EP1548201B1 - Systeme de construction pour amortir des vibrations - Google Patents

Systeme de construction pour amortir des vibrations Download PDFInfo

- Publication number

- EP1548201B1 EP1548201B1 EP04029896A EP04029896A EP1548201B1 EP 1548201 B1 EP1548201 B1 EP 1548201B1 EP 04029896 A EP04029896 A EP 04029896A EP 04029896 A EP04029896 A EP 04029896A EP 1548201 B1 EP1548201 B1 EP 1548201B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- silent block

- construction system

- silent

- rubber

- block

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000010276 construction Methods 0.000 title claims abstract description 25

- 238000013016 damping Methods 0.000 title abstract 2

- 229920001971 elastomer Polymers 0.000 claims abstract description 39

- 238000007667 floating Methods 0.000 claims abstract description 15

- 239000000463 material Substances 0.000 claims abstract description 6

- 239000002184 metal Substances 0.000 claims description 47

- 238000009413 insulation Methods 0.000 abstract description 2

- 230000004888 barrier function Effects 0.000 abstract 1

- 230000005540 biological transmission Effects 0.000 abstract 1

- 239000000806 elastomer Substances 0.000 abstract 1

- 238000009432 framing Methods 0.000 abstract 1

- 229910000831 Steel Inorganic materials 0.000 description 2

- 230000008878 coupling Effects 0.000 description 2

- 238000010168 coupling process Methods 0.000 description 2

- 238000005859 coupling reaction Methods 0.000 description 2

- 238000009434 installation Methods 0.000 description 2

- 239000010959 steel Substances 0.000 description 2

- 101100437784 Drosophila melanogaster bocks gene Proteins 0.000 description 1

- 208000027418 Wounds and injury Diseases 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- 230000006378 damage Effects 0.000 description 1

- 238000005034 decoration Methods 0.000 description 1

- 230000002708 enhancing effect Effects 0.000 description 1

- 208000014674 injury Diseases 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 230000036544 posture Effects 0.000 description 1

- 230000002265 prevention Effects 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B9/00—Ceilings; Construction of ceilings, e.g. false ceilings; Ceiling construction with regard to insulation

- E04B9/18—Means for suspending the supporting construction

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B9/00—Ceilings; Construction of ceilings, e.g. false ceilings; Ceiling construction with regard to insulation

- E04B9/18—Means for suspending the supporting construction

- E04B2009/186—Means for suspending the supporting construction with arrangements for damping vibration

Definitions

- the present description refers, as its title indicates, to a safe construction system for fixed or removable panels and false ceilings or those of a similar type used in the building industry in general, characterised by the fact that in the proposed system the assembly of a fixed panel is carried out by means of a isolator screwed to a wall and, between adjoining panels, by means of a floating isolator formed by a silent block with or without a spring, including one or more metal "L" shaped angle braces that are housed between the silent block system by means of a through screw and counter nuts, forming a compact block.

- the panels are attached to the "L" shaped angle braces by means of fixing elements, enhancing thermal and acoustic insulation.

- the object of the invention is to achieve a construction system that provides optimum safety guarantees in the coupling of the different elements that it comprises.

- Removable panels are secured using a wall isolator that comprises a metal surface with a vulcanised rubber silent block that remains screwed to a wall, at the same time incorporating a metal angle brace riveted to the silent block.

- a panel can be installed on the aforementioned angle brace by means of the orifices for this purpose, the main disadvantage of this device being its safety due to its poor performance in the event of a fire given the fact that the elements that it comprises do not maintain the structure in a block, with the added disadvantage that if a certain pressure is exerted the structure deforms readily.

- EP-A-0 060 567 discloses an isolator intended for the attachment of wiring or piping, fittings therefore or of other components on ceilings or walls. Such isolator is made using one U-shaped brace with one side of the U fitted to the ceiling by means of a silent block and a screw, and the other side of the U having a screw and nuts for connecting the wiring or piping.

- a different embodiment comprises one silent block which goes through a screw and a brace, being fitted to a wall by means of a screw or a nail.

- DE 299 11 747 discloses an isolator which comprises only one piece of rubber screwed to a wall by means of a screw which goes longitudinally across the piece of rubber.

- Other embodiments are fitted inserting a brace into a boss which runs around the external surface of the piece of rubber, the brace being, in turn, fitted to a surface by means of screws or nails.

- FR-A-2 831 572 describes an isolator intended for hanging steel sections from the ceiling. It comprises a plate assembly for attaching to the steel section and one rubber silent block. The fitting to the ceiling is provided with a threaded section which allows for height calibration.

- US 2003/0066261 discloses an isolator intended for ceiling frameworks which comprises a silent block, a bracket and a threaded rod.

- the threaded rod is connected to the silent block by means of an insert embedded in the rubber silent block, the bracket, in turn, being attached to the silent block by means of an external boss.

- the bracket is obtained simply bending a cut-out blank.

- the safety system for the attachment of fixed or removable panels basically comprises two types of isolators: a wall isolator and a floating isolator.

- the present construction system comprises a base made of die-cut plate with orifices to screw to a wall, forming a compact block by means of a though screw that carries out its torque on a screwed orifice in the base itself, including a silent block that houses, in its middle part, an "L" shaped angle brace with several orifices for the attachment of the panel using fixing means, with the possibility of using a simple drill.

- the wall isolator with a spring has a similar structure, the only difference being the silent blocks, which have a housing to accommodate the spring.

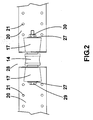

- the floating isolator (for panel to panel attachment) comprises two opposing silent blocks separated by a central silent block; the silent blocks at both ends including an "L" shaped angle brace, forming a compact block by means of a through screw, that exerts its torque on a counter nut. These panels are installed in the same way as described in the previous case.

- the components of the wall isolator with a rubber silent block are a die-cut metal base that is circular at the centre and narrows at the top and bottom, both ends being radially finished off incorporating a perforation of a smaller diameter in its geometric centre.

- This base is fitted to the wall by means of screws and washers.

- a rubber silent block that is basically cylindrical, its centre part being wider and formed by a spoke, both ends being narrower and straight, one end adjoining the metal base and the other the rubber silent block, formed by a cone trunk, that, at its narrowest end, has a boss and a housing box for a bent L-shaped metal angle brace on which the fixed or removable panels are Installed by means of fixing elements, through a plurality of equidistant perforations on said angle brace. All of the silent blocks have a through perforation at their geometric centre to allow the clamping screw to pass through.

- the floating isolator with the rubber silent block is formed by two "L"-shaped metal angle braces, each of which having a silent block formed by a cone trunk, that, in its narrowest part, has a boss and hou5ing box between which there is another cylindrical rubber silent block Whose centre part is wider and formed by a spoke, both of the narrower ends remaining straight.

- the fixed or removable panels are installed on bent L-shaped metal angle braces by means of fixing elements, through a plurality of equidistant perforations on said angle braces. All of the silent blocks have a through perforation at their geometric centre to allow the clamping screw to pass through.

- the components of the wall isolator with a rubber silent block and spring are a die-cut metal base that is circular at the centre and narrows at the top and bottom, both ends being radially finished off incorporating a perforation of a smaller diameter at its geometric centre.

- This base is tatted to the wall by means of screws and washers.

- Both ends, of a smaller diameter, comprise a straight section, a hemispherical boss and a housing box for a bent L-shaped metal angle brace, onto which the fixed or removable panels are installed by means of fixing elements, through a plurality of equidistant perforations on said angle brace.

- the opposite end Whilst one end of the aforementioned silent block remains adjoining the metal base, the opposite end, of the same design, houses a spring that in turn is centred on another cylindrical rubber silent block formed by a larger diameter straight section and a section of a smaller diameter that has a straight section, a hemispherical boss and a housing box in which the apposite endow the spring is housed.

- All of the silent blocks have a through perforation at their geometric centre to allow the clamping screw to pass through. All of this forms a compact block by means of a through screw screwed to the metal base. It is installed with a flat washer to enhance the screw torque.

- the floating isolator with rubber silent block and springs comprises two "L"-shape metal angle braces, each of which has a cylindrical silent block, the centre part of which is of a larger diameter. Both ends, of a smaller diameter comprise a straight section, a hemispherical boss and a housing box between which there is another cylindrical rubber silent block, the centre part being wider and formed by a spoke, both of the narrower ends remaining straight.

- the opposite end Whilst one end of the aforementioned silent block remains adjoining the metal base, the opposite end, of the same design, houses a spring that in turn is centred on another cylindrical rubber silent block formed by a short, larger diameter, straight section and a section of a smaller diameter that has a straight section, a hemispherical boss and a housing box in which the opposite end of the spring is housed.

- the fixed or removable panels are installed on the bent L-shaped metal angle braces by means of fixing elements, through a plurality of equidistant perforations on said angle braces, All of the silent bocks have a through perforation at their geometric centre, to allow the clamping screw to pass through.

- the initial step is to screw the isolators to the wall and on them the corresponding panels, so that to continue prolonging the wall, the floating isolators must be used, attaching, in this way, as many panels as are needed.

- This safe construction system presented provides, in relation to the fixing of panels, numerous advantages over the systems currency available, having a highly effective fire performance in the case of fixed or removable panels, given that, since the system is formed by a compact block by means of a screw that fixes the whole assembly together, in the event of fire the structure will never collapse inwards into the premises, thus preventing, as for as is possible, injury to persons.

- Another important common advantage of the safe construction system is the reduction of assembly times, considerably redudng costs and increasing productivity as well as favouring handling during assembly without fitters having to adopt forced postures, complying in this way with the current legislation on the prevention of risks at work.

- the wall isolator (1) with rubber silent block, basically comprises a die-cut laminar metal base (2) that is Circular in its centre part, narrowing at the top (4) and bottom (5) both ends being radially finished off (6) incorporating a perforation (7) of a smaller diameter in its geometric centre; this base is installed on a walt (8) by means of screws (9) and washers (10).

- the centre part (11) is notably higher due to the spokes (12) that form it, incorporating a threaded perforation (13) at its geometric centre.

- a rubber silent block (14) Centred on the central part (11) of the metal base (2) there is a rubber silent block (14), that is basically cylindrical its central part (15) being wider and formed by an interior spoke, both narrower ends (16) remaining straight.

- a rubber silent block (17) During mounting one end is fitted adjoining the metallic base (2) and the other end adjoining another rubber silent block (17), of a cone trunk shape, with a boss (18) at its narrowest point and a smaller diameter housing box (19), to house a bent t-shaped metal angle brace (20), on which the fixed or removable panels am instated by means of fixing elements though a plurality of equidistant perforation (21) located along the top and bottom part.

- the angle brace (20) is made of thin laminar plate and of a rectangular shape, the edges (22) of its free end being rounded, the opposite end (23), of a reduced length and bent to an "L" shape, with an orifice (24) at its centre and the edges (22) of its free end being rounded.

- the silent block (17) remains secured in the angle brace (20) when the boss (18) is inserted into the orifice (24), maintaining a slight pressure and remaining in position in the box (19).

- All of the silent blocks have a through perforation (25) located at their geometric centre to allow a clamping screw (26) to pass through, producing a compact block when screwed to the metal base (2), a flat washer (27) being fitted to enhance the screw torque.

- the floating isolator (28) with rubber silent black is basically formed by two metal angle braces (20) bent in an L-shape, each of which includes a silent block (17), between both of these there is another cylindrical rubber silent block (14).

- the fixed or removable panels are installed on the metal angle braces (20) by means of fixing elements through a plurality of equidistant perforations (21).

- All of the silent blocks have a through perforation (25) at their geometric centre to allow a clamping screw (29) to pass through, producing a compact block when screwed to a counter nut (30), flat washers (27) being fitted to enhance the tightening torque

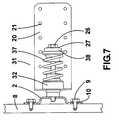

- the wall isolator (31), with rubber silent block and spring is basically formed by a die-cut laminar metal base (2) and it is installed on a wall (8) by means of screws (9) and washes (10).

- a robber silent block that is basically cylindrical, its central part (33) having a larger diameter; both ends being equal and of a smaller diameter comprise a straight section (34), a hemispherical boss (35) and a housing box (36) to accommodate a bent L-shaped metal angle brace (20).

- the opposite end Whilst one end (34) of the aforementioned silent block (32) remains adjoining the metal base (2), the opposite end, formed in the same way, houses a spring (37) that, in turn, is centred on another cylindrical rubber silent block (38), formed by a short straight section (39) of a larger diameter, with one end formed by another short straight section (40) of a smaller diameter and the opposite end, of a smaller diameter, having a straight section (34), a hemispherical boss (35) and a housing box (36) in which the opposite end of the spring (37) is housed.

- a spring that, in turn, is centred on another cylindrical rubber silent block (38), formed by a short straight section (39) of a larger diameter, with one end formed by another short straight section (40) of a smaller diameter and the opposite end, of a smaller diameter, having a straight section (34), a hemispherical boss (35) and a housing box (36) in which the opposite end of the spring (37) is housed.

- the silent block (32) remains secured in the angle brace (20) when the hemispherical boss (35) is inserted into the orifice (24), maintaining a slight pressure, remaining in position in the box (36), the spring (37) then remains positioned between the box (36) and the hemispherical boss (35)

- All of the silent blocks have a through perforation (25) at their geometric center to allow a clamping screw (26) to pass through, providing a compact black when screwed to the metal base (2), a flat washer (27) being fitted to enhance the tightening torque.

- the floating isolator (41), with rubber silent biotic and springs, basically comprises two bent Leaped metal angle braces (20), each one of which has a silent block (32), between each of these there is another cylindrical rubber silent block (14), in turn each silent block (32) takes a spring (37) housing its opposite end in a silent block (38).

- All of the silent blocks have a through perforation (25) at their geometric centre to allow a clamping screw (42) to pass through, providing a compact block when screwed to a counter nut (30), being fitted with flat washers (27) to enhance the tightening torque.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Building Environments (AREA)

- Buildings Adapted To Withstand Abnormal External Influences (AREA)

Claims (13)

- Un système de construction pour l'assemblage de panneaux fixes ou amovibles et de faux plafonds ou du même type utilisés dans l'industrie du bâtiment en général, où le montage comprend un amortisseur mural (1) pouvant être vissé sur un mur, caractérisé par le système de construction comprenant en outre un amortisseur pour l'assemblage entre les panneaux adjoints (28), l'amortisseur mural (1) comportant une base en métal laminaire estampé (2) pour la fixation au mur, un bloc silencieux (14) préférablement en caoutchouc joint à la base en métal (2) avec l'autre extrémité du bloc silencieux mentionné (14) adjoint à une bretelle de support métallique en forme de L (20), et où une vis de serrage (26) passe à travers la base en métal(2), le bloc silencieux (14) et la bretelle de support métallique en forme de L (20) et dans cet amortisseur flottant (28), comprenant deux bretelles de support en métal en forme de L (20), chacun d'eux incorporant un autre bloc silencieux (17) préférablement en caoutchouc, avec un autre bloc silencieux (14) entre les deux autres bretelles de support métallique en forme de L (20) et dans lesquels une vis de serrage (29) passe à travers les deux bretelles de support métallique en forme de L (20) et les trois blocs silencieux (14,17), permettant à la structure de se maintenir en place sans se collapser en cas d'incendie.

- Un système de construction selon la revendication précédente où le bloc silencieux cité (14) est adjoint à un autre bloc silencieux (17) préférablement en caoutchouc, logé dans la bretelle de support métallique en forme de L cité (20) et où une vis (26) est vissée dans un orifice (13) de la base (2) et une rondelle plate (27).

- Un système de construction selon les revendications précédentes, où la vis de serrage (29) de l'amortisseur flottant (28) est vissée à son écrou correspondant (30) et deux rondelles plates (27).

- Un système de construction, selon la revendication 1 ou 2 où l'amortisseur mural (31) incorporant un ressort (37) placé entre le bloc silencieux (32) et un autre bloc silencieux (38) préférablement en caoutchouc et où la vis de serrage (26) est vissée dans un orifice (13) de la base (2) et une rondelle plate (27).

- Un système de construction selon les revendications précédentes, dans lequel chaque bloc silencieux de l'amortisseur flottant (41) qui comprend deux bretelles de support métalliques angulaires en forme de L (20), prend un ressort (37), l'extrémité opposée de celui-ci est logé dans un autre bloc silencieux (38), et où une vis de serrage(42) est vissée dans un écrou d'arrêt (30) et deux rondelles plates (27).

- Un système de construction selon les revendications précédentes, où la base en métal laminaire estampée (2) est formée par un cercle dans sa partie centrale (11) en se rétrécissant dans la partie supérieure (4) et la partie inférieure (5), les deux parties supérieures et inférieures finissant par un rayon (6) comprenant une perforation (7) d'un diamètre inférieur à son centre géométrique, la partie centrale (11) étant notablement plus haute à cause des rayons (12) qui la forment et comprenant une perforation filetée (13) dans son centre géométrique.

- Un système de construction, selon les revendications précédentes, dans lequel la bretelle angulaire en métal (20) est faite en fine plaque laminaire et en forme rectangulaire, les bords (22) de son extrémité libre étant arrondis, l'extrémité opposée plus courte (23), courbée de façon à ce que la bretelle de support ait une forme en L et présente un orifice (24) à son centre et avec les bords (22) de son extrémité libre arrondie, dans la bretelle angulaire de métal mentionnée (20), les panneaux fixes et amovibles peuvent être installés à l'aide d'éléments de fixation, à travers plusieurs perforations équidistantes (21) situées au long des parties supérieure et inférieure de la bretelle de support en métal angulaire mentionnée (20).

- Un système de construction selon les revendications 2,3 et 5 où le bloc silencieux (14) peut être en caoutchouc ou dans un matériel similaire, cylindrique, avec sa partie centrale (15) plus large et dont la forme des extrémités (16) est voûtée et plus étroits, se maintenant droits et ayant une perforation cylindrique longitudinale (25), située au centre géométrique.

- Un système de construction selon les revendications 2 et 3, où le bloc silencieux (17) peut être en caoutchouc ou dans un matériel similaire, formant un tronc conique et ayant dans sa partie la plus étroite un court moyeu (18) et un boîtier de logement (19) d'un diamètre inférieur, avec une perforation cylindrique longitudinale (25), située au centre géométrique.

- Un système de construction selon les revendications 7 et 9, où le bloc silencieux (17) est fixé dans la bretelle de support angulaire (20) lorsque le moyeu (18) est inséré à travers l'orifice (24), en maintenant une légère pression et restant en place dans le boîtier (19).

- Un système de construction, selon les revendications 4 et 5 où le bloc silencieux (32) peut être en caoutchouc ou dans un matériel similaire, surtout cylindrique, sa partie centrale (33) ayant un diamètre supérieur, les deux extrémités étant égales et d'un diamètre inférieur, formées par une section droite (34), un moyeu hémisphérique (35) et un boîtier de logement (36) avec une perforation cylindrique longitudinale (25) située au centre géométrique.

- Un système de construction selon les revendications 4 et 5, où le bloc silencieux (38) peut être en caoutchouc ou dans un matériel similaire, fondamentalement cylindrique, formée dans sa partie centrale par une courte section droite (39) d'un diamètre supérieur, une extrémité formée par une section droite courte (40) d'un diamètre inférieur et l'extrémité opposée, d'un diamètre inférieur, ayant une section droite (34), un moyeu hémisphérique (35) et un boîtier de logement (36).

- Un système de construction, selon la revendication 12, où le bloc silencieux (32) est fixé dans la bretelle de support angulaire (20) lorsque le moyeu hémisphérique (35) est inséré à travers un orifice (24) de la pièce de support angulaire en métal (20) en maintenant une légère pression, et restant à sa place dans le boîtier (36), le ressort (37) se maintient alors à sa place entre le boîtier (36) et le moyeu hémisphérique (35).

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| ES200302961 | 2003-12-16 | ||

| ES200302961A ES2245205B2 (es) | 2003-12-16 | 2003-12-16 | Soporte amortiguador para falsos techos y similares. |

| ES200303036A ES2206076B1 (es) | 2003-12-23 | 2003-12-23 | Sistema de sujecion para paneles fijos o desmontables. |

| ES200303036 | 2003-12-23 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1548201A2 EP1548201A2 (fr) | 2005-06-29 |

| EP1548201A3 EP1548201A3 (fr) | 2005-08-03 |

| EP1548201B1 true EP1548201B1 (fr) | 2008-04-09 |

Family

ID=34553724

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04029896A Expired - Lifetime EP1548201B1 (fr) | 2003-12-16 | 2004-12-16 | Systeme de construction pour amortir des vibrations |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP1548201B1 (fr) |

| AT (1) | ATE391814T1 (fr) |

| DE (1) | DE602004012953T2 (fr) |

| ES (1) | ES2303928T3 (fr) |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CA2485280A1 (fr) | 2004-11-12 | 2006-05-12 | Robert Ducharme | Isolateur acoustique anti-vibration pour plafond suspendu |

| US7735285B2 (en) * | 2006-12-21 | 2010-06-15 | Usg Interiors, Inc. | Acoustical mounting bracket for attaching ceiling suspension to floor joists |

| SE532372C2 (sv) * | 2007-03-21 | 2009-12-29 | Lars Haakan Wernersson | Fjädrande infästande arrangemang |

| ES2584877T3 (es) * | 2007-05-18 | 2016-09-29 | Plakabeton S.A. | Dispositivo de fijación con aislamiento acústico para uso en construcciones de edificios |

| ES2611004B1 (es) * | 2015-10-30 | 2018-02-08 | Suspensiones Elásticas Del Norte, S.L. | Dispositivo de sustentación para techos suspendidos y trasdosados y techo suspendido o trasdosado asociado |

| CN112523416A (zh) * | 2020-11-27 | 2021-03-19 | 广东邦达实业有限公司 | 一种天花板减震器 |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE8107689U1 (de) * | 1981-03-17 | 1981-09-24 | Dipa - Matthias und René Dick GmbH, 5000 Köln | Schalldaemmendes element |

| DE29911747U1 (de) * | 1999-07-09 | 2000-03-09 | Linke, Sander, 21073 Hamburg | Dämpfungselement zur akustisch-entkoppelnden Aufhängung von Bauteilen und Verbindungssystemen für dessen universellen Einsatz vorwiegend im Akustikbau |

| FR2830554B1 (fr) * | 2001-10-08 | 2004-01-30 | Placoplatre Sa | Pied de suspente pour ossature de plafond, suspente ayant un tel pied et ensemble comprenant une ossature de plafond et au moins une telle suspente |

| FR2831572A1 (fr) * | 2001-10-29 | 2003-05-02 | Serge Daniel Robin | Dispositif d'accrochage et de suspension rapide pour profiles porteurs de faux-plafonds |

| ES2206076B1 (es) * | 2003-12-23 | 2005-04-16 | Juan Muñoz Molina | Sistema de sujecion para paneles fijos o desmontables. |

-

2004

- 2004-12-16 ES ES04029896T patent/ES2303928T3/es not_active Expired - Lifetime

- 2004-12-16 AT AT04029896T patent/ATE391814T1/de not_active IP Right Cessation

- 2004-12-16 DE DE602004012953T patent/DE602004012953T2/de not_active Expired - Fee Related

- 2004-12-16 EP EP04029896A patent/EP1548201B1/fr not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| ATE391814T1 (de) | 2008-04-15 |

| EP1548201A2 (fr) | 2005-06-29 |

| ES2303928T3 (es) | 2008-09-01 |

| EP1548201A3 (fr) | 2005-08-03 |

| DE602004012953T2 (de) | 2009-05-28 |

| DE602004012953D1 (de) | 2008-05-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US7028432B2 (en) | Compact ceiling isolation hanger | |

| US20080257567A1 (en) | Decorative support panel | |

| KR20000077172A (ko) | 바아행거 및 장착용 클립조립체 | |

| US20040169113A1 (en) | Para-seismic support for pipes | |

| EP1548201B1 (fr) | Systeme de construction pour amortir des vibrations | |

| US4717101A (en) | Adjustable backing board bracket | |

| SG182046A1 (en) | Hanging type vibration isolator | |

| US6685153B2 (en) | Restraining system and method | |

| CA2673245C (fr) | Support de montage phonique pour fixation de plafond suspendu sur des solives de planchers | |

| US4493468A (en) | Adjustable pipe fastener | |

| JP7240852B2 (ja) | 建物内の非構造部品用耐震クランプ | |

| US20060070967A1 (en) | Overhead attachable storage shelf | |

| US6293056B1 (en) | Multi-purpose above-ceiling utility support system | |

| US10851917B2 (en) | Seismic clamp for non-structural components in a building | |

| US4785887A (en) | Adjustable fire sprinkler head support system | |

| US10683949B1 (en) | Universal, adjustable, spliceable, bracket forming, and strapping material | |

| JP2017125332A (ja) | 減震構造体、及び減震構造体の施工方法 | |

| EP0264276A2 (fr) | Dispositif isolant contre les vibrations et/ou le bruit | |

| US5356103A (en) | Apparatus for providing support on a metal purling | |

| US8076573B1 (en) | Electrical box hanger | |

| US5313748A (en) | Security device for skylights and other vents, shafts or wells | |

| KR200187864Y1 (ko) | 배관용 파이프 고정구의 치수감소 구조 | |

| JP4295294B2 (ja) | 吊り下げ支持具 | |

| KR102881917B1 (ko) | 내진기능을 갖는 전선관 연결기구 | |

| KR102759503B1 (ko) | 비구조요소 내진용 관절형 행거 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR LV MK YU |

|

| RTI1 | Title (correction) |

Free format text: VIBRATION DAMPING CONSTRUCTION SYSTEM |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR LV MK YU |

|

| 17P | Request for examination filed |

Effective date: 20060112 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| 17Q | First examination report despatched |

Effective date: 20060320 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REF | Corresponds to: |

Ref document number: 602004012953 Country of ref document: DE Date of ref document: 20080521 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2303928 Country of ref document: ES Kind code of ref document: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080409 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080709 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080909 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080409 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080409 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080409 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080409 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080809 |

|

| EN | Fr: translation not filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080409 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080709 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080409 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080409 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080409 Ref country code: BE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080409 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080409 |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: EERR Free format text: CORRECTION DE BOPI 09/05 - BREVETS EUROPEENS DONT LA TRADUCTION N A PAS ETE REMISE A L INPI. IL Y A LIEU DE SUPPRIMER : LA MENTION DE LA NON-REMISE. LA REMISE DE LA TRADUCTION EST PUBLIEE DANS LE PRESENT BOPI. |

|

| 26N | No opposition filed |

Effective date: 20090112 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080409 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20081229 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20081218 Year of fee payment: 5 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20081231 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080409 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080409 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20081231 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20081231 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20081216 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20081231 Year of fee payment: 5 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081010 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20081216 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20091216 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080409 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20100831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080710 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100701 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091216 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20240105 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20241230 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20241217 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20241217 |