EP1599671B1 - Kraftstoffeinspritzventil für brennkraftmaschine - Google Patents

Kraftstoffeinspritzventil für brennkraftmaschine Download PDFInfo

- Publication number

- EP1599671B1 EP1599671B1 EP04715357A EP04715357A EP1599671B1 EP 1599671 B1 EP1599671 B1 EP 1599671B1 EP 04715357 A EP04715357 A EP 04715357A EP 04715357 A EP04715357 A EP 04715357A EP 1599671 B1 EP1599671 B1 EP 1599671B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- main

- orifice

- jet

- fuel

- injector

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000000446 fuel Substances 0.000 title claims abstract description 60

- 238000002485 combustion reaction Methods 0.000 title claims description 29

- 239000007921 spray Substances 0.000 claims abstract description 29

- 238000002347 injection Methods 0.000 claims abstract description 20

- 239000007924 injection Substances 0.000 claims abstract description 20

- 238000004519 manufacturing process Methods 0.000 claims abstract description 7

- 238000004891 communication Methods 0.000 claims abstract description 6

- 229910052745 lead Inorganic materials 0.000 claims description 10

- 239000007789 gas Substances 0.000 claims description 8

- 238000005507 spraying Methods 0.000 claims description 7

- 238000009760 electrical discharge machining Methods 0.000 claims 1

- 230000035515 penetration Effects 0.000 description 10

- 238000000889 atomisation Methods 0.000 description 4

- 230000009172 bursting Effects 0.000 description 4

- 239000000203 mixture Substances 0.000 description 3

- 239000002184 metal Substances 0.000 description 2

- 229910052751 metal Inorganic materials 0.000 description 2

- 238000011144 upstream manufacturing Methods 0.000 description 2

- 230000002411 adverse Effects 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 230000000295 complement effect Effects 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 239000003344 environmental pollutant Substances 0.000 description 1

- 238000003754 machining Methods 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 231100000719 pollutant Toxicity 0.000 description 1

- 238000004080 punching Methods 0.000 description 1

- 230000000717 retained effect Effects 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 230000001360 synchronised effect Effects 0.000 description 1

- 230000001960 triggered effect Effects 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M61/00—Fuel-injectors not provided for in groups F02M39/00 - F02M57/00 or F02M67/00

- F02M61/16—Details not provided for in, or of interest apart from, the apparatus of groups F02M61/02 - F02M61/14

- F02M61/18—Injection nozzles, e.g. having valve seats; Details of valve member seated ends, not otherwise provided for

- F02M61/1806—Injection nozzles, e.g. having valve seats; Details of valve member seated ends, not otherwise provided for characterised by the arrangement of discharge orifices, e.g. orientation or size

- F02M61/1826—Discharge orifices having different sizes

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M61/00—Fuel-injectors not provided for in groups F02M39/00 - F02M57/00 or F02M67/00

- F02M61/16—Details not provided for in, or of interest apart from, the apparatus of groups F02M61/02 - F02M61/14

- F02M61/18—Injection nozzles, e.g. having valve seats; Details of valve member seated ends, not otherwise provided for

- F02M61/1806—Injection nozzles, e.g. having valve seats; Details of valve member seated ends, not otherwise provided for characterised by the arrangement of discharge orifices, e.g. orientation or size

Definitions

- the present invention relates to a fuel injector for spraying fuel into the combustion chamber of an engine. More particularly, it relates to an injector comprising a head which has a free outer face and which is provided with at least one main orifice adapted to spray a fuel jet in a so-called main direction and at least one secondary orifice suitable for spraying. a jet of fuel in a so-called secondary direction, said main and secondary openings opening into the outer face and communicating directly with a common injection chamber which is selectively placed in communication with a supply chamber.

- the spray must have a certain directionality and a penetration speed sufficient to obtain a wealth around the candle at the time of ignition, which ignites the mixture.

- the depth of the spray that increases with the injection pressure must not be excessive, especially in order not to spray fuel against the walls of the combustion chamber.

- swirl injector injectors in English, in which the fuel is guided in a vortex movement in the injector before being sprayed.

- These injectors make it possible to obtain a good atomization but, besides their high cost, they have the disadvantage of creating a significant internal pressure drop in the supply pressure and consequently make it essential to apply a high force to operate the needle control of these injectors.

- these injectors create a weakly directional jet with a relatively low rate of penetration into the chamber, which in some cases makes it more difficult to obtain a stratified mixture, i.e. a gas mixture. whose fuel richness is greater in certain parts of the combustion chamber.

- the object of the present invention is to overcome these drawbacks by proposing an injector which allows direct injection under high pressure into the combustion chamber with a high efficiency spray and a certain directionality, without, however, significantly increasing the penetration depth of the combustion chamber. atomized jet of fuel and the cost of the injector.

- the invention relates to a fuel injector of the aforementioned type, characterized in that said secondary direction forms an angle ⁇ of between 10 ° and 80 °, preferably between 15 ° and 45 °, and even more preferentially approximately equal to 25 °, with said main direction so that the secondary jet intercepts the main jet in a so-called burst zone which starts at a distance d , measured along the main direction from the outer face of the head, included between 1 and 15 mm, and preferably between 1 and 5 mm, and in that the flow rate of the secondary jet is between 80% and 100% of the flow of the main jet.

- this injector whose holes can be made by simple cylindrical holes through a metal part, such as a sheet, does not cause significant additional manufacturing cost.

- the invention also relates to the use of an injector as defined above, with a spark ignition engine, wherein the injector is arranged to directly spray the fuel into the combustion chamber.

- Figure 1 schematically shows a cross section of a four-stroke internal combustion engine, spark ignition and direct fuel injection.

- the engine 1 comprises one or more cylinders 2 extending along a longitudinal axis XX and in which is slidably mounted according to the longitudinal axis a piston 3.

- the piston 3 is connected to a crankshaft (not shown) by a connecting rod 4.

- a combustion chamber 5 is delimited by the upper end of the cylinder 2, a cavity 6 formed opposite the piston 3 in a cylinder head 7 attached to the cylinder 2, and by an end face 9 of the piston head 8

- the cavity 6 of the yoke 7 is a cavity called "roof", that is to say it has two inclined planes connecting at a vertex 6a intersecting the longitudinal axis XX of the cylinder 2.

- the cylinder head 7 comprises a spark plug 10 provided with electrodes 11 arranged in the region of the top 6a of the cylinder head.

- the present invention is applied to a diesel-type compression ignition engine.

- the cavity 6 of the cylinder head 7 comprises an intake port 14 at the downstream end of an intake duct 15 and an exhaust port 17 at the upstream end of an exhaust duct 19.

- the lights intake 14 and exhaust 17 are respectively closed by an intake valve 16 and an exhaust valve 18 whose opening and closing are controlled by any known means, such as a camshaft.

- any known means such as a camshaft.

- the shape of the combustion chamber 5 and the number of the valves (16, 18) may be different without departing from the scope of the present invention.

- the yoke 7 also comprises an injector 12 provided with an injection head 13, which extends along a Y-Y axis.

- the head 13 of the injector has an outer face 20 arranged in the combustion chamber 5.

- the injector 12 is connected to a fuel supply line, not shown.

- the driving feedstock contains high pressure fuel, that is to say a pressure which reaches at least momentarily a value greater than 100 bar and which substantially corresponds to the pressure at which the fuel is injected into the combustion chamber.

- high pressure fuel that is to say a pressure which reaches at least momentarily a value greater than 100 bar and which substantially corresponds to the pressure at which the fuel is injected into the combustion chamber.

- common rail common rail

- the head of the injector made according to the invention can be used in an injector-pump type injection system in which the injector is associated with a high pressure pump.

- the external face 20 of the injector head 13 is provided with a main orifice 21 adapted to spray a jet of fuel, represented schematically by the contour 22, coming from a chamber 24.

- the jet 22 of the main orifice 21 is oriented in a direction P, said principal, determined by the shape of the orifice 21 and corresponding to the axis of symmetry of the base of the jet 22.

- the outer face 20 is also provided with a secondary orifice 25 adapted to spray a jet of fuel 26 in a direction S said secondary.

- the outer face 20, and more precisely the portion thereof in which the openings open is free of any obstacle that could hide one or other of the orifices.

- the secondary orifice 25 also communicates directly with the injection chamber 24 which is thus common to the main and secondary orifices, so that the spraying by the two types of orifice is simultaneous.

- the injection chamber 24 is selectively brought into communication with a feed chamber 27 containing pressurized fuel.

- the communication between the injection chamber 24 and the feed chamber 27 is obtained by raising a needle 28 from a seat 29 formed in the head 13 of the injector.

- the lifting of the needle 28 can be controlled by mechanical, electromagnetic or piezoelectric means synchronized with the rotation of the crankshaft.

- end 28a of the needle has a complementary geometry to the inner face of the head 13 to minimize the volume of the injection chamber 24, to prevent fuel flow into the combustion chamber 5 to an unwanted moment.

- the secondary direction S of the secondary jet 26 is oriented towards the main direction P of the main jet 22 so that the secondary jet 26 intercepts the main jet 22 in a so-called burst zone shown schematically by the contour 30, and the flow the secondary jet 26 is at most equal to the flow of the main jet 22.

- the main direction P and the secondary direction S form between them an angle of about 25 °.

- the angle ⁇ may be between 10 ° and 80 °, but it is preferable that the angle ⁇ remains between 15 ° and 45 °.

- the burst zone 30 starts at a distance d measured along the main direction P from the outside face 20 of the injector head 13. This distance d is between 1 and 15 mm to obtain a good compromise between the directionality and the bursting of the main jet 22, but is preferably less than 5 mm to obtain an early burst and a relatively limited penetration depth.

- the directionality and the penetration speed required for the fuel injected into the combustion chamber are obtained, in particular by adjusting the distance between the orifices and the angle ⁇ .

- the atomized fuel jet forms a solid cone, and not a hollow cone such as that obtained with a vortex injector.

- the secondary direction S it is not absolutely necessary for the secondary direction S to cut exactly the main direction P. In fact, given the diameters and the flow rates of the main fuel jet and the secondary jet, it is possible to obtain sufficient interception of the fuel jets with a secondary direction S slightly offset from the main direction P, which limits the depth of penetration.

- the main orifice 21 and the secondary orifice 25 are cylindrical holes opening perpendicular to the face outer 20 of the head. These cylindrical holes opening perpendicularly to the outer face 20 are advantageously made by electroerosion. But it is possible to achieve them by other known techniques, such as punching.

- the orifices (21, 25) could have a different shape, especially in the case of an injector for a diesel engine. Indeed, for this type of engine, the fuel injection pressure is significantly higher, greater than 1000 bar and the wall of the head 13 of the injector is thicker, which allows for the formation of orifices. truncated.

- the orifices (21, 25) open directly into the injection chamber 24, which limits the pressure drops in the head of the injector, unlike the vortex injection nozzles which require a device upstream of the orifice to animate the fuel in a circular motion.

- the outer face 20 of the head 13 comprises a portion 32 having an outwardly oriented concavity and in which the main orifice 21 and the secondary orifice 25 open perpendicularly, so that the secondary direction S is oriented towards the main direction P.

- the concave portion 32 has a continuous curvature that can be obtained by stamping an initially flat sheet metal portion.

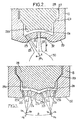

- Figure 3 which shows a second embodiment of a fuel injector according to the invention, it is possible to multiply the number of main orifices and the number of secondary orifices.

- the head 13 of the injector 12 comprises, in this second embodiment, two main orifices (21a, 21b) which respectively spray jets of fuel, not shown, in a main direction Pa and a main direction Pb.

- the main directions Pa and Pb are divergent and form between them an angle ⁇ of about 15 °.

- the outer face 20 of this second embodiment comprises two main orifices (21a, 21b) to which two secondary orifices (25a, 25b) are respectively associated.

- the secondary orifices 25a are situated diametrically opposite to the main orifice 21a, which makes it possible to maintain a certain symmetry of the main jet of fuel from the bursting zone. Note that it is possible to maintain this symmetry by having more than two secondary orifices distributed regularly angularly around the main orifice 21a.

- the secondary directions Sa jets sprayed by the secondary orifices 25a are arranged so that the secondary jets intercept the main jet of the orifice 21a in a same longitudinal position of the main direction Pa.

- the two main orifices (21a, 21b) and the four secondary orifices (25a, 25b) are comprised in the same plane, but it is conceivable to arrange the two main orifices 21a, 21b in a first longitudinal plane of the head 13 of the injector and the secondary orifices (25a, 25b) in two planes perpendicular to the first longitudinal plane.

- the outer face 20 comprises a first portion concave 32a in which open the orifices 21a and 25a and a second concave portion 32b into which the openings 21b and 25b.

- Each concave portion (32a; 32b) has three facets, a central facet into which the main orifice opens perpendicularly and two lateral facets into which the secondary orifices open perpendicularly.

- the wall of the injector having the facets is relatively thin in the case where the pressure in the feed chamber 27 does not exceed 500 bars.

- this portion of the outer face having the concavities (32a, 32b) is then formed by stamping, that is to say by deformation and not machining or molding, a portion initially flat.

- the injector made according to the invention is arranged in a spark ignition engine so as to spray the gasoline directly into the combustion chamber.

- the injector according to the invention makes it possible to very precisely adjust the characteristics of the spray jet, and in particular the direction, speed and depth of penetration, as well as the atomization of the fuel, which is particularly advantageous for this type. engine.

- a spark ignition engine requires a very precise spraying, in particular to have a sufficient wealth in the region of the ignition means at the moment when it is triggered.

- the main direction P of the main orifice, or main orifices is arranged taking into account the geometry of the combustion chamber, such as the presence of a hollow 33 and a flange 34 formed on the end face 9 of the piston, and the circulation gases inside the combustion chamber to obtain a richness between 0.7 and 1.2 near the electrodes 11 of the spark plug 10 at the time of the creation of a spark between the electrodes.

- the main direction P forms a more or less pronounced angle with the longitudinal axis YY of the injector 12, or that in the case of several main orifices, the main directions (Pa, Pb) are not arranged symmetrically with respect to the longitudinal axis YY of the injector.

- the head 13 of the injector made according to the invention creates little internal pressure drop and therefore, the injector 12 can be fed by a common rail containing high pressure fuel.

- the fuel supply pressure of the injector 12 preferably reaches a peak value of between 150 bar and 500 bar.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Fuel-Injection Apparatus (AREA)

- Combustion Methods Of Internal-Combustion Engines (AREA)

Claims (15)

- Kraftstoffeinspritzdüse zum Versprühen des Kraftstoffs in eine Brennkammer (5) eines Fremdzündungsmotors, umfassend einen Kopf (13), der eine freie Außenseite (20) aufweist und der mit mindestens einer Hauptöffnung (21; 21a, 21b) versehen ist, die dafür ausgelegt ist, einen Kraftstoffstrahl in einer sogenannten Hauptrichtung (P; Pa, Pb) zu sprühen, und mindestens einer Nebenöffnung (25; 25a, 25b), die dafür ausgelegt ist, einen Kraftstoffstrahl in einer sogenannten Nebenrichtung (S; Sa, Sb) zu sprühen, wobei die Hauptöffnung und die Nebenöffnung in der Außenseite ausmünden und mit einer gemeinsamen Einspritzkammer (24) im Inneren der Einspritzdüse direkt verbunden sind, die wahlweise mit einer Versorgungskammer (27) in Verbindung gesetzt wird, dadurch gekennzeichnet, dass die Nebenrichtung einen Winkel α zwischen 10° und 80°, vorzugsweise zwischen 15° und 45° und noch bevorzugter etwa gleich 25°, mit der Hauptrichtung bildet, so dass der Nebenstrahl (26) den Hauptstrahl (22) in einer sogenannten Zerstreuungszone (30) schneidet, die in einem Abstand d, gemessen in der Hauptrichtung (P; Pa, Pb) von der Außenseite (20) des Kopfs an, zwischen 1 und 15 mm und vorzugsweise zwischen 1 und 5 mm beginnt, und dass der Durchsatz des Nebenstrahls zwischen 80% und 100% des Durchsatzes des Hauptstrahls beträgt.

- Einspritzdüse nach Anspruch 1, bei der die Außenseite (20) des Kopfs (13) mindestens einen nach außen konkaven Bereich (32; 32a, 32b) aufweist, in dem eine Hauptöffnung (21; 21a, 21b) und mindestens eine Nebenöffnung (25; 25a, 25b) ausmündet.

- Einspritzdüse nach Anspruch 2, bei der die Hauptöffnung (21; 21a, 21b) und die Nebenöffnung (25; 25a, 25b) senkrecht zur Außenseite (20) des Kopfs ausmünden.

- Einspritzdüse nach einem der Ansprüche 1 bis 3, bei der der Kopf (13) mit mindestens zwei Nebenöffnungen (25a, 25b) versehen ist, die um die Hauptöffnung (21a, 21b) herum gleichmäßig verteilt sind.

- Einspritzdüse nach Anspruch 4, bei der die Nebenöffnungen (25a, 25b) Versprühungsnebenrichtungen (Sa, Sb) besitzen, die dafür ausgelegt sind, dass die Nebenstrahlen den Hauptstrahl an der gleichen Längsposition der Hauptrichtung (Pa, Pb) schneiden.

- Einspritzdüse nach einem der Ansprüche 1 bis 5, bei der der Kopf (13) mit mindestens zwei Hauptöffnungen (21a, 21b) versehen ist, die dafür ausgelegt sind, Kraftstoffstrahlen in divergierenden Hauptrichtungen (Pa, Pb) zu sprühen, die miteinander einen Winkel β zwischen 5° und 45° bilden.

- Einspritzdüse nach Anspruch 6, bei der der Hauptstrahl von mindestens zwei Nebenstrahlen geschnitten wird, die durch Nebenöffnungen (24a, 25b) gesprüht werden, die um die Hauptöffnung (21a, 21b) herum gelegen sind.

- Einspritzdüse nach einem der Ansprüche 1 bis 7, bei der die Hauptöffnung (21; 21a, 21b) und die Nebenöffnung (25; 25a, 25b) zylindrische Löcher sind, wobei der Durchmesser der Nebenöffnung kleiner als der Durchmesser der Hauptöffnung ist.

- Kraftstoffeinspritzdüse nach einem der Ansprüche 2 bis 8, bei der der konkave Bereich (32) eine kontinuierliche Krümmung aufweist.

- Einspritzdüse nach einem der Ansprüche 2 bis 8, bei der der konkave Bereich (32a, 32b) von mindestens zwei Facetten gebildet ist, einer ersten Facette, in der eine Hauptöffnung (21a, 21b) ausmündet, und eine zweite Facette, in der eine Nebenöffnung (25a, 25b) ausmündet.

- Verwendung einer Einspritzdüse nach einem der vorhergehenden Ansprüche mit einem Fremdzündungsmotor, bei der die Einspritzdüse (12) so ausgebildet ist, dass sie den Kraftstoff direkt in die Verbrennungskammer (5) sprüht.

- Verwendung einer Einspritzdüse nach Anspruch 11, bei der die Einspritzdüse (12) mit Kraftstoff unter einem Druck versorgt wird, der einen Scheitelwert von 150 bis 500 bar besitzt.

- Verwendung einer Einspritzdüse nach Anspruch 11 oder 12, bei der die Sprührichtung (P; Pa, Pb) der Hauptöffnung (21; 21a, 21b) in Abhängigkeit von der Geometrie der Verbrennungskammer (5) und von der Strömung der Gase in dieser Kammer so angeordnet ist, dass man in Nähe der Zündungssteuermittel (11) zum Zeitpunkt der Zündung ein Gemisch zwischen 0,7 und 1,2 erhält.

- Verfahren zur Herstellung einer Kraftstoffeinspritzdüse zum Versprühen des Kraftstoffs in eine Verbrennungskammer (5) eines Fremdzündungsmotors, umfassend einen Kopf (13), der eine freie Außenseite (20) aufweist und der mit mindestens einer Hauptöffnung (21; 21a, 21b) versehen ist, die dafür ausgelegt ist, einen Kraftstoffstrahl in einer sogenannten Hauptrichtung (P; Pa, Pb) zu sprühen, und mindestens einer Nebenöffnung (25; 25a, 25b), die dafür ausgelegt ist, einen Kraftstoffstrahl in einer sogenannten Nebenrichtung (S; Sa, Sb) zu sprühen, wobei die Hauptöffnung und die Nebenöffnung in der Außenseite ausmünden und mit einer gemeinsamen Einspritzkammer (24) im Inneren der Einspritzdüse direkt verbunden sind, die wahlweise mit einer Versorgungskammer (27) in Verbindung gesetzt wird, dadurch gekennzeichnet, dass ein konkaver Bereich (32; 32a; 32b) der Außenseite (20) des Kopfs (13) durch Verformung eines ursprünglich ebenen Wandbereichs hergestellt wird und dass die Hauptöffnung (21; 21a, 21b) und die Nebenöffnung (25; 25a, 25b) in dem Kopf (13) so gebohrt sind, dass die Nebenrichtung einen Winkel α zwischen 10° und 80°, vorzugsweise zwischen 15° und 45° und noch bevorzugter etwa gleich 25°, mit der Hauptrichtung bildet, so dass der Nebenstrahl (26) den Hauptstrahl (22) in einer sogenannten Zerstreuungszone (30) schneidet, die in einem Abstand d, gemessen in der Hauptrichtung (P; Pa, Pb) von der Außenseite (20) des Kopfs an, zwischen 1 und 15 mm und vorzugsweise zwischen 1 und 5 mm beginnt, und dass der Durchsatz des Nebenstrahls zwischen 80% und 100% des Durchsatzes des Hauptstrahls beträgt.

- Verfahren zur Herstellung einer Einspritzdüse nach Anspruch 14, bei dem die Hauptöffnung (21; 21a; 21b) und die Nebenöffnung (25; 25a; 25b) durch Elektroerosion so gebohrt werden, dass sie senkrecht zur Außenfläche (20) ausmünden.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR0302466 | 2003-02-28 | ||

| FR0302466A FR2851792B1 (fr) | 2003-02-28 | 2003-02-28 | Injecteur de carburant pour moteur a combustion interne |

| PCT/FR2004/000459 WO2004079178A2 (fr) | 2003-02-28 | 2004-02-27 | Injecteur de carburant pour moteur a combustion interne |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1599671A2 EP1599671A2 (de) | 2005-11-30 |

| EP1599671B1 true EP1599671B1 (de) | 2006-07-19 |

Family

ID=32843064

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04715357A Expired - Lifetime EP1599671B1 (de) | 2003-02-28 | 2004-02-27 | Kraftstoffeinspritzventil für brennkraftmaschine |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US7237527B2 (de) |

| EP (1) | EP1599671B1 (de) |

| CN (1) | CN100587253C (de) |

| AT (1) | ATE333586T1 (de) |

| BR (1) | BRPI0407918B1 (de) |

| DE (1) | DE602004001580T2 (de) |

| ES (1) | ES2268634T3 (de) |

| FR (1) | FR2851792B1 (de) |

| WO (1) | WO2004079178A2 (de) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1505342B1 (de) * | 2003-08-04 | 2012-03-07 | Continental Automotive GmbH | Verfahren für die Reduzierung von Ablagerungen in einem Kraftstoffinjektor |

Families Citing this family (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102005023258A1 (de) * | 2004-11-16 | 2006-11-23 | Fan Separator Gmbh | Drehtrommel zur aeroben Erwärmung rieselfähiger Feststoffe |

| FR2881185A1 (fr) * | 2005-01-26 | 2006-07-28 | Magneti Marelli Motopropulsion | Injecteur de carburant et moteur comprenant un tel injecteur |

| WO2006084085A1 (en) * | 2005-02-04 | 2006-08-10 | Ismailov Murad M | Liquid spray system and nozzle with improved spray generation |

| CN101641500B (zh) * | 2007-06-29 | 2012-01-25 | 三菱自动车工业株式会社 | 缸内喷射式内燃机 |

| JP2011506849A (ja) * | 2007-12-21 | 2011-03-03 | ローベルト ボツシユ ゲゼルシヤフト ミツト ベシユレンクテル ハフツング | 燃料噴射弁 |

| US9932883B2 (en) * | 2012-08-29 | 2018-04-03 | Mazda Motor Corporation | Spark-ignition direct-injection engine |

| JP2016501333A (ja) | 2012-11-20 | 2016-01-18 | ノストラム エナジー ピーティーイー.リミテッドNostrum Energy Pte.Ltd. | 衝突ジェットを有する液体噴射噴霧装置 |

| US20140175192A1 (en) * | 2012-12-21 | 2014-06-26 | Quantlogic Corporation | Mixed-mode fuel injector with a variable orifice |

| US9506439B2 (en) * | 2015-04-13 | 2016-11-29 | Caterpillar Inc. | Ducted combustion systems utilizing adjustable length ducts |

| CN106479660B (zh) * | 2016-12-25 | 2022-07-26 | 重庆海国科技有限公司 | 三级高真空滤油系统 |

| US10487787B2 (en) * | 2017-06-20 | 2019-11-26 | Caterpillar Inc. | Injector tip for a fuel injector |

| WO2021059773A1 (ja) * | 2019-09-25 | 2021-04-01 | ボッシュ株式会社 | 燃料噴射弁及び燃料噴射弁を備える内燃機関 |

| CN111482772B (zh) * | 2020-04-21 | 2021-04-20 | 四川航天中天动力装备有限责任公司 | 一种组合式燃油喷嘴的加工工艺 |

| JP7529580B2 (ja) * | 2021-01-19 | 2024-08-06 | 本田技研工業株式会社 | 内燃機関 |

| WO2022261486A1 (en) * | 2021-06-11 | 2022-12-15 | Cummins Inc. | Method and apparatus for hard machining orifices in fuel system and engine components |

| US12078136B2 (en) * | 2022-05-20 | 2024-09-03 | Caterpillar Inc. | Fuel injector nozzle assembly including needle having flow guiding tip for directing fuel flow |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| IT1085959B (it) * | 1977-08-04 | 1985-05-28 | Alfa Romeo Spa | Iniettore di benzina per motori a scoppio |

| US5540200A (en) * | 1993-12-28 | 1996-07-30 | Nissan Motor Co., Ltd. | Fuel injection valve |

| DE19642513A1 (de) * | 1996-10-15 | 1998-04-16 | Bosch Gmbh Robert | Kraftstoffeinspritzventil für Brennkraftmaschinen |

| DE19858345A1 (de) * | 1998-01-06 | 1999-07-08 | Mitsubishi Motors Corp | Brennstoffeinspritzdüse |

| DE19916485C2 (de) * | 1999-04-13 | 2001-10-31 | Daimler Chrysler Ag | Verfahren zum Betrieb einer Hubkolbenbrennkraftmaschine |

| DE19922964C2 (de) * | 1999-05-19 | 2003-03-27 | Daimler Chrysler Ag | Verfahren zum Einspritzen von Dieselkraftstoff |

| US20050224605A1 (en) * | 2004-04-07 | 2005-10-13 | Dingle Philip J | Apparatus and method for mode-switching fuel injector nozzle |

| US7243862B2 (en) * | 2004-04-07 | 2007-07-17 | Delphi Technologies, Inc. | Apparatus and method for mode-switching fuel injector nozzle |

-

2003

- 2003-02-28 FR FR0302466A patent/FR2851792B1/fr not_active Expired - Fee Related

-

2004

- 2004-02-27 DE DE602004001580T patent/DE602004001580T2/de not_active Expired - Lifetime

- 2004-02-27 EP EP04715357A patent/EP1599671B1/de not_active Expired - Lifetime

- 2004-02-27 US US10/547,367 patent/US7237527B2/en not_active Expired - Fee Related

- 2004-02-27 BR BRPI0407918A patent/BRPI0407918B1/pt not_active IP Right Cessation

- 2004-02-27 WO PCT/FR2004/000459 patent/WO2004079178A2/fr active IP Right Grant

- 2004-02-27 AT AT04715357T patent/ATE333586T1/de not_active IP Right Cessation

- 2004-02-27 ES ES04715357T patent/ES2268634T3/es not_active Expired - Lifetime

- 2004-02-27 CN CN200480005419A patent/CN100587253C/zh not_active Expired - Fee Related

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1505342B1 (de) * | 2003-08-04 | 2012-03-07 | Continental Automotive GmbH | Verfahren für die Reduzierung von Ablagerungen in einem Kraftstoffinjektor |

Also Published As

| Publication number | Publication date |

|---|---|

| US7237527B2 (en) | 2007-07-03 |

| WO2004079178A2 (fr) | 2004-09-16 |

| FR2851792A1 (fr) | 2004-09-03 |

| BRPI0407918A (pt) | 2006-03-01 |

| FR2851792B1 (fr) | 2007-02-09 |

| US20060231065A1 (en) | 2006-10-19 |

| DE602004001580T2 (de) | 2007-07-19 |

| DE602004001580D1 (de) | 2006-08-31 |

| ES2268634T3 (es) | 2007-03-16 |

| CN1754041A (zh) | 2006-03-29 |

| BRPI0407918B1 (pt) | 2016-03-01 |

| WO2004079178A3 (fr) | 2004-10-14 |

| CN100587253C (zh) | 2010-02-03 |

| EP1599671A2 (de) | 2005-11-30 |

| ATE333586T1 (de) | 2006-08-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1599671B1 (de) | Kraftstoffeinspritzventil für brennkraftmaschine | |

| US5593095A (en) | Nozzles for fuel injections | |

| FR2585080A1 (fr) | Procede et dispositif d'injection de carburant, moteur a combustion interne a injection, et vehicule equipe d'un tel moteur | |

| EP0526616B1 (de) | Kraftstoffeinspritzvorrichtung für Verbrennungsmotoren | |

| EP1686260A1 (de) | Brennstoffeinspritzventil und Brennkraftmaschine mit einem solchen | |

| FR2760256A1 (fr) | Moteur a combustion interne et allumage par etincelle | |

| FR2880915A1 (fr) | Moteur diesel a combustion interne a chambre de combustion presentant une forme de type "col sonique" | |

| FR2806445A1 (fr) | Procede pour former un melange carburant-air inflammable | |

| FR2770873A1 (fr) | Moteur a combustion interne a allumage par etincelle et a injection directe | |

| EP1105630B1 (de) | Kolben und brennkammer mit aktiver gasführung | |

| FR2727721A1 (fr) | Injecteur a jupe de dispersion de carburant | |

| FR2716495A1 (fr) | Dispositions permettant d'améliorer le fonctionnement des moteurs Diesel à injection directe. | |

| FR3114614A1 (fr) | Dispositif d’allumage à préchambre pour moteur à combustion interne à allumage commandé | |

| FR2463861A1 (fr) | Injecteur de carburant pour moteur diesel | |

| FR2968720A1 (fr) | Injecteur, notamment pour l'injection multipoints de carburant dans un moteur a combustion interne | |

| WO2003042519A1 (fr) | Moteur a combustion interne, a allumage commande, et a injection directe d'essence, comportant un systeme d'injection directe a tres haute pression | |

| FR3042545B1 (fr) | Buse d'injection de carburant | |

| FR2887304A1 (fr) | Moteur a combustion interne comprenant un injecteur de carburant adapte pour le demarrage dudit moteur | |

| FR2895465A3 (fr) | Buse d'injecteur pour injection directe | |

| EP1071879B1 (de) | Schrägstrahlzerstäuber für einspritzventil einer fremdgezündeten brennkraftmaschine mit direkteinspritzung | |

| FR2903458A1 (fr) | Injecteur de carburant pour moteur a combustion interne. | |

| FR2807103A1 (fr) | Chambre de combustion pour moteur a allumage commande et a injection directe | |

| EP3987165A1 (de) | Verbrennungssystem mit konstantem volumen und synchronisierter einspritzung | |

| FR2856114A1 (fr) | Injecteur pour moteur a combustion interne a faible taux de polluants | |

| FR2857698A1 (fr) | Moteur diesel a injection directe ayant une puissance specifique elevee et une emission reduite de fumees |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20050825 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: PONTOPPIDAN, MICHAEL |

|

| DAX | Request for extension of the european patent (deleted) | ||

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20060719 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060719 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060719 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060719 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060719 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060719 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060719 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060719 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060719 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: FRENCH |

|

| REF | Corresponds to: |

Ref document number: 602004001580 Country of ref document: DE Date of ref document: 20060831 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061019 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061019 |

|

| RAP2 | Party data changed (patent owner data changed or rights of a patent transferred) |

Owner name: MAGNETI MARELLI MOTOPROPULSION FRANCE SAS |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061219 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20061123 |

|

| NLT2 | Nl: modifications (of names), taken from the european patent patent bulletin |

Owner name: MAGNETI MARELLI MOTOPROPULSION FRANCE SAS Effective date: 20061102 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070228 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2268634 Country of ref document: ES Kind code of ref document: T3 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20070420 |

|

| BERE | Be: lapsed |

Owner name: MAGNETI MARELLI MOTOPROPULSION FRANCE SAS Effective date: 20070228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061020 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060719 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080229 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080229 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060719 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070227 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070120 Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060719 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20100322 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20100218 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20100222 Year of fee payment: 7 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20110227 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110227 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20120411 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110228 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20170228 Year of fee payment: 14 Ref country code: DE Payment date: 20170210 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20170217 Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 602004001580 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20181031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180901 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180227 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180228 |