF HIGH PRESSURE OR HIGH VELOCITY, e.g. GAS-TURBINE COMBUSTION CHAMBERS

- F23R3/00—Continuous combustion chambers using liquid or gaseous fuel

- F23R3/02—Continuous combustion chambers using liquid or gaseous fuel characterised by the air-flow or gas-flow configuration

- F23R3/04—Air inlet arrangements

- F23R3/06—Arrangement of apertures along the flame tube

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23R—GENERATING COMBUSTION PRODUCTS OF HIGH PRESSURE OR HIGH VELOCITY, e.g. GAS-TURBINE COMBUSTION CHAMBERS

- F23R2900/00—Special features of, or arrangements for continuous combustion chambers; Combustion processes therefor

- F23R2900/03041—Effusion cooled combustion chamber walls or domes

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23R—GENERATING COMBUSTION PRODUCTS OF HIGH PRESSURE OR HIGH VELOCITY, e.g. GAS-TURBINE COMBUSTION CHAMBERS

- F23R2900/00—Special features of, or arrangements for continuous combustion chambers; Combustion processes therefor

- F23R2900/03042—Film cooled combustion chamber walls or domes

Definitions

- the present invention relates to the general field of turbomachine combustion chambers. It relates more particularly to an annular wall for combustion chamber cooled by a so-called "multiperforation" process.

- annular turbomachine combustion chamber is formed of an inner annular wall and an outer annular wall which are connected upstream by a transverse wall forming a chamber bottom.

- the inner and outer walls are each provided with a plurality of holes and various orifices allowing air circulating around the combustion chamber to penetrate inside thereof.

- so-called “primary” and “dilution” holes are formed in these walls to convey air inside the combustion chamber.

- the air passing through the primary holes helps to create an air / fuel mixture that is burned in the chamber, while the air from the dilution holes is intended to promote the dilution of the same air / fuel mixture.

- the inner and outer walls which are generally metallic, are subject to the high temperatures of the gases from the combustion of the air / fuel mixture.

- additional holes called multiperforation holes are also drilled through the walls over their entire surface. These multiperforation holes allow the air circulating outside the chamber to penetrate inside thereof by forming along the walls of the cooling air films.

- annular wall of turbomachine combustion chamber being provided with a plurality of primary holes and dilution holes. Cooling orifices are distributed in circumferential rows, the number of these orifices being identical in each row. A plurality of bores are disposed directly downstream of the primary holes and the dilution holes. These holes are distributed in circumferential rows. The bores of the same row have a substantially identical diameter, and are spaced a constant pitch throughout the row. Variations in inclination or frequency of said holes relative to the other cooling orifices are not discussed in the document.

- Patent documents EP 1001222 and US 5775108 describe similar annular combustion chamber walls, and there are discussed variations in number (EP) or inclination (US) of the cooling orifices.

- the main object of the present invention is therefore to overcome such drawbacks by proposing an annular wall of a combustion chamber provided with additional bores intended to cool the zones situated directly downstream of the primary and dilution holes.

- annular wall of a turbomachine combustion chamber according to claim 1.

- intrinsic characteristics of the holes we mean the number, the inclination and the diameter of these holes.

- the presence of holes having intrinsic characteristics different from those of the cooling orifices and arranged directly downstream of the primary and dilution holes makes it possible to ensure effective cooling of these areas. Any risk of formation of cracks is thus avoided.

- the specific bores are distributed in circumferential rows, have the same diameter and are spaced a constant pitch which greatly facilitates drilling operations and thus reduces the costs and manufacturing time of the wall.

- the number of holes in the same row may be different from the number of cooling orifices of the adjacent rows, and / or the inclination of the bores of the same row relative to a normal to the wall may be different from that of the cooling holes in adjacent rows.

- the diameter of the bores of the same row may be different from that of the cooling holes of the adjacent rows.

- the present invention also relates to a combustion chamber and a turbomachine (having a combustion chamber) comprising an annular wall as defined above.

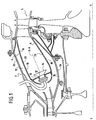

- the figure 1 illustrates a combustion chamber for a turbomachine.

- a turbomachine comprises in particular a compression section (not shown) in which air is compressed before being injected into a chamber housing 2, then into a combustion chamber 4 mounted inside thereof.

- Compressed air is introduced into the combustion chamber and mixed with fuel before being burned.

- the gases resulting from this combustion are then directed to a high-pressure turbine 5 disposed at the outlet of the combustion chamber 4.

- the combustion chamber 4 is of annular type. It is formed of an inner annular wall 6 and an outer annular wall 8 which are connected upstream by a transverse wall 10 forming a chamber bottom.

- the inner 6 and outer 8 walls extend along a longitudinal axis X-X slightly inclined relative to the longitudinal axis Y-Y of the turbomachine.

- the chamber bottom 10 is provided with a plurality of openings 12 in which fuel injectors 14 are mounted.

- the chamber casing 2 which is formed of an inner casing 2a and an outer casing 2b, furnishes with the combustion chamber 4 an annular space 16 in which compressed air for combustion is admitted to the chamber. dilution and cooling of the chamber.

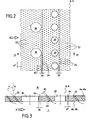

- the inner 6 and outer 8 walls each have a cold side 6a, 8a disposed on the side of the annular space 16 in which the compressed air circulates and a hot side 6b, 8b facing the inside of the combustion chamber 4 ( figure 3 ).

- the combustion chamber 4 is divided into a so-called “primary” zone (or combustion zone) and a so-called “secondary” zone (or dilution zone) located downstream of the previous one (the downstream means with respect to the general direction of flow of gases from the combustion of the air / fuel mixture inside the combustion chamber).

- the air which supplies the primary zone of the combustion chamber 4 is introduced by one or more circumferential rows of primary holes 18 made in the inner and outer walls 6 of the chamber.

- the air supplying the secondary zone of the chamber it borrows a plurality of dilution holes 20 also formed in the inner 6 and outer 8 walls. These dilution holes 20 are aligned in one or more circumferential rows which are axially offset. downstream from the rows of primary holes 18.

- the primary holes 18 and the dilution holes 20 are distributed on the inner 6 and outer 8 walls in rows extending over the entire circumference of the walls.

- a plurality of cooling orifices 22 are provided ( Figures 2 and 3 ).

- These orifices 22, which provide a cooling of the walls 6, 8 by multiperforation, are distributed in a plurality of circumferential rows spaced axially from each other. These rows of multiperforation holes cover almost the entire surface of the walls 6, 8 of the chamber.

- the number and the diameter d1 of the cooling orifices 22 are identical in each of the rows.

- the pitch p1 between two orifices 22 of the same row is also identical throughout the row.

- the adjacent rows of cooling orifices are arranged so that the orifices 22 are arranged in staggered rows as shown in FIG. figure 1 .

- the cooling orifices 22 generally have an angle of inclination ⁇ with respect to a normal N to the annular wall 6, 8 through which they are pierced.

- This inclination ⁇ allows the air passing through these orifices to form a film of air along the hot side 6b, 8b of the annular wall 6, 8.

- it also makes it possible to increase the surface area. of the annular wall which is cooled.

- the inclination ⁇ of the cooling orifices 22 is directed so that the film of air thus formed flows in the direction of flow of the combustion gases inside the chamber (shown schematically by the arrow on the figure 3 ).

- the diameter d 1 of the cooling orifices 22 may be between 0.3 and 1. mm, the pitch p1 between 1 and 10 mm and their inclination ⁇ between -80 ° and + 80 °.

- primary holes 18 and the dilution holes 20 have a diameter of the order of 5 to 20 mm.

- each annular wall 6, 8 of the combustion chamber further comprises a plurality of bores 24 which are arranged directly downstream of the primary holes 18 and dilution 20 and which are distributed in circumferential rows.

- the bores 24 of the same row have a substantially identical diameter d2 , are spaced at a constant pitch P2 and have intrinsic characteristics different from those of the cooling orifices 22 of adjacent rows.

- these holes 24 are thus distributed in one or more rows (for example from 1 to 3 rows) which are arranged directly downstream of said hole 18, 20.

- the intrinsic characteristics of these holes 24 are different from those of the cooling orifices 22, that is to say that the number of holes in the same row is different from that of a row of cooling orifices, and / or or the inclination of the bores of the same row with respect to a normal N to the wall 6, 8 is different from that of the cooling orifices, and / or the diameter d2 of the bores of the same row is different from that of d1 22. It should be noted that these three intrinsic characteristics of the holes 24 can be added.

- the number of bores 24 on the same row may be, over the entire circumference of the wall, of the order of 860 when the number of cooling orifices 22 is of the order of 576. .

- the inclination of the bores 24 relative to a normal to the walls 6, 8 is zero (that is to say that the holes are substantially perpendicular to the walls), while the inclination ⁇ of the cooling orifices 22 relative to at this same normal is between 30 ° and 70 °.

- the bores 24 of the same row have an identical diameter d2 and are spaced by a constant pitch p2 .

- Such holes are typically made by laser using a machine programmed according to the position of each of the holes to be made.

- the characteristics of the holes according to the invention make it possible, with respect to a localized treatment (for which the bores are made only in the direct vicinity of each of the primary and dilution holes), to considerably simplify the programming of the machine, and thus to reduce the costs and manufacturing delays.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Turbine Rotor Nozzle Sealing (AREA)

Claims (3)

- Ringförmige Wand (6, 8) einer Brennkammer (4) einer Turbomaschine, umfassend eine kalte Seite (6a, 8a) und eine heiße Seite (6b, 8b), wobei die Wand versehen ist:mit einer Vielzahl von Primärlöchern (18) und von Verdünnungslöchern (20), um Luft, die auf der kalten Seite (6a, 8a) der Wand (6, 8) zirkuliert, zu ermöglichen, auf die heiße Seite (6b, 8b) zu dringen, um die Verbrennung bzw. die Verdünnung eines Luft/Treibstoff-Gemischs sicherzustellen, wobei die Primärlöcher (18) und die Verdünnungslöcher (20) entlang von Umfangsreihen verteilt sind,mit einer Vielzahl von Kühlöffnungen (22), um der auf der kalten Seite (6a, 8a) der Wand (6, 8) zirkulierenden Luft zu ermöglichen, auf die heiße Seite (6b, 8b) zu dringen, um einen Kühlluftfilm entlang der Wand auszubilden, wobei die Kühlöffnungen (22) entlang einer Vielzahl von Umfangsreihen, die axial voneinander beabstandet sind, verteilt sind, wobei die Anzahl an Kühlöffnungen (22) in jeder Reihe identisch ist, undmit einer Vielzahl von Bohrungen (24), die direkt stromabwärts der Primärlöcher (18) und der Verdünnungslöcher (20) angeordnet und entlang von Umfangsreihen verteilt sind, wobei die Bohrungen (24) einer gleichen Reihe einen im Wesentlichen identischen Durchmesser (d2) aufweisen und um einen kostanten Abstand (p2) beabstandet sind,wobei die Anzahl an Bohrungen (24) einer gleichen Reihe von der Anzahl an Kühlöffnungen (22) der benachbarten Reihen verschieden ist, und/oderwobei die Neigung der Bohrungen (24) einer gleichen Reihe gegenüber einer Normalen (N) zu der Wand von derjenigen der Kühlöffnungen (22) der benachbarten Reihen verschieden ist.

- Brennkammer (4) einer Turbomaschine, umfassend wenigstens eine ringförmige Wand (6, 8) nach Anspruch 1.

- Turbomaschine, umfassend eine Brennkammer (4) mit wenigstens einer ringförmigen Wand (6, 8) nach Anspruch 1.

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR0510584A FR2892180B1 (fr) | 2005-10-18 | 2005-10-18 | Amelioration des perfomances d'une chambre de combustion par multiperforation des parois |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1777458A1 EP1777458A1 (de) | 2007-04-25 |

| EP1777458B1 true EP1777458B1 (de) | 2015-08-12 |

Family

ID=36263914

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP06120816.1A Active EP1777458B1 (de) | 2005-10-18 | 2006-09-18 | Leistungsverbesserung einer Brennkammer durch vielfache Perforierung der Wände |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US7748222B2 (de) |

| EP (1) | EP1777458B1 (de) |

| FR (1) | FR2892180B1 (de) |

| RU (1) | RU2413134C2 (de) |

Families Citing this family (34)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7614235B2 (en) * | 2005-03-01 | 2009-11-10 | United Technologies Corporation | Combustor cooling hole pattern |

| US8171634B2 (en) * | 2007-07-09 | 2012-05-08 | Pratt & Whitney Canada Corp. | Method of producing effusion holes |

| US7905094B2 (en) * | 2007-09-28 | 2011-03-15 | Honeywell International Inc. | Combustor systems with liners having improved cooling hole patterns |

| FR2922630B1 (fr) * | 2007-10-22 | 2015-11-13 | Snecma | Paroi de chambre de combustion a dilution et refroidissement optimises,chambre de combustion et turbomachine en etant munies |

| FR2922629B1 (fr) * | 2007-10-22 | 2009-12-25 | Snecma | Chambre de combustion a dilution optimisee et turbomachine en etant munie |

| US8127554B2 (en) * | 2007-11-29 | 2012-03-06 | Honeywell International Inc. | Quench jet arrangement for annular rich-quench-lean gas turbine combustors |

| US8616004B2 (en) * | 2007-11-29 | 2013-12-31 | Honeywell International Inc. | Quench jet arrangement for annular rich-quench-lean gas turbine combustors |

| US8056342B2 (en) * | 2008-06-12 | 2011-11-15 | United Technologies Corporation | Hole pattern for gas turbine combustor |

| US8091367B2 (en) * | 2008-09-26 | 2012-01-10 | Pratt & Whitney Canada Corp. | Combustor with improved cooling holes arrangement |

| US8438856B2 (en) * | 2009-03-02 | 2013-05-14 | General Electric Company | Effusion cooled one-piece can combustor |

| FR2972027B1 (fr) * | 2011-02-25 | 2013-03-29 | Snecma | Chambre annulaire de combustion de turbomachine comprenant des orifices de dilution ameliores |

| FR2974162B1 (fr) * | 2011-04-14 | 2018-04-13 | Safran Aircraft Engines | Virole de tube a flamme dans une chambre de combustion de turbomachine |

| FR2975465B1 (fr) * | 2011-05-19 | 2018-03-09 | Safran Aircraft Engines | Paroi pour chambre de combustion de turbomachine comprenant un agencement optimise d'orifices d'entree d'air |

| US9062884B2 (en) | 2011-05-26 | 2015-06-23 | Honeywell International Inc. | Combustors with quench inserts |

| FR2981733B1 (fr) * | 2011-10-25 | 2013-12-27 | Snecma | Module de chambre de combustion de turbomachine d'aeronef et procede de conception de celui-ci |

| FR2982008B1 (fr) * | 2011-10-26 | 2013-12-13 | Snecma | Paroi annulaire de chambre de combustion a refroidissement ameliore au niveau des trous primaires et de dilution |

| FR2991028B1 (fr) * | 2012-05-25 | 2014-07-04 | Snecma | Virole de chambre de combustion de turbomachine |

| US10260748B2 (en) * | 2012-12-21 | 2019-04-16 | United Technologies Corporation | Gas turbine engine combustor with tailored temperature profile |

| EP2971970B1 (de) * | 2013-03-15 | 2019-10-30 | Rolls-Royce Corporation | Dublettenbrenner mit gegenwirbel |

| EP2971966B1 (de) * | 2013-03-15 | 2017-04-19 | Rolls-Royce Corporation | Innenverkleidung für eine gasturbinenbrennkammer |

| EP3077728B8 (de) | 2013-12-06 | 2021-03-31 | Raytheon Technologies Corporation | Gasturbinenbrennkammer mit co-swirl-ausrichtung von effusionslöchern, und methode |

| US20160178199A1 (en) * | 2014-12-17 | 2016-06-23 | United Technologies Corporation | Combustor dilution hole active heat transfer control apparatus and system |

| FR3035707B1 (fr) * | 2015-04-29 | 2019-11-01 | Safran Aircraft Engines | Chambre de combustion coudee d'une turbomachine |

| US10670267B2 (en) * | 2015-08-14 | 2020-06-02 | Raytheon Technologies Corporation | Combustor hole arrangement for gas turbine engine |

| GB201518345D0 (en) * | 2015-10-16 | 2015-12-02 | Rolls Royce | Combustor for a gas turbine engine |

| JP6026028B1 (ja) * | 2016-03-10 | 2016-11-16 | 三菱日立パワーシステムズ株式会社 | 燃焼器用パネル、燃焼器、燃焼装置、ガスタービン、及び燃焼器用パネルの冷却方法 |

| DE102016219424A1 (de) * | 2016-10-06 | 2018-04-12 | Rolls-Royce Deutschland Ltd & Co Kg | Brennkammeranordnung einer Gasturbine sowie Fluggasturbine |

| US11015529B2 (en) | 2016-12-23 | 2021-05-25 | General Electric Company | Feature based cooling using in wall contoured cooling passage |

| US20180266687A1 (en) * | 2017-03-16 | 2018-09-20 | General Electric Company | Reducing film scrubbing in a combustor |

| US10816202B2 (en) | 2017-11-28 | 2020-10-27 | General Electric Company | Combustor liner for a gas turbine engine and an associated method thereof |

| US11255543B2 (en) | 2018-08-07 | 2022-02-22 | General Electric Company | Dilution structure for gas turbine engine combustor |

| DE102019105442A1 (de) * | 2019-03-04 | 2020-09-10 | Rolls-Royce Deutschland Ltd & Co Kg | Verfahren zur Herstellung eines Triebwerksbauteils mit einer Kühlkanalanordnung und Triebwerksbauteil |

| EP3848556A1 (de) * | 2020-01-13 | 2021-07-14 | Ansaldo Energia Switzerland AG | Gasturbinentriebwerk mit übergangsstück mit geneigten kühlöffnungen |

| CN116202106B (zh) * | 2023-03-08 | 2024-05-03 | 中国科学院工程热物理研究所 | 一种气膜孔与掺混孔耦合设计的发动机燃烧室火焰筒结构 |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1632720A1 (de) * | 2004-09-03 | 2006-03-08 | General Electric Company | Einstellen der Luftströmungsmenge an einem Bauteil einer Turbine durch Aufbringen einer metallischen Beschichtung |

Family Cites Families (25)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1493144A (fr) * | 1966-08-19 | 1967-08-25 | Lucas Industries Ltd | Perfectionnements aux appareils de combustion pour moteurs de turbines à gaz |

| US3572031A (en) * | 1969-07-11 | 1971-03-23 | United Aircraft Corp | Variable area cooling passages for gas turbine burners |

| GB1492049A (en) * | 1974-12-07 | 1977-11-16 | Rolls Royce | Combustion equipment for gas turbine engines |

| US4244178A (en) * | 1978-03-20 | 1981-01-13 | General Motors Corporation | Porous laminated combustor structure |

| US4180972A (en) * | 1978-06-08 | 1980-01-01 | General Motors Corporation | Combustor support structure |

| US4302940A (en) * | 1979-06-13 | 1981-12-01 | General Motors Corporation | Patterned porous laminated material |

| US4269032A (en) * | 1979-06-13 | 1981-05-26 | General Motors Corporation | Waffle pattern porous material |

| US4296606A (en) * | 1979-10-17 | 1981-10-27 | General Motors Corporation | Porous laminated material |

| SU1373045A1 (ru) * | 1986-05-26 | 1996-12-20 | В.М. Кофман | Охлаждаемый корпус |

| US5181379A (en) * | 1990-11-15 | 1993-01-26 | General Electric Company | Gas turbine engine multi-hole film cooled combustor liner and method of manufacture |

| US5241827A (en) * | 1991-05-03 | 1993-09-07 | General Electric Company | Multi-hole film cooled combuster linear with differential cooling |

| US5261223A (en) * | 1992-10-07 | 1993-11-16 | General Electric Company | Multi-hole film cooled combustor liner with rectangular film restarting holes |

| FR2733582B1 (fr) * | 1995-04-26 | 1997-06-06 | Snecma | Chambre de combustion comportant une multiperforation d'inclinaison axiale et tangentielle variable |

| US6192689B1 (en) * | 1998-03-18 | 2001-02-27 | General Electric Company | Reduced emissions gas turbine combustor |

| US6474070B1 (en) * | 1998-06-10 | 2002-11-05 | General Electric Company | Rich double dome combustor |

| US6145319A (en) * | 1998-07-16 | 2000-11-14 | General Electric Company | Transitional multihole combustion liner |

| US6205789B1 (en) * | 1998-11-13 | 2001-03-27 | General Electric Company | Multi-hole film cooled combuster liner |

| RU2162194C1 (ru) * | 1999-11-24 | 2001-01-20 | Общество с ограниченной ответственностью Научно-производственное предприятие "ЭСТ" | Камера сгорания |

| US6434821B1 (en) * | 1999-12-06 | 2002-08-20 | General Electric Company | Method of making a combustion chamber liner |

| US6427446B1 (en) * | 2000-09-19 | 2002-08-06 | Power Systems Mfg., Llc | Low NOx emission combustion liner with circumferentially angled film cooling holes |

| US6408629B1 (en) * | 2000-10-03 | 2002-06-25 | General Electric Company | Combustor liner having preferentially angled cooling holes |

| US6620457B2 (en) * | 2001-07-13 | 2003-09-16 | General Electric Company | Method for thermal barrier coating and a liner made using said method |

| US6513331B1 (en) * | 2001-08-21 | 2003-02-04 | General Electric Company | Preferential multihole combustor liner |

| US7093439B2 (en) * | 2002-05-16 | 2006-08-22 | United Technologies Corporation | Heat shield panels for use in a combustor for a gas turbine engine |

| US7895841B2 (en) * | 2006-07-14 | 2011-03-01 | General Electric Company | Method and apparatus to facilitate reducing NOx emissions in turbine engines |

-

2005

- 2005-10-18 FR FR0510584A patent/FR2892180B1/fr not_active Expired - Lifetime

-

2006

- 2006-09-18 EP EP06120816.1A patent/EP1777458B1/de active Active

- 2006-10-10 US US11/544,554 patent/US7748222B2/en active Active

- 2006-10-17 RU RU2006136873/06A patent/RU2413134C2/ru active

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1632720A1 (de) * | 2004-09-03 | 2006-03-08 | General Electric Company | Einstellen der Luftströmungsmenge an einem Bauteil einer Turbine durch Aufbringen einer metallischen Beschichtung |

Also Published As

| Publication number | Publication date |

|---|---|

| FR2892180B1 (fr) | 2008-02-01 |

| RU2006136873A (ru) | 2008-04-27 |

| US7748222B2 (en) | 2010-07-06 |

| RU2413134C2 (ru) | 2011-02-27 |

| FR2892180A1 (fr) | 2007-04-20 |

| EP1777458A1 (de) | 2007-04-25 |

| US20070084219A1 (en) | 2007-04-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1777458B1 (de) | Leistungsverbesserung einer Brennkammer durch vielfache Perforierung der Wände | |

| EP2771618B1 (de) | Ringförmige brennkammerwand mit verbesserter kühlung an den primär- und/oder verdünnungsluftlöchern | |

| EP3303774B1 (de) | Ringförmige wand einer brennkammer mit optimierter kühlung | |

| EP2042806B1 (de) | Brennkammer einer Strömungsmaschine | |

| EP1644615B1 (de) | Kühlkanäle in einem befestigungsring einer gasturbine | |

| EP1634021B1 (de) | Ringförmige brennkammer einer turbomaschine | |

| EP1593814B1 (de) | Anordnung von Dichtsreifen bei einem Mantelring einer Gasturbine | |

| CA2412982C (fr) | Plate-forme d'aube de distributeur pour moteur a turbine a gaz | |

| EP1818617B1 (de) | Querwand einer Brennkammer, die mit Multiperforationslöchern ausgestattet ist | |

| EP1489359B1 (de) | Ringförmige Brennkammer für eine Turbomaschine | |

| EP2053311B1 (de) | Wände einer Brennkammer mit optimierter Verdünnung und Abkühlung, damit ausgerüstete Brennkammer und Turbomaschine | |

| FR2982009A1 (fr) | Paroi annulaire de chambre de combustion a refroidissement ameliore au niveau des trous primaires et/ou de dilution | |

| FR3072448B1 (fr) | Chambre de combustion de turbomachine | |

| FR3019270A1 (fr) | Paroi annulaire de chambre de combustion a orifices de refroidissement ameliores au niveau des jonctions brides | |

| EP4179256B1 (de) | Ringbrennkammer für eine flugzeugturbomaschine | |

| FR3070751A1 (fr) | Chambre de combustion comportant une repartition amelioree de trous de refroidissement | |

| FR3081974A1 (fr) | Chambre de combustion d'une turbomachine | |

| WO2018134501A2 (fr) | Chambre de combustion de turbomachine a haute permeabilite | |

| WO2025056848A1 (fr) | Systeme ameliore de refroidissement d'anneau fixe de turbine a gaz | |

| FR2893389A1 (fr) | Paroi transversale de chambre de combustion munie de trous de multiperforation | |

| FR2896304A1 (fr) | Paroi annulaire transversale de chambre de combustion de turbomachine | |

| FR3033028A1 (fr) | Chambre de combustion de turbomachine comportant une piece penetrante avec ouverture |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20060918 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK YU |

|

| AKX | Designation fees paid |

Designated state(s): DE FR GB IT |

|

| 17Q | First examination report despatched |

Effective date: 20130326 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20150410 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FR GB IT |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602006046235 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602006046235 Country of ref document: DE |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20160513 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 11 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: CD Owner name: SAFRAN AIRCRAFT ENGINES, FR Effective date: 20170719 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20250919 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20250923 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20250924 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20250930 Year of fee payment: 20 |