EP1370161B1 - Verfahren zur herstellung von unterhosen, höschen und dergleichen - Google Patents

Verfahren zur herstellung von unterhosen, höschen und dergleichen Download PDFInfo

- Publication number

- EP1370161B1 EP1370161B1 EP01273828A EP01273828A EP1370161B1 EP 1370161 B1 EP1370161 B1 EP 1370161B1 EP 01273828 A EP01273828 A EP 01273828A EP 01273828 A EP01273828 A EP 01273828A EP 1370161 B1 EP1370161 B1 EP 1370161B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- article

- manufacture

- fabric

- layer

- portions

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000000034 method Methods 0.000 title claims abstract description 38

- 239000004744 fabric Substances 0.000 claims abstract description 31

- 238000004519 manufacturing process Methods 0.000 claims abstract description 27

- 239000000463 material Substances 0.000 claims abstract description 16

- 239000004033 plastic Substances 0.000 claims abstract description 7

- 229920003023 plastic Polymers 0.000 claims abstract description 7

- 238000005304 joining Methods 0.000 claims abstract 2

- 230000002787 reinforcement Effects 0.000 claims description 8

- 238000007789 sealing Methods 0.000 claims description 7

- 238000005520 cutting process Methods 0.000 claims description 6

- 239000000835 fiber Substances 0.000 claims description 4

- 230000002093 peripheral effect Effects 0.000 claims description 4

- 229920002994 synthetic fiber Polymers 0.000 claims description 4

- 238000007688 edging Methods 0.000 claims description 3

- 229920002635 polyurethane Polymers 0.000 claims description 2

- 239000004814 polyurethane Substances 0.000 claims description 2

- 239000012209 synthetic fiber Substances 0.000 claims 2

- 229920003002 synthetic resin Polymers 0.000 claims 2

- 239000000057 synthetic resin Substances 0.000 claims 2

- 230000000063 preceeding effect Effects 0.000 claims 1

- 238000004826 seaming Methods 0.000 description 6

- 239000004831 Hot glue Substances 0.000 description 1

- 210000002414 leg Anatomy 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 239000011347 resin Substances 0.000 description 1

- 229920005989 resin Polymers 0.000 description 1

- 238000003892 spreading Methods 0.000 description 1

- 210000000689 upper leg Anatomy 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A41—WEARING APPAREL

- A41D—OUTERWEAR; PROTECTIVE GARMENTS; ACCESSORIES

- A41D27/00—Details of garments or of their making

- A41D27/24—Hems; Seams

- A41D27/245—Hems; Seams made by welding or gluing

-

- A—HUMAN NECESSITIES

- A41—WEARING APPAREL

- A41B—SHIRTS; UNDERWEAR; BABY LINEN; HANDKERCHIEFS

- A41B9/00—Undergarments

- A41B9/04—Knickers for ladies, with or without inserted crotch or seat parts

Definitions

- the present invention relates to a method for making underpants, panties and the like, as well as the underpants, panties or briefs and the like obtained thereby.

- the fabric portions provided for forming said articles of manufacture are conventionally assembled, said fabric portions comprising fabric elements of different types, such as laces, resilient fabrics, strips and the like, which are joined by seaming operations, thereby providing underpants having a desired configuration.

- seams would inevitably provide a projecting region, which can irritate the user skin, mainly at the top portion of the leg and at the thigh inner region.

- a further problem affecting the prior art solutions is that possible reinforcement or stiffening elements, which are typically arranged at the inguinal regions, require a further processing step which negatively affects the end cost of the article of manufacture.

- EP 1 033 084 discloses an article of manufacture and a method for making it according to the preambles of claims 15 and 1 respectively.

- the aim of the present invention is to overcome the above mentioned drawbacks, by providing a method for making underpants, panties, briefs and the like which allows to fully eliminate the seaming operations or steps, while providing an article of manufacture perfectly fitting the user body.

- a main object of the present invention is to provide such underpants, or briefs, allowing to form reinforcement or stiffening regions, thereby meeting the requirements of the user.

- thermosealing operation to connect to one another synthetic material fabric portions, or portions of fabrics preliminarily coated or spread upon to which a thermofusible material is applied.

- thermofusible material flaps or strips are arranged between the fabric portions or flaps, allowing, by a thermosealing or high frequency sealing operation, to stabilize the fabric peripheral portions or flaps, and/or connect them without the need of performing seaming operations.

- Yet another object of the present invention is to provide such an underpants, panty or brief article which, owing to its specifically designed constructional features, provides a very high reliability and safety in operation.

- Yet another object of the present invention is to provide such a method allowing to make underpants, briefs, panties and the like, by using easily available elements and materials, and at a very reduced cost.

- the edging of the peripheral portions of the subject article of manufacture, and the connection of the edges to be connected are performed by a high frequency thermosealing method.

- thermosealing method causes a thermomelting of the fabric fibers in synthetic and/or resin coated fibers, which must be stabilized at their peripheral edges or which must be mutually connected.

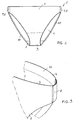

- the method for making underpants, panties, briefs and the like comprises a step of providing a semi-finished article of manufacture 1, which is made of an elasticized fabric, and which has preferably a substantially hourglass configuration.

- the layer 1 is advantageously made by die-cutting a fabric piece or by manually or mechanically cutting through said fabric piece.

- the layer 1 which has substantially a hourglass configuration, comprises a front portion 2 tapering toward a central region 3, and then widening again toward a rear region.

- the front region 2 and rear region 4 end with base edges 5 and 6 which, at their ends, are coupled to respective cross portions 7 and 8 practically delimiting the saddle region formed at the central portion of the layer 1.

- a plastics material finishing strip 10 which can be made of polyurethane or other synthetic materials, and is provided to be intimely coupled to the half finished article of manufacture.

- finishing strip 10 can be made by spreading a hot-melt adhesive materials, or by other analogous methods suitable to cause the plastic material layer to adhere to the fabric material.

- the plastic material to be specifically used, and its specific characteristics, will depend on the need of providing stable edges, which, however, would be provided with a desired softness property.

- a reinforcement layer 20 is applied, which is overlapped on the narrowed region 3 to practically correspond to the inguinal region, thereby allowing to easily apply a reinforcement element without the need of performing seaming operations.

- the subject article of manufacture can also be made starting from a fabric material having a hourglass configuration, as shown in figure 1.

- the body of the subject article of manufacture can be made starting from several flat flaps separated and connected to one another by a high frequency sealing or thermosealing operation.

- Said article of manufacture can also be made by suitably cutting, edging and sealing a tubular resilient fabric portion.

- the thus obtained article of manufacture provides the great advantage that it can perfectly fit to the user body and that it is provided with very soft edges, practically free of thickness, which, consequently, do not irritate the user skin.

- Another important aspect of the invention is that it is possible to provide a very good comfort level, together with a very good supporting of the user body owing to the capability of the subject article of manufacture to perfectly self-fitting to the user body.

- the used materials, as well as the contingent size and shapes can be any, depending on requirements.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Undergarments, Swaddling Clothes, Handkerchiefs Or Underwear Materials (AREA)

- Treatment Of Fiber Materials (AREA)

- Multi-Process Working Machines And Systems (AREA)

- Seeds, Soups, And Other Foods (AREA)

Claims (15)

- Verfahren zur Herstellung von Unterhosen, Damenschlüpfern, Herrenslips und dergleichen, wobei das Verfahren folgende Schritte umfasst: Bereitstellen eines Halbfertigprodukts (3), umfassend eine flache Schicht (1) eines elastischen Gewebes, die an den Kanten der flachen Schicht aus elastischem Gewebe überlappt, einen Appreturstreifen (10) aus einem Kunststoffmaterial, und Zusammenfügen der Kreuzabschnitte (7, 8), die an den Enden der einander gegenüberliegenden Basiskanten angeordnet sind, dadurch gekennzeichnet, dass das Verfahren des Weiteren vor dem Schritt des Zusammenfügens der Kreuzabschnitte (7, 8) den Schritt des Anbringens einer Verstärkungsschicht (20) an einer schmaler gestalteten mittleren Region (3) der flachen Gewebeschicht umfasst, wobei die Verstärkungsschicht (20) über den Appreturstreifen (10) mit der flachen Gewebeschicht (1) verbunden ist.

- Verfahren nach Anspruch 1, dadurch gekennzeichnet, dass die flache Schicht (1) aus elastischem Gewebe durch einen Schritt des Ausstanzens aus einem Gewebestück erhalten wird.

- Verfahren nach Anspruch 2, dadurch gekennzeichnet, dass der Ausstanzschritt ausgeführt wird, nachdem der Appreturstreifen (10) aus einem Kunststoffmaterial angebracht wurde.

- Verfahren nach Anspruch 1, dadurch gekennzeichnet, dass der Appreturstreifen (10) eine Polyurethanschicht umfasst, die mit dem elastischen Gewebe verbunden ist.

- Verfahren nach einem oder mehreren der vorangehenden Ansprüche, dadurch gekennzeichnet, dass der Appreturstreifen (10) aus einer aufgestrichenen Schicht erhalten wird.

- Verfahren nach einem oder mehreren der vorangehenden Ansprüche, dadurch gekennzeichnet, dass zwischen den Kreuzabschnitten (7, 8) eine Schicht aus einem wärmeschmelzbaren Material angeordnet sein kann, um die Kreuzabschnitte miteinander zu verbinden.

- Verfahren nach einem oder mehreren der vorangehenden Ansprüche, dadurch gekennzeichnet, dass der Abschluss der Randabschnitte des Produktionsartikels und die Verbindung der zu verbindenden Kanten mittels eines Hochfrequenz-Wärmeschweißverfahrens hergestellt werden.

- Verfahren nach einem oder mehreren der vorangehenden Ansprüche, dadurch gekennzeichnet, dass die flache Gewebeschicht (1) aus Synthesefasern und/oder harzbeschichteten Fasern mittels eines Hochfrequenz-Wärmeschmelzverfahrens gesäumt wird, das zum Wärmeschmelzen der Umfangskanten (5, 6) der flachen Gewebeschicht (1) ausgelegt ist.

- Verfahren nach einem oder mehreren der vorangehenden Ansprüche, dadurch gekennzeichnet, dass die Abschnitte oder Klappen der flachen Gewebeschicht (1), die verbunden werden sollen, um einen gewünschten Produktionsartikel zu erhalten, in der Weise miteinander verbunden werden, dass man die flache Gewebeschicht (1) aus Synthesefasern und/oder harzbeschichteten Fasern einem Hochfrequenz-Wärmeschmelzverfahren unterzieht.

- Verfahren nach einem oder mehreren der vorangehenden Ansprüche zur Herstellung von Unterhosen, Damenschlüpfern, Herrenslips und dergleichen, dadurch gekennzeichnet, dass das Verfahren den Schritt der Herstellung des Produktionsartikels ausgehend von zwei getrennten Abschnitten umfasst.

- Verfahren nach Anspruch 10, dadurch gekennzeichnet, dass das Verfahren den Schritt des Ausführens einer Schweißoperation mittels Wärmeschmelzen benachbarter Abschnitte oder Klappen umfasst, die nahe einer Strichlinie (a) angeordnet sind.

- Verfahren nach einem oder mehreren der vorangehenden Ansprüche, dadurch gekennzeichnet, dass das Verfahren vorsieht, den Produktionsartikel unter Verwendung eines elastischen Gewebes herzustellen, das - in Draufsicht gesehen - eine Sanduhrform aufweist.

- Verfahren nach einem oder mehreren der vorangehenden Ansprüche, dadurch gekennzeichnet, dass der Körper des Produktionsartikels ausgehend von verschiedenen flachen Abschnitten eines elastischen Gewebes hergestellt wird, die voneinander getrennt sind und durch Hochfrequenzschweiß- oder Wärmeschweißverfahren miteinander verbunden werden.

- Verfahren nach einem oder mehreren der vorangehenden Ansprüche, dadurch gekennzeichnet, dass das Verfahren vorsieht, den Produktionsartikel durch Schneiden, Säumen und Verschweißen eines Abschnitts eines elastischen röhrenförmigen Gewebes herzustellen.

- Unterhosen-, Männerslip- oder Damenschlüpfer-Produktionsartikel (1), der mittels eines Verfahrens nach Anspruch 1 hergestellt ist, umfassend eine flache Schicht (1) eines elastischen Gewebes, das im Wesentlichen eine Sanduhrform aufweist, wobei eine vordere Region (2) über eine schmal gestaltete mittige Region (3) mit einer hinteren Region (4) verbunden ist, wobei an den Kanten des Produktionsartikels ein Appreturstreifen (10) aus einem Kunststoffmaterial angebracht ist, wobei die Kreuzabschnitte, die an den Enden der einander gegenüberliegenden Kanten der flachen Schicht ausgebildet sind, dafür konfiguriert sind, miteinander verbunden zu werden, um den Produktionsartikel an seinen Seitenabschnitten zu schließen, dadurch gekennzeichnet, dass der Produktionsartikel eine Verstärkungsschicht umfasst, die an der mittigen, schmaler gestalteten Region (3) angeordnet werden kann und mit dem Appreturstreifen (10) verbunden werden kann.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| IT2001MI000413A ITMI20010413A1 (it) | 2001-02-28 | 2001-02-28 | Procedimento per la realizzazione di slip mutandine e simili |

| ITMI20010041 | 2001-02-28 | ||

| PCT/IT2001/000559 WO2002067705A1 (en) | 2001-02-28 | 2001-11-07 | Method for making underpants, panties and the like |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1370161A1 EP1370161A1 (de) | 2003-12-17 |

| EP1370161B1 true EP1370161B1 (de) | 2006-05-03 |

Family

ID=11447060

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP01273828A Expired - Lifetime EP1370161B1 (de) | 2001-02-28 | 2001-11-07 | Verfahren zur herstellung von unterhosen, höschen und dergleichen |

Country Status (6)

| Country | Link |

|---|---|

| EP (1) | EP1370161B1 (de) |

| AT (1) | ATE324807T1 (de) |

| DE (1) | DE60119390T2 (de) |

| ES (1) | ES2263552T3 (de) |

| IT (1) | ITMI20010413A1 (de) |

| WO (1) | WO2002067705A1 (de) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2991605B1 (de) | 2013-05-03 | 2020-03-25 | Knix Wear Inc. | Saugfähiges kleidungsstück |

| DE102009052540B4 (de) * | 2009-11-11 | 2020-11-19 | Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e.V. | Bodenbearbeitungsgerät |

| US12121431B2 (en) | 2019-10-07 | 2024-10-22 | The Procter & Gamble Company | Durable underwear adapted for use with absorbent component |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102014116540A1 (de) | 2014-11-12 | 2016-05-12 | TEG Textile Expert Germany GmbH | Textile Decke |

| EP4096607B1 (de) | 2020-01-27 | 2024-07-24 | The Procter & Gamble Company | Dauerhafte absorbierende hose |

| US11590034B2 (en) | 2021-07-08 | 2023-02-28 | Knix Wear Inc. | Reusable absorbent accessories and associated methods |

| CA3162293C (en) | 2021-07-08 | 2023-11-28 | Knix Wear Inc. | Garments with moisture capture assemblies and associated methods |

| US11497263B1 (en) | 2021-07-08 | 2022-11-15 | Knix Wear Inc. | Garments with moisture capture assemblies and associated methods |

| CA3135873C (en) | 2021-10-25 | 2024-02-27 | Knix Wear Inc. | Garments with moisture capture assemblies and associated methods |

| US12048335B2 (en) | 2022-07-29 | 2024-07-30 | Knix Wear Inc. | Lower body garments with an interior lining and related methods |

| US12097103B1 (en) | 2023-06-01 | 2024-09-24 | Knix Wear Inc. | Garments with fluid retention assemblies and related methods |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1296202A (de) * | 1968-09-24 | 1972-11-15 | ||

| FR2177425A1 (en) * | 1971-10-13 | 1973-11-09 | Elastelle Fontanille | Disposable garments - having elasticated borders |

| FR2255023A1 (en) * | 1973-12-21 | 1975-07-18 | Lingerie Indemaillable Ste Par | Stretchable synthetic fibre underwear - e.g. brassieres, briefs, girdles, with hems and seams |

| US4355425A (en) * | 1980-02-01 | 1982-10-26 | The Procter & Gamble Company | Panty with a built-in elastic system to minimize gathering and provide a comfortable, conforming fit and method to assemble a panty |

| US5772825A (en) * | 1994-12-22 | 1998-06-30 | The Procter & Gamble Company | Method for making an undergarment having side seams |

| US5855123A (en) * | 1996-03-19 | 1999-01-05 | The Russell Group, Ltd. | Knitted textile fabric having integral seamless elasticated contours, panty blank formed thereof, and fabricating a panty garment therefrom |

| ATE237959T1 (de) * | 1999-02-26 | 2003-05-15 | Triumph International Ag | Unterbekleidungsstück, insbesondere damenunterbekleidungsstück |

-

2001

- 2001-02-28 IT IT2001MI000413A patent/ITMI20010413A1/it unknown

- 2001-11-07 WO PCT/IT2001/000559 patent/WO2002067705A1/en not_active Ceased

- 2001-11-07 AT AT01273828T patent/ATE324807T1/de not_active IP Right Cessation

- 2001-11-07 DE DE60119390T patent/DE60119390T2/de not_active Expired - Fee Related

- 2001-11-07 EP EP01273828A patent/EP1370161B1/de not_active Expired - Lifetime

- 2001-11-07 ES ES01273828T patent/ES2263552T3/es not_active Expired - Lifetime

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102009052540B4 (de) * | 2009-11-11 | 2020-11-19 | Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e.V. | Bodenbearbeitungsgerät |

| EP2991605B1 (de) | 2013-05-03 | 2020-03-25 | Knix Wear Inc. | Saugfähiges kleidungsstück |

| US12121431B2 (en) | 2019-10-07 | 2024-10-22 | The Procter & Gamble Company | Durable underwear adapted for use with absorbent component |

Also Published As

| Publication number | Publication date |

|---|---|

| ATE324807T1 (de) | 2006-06-15 |

| ITMI20010413A1 (it) | 2002-08-28 |

| DE60119390T2 (de) | 2007-04-19 |

| EP1370161A1 (de) | 2003-12-17 |

| DE60119390D1 (de) | 2006-06-08 |

| ES2263552T3 (es) | 2006-12-16 |

| WO2002067705A1 (en) | 2002-09-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1370161B1 (de) | Verfahren zur herstellung von unterhosen, höschen und dergleichen | |

| US7771407B2 (en) | Method of producing disposable pants having discontinuous elastic elements | |

| CA2541194C (en) | Pants type product and method of making the same | |

| EP0625346B2 (de) | Schweissmethode für Wegwerfwindeln | |

| US6817037B1 (en) | Stretchable athletic pants having an overlapping bonded seam | |

| US20120246792A1 (en) | Method of forming garments having seamless edge bands | |

| US20020106970A1 (en) | Undergarments made from multi-layered fabric laminate material | |

| US6769358B2 (en) | Method for manufacturing an article of clothing | |

| JPH06327714A (ja) | パンツ型使い捨ておむつの製造方法 | |

| US20080282451A1 (en) | Undergarment, for example a pair of panties, especially for women | |

| US5536350A (en) | Disposable garment with noodle cuff and method for manufacturing same | |

| US4736468A (en) | Method of forming a brief | |

| KR101382623B1 (ko) | 속옷 제조방법 | |

| US6988931B1 (en) | Pad with graduated thickness and very thin neckline and method for making the same | |

| KR200325456Y1 (ko) | 재봉선이 없는 무봉제 팬티 | |

| US3693191A (en) | Shirt collar and method of making same | |

| US20040238103A1 (en) | Method of producing seamless elastic trim | |

| JPH07110280B2 (ja) | 弾性体入り生理用ナプキンの製造方法 | |

| EP3977970B1 (de) | Herstellungsverfahren für wearable-artikel | |

| US3624664A (en) | Shirt collar and method of making same | |

| US9433244B2 (en) | Brassiere cup and method of manufacture | |

| WO2002037992A2 (en) | Method for making bras and the bras made thereby | |

| JPS5813165B2 (ja) | スラッシュ靴の製造方法 | |

| US2118407A (en) | Fold lines | |

| WO2020188612A1 (en) | Process for making a composite elastic tape, elastic tape so obtained and panty diaper comprising said elastic tape |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20030925 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO SI |

|

| 17Q | First examination report despatched |

Effective date: 20050404 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20060503 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060503 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060503 Ref country code: BE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060503 Ref country code: CH Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060503 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060503 Ref country code: LI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060503 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 60119390 Country of ref document: DE Date of ref document: 20060608 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060803 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060803 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061003 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061107 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061130 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2263552 Country of ref document: ES Kind code of ref document: T3 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20070206 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060804 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060503 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061107 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060503 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20081107 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20081104 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20081024 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20081127 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20081027 Year of fee payment: 8 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20091107 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20100730 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100601 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091107 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20110329 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091107 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110316 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091108 |