EP1471326B1 - Electric switch for a projectile fuze, which switch is activated by gas pressure - Google Patents

Electric switch for a projectile fuze, which switch is activated by gas pressure Download PDFInfo

- Publication number

- EP1471326B1 EP1471326B1 EP04002749A EP04002749A EP1471326B1 EP 1471326 B1 EP1471326 B1 EP 1471326B1 EP 04002749 A EP04002749 A EP 04002749A EP 04002749 A EP04002749 A EP 04002749A EP 1471326 B1 EP1471326 B1 EP 1471326B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- gas

- pressure switch

- switching piston

- contact

- switch according

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000007789 gas Substances 0.000 claims description 51

- 238000007789 sealing Methods 0.000 claims description 15

- 239000012528 membrane Substances 0.000 claims description 11

- 239000003380 propellant Substances 0.000 claims description 7

- 239000000919 ceramic Substances 0.000 claims description 6

- 238000013016 damping Methods 0.000 claims description 6

- 239000000463 material Substances 0.000 claims description 3

- ATJFFYVFTNAWJD-UHFFFAOYSA-N Tin Chemical compound [Sn] ATJFFYVFTNAWJD-UHFFFAOYSA-N 0.000 claims description 2

- 239000011521 glass Substances 0.000 claims description 2

- 239000012811 non-conductive material Substances 0.000 claims 2

- 238000006073 displacement reaction Methods 0.000 description 6

- 238000010304 firing Methods 0.000 description 3

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 2

- 239000011248 coating agent Substances 0.000 description 2

- 238000000576 coating method Methods 0.000 description 2

- 229910052802 copper Inorganic materials 0.000 description 2

- 239000010949 copper Substances 0.000 description 2

- 238000005553 drilling Methods 0.000 description 2

- 230000007246 mechanism Effects 0.000 description 2

- 230000001133 acceleration Effects 0.000 description 1

- 239000000853 adhesive Substances 0.000 description 1

- 230000001070 adhesive effect Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000005474 detonation Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000002474 experimental method Methods 0.000 description 1

- 239000002360 explosive Substances 0.000 description 1

- 210000003746 feather Anatomy 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 239000011810 insulating material Substances 0.000 description 1

- ORQBXQOJMQIAOY-UHFFFAOYSA-N nobelium Chemical compound [No] ORQBXQOJMQIAOY-UHFFFAOYSA-N 0.000 description 1

- 239000000565 sealant Substances 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 229910001220 stainless steel Inorganic materials 0.000 description 1

- 239000010935 stainless steel Substances 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F42—AMMUNITION; BLASTING

- F42C—AMMUNITION FUZES; ARMING OR SAFETY MEANS THEREFOR

- F42C19/00—Details of fuzes

- F42C19/06—Electric contact parts specially adapted for use with electric fuzes

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F42—AMMUNITION; BLASTING

- F42B—EXPLOSIVE CHARGES, e.g. FOR BLASTING, FIREWORKS, AMMUNITION

- F42B3/00—Blasting cartridges, i.e. case and explosive

- F42B3/006—Explosive bolts; Explosive actuators

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F42—AMMUNITION; BLASTING

- F42C—AMMUNITION FUZES; ARMING OR SAFETY MEANS THEREFOR

- F42C15/00—Arming-means in fuzes; Safety means for preventing premature detonation of fuzes or charges

- F42C15/28—Arming-means in fuzes; Safety means for preventing premature detonation of fuzes or charges operated by flow of fluent material, e.g. shot, fluids

- F42C15/30—Arming-means in fuzes; Safety means for preventing premature detonation of fuzes or charges operated by flow of fluent material, e.g. shot, fluids of propellant gases, i.e. derived from propulsive charge or rocket motor

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H35/00—Switches operated by change of a physical condition

- H01H35/24—Switches operated by change of fluid pressure, by fluid pressure waves, or by change of fluid flow

Definitions

- the invention relates to a gas pressure switch for an ignition and safety device of an ammunition according to the features indicated in the preamble of claim 1.

- Munitions Ignition and Safety Devices require two physically independent release mechanisms to enable firing circuits.

- a spin-stabilized projectile for example, the launch acceleration and the projectile spin are used for this purpose.

- plain tube ammunition for example, 120 mm HE ammunition, however, a spin-dependent release mechanism can not be used.

- a gas pressure switch for an ignition and security device of an ammunition is from the FR 2 070 544 A known.

- the gas pressure switch has a shear-off locking pin, which holds a switching piston until it reaches a defined gas pressure in the rest position and shears when reaching the defined gas pressure, whereby the control piston is free and can be moved into its contact position.

- Same principle is the FR 1 417 132 A removable.

- the invention is based essentially on the idea to perform the gas pressure switch as an assembly that is designed as a "switching element" once and preferably has the form of a screw which is obliquely screwed from the back into the projectile tail of a corresponding ammunition.

- the gas pressure switch comprises a displaceable in the direction of the longitudinal axis of the switch switch piston, which is secured in its rest position by a perpendicular to the longitudinal axis of the switch arranged locking pin against unintentional displacement.

- This locking pin is designed and arranged such that the control piston can not be damaged or moved in case of transport loads occurring and rough handling of the ammunition.

- the locking pin is preferably sealed on the side facing the charge space by a membrane of a plastic material which is welded to the housing of the gas pressure switch.

- the membrane presses against the head side of the control piston. As soon as the gas pressure has reached a predetermined value, the locking pin shears off and the switching piston is displaced axially into a sealing seat. During this displacement, the switching piston closes with its lower end two contacts, which forward a signal for ignition release. The plastically deformable membrane also causes the switching piston is held in its contact position, so that the contacts then remain securely closed.

- the gas pressure switch according to the invention represents a crucial securing element for the firing and safety system of a projectile.

- the gas pressure switch Before the single switching operation, the gas pressure switch is safely electrically opened until a predetermined pressure (for example 345 bar) is reached. The switching function takes place only when this defined pressure is exceeded. Within about 15 milliseconds after this pressurization, the switch is then closed and remains closed until the detonation of the explosive charge without bouncing. When the gas pressure switch is stored, it remains securely in its open position even after 15 years and meets all functional requirements.

- Fig.1 illustrates the installation of a gas pressure switch 1 according to the invention in the rear-side region of a smooth-tube projectile, preferably HE projectile 114, wherein the gas pressure switch 1 has the shape of a hexagonal screw.

- This hex screw 1 is screwed through a thread 14 in a bore of the bullet tail 17 and the screw receptacle sealed by a sealing ring 22.

- the propellant charge of the projectile 114 is located in a manner known per se in a propellant charge shell 18. Since the projectile shown here is a wing-stabilized projectile, hinged tail wings 19 are arranged on the projectile tail 17.

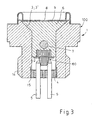

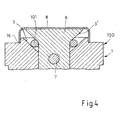

- the gas pressure switch 1 ( Fig.2 and 3 ) comprises a housing 100 made of stainless steel, which is designed in its outer shape like a hexagon screw. Inside the housing 100, a cylindrical bore 2 is arranged, which is designed as a conical countersinking 3 towards the upper end and with respect to a guided in the bore 2 control piston 6, which has a corresponding conical surface 3 'in the region of the countersink 3, with a sealing seat forms the sealing surfaces 3 and 3 '. As Figure 4 can be seen, between the sealing surfaces 3 and 3 'additionally an annular damping element 101 made of a plastic material (eg tin or lead) may be arranged.

- a plastic material eg tin or lead

- the housing 100 of the gas pressure switch 1 is provided on the outside with a fine thread 14 in the lower area, with the aid of which the gas pressure switch 1 is screwed into the projectile 114 and by means of the metallic sealing ring 22 (FIGS. Fig.1 ) is sealed.

- the switching piston 6 is surrounded on the upper side by a hat-shaped, plastically deformable and welded to the switch housing 100 hat-shaped membrane 8 and is connected on its underside with a contact device 60 which consists essentially of a pin-shaped element 11, which is a ceramic insert with gold-plated contact surfaces 10 acts.

- the pin-shaped element 11, which is arranged in an electrically insulated manner on the switching piston 6, is fastened in the region 13 by means of a retaining ring 12 (which is welded to the switching piston 6, for example, by means of laser light).

- the gas pressure switch 1 may be a provided with the gas pressure switch ammunition body in a corresponding weapon and the control piston 6 in Fig.2 take shown rest position.

- the pin-shaped element 11 of the contact device 60 is pressed between the two housing-fixed contact pins 5 and electrically connects them together, so that a signal for ignition release to the corresponding (not shown) device is forwarded.

- the gold-plated contact points of arranged on the control piston 6 ceramic insert 11 and the contact pins 5 guarantee a perfect transfer function of the signal.

- the membrane 8 Since the membrane 8 is plastically deformed by the gas pressure, it remains in the "everted” state, so that it the switching piston 6 in the lower closed position ( FIG. 3 ) positively fixed and the gas pressure switch 1 remains securely closed.

- the gas pressure switch 1 according to the invention is gas-tight, if it is pressurized with pressures up to 6,500 bar up to 15 milliseconds. It has proved to be useful if not only the carrier 4 in the region 15, but also the metallic membrane 8 are welded to the housing 100 in the region 16.

- the Figure 5 and 6 show a second embodiment of a gas pressure switch according to the invention, which is substantially in the Fig.2 and 3 illustrated gas pressure switch differs in that the designated 60 'contact device is not made of a ceramic insert with metallized contact surfaces, but of a metallic contact pin 102 which is connected to a plunger 102'.

- the plunger 102 ' is held by an in the switching piston 6 holding device 103 made of an insulating material, preferably glass.

- the switching pin 102 has a diameter and a shape that are selected such that it is in the contact position of the switching piston 6 (FIG. Figure 6 ) in the contact pins 5 "clawed".

- FIG. 7 and 8th illustrated gas pressure switch differs from that in the Fig.2 and 3 illustrated gas pressure switch substantially by the designated 60 "contact device.

- the switching piston 6 in its displacement from its rest position ( Figure 7 ) in his contact position ( Figure 8 ) causes a displacement of the contact device 60 "via a plan formed bottom side 105.

- the contact device 60 "consists of a printed circuit board arrangement comprising four printed circuit boards 106-109 which adjoin one another axially, wherein the first printed circuit board 106 facing the housing-fixed contact pins 5 is intended to effect a centering of the contact pins 5.

- the second printed circuit board 107 adjoining the first printed circuit board 106 is provided with bores 110 which are arranged above the contact pins 5 and in the rest position of the switching piston 6 (FIG. Figure 7 ) have a relation to the diameter of the contact pins 5 smaller diameter.

- the second circuit board 107 is followed by a third circuit board 108, which is provided with two sleeve-shaped metallic receptacles 104, which are electrically conductively connected to one another via a copper coating 115.

- the position of the two receptacles 104 in the third circuit board 108 is selected such that upon displacement of the control piston 6 from its rest to its contact position, the two housing-fixed contact pins 5 are pressed into one of the two sleeve-shaped receptacles 104.

- a fourth circuit board 109 connects to the upper side, which abuts against the end face 105 of the control piston 6 and on the end face 112 of the third printed circuit board 108, to a movement of the circuit board assembly 60 "in the rest position of the control piston 6 (FIG. Figure 7 ) to prevent.

- the locking pin 7 When this gas pressure switch is acted upon by a defined gas pressure, the locking pin 7 in turn shears off and the actuating piston 6 pushes down the entire printed circuit board arrangement 60 "via the fourth printed circuit board 109.

- the contact pins 5 are pressed through the bores 110 of the second printed circuit board 107 and the sleeve-shaped receivers 104 of the third printed circuit board 108 slide over the contact pins 5 so that the gas pressure switch is closed, since the individual printed circuit boards 106-109 are insulated from the housing 100 of the gas pressure switch, between the elements of the printed circuit board assembly 60 "and the housing 100 no electrically conductive connection.

- the housing-fixed contacts not only rigid, but also be resiliently connected to the housing 100 of the gas pressure switch.

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Switches Operated By Changes In Physical Conditions (AREA)

- Emergency Lowering Means (AREA)

Description

Die Erfindung betrifft einen Gasdruckschalter für eine Zünd- und Sicherungseinrichtung einer Munition nach den im Oberbegriff des Patentanspruches 1 angegebenen Merkmalen.The invention relates to a gas pressure switch for an ignition and safety device of an ammunition according to the features indicated in the preamble of

Zünd- und Sicherungseinrichtungen (ZUSE) von Munition benötigen zur Freigabe von Zündkreisen zwei physikalisch unabhängige Freigabemechanismen. Bei einem drallstabilisierten Geschoss wird hierzu beispielsweise die Abschussbeschleunigung und der Geschoss- Drall herangezogen. Bei Glattrohrmunition, beispielsweise 120 mm HE-Munition, ist jedoch ein drallabhängiger Freigabemechanismus nicht einsetzbar.Munitions Ignition and Safety Devices (ZUSE) require two physically independent release mechanisms to enable firing circuits. In a spin-stabilized projectile, for example, the launch acceleration and the projectile spin are used for this purpose. In plain tube ammunition, for example, 120 mm HE ammunition, however, a spin-dependent release mechanism can not be used.

Ein Gasdruckschalter für eine Zünd- und Sicherungseinrichtung einer Munition ist aus der

Eine weitere Größe, die zur definierten Zündfreigabe herangezogen werden kann, ist der beim Abschuss von Rohrwaffenmunition auftretende Gasdruck. Versuche, bekannte Druckaufnehmer bzw. Druckschalter in einer Glattrohr- Munition einzusetzen, verliefen aufgrund einer relativ großen Temperaturabhängigkeit des Schaltdruckes nicht zufrieden stellend. Außerdem hat sich gezeigt, dass bekannte Gasdruckschalter häufig nicht in ihrer geschlossenen Schaltposition (Kontaktstellung) verbleiben, sondern sich unter Einwirkung der Abschussbelastung wieder öffnen. Schließlich haben Versuche der Anmelderin ergeben, dass die bei bekannten Gasdruckschaltern häufig verwendeten Druckfedern nicht ausreichen, um die Schalterorgane in ihrer Kontaktstellung zu halten.Another variable that can be used for the defined ignition release is the gas pressure that occurs during the firing of gun ammunition. Attempts to use known pressure transducer or pressure switch in a smooth-tube ammunition were not satisfactory due to a relatively large temperature dependence of the switching pressure. In addition, it has been found that known gas pressure switches often do not remain in their closed switching position (contact position), but open again under the action of the launching load. Finally, attempts by the applicant have shown that the pressure springs commonly used in known gas pressure switches are not sufficient to keep the switch members in their contact position.

Es ist Aufgabe der vorliegenden Erfindung, einen Druckschalter für eine Zünd- und Sicherungseinrichtung von Munition der eingangs genannten Art bereitzustellen, der eine sichere Funktion beim Einsatz in einer Glattrohrmunition, vorzugsweise HE-Panzermunition, garantiert und erst beim Erreichen eines definierten Treibladungsdrukkes die geforderte Entsicherung der Zünd- und Sicherheitseinrichtung gewährleistet.It is an object of the present invention to provide a pressure switch for an ignition and safety device of ammunition of the type mentioned, which has a safe function when used in a smooth-tube ammunition, preferably HE tank ammunition, guaranteed and only when reaching a defined Treibladungsdrukkes the required protection of the ignition and safety device guaranteed.

Gelöst wird diese Aufgabe durch die im Anspruch 1 angegebenen Merkmale.This object is achieved by the features specified in

Die Merkmale der Unteransprüche verdeutlichen weitere vorteilhafte Ausgestaltungen der Erfindung.The features of the subclaims illustrate further advantageous embodiments of the invention.

Der Erfindung liegt im wesentlichen der Gedanke zugrunde, den Gasdruckschalter als eine Baugruppe auszuführen, die als "einmal" schaltendes Element ausgebildet ist und vorzugsweise die Form einer Schraube aufweist, die von der Rückseite aus schräg in das Geschoßheck einer entsprechenden Munition einschraubbar ist. Der Gasdruckschalter umfaßt einen in Richtung der Längsachse des Schalters verschiebbaren Schaltkolben, der in seiner Ruhestellung durch einen senkrecht zur Längsachse des Schalters angeordneten Sicherungsstift gegen unbeabsichtigtes Verschieben gesichert ist. Dieser Sicherungsstift ist derart ausgebildet und angeordnet, daß der Schaltkolben bei gegebenenfalls auftretenden Transportbelastungen sowie bei rauher Handhabung der Munition nicht beschädigt oder bewegt werden kann. Der Sicherungsstift wird auf der dem Ladungsraum zugewandten Seite vorzugsweise von einer Membran aus einem plastischen Material, die mit dem Gehäuse des Gasdruckschalters verschweißt ist, abgedichtet.The invention is based essentially on the idea to perform the gas pressure switch as an assembly that is designed as a "switching element" once and preferably has the form of a screw which is obliquely screwed from the back into the projectile tail of a corresponding ammunition. The gas pressure switch comprises a displaceable in the direction of the longitudinal axis of the switch switch piston, which is secured in its rest position by a perpendicular to the longitudinal axis of the switch arranged locking pin against unintentional displacement. This locking pin is designed and arranged such that the control piston can not be damaged or moved in case of transport loads occurring and rough handling of the ammunition. The locking pin is preferably sealed on the side facing the charge space by a membrane of a plastic material which is welded to the housing of the gas pressure switch.

Beim Abbrand der Treibladung der gezündeten Munition drückt die Membran gegen die Kopfseite des Schaltkolbens. Sobald der Gasdruck einen vorgegebenen Wert erreicht hat, schert der Sicherungsstift ab und der Schaltkolben wird axial in einen Dichtsitz verschoben. Bei dieser Verschiebung schließt der Schaltkolben mit seinem unteren Ende zwei Kontakte, die ein Signal zur Zündfreigabe weiterleiten. Die plastisch verformbare Membran bewirkt überdies, daß der Schaltkolben in seiner Kontaktstellung gehalten wird, so daß die Kontakte anschließend sicher geschlossen bleiben.When burned the propellant charge the ignited ammunition, the membrane presses against the head side of the control piston. As soon as the gas pressure has reached a predetermined value, the locking pin shears off and the switching piston is displaced axially into a sealing seat. During this displacement, the switching piston closes with its lower end two contacts, which forward a signal for ignition release. The plastically deformable membrane also causes the switching piston is held in its contact position, so that the contacts then remain securely closed.

Anders als bei bekannten Gasdruckschaltern erfolgt bei dem erfindungsgemäßen Schalter also eine funktionelle Trennung zwischen Abdichten und Schalten. Durch die Umformung der hutförmigen Membran verbleibt diese in dem "umgestülpten" Zustand und arretiert hiermit den Schaltkolben. Es ist darüber hinaus keine Feder oder ein anderes Element zur Sicherstellung des geschalteten Zustandes erforderlich. Der Gasdruckschalter braucht daher keine Kunst-, Dicht- oder Klebstoffe zu enthalten, so daß eine sehr lange Lagerungsfähigkeit bei voller Funktionszuverlässigkeit gegeben ist.In contrast to known gas pressure switches, a functional separation between sealing and switching thus takes place in the switch according to the invention. By reshaping the hat-shaped membrane this remains in the "everted" state and locks hereby the switching piston. It is not a feather or another Element required to ensure the switched state. Therefore, the gas pressure switch does not need to contain any art, sealants or adhesives, so that a very long shelf life is given full functional reliability.

Der erfindungsgemäße Gasdruckschalter stellt ein entscheidendes Sicherungselement für das Zünd- und Sicherungssystem eines Geschosses dar. Vor dem einmaligen Schaltvorgang ist der Gasdruckschalter bis zum Erreichen eines vorgegebenen Druckes (z.B. 345 bar) sicher elektrisch geöffnet. Die Schaltfunktion erfolgt erst bei Überschreitung dieses definierten Druckes. Innerhalb von etwa 15 Millisekunden nach dieser Druckbeaufschlagung ist der Schalter dann geschlossen und bleibt bis zur Zündung der Sprengladung -ohne zu prellen- sicher geschlossen. Bei einer Lagerung des Gasdruckschalters bleibt dieser auch nach 15 Jahren noch sicher in seiner offenen Stellung und erfüllt alle funktionalen Anforderungen.The gas pressure switch according to the invention represents a crucial securing element for the firing and safety system of a projectile. Before the single switching operation, the gas pressure switch is safely electrically opened until a predetermined pressure (for example 345 bar) is reached. The switching function takes place only when this defined pressure is exceeded. Within about 15 milliseconds after this pressurization, the switch is then closed and remains closed until the detonation of the explosive charge without bouncing. When the gas pressure switch is stored, it remains securely in its open position even after 15 years and meets all functional requirements.

Weitere Einzelheiten und Vorteile der Erfindung ergeben sich aus den nachfolgend anhand von Zeichnungen beschriebenen Ausführungsbeispielen. Es zeigen:

-

Fig. 1 die Anordnung eines einen Schaltkolben enthaltenden erfindungsgemäßen Gasdruckschalters in dem Heck des Geschosses einer Munition; -

Fig.2 den Längsschnitt durch ein erstes Ausführungsbeispiel eines erfindungsgemäßen Gasdruckschalters, wobei sich der Schaltkolben in seiner Ruhestellung befindet; -

Fig.3 den inFig.2 dargestellten Gasdruckschalter, wobei sich der Schaltkolben in seiner Kontaktstellung befindet; -

Fig.4 eine Teilansicht des inFigur 2 -

Fig.5 und6 denFig.2 und3 entsprechenden Ansichten eines zweiten Ausführungsbeispieles eines Gasdruckschalters; -

Fig.7 und8 denFig.2 und3 entsprechenden Ansichten eines dritten Ausfiihrungsbeispieles eines Gasdruckschalters.

-

Fig. 1 the arrangement of a switching piston containing inventive gas pressure switch in the rear of the bullet of an ammunition; -

Fig.2 the longitudinal section through a first embodiment of a gas pressure switch according to the invention, wherein the switching piston is in its rest position; -

Figure 3 the inFig.2 illustrated gas pressure switch, wherein the switching piston is in its contact position; -

Figure 4 a partial view of the inFIG. 2 illustrated gas pressure switch with a damping element between the switching piston and the housing of the gas pressure switch; -

Figure 5 and6 theFig.2 and3 corresponding views of a second embodiment of a gas pressure switch; -

Figure 7 and8th theFig.2 and3 corresponding views of a third embodiment of a gas pressure switch.

Die Treibladung des Geschosses 114 befindet sich in an sich bekannter Weise in einer Treibladungshülse 18. Da es sich bei dem hier dargestellten Geschoß um ein flügelstabilisiertes Geschoß handelt, sind an dem Geschoßheck 17 aufklappbare Leitwerksflügel 19 angeordnet.The propellant charge of the

Das in

Der erfindungsgemäße Gasdruckschalter 1 (

Am unteren Ende des Gehäuses 100 befindet sich in der zylindrischen Bohrung 2 ein Träger 4 mit isolierten Kontaktstiften 5, wobei der Träger 4 in dem Gehäuse 100 eingeschraubt und von außen verschweißt ist. Das Gehäuse 100 des Gasdruckschalters 1 ist im unteren Bereich außenseitig mit einem Feingewinde 14 versehen, mit Hilfe dessen der Gasdruckschalter 1 in das Geschoß 114 eingeschraubt und mittels des metallischen Dichtringes 22 (

Der Schaltkolben 6 wird oberseitig von einer hutförmig ausgebildeten, plastisch verformbaren und mit dem Schaltergehäuse 100 verschweißten hutförmigen Membrane 8 umgeben und ist auf seiner Unterseite mit einer Kontakteinrichtung 60 verbunden, welche im wesentlichen aus einem stiftförmigen Element 11 besteht, bei dem es sich um einen Keramikeinsatz mit vergoldeten Kontaktflächen 10 handelt. Das an dem Schaltkolben 6 elektrisch isoliert angeordnete stiftförmige Element 11 ist im Bereich 13 mittels eines Halteringes 12 befestigt (der z.B. mit Hilfe von Laserlicht an den Schaltkolben 6 angeschweißt ist).The

Außerdem wird der Schaltkolben in seiner, in

Nachfolgend wird auf die Wirkungsweise des erfindungsgemäßen Gasdruckschalters 1 eingegangen. Dabei möge sich ein mit dem Gasdruckschalter versehener Munitionskörper in einer entsprechenden Waffe befinden und der Schaltkolben 6 die in

Wird nun die Munition gezündet, so bilden sich Treibladungsgase und der Druck in dem Ladungsraum der Waffe steigt schnell an. Dadurch wird die hutförmige Membrane 8 gegen die äußere Stirnfläche 9 des Schaltkolbens 6 gedrückt. Bei einem definierten Druck schert der Schaltkolben 6 den Sicherungsstift 7 an den Scherflächen zum Gehäuse 100 ab und wird axial in den Dichtsitz verschoben (

Bei der Verschiebung des Schaltkolbens 6 wird das stiftförmige Element 11 der Kontakteinrichtung 60 zwischen die beiden gehäusefesten Kontaktstifte 5 gedrückt und verbindet diese elektrisch miteinander, so daß ein Signal zur Zündfreigabe an die entsprechende (nicht dargestellte) Einrichtung weitergeleitet wird.During the displacement of the

Die vergoldeten Kontaktstellen des an dem Schaltkolben 6 angeordneten Keramikeinsatzes 11 und der Kontaktstifte 5 garantieren eine einwandfreie Übertragungsfunktion des Signales.The gold-plated contact points of arranged on the

Da die Membrane 8 durch den Gasdruck plastisch verformt wird, verbleibt sie in dem "umgestülpten" Zustand, so daß sie den Schaltkolben 6 in der unteren geschlossenen Stellung (

Bei Versuchen hat sich gezeigt, daß der erfindungsgemäße Gasdruckschalter 1 gasdicht ist, wenn dieser mit Drücken bis zu 6.500 bar bis zu 15 Millisekunden beaufschlagt wird. Dabei hat es sich als zweckmäßig erwiesen, wenn nicht nur der Träger 4 im Bereich 15, sondern auch die metallische Membrane 8 mit dem Gehäuse 100 im Bereich 16 verschweißt sind.In experiments it has been found that the

Die

Auch der in den

Die Kontakteinrichtung 60" besteht aus einer Leiterplattenanordnung aus vier sich axial aneinander anschließenden Leiterplatten 106-109. Dabei soll die erste, den gehäusefesten Kontaktstiften 5 zugewandte Leiterplatte 106 eine Zentrierung der Kontaktstifte 5 bewirken.The

Die sich oberhalb der ersten Leiterplatte 106 anschließende zweite Leiterplatte 107 ist mit Bohrungen 110 versehen, die oberhalb der Kontaktstifte 5 angeordnet sind und in der Ruhestellung des Schaltkolbens 6 (

An die zweite Leiterplatte 107 schließt sich eine dritte Leiterplatte 108 an, welche mit zwei hülsenförmigen metallischen Aufnahmen 104 versehen ist, die über eine Kupferbeschichtung 115 elektrisch leitend miteinander verbunden sind. Dabei ist die Lage der beiden Aufnahmen 104 in der dritten Leiterplatte 108 derart gewählt, daß bei einer Verschiebung des Schaltkolbens 6 von seiner Ruhe- in seine Kontaktstellung die beiden gehäusefesten Kontaktstifte 5 jeweils in eine der beiden hülsenförmigen Aufnahmen 104 gedrückt werden.The

An die dritte Leiterplatte 108 schließt sich oberseitig eine vierte Leiterplatte 109 an, die an der Stirnseite 105 des Schaltkolbens 6 und an der Stirnseite 112 der dritten Leiterplatte 108 anliegt, um eine Bewegung der Leiterplattenanordnung 60" in der Ruhestellung des Schaltkolbens 6 (

Bei der Beaufschlagung dieses Gasdruckschalters mit einem definierten Gasdruck schert wiederum zunächst der Sicherungsstift 7 ab und der Schaltkolben 6 drückt über die vierte Leiterplatte 109 die gesamte Leiterplattenanordnung 60" nach unten. Dabei werden die Kontaktstifte 5 durch die Bohrungen 110 der zweiten Leiterplatte 107 hindurchgedrückt und die hülsenförmigen Aufnahmen 104 der dritten Leiterplatte 108 schieben sich über die Kontaktstifte 5, so daß der Gasdruckschalter geschlossen wird. Da die einzelnen Leiterplatten 106-109 gegenüber dem Gehäuse 100 des Gasdruckschalters isoliert angeordnet sind, gibt es zwischen den Elementen der Leiterplattenanordnung 60" und dem Gehäuse 100 keine elektrisch leitende Verbindung.When this gas pressure switch is acted upon by a defined gas pressure, the locking

Die Erfindung ist selbstverständlich nicht auf die vorstehend beschriebenen Ausführungsbeispiele beschränkt. So können beispielsweise die gehäusefesten Kontakte nicht nur starr, sondern auch federelastisch mit dem Gehäuse 100 des Gasdruckschalters verbunden sein.The invention is of course not limited to the embodiments described above. Thus, for example, the housing-fixed contacts not only rigid, but also be resiliently connected to the

- 11

- Gasdruckschalter, SechskantschraubeGas pressure switch, hexagon screw

- 22

- Bohrungdrilling

- 33

- kegelförmige Senkung, Dichtflächeconical countersink, sealing surface

- 3'3 '

- Kegelfläche, DichtflächeConical surface, sealing surface

- 44

- Trägercarrier

- 55

- Kontaktstiftpin

- 66

- Schaltkolbenswitching piston

- 77

- Sicherungsstiftsafety pin

- 88th

- Membranemembrane

- 99

- Stirnflächeface

- 1010

- Kontaktflächecontact area

- 1111

- Stiftförmiges Element, KeramikeinsatzPin-shaped element, ceramic insert

- 1212

- Halteringretaining ring

- 1313

- BereichArea

- 1414

- Gewindethread

- 1515

- BereichArea

- 1616

- BereichArea

- 1717

- Geschoßheckbullet base

- 1818

- TreibladungshülseCartridge case

- 1919

- Leitwerksflügeltail wing

- 2020

- Führungsbandguide band

- 2121

- Spitzetop

- 2222

- Dichtringseal

- 60,60'60.60 '

- Kontakteinrichtungcontactor

- 60"60 "

- Kontakteinrichtung, LeiterplattenanordnungContact device, circuit board assembly

- 100100

- Gehäusecasing

- 101101

- Dämpfungselementdamping element

- 102102

- stiftförmige Element, Schaltstiftpin-shaped element, switching pin

- 102'102 '

- Stößeltappet

- 103103

- Halteeinrichtungholder

- 104104

- hülsenförmige Aufnahmesleeve-shaped receptacle

- 105105

- Unterseite, Stirnseite (Schaltkolben)Underside, front side (control piston)

- 106106

- erste Leiterplattefirst circuit board

- 107107

- zweite Leiterplattesecond circuit board

- 108108

- dritte Leiterplattethird circuit board

- 109109

- vierte Leiterplattefourth circuit board

- 110110

- Bohrungdrilling

- 112112

- Stirnseite (dritte Leiterplatte)Front side (third circuit board)

- 114114

- GeschoßBullet

- 115115

- Kupferbeschichtungcopper coating

Claims (17)

- Gas-pressure switch (1) for a safety and arming unit for a munition, comprising- a housing (100) and a switching piston (6) which can be moved from a rest position to a contact position, when used correctly, by the propellant charge gases from the munition and which, on its side facing away from the propellant charge gases, has a contact device (60-60") which electrically conductively connects at least two contact pins (5) which are fixed to the housing, to one another when the switching piston (6) is in the contact position,- a safety pin (7) which can be sheared off, holds the switching piston (6) in its rest position until a predetermined gas pressure is reached, and is sheared off when the defined gas pressure is reached, as a result of which the switching piston (6) can then be moved to its contact position, characterized in that- the switching piston (6) is surrounded on its outside facing the propellant charge gases by a plastically deformable membrane (8), which is connected to the housing (100) of the gas-pressure switch (1), presses against the switching piston (6) after reaching a predetermined gas pressure, and holds the switching piston (6) in this position after reaching its contact position.

- Gas-pressure switch according to Claim 1, characterized in that the switching piston (6) and the housing (100) of the gas-pressure switch (1) have sealing surfaces (3; 3') which move towards one another during the movement of the switching piston (6) from the rest position to the contact position.

- Gas-pressure switch according to Claim 2, characterized in that the switching piston (6) and the housing (100) of the gas-pressure switch (1) have conical sealing surfaces (3; 3') for sealing.

- Gas-pressure switch according to Claim 2 or 3, characterized in that an annular damping element (101) composed of a plastic material is arranged between the sealing surfaces (3; 3') of the switching piston (6) and the housing (100).

- Gas-pressure switch according to Claim 4, characterized in that the damping element (101) is composed of tin or lead.

- Gas-pressure switch according to one of Claims 1 to 5, characterized in that the contact device (60; 60') has an element (11; 102) which is in the form of a pin, is pressed between the two contact pins (5) which are fixed to the housing, during the movement of the switching piston (6) from its rest position to its contact position, and electrically connects the contact pins (5) to one another.

- Gas-pressure switch according to Claim 6, characterized in that the element (11) of the contact device (60) which is in the form of a pin is a ceramic insert with preferably gold-plated contact surfaces.

- Gas-pressure switch according to Claim 7, characterized in that the ceramic insert (11) is firmly connected to the switching piston (6).

- Gas-pressure switch according to Claim 6, characterized in that the element (102) of the contact device (60') which is in the form of a pin is a metallic switching pin (102) which is held directly or via a plunger (102') composed of an electrically non-conductive material by a holding device (103), which is arranged in the switching piston (6) and is composed of an electrically non-conductive material.

- Gas-pressure switch according to Claim 9, characterized in that the holding device (103) of the switching pin (102) is composed of glass.

- Gas-pressure switch according to one of Claims 1 to 5, characterized in that the contact device (60") comprises a printed circuit board arrangement (60"), which comprises two receptacles (104) which are in the form of sleeves and are electrically conductively connected to one another, such that, while the switching piston (6) is being moved from its rest position to its contact position, the two contact pins (5) which are fixed to the housing are each pressed into one of the receptacles (104) which are in the form of sleeves.

- Gas-pressure switch according to Claim 11, characterized in that the printed circuit board arrangement (60") is a separate assembly which is connected to the switching piston (6), wherein, during its movement over its planar lower face (105), the switching piston (6) corresponding movement of the printed circuit board arrangement (60").

- Gas-pressure switch according to Claim 11 or 12, characterized in that the printed circuit board arrangement (60") comprises at least four printed circuit boards (106-109) which are axially connected to one another, a first printed circuit board (106) which faces the contact pins (5) which are fixed to the housing and results in centring of the contact pins (5), a second printed circuit board (107) with holes (110) whose diameter is smaller than the diameter of the contact pins (5), in order to prevent contact being made between the receptacles (104), which are in the form of sleeves, and the contact pins (5) when the switching piston (6) is in the rest position, a third printed circuit board (108) with the receptacles (104) which are in the form of sleeves, and a fourth printed circuit board (109) which rests on the end faces (105, 112) of the switching piston (6) and of the third printed circuit board (108), in order to prevent movement of the printed circuit board arrangement (60") when the switching piston (6) is in the rest position.

- Gas-pressure switch according to one of Claims 1 to 13, characterized in that the contact pins (5) have gold-plated points (21) at the contact points of the contact device (60-60") which is associated with the switching piston (6).

- Gas-pressure switch according to one of Claims 1 to 14, characterized in that the contact pins (5) are arranged in an isolated manner in a support (4) and the support (4) is connected via a thread, and welded such that it is gas-tight, to the housing (100) of the gas-pressure switch (1).

- Gas-pressure switch according to one of Claims 1 to 15, characterized by a design in the form of a screw, which can be screwed obliquely into the rear of a projectile (17) from the rear face.

- Gas-pressure switch according to one of Claims 1 to 16, characterized in that the membrane (8) is in the form of a hat and is welded to the housing (100).

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10319265 | 2003-04-26 | ||

| DE10319265 | 2003-04-26 | ||

| DE10354012 | 2003-11-19 | ||

| DE10354012A DE10354012B4 (en) | 2003-04-26 | 2003-11-19 | Gas pressure switch for an ignition and safety device of ammunition |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1471326A1 EP1471326A1 (en) | 2004-10-27 |

| EP1471326B1 true EP1471326B1 (en) | 2010-04-07 |

Family

ID=32963541

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04002749A Expired - Lifetime EP1471326B1 (en) | 2003-04-26 | 2004-02-07 | Electric switch for a projectile fuze, which switch is activated by gas pressure |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US7150228B2 (en) |

| EP (1) | EP1471326B1 (en) |

| JP (1) | JP4541747B2 (en) |

| IL (1) | IL161577A (en) |

| NO (1) | NO329475B1 (en) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8239699B2 (en) * | 2009-06-26 | 2012-08-07 | Intel Corporation | Method and apparatus for performing energy-efficient network packet processing in a multi processor core system |

| KR101473897B1 (en) * | 2013-04-26 | 2014-12-17 | 이노크린 주식회사 | Bomb using non-explosive solid or non-explosive liquid |

| US9470498B1 (en) * | 2014-09-05 | 2016-10-18 | The United States Of America As Represented By The Secretary Of The Army | High pressure isolated latching safety switch device |

| US10510504B2 (en) * | 2017-12-08 | 2019-12-17 | Eagle Technology, Llc | Force amplified low pressure depth activated switch |

| CN114508975B (en) * | 2022-02-15 | 2023-10-13 | 南京理工大学 | Fuse rigid safety inertial motion mechanism for reducing friction influence of shearing section |

Family Cites Families (26)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2458478A (en) | 1943-04-10 | 1949-01-04 | Riehard L Maneval | Setback switch |

| US2873681A (en) | 1945-02-03 | 1959-02-17 | Charles C Lauritsen | Fuze |

| US2674946A (en) * | 1950-06-14 | 1954-04-13 | Bofors Ab | Control device for an electric circuit |

| US2721913A (en) * | 1950-07-17 | 1955-10-25 | Jr Raymond C Kent | Shock and static pressure discriminating switch |

| US2931874A (en) * | 1953-10-08 | 1960-04-05 | Audley B Leaman | Explosive switch |

| US3698323A (en) * | 1955-12-23 | 1972-10-17 | Us Army | Explosive operated switch for bomb fuzing system |

| FR79714E (en) * | 1959-11-06 | 1963-01-11 | Soc Tech De Rech Ind | Improvements to the electric initiation of shaped charge projectiles |

| US3167018A (en) | 1962-03-19 | 1965-01-26 | Aeronca Mfg Corp | Missile safety and arming circuit |

| US3248504A (en) | 1962-10-08 | 1966-04-26 | Atlas Chem Ind | Connecting switch |

| US3155800A (en) * | 1963-01-02 | 1964-11-03 | Genisco Technology Corp | Single action temperature sensitive electrical switch including camming means for a plunger retaining member |

| FR1417132A (en) * | 1964-04-14 | 1965-11-12 | Charbonnages De France | New device for shorting electrical conductors |

| US3275770A (en) * | 1965-02-26 | 1966-09-27 | Sinclair Research Inc | Explosion pressure responsive switch |

| US3500279A (en) | 1968-07-26 | 1970-03-10 | Us Navy | Exploding bridgewire operated switch |

| US3601057A (en) * | 1969-02-11 | 1971-08-24 | Gibbs Mfg And Research Corp | Arming switch |

| FR2070544A5 (en) * | 1969-12-09 | 1971-09-10 | Serat | |

| US3675579A (en) * | 1970-02-25 | 1972-07-11 | Us Navy | Pressure actuated safety and arming device |

| US3991649A (en) * | 1975-06-27 | 1976-11-16 | Networks Electronic Corporation | Pyrotechnic wire cutter |

| US4150266A (en) | 1977-01-27 | 1979-04-17 | Networks Electronic Corp. | Miniature pyrotechnic squib switch, single pole, normally open |

| DE2755322A1 (en) | 1977-12-12 | 1979-06-13 | Dynamit Nobel Ag | Pyrotechnically operated switch with latched contacts - has piston contact stud displaced by detonation gas pressure to contact counter contact insulated from casing |

| JPS573000A (en) * | 1980-06-06 | 1982-01-08 | Mitsubishi Electric Corp | Flying object |

| US4339638A (en) * | 1980-10-15 | 1982-07-13 | Mcdonnell Douglas Corporation | Electrical switch |

| US4527025A (en) | 1983-02-02 | 1985-07-02 | Networks Electronic Corp. | Miniature delay switch |

| US4852494A (en) * | 1987-11-16 | 1989-08-01 | Williams Robert A | Explosively actuated switch |

| FR2633385B1 (en) | 1988-06-23 | 1990-08-31 | France Etat Armement | SECURITY AND ARMING SYSTEM FOR PROJECTILE USING COMBUSTION GAS PRESSURE |

| FR2679697B1 (en) | 1991-07-25 | 1994-05-20 | Giat Industries | ELECTRIC CONTACTOR WITH PYROTECHNIC CONTROL. |

| US5131328A (en) * | 1991-12-13 | 1992-07-21 | The United States Of America As Represented By The Secretary Of The Navy | Safety and arming system for tube launched projectile |

-

2004

- 2004-02-07 EP EP04002749A patent/EP1471326B1/en not_active Expired - Lifetime

- 2004-03-09 NO NO20041025A patent/NO329475B1/en not_active IP Right Cessation

- 2004-04-16 JP JP2004121492A patent/JP4541747B2/en not_active Expired - Fee Related

- 2004-04-22 IL IL161577A patent/IL161577A/en active IP Right Grant

- 2004-04-22 US US10/829,278 patent/US7150228B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| IL161577A0 (en) | 2004-09-27 |

| IL161577A (en) | 2008-11-03 |

| EP1471326A1 (en) | 2004-10-27 |

| NO20041025L (en) | 2004-10-27 |

| US20050188877A1 (en) | 2005-09-01 |

| NO329475B1 (en) | 2010-10-25 |

| JP2004325067A (en) | 2004-11-18 |

| JP4541747B2 (en) | 2010-09-08 |

| US7150228B2 (en) | 2006-12-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0164732B1 (en) | Apparatus for generating decoy clouds, in particular those emitting ir radiation | |

| DE2832879A1 (en) | DRIVE CHARGE LIGHT | |

| DE2443793A1 (en) | COMBINED HATCHES | |

| DE2907308C2 (en) | Floor with at least one pushable daughter floor | |

| DE2227104A1 (en) | FLOOR OR ROCKET WITH OPENING TAIL | |

| EP1471326B1 (en) | Electric switch for a projectile fuze, which switch is activated by gas pressure | |

| DE2838381C2 (en) | Safety device for ignition devices | |

| EP3767223B1 (en) | System, especially a hand grenade | |

| DE10354012B4 (en) | Gas pressure switch for an ignition and safety device of ammunition | |

| EP0156763A1 (en) | Method and device for increasing the energy in an electromagnetic fuze system | |

| CH674078A5 (en) | ||

| EP0341543A1 (en) | Shotgun slug cartridge | |

| EP2872850B1 (en) | Grenade, in particular 40 mm grenade | |

| EP0731331A2 (en) | Launcher for self-propelled missiles, in particular for artillery rockets | |

| EP0116322B1 (en) | Nose fuse | |

| DE2842882C3 (en) | Impact fuse with a primer | |

| EP0129679B1 (en) | Proximity fuze arrangement for missiles | |

| DE3717458A1 (en) | Pyrotechnic force element | |

| EP1357349B1 (en) | Cartridge | |

| DE2002288A1 (en) | Mechanical ignition device | |

| DE10039911B4 (en) | Ejector for ejecting submunitions from a projectile | |

| WO2011128234A1 (en) | Current interrupter for an energy line | |

| DE19540863B3 (en) | Ignition apparatus installed in warhead of e.g. rocket, has trigger units that enables simultaneous activation of relay charge unit to ensure triggering of explosive apparatus so that shock waves are generated in explosive apparatus | |

| DE102021123375A1 (en) | Ignition device for ammunition, in particular medium-caliber ammunition, and associated method for detonating or self-destructing ammunition, in particular medium-caliber ammunition | |

| DE2148197C3 (en) | Detonators for igniter cartridges for separators for mine mooring lines |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| 17P | Request for examination filed |

Effective date: 20041009 |

|

| AKX | Designation fees paid |

Designated state(s): CH DE FR GB LI |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: RHEINMETALL WAFFE MUNITION GMBH |

|

| 17Q | First examination report despatched |

Effective date: 20070524 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: RHEINMETALL WAFFE MUNITION GMBH |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): CH DE FR GB LI |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: E. BLUM & CO. AG PATENT- UND MARKENANWAELTE VSP |

|

| REF | Corresponds to: |

Ref document number: 502004010986 Country of ref document: DE Date of ref document: 20100520 Kind code of ref document: P |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20110110 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20210224 Year of fee payment: 18 Ref country code: CH Payment date: 20210217 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20210219 Year of fee payment: 18 Ref country code: DE Payment date: 20210217 Year of fee payment: 18 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502004010986 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20220207 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220228 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220207 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220901 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220228 |