EP1370161B1 - Method for making underpants, panties and the like - Google Patents

Method for making underpants, panties and the like Download PDFInfo

- Publication number

- EP1370161B1 EP1370161B1 EP01273828A EP01273828A EP1370161B1 EP 1370161 B1 EP1370161 B1 EP 1370161B1 EP 01273828 A EP01273828 A EP 01273828A EP 01273828 A EP01273828 A EP 01273828A EP 1370161 B1 EP1370161 B1 EP 1370161B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- article

- manufacture

- fabric

- layer

- portions

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A41—WEARING APPAREL

- A41D—OUTERWEAR; PROTECTIVE GARMENTS; ACCESSORIES

- A41D27/00—Details of garments or of their making

- A41D27/24—Hems; Seams

- A41D27/245—Hems; Seams made by welding or gluing

-

- A—HUMAN NECESSITIES

- A41—WEARING APPAREL

- A41B—SHIRTS; UNDERWEAR; BABY LINEN; HANDKERCHIEFS

- A41B9/00—Undergarments

- A41B9/04—Knickers for ladies, with or without inserted crotch or seat parts

Definitions

- the present invention relates to a method for making underpants, panties and the like, as well as the underpants, panties or briefs and the like obtained thereby.

- the fabric portions provided for forming said articles of manufacture are conventionally assembled, said fabric portions comprising fabric elements of different types, such as laces, resilient fabrics, strips and the like, which are joined by seaming operations, thereby providing underpants having a desired configuration.

- seams would inevitably provide a projecting region, which can irritate the user skin, mainly at the top portion of the leg and at the thigh inner region.

- a further problem affecting the prior art solutions is that possible reinforcement or stiffening elements, which are typically arranged at the inguinal regions, require a further processing step which negatively affects the end cost of the article of manufacture.

- EP 1 033 084 discloses an article of manufacture and a method for making it according to the preambles of claims 15 and 1 respectively.

- the aim of the present invention is to overcome the above mentioned drawbacks, by providing a method for making underpants, panties, briefs and the like which allows to fully eliminate the seaming operations or steps, while providing an article of manufacture perfectly fitting the user body.

- a main object of the present invention is to provide such underpants, or briefs, allowing to form reinforcement or stiffening regions, thereby meeting the requirements of the user.

- thermosealing operation to connect to one another synthetic material fabric portions, or portions of fabrics preliminarily coated or spread upon to which a thermofusible material is applied.

- thermofusible material flaps or strips are arranged between the fabric portions or flaps, allowing, by a thermosealing or high frequency sealing operation, to stabilize the fabric peripheral portions or flaps, and/or connect them without the need of performing seaming operations.

- Yet another object of the present invention is to provide such an underpants, panty or brief article which, owing to its specifically designed constructional features, provides a very high reliability and safety in operation.

- Yet another object of the present invention is to provide such a method allowing to make underpants, briefs, panties and the like, by using easily available elements and materials, and at a very reduced cost.

- the edging of the peripheral portions of the subject article of manufacture, and the connection of the edges to be connected are performed by a high frequency thermosealing method.

- thermosealing method causes a thermomelting of the fabric fibers in synthetic and/or resin coated fibers, which must be stabilized at their peripheral edges or which must be mutually connected.

- the method for making underpants, panties, briefs and the like comprises a step of providing a semi-finished article of manufacture 1, which is made of an elasticized fabric, and which has preferably a substantially hourglass configuration.

- the layer 1 is advantageously made by die-cutting a fabric piece or by manually or mechanically cutting through said fabric piece.

- the layer 1 which has substantially a hourglass configuration, comprises a front portion 2 tapering toward a central region 3, and then widening again toward a rear region.

- the front region 2 and rear region 4 end with base edges 5 and 6 which, at their ends, are coupled to respective cross portions 7 and 8 practically delimiting the saddle region formed at the central portion of the layer 1.

- a plastics material finishing strip 10 which can be made of polyurethane or other synthetic materials, and is provided to be intimely coupled to the half finished article of manufacture.

- finishing strip 10 can be made by spreading a hot-melt adhesive materials, or by other analogous methods suitable to cause the plastic material layer to adhere to the fabric material.

- the plastic material to be specifically used, and its specific characteristics, will depend on the need of providing stable edges, which, however, would be provided with a desired softness property.

- a reinforcement layer 20 is applied, which is overlapped on the narrowed region 3 to practically correspond to the inguinal region, thereby allowing to easily apply a reinforcement element without the need of performing seaming operations.

- the subject article of manufacture can also be made starting from a fabric material having a hourglass configuration, as shown in figure 1.

- the body of the subject article of manufacture can be made starting from several flat flaps separated and connected to one another by a high frequency sealing or thermosealing operation.

- Said article of manufacture can also be made by suitably cutting, edging and sealing a tubular resilient fabric portion.

- the thus obtained article of manufacture provides the great advantage that it can perfectly fit to the user body and that it is provided with very soft edges, practically free of thickness, which, consequently, do not irritate the user skin.

- Another important aspect of the invention is that it is possible to provide a very good comfort level, together with a very good supporting of the user body owing to the capability of the subject article of manufacture to perfectly self-fitting to the user body.

- the used materials, as well as the contingent size and shapes can be any, depending on requirements.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Undergarments, Swaddling Clothes, Handkerchiefs Or Underwear Materials (AREA)

- Treatment Of Fiber Materials (AREA)

- Multi-Process Working Machines And Systems (AREA)

- Seeds, Soups, And Other Foods (AREA)

Abstract

Description

- The present invention relates to a method for making underpants, panties and the like, as well as the underpants, panties or briefs and the like obtained thereby.

- As is known, for making underpants, panties, briefs and the like, in particular for a woman use, the fabric portions provided for forming said articles of manufacture are conventionally assembled, said fabric portions comprising fabric elements of different types, such as laces, resilient fabrics, strips and the like, which are joined by seaming operations, thereby providing underpants having a desired configuration.

- As it should be apparent, such a method is affected by several problems, the main of which is its high operating cost, since the seaming operations are mainly manually carried out.

- Another problem is that the seams would inevitably provide a projecting region, which can irritate the user skin, mainly at the top portion of the leg and at the thigh inner region.

- A further problem affecting the prior art solutions is that possible reinforcement or stiffening elements, which are typically arranged at the inguinal regions, require a further processing step which negatively affects the end cost of the article of manufacture.

- The document EP 1 033 084 discloses an article of manufacture and a method for making it according to the preambles of claims 15 and 1 respectively.

- Accordingly, the aim of the present invention is to overcome the above mentioned drawbacks, by providing a method for making underpants, panties, briefs and the like which allows to fully eliminate the seaming operations or steps, while providing an article of manufacture perfectly fitting the user body.

- Within the scope of the above mentioned aim, a main object of the present invention is to provide such underpants, or briefs, allowing to form reinforcement or stiffening regions, thereby meeting the requirements of the user.

- The above mentioned results are achieved by performing high frequency seaming operations or thermosealing operation, to connect to one another synthetic material fabric portions, or portions of fabrics preliminarily coated or spread upon to which a thermofusible material is applied.

- Alternatively, between the fabric portions or flaps, are arranged thermofusible material flaps or strips, allowing, by a thermosealing or high frequency sealing operation, to stabilize the fabric peripheral portions or flaps, and/or connect them without the need of performing seaming operations.

- Yet another object of the present invention is to provide such an underpants, panty or brief article which, owing to its specifically designed constructional features, provides a very high reliability and safety in operation.

- Yet another object of the present invention is to provide such a method allowing to make underpants, briefs, panties and the like, by using easily available elements and materials, and at a very reduced cost.

- According to one aspect of the present invention, the above mentioned aim and objects, as well as yet other objects, which will become more apparent hereinafter, are achieved by a method for making underpants, panties, briefs and the like, according to claim 1.

- The edging of the peripheral portions of the subject article of manufacture, and the connection of the edges to be connected are performed by a high frequency thermosealing method.

- The above mentioned high frequency thermosealing method causes a thermomelting of the fabric fibers in synthetic and/or resin coated fibers, which must be stabilized at their peripheral edges or which must be mutually connected.

- Further characteristics and advantages of the present invention will become more apparent hereinafter from the following detailed disclosure of a preferred, though not exclusive, embodiment of a method for making underpants, panties and the like, which is illustrated, by way of an indicative but not limitative example, in the accompanying drawings, where:

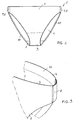

- Figure 1 schematically illustrates the subject semi-finished article of manufacture, and further represents, in an exploded form, a reinforcement element therefor;

- Figure 2 is a further schematic view illustrating a made underpants article of manufacture;

- Figure 3 illustrates, on an enlarged scale, the connection of the cross portions of the opposite base edges which are arranged at a side region.

- With reference to the number references of the above mentioned figures, the method for making underpants, panties, briefs and the like, according to the present invention, comprises a step of providing a semi-finished article of manufacture 1, which is made of an elasticized fabric, and which has preferably a substantially hourglass configuration.

- The layer 1 is advantageously made by die-cutting a fabric piece or by manually or mechanically cutting through said fabric piece.

- The layer 1, which has substantially a hourglass configuration, comprises a

front portion 2 tapering toward acentral region 3, and then widening again toward a rear region. - The

front region 2 andrear region 4 end withbase edges respective cross portions 7 and 8 practically delimiting the saddle region formed at the central portion of the layer 1. - On the semi-finished article of manufacture comprising the layer 1, at the edge thereof, is overlapped a plastics

material finishing strip 10, which can be made of polyurethane or other synthetic materials, and is provided to be intimely coupled to the half finished article of manufacture. - In this connection it should be pointed out that it would be also possible to cut the layer 1 after having applied the finishing layer comprising said

strip 10. - Moreover, the

finishing strip 10 can be made by spreading a hot-melt adhesive materials, or by other analogous methods suitable to cause the plastic material layer to adhere to the fabric material. - The plastic material to be specifically used, and its specific characteristics, will depend on the need of providing stable edges, which, however, would be provided with a desired softness property.

- In order to finish the underpants article, it is necessary to connect to one another the

cross portions 7 and 8 which are practically sealed to one another by directly using thefinishing layer 10 or, possibly, by interposing a thermofusible material strip, allowing to perform the sealing operation. - With the underpants article in a finished condition, before performing the connecting step for mutually connecting the

cross portions 7 and 8, areinforcement layer 20 is applied, which is overlapped on the narrowedregion 3 to practically correspond to the inguinal region, thereby allowing to easily apply a reinforcement element without the need of performing seaming operations. - In this connection it should be apparent that the subject underpants article, in addition to being made of a single piece and by thermosealing the edges and flaps to be connected, can also be made starting from two portions, separated by a dashed line (a) as shown in figure 1.

- In this case, the adjoining portions or flaps arranged near said dashed line (a) will be sealed by thermomelting.

- The subject article of manufacture can also be made starting from a fabric material having a hourglass configuration, as shown in figure 1.

- Alternatively, the body of the subject article of manufacture can be made starting from several flat flaps separated and connected to one another by a high frequency sealing or thermosealing operation.

- Said article of manufacture can also be made by suitably cutting, edging and sealing a tubular resilient fabric portion.

- The thus obtained article of manufacture provides the great advantage that it can perfectly fit to the user body and that it is provided with very soft edges, practically free of thickness, which, consequently, do not irritate the user skin.

- Another important aspect of the invention is that it is possible to provide a very good comfort level, together with a very good supporting of the user body owing to the capability of the subject article of manufacture to perfectly self-fitting to the user body.

- The invention, as disclosed, is susceptible to several modifications and variations, all of which will come within the inventive idea scope.

- Moreover, all the constructional details can be replaced by other technically equivalent elements.

- In practicing the invention, the used materials, as well as the contingent size and shapes, can be any, depending on requirements.

Claims (15)

- A method for making underpants, panties, briefs and the like, wherein said method comprises the steps of providing a semi-finished article of manufacture (3), comprising a flat layer (1) of an elasticized fabric, overlapping on the edges of said elasticized fabric flat layer, a plastic material finishing strip (10), and joining to one another the cross portions (7, 8) arranged at the ends of the opposite base edges, characterized in that said method further comprises, before the step of connecting said cross portions (7, 8), the step of applying a reinforcement layer (20) at a narrowed middle region (3) of the fabric flat layer, said reinforcement layer (20) being coupled to said fabric flat layer (1) by said finishing strip (10).

- A method, according to claim 1, characterized in that said elasticized fabric flat layer (1) is obtained by a die-cutting step from a fabric piece.

- A method, according to claim 2, characterized in that said die-cutting step is carried out after having applied said plastic material finishing strip (10).

- A method, according to claim 1, characterized in that said finishing strip (10) comprises a polyurethane layer, coupled to said elasticized fabric.

- A method, according to one or more of the preceding claims, characterized in that said finishing strip (10) is obtained from a spread-upon layer.

- A method, according to one or more of the preceding claims, characterized in that between said cross portions (7, 8) a thermofusible material layer can be arranged, in order to connect said cross portions.

- A method, according to one or more of the preceding claims, characterized in that the ending of the peripheral portions of the article of manufacture and the connection of the edges to be coupled are performed by a high frequency thermosealing method.

- A method, according to one or more of the preceding claims, characterized in that said fabric flat layer (1) of synthetic fibers and/or resin coated fibers is edged by a high frequency thermomelting method designed for thermomelting the perimetrical edges (5, 6) of said fabric flat layer (1).

- A method, according to one or more of the preceding claims, characterized in that the portions or flaps of said fabric flat layer (1), to be connected to provide a desired article of manufacture, are coupled by subjecting said flat fabric layer (1) of synthetic fibers and/or resin coated fibers to a high frequency thermomelting process.

- A method according to one or more of the preceeding claims for making underpants, panties, briefs and the like, characterized in that said method comprises the step of making said article of manufacture starting from two separated portions.

- A method, according to claim 10, characterized in that said method comprises the step of performing a sealing operation by thermomelting adjacent portions or flaps arranged near a dashed line (a).

- A method, according to one or more of the preceding claims, characterized in that said method provides to form said article of manufacture by using an elasticized fabric having a hourglass configuration in plan.

- A method, according to one or more of the preceding claims, characterized in that the body of said article of manufacture is made starting from several elasticized fabric flat portions, separated and connected to one another by high frequency sealing or thermosealing processes.

- A method, according to one or more of the preceding claims, characterized in that said method provides that said article of manufacture are made by suitably cutting, edging and sealing a portion of a resilient tubular fabric.

- An underpants, brief and panty article of manufacture (1) made by a method according to claim 1, comprising a flat layer (1) of an elasticized fabric having a substantially hourglass configuration with a front region (2) coupled, by a narrowed central region (3), to a rear region (4), at the edges of said article of manufacture being applied a plastic material finishing strip (10), the cross portions, defined at the ends of the opposite edges of said flat layer being adapted to be connected to one another for closing said article of manufacture at the side portions thereof, characterized in that said article of manufacture comprises a reinforcement layer which can be arranged at said central narrowed region (3) and coupled to said finishing strip (10).

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| ITMI20010041 | 2001-02-28 | ||

| IT2001MI000413A ITMI20010413A1 (en) | 2001-02-28 | 2001-02-28 | PROCEDURE FOR THE PRODUCTION OF SLIP PANTIES AND SIMILAR |

| PCT/IT2001/000559 WO2002067705A1 (en) | 2001-02-28 | 2001-11-07 | Method for making underpants, panties and the like |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1370161A1 EP1370161A1 (en) | 2003-12-17 |

| EP1370161B1 true EP1370161B1 (en) | 2006-05-03 |

Family

ID=11447060

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP01273828A Expired - Lifetime EP1370161B1 (en) | 2001-02-28 | 2001-11-07 | Method for making underpants, panties and the like |

Country Status (6)

| Country | Link |

|---|---|

| EP (1) | EP1370161B1 (en) |

| AT (1) | ATE324807T1 (en) |

| DE (1) | DE60119390T2 (en) |

| ES (1) | ES2263552T3 (en) |

| IT (1) | ITMI20010413A1 (en) |

| WO (1) | WO2002067705A1 (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2991605B1 (en) | 2013-05-03 | 2020-03-25 | Knix Wear Inc. | Absorbent garment |

| DE102009052540B4 (en) * | 2009-11-11 | 2020-11-19 | Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e.V. | Tillage implement |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102014116540A1 (en) | 2014-11-12 | 2016-05-12 | TEG Textile Expert Germany GmbH | Textile blanket |

| US11497263B1 (en) | 2021-07-08 | 2022-11-15 | Knix Wear Inc. | Garments with moisture capture assemblies and associated methods |

| US11590034B2 (en) | 2021-07-08 | 2023-02-28 | Knix Wear Inc. | Reusable absorbent accessories and associated methods |

| CA3135873C (en) | 2021-10-25 | 2024-02-27 | Knix Wear Inc. | Garments with moisture capture assemblies and associated methods |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1296202A (en) * | 1968-09-24 | 1972-11-15 | ||

| FR2177425A1 (en) * | 1971-10-13 | 1973-11-09 | Elastelle Fontanille | Disposable garments - having elasticated borders |

| FR2255023A1 (en) * | 1973-12-21 | 1975-07-18 | Lingerie Indemaillable Ste Par | Stretchable synthetic fibre underwear - e.g. brassieres, briefs, girdles, with hems and seams |

| US4355425A (en) * | 1980-02-01 | 1982-10-26 | The Procter & Gamble Company | Panty with a built-in elastic system to minimize gathering and provide a comfortable, conforming fit and method to assemble a panty |

| US5772825A (en) * | 1994-12-22 | 1998-06-30 | The Procter & Gamble Company | Method for making an undergarment having side seams |

| US5855123A (en) * | 1996-03-19 | 1999-01-05 | The Russell Group, Ltd. | Knitted textile fabric having integral seamless elasticated contours, panty blank formed thereof, and fabricating a panty garment therefrom |

| ATE237959T1 (en) * | 1999-02-26 | 2003-05-15 | Triumph International Ag | UNDERCLOTHING, ESPECIALLY WOMEN'S UNDERCLOTHING |

-

2001

- 2001-02-28 IT IT2001MI000413A patent/ITMI20010413A1/en unknown

- 2001-11-07 ES ES01273828T patent/ES2263552T3/en not_active Expired - Lifetime

- 2001-11-07 WO PCT/IT2001/000559 patent/WO2002067705A1/en active IP Right Grant

- 2001-11-07 DE DE60119390T patent/DE60119390T2/en not_active Expired - Fee Related

- 2001-11-07 EP EP01273828A patent/EP1370161B1/en not_active Expired - Lifetime

- 2001-11-07 AT AT01273828T patent/ATE324807T1/en not_active IP Right Cessation

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102009052540B4 (en) * | 2009-11-11 | 2020-11-19 | Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e.V. | Tillage implement |

| EP2991605B1 (en) | 2013-05-03 | 2020-03-25 | Knix Wear Inc. | Absorbent garment |

Also Published As

| Publication number | Publication date |

|---|---|

| DE60119390T2 (en) | 2007-04-19 |

| EP1370161A1 (en) | 2003-12-17 |

| ATE324807T1 (en) | 2006-06-15 |

| ES2263552T3 (en) | 2006-12-16 |

| ITMI20010413A1 (en) | 2002-08-28 |

| WO2002067705A1 (en) | 2002-09-06 |

| DE60119390D1 (en) | 2006-06-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US7771407B2 (en) | Method of producing disposable pants having discontinuous elastic elements | |

| EP0626161B1 (en) | Absorbent article and method of manufacturing the same | |

| CA2541194C (en) | Pants type product and method of making the same | |

| EP0625346B2 (en) | Welding method for disposable diapers | |

| US20120246792A1 (en) | Method of forming garments having seamless edge bands | |

| US6817037B1 (en) | Stretchable athletic pants having an overlapping bonded seam | |

| JPH06327714A (en) | Manufacture of shorts-shaped disposable diaper | |

| WO2002062163A3 (en) | Undergarments made from multi-layered fabric laminate material | |

| US20080282451A1 (en) | Undergarment, for example a pair of panties, especially for women | |

| EP1370161B1 (en) | Method for making underpants, panties and the like | |

| US7048606B1 (en) | Pad with graduated thickness and very thin neckline and method for making the same | |

| KR101382623B1 (en) | Method for manufacturing underwear | |

| US5536350A (en) | Disposable garment with noodle cuff and method for manufacturing same | |

| US4736468A (en) | Method of forming a brief | |

| US20040238103A1 (en) | Method of producing seamless elastic trim | |

| KR200325456Y1 (en) | Seamless panty without sewing line | |

| US3693191A (en) | Shirt collar and method of making same | |

| US11648154B2 (en) | Method for manufacturing worn article | |

| US3624664A (en) | Shirt collar and method of making same | |

| EP1341425A2 (en) | Method for making bras and the bras made thereby | |

| JPH07110280B2 (en) | Method for manufacturing sanitary napkin with elastic body | |

| US9433244B2 (en) | Brassiere cup and method of manufacture | |

| US2118407A (en) | Fold lines | |

| JPS5813165B2 (en) | How to make slash shoes | |

| CN210447382U (en) | Full-surrounding leakage-proof paper diaper |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20030925 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO SI |

|

| 17Q | First examination report despatched |

Effective date: 20050404 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20060503 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060503 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060503 Ref country code: BE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060503 Ref country code: CH Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060503 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060503 Ref country code: LI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060503 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 60119390 Country of ref document: DE Date of ref document: 20060608 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060803 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060803 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061003 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061107 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061130 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2263552 Country of ref document: ES Kind code of ref document: T3 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20070206 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060804 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060503 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061107 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060503 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20081107 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20081104 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20081024 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20081127 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20081027 Year of fee payment: 8 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20091107 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20100730 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100601 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091107 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20110329 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091107 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110316 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091108 |