EP1560769B1 - Verriegelungsanordnung für einen verschluss auf einen behälter und entsprechender behälter - Google Patents

Verriegelungsanordnung für einen verschluss auf einen behälter und entsprechender behälter Download PDFInfo

- Publication number

- EP1560769B1 EP1560769B1 EP03770196A EP03770196A EP1560769B1 EP 1560769 B1 EP1560769 B1 EP 1560769B1 EP 03770196 A EP03770196 A EP 03770196A EP 03770196 A EP03770196 A EP 03770196A EP 1560769 B1 EP1560769 B1 EP 1560769B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- closure

- container

- locking

- locking ring

- ring

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000007789 sealing Methods 0.000 claims description 4

- 239000007788 liquid Substances 0.000 abstract description 9

- 239000007787 solid Substances 0.000 abstract description 7

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 abstract description 3

- 239000000126 substance Substances 0.000 abstract description 2

- 239000000463 material Substances 0.000 description 6

- 239000002775 capsule Substances 0.000 description 4

- 238000007689 inspection Methods 0.000 description 4

- 239000006187 pill Substances 0.000 description 4

- 239000000825 pharmaceutical preparation Substances 0.000 description 2

- 229940127557 pharmaceutical product Drugs 0.000 description 2

- 238000005452 bending Methods 0.000 description 1

- 239000003814 drug Substances 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 201000008482 osteoarthritis Diseases 0.000 description 1

- 206010039073 rheumatoid arthritis Diseases 0.000 description 1

- 210000000707 wrist Anatomy 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D50/00—Closures with means for discouraging unauthorised opening or removal thereof, with or without indicating means, e.g. child-proof closures

- B65D50/02—Closures with means for discouraging unauthorised opening or removal thereof, with or without indicating means, e.g. child-proof closures openable or removable by the combination of plural actions

- B65D50/06—Closures with means for discouraging unauthorised opening or removal thereof, with or without indicating means, e.g. child-proof closures openable or removable by the combination of plural actions requiring the combination of different actions in succession

- B65D50/061—Closures with means for discouraging unauthorised opening or removal thereof, with or without indicating means, e.g. child-proof closures openable or removable by the combination of plural actions requiring the combination of different actions in succession being disengageable from container only after rotational alignment of closure, or other means inhibiting removal of closure, with container, e.g. tortuous path type

- B65D50/062—Closures with means for discouraging unauthorised opening or removal thereof, with or without indicating means, e.g. child-proof closures openable or removable by the combination of plural actions requiring the combination of different actions in succession being disengageable from container only after rotational alignment of closure, or other means inhibiting removal of closure, with container, e.g. tortuous path type the closure removal inhibiting means being a displaceable ring

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D55/00—Accessories for container closures not otherwise provided for

- B65D55/02—Locking devices; Means for discouraging or indicating unauthorised opening or removal of closure

- B65D55/14—Applications of locks, e.g. of permutation or key-controlled locks

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D50/00—Closures with means for discouraging unauthorised opening or removal thereof, with or without indicating means, e.g. child-proof closures

- B65D50/02—Closures with means for discouraging unauthorised opening or removal thereof, with or without indicating means, e.g. child-proof closures openable or removable by the combination of plural actions

Definitions

- the present invention relates to a container which can hold tablets or liquids, for example, for use in the pharmaceutical, chemical and food industries and in particular to a locking arrangement for a container and/or a secondary containment region for a container.

- Containers that have child resistant features are now generally available but these containers are typically very difficult for elderly or disabled persons to open.

- US patent No. 5908125 and other patents in the same area of technology In general, child resistant containers require the user to simultaneously squeeze and turn the closure, or push and turn the closure, in order to release the closure from the container body.

- elderly persons or persons with dexterity problems find that the force required to squeeze or push the closure and simultaneously rotate the closure is too great or that they experience pain in attempting to open the closure.

- Those suffering from rheumatoid arthritis and osteoarthritis will find that they have to avoid any movement, which involves gripping, twisting or bending of the wrist.

- US-6,082,572 there is disclosed a security container.

- the container includes a hollow body and a lid attached to the hollow body which opens in a given direction.

- the container also includes a manually-operable cylindrical member that is biased by a biasing element into a first position at which the member engages the closed lid.

- the cylindrical member is moveable against the biasing element into a second position at which the lid is releasable.

- the lid positively engages the member, and is disengageable from the member by first moving the lid in a direction other than the given direction in which the lid opens.

- the lid is closeable when the member is in the first position.

- the cylindrical member is rotatable relative to a lug 51 and includes a slanted groove 52, see Figs 11A to 11D.

- a ratchet mechanism may be incorporated on the upper cylindrical member bearing. Such a mechanism may also be incorporated on any or all of the bearings. This means that the cylindrical member can only fully turn in one direction. With the ratchet device, the lug cannot force the cylindrical member back in the direction it has come, and this in combination with the slanted groove 42 means that the lock is self-locking.

- Known child resistant containers comprise a cap locking arrangement whereby the user has to turn a cap and align two dots on the respective outer surfaces of the container and the cap. In this position the cap can be pushed open.

- the cap partially obscures the view of the contents of the container.

- the patient only has to take half a tablet dose.

- a further disadvantage of the present containers is that once the tablet has been removed from the container it has to be either stored in a separate location or placed back into the container with the other tablets. In this arrangement the part tablet can be hard to find at a later time.

- a locking arrangement for a closure on a container comprising a hollow body, a closure movable between a closed condition and an open condition, a locking part for securing the closure in the closed condition, the locking part being moveable between a locking position and an unlocked position, and actuator means for moving the locking part from the unlocked position to the locking position as the closure is transferred between the respective conditions.

- the arrangement is such that as the closure is moved to the open condition and the locking part is in the unlocked position the actuator means moves the locking part to the locked position.

- the arrangement is such that as the closure is moved to the closed condition and the locking part is in the unlocked position the actuator means moves the locking part to the locked position.

- the actuator means helps to ensure that the locking part is in a locking position after the closure has been opened and/or closed.

- the actuator means automatically moves the locking part as the closure is being opened and/or closed; therefore the child resistant feature is automatically activated when necessary during the opening operation and the closing operation.

- the present invention aims to overcome the disadvantages we have found of the prior art containers by providing a locking arrangement for a container that is automatically placed in a locked condition.

- closure and the locking part comprise respective cooperating locking elements, the arrangement being such that as the closure is removed from the body to open the container, the actuator means moves one of the locking elements relative to the other locking element.

- the arrangement of the cooperating locking elements located on the closure and the locking part is such that as the closure is pushed back onto the body to close the container, the actuator means moves one of the locking elements relative to the other locking element.

- the locking part carries an indicator that must be aligned with an indicator on the hollow body and/or the closure, the arrangement being such that in use the indicators are moved from an aligned position to a misaligned position by the actuator means.

- the cooperating locking elements are located on the body and the locking part, the arrangement being such that as the closure is removed from the body to open the container, the actuation means moves one of the locking elements relative to the other locking element.

- the arrangement of the cooperating locking elements located on the body and the locking part is such that as the closure is pushed back onto the body to close the container, the actuation means moves one of the locking elements relative to the other locking element.

- the locking part is preferably an annular locking ring.

- the actuator means comprises an elongate member disposed on the inside of the closure, and the locking ring comprises a ramp, the ramp being sloped such that as the elongate member makes contact with the ramp and is slid progressively along a surface of the ramp rotation of the locking ring results such that the indicators on the body and/or closure and the locking part are no longer aligned.

- the arrangement of the elongate member and the ramp is such that as the closure is removed from the body to open the container, the elongate member makes contact with a first surface of the ramp and rotation of the locking ring results such that the indicators on the body and/or closure and the locking part are no longer aligned.

- the arrangement of the elongate member and the ramp is such that as the closure is placed back onto the body to close the container and the indicators are aligned, the elongate member makes contact with a second surface of the ramp and rotation of the locking ring results such that the indicators on the body and/or closure and the locking part are no longer aligned.

- the ramp protrudes from a radially inner surface of the locking ring.

- the ramp is a channel formed in the wall of locking ring, the central axis of the channel being at an angle from the axis of the ring.

- the elongate member is a flexible cantilever.

- the elongate member is hook shaped cantilever, extending from the inside surface of the closure.

- the locking part is preferably located between the body and the closure.

- the cooperating locking element located on the closure is preferably a lug.

- the cooperating locking element located on the locking part is a circumferential flange disposed on the inside surface of the locking part and the lug is formed on the elongate member, the flange being formed with a recessed portion through which the lug can pass during opening and closing of the closure.

- the ramp is preferably disposed axially below the circumferential flange and generally inline with the recessed portion of the flange, the arrangement being such that there is a gap between the uppermost part of the ramp and the circumferential flange.

- the cooperating locking element located the locking part is a circumferential track attached to the inside surface of the locking part and the lug is formed with a distal head part, the lug extends from an inner surface of the closure, the track being formed with an access hole through which the head of the lug can pass during opening and closing of the closure.

- the ramp is preferably disposed axially above the circumferential track.

- the arrangement of the ramp and the flange is such that upon rotation of the locking part in one direction the lug first passes through the gap and generally aligns with the recess before the elongate member makes contact with the ramp.

- the body has an outlet, which can be sealed by a sealing element located on the closure.

- the lug comprises a member formed with a barbed distal end.

- a container comprising the locking arrangement according to claim 1.

- the second containment region is disposed at the upper region of the body and is sealed by the closure of the container.

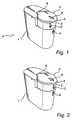

- FIGs 1 to 11 the first embodiment of a container according to the present invention is depicted.

- the container comprises a hollow body 1 for holding solid or liquid contents and a closure 2, which closes the container.

- a locking part in the form of a locking ring 3 is provided between the body 1 and closure 2.

- the locking ring 3 is rotatable on the body 1.

- An indicator arrow- A is located on the body 1 and an indicator arrow B. is located on the closure 2.

- the locking ring 3 also carries an indicator arrow C and it is only when the indicator arrow C is aligned, by turning the locking ring 3, with the indicator arrows A and B (see Figure 2 ) that the closure 2 can be opened by lifting or flipping the projecting edge 4 of the closure 2.

- an indicator arrow need only be provided on either the body 1 or the closure 2 but the user benefits from being able to align indicator arrow C on the locking ring 3 with either indicator arrow A or indicator arrow B.

- the container also comprises actuator means in the form of an elongate member 6 that extends in a direction away from the inner surface of the closure 2.

- the member 6 comprises a hook shaped distal end 6a. Disposed between the distal end 6a and the closure 2 is a wedge shaped lug 10.

- the locking ring 3 is located on the body 1 by way of a snap fit between circular rib formed on an annular shoulder (not shown) on the body 1 and a corresponding circular recess 12 formed adjacent the lower inner edge of the ring 3.

- the arrangement of the ring 3 and the body 1 is such that the ring 3 is secured to the body 1 but will rotate freely on the body 1.

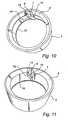

- the locking ring 3 has a circumferential flange 8 on its inside surface.

- This flange 8 is formed with a recessed portion 9 through which the hook 6 and lug 10 can pass during opening and closing of the closure 2 if the arrows A, B, C are aligned.

- the lug 10 will sit under the flange 8 when the arrows are not aligned, thereby locking the closure 2 onto the body 1.

- the locking ring 3 comprises a ramp 7 that is sloped from the axial direction of the ring 3 and extends from the inner surface of the ring 3. There is a gap 13 between the uppermost part of the ramp 7 and the flange 8 through which the lug 10 may pass when the arrows A, B, C are aligned.

- the ramp 7 comprises an upper inclined surface 14 and a lower inclined surface 16 (hidden in the Figures). The arrangement is such that if the arrows A, B, C are aligned and the closure 2 is opened the lug 10 passes through the opening 9 and the distal end 6a of the hook 6 will make contact with the lower inclined surface 16 of the ramp 7 and rotate the locking ring 3 i.e., back to the locked position.

- the arrangement is such that if the arrows A, B, C are aligned and the closure 2 is closed the distal end 6a of the hook 6 will make contact with upper inclined surface 14 of the ramp 7 and rotate the locking ring 3 i.e., back to the locked position.

- the locking ring 3 is freely rotatable on the body 1 once the hook 6 has travelled down the ramp 7.

- the locking part is preferably in the form of a locking ring 3, however the locking part may be a non-annular shape for example a slideable element that is moveable by the actuator means in an arc or linear direction.

- the ramp 7 could include a channel, which captures the tip of the hook 6 at the bottom of the ramp 7 whereby the hook 6 is only released when it has travelled to the top of the ramp 7.

- the indicator arrow C is not aligned when the closure 2 has opened and the user can simply push the hook 6 over the flange 8 to close the closure 2.

- the distal end 6a acts as an actuator that ensures that the respective arrow indicators are misaligned following the opening and/or closing of the container.

- the distal end 6a automatically moves the arrow indicators out of alignment during the opening operation and if necessary the closing operation. Therefore the child resistant feature is automatically activated during the opening operation and if necessary during the closing operation.

- the hook 6 is flexible so that it is possible to push the closure 2 closed without aligning the hook 6 with the recessed portion 9.

- the lug 10 is sloped corresponding to the slope on the flange 8 so that it can simply be pushed over the flange 8 until the lug 10 slips beneath the flange 8 to lock the closure 2 onto the body 1.

- the width of the recessed portion 9 is such that when the arrows A, B, C are aligned and the hook 6 sits at the bottom of the ramp 7, the lug 10 will be free to move out of the locking ring 3.

- the body 1 in this embodiment has an annular opening 11 that is sealable by an annular rim 12 on the closure 2.

- This sealing arrangement helps prevent the ingress of water vapour, which could affect the stability of the contents and also acts to prevent leakage if the contents are liquid.

- the flange 8 and the annular opening 11 form a secondary containment volume 17.

- the volume 17 and the internal volume of the body 1 are separated from each other by an annular wall (not shown in the Figures).

- the volume 17 may be used to store material, such as part or whole pharmaceutical tables that have been removed from the container body 1.

- the containment volume 17 also provides an area that may be used to inspection the material that has been removed from the body.

- FIG. 12 a second embodiment of a container is depicted.

- the container comprises a tubular hollow body 20 holding solid or liquid contents and a closure 21, which closes the container.

- a locking ring 23 is provided between the body 20 and closure 21 which can rotate between body 20 and closure 21.

- An indicator arrow D is located on body 20 and an indicator arrow E is located the locking ring 23.

- the closure 21 can be opened by lifting or flipping the projecting edge 24 of the closure 21.

- the closure 21 is formed with an annular collar 25 extending around the perimeter of the closure 21. Extending from an inner surface of the closure 21 is an elongate member 26 formed with a frusto conical end 28 at the distal end thereof. A wedge shaped locking lug 38 is formed on an outer surface of the annular collar 25.

- the locking ring 23 comprises an outer annular collar 31 and a radially inner annular track 32 formed with an inner annular channel and an upper annular slot 34.

- the inner annular channel is directly below the slot 34.

- the width of the slot 34 is less than the width of the annular channel. At one point on the slot 34 the width increases forming a circular access hole 36.

- the outer annular collar 31 is formed with a channel 37 that is sloped from the axial direction of the ring 23.

- the locking ring 23 is located on the body 20 by way of a snap fit between a circular rib (not shown) formed on the body 20 and a corresponding circular recess (not shown) formed adjacent the lower inner edge of the ring 23 such that the ring 23 is secured to the body 20 but will rotate freely on the body.

- the arrangement is such that if the arrows D and E are aligned the end 28 will be adjacent the hole 36 and the lug 38 will be at the lowermost end of the channel 37 and the closure 21 can be opened. As the closure 21 is opened the end 28 will pass through the hole 36 and the lug 38 will make contact with the upper inclined surface of the channel 37 and rotate the locking ring 23 i.e., back to the locked position. Also, the arrangement is such that if the arrows D and E are aligned and the closure 21 is closed the end 28 will pass through the hole 36 and then the lug 38 will make contact with lower inclined surface of the channel 37 and rotate the locking ring 23 i.e., back to the locked position. In this respect, it should be noted that the locking ring 23 is freely rotatable on the body 20 once the lug 38 has travelled down the channel 37.

- the body 20 in this embodiment has an annular opening 40 formed in an upper wall 41.

- the opening 40 is sealable by an annular rim 42 on the closure 2.

- This sealing arrangement helps prevent the ingress of water vapour which cold affect the stability of the contents and also acts to prevent leakage if the contents are liquid.

- the upper wall 41 and annular track 32 form a secondary containment volume 43.

- the volume 43 may be used to store material, such as part or whole pharmaceutical tables that have been removed from the container body 20.

- the containment volume 43 also provides an area that may be used to inspection the material that has been removed from the body.

- the lug 38 acts as an actuator that ensures that the respective arrow indicators are misaligned following the opening and/or closing of the container.

- the lug 38 automatically moves the arrow indicators out of alignment during the opening operation and if necessary the closing operation. Therefore the child resistant feature is automatically activated during the opening operation and if necessary during the closing operation.

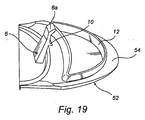

- FIG. 15 to 19 a third embodiment of a container according to the present invention is depicted.

- the third embodiment comprises many common features as the first embodiment herein before described and the same reference numbers have been used to depict those common features.

- the third embodiment container 50 comprises a hollow body 51 for holding solid or liquid contents and a closure 52, which closes the container.

- a locking part in the form of a locking ring 53 is provided between the body 51 and closure 52.

- the locking ring 53 is rotatable on the body 51.

- An indicator arrow B is located on the closure 52.

- the locking ring 53 also carries an indicator arrow C and it is only when the indicator arrow C is aligned, by turning the locking ring 53, with the indicator arrows B (see Figure 15 ) that the closure 52 can be opened by lifting or flipping the projecting edge 54 of the closure 52.

- the container 51 also comprises actuator means in the form of an elongate member 6 that extends in a direction away from the inner surface of the closure 52.

- the member 6 comprises a hook shaped distal end 6a. Disposed between the distal end 6a and the closure 52 is a wedge shaped lug 10.

- the locking ring 53 is located on the body 51 by way of a snap fit between circular rib formed on an annular shoulder (not shown) on the body 51 and a corresponding circular recess (not shown) formed adjacent the lower inner edge of the ring 53.

- the arrangement of the ring 53 and the body 51 is such that the ring 53 is secured to the body 51 but will rotate freely on the body 51.

- the locking ring 53 and the actuator 6 is substantially the same as the description of the corresponding features of Figures 1 to 11 of the first aspect of the invention. It will be noted however that the locking ring 53 is disposed substantially about the central axis of the container 51.

- the container 51 is formed with an opening 55 located at one side of the container 51. The opening 55 provides access to the interior volume of the container 51.

- a solid panel 63 seals a portion of the upper volume of the container 51.

- the panel 63 and an annular collar 61 form a second containment volume 64.

- a third containment volume 65 is formed by a portion of the panel 63, a portion of the radially outermost wall of the body 51 and actuate wall 67.

- the second and third containment volumes 64, 65 may be used to store solids of liquids.

- the second and third containment volumes 64, 65 may be used for storing pharmaceutical products such as pills or capsules and are particularly useful for storing partial pills or capsules.

- the containment volumes 64, 65 are sealed by the closure 52.

- the containment volumes 64, 65 also provide areas that may be used to inspection the material that has been removed from the body.

- FIG. 20 to 23 a fourth embodiment of a container according to the present invention is depicted.

- the fourth embodiment comprises many common features as the first embodiment herein before described and the same reference numbers have been used to depict those common features.

- the container 70 of the third embodiment differs from that of the first embodiment by the fact that the closure 72 of the container 70 extends across the uppermost end volume of the hollow body 1.

- the horizontal cross-section of the closure 72 is substantially the same as the horizontal cross-section of the body 1.

- a solid panel 74 seals a portion of the upper volume of the container 1.

- the panel 74 and an upwardly extending collar 76 form a second containment volume 68.

- the second containment volume 68 may be used for storing pharmaceutical products such as pills or capsules and is particularly useful for storing partial pills or capsules.

- the containment volume 68 is sealed by the closure 72.

- the containment volume 68 also provides an area that may be used to inspection the material that has been removed from the body.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Closures For Containers (AREA)

- Medical Preparation Storing Or Oral Administration Devices (AREA)

- Cartons (AREA)

- Medicines Containing Material From Animals Or Micro-Organisms (AREA)

- Packages (AREA)

Claims (12)

- Verriegelungsanordnung für einen Verschluss (2) auf einem Behälter (1), wobei der Behälter Folgendes umfasst: einen mit einer Öffnung ausgebildeten Hohlkörper, wobei der Verschluss am Körper befestigt und zwischen einer geschlossenen Position und einer geöffneten Position und umgekehrt beweglich ist;

einen Verriegelungsring (3; 53) zum Verriegeln des Verschlusses im geschlossenen Zustand, wobei der Verriegelungsring zwischen dem Behälterkörper und dem Verschluss (2) vorgesehen und am Körper um eine Achse herum beweglich ist;

ein am Verschluss (2) befestigtes Betätigungsglied (6) in Form eines Elements (6), das sich von der Innenfläche des Verschlusses (2) weg erstreckt;

wobei

der bewegliche Verriegelungsring (3; 53) eine Rampe (7; 37) mit einer oberen und einer unteren geneigten Fläche (14, 16) umfasst, die von der Axialrichtung des Verriegelungsrings (3; 53) geneigt sind, und wobei

das Betätigungsglied ein Mittel (6a) zur Herstellung eines Kontakts mit der oberen oder unteren geneigten Fläche (14, 16) am beweglichen Verriegelungsring (3; 53) während des Öffnens oder Schließens des Verschlusses, um den Verriegelungsring in eine Position zu bewegen, in der er den Verschluss (2) verriegelt, umfasst; gekennzeichnet durch

einen Umfangsflansch (8) an der Innenfläche des Verriegelungsrings;

einen am Betätigungsglied ausgebildeten Ansatz (10); wobei

der Flansch mit einem ausgesparten Teil (9) ausgebildet ist, durch den sich der Ansatz (10) beim Öffnen und Schließen des Verschlusses erstrecken kann; und wobei

die Rampe (7; 37) von einer radial innen liegenden Fläche des Verriegelungsrings ragt und axial unter dem Umfangsflansch und allgemein in einer Linie mit dem ausgesparten Teil des Flansches angeordnet ist, wobei die Anordnung derart ist, dass zwischen dem obersten Teil der Rampe (7) und dem Umfangsflansch ein Spalt (13) besteht. - Verriegelungsanordnung nach Anspruch 1, wobei das Betätigungsgliedmittel (6) ein an der Innenseite des Verschlusses (2) angeordnetes längliches Glied (10, 6, 6a) umfasst.

- Verriegelungsanordnung nach Anspruch 1 oder 2, wobei der Verriegelungsring (3; 53) und/oder der Behälter (1) Ausrichtungsanzeigemittel (A; C) umfassen/umfasst.

- Verriegelungsanordnung nach einem der Ansprüche 1 bis 3, wobei die Rampe eines Kanal (37) umfasst, der in der Wand des Verriegelungsrings ausgebildet ist, wobei die mittlere Achse des Kanals in einem Winkel zur Achse des Rings verläuft.

- Verriegelungsanordnung nach einem der Ansprüche 1 bis 4, wobei das Betätigungsglied (6) eine flexible Auskragung ist.

- Verriegelungsanordnung nach einem der Ansprüche 1 bis 5, wobei das Betätigungsglied eine hakenförmige Auskragung ist, die sich von der Innenfläche des Verschlusses aus erstreckt.

- Verriegelungsanordnung nach einem der vorhergehenden Ansprüche, wobei der Körper einen Auslass aufweist, der durch ein am Verschluss angeordnetes Schließelement verschlossen werden kann.

- Behälter mit einer Verriegelungsanordnung nach einem der vorhergehenden Ansprüche.

- Behälter nach Anspruch 8, der ein zweites Aufnahmevolumen umfasst.

- Behälter nach Anspruch 9, der ein drittes Aufnahmevolumen umfasst.

- Behälter nach einem der Ansprüche 8 bis 10, wobei mindestens eines der weiteren Aufnahmevolumen am oberen Volumen des Körpers angeordnet ist.

- Behälter nach einem der Ansprüche 9 bis 11, wobei mindestens eines der weiteren Aufnahmevolumen durch den Verschluss verschlossen wird.

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| SE0203261A SE0203261D0 (sv) | 2002-11-05 | 2002-11-05 | A container |

| SE0203261 | 2002-11-05 | ||

| SE0203262 | 2002-11-05 | ||

| SE0203262A SE0203262D0 (sv) | 2002-11-05 | 2002-11-05 | A container |

| PCT/SE2003/001704 WO2004041671A1 (en) | 2002-11-05 | 2003-11-05 | Security container with locking closure and method for locking a closure |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1560769A1 EP1560769A1 (de) | 2005-08-10 |

| EP1560769B1 true EP1560769B1 (de) | 2008-02-27 |

Family

ID=32314177

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03770196A Expired - Lifetime EP1560769B1 (de) | 2002-11-05 | 2003-11-05 | Verriegelungsanordnung für einen verschluss auf einen behälter und entsprechender behälter |

Country Status (14)

| Country | Link |

|---|---|

| US (1) | US20060108364A1 (de) |

| EP (1) | EP1560769B1 (de) |

| JP (1) | JP2006505461A (de) |

| KR (1) | KR20050072786A (de) |

| AT (1) | ATE387385T1 (de) |

| AU (1) | AU2003278663B8 (de) |

| BR (1) | BR0315875A (de) |

| CA (1) | CA2501598A1 (de) |

| DE (1) | DE60319409T2 (de) |

| ES (1) | ES2299734T3 (de) |

| IL (1) | IL168109A (de) |

| MX (1) | MXPA05004630A (de) |

| NZ (1) | NZ539689A (de) |

| WO (1) | WO2004041671A1 (de) |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8251251B2 (en) * | 2006-01-20 | 2012-08-28 | Astrazeneca Ab | Container |

| USD578302S1 (en) * | 2006-03-10 | 2008-10-14 | Astrazeneca Ab | Container device |

| KR100735846B1 (ko) * | 2006-06-02 | 2007-07-04 | 박석우 | 위험물 안전 개폐 용기 |

| USD565838S1 (en) | 2006-10-03 | 2008-04-08 | Astrazeneca Ab | Container device |

| FR2908392B1 (fr) * | 2006-11-09 | 2010-11-12 | Lindal France | Tube souple muni d'une tete distributrice et d'une coiffe charniere |

| FR2924097A1 (fr) * | 2007-03-26 | 2009-05-29 | Lindal France Soc Par Actions | Capuchon pour pulverisateur. |

| US20100193522A1 (en) * | 2009-02-05 | 2010-08-05 | Wisniewski John M | Closure with shipping latch |

| EP2489602A1 (de) * | 2011-02-15 | 2012-08-22 | The Procter & Gamble Company | Klappverschluss zum Verschließen eines Behälters |

| US10189619B1 (en) | 2013-03-27 | 2019-01-29 | Caren Crawley | Lockable food container |

| US10173811B2 (en) * | 2014-06-18 | 2019-01-08 | Weatherchem Corporation | Dual hinge flip cap closure |

| US11124340B2 (en) | 2020-02-10 | 2021-09-21 | Caren Crawley | Anti-theft storage container system |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3693820A (en) * | 1971-06-03 | 1972-09-26 | Robert P Linkletter | Safety closure cap |

| US3931891A (en) * | 1974-10-11 | 1976-01-13 | Peppler Stanley R K | Pill container with pocket |

| FR2603871B1 (fr) * | 1986-09-16 | 1988-12-02 | Morel Simone | Capsule de securite formant bouchon pour flacons et objets analogues |

| GB9601960D0 (en) * | 1996-01-31 | 1996-04-03 | Galton Fenzi Miles D M | Containers |

| US5908125A (en) * | 1997-04-16 | 1999-06-01 | Weatherchem Corporation | Child-resistant screw-on cap and bottle |

| WO2000002859A1 (en) * | 1998-07-10 | 2000-01-20 | Astrazeneca Ab | N-substituted naphthalene carboxamides as neurokinin-receptor antagonists |

| GB9907571D0 (en) * | 1999-04-06 | 1999-05-26 | Zeneca Ltd | Compounds |

| ES2321092T3 (es) * | 2002-08-29 | 2009-06-02 | Astrazeneca Ab | Derivados naftamida y sus usos. |

-

2003

- 2003-11-05 KR KR1020057007875A patent/KR20050072786A/ko not_active Ceased

- 2003-11-05 CA CA002501598A patent/CA2501598A1/en not_active Abandoned

- 2003-11-05 WO PCT/SE2003/001704 patent/WO2004041671A1/en not_active Ceased

- 2003-11-05 NZ NZ539689A patent/NZ539689A/en unknown

- 2003-11-05 AT AT03770196T patent/ATE387385T1/de not_active IP Right Cessation

- 2003-11-05 US US10/533,834 patent/US20060108364A1/en not_active Abandoned

- 2003-11-05 BR BR0315875-6A patent/BR0315875A/pt not_active IP Right Cessation

- 2003-11-05 JP JP2004549773A patent/JP2006505461A/ja active Pending

- 2003-11-05 AU AU2003278663A patent/AU2003278663B8/en not_active Ceased

- 2003-11-05 DE DE60319409T patent/DE60319409T2/de not_active Expired - Fee Related

- 2003-11-05 ES ES03770196T patent/ES2299734T3/es not_active Expired - Lifetime

- 2003-11-05 EP EP03770196A patent/EP1560769B1/de not_active Expired - Lifetime

- 2003-11-05 MX MXPA05004630A patent/MXPA05004630A/es active IP Right Grant

-

2005

- 2005-04-18 IL IL168109A patent/IL168109A/en not_active IP Right Cessation

Also Published As

| Publication number | Publication date |

|---|---|

| IL168109A (en) | 2009-02-11 |

| ATE387385T1 (de) | 2008-03-15 |

| JP2006505461A (ja) | 2006-02-16 |

| EP1560769A1 (de) | 2005-08-10 |

| AU2003278663B8 (en) | 2008-04-03 |

| WO2004041671A8 (en) | 2005-03-10 |

| WO2004041671A1 (en) | 2004-05-21 |

| AU2003278663B2 (en) | 2008-02-07 |

| NZ539689A (en) | 2008-01-31 |

| DE60319409T2 (de) | 2009-02-19 |

| CA2501598A1 (en) | 2004-05-21 |

| US20060108364A1 (en) | 2006-05-25 |

| BR0315875A (pt) | 2005-09-27 |

| MXPA05004630A (es) | 2005-06-08 |

| AU2003278663A1 (en) | 2004-06-07 |

| HK1079499A1 (en) | 2006-04-07 |

| ES2299734T3 (es) | 2008-06-01 |

| KR20050072786A (ko) | 2005-07-12 |

| DE60319409D1 (de) | 2008-04-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| AU2007206116B2 (en) | A child resistant locking arrangement for a container | |

| US9981789B2 (en) | Container assembly with one-piece child resistant closure | |

| EP1560769B1 (de) | Verriegelungsanordnung für einen verschluss auf einen behälter und entsprechender behälter | |

| US6065648A (en) | Child resistant dispenser | |

| US20040007556A1 (en) | Helical lock closure system | |

| US8141729B2 (en) | Convertible closure for a container | |

| US20150321804A1 (en) | Child-resistant cap and container assembly | |

| US10457474B2 (en) | Individual pill dispenser | |

| US7513388B2 (en) | Retractable straw device | |

| ZA200502931B (en) | Security container with locking closure and method for locking a closure | |

| HK1079499B (en) | Locking arrangement for a closure on a container and corresponding container | |

| US20020027119A1 (en) | Convertible child resistant closure | |

| JP2021006468A (ja) | 安全キャップおよびキャップ付き容器ユニット | |

| KR101924033B1 (ko) | 내용물 배출 조정 용기 | |

| JPH0234211Y2 (de) | ||

| WO2018111344A1 (en) | Individual pill dispenser | |

| US20200031565A1 (en) | Medication dispensing system | |

| CA2134911A1 (en) | Safety maze closure |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20050606 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| DAX | Request for extension of the european patent (deleted) | ||

| REG | Reference to a national code |

Ref country code: HK Ref legal event code: DE Ref document number: 1079499 Country of ref document: HK |

|

| 17Q | First examination report despatched |

Effective date: 20070411 |

|

| RTI1 | Title (correction) |

Free format text: LOCKING ARRANGEMENT FOR A CLOSURE ON A CONTAINER AND CORRESPONDING CONTAINER |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: VEJBRINK, ULRIKA,ERGONOMI DESIGN GRUPPEN AB Inventor name: BENKTZON, MARIA,ERGONOMI DESIGN GRUPPEN AB Inventor name: NILSSON, THOMAS,ERGONOMI DESIGN GRUPPEN AB |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REF | Corresponds to: |

Ref document number: 60319409 Country of ref document: DE Date of ref document: 20080410 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2299734 Country of ref document: ES Kind code of ref document: T3 |

|

| REG | Reference to a national code |

Ref country code: HK Ref legal event code: GR Ref document number: 1079499 Country of ref document: HK |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080227 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080227 |

|

| ET | Fr: translation filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080227 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080227 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080227 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080227 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080721 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080227 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080227 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080227 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20081028 Year of fee payment: 6 |

|

| 26N | No opposition filed |

Effective date: 20081128 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20081118 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20081107 Year of fee payment: 6 Ref country code: IT Payment date: 20081126 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080527 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080227 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20081106 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20081128 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20081130 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20081008 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080227 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20081105 |

|

| EUG | Se: european patent has lapsed | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20091105 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080828 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20081105 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20100730 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080227 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091130 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091130 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080528 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100601 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091105 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20110330 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091105 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091106 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110317 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091106 |