EP1663809B1 - Water soluble container - Google Patents

Water soluble container Download PDFInfo

- Publication number

- EP1663809B1 EP1663809B1 EP03762682A EP03762682A EP1663809B1 EP 1663809 B1 EP1663809 B1 EP 1663809B1 EP 03762682 A EP03762682 A EP 03762682A EP 03762682 A EP03762682 A EP 03762682A EP 1663809 B1 EP1663809 B1 EP 1663809B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- container

- wall

- chamber

- panel

- remainder

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Revoked

Links

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 title description 4

- 239000000463 material Substances 0.000 claims description 26

- 239000004372 Polyvinyl alcohol Substances 0.000 claims description 6

- 229920002451 polyvinyl alcohol Polymers 0.000 claims description 6

- 238000001746 injection moulding Methods 0.000 claims description 3

- 229920002472 Starch Polymers 0.000 claims description 2

- 229920000747 poly(lactic acid) Polymers 0.000 claims description 2

- 239000004626 polylactic acid Substances 0.000 claims description 2

- 235000019698 starch Nutrition 0.000 claims description 2

- 239000008107 starch Substances 0.000 claims description 2

- 239000000047 product Substances 0.000 description 23

- 238000004090 dissolution Methods 0.000 description 8

- 238000005406 washing Methods 0.000 description 6

- 238000005192 partition Methods 0.000 description 4

- 239000003599 detergent Substances 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 3

- 239000011324 bead Substances 0.000 description 2

- 239000002195 soluble material Substances 0.000 description 2

- 239000004902 Softening Agent Substances 0.000 description 1

- 230000004913 activation Effects 0.000 description 1

- 239000006227 byproduct Substances 0.000 description 1

- 239000012611 container material Substances 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 238000004851 dishwashing Methods 0.000 description 1

- 238000002347 injection Methods 0.000 description 1

- 239000007924 injection Substances 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 229920006395 saturated elastomer Polymers 0.000 description 1

- 238000003466 welding Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D65/00—Wrappers or flexible covers; Packaging materials of special type or form

- B65D65/38—Packaging materials of special type or form

- B65D65/46—Applications of disintegrable, dissolvable or edible materials

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D81/00—Containers, packaging elements, or packages, for contents presenting particular transport or storage problems, or adapted to be used for non-packaging purposes after removal of contents

- B65D81/32—Containers, packaging elements, or packages, for contents presenting particular transport or storage problems, or adapted to be used for non-packaging purposes after removal of contents for packaging two or more different materials which must be maintained separate prior to use in admixture

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D81/00—Containers, packaging elements, or packages, for contents presenting particular transport or storage problems, or adapted to be used for non-packaging purposes after removal of contents

- B65D81/32—Containers, packaging elements, or packages, for contents presenting particular transport or storage problems, or adapted to be used for non-packaging purposes after removal of contents for packaging two or more different materials which must be maintained separate prior to use in admixture

- B65D81/3205—Separate rigid or semi-rigid containers joined to each other at their external surfaces

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D81/00—Containers, packaging elements, or packages, for contents presenting particular transport or storage problems, or adapted to be used for non-packaging purposes after removal of contents

- B65D81/32—Containers, packaging elements, or packages, for contents presenting particular transport or storage problems, or adapted to be used for non-packaging purposes after removal of contents for packaging two or more different materials which must be maintained separate prior to use in admixture

- B65D81/3261—Flexible containers having several compartments

Definitions

- the present invention relates generally to a water-soluble container.

- Water-soluble containers as such are well-known and have a variety of uses, such as in clothes washing.

- CA 1112534 describes a water-soluble container for a detergent composition.

- the water-soluble material may be, for example, polyvinyl alcohol (PVOH).

- PVOH polyvinyl alcohol

- This document describes a single chamber with a film form wall of constant thickness. Because the chamber wall is of constant thickness, the entire wall must be dissolved before any product can escape. In certain circumstances product may be required quickly, before the time when the entire container has dissolved.

- WO 01/83668 , EP 593 952 , GB 2 356 842 and WO 01/36290 all disclose prior art containers in accordance with the preamble of appended claim 1.

- a water-soluble container comprising one ore more discrete chambers for containing product, wherein at least part of a wall of the or at least one of the chamber/s is adapted to dissolve before the remainder of the chamber to allow product to escape, characterised in that the at least part of the wall adapted to dissolve before the remainder of each chamber defines a panel and the at least part of the wall at least partly surrounds the panel, such that when the at least part of the wall dissolves the panel is either partly or completely released undissolved.

- product can escape from a chamber without requiring complete dissolution of the chamber. This can be useful for decreasing the time taken for product to be released. It can also allow for a greater degree of control over when product is released because the area required to be dissolved is reduced.

- a container according to the present invention for a system combining the advantage of not requiring a whole chamber to dissolve before a product is released, together with the possibility of sequential release of products.

- a chamber provided with the means for allowing product to escape before complete dissolution could be associated with a chamber not having those means. More complicated systems could involve chambers which allow products to escape after different times before complete dissolution.

- the present invention removes the need for manual intervention at different stages of washing cycles and allows the complete washing product to be packaged and supplied together.

- the at least part of the wall will most usually be an exterior surface of the container thereby releasing product from the container when it dissolves.

- the at least part of the wall forms part of a chamber which is housed within another chamber which itself includes water, whereby the contents of the chambers are mixed when the at least part of the wall dissolves. This might be useful, for example, if the product in the inner chamber is activated by product in the outer chamber. This allows activation in a controlled environment before the activated product is released into the exterior of the container and could be useful for products which become unstable once activated.

- the container could be formed in order that product is released from the chamber when the part of the wall dissolves.

- the part of the wall may comprise one or more clip elements, such as a hook.

- the clip elements initially clip the closure part to the container but then dissolve and release the releasable panel. In this way only a small section of the wall dissolves and yet a large opening can be provided quickly.

- the part of the wall could be formed in order that it dissolves before the remainder of the container.

- the at least part of the wall could be made from a thinner section of material and/or from a different material with a faster rate of dissolution than the remainder of the container.

- the material thinning may be arranged on the interior surface of the chamber wall. This is particularly relevant when the at least part of the wall defines a thin channel, because if the material thinning was arranged on the exterior surface the channel could become saturated with dissolved material, which would impede further dissolution.

- the container may be formed by injection moulding.

- the area of the panel may form the gate region for injection moulding. This ensures that the thin section is correctly moulded by avoiding problems with moulded regions which are remote from the injection point.

- differential dissolution characteristics may be achieved by forming the container from two or more different materials at least some of which are water-soluble. It may, however, be preferable for simplification of the production process for the whole of the container to be formed from the same material.

- At least part of the material from which the container is formed is a polyvinyl alcohol.

- at least part of the material may be a polylactic acid or a starch based material.

- the container may be flexible. This may be as a result of the choice of material and/or the thickness of the walls.

- wall can refer to any one or more of the walls.

- a spherical container for example, has a single wall whereas a cube has six walls. The term is therefore generic and could refer to any part of the material defining the chamber.

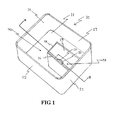

- a housing 10 of generally parallelepiped shape comprising a base wall 11, side walls 12,13 and end walls 14,15.

- the housing is hollow and is open opposite the base 11 to form a tray-like structure.

- the housing 10 is formed from a water-soluble material.

- the material could be, for example, a grade of PVOH which dissolves at approximately 50°C.

- the interior of the housing 10 is divided into two discrete chambers 30, 31 by spaced parallel partition side walls 16, 17 which extend from end wall 15 and are joined at their ends by a partition end wall 18.

- Each of the partition walls 16, 17, 18 extends the full height of the housing walls 11, 12, 13, 14, 15.

- the portion of the base wall 14 which is bounded by the partition walls 16, 17, 18 includes a panel 19 surrounded by a region of material thinning 20 the purpose of which will be described in more detail below.

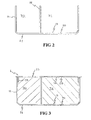

- Fig 3 the housing of Figs 1 and 2 is shown forming part of a container 1.

- the housing 10 is closed by a lid 25.

- the chambers 30, 31 are filled with different products before the lid 25 is applied.

- the lid 25 includes a panel 26 and region of material thinning 27 opposite and identical to those of the housing 10.

- the lid 25 may be secured to the housing 10 by any convenient means such as welding adhesion, interference fit or clipping.

- the seal is a face seal bond which is chemically activated, in this case by water, and supported internally by a wall 28 depending from the lid 25.

- the thickness of the housing walls and the lid is approximately 0.4mm. This is about the thinnest that material can be without a risk of 'pin holes' i.e. tiny holes in the material which could compromise the integrity of the chamber.

- the material thinnings are approximately 0.15mm thick and are formed by reducing a small part of the uniform thickness of the container.

- the container 1 In use, the container 1 is placed in an aqueous environment and the temperature is raised beyond the dissolution temperature of the container material. As the container 1 begins to dissolve the material thinned regions 20, 27 will completely dissolve before the remainder of the container. As a result, the panels 19, 26 are released from the lid 25 and the base wall 14 such that product can escape from the chamber 31. Of course, the panels 19, 26 do not have to be completely released to be effective. For example the material thinned regions 20, 27 could extend part way round the panels 19, 26 such that the panels 19, 26 become flaps which hinge open. Product from the chamber cannot escape until the remainder of the container has dissolved.

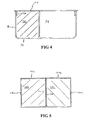

- Fig 5 there is shown an alternative arrangement.

- two discrete chambers 130, 131 are formed from two separate, hollow cube-shape housings 110a, 110b which are bonded together along adjacent side walls 112a, 112b.

- Each housing 110a, 110b is open along one side by closed by a lid 125a, 125b in this embodiment sealed to the housings by adhesion.

- the lids 125a, 125b are formed from different grades of PVOH which dissolve at different rates, with the material of the lid 125a having the faster dissolution rate. In this embodiment therefore the lid 125a of the housing 110a dissolves before the lid of housing 110b, to allow its product to escape first.

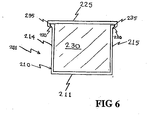

- a generally cuboid housing 210 comprises a base wall 211 and side walls 214, 215. An open side of the housing 210 is closed by a lid 225.

- the lid 225 is held onto the housing 210 by a clip 220 extending from its periphery.

- the clip 220 engages under a bead 235 formed around the open side of the housing 210.

- the clip 220 is thinner than the remainder of the container 201. Accordingly, in use of the container the clip 220 dissolves before the remainder of the container so that the bead 235 no longer retains the lid 225, and therefore allows the lid 225 to be released from the housing 210.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Packages (AREA)

- Package Specialized In Special Use (AREA)

- Wrappers (AREA)

- Bidet-Like Cleaning Device And Other Flush Toilet Accessories (AREA)

- Packging For Living Organisms, Food Or Medicinal Products That Are Sensitive To Environmental Conditiond (AREA)

Abstract

Description

- The present invention relates generally to a water-soluble container.

- Water-soluble containers as such are well-known and have a variety of uses, such as in clothes washing. For example,

CA 1112534 describes a water-soluble container for a detergent composition. The water-soluble material may be, for example, polyvinyl alcohol (PVOH). This document describes a single chamber with a film form wall of constant thickness. Because the chamber wall is of constant thickness, the entire wall must be dissolved before any product can escape. In certain circumstances product may be required quickly, before the time when the entire container has dissolved.WO 01/83668 EP 593 952 GB 2 356 842 WO 01/36290 claim 1. According to the present invention there is provided a water-soluble container comprising one ore more discrete chambers for containing product, wherein at least part of a wall of the or at least one of the chamber/s is adapted to dissolve before the remainder of the chamber to allow product to escape, characterised in that the at least part of the wall adapted to dissolve before the remainder of each chamber defines a panel and the at least part of the wall at least partly surrounds the panel, such that when the at least part of the wall dissolves the panel is either partly or completely released undissolved. This means that product can escape from a chamber without requiring complete dissolution of the chamber. This can be useful for decreasing the time taken for product to be released. It can also allow for a greater degree of control over when product is released because the area required to be dissolved is reduced. - A container according to the present invention for a system combining the advantage of not requiring a whole chamber to dissolve before a product is released, together with the possibility of sequential release of products. In its simplest form a chamber provided with the means for allowing product to escape before complete dissolution could be associated with a chamber not having those means. More complicated systems could involve chambers which allow products to escape after different times before complete dissolution.

- The ability of such containers to provide for sequential release of multiple products is extremely useful. For example, clothing washing usually includes a detergent stage and a stage later in the washing cycle in which a softening agent is introduced. Dish-washing sometimes includes a detergent stage and a separate rinsing stage. In many cases it would be preferable and sometimes essential for different stages of washing operations to be kept completely separate.

- By providing for sequential release of products the present invention removes the need for manual intervention at different stages of washing cycles and allows the complete washing product to be packaged and supplied together.

- The at least part of the wall will most usually be an exterior surface of the container thereby releasing product from the container when it dissolves. However, it is also possible that the at least part of the wall forms part of a chamber which is housed within another chamber which itself includes water, whereby the contents of the chambers are mixed when the at least part of the wall dissolves. This might be useful, for example, if the product in the inner chamber is activated by product in the outer chamber. This allows activation in a controlled environment before the activated product is released into the exterior of the container and could be useful for products which become unstable once activated.

- There are many ways in which the container could be formed in order that product is released from the chamber when the part of the wall dissolves.

- The part of the wall may comprise one or more clip elements, such as a hook. The clip elements initially clip the closure part to the container but then dissolve and release the releasable panel. In this way only a small section of the wall dissolves and yet a large opening can be provided quickly.

- There are many ways in which the part of the wall could be formed in order that it dissolves before the remainder of the container. For example, the at least part of the wall could be made from a thinner section of material and/or from a different material with a faster rate of dissolution than the remainder of the container.

- In embodiments where the at least part of the wall is thinner than the remainder of the container the material thinning may be arranged on the interior surface of the chamber wall. This is particularly relevant when the at least part of the wall defines a thin channel, because if the material thinning was arranged on the exterior surface the channel could become saturated with dissolved material, which would impede further dissolution.

- In order to simplify production and allow for high volume production the container may be formed by injection moulding. In embodiments where the at least part of the wall is a thin section surrounding a panel, the area of the panel may form the gate region for injection moulding. This ensures that the thin section is correctly moulded by avoiding problems with moulded regions which are remote from the injection point.

- As stated above, differential dissolution characteristics may be achieved by forming the container from two or more different materials at least some of which are water-soluble. It may, however, be preferable for simplification of the production process for the whole of the container to be formed from the same material.

- In some embodiments at least part of the material from which the container is formed is a polyvinyl alcohol. Alternatively at least part of the material may be a polylactic acid or a starch based material.

- The container may be flexible. This may be as a result of the choice of material and/or the thickness of the walls.

- Where a container has several walls, the term "wall" can refer to any one or more of the walls. A spherical container, for example, has a single wall whereas a cube has six walls. The term is therefore generic and could refer to any part of the material defining the chamber.

- The present invention will now be more particularly described, by way of example, with reference to the accompanying drawings, in which:

-

Fig 1 is a perspective view of a housing formed as part of a container according to a first embodiment; -

Fig 2 is a section along line II - II ofFig 1 , -

Fig 3 shows the housing ofFig 2 with a lid component attached; -

Fig 4 shows the container ofFig 3 following an initial exposure to water; -

Fig 5 is a section through a container according to an alternative arrangement not covered by the appended claims; and -

Fig 6 is a section of a container according to an alternative embodiment. - Referring first to

Figs 1 and2 there is shown ahousing 10 of generally parallelepiped shape comprising abase wall 11,side walls end walls base 11 to form a tray-like structure. Thehousing 10 is formed from a water-soluble material. The material could be, for example, a grade of PVOH which dissolves at approximately 50°C. The interior of thehousing 10 is divided into twodiscrete chambers partition side walls 16, 17 which extend fromend wall 15 and are joined at their ends by apartition end wall 18. Each of thepartition walls housing walls base wall 14 which is bounded by thepartition walls panel 19 surrounded by a region of material thinning 20 the purpose of which will be described in more detail below. - Referring now to

Fig 3 the housing ofFigs 1 and2 is shown forming part of acontainer 1. Thehousing 10 is closed by alid 25. Thechambers lid 25 is applied. Thelid 25 includes apanel 26 and region of material thinning 27 opposite and identical to those of thehousing 10. Thelid 25 may be secured to thehousing 10 by any convenient means such as welding adhesion, interference fit or clipping. In this embodiment the seal is a face seal bond which is chemically activated, in this case by water, and supported internally by a wall 28 depending from thelid 25. - In this embodiment the thickness of the housing walls and the lid is approximately 0.4mm. This is about the thinnest that material can be without a risk of 'pin holes' i.e. tiny holes in the material which could compromise the integrity of the chamber. The material thinnings are approximately 0.15mm thick and are formed by reducing a small part of the uniform thickness of the container.

- In use, the

container 1 is placed in an aqueous environment and the temperature is raised beyond the dissolution temperature of the container material. As thecontainer 1 begins to dissolve the material thinnedregions panels lid 25 and thebase wall 14 such that product can escape from thechamber 31. Of course, thepanels regions panels panels - Referring now to

Fig 5 there is shown an alternative arrangement. In this arrangement twodiscrete chambers lid 125a, 125b in this embodiment sealed to the housings by adhesion. Thelids 125a, 125b are formed from different grades of PVOH which dissolve at different rates, with the material of thelid 125a having the faster dissolution rate. In this embodiment therefore thelid 125a of the housing 110a dissolves before the lid of housing 110b, to allow its product to escape first. - Referring to

Fig 6 there is shown acontainer 201 with asingle chamber 230. A generallycuboid housing 210 comprises abase wall 211 andside walls housing 210 is closed by alid 225. - The

lid 225 is held onto thehousing 210 by aclip 220 extending from its periphery. Theclip 220 engages under abead 235 formed around the open side of thehousing 210. - The

clip 220 is thinner than the remainder of thecontainer 201. Accordingly, in use of the container theclip 220 dissolves before the remainder of the container so that thebead 235 no longer retains thelid 225, and therefore allows thelid 225 to be released from thehousing 210.

Claims (11)

- A water-soluble container (1) comprising one ore more discrete chambers (30, 31) for containing product, wherein at least part (20, 27) of a wall (11, 25) of the or at least one of the chamber/s is adapted to dissolve before the remainder of the chamber to allow product to escape,

characterised in that

the at least part (20, 27) of the wall (11, 25) adapted to dissolve before the remainder of each chamber defines a panel (19, 26) and the at least part of the wall at least partly surrounds the panel, such that when the at least part of the wall dissolves the panel is either partly or completely released undissolved. - A container (201) according to Claim 1, wherein the at least part of the wall (225) comprises one or more clip elements (220) adapted to retain the panel (225) until dissolved.

- A container (1) according to Claim 1 or Claim 2, wherein the at least part (20, 27) of the wall is thinner than the remainder of the container.

- A container (1) according to Claim 3, wherein the material thinning (20, 27) is arranged on the interior surface of the chamber wall.

- A container (1) according to any preceding claim, wherein the container is formed by injection moulding.

- A container (1) according to any preceding claim, wherein at least part of the material from which the container is formed is a polyvinyl alcohol.

- A container (1) according to any preceding claim, wherein at least part of the material from which the container is formed is a polylactic acid.

- A container (1) according to any preceding claim, wherein at least part of the material from which the container is formed is starch-based.

- A container (1) according to any preceding claim, wherein the whole of the container is formed from the same material.

- A container (1) according to any preceding claim, wherein the container is flexible.

- A container according to any preceding claim, comprising two or more chambers, wherein each chamber has a panel and the at least parts of the wall for each panel dissolve at different rates so that the products contained in the chambers are allowed to escape sequentially.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP03762682A EP1663809B1 (en) | 2002-07-03 | 2003-06-26 | Water soluble container |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP02254680 | 2002-07-03 | ||

| PCT/EP2003/007798 WO2004005156A1 (en) | 2002-07-03 | 2003-06-26 | Water-soluble container |

| EP03762682A EP1663809B1 (en) | 2002-07-03 | 2003-06-26 | Water soluble container |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1663809A1 EP1663809A1 (en) | 2006-06-07 |

| EP1663809B1 true EP1663809B1 (en) | 2008-10-15 |

Family

ID=30011232

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03762682A Revoked EP1663809B1 (en) | 2002-07-03 | 2003-06-26 | Water soluble container |

Country Status (12)

| Country | Link |

|---|---|

| US (1) | US20060124646A1 (en) |

| EP (1) | EP1663809B1 (en) |

| AT (1) | ATE411236T1 (en) |

| AU (1) | AU2003246714A1 (en) |

| BR (1) | BR0312397A (en) |

| CA (1) | CA2491283A1 (en) |

| DE (1) | DE60324205D1 (en) |

| ES (1) | ES2315533T3 (en) |

| MX (1) | MXPA05000096A (en) |

| PL (1) | PL202692B1 (en) |

| RU (1) | RU2005102594A (en) |

| WO (1) | WO2004005156A1 (en) |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7830263B2 (en) | 2006-04-28 | 2010-11-09 | Obrist Closures Switzerland Gmbh | Closure with RFID device |

| USD630093S1 (en) | 2010-06-11 | 2011-01-04 | Obrist Closures Switzerland Gmbh | Closure |

| US8413830B2 (en) | 2008-04-04 | 2013-04-09 | Obrist Closures Switzerland Gmbh | Closure |

| US8453856B2 (en) | 2007-07-13 | 2013-06-04 | Obrist Closures Switzerland Gmbh | Tamper-evident closure |

| US8490804B2 (en) | 2007-10-31 | 2013-07-23 | Obrist Closures Switzerland Gmbh | Closure with movable tamper-evident member |

| US8522991B2 (en) | 2003-10-31 | 2013-09-03 | Obrist Closures Switzerland Gmbh | Tamper evident closure |

| US9102448B2 (en) | 2007-07-13 | 2015-08-11 | Obrist Closures Switzerland Gmbh | Tamper-evident closure |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| MY140144A (en) * | 2004-06-30 | 2009-11-30 | Obrist Closures Switzerland | Dispensing closure |

| DE102006021016A1 (en) * | 2006-05-05 | 2007-11-15 | Dürschinger, Günter | Chemically activatable capsule for continuity check and treatment of intestinal tract, comprises interior covering with opposite discharge openings and with a filling from granulates, powder, gel or liquid, and outer covering |

| DE102006036438A1 (en) | 2006-08-04 | 2008-02-14 | Fischerwerke Artur Fischer Gmbh & Co. Kg | Use of synthetic resins when fastening screws and similar anchoring means, related processes and synthetic resins |

| US20090108006A1 (en) * | 2007-10-26 | 2009-04-30 | Coollid Corporation | Beverage container lid having liquid cooling effect |

| US20100320168A1 (en) * | 2008-02-19 | 2010-12-23 | Martin Carey Bull | Child-resistant closure |

| DE102008018861A1 (en) | 2008-04-15 | 2009-12-17 | Fischerwerke Gmbh & Co. Kg | Use of defined synthetic resins for fastening screws and similar anchoring means, corresponding processes and synthetic resins |

| GB0816643D0 (en) * | 2008-09-11 | 2008-10-22 | Obrist Closures Switzerland | A closure |

| RU2575930C2 (en) * | 2010-01-29 | 2016-02-27 | МОНОСОЛ, ЭлЭлСи | Improved water-soluble films based on mixture of pvc polymers and packets made therefrom |

| US9102444B2 (en) | 2012-10-26 | 2015-08-11 | Enterprise Express, Inc. | Beverage container lid |

| EP3458380A1 (en) * | 2016-05-17 | 2019-03-27 | Unilever Plc. | Laundry detergent capsule |

| CN109153949A (en) | 2016-05-17 | 2019-01-04 | 荷兰联合利华有限公司 | The method of box and transmission capsule including capsule |

| USD1036258S1 (en) | 2018-03-09 | 2024-07-23 | Coollid Corporation | Beverage container lid |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2003016165A1 (en) * | 2001-08-16 | 2003-02-27 | Warner-Lambert Company Llc | Water soluble packaging |

Family Cites Families (57)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1798151A (en) * | 1929-12-16 | 1931-03-31 | Guardian Safety Seal Company | Sealing cap for bottles |

| DE809896C (en) * | 1946-09-13 | 1951-08-02 | Albert Gourgues | Airtight infusion pack |

| US2858054A (en) * | 1955-03-09 | 1958-10-28 | Stuard K Harkrader | Dispensing device |

| NL127574C (en) * | 1965-01-20 | |||

| GB1207487A (en) * | 1966-11-30 | 1970-10-07 | Metal Closures Ltd | Improved bottle closure |

| US3425578A (en) * | 1967-09-05 | 1969-02-04 | Nicoli Owens | Pill container |

| US3412890A (en) * | 1967-12-22 | 1968-11-26 | Clark Mfg Co J L | Hinged container closure |

| US3603470A (en) * | 1970-01-02 | 1971-09-07 | Monsanto Co | Compressible safety closure |

| DE2230330A1 (en) * | 1971-06-25 | 1973-03-01 | Bouchage Mecanique | INVALIBLE CAPSULE |

| US3820683A (en) * | 1972-02-10 | 1974-06-28 | A Jasinski | Spray can safety cap |

| BE802220A (en) * | 1973-07-16 | 1973-11-05 | Astra Plastique | DOUBLE STOPPER CLOSURE FOR VIALS, BOTTLES AND SIMILAR CONTAINERS |

| US3892351A (en) * | 1974-07-12 | 1975-07-01 | Procter & Gamble | Container subassembly having a membrane-type closure |

| CA1112534A (en) | 1976-11-03 | 1981-11-17 | John Pardo | Detergent article for use in automatic dishwasher |

| US4091949A (en) * | 1977-03-14 | 1978-05-30 | Baxter Travenol Laboratories, Inc. | Antibackoff threaded ring closure using ratchet means |

| US4303171A (en) * | 1979-08-03 | 1981-12-01 | Aladdin Industries Pty. Limited | Container closures |

| US4310105A (en) * | 1980-04-24 | 1982-01-12 | Sunbeam Plastics Corporation | Child-resistant dispensing closure |

| IT8322185V0 (en) * | 1983-06-22 | 1983-06-22 | Victor Wassilieff | CLOSING DEVICE FOR FLUID CONTAINERS. |

| US4531649A (en) * | 1984-04-23 | 1985-07-30 | Anchor Hocking Corporation | Molded plastic cap with sealing liner |

| US4637519A (en) * | 1985-09-03 | 1987-01-20 | Sun Coast Plastics, Inc. | Two part closure |

| CA1282465C (en) * | 1986-02-27 | 1991-04-02 | Hitachi, Ltd. | Phase-locked loop |

| US4697719A (en) * | 1986-11-03 | 1987-10-06 | Allen Tool Company, Inc. | Foil-lid combination for containers |

| DE3730225A1 (en) * | 1987-09-09 | 1989-03-23 | Berg Jacob Gmbh Co Kg | PLASTIC LOCK FOR A PLASTIC CONTAINER |

| US4838441A (en) * | 1988-04-11 | 1989-06-13 | Chernack Milton P | Child resistant closure |

| US4790442A (en) * | 1988-04-22 | 1988-12-13 | Sunbeam Plastics Corporation | Child resistant closure |

| US4942970A (en) * | 1988-07-14 | 1990-07-24 | Vivian Jay | Hermetically sealed canister |

| US5332113A (en) * | 1989-11-30 | 1994-07-26 | Elan Pharmaceutical Research Corporation | Cap assembly |

| US5588545A (en) * | 1991-09-23 | 1996-12-31 | Beeson And Sons Limited | Child-resistant and elderly friendly closure for containers |

| JP2849013B2 (en) * | 1991-12-14 | 1999-01-20 | 株式会社日章 | Method for extracting physiologically active substances from coral sand |

| DE4204489C2 (en) * | 1992-02-14 | 1997-07-24 | Ecosan Hygiene Gmbh | Process for the preparation of detergents, cleaners, disinfectants and / or preservatives, recyclable reusable containers, in particular for carrying out the method, reusable containers containing washing, cleaning, disinfecting and / or preserving agents, and use of the reusable container |

| ES2085232B1 (en) * | 1992-03-06 | 1998-11-01 | Ernst Herrmann | PLUG WITH GUARANTEE. |

| DE9214065U1 (en) * | 1992-10-17 | 1993-06-03 | Dispo-Kommerz Ag, Huenenberg, Zug | Product for the release of treatment agents into the washing liquid of an automatic washing or dishwasher machine |

| ES2103502T3 (en) * | 1992-11-13 | 1997-09-16 | Beeson & Sons Ltd | CLOSURE OF PACKAGING WITH RING TO TAMPER PROOF. |

| IT1275356B1 (en) * | 1993-05-06 | 1997-08-05 | Taplast Srl Ora Taplast S P A | PLASTIC PLUG FOR THE DISTRIBUTION OF LIQUIDS |

| US6036036A (en) * | 1995-06-28 | 2000-03-14 | The Procter & Gamble Company | Adult friendly child-resistant package |

| US6484879B2 (en) * | 1997-04-07 | 2002-11-26 | Syngenta Crop Protection, Inc. | Water soluble packaging system and method |

| GB2325924B (en) * | 1997-06-04 | 2001-04-18 | Lawson Mardon Sutton Ltd | A container closure |

| US6095375A (en) * | 1998-09-15 | 2000-08-01 | Portola Packaging, Inc. | Dust cover attachment for push-pull cap |

| GB2357488A (en) * | 1999-11-17 | 2001-06-27 | Aquasol Ltd | Capsules by injection moulding |

| ES2222253T3 (en) * | 1999-11-17 | 2005-02-01 | Reckitt Benckiser (Uk) Limited | WATER SOLUBLE CONTAINERS MOLDED BY INJECTION. |

| DE60113979T2 (en) * | 2000-04-28 | 2006-07-27 | The Procter & Gamble Company, Cincinnati | COMPOSITIONS IN BAGS |

| BR0111425A (en) * | 2000-06-09 | 2003-12-23 | Seaquist Closures | Distribution Closure for Dispersible Product |

| US6269986B1 (en) * | 2000-06-20 | 2001-08-07 | Seaquist Closures Foreign, Inc. | Dispensing closure with tamper evident lid panel |

| GB2365018A (en) * | 2000-07-24 | 2002-02-13 | Procter & Gamble | Water soluble pouches |

| GB2355269A (en) * | 2000-08-08 | 2001-04-18 | Procter & Gamble | Liquid cleaning composition |

| US7125828B2 (en) * | 2000-11-27 | 2006-10-24 | The Procter & Gamble Company | Detergent products, methods and manufacture |

| JP4646387B2 (en) * | 2000-12-01 | 2011-03-09 | セレック株式会社 | Food storage container |

| EP1251076A1 (en) * | 2001-04-20 | 2002-10-23 | Crown Cork & Seal Technologies Corporation | A closure |

| US6866164B2 (en) * | 2002-04-26 | 2005-03-15 | Rexam Medical Packaging Inc. | Child resistant dispenser |

| US6880729B2 (en) * | 2002-07-12 | 2005-04-19 | Stull Technologies | Secure lock closure |

| US6492315B1 (en) * | 2002-07-31 | 2002-12-10 | Colgate-Palmolive Company | Unit dose nonaqueous liquid softener disposed in water soluble container |

| US20040026420A1 (en) * | 2002-08-01 | 2004-02-12 | Huhtamaki Consumer Packaging, Inc. | Rotatable dispenser closure for use with a container |

| US20040143505A1 (en) * | 2002-10-16 | 2004-07-22 | Aram Kovach | Method for tracking and disposition of articles |

| KR20050062289A (en) * | 2003-12-20 | 2005-06-23 | 삼성전기주식회사 | Method for producing a micro lenz |

| US20050205607A1 (en) * | 2004-03-22 | 2005-09-22 | Valentin Hierzer | Child-resistant flip-top closure |

| US20080277613A1 (en) * | 2004-07-16 | 2008-11-13 | Roemerstrasse 83 | Valve |

| US20060043052A1 (en) * | 2004-08-25 | 2006-03-02 | Robert Lin | Bottle closure |

| US7378971B2 (en) * | 2004-10-01 | 2008-05-27 | Hitachi America, Ltd. | Radio frequency identification tags for digital storage discs |

-

2003

- 2003-06-26 RU RU2005102594/12A patent/RU2005102594A/en not_active Application Discontinuation

- 2003-06-26 PL PL373174A patent/PL202692B1/en not_active IP Right Cessation

- 2003-06-26 BR BR0312397-9A patent/BR0312397A/en not_active IP Right Cessation

- 2003-06-26 MX MXPA05000096A patent/MXPA05000096A/en active IP Right Grant

- 2003-06-26 US US10/519,915 patent/US20060124646A1/en not_active Abandoned

- 2003-06-26 AT AT03762682T patent/ATE411236T1/en not_active IP Right Cessation

- 2003-06-26 CA CA002491283A patent/CA2491283A1/en not_active Abandoned

- 2003-06-26 WO PCT/EP2003/007798 patent/WO2004005156A1/en not_active Ceased

- 2003-06-26 DE DE60324205T patent/DE60324205D1/en not_active Expired - Lifetime

- 2003-06-26 ES ES03762682T patent/ES2315533T3/en not_active Expired - Lifetime

- 2003-06-26 EP EP03762682A patent/EP1663809B1/en not_active Revoked

- 2003-06-26 AU AU2003246714A patent/AU2003246714A1/en not_active Abandoned

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2003016165A1 (en) * | 2001-08-16 | 2003-02-27 | Warner-Lambert Company Llc | Water soluble packaging |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8522991B2 (en) | 2003-10-31 | 2013-09-03 | Obrist Closures Switzerland Gmbh | Tamper evident closure |

| US7830263B2 (en) | 2006-04-28 | 2010-11-09 | Obrist Closures Switzerland Gmbh | Closure with RFID device |

| US8453856B2 (en) | 2007-07-13 | 2013-06-04 | Obrist Closures Switzerland Gmbh | Tamper-evident closure |

| US9102448B2 (en) | 2007-07-13 | 2015-08-11 | Obrist Closures Switzerland Gmbh | Tamper-evident closure |

| US8490804B2 (en) | 2007-10-31 | 2013-07-23 | Obrist Closures Switzerland Gmbh | Closure with movable tamper-evident member |

| US8413830B2 (en) | 2008-04-04 | 2013-04-09 | Obrist Closures Switzerland Gmbh | Closure |

| USD630093S1 (en) | 2010-06-11 | 2011-01-04 | Obrist Closures Switzerland Gmbh | Closure |

Also Published As

| Publication number | Publication date |

|---|---|

| PL373174A1 (en) | 2005-08-22 |

| MXPA05000096A (en) | 2005-04-11 |

| RU2005102594A (en) | 2005-10-10 |

| WO2004005156A1 (en) | 2004-01-15 |

| ES2315533T3 (en) | 2009-04-01 |

| BR0312397A (en) | 2005-04-12 |

| EP1663809A1 (en) | 2006-06-07 |

| US20060124646A1 (en) | 2006-06-15 |

| AU2003246714A1 (en) | 2004-01-23 |

| DE60324205D1 (en) | 2008-11-27 |

| CA2491283A1 (en) | 2004-01-15 |

| PL202692B1 (en) | 2009-07-31 |

| ATE411236T1 (en) | 2008-10-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1663809B1 (en) | Water soluble container | |

| EP1161370B1 (en) | A process for producing a water soluble package | |

| US7219518B2 (en) | Sequential dispensing of laundry additives during automatic machine laundering of fabrics | |

| US4874107A (en) | Multiple compartment container | |

| US7036177B2 (en) | Dispensing of rinse additives into the rinse cycle during automatic machine laundering of fabrics | |

| EP2567898B1 (en) | Multi-compartment pouch and method for making it | |

| CA2659780A1 (en) | Detergent pack | |

| WO2002042400A8 (en) | Dishwashing method | |

| CA2360809A1 (en) | Process for producing a water soluble package | |

| EP1412257B1 (en) | A blister pack | |

| US5967158A (en) | Dispensing device for tablets | |

| TR200100093T2 (en) | Detergent tablet | |

| US7086110B2 (en) | Selective dispensing of laundry additives during automatic machine laundering of fabric | |

| CA2446071A1 (en) | Water-soluble containers with gas release means | |

| CA2127564A1 (en) | Process for delivering a selected effective amount of a dry granular antimicrobial composition to an aqueous system | |

| CA2443162A1 (en) | Container suitable for dispensing wet wipes | |

| EP1592833A1 (en) | Selective dispensing of laundry additives during automatic machine laundering of fabrics | |

| JPH06510265A (en) | container | |

| EP2620383B1 (en) | Device for the preservation of substances to be kept separate until their application | |

| JPH03187867A (en) | Individual package | |

| KR200235386Y1 (en) | Breathable Packaging | |

| CN113353403A (en) | Food box and intelligent cupboard | |

| RU186167U1 (en) | Egg packaging | |

| WO2003029102A1 (en) | Unit dose laundering products | |

| WO2006037512A1 (en) | Package for a water-soluble capsule |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20041216 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| 17Q | First examination report despatched |

Effective date: 20060712 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: CROWN OBRIST GMBH |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: OBRIST CLOSURES SWITZERLAND GMBH |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REF | Corresponds to: |

Ref document number: 60324205 Country of ref document: DE Date of ref document: 20081127 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: RO Ref legal event code: EPE |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2315533 Country of ref document: ES Kind code of ref document: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090115 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081015 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081015 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081015 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090316 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081015 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081015 Ref country code: BE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081015 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081015 |

|

| 26 | Opposition filed |

Opponent name: THE PROCTER & GAMBLE COMPANY Effective date: 20090713 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090115 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081015 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081015 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090630 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090626 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090630 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090630 |

|

| PLAY | Examination report in opposition despatched + time limit |

Free format text: ORIGINAL CODE: EPIDOSNORE2 |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| R26 | Opposition filed (corrected) |

Opponent name: THE PROCTER & GAMBLE COMPANY Effective date: 20090713 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090116 |

|

| PLAH | Information related to despatch of examination report in opposition + time limit modified |

Free format text: ORIGINAL CODE: EPIDOSCORE2 |

|

| PLBC | Reply to examination report in opposition received |

Free format text: ORIGINAL CODE: EPIDOSNORE3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090626 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090416 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20110630 Year of fee payment: 9 Ref country code: ES Payment date: 20110624 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081015 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20110620 Year of fee payment: 9 Ref country code: RO Payment date: 20110615 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081015 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20110622 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20110623 Year of fee payment: 9 |

|

| APAH | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOSCREFNO |

|

| APBM | Appeal reference recorded |

Free format text: ORIGINAL CODE: EPIDOSNREFNO |

|

| APBP | Date of receipt of notice of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA2O |

|

| APBQ | Date of receipt of statement of grounds of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA3O |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20120626 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120626 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20130228 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 60324205 Country of ref document: DE Effective date: 20130101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120626 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130101 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120702 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120626 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20131018 |

|

| APBY | Invitation to file observations in appeal sent |

Free format text: ORIGINAL CODE: EPIDOSNOBA2O |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120627 |

|

| APCA | Receipt of observations in appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNOBA4O |

|

| APBU | Appeal procedure closed |

Free format text: ORIGINAL CODE: EPIDOSNNOA9O |

|

| RDAF | Communication despatched that patent is revoked |

Free format text: ORIGINAL CODE: EPIDOSNREV1 |

|

| RDAG | Patent revoked |

Free format text: ORIGINAL CODE: 0009271 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT REVOKED |

|

| 27W | Patent revoked |

Effective date: 20140303 |