EP1515095B1 - Indoor unit for air conditioner - Google Patents

Indoor unit for air conditioner Download PDFInfo

- Publication number

- EP1515095B1 EP1515095B1 EP03721034A EP03721034A EP1515095B1 EP 1515095 B1 EP1515095 B1 EP 1515095B1 EP 03721034 A EP03721034 A EP 03721034A EP 03721034 A EP03721034 A EP 03721034A EP 1515095 B1 EP1515095 B1 EP 1515095B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- heat exchanger

- indoor unit

- side heat

- space

- refrigerant

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000003507 refrigerant Substances 0.000 claims abstract description 52

- 230000005494 condensation Effects 0.000 claims abstract description 3

- 238000009833 condensation Methods 0.000 claims abstract description 3

- 238000005192 partition Methods 0.000 claims description 34

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 14

- 239000002184 metal Substances 0.000 claims description 11

- 230000001143 conditioned effect Effects 0.000 claims 1

- 230000002159 abnormal effect Effects 0.000 description 8

- 230000005540 biological transmission Effects 0.000 description 2

- 239000000470 constituent Substances 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 239000007788 liquid Substances 0.000 description 2

- 239000011347 resin Substances 0.000 description 2

- 229920005989 resin Polymers 0.000 description 2

- 238000007664 blowing Methods 0.000 description 1

- 238000004140 cleaning Methods 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 210000004243 sweat Anatomy 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F13/00—Details common to, or for air-conditioning, air-humidification, ventilation or use of air currents for screening

- F24F13/24—Means for preventing or suppressing noise

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F1/00—Room units for air-conditioning, e.g. separate or self-contained units or units receiving primary air from a central station

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F1/00—Room units for air-conditioning, e.g. separate or self-contained units or units receiving primary air from a central station

- F24F1/0007—Indoor units, e.g. fan coil units

- F24F1/0059—Indoor units, e.g. fan coil units characterised by heat exchangers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F1/00—Room units for air-conditioning, e.g. separate or self-contained units or units receiving primary air from a central station

- F24F1/0007—Indoor units, e.g. fan coil units

- F24F1/0043—Indoor units, e.g. fan coil units characterised by mounting arrangements

- F24F1/0057—Indoor units, e.g. fan coil units characterised by mounting arrangements mounted in or on a wall

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F1/00—Room units for air-conditioning, e.g. separate or self-contained units or units receiving primary air from a central station

- F24F1/0007—Indoor units, e.g. fan coil units

- F24F1/0068—Indoor units, e.g. fan coil units characterised by the arrangement of refrigerant piping outside the heat exchanger within the unit casing

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F13/00—Details common to, or for air-conditioning, air-humidification, ventilation or use of air currents for screening

- F24F13/30—Arrangement or mounting of heat-exchangers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F1/00—Room units for air-conditioning, e.g. separate or self-contained units or units receiving primary air from a central station

- F24F1/0007—Indoor units, e.g. fan coil units

- F24F1/0018—Indoor units, e.g. fan coil units characterised by fans

- F24F1/0025—Cross-flow or tangential fans

Definitions

- the present invention relates to an indoor unit of an air conditioner, and more particularly relates to an indoor unit of an air conditioner comprising a heat exchanger and refrigerant circuit parts, and that air conditions by condensation and expansion of the refrigerant.

- separate-type air conditioners that are divided into an indoor unit and an outdoor unit

- a multi-split type air conditioner that connects a plurality of indoor units in parallel to one outdoor unit.

- FIG. 1 shows an exterior view of a pair type air conditioner.

- an air conditioner 81 shown therein there is a correspondence of one indoor unit 83 for one outdoor unit 82, and both 82, 83 are connected by a connecting part 89 comprising refrigerant piping, a transmission line, and the like.

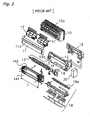

- the indoor unit of the pair type air conditioner comprises a fan rotor 3, a heat exchanger 4, an electrical equipment box 30, and the like. These constituent parts are arranged inside a casing comprising a front surface grille assembly 10, a front surface panel 11, a bottom frame 12, and the like.

- the bottom frame 12 is fixed to an indoor wall and the like by mounting it to a mounting plate 15 fixed to an indoor wall surface.

- An upper inlet 10a having slits is provided in the upper surface of the front surface grille assembly 10, and a front surface inlet 11a is also provided at the top and sides of the front surface panel 11.

- Air cleaning air filters 17 are arranged on the inside of these inlets 10a,11 a.

- an outlet for blowing out the airflow generated by the fan rotor 3 is formed at the front bottom part of the front surface grille assembly 10.

- the fan rotor 3 is arranged in a fan housing part 12a formed in the bottom frame 12, with one end being attached to the bottom frame 12 via a bearing 13, and the other end being coupled to the rotational shaft of a motor 14.

- This motor 14 is fixed to the bottom frame 12 by a motor fixed member 16.

- the heat exchanger 4 is provided so that it surrounds the front, upper, and rear upper parts of the fan rotor 3, and is also split into a front side heat exchanger 141 and a rear side heat exchanger 142, each having an effective length L.

- a front side heat exchanger 141 and a rear side heat exchanger 142 each having an effective length L.

- numerous heat radiating fins are attached to a heat transfer pipe bent a plurality of times at both the left and right ends, the air sucked in from the upper inlet 10a and the front surface inlet 11 a by the drive of the fan rotor 3 is made to pass through to the fan rotor 3 side, and heat is exchanged between the air and the refrigerant that passes through the inside of the heat transfer pipe.

- the heat exchanger 4 is connected via the refrigerant piping to the refrigerant piping from the outdoor unit.

- a drain pan assembly 18 that includes a front drain pan, a vane for adjusting the direction of the blown out air, and the like.

- the effective length of a front side heat exchanger and a rear side heat exchanger of a heat exchanger may not necessarily be the same.

- the indoor unit of the above pair type air conditioner as shown in FIG. 1 and FIG. 2 and the indoor unit employed by a multi-split type air conditioner that connects a plurality of indoor units in parallel to one outdoor unit were conventionally designed separately. Given this situation, attempts are recently being made to standardize parts between pair type indoor units and multi-split type indoor units. Although the specifications for the heat exchanger often differ between a pair type and a multi-split type, the standardization of the casing parts and the like is conceivable.

- the indoor unit of a multi-split type air conditioner is often internally provided with a motor operated valve because the plurality of indoor units are separately started and stopped, and controlled.

- This motor operated valve serves the role of adjusting the amount of refrigerant flowing in the heat exchanger of the indoor unit, and generates a relatively loud noise, such as when the refrigerant expands in the liquid-gas mixture state.

- a noise source of the motor operated valve and the like which are parts inherent to the multi-split type indoor unit, is arranged inside a regular pair type casing

- the refrigerant piping bank in the pair type indoor unit is arranged in the space on the side of the centrally disposed heat exchanger.

- the abnormal noise will cease if it is a pair type indoor unit, although it is assumed that abnormal noise from the motor operated valve and the like will leak out into the room if it is a multi-split type indoor unit.

- JP-A-09-280597 discloses to cover refrigerant circuit parts with a sound proofing plate fixed to a heat exchanger and a water pan.

- An indoor unit of an air conditioner according to the invention comprises the features of claims 1.

- the present invention herein is constituted so that the effective length of the rear side heat exchanger is less than the effective length of the front side heat exchanger, and a prescribed space is created on the backside of the indoor unit. Furthermore, refrigerant circuit parts, such as the motor operated valve and the distributor that generate relatively loud sounds when changing the flow of the refrigerant, are arranged in that space. Thus, because the refrigerant circuit parts that constitute noise sources herein are arranged in the space on the backside inside the indoor unit, the amount of sound leaking out to the front side of the indoor unit is reduced, thus suppressing discomfort to people in the room.

- the indoor unit is constituted so that the effective length of the rear side heat exchanger is less than the effective length of the front side heat exchanger, then the length of the fan rotor is matched to the front side heat exchanger, whose effective length would normally be thought to be long. Consequently, the abovementioned space (space created by the difference in the effective lengths of the front side heat exchanger and the rear side heat exchanger) is contiguous to a part of the fan rotor. In this case, even if nothing is provided between that space and the fan rotor, there is a risk that air will flow from the abovementioned space directly into the fan rotor without passing through the heat exchanger.

- the partition plates are arranged between the space, wherein the refrigerant circuit parts are arranged, and the fan rotor, the problem of air flowing into the fan rotor without passing by the indoor heat exchanger is suppressed.

- the indoor unit of the air conditioner may be the indoor unit of an air conditioner comprising an outdoor unit and a plurality of indoor units.

- the refrigerant circuit parts arranged in the space, created because the effective length of the rear side heat exchanger is less than the front side heat exchanger, includes at least a motor-operated valve.

- the motor operated valve is provided for adjusting the amount of refrigerant flowing to the plurality of indoor units.

- the motor operated valve which is usually built into the indoor unit of a multi-split type air conditioner, is arranged in the space on the backside inside the indoor unit, which easily confines noise.

- the motor operated valve sometimes generates a relatively loud abnormal sound when adjusting the amount of refrigerant; however, because it is arranged herein in the abovementioned space, which tends not to leak sound out of the indoor unit, a loud abnormal sound is no longer heard by people in the room.

- the indoor unit may further comprise a metal member that covers the space wherein the refrigerant circuit parts are arranged.

- the space is further covered by a metal member. Accordingly, even in a case where a loud abnormal noise generated from the refrigerant circuit parts passes through the casing, which is usually made of resin, and leaks out of the indoor unit, the leakage of that abnormal noise out of the indoor unit can be suppressed by the noise insulating effect of the metal member.

- the indoor unit may further comprise a drain pan that receives drain water falling from the heat exchanger. Further, the lower ends of the (partition plates) windbreaking members extend to the drain pan.

- This drain pan is arranged below the lower end of the front side heat exchanger and below the lower end of the rear side heat exchanger, and receives the drain water; it is also widely used in conventional indoor units.

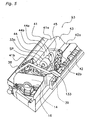

- An indoor unit of an air conditioner according to one embodiment of the present invention is used in a multi-split type air conditioner, as shown in FIG. 3 .

- a multi-split type air conditioner 91 a plurality of indoor units 93 - 96 are connected to one outdoor unit 92.

- the outdoor unit 92 and the indoor units 93 - 96 are connected by connecting parts 99a - 99d comprising refrigerant piping and a transmission line.

- Four indoor units 93 - 96 are respectively arranged in separate rooms in, for example, a home, a building, or a store.

- FIG. 4 depicts a refrigerant circuit 190 of the multi-split type air conditioner 91.

- the refrigerant circuit 190 comprises one outdoor unit 92, four indoor units 93 - 96 connected in parallel to the outdoor unit 92, and refrigerant piping.

- the outdoor unit 92 comprises a compressor 20, a four-way switching valve 21, an outdoor heat exchanger 22, an accumulator 23, and the like.

- a discharge pipe thermistor 24 is attached to the discharge side of the compressor 20 for detecting the discharge pipe temperature on the discharge side of the compressor 20.

- the outdoor unit 92 is provided with an outside air thermistor 25 for detecting the outside air temperature, and an outdoor heat exchange thermistor 26 for detecting the temperature of the outdoor heat exchanger 22.

- Each of the indoor units 93 - 96 has the same constitution. The following explains the indoor units 93 - 96 using the indoor unit 93 as an example.

- the indoor unit 93 comprises an indoor heat exchanger 4a and a motor-operated valve (expansion valve) 33a mutually connected in series.

- the motor-operated valve 33a is provided on the refrigerant exit side of the indoor heat exchanger 4a and adjusts the amount of refrigerant flowing to the indoor heat exchanger 4a.

- the indoor unit 93 respectively comprises a room temperature thermistor 31 a for detecting the indoor temperature, and an indoor heat exchange thermistor 32a for detecting the temperature of the indoor heat exchanger 4a.

- a liquid pipe thermistor 34a for detecting the liquid pipe temperature between the indoor heat exchanger 4a and the motor-operated valve 33a is provided in the piping between the indoor heat exchanger 4a and the motor-operated valve 33a.

- a gas pipe thermistor 35a is provided on the gas pipe side (refrigerant entrance side) of the indoor heat exchanger 4a for detecting the refrigerant temperature passing therethrough internally.

- the other indoor units 94, 95, 96 are likewise constituted the same as the indoor unit 93, and their indoor heat exchangers, motor operated valves, and various thermistors are assigned equivalent symbols in FIG. 4 .

- the indoor units 93 - 96 used in the multi-split type air conditioner 91 have built-in motor-operated valves 33a - 33d.

- the following explains the indoor unit used in the multi-split type air conditioner, using the indoor unit 93 as an example, and focusing on the arrangement of the parts.

- the indoor heat exchanger 4a that partially covers the front, upper, and rear parts of a fan rotor 3 principally comprises a front side heat exchanger 41 and a rear side heat exchanger 42, as shown in FIG. 5 and FIG. 6 .

- the rear side heat exchanger 42 has an effective length that is less than the front side heat exchanger 41, and an end part 42b on a motor 14 side thereof is positioned closer to the central portion in the latitudinal direction of the indoor unit 93 than an end part 41b of the front side heat exchanger 41 (refer to FIG. 5 ).

- a relatively large space SP is ensured on the outer side of the rear side heat exchanger 42 (the side on the motor 14 side).

- the width dimension of this space SP is substantially the same dimension as the difference in the effective lengths of the front side heat exchanger 41 and the rear side heat exchanger 42, and is 100 - 150 mm.

- a structure is employed in the indoor unit 93 wherein an upper end 41 a of the front side heat exchanger 41 is slightly spaced apart from an upper end 42a of the rear side heat exchanger 42, and a connecting plate 43 extends therebetween.

- This connecting plate 43 integrates the front side heat exchanger 41 and the rear side heat exchanger 42 as the indoor heat exchanger 4a, and serves the role of preventing the unfortunate passage of the air from above the indoor heat exchanger 4a to the fan rotor 3 below without passing through the front side heat exchanger 41, the rear side heat exchanger 42, and the like.

- the motor-operated valve 33a in the indoor unit 93, the motor-operated valve 33a, refrigerant piping 133 that connects to the motor-operated valve 33a, and a distributor 39 that divides the flow of refrigerant exiting the motor-operated valve 33a to each of the heat transfer passageways of the indoor heat exchanger 4a, and the like, are arranged in the space SP created by the difference in the effective lengths of the front side heat exchanger 41 and the rear side heat exchanger 42. As shown in FIG. 5 , the motor-operated valve 33a is arranged laterally to improve maintainability.

- the space SP is enclosed by a metal cover 50, a vertical partition plate 44, and a lateral partition plate 45.

- the metal cover 50 is a plate member integrally formed from a first cover part 51 that covers the upper part of the space SP, a second cover part 52 that extends downward diagonally from the front end of the first cover part 51 along the front surface of the front side heat exchanger 41, and a third cover part 53 that extends downward diagonally from the rear end of the first cover part 51 and covers the rear of the space SP.

- This metal cover 50 is provided principally for the purpose of isolating noise.

- the vertical partition plate 44 and the lateral partition plate 45 are plate-shaped members made of metal and provided to prevent the leakage of air that flows into the space SP out to the fan rotor side.

- the vertical partition plate 44 is positioned above the fan rotor 3, and partitions the space surrounding the fan rotor 3 and the space SP wherein the motor-operated valve 33a and the like are arranged.

- the lateral partition plate 45 is a substantially triangular member that extends perpendicularly frontward from the end part 42b on the space SP side of the rear side heat exchanger 42, and the sides abut orthogonally with the end part 42b of the rear side heat exchanger 42, the end part on the space SP side of the connecting plate 43, and the end part of the vertical partition plate 44.

- a front drain pan 61 is arranged below the lower end of the front side heat exchanger 41, and a rear drain pan 62 is arranged below the lower end of the rear side heat exchanger 42, respectively.

- These drain pans 61, 62 form a bottom frame and a drain pan assembly having a constitution the same as the conventional bottom frame 12 and drain pan assembly 18 in FIG. 2 , and serve the role of receiving the drain water that drips downward from the indoor heat exchanger 4a and the like.

- a drain route 63 is formed below the portion where the abovementioned vertical partition plate 44, the lateral partition plate 45, and the end part 42b on the space SP side of the rear side heat exchanger 42, which surround the space SP, intersect so that the drain water from that portion does not drip down to the fan rotor 3.

- This drain route 63 is structured so that a metal plate is bent at the intersecting portion of the vertical partition plate 44 and the lateral partition plate 45 (a part of the vertical partition plate 44, a part of the lateral partition plate 45, or separate members mounted to these partition plates 44, 45), and so that its cross-section is pocket-shaped.

- the drain water that drops from the end part 42b of the rear side heat exchanger 42 along the lateral partition plate 45, and the drain water that sweats out from the intersecting portion of the vertical partition plate 44 and the lateral partition plate 45 to the fan rotor 3 side along a gap from the space SP due to the pressure differential are guided to the drain route 63 and flow into the rear drain pan 62 (refer to FIG. 6 ).

- the heat exchanger unit reduces the amount of noise leaking out to the front side of the indoor unit and suppresses discomfort to people in the room because the effective length of the rear side heat exchanger is less than the effective length of the front side heat exchanger, a prescribed space is created on the back side of the indoor unit, and the refrigerant circuit parts, such as the motor operated valve and the distributor, which generate a relatively loud sound when changing the flow of the refrigerant, are arranged in that space.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Air Filters, Heat-Exchange Apparatuses, And Housings Of Air-Conditioning Units (AREA)

- Air-Conditioning Room Units, And Self-Contained Units In General (AREA)

- Devices For Blowing Cold Air, Devices For Blowing Warm Air, And Means For Preventing Water Condensation In Air Conditioning Units (AREA)

- Air Conditioning Control Device (AREA)

Abstract

Description

- The present invention relates to an indoor unit of an air conditioner, and more particularly relates to an indoor unit of an air conditioner comprising a heat exchanger and refrigerant circuit parts, and that air conditions by condensation and expansion of the refrigerant.

- Among separate-type air conditioners that are divided into an indoor unit and an outdoor unit, there are a pair type air conditioner that connects just one indoor unit to one outdoor unit, and a multi-split type air conditioner that connects a plurality of indoor units in parallel to one outdoor unit.

-

FIG. 1 shows an exterior view of a pair type air conditioner. In anair conditioner 81 shown therein, there is a correspondence of oneindoor unit 83 for oneoutdoor unit 82, and both 82, 83 are connected by a connectingpart 89 comprising refrigerant piping, a transmission line, and the like. - As shown in

FIG. 2 , the indoor unit of the pair type air conditioner comprises afan rotor 3, a heat exchanger 4, anelectrical equipment box 30, and the like. These constituent parts are arranged inside a casing comprising a frontsurface grille assembly 10, afront surface panel 11, abottom frame 12, and the like. Thebottom frame 12 is fixed to an indoor wall and the like by mounting it to amounting plate 15 fixed to an indoor wall surface. An upper inlet 10a having slits is provided in the upper surface of the frontsurface grille assembly 10, and a front surface inlet 11a is also provided at the top and sides of thefront surface panel 11. Aircleaning air filters 17 are arranged on the inside of these inlets 10a,11 a. In addition, an outlet for blowing out the airflow generated by thefan rotor 3 is formed at the front bottom part of the frontsurface grille assembly 10. - The

fan rotor 3 is arranged in afan housing part 12a formed in thebottom frame 12, with one end being attached to thebottom frame 12 via abearing 13, and the other end being coupled to the rotational shaft of amotor 14. Thismotor 14 is fixed to thebottom frame 12 by a motor fixedmember 16. - The heat exchanger 4 is provided so that it surrounds the front, upper, and rear upper parts of the

fan rotor 3, and is also split into a frontside heat exchanger 141 and a rearside heat exchanger 142, each having an effective length L. In each of theheat exchangers fan rotor 3 is made to pass through to thefan rotor 3 side, and heat is exchanged between the air and the refrigerant that passes through the inside of the heat transfer pipe. The heat exchanger 4 is connected via the refrigerant piping to the refrigerant piping from the outdoor unit. In addition, below the frontside heat exchanger 141 is arranged adrain pan assembly 18 that includes a front drain pan, a vane for adjusting the direction of the blown out air, and the like. - Furthermore, the effective length of a front side heat exchanger and a rear side heat exchanger of a heat exchanger may not necessarily be the same. For example, as disclosed in

JP-A-2001-82795 - The indoor unit of the above pair type air conditioner as shown in

FIG. 1 andFIG. 2 , and the indoor unit employed by a multi-split type air conditioner that connects a plurality of indoor units in parallel to one outdoor unit were conventionally designed separately. Given this situation, attempts are recently being made to standardize parts between pair type indoor units and multi-split type indoor units. Although the specifications for the heat exchanger often differ between a pair type and a multi-split type, the standardization of the casing parts and the like is conceivable. - However, unlike a pair type, the indoor unit of a multi-split type air conditioner is often internally provided with a motor operated valve because the plurality of indoor units are separately started and stopped, and controlled. This motor operated valve serves the role of adjusting the amount of refrigerant flowing in the heat exchanger of the indoor unit, and generates a relatively loud noise, such as when the refrigerant expands in the liquid-gas mixture state.

- If a noise source of the motor operated valve and the like, which are parts inherent to the multi-split type indoor unit, is arranged inside a regular pair type casing, then the refrigerant piping bank in the pair type indoor unit is arranged in the space on the side of the centrally disposed heat exchanger. In this case, if the same casing is used, then the abnormal noise will cease if it is a pair type indoor unit, although it is assumed that abnormal noise from the motor operated valve and the like will leak out into the room if it is a multi-split type indoor unit. Thus, it is difficult to standardize parts like the casing between a pair type indoor unit and a multi-split type indoor unit.

- Further,

JP-A-09-280597 - It is an object of the present invention to provide an indoor unit of an air conditioner wherein noise does not tend to leak out of the indoor unit, even if refrigerant circuit parts such as a motor operated valve, which constitutes a noise source, are arranged in the indoor unit.

- An indoor unit of an air conditioner according to the invention comprises the features of claims 1.

- First, the present invention herein is constituted so that the effective length of the rear side heat exchanger is less than the effective length of the front side heat exchanger, and a prescribed space is created on the backside of the indoor unit. Furthermore, refrigerant circuit parts, such as the motor operated valve and the distributor that generate relatively loud sounds when changing the flow of the refrigerant, are arranged in that space. Thus, because the refrigerant circuit parts that constitute noise sources herein are arranged in the space on the backside inside the indoor unit, the amount of sound leaking out to the front side of the indoor unit is reduced, thus suppressing discomfort to people in the room.

- Second, if the indoor unit is constituted so that the effective length of the rear side heat exchanger is less than the effective length of the front side heat exchanger, then the length of the fan rotor is matched to the front side heat exchanger, whose effective length would normally be thought to be long. Consequently, the abovementioned space (space created by the difference in the effective lengths of the front side heat exchanger and the rear side heat exchanger) is contiguous to a part of the fan rotor. In this case, even if nothing is provided between that space and the fan rotor, there is a risk that air will flow from the abovementioned space directly into the fan rotor without passing through the heat exchanger.

- In contrast, in the indoor unit according to the invention, because the partition plates (windbreaking members) are arranged between the space, wherein the refrigerant circuit parts are arranged, and the fan rotor, the problem of air flowing into the fan rotor without passing by the indoor heat exchanger is suppressed.

- Embodiments of the invention are named in the dependent claims.

- The indoor unit of the air conditioner may be the indoor unit of an air conditioner comprising an outdoor unit and a plurality of indoor units. Further, the refrigerant circuit parts arranged in the space, created because the effective length of the rear side heat exchanger is less than the front side heat exchanger, includes at least a motor-operated valve. The motor operated valve is provided for adjusting the amount of refrigerant flowing to the plurality of indoor units.

- Herein, the motor operated valve, which is usually built into the indoor unit of a multi-split type air conditioner, is arranged in the space on the backside inside the indoor unit, which easily confines noise. The motor operated valve sometimes generates a relatively loud abnormal sound when adjusting the amount of refrigerant; however, because it is arranged herein in the abovementioned space, which tends not to leak sound out of the indoor unit, a loud abnormal sound is no longer heard by people in the room.

- The indoor unit may further comprise a metal member that covers the space wherein the refrigerant circuit parts are arranged.

- Herein, not only is the amount of noise that leaks out to the front side of the indoor unit suppressed by arranging the refrigerant circuit parts in the space on the back side inside the indoor unit, but the space is further covered by a metal member. Accordingly, even in a case where a loud abnormal noise generated from the refrigerant circuit parts passes through the casing, which is usually made of resin, and leaks out of the indoor unit, the leakage of that abnormal noise out of the indoor unit can be suppressed by the noise insulating effect of the metal member.

- The indoor unit may further comprise a drain pan that receives drain water falling from the heat exchanger. Further, the lower ends of the (partition plates) windbreaking members extend to the drain pan.

- This drain pan is arranged below the lower end of the front side heat exchanger and below the lower end of the rear side heat exchanger, and receives the drain water; it is also widely used in conventional indoor units.

- Herein, because the lower ends of the windbreaking members extend to the drain pan, water that drips down from the heat exchanger and the like to the windbreaking members flows to the drain pan, which has been available conventionally. Thereby, the problem of the water dropping down from the windbreaking members to the fan rotor is suppressed.

-

-

FIG. 1 is an exterior perspective view of a conventional pair type air conditioner. -

FIG. 2 is an assembly exploded view of a conventional indoor unit. -

FIG. 3 is a schematic of a multi-split type air conditioner that includes the indoor unit according to one embodiment of the present invention. -

FIG. 4 is a view that depicts a refrigerant circuit of the multi-split type air conditioner. -

FIG. 5 is an internal perspective view of the side portion of a motor of the indoor unit. -

FIG. 6 is a cross-sectional schematic of the indoor unit. - An indoor unit of an air conditioner according to one embodiment of the present invention is used in a multi-split type air conditioner, as shown in

FIG. 3 . In this multi-splittype air conditioner 91, a plurality of indoor units 93 - 96 are connected to oneoutdoor unit 92. Theoutdoor unit 92 and the indoor units 93 - 96 are connected by connectingparts 99a - 99d comprising refrigerant piping and a transmission line. Four indoor units 93 - 96 are respectively arranged in separate rooms in, for example, a home, a building, or a store. -

FIG. 4 depicts arefrigerant circuit 190 of the multi-splittype air conditioner 91. Therefrigerant circuit 190 comprises oneoutdoor unit 92, four indoor units 93 - 96 connected in parallel to theoutdoor unit 92, and refrigerant piping. - The

outdoor unit 92 comprises acompressor 20, a four-way switching valve 21, anoutdoor heat exchanger 22, anaccumulator 23, and the like. Adischarge pipe thermistor 24 is attached to the discharge side of thecompressor 20 for detecting the discharge pipe temperature on the discharge side of thecompressor 20. In addition, theoutdoor unit 92 is provided with anoutside air thermistor 25 for detecting the outside air temperature, and an outdoorheat exchange thermistor 26 for detecting the temperature of theoutdoor heat exchanger 22. - Each of the indoor units 93 - 96 has the same constitution. The following explains the indoor units 93 - 96 using the

indoor unit 93 as an example. - The

indoor unit 93 comprises an indoor heat exchanger 4a and a motor-operated valve (expansion valve) 33a mutually connected in series. The motor-operatedvalve 33a is provided on the refrigerant exit side of the indoor heat exchanger 4a and adjusts the amount of refrigerant flowing to the indoor heat exchanger 4a. In addition, theindoor unit 93 respectively comprises a room temperature thermistor 31 a for detecting the indoor temperature, and an indoor heat exchange thermistor 32a for detecting the temperature of the indoor heat exchanger 4a. Aliquid pipe thermistor 34a for detecting the liquid pipe temperature between the indoor heat exchanger 4a and the motor-operatedvalve 33a is provided in the piping between the indoor heat exchanger 4a and the motor-operatedvalve 33a. Agas pipe thermistor 35a is provided on the gas pipe side (refrigerant entrance side) of the indoor heat exchanger 4a for detecting the refrigerant temperature passing therethrough internally. - The other

indoor units indoor unit 93, and their indoor heat exchangers, motor operated valves, and various thermistors are assigned equivalent symbols inFIG. 4 . - As described above, the indoor units 93 - 96 used in the multi-split

type air conditioner 91 have built-in motor-operatedvalves 33a - 33d. The following explains the indoor unit used in the multi-split type air conditioner, using theindoor unit 93 as an example, and focusing on the arrangement of the parts. - In the

indoor unit 93, the indoor heat exchanger 4a that partially covers the front, upper, and rear parts of afan rotor 3 principally comprises a frontside heat exchanger 41 and a rearside heat exchanger 42, as shown inFIG. 5 andFIG. 6 . The rearside heat exchanger 42 has an effective length that is less than the frontside heat exchanger 41, and anend part 42b on amotor 14 side thereof is positioned closer to the central portion in the latitudinal direction of theindoor unit 93 than anend part 41b of the front side heat exchanger 41 (refer toFIG. 5 ). Thereby, a relatively large space SP is ensured on the outer side of the rear side heat exchanger 42 (the side on themotor 14 side). The width dimension of this space SP is substantially the same dimension as the difference in the effective lengths of the frontside heat exchanger 41 and the rearside heat exchanger 42, and is 100 - 150 mm. - In addition, a structure is employed in the

indoor unit 93 wherein anupper end 41 a of the frontside heat exchanger 41 is slightly spaced apart from an upper end 42a of the rearside heat exchanger 42, and a connectingplate 43 extends therebetween. This connectingplate 43 integrates the frontside heat exchanger 41 and the rearside heat exchanger 42 as the indoor heat exchanger 4a, and serves the role of preventing the unfortunate passage of the air from above the indoor heat exchanger 4a to thefan rotor 3 below without passing through the frontside heat exchanger 41, the rearside heat exchanger 42, and the like. - Further, in the

indoor unit 93, the motor-operatedvalve 33a,refrigerant piping 133 that connects to the motor-operatedvalve 33a, and adistributor 39 that divides the flow of refrigerant exiting the motor-operatedvalve 33a to each of the heat transfer passageways of the indoor heat exchanger 4a, and the like, are arranged in the space SP created by the difference in the effective lengths of the frontside heat exchanger 41 and the rearside heat exchanger 42. As shown inFIG. 5 , the motor-operatedvalve 33a is arranged laterally to improve maintainability. - Furthermore, in the

indoor unit 93, the space SP, wherein the motor-operatedvalve 33a and the like is arranged, is enclosed by ametal cover 50, avertical partition plate 44, and alateral partition plate 45. Themetal cover 50 is a plate member integrally formed from afirst cover part 51 that covers the upper part of the space SP, asecond cover part 52 that extends downward diagonally from the front end of thefirst cover part 51 along the front surface of the frontside heat exchanger 41, and athird cover part 53 that extends downward diagonally from the rear end of thefirst cover part 51 and covers the rear of the space SP. Thismetal cover 50 is provided principally for the purpose of isolating noise. However, thevertical partition plate 44 and thelateral partition plate 45 are plate-shaped members made of metal and provided to prevent the leakage of air that flows into the space SP out to the fan rotor side. Thevertical partition plate 44 is positioned above thefan rotor 3, and partitions the space surrounding thefan rotor 3 and the space SP wherein the motor-operatedvalve 33a and the like are arranged. Thelateral partition plate 45 is a substantially triangular member that extends perpendicularly frontward from theend part 42b on the space SP side of the rearside heat exchanger 42, and the sides abut orthogonally with theend part 42b of the rearside heat exchanger 42, the end part on the space SP side of the connectingplate 43, and the end part of thevertical partition plate 44. - In addition, a

front drain pan 61 is arranged below the lower end of the frontside heat exchanger 41, and arear drain pan 62 is arranged below the lower end of the rearside heat exchanger 42, respectively. These drain pans 61, 62 form a bottom frame and a drain pan assembly having a constitution the same as theconventional bottom frame 12 anddrain pan assembly 18 inFIG. 2 , and serve the role of receiving the drain water that drips downward from the indoor heat exchanger 4a and the like. Further, in theindoor unit 93, adrain route 63 is formed below the portion where the abovementionedvertical partition plate 44, thelateral partition plate 45, and theend part 42b on the space SP side of the rearside heat exchanger 42, which surround the space SP, intersect so that the drain water from that portion does not drip down to thefan rotor 3. Thisdrain route 63 is structured so that a metal plate is bent at the intersecting portion of thevertical partition plate 44 and the lateral partition plate 45 (a part of thevertical partition plate 44, a part of thelateral partition plate 45, or separate members mounted to thesepartition plates 44, 45), and so that its cross-section is pocket-shaped. Thereby, the drain water that drops from theend part 42b of the rearside heat exchanger 42 along thelateral partition plate 45, and the drain water that sweats out from the intersecting portion of thevertical partition plate 44 and thelateral partition plate 45 to thefan rotor 3 side along a gap from the space SP due to the pressure differential are guided to thedrain route 63 and flow into the rear drain pan 62 (refer toFIG. 6 ). -

- [1] First, the

indoor unit 93 is constituted so that the effective length of the rearside heat exchanger 42 is less than the effective length of the frontside heat exchanger 41, and a prescribed space SP is created on the rear side of theindoor unit 93. Furthermore, refrigerant circuit parts, such as the motor operatedvalve 33a and thedistributor 39 that generate comparatively loud sounds when changing the flow of the refrigerant, are arranged in that space SP. Thus, because noise sources such as the motor-operatedvalve 33a can be arranged on the rear side of theindoor unit 93, the noise level that can be heard by people in the room, judging from the directionality of the noise, can be kept low. - [2] In the

indoor unit 93, not only is the amount of noise that leaks out to the front side of theindoor unit 93 suppressed by arranging the refrigerant circuit parts that form the noise sources, such as the motor-operatedvalve 33a, in the space SP on the back side of theindoor unit 93, but the space SP is further covered by ametal cover 50. Accordingly, even in a case where a loud abnormal noise generated by the motor-operatedvalve 33a and the like passes through the casing, which is usually made of resin, and leaks out of theindoor unit 93, the leakage of that abnormal noise out of theindoor unit 93 will be suppressed by the noise insulating effect of themetal cover 50.

Furthermore, it is preferable to take conventional sound insulating measures in parallel by covering the motor-operatedvalve 3 3 a with putty, rubber, and the like. - [3] Because the

indoor unit 93 is constituted so that the effective length of the rearside heat exchanger 42 is less than the effective length of the frontside heat exchanger 41, the length of thefan rotor 3 corresponding to the effective length of the frontside heat exchanger 41 is greater than the rearside heat exchanger 42. Thereby, the space SP is positioned above a portion of themotor 14 side of thefan rotor 3.

In this case, even if nothing is provided between the space SP and thefan rotor 3, there is a risk that air will flow from the space SP directly into thefan rotor 3 without passing through either of theheat exchangers

In contrast, in theindoor unit 93, because thevertical partition plate 44 and thelateral partition plate 45 are arranged between the space SP, wherein the motor operatedvalve 33a and the like are arranged, and thefan rotor 3, the problem of air flowing into thefan rotor 3 without passing by the indoor heat exchanger 4a is suppressed. - [4] In the

indoor unit 93, thevertical partition plate 44 prevents air from flowing down from the space SP to thefan rotor 3, and thelateral partition plate 45 prevents the air from flowing from the space SP to thefan rotor 3 through the space between the frontside heat exchanger 41 and theend part 42b of the rearside heat exchanger 42. Further, as shown inFIG. 6 , because the lower ends of thevertical partition plate 44 and thelateral partition plate 45 are positioned above therear drain pan 62, even when water droplets flow to thepartition plates end part 42b of the rearside heat exchanger 42 and the like, that water flows into therear drain pan 62.

In addition, the drain water that exits from the intersecting portion of theend part 42b of the rearside heat exchanger 42, which is shorter than thefan rotor 3, and bothpartition plates fan rotor 3 side via the gap due to the pressure differential and the like is guided to therear drain pan 62 by thedrain route 63. Consequently, the problem of the drain water dripping down to thefan rotor 3 is suppressed even if the space SP is provided as described above and the space SP is enclosed by thepartition plates - [5] The

indoor unit 93 comprises the motor-operatedvalve 33a, and it is difficult to conceive of also using it as is in a pair type air conditioner, such as a room air conditioner. However, it is possible to design a structure so that the indoor heat exchanger 4a of theindoor unit 93 is replaced with an indoor heat exchanger for a pair type air conditioner, thereby standardizing the casing portion for both multi-split types and pair types.

For example, in standardizing the casing, it is possible to design so that, in a multi-split type indoor unit that is often used for business, an indoor heat exchanger is installed wherein the effective lengths of a front side heat exchanger and a rear side heat exchanger differ as in the abovementionedindoor unit 93, and, in a pair type indoor unit, an indoor heat exchanger is installed wherein the effective lengths of the front side heat exchanger and the rear side heat exchanger are the same. - Using the heat exchanger unit according to the present invention reduces the amount of noise leaking out to the front side of the indoor unit and suppresses discomfort to people in the room because the effective length of the rear side heat exchanger is less than the effective length of the front side heat exchanger, a prescribed space is created on the back side of the indoor unit, and the refrigerant circuit parts, such as the motor operated valve and the distributor, which generate a relatively loud sound when changing the flow of the refrigerant, are arranged in that space.

Claims (5)

- An indoor unit of an air conditioner that air-conditions by the condensation and expansion of a refrigerant, comprising:a heat exchanger (4a) comprising a front side heat exchanger (41) and a rear side heat exchanger (42), and that exchanges heat between a refrigerant and air; andrefrigerant circuit parts (33a, 39) that change the flow of said refrigerant;a fan rotor (3) for sending air conditioned air indoors;wherein,said rear side heat exchanger (42) has an effective length less than said front side heat exchanger (41); andsaid refrigerant circuit parts (33a, 39) are arranged in a space (SP) created by the difference in the effective lengths of said front side heat exchanger (41) and said rear side heat exchanger (42), characterized by partition plates (44, 45) arranged between said space (SP) and said fan rotor (3), suppressing air flowing from said space (SP) directly into said fan rotor (3) without passing through the heat exchanger (4).

- The indoor unit of the air conditioner as recited in Claim 1, further comprising:a metal member (50) that covers said space (SP).

- The indoor unit of the air conditioner as recited in Claim 1 or Claim 2, wherein said partition plates include a vertical partition plate (44) positioned above the fan rotor (3) and a lateral partition plate (45) being a substantially triangular member extending perpendicularly frontward from an end part (42b) on said space (SP) side of said rear side heat exchanger (42).

- The indoor unit of the air conditioner as recited in any one of the preceding Claims, further comprising:a drain pan (62) that receives drain water falling from said heat exchanger (4a);wherein,lower ends of said partition plates (44, 45) extend to said drain pan (62).

- Air conditioner comprising an outdoor unit (92) and a plurality of indoor units (93 - 96) according to any one of the preceding Claims, wherein

said refrigerant circuit parts arranged in said space (SP) include at least a motor-operated valve (33a) for adjusting the amount of refrigerant flowing to said plurality of indoor units (93 - 96).

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2002139745 | 2002-05-15 | ||

| JP2002139745A JP3731067B2 (en) | 2002-05-15 | 2002-05-15 | Air conditioner indoor unit |

| PCT/JP2003/005671 WO2003098119A1 (en) | 2002-05-15 | 2003-05-06 | Indoor unit for air conditioner |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1515095A1 EP1515095A1 (en) | 2005-03-16 |

| EP1515095A4 EP1515095A4 (en) | 2010-07-14 |

| EP1515095B1 true EP1515095B1 (en) | 2011-10-26 |

Family

ID=29544903

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03721034A Expired - Lifetime EP1515095B1 (en) | 2002-05-15 | 2003-05-06 | Indoor unit for air conditioner |

Country Status (8)

| Country | Link |

|---|---|

| EP (1) | EP1515095B1 (en) |

| JP (1) | JP3731067B2 (en) |

| KR (1) | KR100605844B1 (en) |

| CN (2) | CN1294386C (en) |

| AT (1) | ATE530856T1 (en) |

| AU (1) | AU2003235853B2 (en) |

| ES (1) | ES2373546T3 (en) |

| WO (1) | WO2003098119A1 (en) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2008224179A (en) * | 2007-03-15 | 2008-09-25 | Sanyo Electric Co Ltd | Air conditioner |

| JP2008309444A (en) * | 2007-06-18 | 2008-12-25 | Fujitsu General Ltd | Air conditioner |

| US9267701B2 (en) * | 2010-10-25 | 2016-02-23 | Thomas L Purnell | Temperature control system for a controlled environmental vault |

| JP6616076B2 (en) * | 2015-02-09 | 2019-12-04 | シャープ株式会社 | Air conditioner |

| JP7244773B2 (en) * | 2021-01-22 | 2023-03-23 | ダイキン工業株式会社 | Wall-mounted air conditioning indoor units and air conditioners |

| CN113108419B (en) * | 2021-03-15 | 2022-06-17 | 珠海格力电器股份有限公司 | Control method of multi-split air conditioning system |

| CN113432190A (en) * | 2021-07-08 | 2021-09-24 | 宁波奥克斯电气股份有限公司 | Machine and air conditioner in air conditioning |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH07139837A (en) * | 1993-11-12 | 1995-06-02 | Sanyo Electric Co Ltd | Air conditioner |

| JP3121505B2 (en) * | 1994-11-02 | 2001-01-09 | 三菱電機株式会社 | Air conditioner |

| JPH09280597A (en) * | 1996-04-09 | 1997-10-31 | Hitachi Ltd | Wall mounted air conditioner |

| JPH10205877A (en) * | 1997-01-20 | 1998-08-04 | Fujitsu General Ltd | Air conditioner |

| JP3276918B2 (en) * | 1998-02-25 | 2002-04-22 | 三洋電機株式会社 | Air conditioner |

| JP4296649B2 (en) | 1999-09-13 | 2009-07-15 | ダイキン工業株式会社 | Air conditioner indoor unit |

| JP2001090985A (en) * | 1999-09-27 | 2001-04-03 | Daikin Ind Ltd | Indoor unit for air-conditioner |

-

2002

- 2002-05-15 JP JP2002139745A patent/JP3731067B2/en not_active Expired - Fee Related

-

2003

- 2003-05-06 CN CNB038097176A patent/CN1294386C/en not_active Expired - Fee Related

- 2003-05-06 AT AT03721034T patent/ATE530856T1/en not_active IP Right Cessation

- 2003-05-06 EP EP03721034A patent/EP1515095B1/en not_active Expired - Lifetime

- 2003-05-06 KR KR1020047017783A patent/KR100605844B1/en not_active IP Right Cessation

- 2003-05-06 AU AU2003235853A patent/AU2003235853B2/en not_active Ceased

- 2003-05-06 ES ES03721034T patent/ES2373546T3/en not_active Expired - Lifetime

- 2003-05-06 WO PCT/JP2003/005671 patent/WO2003098119A1/en active Application Filing

- 2003-05-13 CN CN032575602U patent/CN2723879Y/en not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| CN1650134A (en) | 2005-08-03 |

| EP1515095A4 (en) | 2010-07-14 |

| CN2723879Y (en) | 2005-09-07 |

| AU2003235853B2 (en) | 2006-07-27 |

| KR100605844B1 (en) | 2006-08-01 |

| EP1515095A1 (en) | 2005-03-16 |

| ATE530856T1 (en) | 2011-11-15 |

| KR20050007388A (en) | 2005-01-17 |

| AU2003235853A1 (en) | 2003-12-02 |

| WO2003098119A1 (en) | 2003-11-27 |

| ES2373546T3 (en) | 2012-02-06 |

| CN1294386C (en) | 2007-01-10 |

| JP2003336857A (en) | 2003-11-28 |

| JP3731067B2 (en) | 2006-01-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US20080087030A1 (en) | Water-cooled air conditioner | |

| CN106949557B (en) | Wall-mounted air conditioner all-in-one machine | |

| KR100356245B1 (en) | Window room air conditioner | |

| EP1515095B1 (en) | Indoor unit for air conditioner | |

| US6155065A (en) | Evaporator coil support for a room air conditioner | |

| JP6126447B2 (en) | Air conditioner | |

| KR20050012223A (en) | Front suction/discharge type outdoor unit for air conditioner | |

| JP2000065376A (en) | Ceiling cassette type air conditioner | |

| JP2014240713A (en) | Outdoor unit for air conditioner | |

| KR100652805B1 (en) | Installing structure for outdoor unit of air conditioner | |

| JP4109813B2 (en) | Air conditioner outdoor unit | |

| JP3900004B2 (en) | Air conditioner | |

| KR100432744B1 (en) | Interior parts structure of casement window type airconditioner | |

| CN219612444U (en) | Air conditioner external unit and data center air conditioning system | |

| KR100291777B1 (en) | Indoor air conditioner of split type air conditioner | |

| KR20050064963A (en) | The supporting structure of pipe for duct type air-conditioner | |

| KR20030046365A (en) | Safety operation apparatus and its method for outdoor's unit | |

| US11774133B2 (en) | Air conditioning appliance having a plenum for make-up air | |

| JP2018119714A (en) | Ceiling-embedded air conditioner | |

| KR100982857B1 (en) | Front suction and discharge type outdoor unit for air-conditioner | |

| WO2005052457A1 (en) | Air conditioner | |

| JP2006038361A (en) | Built-in type air conditioner and blowout chamber | |

| KR200334459Y1 (en) | Fender plate for Air-conditioner filled in ceiling | |

| JP2021085648A (en) | Air conditioner | |

| KR20000008757A (en) | Indoor unit of separate type air conditioner |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20041214 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| DAX | Request for extension of the european patent (deleted) | ||

| A4 | Supplementary search report drawn up and despatched |

Effective date: 20100610 |

|

| 17Q | First examination report despatched |

Effective date: 20100917 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: F24F 1/00 20110101AFI20110421BHEP |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 60338900 Country of ref document: DE Effective date: 20111222 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2373546 Country of ref document: ES Kind code of ref document: T3 Effective date: 20120206 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20111026 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 530856 Country of ref document: AT Kind code of ref document: T Effective date: 20111026 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111026 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120127 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111026 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111026 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120227 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111026 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111026 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111026 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111026 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120126 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111026 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111026 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111026 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20120727 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 60338900 Country of ref document: DE Effective date: 20120727 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120531 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111026 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120531 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120531 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120506 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111026 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111026 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120506 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20030506 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 15 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20180329 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20180605 Year of fee payment: 16 Ref country code: DE Payment date: 20180424 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20180412 Year of fee payment: 16 Ref country code: IT Payment date: 20180522 Year of fee payment: 16 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 60338900 Country of ref document: DE |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20190506 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20191203 Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190506 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190506 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190531 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20200925 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190507 |