EP1577431B1 - Chain stitch sewing machine - Google Patents

Chain stitch sewing machine Download PDFInfo

- Publication number

- EP1577431B1 EP1577431B1 EP05001358A EP05001358A EP1577431B1 EP 1577431 B1 EP1577431 B1 EP 1577431B1 EP 05001358 A EP05001358 A EP 05001358A EP 05001358 A EP05001358 A EP 05001358A EP 1577431 B1 EP1577431 B1 EP 1577431B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- thread

- catcher

- needle

- thread catcher

- sewn material

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 238000009958 sewing Methods 0.000 title claims description 48

- 239000000463 material Substances 0.000 claims description 21

- 239000004744 fabric Substances 0.000 description 24

- 230000015572 biosynthetic process Effects 0.000 description 3

- 230000001133 acceleration Effects 0.000 description 1

- 230000001154 acute effect Effects 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000002996 emotional effect Effects 0.000 description 1

- 230000004886 head movement Effects 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- 210000000056 organ Anatomy 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D05—SEWING; EMBROIDERING; TUFTING

- D05B—SEWING

- D05B1/00—General types of sewing apparatus or machines without mechanism for lateral movement of the needle or the work or both

- D05B1/02—General types of sewing apparatus or machines without mechanism for lateral movement of the needle or the work or both for making single-thread seams

- D05B1/06—Single chain-stitch seams

-

- D—TEXTILES; PAPER

- D05—SEWING; EMBROIDERING; TUFTING

- D05B—SEWING

- D05B57/00—Loop takers, e.g. loopers

- D05B57/02—Loop takers, e.g. loopers for chain-stitch sewing machines, e.g. oscillating

-

- D—TEXTILES; PAPER

- D05—SEWING; EMBROIDERING; TUFTING

- D05B—SEWING

- D05B61/00—Loop holders; Loop spreaders; Stitch-forming fingers

-

- D—TEXTILES; PAPER

- D05—SEWING; EMBROIDERING; TUFTING

- D05B—SEWING

- D05B85/00—Needles

- D05B85/006—Hooked needles

Definitions

- the invention relates to a chain stitch sewing apparatus having a sewing head movable parallel to a sewing material plane, comprising a needle bar for a thread-guiding needle, a needle drive for rectilinear reciprocating movement of the needle bar transversely to the sewing material plane, a needle-shaped thread catcher provided with an open catch hook and a catcher drive for rectilinear approach - And move the thread catcher transversely to the Nähgutebene, the trajectories of the needle and the thread catcher form an acute angle with each other, the vertex is below the Nähgutebene and wherein the needle drive and the catcher drive are controlled so that when retracting the needle from the fabric below the same formed thread loop detected by the thread catcher and pulled up through the fabric.

- Such a sewing device is for example from the DE 197 51 011 A1 known.

- the thread catcher is driven during its up and down movement to rotate about its direction of rotation.

- the thread catcher assumes a rotational position in which the hook opening points at least approximately in the feed direction of the sewing head, so that the thread loop when advancing the sewing head does not slip from the catcher and the new loop can be pulled through the previous loop to allow a secure chaining of the loops.

- the invention has for its object to provide a sewing device of the type mentioned, which is not only reliable, but also simple in construction.

- the thread catcher is associated with a drivable thread puller, which has a transverse to the trajectory of the thread catcher in the path of the thread catcher hanging thread loop movable arm and its drive is controlled so that the arm near the upper position of Yarn catcher deflects the thread loop hanging on the thread catcher transversely to the path of movement of the thread catcher after the side opposite the hook opening.

- the thread catcher is only moved up and down, but otherwise retains a position at which the hook opening points against the sewing direction. This avoids the risk that the thread catcher again detects the thread loop already deposited on the sewing surface when pulling up the new thread loop.

- the new thread loop hanging on the hook of the thread catcher in its upper position is stretched into the hook by the thread-pulling device, see above that it can not slide off the thread catcher when it reverses its direction of movement to stab back into the fabric. This ensures that the thread catcher punctures in its downward movement through the loop into the fabric and pulls the new loop on its return through the deposited on the top of the fabric loop.

- the device according to the invention is easy to implement and ensures safe chain formation.

- the arm of the thread puller may for example be formed by a wire-shaped bracket, which extends substantially parallel to the material plane and is mounted such that its free end upon actuation of its drive along a - viewed in a vertical projection on the fabric plane - annular closed path emotional. By this trajectory it is avoided that the thread catcher and the thread puller interfere with each other.

- the trajectory of the yarn catcher is expediently directed substantially perpendicular to the material plane, wherein the trajectories of the needle and the yarn catcher lie in a direction transverse to the feed direction of the sewing head and perpendicular to the Nähgutebene plane.

- the angle between the trajectories of the thread catcher and the needle is preferably in the range of 30 ° to 60 °.

- the sewing head as a whole has a relatively large mass, it is expedient if it can be moved continuously in order to avoid constant deceleration and acceleration of the sewing head.

- at least the needle and the thread catcher, possibly also the thread puller are expediently arranged together with their respective drive on a frame which can be moved back and forth parallel to the sewing direction in the sewing head housing, so that the sewing head as a whole can also be moved in sewing direction when the needle and / or the thread catcher are still in the fabric.

- the frame follows the sewing head movement within the sewing head housing until the needle again pierces the fabric.

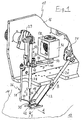

- Fig.1 is denoted by 10 a schematically illustrated sewing head, which can hang in a conventional manner on a robot arm, not shown, and with the aid of which in the direction of arrow A can be transported parallel to a Nähgutauflage representation 12 via a workpiece lying thereon 14.

- a Nähgutniederhalter 18 is arranged on the housing 16 of the sewing head 10 .

- a needle bar 20 which carries a needle 22 and about a disposed within the housing 16, not completely shown drive 24 in the direction of the arrow B back and forth.

- the needle 22 is intended to pierce the fabric 14 while pulling a thread through the fabric 14.

- a needle-shaped thread catcher 26 is arranged on the sewing head, which is held by a catcher rod 28 and by means of a catcher drive 29 within the Nähkopfgeophuses 16 in the direction of arrow C is substantially perpendicular to the fabric support 12 up and down movable.

- the thread catcher 26 is aligned so that the opening 34 of the hook 30 opposite to the feed direction A of the sewing head 10 has. As well as the thread catcher 26 has been pulled out of the fabric 14, move the sewing head 10 or the seam-forming members 22 and 26 in the direction of arrow A, before by piercing the needle 22 into the fabric 14, a new cycle begins.

- the needle bar 20 and the catcher rod 28 are guided in a frame, which because of the clarity of the illustration in the Fig.1 is not shown and which is arranged in a conventional manner within the housing 16 so that it is parallel to the sewing direction A relative to the housing 16 back and forth.

- the housing 16 of the sewing head 10 can be moved continuously, while the needle 22 and the thread catcher 26 are only advanced when they are outside the material 14.

- a thread pulling device generally designated 36, is provided.

- This comprises a substantially vertical rod 38, at its lower end a directed substantially parallel to the fabric support 12 arm 40 is fixed with a U-shaped hook-shaped end 42.

- the rod 38 is fixed to the one end of a horizontal lever 44 which is slidably mounted by means of a slot 46 on a sliding block 48 in the direction of arrow D and about the axis 50 of a bolt 52 pivotally.

- the sliding block 48 is fastened with the bolt 52 to a housing-fixed support, not shown.

- the other end of the lever 44 is connected to an eccentric 54 which is mounted in a housing-fixed bearing part 56 and driven by bevel gears 58.

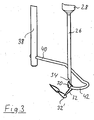

- Fig.2 shows a position of the thread catcher 26 and the arm 38 of the thread puller according to the Fig.1 , ie shortly before or when the thread catcher 26 has reached its top dead center and the loop 32 has pulled out of the fabric 14.

- the arm 40 is pivoted in the direction of the loop 32, wherein it deflects approximately in the feed direction of the sewing head 10, so that the loop 32 is pulled into the hook 30, as shown in Figure 3 can be seen. It can be seen that during a downward movement of the thread catcher 26 from the in Figure 3 shown position of the thread catcher 26 passes through the loop 32, which slides out of the hook 30 on the yarn catcher 26 upwards.

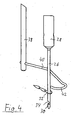

- the arm 40 of the thread pulling device 36 is retracted ( Figure 4 ). This ensures that the thread catcher 26 passes through the loop 32 during insertion into the sewing material 14 and also pulls the new loop through the then lying on the fabric surface loop 32 'in its upward movement, so as to form a chain seam.

- the thread-pulling device 36 can be realized by simple means and ensures reliable operation of the sewing device.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Sewing Machines And Sewing (AREA)

Description

Die Erfindung betrifft eine Kettenstichnähvorrichtung mit einem parallel zu einer Nähgutebene bewegbaren Nähkopf, umfassend eine Nadelstange für eine fadenführende Nadel, einen Nadelantrieb zum geradlinigen Hin- und Herbewegen der Nadelstange quer zur Nähgutebene, einen mit einem offenen Fanghaken versehenen nadelförmigen Fadenfänger und einen Fängerantrieb zum geradlinigen hin- und herbewegen des Fadenfängers quer zur Nähgutebene, wobei die Bewegungsbahnen der Nadel und des Fadenfängers einen spitzen Winkel miteinander bilden, dessen Scheitel unterhalb der Nähgutebene liegt und wobei der Nadelantrieb und der Fängerantrieb so gesteuert sind, daß eine beim Zurückziehen der Nadel aus dem Nähgut unterhalb desselben gebildete Fadenschlaufe von dem Fadenfänger erfaßt und durch das Nähgut nach oben gezogen wird.The invention relates to a chain stitch sewing apparatus having a sewing head movable parallel to a sewing material plane, comprising a needle bar for a thread-guiding needle, a needle drive for rectilinear reciprocating movement of the needle bar transversely to the sewing material plane, a needle-shaped thread catcher provided with an open catch hook and a catcher drive for rectilinear approach - And move the thread catcher transversely to the Nähgutebene, the trajectories of the needle and the thread catcher form an acute angle with each other, the vertex is below the Nähgutebene and wherein the needle drive and the catcher drive are controlled so that when retracting the needle from the fabric below the same formed thread loop detected by the thread catcher and pulled up through the fabric.

Eine solche Nähvorrichtung ist beispielsweise aus der

Der Erfindung liegt die Aufgabe zugrunde, eine Nähvorrichtung der eingangs genannten Art anzugeben, die nicht nur funktionssicher, sondern auch einfach im Aufbau ist.The invention has for its object to provide a sewing device of the type mentioned, which is not only reliable, but also simple in construction.

Diese Aufgabe wird erfindungsgemäß dadurch gelöst, daß dem Fadenfänger ein antreibbarer Fadenzieher zugeordnet ist, der einen quer zur Bewegungsbahn des Fadenfängers in den Weg der an dem Fadenfänger hängenden Fadenschlaufe bewegbaren Arm hat und dessen Antrieb so gesteuert ist, daß der Arm nahe der oberen Stellung des Fadenfängers die an dem Fadenfänger hängende Fadenschlaufe quer zur Bewegungsbahn des Fadenfängers nach der der Hakenöffnung entgegengesetzten Seite auslenkt.This object is achieved in that the thread catcher is associated with a drivable thread puller, which has a transverse to the trajectory of the thread catcher in the path of the thread catcher hanging thread loop movable arm and its drive is controlled so that the arm near the upper position of Yarn catcher deflects the thread loop hanging on the thread catcher transversely to the path of movement of the thread catcher after the side opposite the hook opening.

Bei der erfindungsgemäßen Nähvorrichtung wird der Fadenfänger nur auf- und abbewegt, behält im übrigen aber eine Stellung bei, bei welcher die Hakenöffnung entgegen der Nährichtung zeigt. Damit wird die Gefahr vermieden, daß der Fadenfänger die auf der Nähoberfläche bereits abgelegte Fadenschlaufe beim Hochziehen der neuen Fadenschlaufe wieder mit erfaßt. Andererseits wird durch den Fadenzieher die am Haken des in seiner oberen Stellung befindlichen Fadenfängers hängende neue Fadenschlaufe in den Haken gespannt, so daß sie nicht von dem Fadenfänger abgleiten kann, wenn dieser seine Bewegungsrichtung umkehrt, um wieder in das Nähgut einzustechen. Dadurch ist sichergestellt, daß der Fadenfänger bei seiner Abwärtsbewegung durch die Schlaufe hindurch in das Nähgut einsticht und die neue Schlaufe bei seiner Rückkehr durch die auf der Oberseite des Nähgutes abgelegte Schlaufe zieht. Die erfindungsgemäße Vorrichtung ist einfach zu realisieren und gewährleistet eine sichere Kettenbildung.In the sewing device according to the invention, the thread catcher is only moved up and down, but otherwise retains a position at which the hook opening points against the sewing direction. This avoids the risk that the thread catcher again detects the thread loop already deposited on the sewing surface when pulling up the new thread loop. On the other hand, the new thread loop hanging on the hook of the thread catcher in its upper position is stretched into the hook by the thread-pulling device, see above that it can not slide off the thread catcher when it reverses its direction of movement to stab back into the fabric. This ensures that the thread catcher punctures in its downward movement through the loop into the fabric and pulls the new loop on its return through the deposited on the top of the fabric loop. The device according to the invention is easy to implement and ensures safe chain formation.

Der Arm des Fadenziehers kann beispielsweise von einem drahtförmigen Bügel gebildet sein, der sich im wesentlichen parallel zur Nähgutebene erstreckt und derart gelagert ist, dass sein freies Ende bei Betätigung seines Antriebes sich entlang einer - in einer senkrechten Projektion auf die Nähgutebene betrachtet - ringförmig geschlossenen Bahn bewegt. Durch diese Bewegungsbahn wird vermieden, dass sich der Fadenfänger und der Fadenzieher gegenseitig behindern.The arm of the thread puller may for example be formed by a wire-shaped bracket, which extends substantially parallel to the material plane and is mounted such that its free end upon actuation of its drive along a - viewed in a vertical projection on the fabric plane - annular closed path emotional. By this trajectory it is avoided that the thread catcher and the thread puller interfere with each other.

Um eine sichere Stichbildung zu gewährleisten, ist die Bewegungsbahn des Fadenfängers zweckmäßigerweise im wesentlichen senkrecht zur Nähgutebene gerichtet, wobei die Bewegungsbahnen der Nadel und des Fadenfängers in einer quer zur Vorschubrichtung des Nähkopfes und senkrecht zur Nähgutebene gerichteten Ebene liegen. Der Winkel zwischen den Bewegungsbahnen des Fadenfängers und der Nadel liegt vorzugsweise im Bereich von 30° bis 60°.In order to ensure a secure stitch formation, the trajectory of the yarn catcher is expediently directed substantially perpendicular to the material plane, wherein the trajectories of the needle and the yarn catcher lie in a direction transverse to the feed direction of the sewing head and perpendicular to the Nähgutebene plane. The angle between the trajectories of the thread catcher and the needle is preferably in the range of 30 ° to 60 °.

Da der Nähkopf insgesamt eine relativ große Masse hat, ist es zweckmäßig, wenn er kontinuierlich bewegt werden kann, um ein ständiges Abbremsen und Beschleunigen des Nähkopfes zu vermeiden. Um eine solche kontinuierliche Bewegung zu ermöglichen, sind mindestens die Nadel und der Fadenfänger, gegebenenfalls auch der Fadenzieher zusammen mit ihrem jeweiligen Antrieb zweckmäßigerweise an einem in dem Nähkopfgehäuse parallel zur Nährichtung hin- und herverstellbaren Rahmen angeordnet, so daß der Nähkopf als Ganzes auch dann in Nährichtung bewegt werden kann, wenn sich die Nadel und/oder der Fadenfänger noch im Nähgut befinden. Sowie der Fadenfänger und die Nadel gleichzeitig aus dem Nähgut herausgezogen sind, folgt der Rahmen der Nähkopfbewegung innerhalb des Nähkopfgehäuses, bis die Nadel wieder in das Nähgut einsticht.Since the sewing head as a whole has a relatively large mass, it is expedient if it can be moved continuously in order to avoid constant deceleration and acceleration of the sewing head. In order to enable such a continuous movement, at least the needle and the thread catcher, possibly also the thread puller are expediently arranged together with their respective drive on a frame which can be moved back and forth parallel to the sewing direction in the sewing head housing, so that the sewing head as a whole can also be moved in sewing direction when the needle and / or the thread catcher are still in the fabric. As the thread catcher and the needle are simultaneously pulled out of the fabric, the frame follows the sewing head movement within the sewing head housing until the needle again pierces the fabric.

Weitere Merkmale und Vorteile der Erfindung ergeben sich aus-der folgenden Beschreibung, welche in Verbindung mit den beigefügten Zeichnungen die Erfindung anhand eines Ausführungsbeispieles erläutert. Es zeigen:

- Fig.1

- eine schematische perspektivische Teilansicht einer erfindungsgemäßen Nähvorrichtung und

- Fig.2 bis 4

- schematische Darstellungen des Fadenfängers und des ihm zugeordneten Fadenziehers zur Erläuterung der Funktion des letzteren.

- Fig.1

- a schematic perspective partial view of a sewing device according to the invention and

- 2 to 4

- schematic representations of the thread catcher and its associated thread puller to explain the function of the latter.

In der

Ferner ist an dem Nähkopf ein nadelförmiger Fadenfänger 26 angeordnet, der von einer Fängerstange 28 gehalten wird und mittels eines Fängerantriebes 29 innerhalb, des Nähkopfgehäuses 16 in Richtung des Pfeiles C im wesentlichen senkrecht zur Nähgutauflage 12 auf und ab bewegbar ist.Further, a needle-

Wie man in

Die Nadelstange 20 und die Fängerstange 28 sind in einem Rahmen geführt, der wegen der besseren Übersichtlichkeit der Darstellung in der

Wie man bei der Beschreibung der Nahtbildung erkennt, bestünde dabei die Gefahr, daß beim Vorschub des Nähkopfes 10 bzw. der nahtbildenden Organe die Schlaufe 32 aus dem Haken herausrutscht bzw. so gespannt wird, daß der Fadenfänger 26 beim Einstechen in das Nähgut 14 nicht mehr durch die Schlaufe 32 tritt. Dies ist aber notwendig, damit eine Verkettung der Schlaufen erfolgt.As can be seen in the description of the seam formation, there would be the danger that when feeding the

Um sicherzustellen, daß der Fadenfänger 26 beim Einstechen in das Nähgut 14 auch durch die Schlaufe 32 tritt, ist ein allgemein mit 36 bezeichneter Fadenzieher vorgesehen. Dieser umfasst eine im wesentlichen vertikale Stange 38, an deren unterem Ende ein im wesentlichen parallel zur Nähgutauflage 12 gerichteter Arm 40 mit einem U-förmig gebogenen hakenförmigen Ende 42 befestigt ist. Die Stange 38 ist an dem einen Ende eines horizontalen Hebels 44 befestigt, der mittels eines Langloches 46 an einem Gleitstein 48 in Richtung des Pfeiles D verschiebbar und um die Achse 50 eines Bolzen 52 schwenkbar gelagert ist. Der Gleitstein 48 ist mit dem Bolzen 52 an einem nicht dargestellten gehäusefesten Träger befestigt. Das andere Ende des Hebels 44 ist mit einem Exzenter 54 verbunden, der in einem gehäusefesten Lagerteil 56 gelagert und über Kegelzahnräder 58 antreibbar ist.In order to ensure that the

Durch den Antrieb des Hebels 44 über den Exzenter 54 führt das hakenförmige Ende 42 des Armes 40 eine Bewegung entlang einer ringförmig geschlossenen, annähernd elliptischen Bahnkurve aus. Die Wirkungsweise des Fadenziehers 36 soll nun anhand der

Claims (5)

- A chain stitch sewing mechanism with a sewing head (10) movable parallel to a sewn material plane (12), which sewing head includes a needle rod (20) for a thread carrying needle (22), a needle drive (24) for linearly moving the needle rod (20) back and forth transversely to the sewn material plane (12), a needle-shaped thread catcher (26) provided with an open catching hook (30) and a catcher drive (29) for linearly moving the thread catcher (26) back and forth transversely to the sewn material plane (12), with the movement paths of the needle (22) and of the thread catcher (26) forming a sharp angle α with one another whose apex S lies below the sewn material plane (12) and with the needle drive and the catcher drive being so controlled that a thread loop (32) formed by the withdrawal of the needle (22) out of the sewn material (14) and located below the sewn material (14) is caught by the thread catcher (26) and pulled by the thread catcher upwardly through the sewn material (14), characterized in that a driven thread puller (36) is associated with the thread catcher (26), which thread puller has an arm (40) movable transversely to the movement path of the thread catcher (26) into the path of the thread loop (32) hanging on the thread catcher (26) and whose drive is so controlled that the arm (40) near the uppermost position of the thread catcher (26) deflects the thread loop (32) hanging from the thread catcher (26) transversely to the movement path of the thread catcher (26) and toward the side opposite to that of the hook opening (34).

- A chain stitch sewing mechanism according to claim 1, characterized in that the arm (40) of the thread puller (36) is made from a wire-shaped bow, which bow extends essentially parallel to the sewn material plane (12) and is so supported that its free end (42) upon actuation of its drive moves along - as seen in a perpendicular projection onto the sewn material plane (12) - an annular closed path.

- A chain stitch sewing mechanism according to claim 1 or 2, characterized in that the movement path of the thread catcher (26) is oriented essentially perpendicularly to the sewn material plane (12) and that the movement paths of the needle (22) and of the thread catcher (26) lie in a plane transversely to the advancement direction A of the sewing head (10) and perpendicular to the sewn material plane (12).

- A chain stitch sewing mechanism according to one of claims 1 to 3, characterized in that the angle α between the movement paths of the thread catcher (26) and of the needle (22) has a value of about 30° to 60°.

- A chain stitch sewing mechanism according to one of the claims 1 to 4, characterized in that at least the needle (22) and the thread catcher (26) together with their individual drives are arranged on a frame located in the sewing head housing (16) and movable back and forth parallel to the advancement direction A of the sewing head (10).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102004012822A DE102004012822B3 (en) | 2004-03-16 | 2004-03-16 | Sewing machine needle chain stitch mechanism has thread trap operating in conjunction with powered thread puller |

| DE102004012822 | 2004-03-16 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1577431A1 EP1577431A1 (en) | 2005-09-21 |

| EP1577431B1 true EP1577431B1 (en) | 2008-03-12 |

Family

ID=34585425

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP05001358A Ceased EP1577431B1 (en) | 2004-03-16 | 2005-01-24 | Chain stitch sewing machine |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US6973887B2 (en) |

| EP (1) | EP1577431B1 (en) |

| DE (2) | DE102004012822B3 (en) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2004099481A1 (en) * | 2003-05-05 | 2004-11-18 | Georg Janouschek | Sewing machine |

| JP5095314B2 (en) * | 2007-09-03 | 2012-12-12 | Juki株式会社 | sewing machine |

| JP2009066127A (en) * | 2007-09-12 | 2009-04-02 | Juki Corp | Threading device of sewing machine |

| JP2022175479A (en) * | 2021-05-13 | 2022-11-25 | 株式会社ジャノメ | Top stitching mechanism and sewing machine |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1590686A (en) * | 1918-11-14 | 1926-06-29 | Holtermand Jens | Method of sewing two articles together |

| US1714928A (en) * | 1926-06-23 | 1929-05-28 | Victor J Sigoda | Stitch-forming mechanism for sewing machines |

| US2369183A (en) * | 1939-10-05 | 1945-02-13 | Mansew Pinking Attachment Corp | Multiple needle stitching mechanism |

| US2533292A (en) * | 1947-10-22 | 1950-12-12 | Man Sew Corp | Multiple needle stitching mechanism |

| US2687103A (en) * | 1952-11-18 | 1954-08-24 | Mosberg Abraham | Blindstitch attachment for sewing machines |

| DE3515189C1 (en) * | 1985-04-26 | 1986-11-06 | J. Strobel & Söhne - GmbH & Co, 8000 München | Chainstitch blindstitch sewing machine for sewing the sewing material point by point |

| GB9406537D0 (en) * | 1994-03-31 | 1994-05-25 | British Aerospace | Blind stitching apparatus and composite material manufacturing methods |

| JP3688076B2 (en) * | 1996-09-12 | 2005-08-24 | ジューキ株式会社 | sewing machine |

| DE19751011C2 (en) * | 1997-11-18 | 2000-12-07 | Altin Naehtechnik Gmbh | sewing machine |

| DE19813887A1 (en) * | 1998-03-28 | 1999-09-30 | Freundes Und Foerderkreis Des | Method and device for producing sewing seams |

-

2004

- 2004-03-16 DE DE102004012822A patent/DE102004012822B3/en not_active Expired - Fee Related

-

2005

- 2005-01-24 DE DE502005003159T patent/DE502005003159D1/en not_active Expired - Fee Related

- 2005-01-24 EP EP05001358A patent/EP1577431B1/en not_active Ceased

- 2005-03-09 US US11/076,370 patent/US6973887B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| DE102004012822B3 (en) | 2005-06-16 |

| EP1577431A1 (en) | 2005-09-21 |

| DE502005003159D1 (en) | 2008-04-24 |

| US20050204976A1 (en) | 2005-09-22 |

| US6973887B2 (en) | 2005-12-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE10116171B4 (en) | Endoscopic sewing machine | |

| DE2905226A1 (en) | DEVICE FOR CUTTING AND POSITIONING A STITCH CHAIN ON A SEWING MACHINE | |

| EP1577431B1 (en) | Chain stitch sewing machine | |

| DE102007045599A1 (en) | Sewing machine cutting mechanism for upper and lower threads, includes thread capture section in moving blade, operating with cutting edges and thread relief groove | |

| EP0832758A2 (en) | Method for making book blocks | |

| DE1485276B1 (en) | Sewing machine with a device for pulling out the needle and looper thread before cutting through | |

| DE2638264C3 (en) | Sewing machine for making preliminary or decorative stitches on fabric | |

| DE2026523C3 (en) | Control device on a weaving machine for driving an edging needle | |

| DE10040807B4 (en) | Blind stitch sewing machine | |

| DE10349127A1 (en) | Blind stitch sewing head, e.g. for carbon fiber mats, includes rotary gripper hook and curved needle swinging with parallel axes and assisted by a loop spreader | |

| DE3419950C2 (en) | Stitch type and method and device for its production | |

| EP3482966B1 (en) | Method and device for sewing | |

| DE4118008C2 (en) | ||

| DE2163232A1 (en) | Double chain lock stitch machine | |

| DE824585C (en) | Two-thread sewing machine | |

| DE2743727C3 (en) | Device for cutting the needle and bobbin thread on an automatic sewing machine | |

| DE102011102928A1 (en) | Sewing machine with thread clamp | |

| DE102005004124A1 (en) | Double chain stitch sewing machine, e.g. for sewing quilts or mattress covers, includes synchronized moving needle stabilizing guides to prevent lateral needle deflection | |

| DE827894C (en) | Device for creating overlock stitches on sewing machines | |

| DE631588C (en) | Machine for producing edging | |

| EP1620592B1 (en) | Sewing machine | |

| DE1011703B (en) | Lockstitch sewing machine | |

| WO2020207769A1 (en) | Sewing machine having a thread finger assembly | |

| AT162750B (en) | Blind stitch and pricking device | |

| DE1901722C3 (en) | Needle component for tufting machines |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR LV MK YU |

|

| 17P | Request for examination filed |

Effective date: 20060321 |

|

| AKX | Designation fees paid |

Designated state(s): DE ES FR GB IT |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE ES FR GB IT |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REF | Corresponds to: |

Ref document number: 502005003159 Country of ref document: DE Date of ref document: 20080424 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080623 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20081215 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080312 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090801 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 732E Free format text: REGISTERED BETWEEN 20140821 AND 20140827 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: TP Owner name: KSL KEILMANN SONDERMASCHINENBAU GMBH, DE Effective date: 20140925 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 732E Free format text: REGISTERED BETWEEN 20150514 AND 20150520 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: TP Owner name: PFAFF INDUSTRIESYSTEME UND MASCHINEN GMBH, DE Effective date: 20150723 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20210120 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20210122 Year of fee payment: 17 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20220124 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220124 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220131 |