EP1425762B1 - Electrical multi-layer component - Google Patents

Electrical multi-layer component Download PDFInfo

- Publication number

- EP1425762B1 EP1425762B1 EP02754524A EP02754524A EP1425762B1 EP 1425762 B1 EP1425762 B1 EP 1425762B1 EP 02754524 A EP02754524 A EP 02754524A EP 02754524 A EP02754524 A EP 02754524A EP 1425762 B1 EP1425762 B1 EP 1425762B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- resistor

- component according

- dielectric layers

- electrode layers

- base body

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000000919 ceramic Substances 0.000 claims abstract description 17

- KDLHZDBZIXYQEI-UHFFFAOYSA-N Palladium Chemical compound [Pd] KDLHZDBZIXYQEI-UHFFFAOYSA-N 0.000 claims description 25

- 239000000463 material Substances 0.000 claims description 23

- 229910010293 ceramic material Inorganic materials 0.000 claims description 10

- 229910052763 palladium Inorganic materials 0.000 claims description 8

- 238000005245 sintering Methods 0.000 claims description 8

- 239000000654 additive Substances 0.000 claims description 7

- 229910001252 Pd alloy Inorganic materials 0.000 claims description 5

- 229910045601 alloy Inorganic materials 0.000 claims description 5

- 239000000956 alloy Substances 0.000 claims description 5

- 229910001316 Ag alloy Inorganic materials 0.000 claims description 4

- 230000000996 additive effect Effects 0.000 claims description 3

- 229910002113 barium titanate Inorganic materials 0.000 claims description 2

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 claims 1

- 239000000470 constituent Substances 0.000 claims 1

- 229910052593 corundum Inorganic materials 0.000 claims 1

- 229910001845 yogo sapphire Inorganic materials 0.000 claims 1

- 239000003990 capacitor Substances 0.000 description 8

- 238000005516 engineering process Methods 0.000 description 5

- 238000013016 damping Methods 0.000 description 3

- 238000003780 insertion Methods 0.000 description 3

- 230000037431 insertion Effects 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 3

- 238000000034 method Methods 0.000 description 3

- 229910018072 Al 2 O 3 Inorganic materials 0.000 description 2

- XLOMVQKBTHCTTD-UHFFFAOYSA-N Zinc monoxide Chemical compound [Zn]=O XLOMVQKBTHCTTD-UHFFFAOYSA-N 0.000 description 2

- 230000008878 coupling Effects 0.000 description 2

- 238000010168 coupling process Methods 0.000 description 2

- 238000005859 coupling reaction Methods 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 239000003989 dielectric material Substances 0.000 description 2

- 230000010354 integration Effects 0.000 description 2

- 238000007650 screen-printing Methods 0.000 description 2

- 229910052772 Samarium Inorganic materials 0.000 description 1

- 230000002238 attenuated effect Effects 0.000 description 1

- 229910052788 barium Inorganic materials 0.000 description 1

- JRPBQTZRNDNNOP-UHFFFAOYSA-N barium titanate Chemical compound [Ba+2].[Ba+2].[O-][Ti]([O-])([O-])[O-] JRPBQTZRNDNNOP-UHFFFAOYSA-N 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 229910000416 bismuth oxide Inorganic materials 0.000 description 1

- 239000003985 ceramic capacitor Substances 0.000 description 1

- 239000004020 conductor Substances 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- TYIXMATWDRGMPF-UHFFFAOYSA-N dibismuth;oxygen(2-) Chemical compound [O-2].[O-2].[O-2].[Bi+3].[Bi+3] TYIXMATWDRGMPF-UHFFFAOYSA-N 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 239000004615 ingredient Substances 0.000 description 1

- 239000011159 matrix material Substances 0.000 description 1

- TWNQGVIAIRXVLR-UHFFFAOYSA-N oxo(oxoalumanyloxy)alumane Chemical compound O=[Al]O[Al]=O TWNQGVIAIRXVLR-UHFFFAOYSA-N 0.000 description 1

- SWELZOZIOHGSPA-UHFFFAOYSA-N palladium silver Chemical compound [Pd].[Ag] SWELZOZIOHGSPA-UHFFFAOYSA-N 0.000 description 1

- PUDIUYLPXJFUGB-UHFFFAOYSA-N praseodymium atom Chemical compound [Pr] PUDIUYLPXJFUGB-UHFFFAOYSA-N 0.000 description 1

- 229910003447 praseodymium oxide Inorganic materials 0.000 description 1

- 229910052709 silver Inorganic materials 0.000 description 1

- 239000004332 silver Substances 0.000 description 1

- 239000002904 solvent Substances 0.000 description 1

- 239000007858 starting material Substances 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 238000009827 uniform distribution Methods 0.000 description 1

- 239000011787 zinc oxide Substances 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01C—RESISTORS

- H01C7/00—Non-adjustable resistors formed as one or more layers or coatings; Non-adjustable resistors made from powdered conducting material or powdered semi-conducting material with or without insulating material

- H01C7/18—Non-adjustable resistors formed as one or more layers or coatings; Non-adjustable resistors made from powdered conducting material or powdered semi-conducting material with or without insulating material comprising a plurality of layers stacked between terminals

Definitions

- the invention relates to an electrical multilayer component, which contains a base body with a stack of superimposed ceramic dielectric layers.

- external contacts are arranged on the outside of the main body.

- a resistor is arranged, which is connected to the external contacts.

- Multi-layer devices of the type mentioned are usually produced in the so-called multilayer technology.

- multilayer varistors or even ceramic capacitors can be produced with the aid of this technology.

- the integration of a resistor is often necessary.

- properties such as the frequency response, the insertion loss or the course of the terminal voltage can be changed in a positive manner in an electrical pulse coupled into a varistor.

- the known ceramic components additionally contain electrically conductive electrode layers in addition to the dielectric layers and thus form a stack of superimposed electrode layers separated from one another by dielectric layers. Such stacks can form, for example, capacitors or even varistors.

- the known resistor has the disadvantage that the material forming the resistor is printed along a wide path on a dielectric layer. This makes it difficult to realize high resistance values as they are normally desired.

- the realization of high resistance values is made possible according to the prior art by using special resistor pastes.

- these special resistor pastes have the disadvantage that they can not withstand the high sintering temperatures usually occurring in the production of ceramic components> 1000 ° C.

- the multilayer component is limited to ceramic materials which can be sintered by means of the so-called "LTCC sintering process". These are ceramic materials that can be sintered at low temperatures ⁇ 800 ° C. Naturally, according to this requirement, the choice of ceramic materials is severely limited, which means a further disadvantage of the known multilayer component.

- the aim of the present invention is therefore to provide a multilayer component which allows a high degree of flexibility in the integration of resistors in multilayer components.

- the invention is defined by the features of claim 1 and provides a multilayer electrical component comprising a base body containing a stack of superimposed ceramic dielectric layers. Outside of the main body at least two external contacts are arranged. In the interior of the main body, a resistor is arranged between two dielectric layers, which is contacted with two of the external contacts.

- the resistor has the form of a structured layer, which forms at least one multiply curved path as a current path between the external contacts.

- the multilayer component according to the invention has the advantage that, owing to the structuring of the layer forming the resistance, there is a greater choice in the resistance values to be realized, and in particular relatively large resistance values can be achieved.

- the ratio of the length of the web to the width of the web is particularly important. The longer the train is, the greater its resistance. Conversely, with decreasing width of the track, the resistance increases. A large ratio length / width is therefore favorable for the realization of a large resistance.

- the resistor is arranged in a plane of the multilayer component which is free of electrically conductive electrode layers. This means that the entire area of one plane of the multilayer component is available for the formation of the resistor. Together with the multi-curved path can thus be provided an optimally large area for the realization of a particularly high resistance.

- the multilayer device of the invention because of the patterned layer for the resistor, allows the internal sintering of the dielectric layers with the resistor in a single step. Thereby, a monolithic body can be formed, as it is common for use in multilayer technology and which has the usual advantages.

- the resistance between the external contacts runs in the form of a web whose length is at least ten times greater than its width.

- the resistor may be formed in one embodiment of the invention of a closed resistance layer, which is subsequently provided with recesses.

- the resistor can also be designed as a meandering path.

- a meandering path with a plurality of turns allows the realization of a very long current path along the longitudinal direction of the meander.

- a large amount of resistance can be realized by a plurality of successive bends made in opposite directions.

- the resistive material may include, for example, an alloy of silver and palladium, wherein palladium has a weight fraction of 15 to ⁇ 100% of the alloy. Pure palladium can also be used.

- Such materials are known in multilayer technology in the manufacture of multilayer devices. So far, however, only electrode layers were made from these materials, where it depends on a good conductivity. These materials have the advantage that they are sintered together with a variety of ceramic materials. Although they do not have a very high resistance, but the structuring according to the invention, the resistance can be sufficiently increased.

- the resistance material contains an alloy of silver and palladium, wherein palladium has a weight fraction of between 50 and 70% of the alloy. Due to the high palladium content, the resistance can be increased approximately by a factor of three because of the poorer conductivity of palladium compared to silver.

- the resistance can be increased by forming the resistor from a resistive material having a sheet resistance of at least 0.1 ohms in the patterned layer.

- the resistance of the resistance material can be increased, for example, by adding the resistance material in addition to an electrically conductive component nor additives in an amount of up to 70 vol .-%.

- Such additives may have a resistivity at least ten times greater than the resistivity of the conductive component. It is important to ensure that the conductive components are not isolated in a matrix of insulating additives, because then no conductivity at all would be available.

- aluminum oxide Al 2 O 3

- the sheet resistance is the specific resistance of the material divided by the thickness of a layer to be considered in the form of a rectangle.

- the resistance of the layer is then obtained by multiplying the sheet resistance with the layer length and then dividing by the layer width.

- the ceramic material of the dielectric layers materials whose sintering temperature is between 950 and 1200 ° C. This has the advantage that a multiplicity of ceramic materials are available for the multilayer component according to the invention, which makes it possible to produce components with optimum ceramic properties.

- ceramic materials based on barium titanate are suitable for the dielectric layers.

- capacitors can be realized.

- COG so-called "COG” ceramic

- a so-called "COG” ceramic for the dielectric layers.

- Such a material would be, for example, a (Sm, Ba) NdTiO 3 ceramic.

- class 1 dielectrics so-called class 2 dielectrics such as X7R ceramics are also suitable.

- zinc oxide is suitable for the production of a varistor, optionally with doping of praseodymium or bismuth oxide.

- the multilayer component may be designed such that two juxtaposed multilayer varistors are contained therein.

- a ⁇ filter can be realized by such a device.

- Such ⁇ filters are based on the fact that multilayer varistors naturally also have not inconsiderable capacitance in addition to their varistor characteristic which is responsible for the attenuation behavior of such a filter.

- Such a ⁇ filter can be formed in the form of a component in which two stacks of superimposed electrode layers separated from one another by dielectric layers are arranged in the main body next to each other.

- the electrode layers of the first stack are alternately contacted with the first and second external contacts of a first pair of external contacts.

- the electrode layers of the second stack are also contacted alternately with the first and the second external contact of a second pair of external contacts.

- the ⁇ filter corresponding connection of the two multilayer components thus formed by a resistor is realized in that belonging to different pairs and lying on opposite side surfaces of the body external contacts are connected by a resistor.

- the external contacts of each pair lie on opposite side surfaces of the body.

- two external contacts are arranged on two opposite side surfaces of the base body. This corresponds to the so-called "feedthrough" embodiment of components.

- each of the stacks of electrode layers is part of a multilayer varistor.

- the two external contacts connecting resistor can be formed from the two varistors a ⁇ -filter.

- such a ⁇ filter Due to the increased coupling resistance, such a ⁇ filter has an improved damping behavior, whereby an entire frequency band extending between the two damping frequencies defined by the capacitances of the varistors can be attenuated.

- the component is formed symmetrically to a plane which runs parallel to a dielectric layer.

- a resistor is arranged above and below the stack. These resistors would then be connected in parallel.

- a symmetrical embodiment of the device has the advantage that it is in the assembly of the device On a printed circuit board, in particular in the case of high-frequency applications, it no longer matters whether the layer stack of the component with the lower side or with the upper side rests on the circuit board.

- the component according to the invention can be produced particularly advantageously by sintering a stack of superposed ceramic green sheets. This creates a monolithic, compact component that can be produced very quickly and easily in large quantities.

- the component according to the invention can be embodied in particular in a miniaturized form, the base area of the main body being less than 2.5 mm 2 .

- a base could be realized for example by a design of the body, in which the length is 1.25 mm and the width is 1.0 mm. This design is also known under the name "0405".

- FIG. 2 shows a multilayer component according to the invention in a schematic longitudinal section. It comprises a main body 1, which contains superimposed dielectric layers 2 in the form of a stack.

- the dielectric layers 2 contain a ceramic material. They are indicated in Figure 2 by the dotted lines.

- stacks 7, 8 of superimposed electrode layers 9 are contained in the main body 1. These stacks 7, 8 each form a varistor VDR1, VDR2.

- a resistor 41, 42 is arranged in each case.

- the resistors 41, 42 are formed from a structured layer 5 whose shape is apparent in particular from FIG. In FIG. 2, only individual sections of a meander can be seen in cross section.

- the symmetry of the device has particular advantages for applications in the high-frequency range, where it depends on the orientation of the components on the circuit board.

- a symmetrical design of the component means that it is not necessary to pay attention to the position of the component with respect to the plane of symmetry.

- FIG. 1 shows the section DD of the component in FIG. 2.

- FIG. 1 shows the shape of the resistor 41. It has the shape of a meander.

- the meander is formed by a web having the width b. In the example shown in FIG. 1, the width b is 50 ⁇ m .

- the length of the meander shown in FIG. 1 is approximately 4000 .mu.m . The length is determined by adding the lengths of the individual rectangles from which the meander can be composed. Accordingly, the embodiment of the invention according to Figure 1 with respect to the resistance of a ratio L / B of 80. This makes it possible to produce large resistances.

- the resistance shown in Figure 1 is about 3 ohms.

- the web shown in FIG. 1 is applied in the form of a structured layer 5, the layer thickness being approximately 2 ⁇ m .

- the resistor shown in Figure 1 is formed of a material containing a silver-palladium alloy, wherein palladium has a weight fraction of 30% of the alloy.

- the starting material of the resistor contains an organic substance and a solvent. These latter additives are contained only in the resistance material in order to apply the resistance in the form of a screen printing paste by means of a screen printing process on a ceramic layer can. These ingredients are removed by burnout during sintering. These are organic components.

- FIG. 1 also shows that the resistor 41 connects two external contacts 3 of the component to one another.

- FIG. 1 also shows that, in the plane shown in FIG. 1, apart from the resistor 41, there are no electrode layers belonging to a capacitor or to a varistor. Accordingly, the entire surface shown in FIG. 1 is available for filling with the meander forming a resistance.

- FIG. 3 shows the section EE of the component from FIG. 2.

- Several similar such electrode layers 9 are stacked in the device. Due to the varistor material arranged between the electrode layers 9, they each form a varistor VDR1, VDR2, which, however, also has a high capacitive component due to the large-area electrode layers 9 facing one another. From a combination of Figure 1 and Figure 3 it can be seen that the device according to the invention according to the specific embodiment is designed as a feed-through device.

- Each stack 7, 8 of electrode layers 9 is associated with a pair of external contacts 10, 11 and 12, 13, respectively.

- FIGS. 4 and 5 show the position of the external contacts 3. They are arranged on two opposite side surfaces of the main body 1.

- the plan view of Figure 4 shows that the external contacts 3 engage around on the top or corresponding to the underside of the base body 1.

- the component can be electrically conductively connected to a printed circuit board on the upper side or on the lower side by a surface mounting technique.

- FIG. 6 shows an equivalent circuit diagram of the component according to the invention shown in FIGS. 1 to 3. It can be seen that the two varistors VDR1, VDR2 are coupled together by a circuit resistor R to form a ⁇ -filter.

- the circuit resistance R results from a parallel connection of the two resistors 41, 42 of Figure 2. This results from the fact that the resistance 42 in Figure 2 looks exactly the same as the resistor 41 in Figure 1.

- Figure 6 are still the external contacts 3 of the device in detail denoted by reference numerals, so that the circuitry assignment of the physical external contacts of the device can take place.

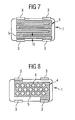

- Figures 7 and 8 show further embodiments of a resistor 4, as it could be used in place of the resistor 41 shown in Figure 1. Accordingly, Figure 7 shows a further meandering structure for the resistor 4.

- the layer 4 forming the resistor 4 is structured in the form of a meander.

- the meander is formed by a web with the width b, which may correspond to the width b of FIG.

- the meander in FIG. 7 does not run in the longitudinal direction of the main body 1, but in the transverse direction.

- a resistor 4 is shown, which is formed of a rectangular closed layer 5 by arranging recesses 6 in the layer 5. These recesses 6 may be circular, but they may also have other shapes, such as rectangles. By a uniform distribution of a plurality of recesses 6, the resistance of the originally rectangular layer 5 can be significantly increased. As an effect of the recesses 6 results in a plurality of multiply curved current paths between the external contacts 3, which have a high resistance.

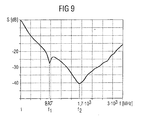

- FIG. 9 shows the insertion loss of the component shown in FIG. 2 or in FIG. 6.

- the insertion loss S is plotted in the unit dB over the frequency f [MHz].

- Resonance frequencies f 1 , f 2 are formed by the two capacitors C1, C2 contained in the varistors VDR1, VDR2. At the locations of the resonant frequencies f 1, f 2 the device exhibits an increased attenuation. Also between the resonant frequencies f 1 , f 2 , the device due to the ⁇ circuit realizing resistor R a very good attenuation, which is better than -20 dB in the frequency interval between 740 MHz and 2.7 GHz.

- the component is suitable for suppressing a frequency band which lies between the resonance frequencies f 1 (part of C1) and the resonance frequency f 2 (part of C2).

- the resistance R is 1.8 ⁇ in the embodiment shown in the figures.

Landscapes

- Engineering & Computer Science (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- Thermistors And Varistors (AREA)

- Fixed Capacitors And Capacitor Manufacturing Machines (AREA)

- Details Of Resistors (AREA)

- Coils Or Transformers For Communication (AREA)

- Control Of Motors That Do Not Use Commutators (AREA)

Abstract

Description

Die Erfindung betrifft ein elektrisches Vielschichtbauelement, was einen Grundkörper mit einem Stapel von übereinanderliegenden keramischen Dielektrikumschichten enthält. Darüber hinaus sind außen am Grundkörper Außenkontakte angeordnet. Im Innern des Grundkörpers ist ein Widerstand angeordnet, der mit den Außenkontakten verbunden ist.The invention relates to an electrical multilayer component, which contains a base body with a stack of superimposed ceramic dielectric layers. In addition, external contacts are arranged on the outside of the main body. In the interior of the base body, a resistor is arranged, which is connected to the external contacts.

Vielschichtbauelemente der eingangs genannten Art werden üblicherweise in der sogenannten Multilayer-Technologie hergestellt. Mit Hilfe dieser Technologie lassen sich beispielsweise Vielschichtvaristoren oder auch keramische Kondensatoren herstellen. Um diesen Bauelementen hinsichtlich ihrer Anwendung spezifische Eigenschaften zu verleihen, ist oftmals die Integration eines Widerstandes notwendig. Mittels eines solchen Widerstandes können beispielsweise Eigenschaften, wie das Frequenzverhalten, die Einfügedämpfung oder auch der Verlauf der Klemmenspannung bei einem in einen Varistor eingekoppelten elektrischen Puls in positiver Weise verändert werden. Die bekannten keramischen Bauelemente enthalten zusätzlich zu den Dielektrikumschichten noch elektrisch leitende Elektrodenschichten und bilden so einen Stapel von durch Dielektrikumschichten voneinander getrennten übereinanderliegenden Elektrodenschichten. Solche Stapel können beispielsweise Kondensatoren oder auch Varistoren bilden.Multi-layer devices of the type mentioned are usually produced in the so-called multilayer technology. For example, multilayer varistors or even ceramic capacitors can be produced with the aid of this technology. In order to give these components specific properties with regard to their application, the integration of a resistor is often necessary. By means of such a resistor, for example, properties such as the frequency response, the insertion loss or the course of the terminal voltage can be changed in a positive manner in an electrical pulse coupled into a varistor. The known ceramic components additionally contain electrically conductive electrode layers in addition to the dielectric layers and thus form a stack of superimposed electrode layers separated from one another by dielectric layers. Such stacks can form, for example, capacitors or even varistors.

Aus der Druckschrift US 5,889,445 sind Vielschichtbauelemente der eingangs genannten Art bekannt, bei denen an den beiden Stirnseiten und an zwei Längsseiten des Grundkörpers jeweils ein Außenkontakt angeordnet ist. Diese Bauelemente sind dem Fachmann auch bekannt unter dem Namen "Feedthrough-Bauelemente". Bei dem bekannten Bauelement sind Widerstände integriert, die in Form einer entlang einer rechteckförmigen Bahn aufgedruckten Widerstandspaste zwischen zwei Keramikschichten integriert sind. Sie verbinden einen Außenkontakt des Bauelements mit einer Elektrodenschicht, die zu einem im Bauelement ebenfalls integrierten Kondensator gehört. Die Widerstandsstruktur befindet sich in derselben Ebene wie die zum Aufbau einer Kapazität benötigten Innenelektroden. Dadurch werden gemäß dem Stand der Technik Reihenschaltungen von Kondensatoren und Widerständen in ein Vielschichtbauelement integriert.From the document US 5,889,445 multilayer components of the type mentioned are known in which an external contact is arranged in each case on the two end faces and on two longitudinal sides of the base body. These components are also known to the person skilled in the art under the name "feedthrough components". In the known device resistors are integrated, in the form of a printed along a rectangular path resistance paste between two ceramic layers are integrated. They connect an external contact of the component with an electrode layer which belongs to a capacitor which is likewise integrated in the component. The resistor structure is in the same plane as the internal electrodes needed to build up a capacitance. As a result, series circuits of capacitors and resistors are integrated into a multilayer component according to the prior art.

Der bekannte Widerstand hat den Nachteil, daß das den Widerstand bildende Material entlang einer breiten Bahn auf eine Dielektrikumschicht aufgedruckt ist. Dadurch ist es schwierig, große Widerstandswerte, wie sie normalerweise gewünscht werden, zu realisieren. Die Realisierung großer Widerstandswerte wird gemäß dem Stand der Technik dadurch ermöglicht, daß spezielle Widerstandspasten zur Anwendung gelangen. Diese speziellen Widerstandspasten haben jedoch den Nachteil, daß sie die üblicherweise bei der Herstellung von keramischen Bauelementen auftretenden hohen Sintertemperaturen > 1000°C nicht aushalten. Demnach ist gemäß dem Stand der Technik das Vielschichtbauelement eingeschränkt auf Keramikmaterialien, die mittels des sogenannten "LTCC-Sinterprozesses" gesintert werden können. Dabei handelt es sich um Keramikmaterialien, die bei niedrigen Temperaturen < 800°C gesintert werden können. Naturgemäß ist entsprechend dieser Anforderung die Auswahl an Keramikmaterialien stark eingeschränkt, was einen weiteren Nachteil des bekannten Vielschichtbauelements bedeutet.The known resistor has the disadvantage that the material forming the resistor is printed along a wide path on a dielectric layer. This makes it difficult to realize high resistance values as they are normally desired. The realization of high resistance values is made possible according to the prior art by using special resistor pastes. However, these special resistor pastes have the disadvantage that they can not withstand the high sintering temperatures usually occurring in the production of ceramic components> 1000 ° C. Accordingly, according to the prior art, the multilayer component is limited to ceramic materials which can be sintered by means of the so-called "LTCC sintering process". These are ceramic materials that can be sintered at low temperatures <800 ° C. Naturally, according to this requirement, the choice of ceramic materials is severely limited, which means a further disadvantage of the known multilayer component.

Aus DE 3125281 A1 ist eine elektrische Bauelementenkombination bekannt, bei die Deckfläche eines Vielschichtkondensators mit einer Widerstandsbahn versehen ist, die durch Materialabgleich auf den gewünschten Widerstandswert abgleichbar ist und aus einem Material besteht, dessen Temperaturkoeffizient im Hinblick zum Temperaturkoeffizient des Kondensators gegenläufig ist.From DE 3125281 A1 an electrical component combination is known in which the top surface of a multilayer capacitor is provided with a resistance track which can be adjusted to the desired resistance value by material balance and consists of a material whose temperature coefficient is opposite in terms of the temperature coefficient of the capacitor.

Ziel der vorliegenden Erfindung ist es daher, ein Vielschichtbauelement anzugeben, das eine hohe Flexibilität bei der Integration von Widerständen in Vielschichtbauelemente ermöglicht.The aim of the present invention is therefore to provide a multilayer component which allows a high degree of flexibility in the integration of resistors in multilayer components.

Dieses Ziel wird erfindungsgemäß durch ein elektrisches Vielschichtbauelement nach Patentanspruch 1 erreicht. Weitere Ausgestaltungen der Erfindung sind den abhängigen Patentansprüchen zu entnehmen.This object is achieved by an electric multilayer component according to

Die Erfindung ist mit den merkmale des Anspruchs 1 definiert und gibt ein elektrisches Vielschichtbauelement an, das einen Grundkörper umfaßt, welcher einen Stapel von übereinanderliegenden keramischen Dielektrikumschichten enthält. Außen am Grundkörper sind wenigstens zwei Außenkontakte angeordnet. Im Innern des Grundkörpers ist zwischen zwei Dielektrikumschichten ein Widerstand angeordnet, der mit zwei der Außenkontakte Kontaktiert ist. Der Widerstand hat die Form einer strukturierten Schicht, welche wenigstens eine mehrfach gekrümmte Bahn als Strompfad zwischen den Außenkontakten bildet.The invention is defined by the features of

Das erfindungsgemäße Vielschichtbauelement hat den Vorteil, daß aufgrund der Strukturierung der den Widerstand bildenden Schicht eine größere Auswahl bei den zu realisierenden Widerstandswerten besteht und daß insbesondere relativ große Widerstandswerte erzielt werden können.The multilayer component according to the invention has the advantage that, owing to the structuring of the layer forming the resistance, there is a greater choice in the resistance values to be realized, and in particular relatively large resistance values can be achieved.

Bei in Form von gedruckten Bahnen entsprechend der Leiterbahnen-Technologie hergestellten Widerständen kommt es insbesondere auf das Verhältnis von Länge der Bahn zu Breite der Bahn an. Je länger die Bahn ist, desto größer ist auch ihr Widerstand. Umgekehrt gilt, daß mit sinkender Breite der Bahn der Widerstand ansteigt. Ein großes Verhältnis Länge/Breite ist also günstig für die Realisierung eines großen Widerstands. Durch die Ausführung des Widerstands in Form einer strukturierten Schicht kann nun der - insbesondere bei kleinen Bauelement-Größen - zwischen den beiden Außenkontakten nur begrenzt zur Verfügung stehende Platz optimal zur Bildung eines großen Widerstands benutzt werden. Demgegenüber würde eine nicht gekrümmte, lediglich geradlinig zwischen den beiden Außenkontakten verlaufende Widerstandsbahn nur einen sehr kleinen Widerstand erlauben. Zwar wäre es möglich, durch Verändern der Bahnbreite, insbesondere durch Verringerung der Bahnbreite, den Widerstand abzusenken. Jedoch würde eine zu geringe Bahnbreite bedeuten, daß auch die Stromtragfähigkeit des Widerstands gering ist, so daß der Widerstand bei einer entsprechend der Anwendung des Vielschichtbauelements auftretenden pulsartigen Hochstrombelastung oder auch bei dauerhafter Gleichstrombelastung durchschmelzen würde.In the case of resistors produced in the form of printed tracks in accordance with the printed conductor technology, the ratio of the length of the web to the width of the web is particularly important. The longer the train is, the greater its resistance. Conversely, with decreasing width of the track, the resistance increases. A large ratio length / width is therefore favorable for the realization of a large resistance. By carrying out the resistor in the form of a structured layer, the space which is available only to a limited extent between the two external contacts, in particular for small component sizes, can now be optimally used to form a large resistor. In contrast, a non-curved, only rectilinearly extending between the two external contacts resistance path would allow only a very small resistance. Although it would be possible to lower the resistance by changing the web width, in particular by reducing the web width. However, too small a web width would mean that the current carrying capacity of the resistor is low, so that the resistance at a would melt according to the application of the multilayer component occurring pulsed high current load or even with permanent DC load.

In einer weiteren vorteilhaften Ausführungsform der Erfindung ist der Widerstand in einer Ebene des Vielschichtbauelements angeordnet, die frei von elektrisch leitenden Elektrodenschichten ist. Dies bedeutet, daß die gesamte Fläche einer Ebene des Vielschichtbauelements für die Ausbildung des Widerstands zur Verfügung steht. Zusammen mit der mehrfach gekrümmten Bahn kann somit eine optimal große Fläche für die Realisierung eines besonders hohen Widerstands zur Verfügung gestellt werden.In a further advantageous embodiment of the invention, the resistor is arranged in a plane of the multilayer component which is free of electrically conductive electrode layers. This means that the entire area of one plane of the multilayer component is available for the formation of the resistor. Together with the multi-curved path can thus be provided an optimally large area for the realization of a particularly high resistance.

Das erfindungsgemäße Vielschichtbauelement erlaubt aufgrund der strukturierten Schicht für den Widerstand das Gemeinsamsintern der Dielektrikumschichten mit dem Widerstand in einem einzigen Schritt. Dadurch kann ein monolithischer Körper gebildet werden, wie er für die Verwendung in der Multilayer-Technologie üblich ist und welcher die üblichen Vorteile aufweist.The multilayer device of the invention, because of the patterned layer for the resistor, allows the internal sintering of the dielectric layers with the resistor in a single step. Thereby, a monolithic body can be formed, as it is common for use in multilayer technology and which has the usual advantages.

In Bezug auf die Erzielung besonders großer Widerstände ist es desweiteren vorteilhaft, wenn der Widerstand zwischen den Außenkontakten in Form einer Bahn verläuft, deren Länge mindestens zehnmal größer ist als deren Breite.With regard to the achievement of particularly large resistors, it is furthermore advantageous if the resistance between the external contacts runs in the form of a web whose length is at least ten times greater than its width.

Der Widerstand kann in einer Ausführungsform der Erfindung aus einer geschlossenen Widerstandsschicht gebildet sein, die nachträglich mit Aussparungen versehen ist. Dadurch kann der geradlinige Strompfad zwischen den Außenkontakten unterbrochen werden und der Strom auf mehrmals gekrümmte Bahnen gezwungen werden. Dadurch läßt sich ein hoher Widerstand erzielen.The resistor may be formed in one embodiment of the invention of a closed resistance layer, which is subsequently provided with recesses. As a result, the rectilinear current path between the external contacts can be interrupted and the current forced to multiple curved paths. As a result, a high resistance can be achieved.

In einer weiteren Ausführungsform der Erfindung kann der Widerstand auch als mäanderförmige Bahn ausgeführt sein. Eine mäanderförmige Bahn mit einer Vielzahl von Windungen erlaubt die Realisierung eines sehr langen Strompfads entlang der Längsrichtung des Mäanders. Insbesondere kann durch eine Vielzahl von aufeinanderfolgenden, in entgegengesetzte Richtungen ausgeführte Krümmungen ein großer Widerstand realisiert werden.In a further embodiment of the invention, the resistor can also be designed as a meandering path. A meandering path with a plurality of turns allows the realization of a very long current path along the longitudinal direction of the meander. In particular, a large amount of resistance can be realized by a plurality of successive bends made in opposite directions.

Das Widerstandsmaterial kann beispielsweise eine Legierung aus Silber und Palladium enthalten, wobei Palladium einen Gewichtsanteil von 15 bis zu < 100 % an der Legierung aufweist. Es kann auch reines Palladium verwendet werden. Solche Materialien sind in der Multilayer-Technologie bei der Herstellung von Vielschichtbauelementen bekannt. Bislang wurden aus diesen Materialien jedoch lediglich Elektrodenschichten hergestellt, bei denen es auf eine gute Leitfähigkeit ankommt. Diese Materialien haben den Vorteil, daß sie mit einer Vielzahl von Keramikmaterialien gemeinsam sinterbar sind. Sie weisen zwar keinen ausgesprochen hohen Widerstand auf, durch die erfindungsgemäße Strukturierung kann jedoch der Widerstand hinreichend erhöht werden.The resistive material may include, for example, an alloy of silver and palladium, wherein palladium has a weight fraction of 15 to <100% of the alloy. Pure palladium can also be used. Such materials are known in multilayer technology in the manufacture of multilayer devices. So far, however, only electrode layers were made from these materials, where it depends on a good conductivity. These materials have the advantage that they are sintered together with a variety of ceramic materials. Although they do not have a very high resistance, but the structuring according to the invention, the resistance can be sufficiently increased.

Besonders vorteilhaft ist es, wenn das Widerstandsmaterial eine Legierung aus Silber und Palladium enthält, wobei Palladium einen Gewichtsanteil zwischen 50 und 70 % an der Legierung aufweist. Durch den hohen Palladiumanteil kann aufgrund der gegenüber Silber schlechteren Leitfähigkeit von Palladium der Widerstand etwa um den Faktor drei erhöht werden.It is particularly advantageous if the resistance material contains an alloy of silver and palladium, wherein palladium has a weight fraction of between 50 and 70% of the alloy. Due to the high palladium content, the resistance can be increased approximately by a factor of three because of the poorer conductivity of palladium compared to silver.

Desweiteren kann der Widerstand dadurch erhöht werden, daß der Widerstand aus einem Widerstandsmaterial gebildet ist, das in der strukturierten Schicht einen Flächenwiderstand von mindestens 0,1 Ohm aufweist.Furthermore, the resistance can be increased by forming the resistor from a resistive material having a sheet resistance of at least 0.1 ohms in the patterned layer.

Der Widerstand des Widerstandsmaterials kann zum Beispiel erhöht werden, indem das Widerstandsmaterial neben einer elektrisch leitenden Komponente noch Zusatzstoffe in einem Anteil von bis zu 70 Vol.-% beigefügt werden. Solche Zusatzstoffe können einen spezifischen Widerstand haben, der wenigstens zehnmal größer ist als der spezifische Widerstand der leitenden Komponente. Dabei ist darauf zu achten, daß die leitenden Bestandteile nicht isoliert in einer Matrix von isolierenden Zusatzstoffen liegen, da dann überhaupt keine Leitfähigkeit mehr vorhanden wäre.The resistance of the resistance material can be increased, for example, by adding the resistance material in addition to an electrically conductive component nor additives in an amount of up to 70 vol .-%. Such additives may have a resistivity at least ten times greater than the resistivity of the conductive component. It is important to ensure that the conductive components are not isolated in a matrix of insulating additives, because then no conductivity at all would be available.

Als Zusatzstoff kommt beispielsweise Aluminiumoxid (Al2O3) in Betracht.As additive, for example, aluminum oxide (Al 2 O 3 ) into consideration.

Eine Legierung von Silber und Palladium mit einem Gewichtsverhältnis Ag/Pd = 70/30 weist für eine Schicht der Dicke 2 µm einen Flächenwiderstand von 0,04 Ω auf. Der Flächenwiderstand ist dabei der spezifische Widerstand des Material dividiert durch die Dicke einer zu betrachtenden Schicht in Form eines Rechtecks. Der Widerstand der Schicht ergibt sich dann durch Multiplikation des Flächenwiderstands mit der Schichtlänge und anschließende Division durch die Schichtbreite. Durch das Herstellen eines Widerstandsmaterials, das 70 Vol.% Al2O3 und 30 Vol.-% der genannten Legierung enthält, kann der Flächenwiderstand von 0,04 auf 0,12 Ω erhöht werden.An alloy of silver and palladium having a weight ratio Ag / Pd = 70/30 has a sheet resistance of 0.04 Ω for a layer of

Bei der Verwendung eines geeigneten Widerstandsmaterials, ist es möglich, für das Keramikmaterial der Dielektrikumschichten Materialien zu verwenden, deren Sintertemperatur zwischen 950 und 1200°C liegt. Dies hat den Vorteil, daß für das erfindungsgemäße Vielschichtbauelement eine Vielzahl von Keramikmaterialien zur Verfügung steht, wodurch es ermöglicht wird, Bauelemente mit optimalen keramischen Eigenschaften herzustellen.When using a suitable resistance material, it is possible to use for the ceramic material of the dielectric layers materials whose sintering temperature is between 950 and 1200 ° C. This has the advantage that a multiplicity of ceramic materials are available for the multilayer component according to the invention, which makes it possible to produce components with optimum ceramic properties.

Beispielsweise kommen für die Dielektrikumschichten Keramikmaterialien auf der Basis von Bariumtitanat in Betracht. Mit Hilfe solcher Keramikmaterialien können beispielsweise Kondensatoren realisiert werden.For example, ceramic materials based on barium titanate are suitable for the dielectric layers. With the help of such ceramic materials, for example, capacitors can be realized.

Desweiteren kommt es in Betracht, für die Dielektrikumschichten eine sogenannte "COG"-Keramik zu verwenden. Ein solches Material wäre beispielsweise eine (Sm, Ba) NdTiO3-Keramik. Neben diesen Klasse 1 Dielektrika kommen auch sog. Klasse 2 Dielektrika, wie z.B. X7R-Keramiken in Betracht.Furthermore, it is possible to use a so-called "COG" ceramic for the dielectric layers. Such a material would be, for example, a (Sm, Ba) NdTiO 3 ceramic. In addition to these

Für die Herstellung eines Varistors ist insbesondere Zinkoxid geeignet, gegebenenfalls mit Dotierungen von Praseodym oder Wismutoxid.In particular, zinc oxide is suitable for the production of a varistor, optionally with doping of praseodymium or bismuth oxide.

Es besteht desweiteren der Bedarf, die genannten keramischen Bauelemente mit sehr kleinen äußeren Abmessungen herzustellen. Dies erschwert die Realisierung großer Widerstände zusätzlich, da nur sehr kurze geradlinige Widerstandsbahnen dadurch ermöglicht werden. Durch die erfindungsgemäßen Struktur des Widerstands können jedoch hinreichend hohe Werte erzielt werden.There is also the need to produce said ceramic components with very small external dimensions. This complicates the realization of large resistors in addition, since only very short rectilinear resistance paths are made possible thereby. Due to the inventive structure of the resistor, however, sufficiently high values can be achieved.

In einer speziellen Ausführungsform der Erfindung kann das Vielschichtbauelement so gestaltet sein, daß zwei nebeneinanderliegende Vielschichtvaristoren darin enthalten sind. Durch geeignete Anordnung eines oder mehrerer Widerstände kann durch ein solches Bauelement ein π-Filter realisiert werden. Solche π-Filter beruhen darauf, daß Vielschichtvaristoren naturgemäß neben ihrer Varistoreigenschaft auch noch eine nicht unerhebliche Kapazität aufweisen, die für das Dämpfungsverhalten eines solchen Filters verantwortlich ist.In a specific embodiment of the invention, the multilayer component may be designed such that two juxtaposed multilayer varistors are contained therein. By suitable arrangement of one or more resistors, a π filter can be realized by such a device. Such π filters are based on the fact that multilayer varistors naturally also have not inconsiderable capacitance in addition to their varistor characteristic which is responsible for the attenuation behavior of such a filter.

Eines solches π-Filter kann gebildet sein in Form eines Bauelements, bei dem im Grundkörper nebeneinander zwei Stapel von jeweils übereinanderliegenden durch Dielektrikumschichten voneinander getrennten Elektrodenschichten angeordnet sind. Die Elektrodenschichten des ersten Stapels sind abwechselnd mit dem ersten und dem zweiten Außenkontakt eines ersten Paares von Außenkontakten kontaktiert. Durch diese abwechselnde Kontaktierung können kammartig ineinandergreifende Elektrodenstrukturen realisiert werden, die beispielsweise zur Erzielung von hohen Kapazitäten erforderlich sind. Entsprechend dem ersten Stapel sind auch die Elektrodenschichten des zweiten Stapels abwechselnd mit dem ersten und dem zweiten Außenkontakt eines zweiten Paares von Außenkontakten kontaktiert.Such a π filter can be formed in the form of a component in which two stacks of superimposed electrode layers separated from one another by dielectric layers are arranged in the main body next to each other. The electrode layers of the first stack are alternately contacted with the first and second external contacts of a first pair of external contacts. By this alternating contact comb-like interdigitated electrode structures can be realized, for example, to achieve of high capacities are required. According to the first stack, the electrode layers of the second stack are also contacted alternately with the first and the second external contact of a second pair of external contacts.

Die einem π-Filter entsprechende Verbindung der beiden so gebildeten Vielschichtbauelemente durch einen Widerstand wird dadurch realisiert, daß zu verschiedenen Paaren gehörende und auf einander gegenüberliegenden Seitenflächen des Grundkörpers liegende Außenkontakte durch einen Widerstand verbunden sind. Die Außenkontakte eines jeden Paares liegen dabei aufeinander gegenüberliegenden Seitenflächen des Grundkörpers. Insgesamt sind also auf zwei gegenüberliegenden Seitenflächen des Grundkörpers jeweils zwei Außenkontakte angeordnet. Dies entspricht der sogenannten "Feedthrough"-Ausführungsform von Bauelementen.The π filter corresponding connection of the two multilayer components thus formed by a resistor is realized in that belonging to different pairs and lying on opposite side surfaces of the body external contacts are connected by a resistor. The external contacts of each pair lie on opposite side surfaces of the body. Overall, in each case two external contacts are arranged on two opposite side surfaces of the base body. This corresponds to the so-called "feedthrough" embodiment of components.

Indem die Dielektrikumschichten wenigstens teilweise eine Varistorkeramik enthalten, kann dafür gesorgt werden, daß jeder der Stapel von Elektrodenschichten Teil eines Vielschichtvaristors ist. Durch den zwei Außenkontakte verbindenden Widerstand kann aus den beiden Varistoren ein π-Filter gebildet werden.By virtue of the dielectric layers at least partially containing a varistor ceramic, it can be ensured that each of the stacks of electrode layers is part of a multilayer varistor. By the two external contacts connecting resistor can be formed from the two varistors a π-filter.

Ein solches π-Filter weist aufgrund des erhöhten Kopplungswiderstands ein verbessertes Dämpfungsverhalten auf, wobei ein ganzes Frequenzband, das zwischen den beiden durch die Kapazitäten der Varistoren definierten Dämpfungsfrequenzen verläuft, bedämpft werden kann.Due to the increased coupling resistance, such a π filter has an improved damping behavior, whereby an entire frequency band extending between the two damping frequencies defined by the capacitances of the varistors can be attenuated.

Desweiteren ist es vorteilhaft, wenn das Bauelement symmetrisch zu einer Ebene ausgebildet ist, die parallel zu einer Dielektrikumschicht verläuft. Dafür ist es erforderlich, daß beispielsweise oberhalb und unterhalb der Stapel jeweils ein Widerstand angeordnet ist. Diese Widerstände wären dann parallel zu schalten. Eine symmetrische Ausführungsform des Bauelements hat den Vorteil, daß es bei der Montage des Bauelements auf einer Leiterplatte insbesondere im Fall von Hochfrequenzanwendungen nicht mehr darauf ankommt, ob der Schichtstapel des Bauelements mit der- Unterseite oder mit der Oberseite auf der Leiterplatte aufliegt.Furthermore, it is advantageous if the component is formed symmetrically to a plane which runs parallel to a dielectric layer. For this it is necessary that, for example, a resistor is arranged above and below the stack. These resistors would then be connected in parallel. A symmetrical embodiment of the device has the advantage that it is in the assembly of the device On a printed circuit board, in particular in the case of high-frequency applications, it no longer matters whether the layer stack of the component with the lower side or with the upper side rests on the circuit board.

Das erfindungsgemäße Bauelement kann besonders vorteilhaft durch Sintern eines Stapels von übereinanderliegenden keramischen Grünfolien hergestellt sein. Dadurch entsteht ein monolithisches, kompaktes Bauelement, das sehr schnell und einfach in großen Stückzahlen hergestellt werden kann.The component according to the invention can be produced particularly advantageously by sintering a stack of superposed ceramic green sheets. This creates a monolithic, compact component that can be produced very quickly and easily in large quantities.

Das erfindungsgemäße Bauelement kann insbesondere in einer miniaturisierten Form ausgeführt sein, wobei die Grundfläche des Grundkörpers weniger als 2,5 mm2 beträgt. Eine solche Grundfläche ließe sich beispielsweise durch eine Bauform des Grundkörpers realisieren, bei der die Länge 1,25 mm und die Breite 1,0 mm beträgt. Diese Bauform ist auch unter dem Namen "0405" bekannt.The component according to the invention can be embodied in particular in a miniaturized form, the base area of the main body being less than 2.5 mm 2 . Such a base could be realized for example by a design of the body, in which the length is 1.25 mm and the width is 1.0 mm. This design is also known under the name "0405".

Im folgenden wird die Erfindung anhand von Ausführungsbeispielen und den dazugehörigen Figuren näher erläutert:

Figur 1- zeigt den Schnitt

D-D aus Figur 2. Figur 2- zeigt einen Längsschnitt durch ein erfindungsgemäßes Bauelement.

Figur 3- zeigt den Schnitt

E-E aus Figur 2. - Figur 4

- zeigt eine Draufsicht des Bauelements aus Figur 2.

Figur 5- zeigt eine Seitenansicht des Bauelements aus Figur 2.

Figur 6- zeigt ein Ersatzschaltbild für das

Bauelement aus Figur 2. - Figur 7

- 10 zeigt eine weitere mögliche Ausführungsform für den in

Figur 1 dargestellten Widerstand. - Figur 8

- zeigt eine weitere mögliche Ausführungsform für den in

den Figuren 1 und 7 dargestellten Widerstand. Figur 9- zeigt schematisch das Dämpfungsverhalten eines Bau-elements gemäß

Figur 2.

- FIG. 1

- shows the section DD of Figure 2.

- FIG. 2

- shows a longitudinal section through a device according to the invention.

- FIG. 3

- shows the section EE of Figure 2.

- FIG. 4

- shows a plan view of the device of Figure 2.

- FIG. 5

- shows a side view of the device of Figure 2.

- FIG. 6

- shows an equivalent circuit diagram for the device of Figure 2.

- FIG. 7

- 10 shows another possible embodiment for the resistor shown in FIG.

- FIG. 8

- shows a further possible embodiment for the resistor shown in Figures 1 and 7.

- FIG. 9

- schematically shows the damping behavior of a building element according to Figure 2.

Für alle Figuren gilt, daß gleiche Bezugszeichen auch gleiche Elemente bezeichnen.For all figures, the same reference numerals also designate the same elements.

Figur 2 zeigt ein erfindungsgemäßes Vielschichtbauelement im schematischen Längsschnitt. Es umfaßt einen Grundkörper 1, der übereinanderliegende Dielektrikumschichten 2 in Form eines Stapels enthält. Die Dielektrikumschichten 2 enthalten ein Keramikmaterial. Sie sind in Figur 2 durch die gepunkteten Linien angedeutet. In dem Grundkörper 1 sind darüber hinaus Stapel 7, 8 von übereinanderliegenden Elektrodenschichten 9 enthalten. Diese Stapel 7, 8 bilden jeweils einen Varistor VDR1, VDR2. Oberhalb und unterhalb der Varistoren VDR1, VDR2 ist jeweils ein Widerstand 41, 42 angeordnet. Die Widerstände 41, 42 sind aus einer strukturierten Schicht 5 gebildet, deren Form insbesondere aus Figur 1 hervorgeht. In Figur 2 sind lediglich einzelne Streckenabschnitte eines Mäanders im Querschnitt erkennbar. Das in Figur 2 gezeigte Bauelement ist symmetrisch zu einer Ebene 14 ausgebildet, die parallel zu den Dielektrikumschichten 2 verläuft. Durch die Symmetrie hat das Bauelement insbesondere Vorteile für Anwendungen im Hochfrequenz-Bereich, wo es auf die Orientierung der Bauelemente auf der Leiterplatte ankommt. Eine symmetrische Ausführung des Bauelements bedeutet, daß auf die Lage des Bauelements bezüglich der Symmetrieebene nicht geachtet werden muß.FIG. 2 shows a multilayer component according to the invention in a schematic longitudinal section. It comprises a

Figur 1 zeigt den Schnitt D-D des Bauelements in Figur 2.FIG. 1 shows the section DD of the component in FIG. 2.

In Figur 1 ist gezeigt, welche Form der Widerstand 41 aufweist. Er weist die Form eines Mäanders auf. Der Mäander wird geformt durch eine Bahn, die die Breite b aufweist. In dem in Figur 1 gezeigten Beispiel beträgt die Breite b 50 µm. Die Länge des in Figur 1 gezeigten Mäanders beträgt zirka 4000 µm. Die Länge wird dabei bestimmt durch Addition der Längen der einzelnen Rechtecke, aus denen der Mäander zusammengesetzt gedacht sein kann. Demnach weist die Ausführungsform der Erfindung gemäß Figur 1 bezüglich des Widerstands ein Verhältnis L/B von 80 auf. Dadurch lassen sich große Widerstände herstellen. Der in Figur 1 gezeigte Widerstand beträgt ca. 3 Ohm. Die in Figur 1 gezeigte Bahn ist in Form einer strukturierten Schicht 5 aufgetragen, wobei die Schichtdicke ca. 2 µm beträgt. Der in Figur 1 gezeigte Widerstand ist gebildet aus einem Material, das eine Silber-Palladium-Legierung enthält, wobei Palladium einen Gewichtsanteil von 30 % an der Legierung hat. Zudem enthält das Ausgangsmaterial des Widerstands noch eine organische Substanz und ein Lösungsmittel. Diese letztgenannten Zusätze sind lediglich in dem Widerstandsmaterial enthalten, um den Widerstand in Form einer Siebdruckpaste mit Hilfe eines Siebdruckverfahrens auf eine Keramikschicht aufbringen zu können. Diese Bestandteile werden während des Sinterns durch Ausbrennen entfernt. Es handelt sich dabei um organische Bestandteile.FIG. 1 shows the shape of the

Figur 1 ist noch zu entnehmen, daß der Widerstand 41 zwei Außenkontakte 3 des Bauelements miteinander verbindet.FIG. 1 also shows that the

Figur 1 ist weiterhin zu entnehmen, daß in der in Figur 1 gezeigten Ebene neben dem Widerstand 41 keine Elektrodenschichten, die zu einem Kondensator oder zu einem Varistor gehören, enthalten sind. Demnach steht die gesamte in Figur 1 gezeigte Fläche zur Ausfüllung mit dem einen Widerstand bildenden Mäander zur Verfügung.FIG. 1 also shows that, in the plane shown in FIG. 1, apart from the

Figur 3 zeigt den Schnitt E-E des Bauelements aus Figur 2. In Figur 3 ist auf der linken Seite eine Elektrodenschicht 9 eines Stapels 7 von Elektrodenschichten 9 und auf der rechten Seite eine Elektrodenschicht 9 eines Stapels 8 von Elektrodenschichten 9 zu sehen. Mehrere gleichartige solche Elektrodenschichten 9 sind in dem Bauelement übereinandergestapelt. Sie bilden aufgrund des zwischen den Elektrodenschichten 9 angeordneten Varistormaterials jeweils einen Varistor VDR1, VDR2, der jedoch aufgrund der großflächigen einander gegenüberstehenden Elektrodenschichten 9 auch einen hohen kapazitiven Anteil aufweist. Aus einer Zusammenschau von Figur 1 und Figur 3 ist ersichtlich, daß das erfindungsgemäße Bauelement gemäß dem speziellen Ausführungsbeispiel als Feedthrough-Bauelement ausgeführt ist. Jedem Stapel 7, 8 von Elektrodenschichten 9 ist ein Paar von Außenkontakten 10, 11 beziehungsweise 12, 13 zugeordnet. Innerhalb eines Stapels 7, 8 von Elektrodenschichten 9 erfolgt die Kontaktierung der Elektrodenschichten 9 mit den Außenkontakten 10, 11 beziehungsweise 12, 13 abwechselnd. Eine schaltungstechnische Kopplung der durch die Stapel 7, 8 gebildeten Varistoren erfolgt durch den Widerstand 41 beziehungsweise 42, wie aus Figur 1 beziehungsweise Figur 2 ersichtlich.FIG. 3 shows the section EE of the component from FIG. 2. In FIG. 3, on the left side, an

Den Figuren 4 und 5 ist die Lage der Außenkontakte 3 zu entnehmen. Sie sind an zwei gegenüberliegenden Seitenflächen des Grundkörpers 1 angeordnet. Die Draufsicht von Figur 4 zeigt, daß die Außenkontakte 3 auch auf die Oberseite beziehungsweise entsprechend auf die Unterseite des Grundkörpers 1 umgreifen. Dadurch kann das Bauelement auf der Oberseite oder auf der Unterseite durch eine Oberflächenmontagetechnik mit einer Leiterplatte elektrisch leitend verbunden werden.FIGS. 4 and 5 show the position of the

Figur 6 zeigt ein Ersatzschaltbild des in den Figuren 1 bis 3 gezeigten erfindungsgemäßen Bauelements. Dabei ist ersichtlich, daß die beiden Varistoren VDR1, VDR2 durch einen schaltungstechnischen Widerstand R miteinander zu einem π-Filter verkoppelt sind. Der schaltungstechnische Widerstand R ergibt sich dabei durch eine Parallelschaltung der beiden Widerstände 41, 42 aus Figur 2. Dies ergibt sich daraus, daß der Widerstand 42 in Figur 2 genauso aussieht, wie der Widerstand 41 entsprechend Figur 1. In Figur 6 sind noch die Außenkontakte 3 des Bauelements im einzelnen mit Bezugszeichen bezeichnet, so daß die schaltungstechnische Zuordnung der physikalischen Außenkontakte des Bauelements erfolgen kann.FIG. 6 shows an equivalent circuit diagram of the component according to the invention shown in FIGS. 1 to 3. It can be seen that the two varistors VDR1, VDR2 are coupled together by a circuit resistor R to form a π-filter. The circuit resistance R results from a parallel connection of the two

Die Figuren 7 und 8 zeigen weitere Ausführungsformen für einen Widerstand 4, wie er anstelle des in Figur 1 gezeigten Widerstandes 41 zum Einsatz kommen könnte. Demnach zeigt Figur 7 eine weitere Mäanderstruktur für den Widerstand 4. Dabei ist die den Widerstand 4 bildende Schicht 5 in der Form eines Mäanders strukturiert. Der Mäander wird gebildet durch eine Bahn mit der Breite b, die der Breite b aus Figur 1 entsprechen kann. Im Unterschied zu Figur 1 verläuft der Mäander in Figur 7 nicht in Längsrichtung des Grundkörpers 1, sondern in Querrichtung.Figures 7 and 8 show further embodiments of a resistor 4, as it could be used in place of the

In Figur 8 ist ein Widerstand 4 gezeigt, der aus einer rechteckförmigen geschlossenen Schicht 5 gebildet ist durch Anordnen von Ausnehmungen 6 in der Schicht 5. Diese Ausnehmungen 6 können kreisförmig sein, sie können jedoch auch andere Formen, wie beispielsweise Rechtecke aufweisen. Durch eine gleichmäßige Verteilung einer Vielzahl von Aussparungen 6 kann der Widerstand der ursprünglich rechteckförmigen Schicht 5 deutlich erhöht werden. Als Effekt der Aussparungen 6 ergibt sich eine Vielzahl von mehrfach gekrümmten Strompfaden zwischen den Außenkontakten 3, die einen hohen Widerstand aufweisen.In Figure 8, a resistor 4 is shown, which is formed of a rectangular

Figur 9 zeigt die Einfügedämpfung des in Figur 2 beziehungsweise in Figur 6 dargestellten Bauelements. Die Einfügedämpfung S ist in der Einheit dB über der Frequenz f[MHz] aufgetragen. Durch die beiden in den Varistoren VDR1, VDR2 enthaltenen Kapazitäten C1, C2 werden Resonanzfrequenzen f1, f2 gebildet. An den Stellen der Resonanzfrequenzen f1, f2 zeigt das Bauelement eine erhöhte Dämpfung. Auch zwischen den Resonanzfrequenzen f1, f2 weist das Bauelement aufgrund des die π-Schaltung realisierenden Widerstands R eine sehr gute Dämpfung auf, die im Frequenzintervall zwischen 740 MHz und 2,7 GHz besser als -20 dB ist. Dadurch ist das Bauelement zum Entstören eines Frequenzbandes geeignet, welches zwischen den Resonanzfrequenzen f1 (gehört zu C1) und der Resonanzfrequenz f2 (gehört zu C2) liegt. Die Resonanzfrequenzen f1 und f2 werden definiert durch die Kapazitäten C1 und C2 der Varistoren VDR1 und VDR2, welche durch Umrechnung der Frequenzen zu C1 = 40 pF und C2 = 20 pF bestimmt werden können. Der Widerstand R beträgt bei dem in den Figuren gezeigten Ausführungsbeispiel 1,8 Ω.FIG. 9 shows the insertion loss of the component shown in FIG. 2 or in FIG. 6. The insertion loss S is plotted in the unit dB over the frequency f [MHz]. Resonance frequencies f 1 , f 2 are formed by the two capacitors C1, C2 contained in the varistors VDR1, VDR2. At the locations of the resonant frequencies f 1, f 2 the device exhibits an increased attenuation. Also between the resonant frequencies f 1 , f 2 , the device due to the π circuit realizing resistor R a very good attenuation, which is better than -20 dB in the frequency interval between 740 MHz and 2.7 GHz. As a result, the component is suitable for suppressing a frequency band which lies between the resonance frequencies f 1 (part of C1) and the resonance frequency f 2 (part of C2). The resonance frequencies f 1 and f 2 are defined by the capacitances C1 and C2 of the varistors VDR1 and VDR2, which can be determined by converting the frequencies to C1 = 40 pF and C2 = 20 pF. The resistance R is 1.8 Ω in the embodiment shown in the figures.

Claims (18)

- Electrical multilayer component with- a base body (1) containing a stack of ceramic dielectric layers (2) lying one on top of the other,- two external contacts (3) arranged on the outside of the base body (1),- electrode layers (9) forming, together with the dielectric layers, at least one capacitance,- a resistor (4, 41, 42) arranged between two dielectric layers (3) inside the base body (1),characterized in that the resistor is contacted with the external contacts (3) and comprises the form of a structured layer (5) forming at least one multiply curved path as a current path between the external contacts.

- Component according to Claim 1,

wherein the dielectric layers (2) and the resistor (4, 41, 42) are sintered together in a single sintering step and form a monolithic body. - Component according to either of Claims 1 and 2,

wherein electrode layers (9) are arranged in the base body (1) and wherein the plane of the resistor (4, 41, 42) is free of electrode layers (9). - Component according to one of Claims 1 to 3,

wherein the resistor (4) runs between the external contacts (3) in the form of a path whose length is at least ten times larger than its width (b). - Component according to one of Claims 1 to 4,

wherein the resistor (4, 41, 42) is formed from a closed layer (5) provided with recesses (6). - Component according to one of Claims 1 to 4,

wherein the resistor (4, 41, 42) comprises the form of a meander. - Component according to one of Claims 1 to 6,

wherein the resistor (4, 41, 42) is formed from a resistance material having a sheet resistance of at least 0.1 ohm in the structured layer (5). - Component according to one of Claims 1 to 6,

wherein the resistor (4, 41, 42) is formed from a resistance material containing an alloy of silver and palladium, the palladium having a proportion of 15 to < 100% by weight of the alloy. - Component according to Claim 8,

wherein the proportion of palladium is between 50 and 70% by weight. - Component according to one of Claims 1 to 8,

wherein the resistance material additionally contains up to 70% by volume of an additive having a resistivity at least ten times larger than the resistivity of the other constituents of the resistance material. - Component according to Claim 10,

wherein the additive contains Al2O3. - Component according to one of Claims 1 to 11,

wherein the dielectric layers (2) contain a ceramic material whose sintering temperature is between 950 and 1200°C. - Component according to Claim 12,

wherein the dielectric layers (2) contain a ceramic based on BaTiO3. - Component according to Claim 12,

wherein the dielectric layers (2) contain a varistor ceramic. - Component according to one of Claims 1 to 14,- wherein two stacks (7, 8) of electrode layers (9), which respectively lie one on top of the other and are separated from each other by means of dielectric layers (2), are arranged next to each other in the base body (1),- wherein the electrode layers (9) of the first stack (7) are alternately contacted with a first external contact (10) and with a second external contact (11) of a first pair of external contacts,- wherein the electrode layers (9) of the second stack (8) are alternately contacted with a first external contact (12) and with a second external contact (13) of a second pair of external contacts,- and wherein external contacts (10, 13; 11, 12) belonging to different pairs and lying on mutually opposite side surfaces of the base body (1) are connected by means of a resistor (4) arranged inside the base body.

- Component according to Claim 15,

wherein the stacks (7, 8) of electrode layers (9) are each part of a multilayer varistor (VDR1, VDR2). - Component according to Claim 16,

wherein the two varistors (VDR1, VDR2) and the resistor (4) form a π filter. - Component according to Claim 17,

wherein the component is formed symmetrically with respect to a plane (14) that runs parallel to a dielectric layer (2), and wherein a respective resistor (41, 42) is arranged above and below the stack (7, 8) of electrode layers (9).

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10144364A DE10144364A1 (en) | 2001-09-10 | 2001-09-10 | Electrical multilayer component |

| DE10144364 | 2001-09-10 | ||

| PCT/DE2002/002952 WO2003028045A2 (en) | 2001-09-10 | 2002-08-12 | Electrical multi-layer component |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1425762A2 EP1425762A2 (en) | 2004-06-09 |

| EP1425762B1 true EP1425762B1 (en) | 2007-01-24 |

Family

ID=7698380

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP02754524A Expired - Lifetime EP1425762B1 (en) | 2001-09-10 | 2002-08-12 | Electrical multi-layer component |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US7012501B2 (en) |

| EP (1) | EP1425762B1 (en) |

| JP (1) | JP4095961B2 (en) |

| CN (1) | CN100490025C (en) |

| AT (1) | ATE352847T1 (en) |

| DE (2) | DE10144364A1 (en) |

| TW (1) | TW569247B (en) |

| WO (1) | WO2003028045A2 (en) |

Families Citing this family (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10356498A1 (en) * | 2003-12-03 | 2005-07-07 | Epcos Ag | Electrical component and circuit arrangement |

| DE102004010001A1 (en) * | 2004-03-01 | 2005-09-22 | Epcos Ag | Electrical component comprises a stack of ceramic layers which form a base member, electrode layers, and a phase pushing unit |

| US7763833B2 (en) * | 2004-03-12 | 2010-07-27 | Goodrich Corp. | Foil heating element for an electrothermal deicer |

| DE102004037588A1 (en) * | 2004-08-03 | 2006-02-23 | Epcos Ag | Electrical component and method for producing an electrical component |

| JP4715248B2 (en) * | 2005-03-11 | 2011-07-06 | パナソニック株式会社 | Multilayer ceramic electronic components |

| US7923668B2 (en) * | 2006-02-24 | 2011-04-12 | Rohr, Inc. | Acoustic nacelle inlet lip having composite construction and an integral electric ice protection heater disposed therein |

| DE102006060634A1 (en) * | 2006-12-21 | 2008-06-26 | Robert Bosch Gmbh | Method for producing an electrical resistance on a substrate |

| DE102007046607A1 (en) | 2007-09-28 | 2009-04-02 | Epcos Ag | Electrical multilayer component and method for producing an electrical multilayer component |

| US8264816B2 (en) * | 2009-08-24 | 2012-09-11 | Kemet Electronics Corporation | Externally fused and resistively loaded safety capacitor |

| US8849404B2 (en) * | 2011-09-01 | 2014-09-30 | Medtronic, Inc. | Feedthrough assembly including a lead frame assembly |

| US9648743B2 (en) * | 2011-12-16 | 2017-05-09 | Snaptrack, Inc. | Multilayer glass ceramic substrate with embedded resistor |

| KR20150069901A (en) * | 2013-12-16 | 2015-06-24 | 삼성전기주식회사 | Resistor |

| CN110621936A (en) * | 2017-01-06 | 2019-12-27 | 海波威技术有限责任公司 | Operating system for a cooking appliance |

| CN107393784A (en) * | 2017-09-07 | 2017-11-24 | 上海长园维安电子线路保护有限公司 | It is a kind of can be resistant to high pressure from control type protector and preparation method thereof |

| JP7027176B2 (en) * | 2018-01-22 | 2022-03-01 | ラピスセミコンダクタ株式会社 | Semiconductor device |

Family Cites Families (28)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB570026A (en) | 1943-12-14 | 1945-06-19 | Johnson Matthey Co Ltd | Improvements in or relating to the manufacture and production of electrical resistors with a low inductance |

| US3266005A (en) * | 1964-04-15 | 1966-08-09 | Western Electric Co | Apertured thin-film circuit components |

| US3846345A (en) * | 1969-10-06 | 1974-11-05 | Owens Illinois Inc | Electroconductive paste composition and structures formed therefrom |

| DE3125281A1 (en) | 1981-06-26 | 1983-01-13 | Siemens AG, 1000 Berlin und 8000 München | Electrical component combination, especially an R-C combination |

| DE3336229A1 (en) * | 1983-10-05 | 1985-04-25 | Resista Fabrik elektrischer Widerstände GmbH, 8300 Landshut | METHOD FOR ADJUSTING THE VALUE OF RESISTORS |

| US4568908A (en) * | 1984-12-24 | 1986-02-04 | General Electric Company | Compact resistor assembly |

| EP0211331A3 (en) * | 1985-08-02 | 1989-10-25 | Hitachi, Ltd. | Heat-sensitive recording head and method of manufacturing same |

| US4811164A (en) * | 1988-03-28 | 1989-03-07 | American Telephone And Telegraph Company, At&T Bell Laboratories | Monolithic capacitor-varistor |

| US4870746A (en) * | 1988-11-07 | 1989-10-03 | Litton Systems, Inc. | Method of making a multilayer printed circuit board having screened-on resistors |

| JPH02312203A (en) * | 1989-05-26 | 1990-12-27 | Matsushita Electric Ind Co Ltd | Method of trimming thick film resistor |

| ES2079415T3 (en) * | 1989-10-26 | 1996-01-16 | Takeshi Ikeda | LC NOISE FILTER. |

| JPH0833327B2 (en) * | 1990-06-11 | 1996-03-29 | 株式会社村田製作所 | Temperature sensor |

| JPH05275958A (en) * | 1992-03-25 | 1993-10-22 | Murata Mfg Co Ltd | Noise filter |

| JP3097332B2 (en) * | 1992-07-21 | 2000-10-10 | 株式会社村田製作所 | Stacked chip varistor |

| US5430429A (en) * | 1992-09-29 | 1995-07-04 | Murata Manufacturing Co., Ltd. | Ceramic resistor wherein a resistance film is embedded |

| US5379016A (en) * | 1993-06-03 | 1995-01-03 | E. I. Du Pont De Nemours And Company | Chip resistor |

| US5521576A (en) * | 1993-10-06 | 1996-05-28 | Collins; Franklyn M. | Fine-line thick film resistors and resistor networks and method of making same |

| JP3138631B2 (en) * | 1996-01-26 | 2001-02-26 | 太陽社電気株式会社 | Chip resistor and method of manufacturing the same |

| US5815367A (en) * | 1996-03-11 | 1998-09-29 | Murata Manufacturing Co., Ltd. | Layered capacitors having an internal inductor element |

| DE19612841A1 (en) * | 1996-03-30 | 1997-10-02 | Abb Research Ltd | Current limiting resistor with PTC behavior |

| JP3631341B2 (en) * | 1996-10-18 | 2005-03-23 | Tdk株式会社 | Multilayer composite functional element and method for manufacturing the same |

| GB9623460D0 (en) * | 1996-11-09 | 1997-01-08 | Oxley Dev Co Ltd | Electronic components incorporating capacitors |

| JPH1116703A (en) * | 1997-06-20 | 1999-01-22 | Shoei Chem Ind Co | Ultra-small resistance resistor |

| US5889445A (en) * | 1997-07-22 | 1999-03-30 | Avx Corporation | Multilayer ceramic RC device |

| US6362723B1 (en) * | 1999-11-18 | 2002-03-26 | Murata Manufacturing Co., Ltd. | Chip thermistors |

| DE10108662A1 (en) * | 2000-02-23 | 2001-08-30 | Tyco Electronics Amp Gmbh | Conducting track on substrate has first and second straight sections connected by a third section running along an inwardly curved bend divided into mutually insulated sub-sections |

| DE10064447C2 (en) | 2000-12-22 | 2003-01-02 | Epcos Ag | Electrical multilayer component and interference suppression circuit with the component |

| EP1223591A3 (en) | 2001-01-11 | 2007-06-06 | Matsushita Electric Industrial Co., Ltd. | Multilayer electronic component and communication apparatus |

-

2001

- 2001-09-10 DE DE10144364A patent/DE10144364A1/en not_active Ceased

-

2002

- 2002-08-12 CN CNB028176863A patent/CN100490025C/en not_active Expired - Fee Related

- 2002-08-12 WO PCT/DE2002/002952 patent/WO2003028045A2/en active IP Right Grant

- 2002-08-12 US US10/488,518 patent/US7012501B2/en not_active Expired - Lifetime

- 2002-08-12 JP JP2003531482A patent/JP4095961B2/en not_active Expired - Fee Related

- 2002-08-12 AT AT02754524T patent/ATE352847T1/en not_active IP Right Cessation

- 2002-08-12 DE DE50209370T patent/DE50209370D1/en not_active Expired - Lifetime

- 2002-08-12 EP EP02754524A patent/EP1425762B1/en not_active Expired - Lifetime

- 2002-09-09 TW TW091120464A patent/TW569247B/en active

Also Published As

| Publication number | Publication date |

|---|---|

| CN1554101A (en) | 2004-12-08 |

| WO2003028045A3 (en) | 2003-12-04 |

| JP4095961B2 (en) | 2008-06-04 |

| JP2005504438A (en) | 2005-02-10 |

| ATE352847T1 (en) | 2007-02-15 |

| US20040239476A1 (en) | 2004-12-02 |

| TW569247B (en) | 2004-01-01 |

| WO2003028045A2 (en) | 2003-04-03 |

| EP1425762A2 (en) | 2004-06-09 |

| DE10144364A1 (en) | 2003-04-03 |

| US7012501B2 (en) | 2006-03-14 |

| DE50209370D1 (en) | 2007-03-15 |

| CN100490025C (en) | 2009-05-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE4008507C2 (en) | Laminated LC filter | |

| DE102009028629B4 (en) | Ultra wide band capacitor | |

| DE69318879T2 (en) | Ceramic multi-layer substrate for high frequencies | |

| DE69627785T2 (en) | Laminated resonator and laminated bandpass filter with it | |

| DE102006000935B4 (en) | Monolithic ceramic component and method of manufacture | |

| EP1425762B1 (en) | Electrical multi-layer component | |

| EP1350257B1 (en) | Electric multilayer component and interference suppression circuit with said component | |

| EP1606831B1 (en) | Electric multilayer component | |

| DE2952441A1 (en) | LAMINATED ELECTRONIC COMPONENT AND METHOD FOR PRODUCING SUCH COMPONENTS | |

| DE19628890A1 (en) | Electronic parts with built-in inductors | |

| EP1369880B1 (en) | Electrical multilayer component and circuit arrangement | |

| WO2006119753A2 (en) | Electrical feedthrough component with a multilayer structure and method for the production thereof | |

| DE2752333A1 (en) | STRIP LINE CAPACITOR | |

| DE4420060C2 (en) | Stripline filter | |

| EP1369881B1 (en) | Electrical multilayer component | |

| DE102004010001A1 (en) | Electrical component comprises a stack of ceramic layers which form a base member, electrode layers, and a phase pushing unit | |

| DE10064445A1 (en) | Electrical multilayer component and arrangement with the component | |

| EP1391898B1 (en) | Electrical multilayer component | |

| EP2530690B1 (en) | Electric multi-layer element and method for producing an electric multi-layer element | |

| EP1537655B1 (en) | Multiple resonance filter | |

| EP1560235B1 (en) | Electrical multilayer component | |

| WO2003012808A1 (en) | Electroceramic component, multi-layer capacitor and method for production of the multi-layer capacitor | |

| DE102004029411B4 (en) | Ceramic multilayer capacitor for low and medium range voltages has a flat ceramic main body, overlapping electrodes and electric outer contacts | |

| DE10057084B4 (en) | Chip thermistors and method of making same | |

| DE4410753C2 (en) | Capacitor array |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20040123 |

|

| AK | Designated contracting states |