BACKGROUND OF THE INVENTION

1. Field of the Invention

The present invention relates to a slide fastener having

a separable bottom end stop comprising a reinforcement piece

for reinforcing a fastener tape which is provided continuously

to a box pin or an insert pin of the separable bottom end stop

attached on an end portion of the fastener tape.

2. Description of the Related Art

In recent years, there has been a demand in the field of

slide fasteners, for a product that has a simplified structure

and which is low in cost and is of a high quality. This tendency

is remarkable mainly in a slide fastener having a separable

bottom end stop which is used at a front portion for opening

and closing of clothing and can be connected to or separated

from an end portion of the fastener tapes used.

In a conventional slide fastener having a separable

bottom end stop, a typical product has fastener elements

attached along opposing side edges of a pair of fastener tapes,

and the separable bottom end stop formed of a box pin, a box

and an insert pin is continuously attached to a lower end of

the fastener elements. And plain woven fabric (taffeta) or

a reinforcement tape in which an adhesive layer provided on a

rear surface of a synthetic resin film is adhered to a portion

of the fastener tape where the separable bottom end stop is

attached, and after reinforcing the portion so as to have a

stable form, the separable bottom end stop is attached to the

portion.

Also, a separable bottom end stop for a slide fastener

is disclosed in Japanese Utility Model Application Publication

No. 41-17374 (See Fig. 19) in which the reinforcement tape is

not adhered to the end portion of the fastener tape, but rather

using a synthetic resin, a box pin, an insert pin and a mesh-like

reinforcement piece are integrally molded with both front and

rear surfaces of the fastener tape directly by an injection

molding means. Further, a separable bottom end stop for a slide

fastener is disclosed in Japanese Patent Application Laid-Open

No. 50-118848, in which a box pin and an insert pin disposed

at an end portion of a fastener stringer are molded, and at the

same time, a reinforcement piece for reinforcing the tape whose

outer side edge projects in an arc-shape toward a lower end of

the tape is attached.

In the above-described slide fasteners each having a

separable bottom end stop and a reinforcement tape adhered

thereto, a reinforcement tape is required separately in order

to reinforce the fastener tape and the cost of the product is

increased because a larger number of parts are required for the

slide fastener. In addition, the cost of the product becomes

higher because the slide fastener production process cannot be

simplified due to a necessary process for adhering the

reinforcement tape and the like, as well as an adhering device.

In a separable bottom end stop 6' for a slide fastener

shown in Fig. 19, the outer peripheral edge of a reinforcement

piece 13' has a pointed corner, and thus the reinforcement piece

13' easily catches other objects and is easily stripped.

Further, because the reinforcement piece 13' is provided so as

to be wide and large toward the outer side edge of a fastener

tape 4', the portion of the fastener tape 4' where the

reinforcement piece 13' is provided becomes upright, and when

the slide fastener is attached to an object by sewing, the sewing

machine needle (not shown) contacts the reinforcement piece 13'

and the sewing machine needle breaks frequently. Further, when

the operation of joining or separating the separable bottom end

stop 6' is carried out, the external forces of twisting, bending

and the like are repeatedly applied to the reinforcement piece

13', and thus there is a possibility that the reinforcement

piece 13' may break off. Further, the reinforcement piece 13'

whose outer side projects in an arc-shape toward a lower end

of the tape becomes thick and thus the sewing machine needle

may break, and there is also a problem that the reinforcement

piece 13' catches other objects easily.

SUMMARY OF THE INVENTION

The invention is contrived with considering the

above-described problems, and a main object of the invention

is to provide a slide fastener having a separable bottom end

stop in which a reinforcement piece in the separable bottom end

stop is directly molded to a fastener tape by injection molding,

thereby reducing cost of a product; to improve flexibility of

the reinforcement piece; and to provide a high quality product

being difficult to be stripped and damaged in which the sewing

machine needle is not broken easily upon sewing, thereby

improving production efficiency.

Another object of the invention is to provide a slide

fastener having a separable bottom end stop in which a

projecting start edge portion of the reinforcement piece, which

receives the most load when an external force which can deform

the reinforcement piece is applied, is reinforced, and the

reinforcement piece is not broken easily.

Still another object of the invention is to provide a slide

fastener having a separable bottom end stop in which because

of an inclined portion of the reinforcement piece, the frequency

with which the reinforcement piece catches other objects is

reduced, thereby making stripping of the reinforcement piece

difficult, and the bottom end stop comprises an excellent and

strong reinforcement piece whose configuration is novel in

terms of design.

Further object of the invention is to provide a slide

fasteners having a separable bottom end stop in which a lower

end of the fastener tape is prevented from fraying easily, and

thus a beautiful condition is retained for a long period of time.

Another object of the invention is to provide a slide

fastener having a separable bottom end stop in which a molten

resin is thoroughly permeated from the projecting start edge

portion of the reinforcement piece to an edge portion at the

outer side portion when the reinforcement piece is molded by

injection molding, and thereby the reinforcement piece is

molded easily.

Other objects are made clear from the following

description of the embodiments.

In order to attain the above-described objects, according

to the main features of the invention, there is provided a slide

fastener having a separable bottom end stop in which respective

fastener elements are attached to opposing side edges of a pair

of fastener tapes, and the separable bottom end stop formed of

a synthetic resin and comprising a box pin, an insert pin and

a box is attached continuously to a lower end of the fastener

elements, and wherein sheet-like reinforcement pieces, which

project from opposing faces, that is, outer side faces of the

box pin and the insert pin and overhang respectively on at least

one surface of each of the fastener tapes, are provided at the

box pin and the insert pin, the box pin and the insert pin being

attached continuously to lower ends of the fastener elements;

each reinforcement piece has an inclined portion which inclines

towards an outer side edge of each fastener tape close to a lower

end of the fastener tape; the space between a lower end and the

inclined portion of the reinforcement piece is gradually

getting narrow toward an outer side portion of the reinforcement

piece; and the entire reinforcement piece has a substantially

triangular shape.

According to the above features, the following effects

are achieved that flexibility of the reinforcement piece is

improved, material used in the reinforcement piece is reduced

and this leads to a reduction in a product cost. In addition,

this results in a high quality product in which separation of

the reinforcement piece from the fastener tape and breakage

thereof is difficult and also, when the product is being sewn,

breakage of the sewing machine needle (not shown) is difficult,

and manufacturing efficiency is thereby improved.

Further, it is preferable that the reinforcement piece

provided on the other surface, for example a rear surface of

the fastener tape, is smaller than the reinforcement piece

provided on the one surface, for example a front surface of the

fastener tape, and both reinforcement pieces nip and hold the

fastener tape in the vicinity of one of the side faces of the

box pin and the insert pin such that the fastener tape is nipped

from both front and rear surfaces. Consequently, the following

effects are achieved that even if an external force that can

cause deformation of the reinforcement pieces is applied, a

projecting start edge portion of the reinforcement piece

provided on a front surface side of the fastener tape, where

the most load is applied, is reinforced by the reinforcement

piece provided on a rear surface side of the fastener tape, and

also the reinforcement piece on the front surface side cannot

break easily. Alternately, if the reinforcement pieces

disposed on both front and rear surfaces of the fastener tapes

are formed so as to have the same configuration, the following

effects are achieved that the reinforcement pieces do not break

easily at any portion thereof, when an external force which can

cause them to deform is applied thereto, and can be used for

a long period of time.

Further, it is possible that each of the reinforcement

pieces provided at the box pin and the insert pin is provided

with the inclined portion which inclines downward in a linear

form toward the outer side portion of said reinforcement piece

or the inclined portion which does not have a linear form, but

instead is bent inward in a substantially arc-shape. According

to the features, the following effects are achieved that the

frequency with which the inclined portion of the reinforcement

piece catches other objects is reduced and it becomes difficult

for the reinforcement piece to be stripped from the fastener

tape, and a novel design is achieved. Alternately, it is

preferable that an edge surface portion of each of the

reinforcement pieces provided at the box pin and the insert pin

is formed as a slope portion, which has a smooth downward incline

toward the front surface of the fastener tape, because the

frequency with which the entire reinforcement piece catches

other objects is reduced, an area for adhesion to the fastener

tape is ensured, stripping of the reinforcement piece is

prevented, and also a good feel to the touch is obtained.

In order to increase the attaching strength, it is

preferable that the outer side portion which extends in parallel

with the outer side edge of the fastener tape is formed between

the inclined portion and the lower end of the reinforcement

piece; the fastener tape is woven or knitted to allow

penetration of synthetic resins such that a portion of the

fastener tape, which the outer side portion of each of the

reinforcement pieces provided at the box pin and the insert pin,

that is, a front end portion of a side of each reinforcement

piece faces, is formed coarsely; and a welding yarn, which can

be thermally molten, is disposed at a portion of the fastener

tape, which the outer side portion of each of the reinforcement

pieces provided at the box pin and the insert pin, that is, a

front end portion of a side of each reinforcement piece faces,

so that a synthetic resin can be welded.

It is preferable that a plate-like projecting piece is

continuously provided with the outer side portion of each of

the reinforcement pieces provided at the box pin and the insert

pin, that is, with a front end portion of a side of each

reinforcement piece, and the projecting piece is attached so

as to hold and nip the outer side of the fastener tape.

Consequently, the following effects are achieved that an outer

tip portion of the reinforcement piece can be fixed firmly to

the fastener tape and the reinforcement piece never strip from

the fastener tape.

It is preferable that the lower end of each of the

reinforcement pieces provided at the box pin and the insert pin

aligns with the lower end of the fastener tape so as to reinforce

the fastener tape, because thread at a cut end of the fastener

tape can be prevented in advance from fraying easily and thus

the fastener tape can remain in a beautiful configuration for

a long period of time. Further, if except for a peripheral edge

portion which is continuous with the periphery of the

reinforcement piece, the entire inner face of each of the

reinforcement pieces provided at the box pin and the insert pin

is formed as a mesh having a mesh-like configuration, the

flexibility of the reinforcement piece is increased and the

amount of material used is reduced. Also, the design is made

excellent, and at the time of injection molding of the

reinforcement piece, thorough permeation of the molten resin

into the mesh portion can be carried out easily, thereby causing

the mold of the reinforcement piece to be simple.

According to the main features of the invention, there

is provided a slide fastener having a separable bottom end stop

in which respective fastener elements are attached to opposing

side edges of a pair of fastener tapes, and the separable bottom

end stop formed of a synthetic resin and comprising a box pin

and an insert pin is attached continuously to a lower end of

the fastener elements, wherein plate-like reinforcement pieces,

which project from opposing faces of the box pin and insert pin

respectively, that is, outer side surfaces thereof, and

overhang respectively on at least one surface of each of the

fastener tapes, are provided; each reinforcement piece has an

inclined portion which inclines toward an outer side edge close

to a lower end of the fastener tape; a space between a lower

end and the inclined portion of the reinforcement piece is

gradually getting narrow toward an outer side portion of the

reinforcement piece, and the entire reinforcement piece has a

substantially triangular shape. With the features, because

the reinforcement piece is disposed on only one surface of the

fastener tape, flexibility of the reinforcement piece is

improved and amount of material used is reduced and it leads

a reduction in cost of the product, and thus this invention

achieves remarkable effects.

BRIEF DESCRIPTION OF THE DRAWINGS

Fig. 1 is a front view of a main portion of a slide fastener

having a separable bottom end stop.

Fig. 2 is a front view of a main portion of a stringer,

in which a box pin is attached, of the same slide fastener having

the separable bottom end stop.

Fig. 3 is a bottom view of the stringer of the same slide

fastener having the separable bottom end stop.

Fig. 4 is a front view of a main portion of a stringer,

in which an insert pin is attached, of the same slide fastener

having the separable bottom end stop.

Fig. 5 is a bottom view of the stringer of the same slide

fastener having the separable bottom end stop.

Fig. 6 is side view of a box of the same slide fastener

having the separable bottom end stop.

Fig. 7 is a cross sectional view of the box taken along

line VII-VII in Fig. 6 of the same slide fastener having the

separable bottom end stop.

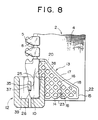

Fig. 8 is a partially cut front view showing a state that

the box pin is fit-inserted into the box of the same slide

fastener having the separable bottom end stop.

Fig. 9 is a partially cut front view showing a last state

in the same separable bottom end stop before the insert pin is

not inserted.

Fig. 10 is a partially cut front view showing a state in

the same separable bottom end stop that insert pin is set.

Fig. 11 is a front view of an end tip of the stringer

showing a modified example of the reinforcement piece.

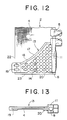

Fig. 12 is a front view of an end tip of the stringer

showing another modified example of the reinforcement piece.

Fig. 13 is a bottom view of the stringer of the same slide

fastener having the separable bottom end stop.

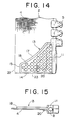

Fig. 14 is a front view of an end tip of the stringer

showing further modified example of the reinforcement piece.

Fig. 15 is a bottom view of the stringer of the same slide

fastener having the separable bottom end stop.

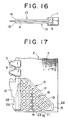

Fig. 16 is a bottom view of the stringer showing further

modified example of the reinforcement piece.

Fig. 17 is a front view of an end tip of the stringer

showing further modified example of the reinforcement piece.

Fig. 18 is a bottom view of the stringer of the same slide

fastener having the separable bottom end stop.

Fig. 19 is a front view of a known separable bottom end

stop.

DESCRIPTION OF THE PREFERRED EMBODIMENTS

The following is a detailed description of a slide

fastener having a separable bottom end stop of the invention,

with reference to the accompanying drawings.

In a slide fastener having a separable bottom end stop

of this invention, as shown in Fig. 1, a fastener chain 1 is

not a stopper with a lower stopper, but rather an open product.

That is to say, the slide fastener comprises a bottom end stop

6, in which right and left fastener stringers 2 can be separated

completely, and fastener elements 5 are attached to a core

portion 8 at a side edge of a fastener tape 4. Each of a box

pin 10 and an insert pin 11 is attached to the core portion 8,

such that the box pin 10 is attached continuously to a lower

portion of the fastener elements 5 of one stringer 2, while the

insert pin 11 is attached continuously to a lower portion of

the fastener elements 5 of the other stringer 2. Then, a box

12 is mounted to the box pin 10 and the separable bottom end

stop is completed.

In the box pin 10 attached to one stringer 2 of the fastener

chain 1, a flexible sheet-like reinforcement piece 13, which

overhang on a front surface of the fastener tape 4, is provided

integrally with a side face of the box pin 10. And in the insert

pin 11 attached to the other stringer 2 of the fastener chain

1, the flexible sheet-like reinforcement piece 13, which

overhang on the front surface of the fastener tape 4, is also

provided integrally with a side face of the insert pin 11. Then,

the fastener elements 5, the box pin 10, the insert pin 11 and

the reinforcement pieces 13 of the fastener chain 1 are

integrally molded with the fastener tapes 4 , respectively using

a thermoplastic resin by an injection molding means.

As shown in Figs. 2 to 5, the flexible sheet-like

reinforcement piece 13 is provided to each of the box pin 10

and the insert pin 11 so as to project outward from a side face

of each of the box pin 10 and the insert pin 11. As shown in

Fig.2, this reinforcement piece 13 at the box pin 10 is formed

with an inclined portion 17 which extends along the entire

length of the box pin 10 from vicinity of an upper end of the

box pin 10 to an outer side edge 22 of the fastener tape 4 close

to a lower end 23 of the fastener tape 4. A space between a

lower end 14 and the inclined portion 17 of the reinforcement

piece 13 is gradually getting narrow toward an outer side

portion 15 of the reinforcement piece 13 disposed in the

vicinity of the outer side edge 22 of the fastener tape 4. That

is, the reinforcement piece 13 is formed so as to be tapered

from a projecting start end at the side face of the box pin 10

toward the outer side portion 15. Thus the reinforcement piece

13 deforms easily in accordance with the deformation of the

fastener tape 4, and further an upper end portion of the

reinforcement piece 13 which tends most to catch other objects,

no longer does so, and stripping of the reinforcement piece 13

by the fastener tape 4 is prevented. Further, as shown in Fig.

3, the reinforcement piece 13 is molded on a front surface of

the fastener tape 4 by the injection molding means and it is

pressed and attached to the fastener tape 4.

The inclined portion 17 of the reinforcement piece 13 is

formed so as to be substantially linear in a downward direction

of the outer side edge 22 of the reinforcement piece 13.

Alternately, the reinforcement piece 13 is formed so as to be

slightly bent inwards to form an arc. Consequently, it hardly

catches other objects. Further, as shown in Fig. 3, an edge

portion of the reinforcement piece 13 has a slope portion 18

which slopes downward gently towards the fastener tape 4, and

thus the reinforcement piece is formed so as not to catch other

objects such as a sewing machine foot. As a result, the

reinforcement piece 13 is prevented from being stripped from

the fastener tape 4. Further, the outer side portion 15 which

extends in parallel with the outer side edge 22 of the fastener

tape 4 is provided in a space between the inclined portion 17

and the lower end 14 of the reinforcement piece 13, and thus

the reinforcement piece 13 is no more tapered than necessary.

That is to say, a front end of the reinforcement piece is no

longer formed as a sharp angle. As a result, an area for

pressing and attaching the outer side portion 15 to the fastener

tape 4 is secured, and thus stripping of the reinforcement piece

13 becomes difficult with the outer side portion 15. Except

for a peripheral edge portion which is continuous to the

periphery of reinforcement piece 13, the entire inner face is

formed as a mesh 16, and the mesh 16 provides the reinforcement

piece 13 with flexibility and elasticity.

The mesh 16 is formed by a tape press member which

positions the fastener tape 4 in the molding cavity of a mold,

such that when the reinforcement piece 13 is molded by injection

molding, the fastener tape 4 does not deform due to injection

pressure. Because the reinforcement piece 13 is formed in a

substantially triangular shape, and because it is formed as a

mesh 16, reduction in the amount of material can be achieved,

and further, the reinforcement piece 13 has an excellent design.

Meanwhile, a V-shaped groove 21 is formed so as to secure a space

for pressing a lower end 23 of the fastener tape 4 with a

tape-pressing member when the reinforcement piece 13 is molded

by injection molding.

As shown in Fig. 2, in the box pin 10, a middle portion

of the outer side face of the box pin 10 is formed as a concave

portion 25, and an engaging portion 26 is provided at a lower

end of the concave portion 25 and is engaged with an engaged

portion 37 provided on the box 12. Further, as shown in Fig.

3, the box pin 10 includes flexible sheet-like reinforcement

piece 20, which projects along the entire length of the box pin

10 on a rear side of the fastener tape 4 and overhangs on a surface

of the fastener tape 4 less than the reinforcement piece 13,

and the reinforcement piece 20 holds and nips the fastener tape

4 in the vicinity of the side face of the box pin 10 with the

reinforcement piece 13 on a front side of the fastener tape 4.

When the box pin 10 is fit-inserted into the box 12 from a lower

end thereof, the reinforcement piece 20 allows the box pin 10

to be guided smoothly. Further, when the slider 7 is moved

downwards from the upper end of the box pin 10 and abuts the

box 12 or when the slider 7 is moved upwards, the reinforcement

piece 20 functions to guide the slider 7 smoothly.

Further, when the reinforcement piece deforms in

accordance with the deformation of the fastener tape,

deformation of the fastener tape is suppressed relative to that

of the other portions at the projecting start edge portion of

the reinforcement piece which breaks off extremely easily, and

the reinforcement piece is reinforced such that breaking off

at the projecting start edge portion thereof is difficult.

The reinforcement piece 13 is provided to the insert pin

11 in the same manner as to the box pin 10. For example, as

shown in Fig. 4, the inclined portion 17 which inclines from

an area close to an upper end of the insert pin 11, that is,

from the same region as the box pin 10, to the outer side edge

22 of the fastener tape 4, close to the lower end 23 thereof.

The space between the lower end 14 and the inclined portion 17

of the reinforcement piece 13 is gradually getting narrowed

toward the outer side portion 15 of the reinforcement piece 13

disposed in the vicinity of the outer side edge 22 of the fastener

tape 4. The reinforcement piece 13 is molded on the front

surface of the fastener tape 4 by an injection molding means,

and pressed and attached onto the fastener tape 4. The inclined

portion 17 is formed so as to be substantially linear in a

downward direction of the outer side edge 22 of the

reinforcement piece 13 or formed so as to be bent inward in a

substantially arc-shape.

As shown in Fig. 5, the reinforcement piece 13 has a slope

portion 18 such that an edge portion of the reinforcement piece

slopes gently toward the front surface of the fastener tape 4,

so that the reinforcement piece is formed so as not to catch

other objects as a sewing machine foot. Further, an outer side

portion 15 which extends in parallel with the outer side edge

22 of the fastener tape 4 is provided between the inclined

portion 17 and the lower end 14 of the reinforcement piece 13.

Also, as shown in Fig. 5, a flexible sheet-like reinforcement

piece 20, which is projected along the entire distance of the

insert pin 11 and overhangs on the surface of the fastener tape

4 with a smaller area than that of the reinforcement piece 13,

is provided on the rear surface of the insert pin 11. The

reinforcement piece 20 holds and nips the fastener tape 4 in

the vicinity of the side face of the insert pin 11 with the

reinforcement piece 13, which is on the front surface. In

addition, the reinforcement 13 at the side of the insert pin

11 has the same configuration of the reinforcement piece at the

side of the box pin and functions similarly, such that entire

face except for the peripheral edge portion of the reinforcement

piece 13 is formed as a mesh 16.

Next, the box 12 will be described. As shown in Figs.

6 and 7, the periphery of the box 12 is surrounded by a front

wall 30, a back wall 31, side walls 32, and a bottom wall 33.

An upper side of the box is provided with an opening portion

34 which is opened and a partitioning wall 35 is provided in

the center of the box 12 between the front wall 30 and the back

wall 31, thus providing a box pin insert portion 38 , and an insert

pin insert portion 39 to the right and left of the box 12. The

partitioning wall 35 is engaged with the concave portion 25 of

the box pin 10 and the engaged portion 37 which is engaged with

the engaging portion 26 of the concave portion 25 is provided

at a lower end of the partitioning wall. Further, a side groove

36 is provided at the center of each of the side walls 32 in

a longitudinal direction thereof, and the reinforcement piece

13 disposed at the fastener tape 4 can be fit-inserted therein.

The material for the box 12 is the same material used for the

box pin 10, the insert pin 11, and the reinforcement piece 13.

The separable bottom end stop 6 is assembled in the

following manner. As shown in Fig. 8, when the box pin 10 which

is attached to an end portion of the stringer 2 is fit-inserted

into the box pin insertion portion 38 of the box pin 12, and

the concave portion 25 which is provided on the side face of

the box pin 10 is fit-inserted into the partitioning wall 35

of the box 12. The engaging portion 26 and the engaged portion

37 are engaged and fixed, and then the box 12 can be attached

to the stringer 2. It is to be noted that the box 12 can be

easily attached to the box pin 10 by a manual operation.

The operation of the separable bottom end stop 6 is as

described in the following. As shown in Fig. 9, at the box 12

which is attached to the stringer 2 on which the box pin 10 is

mounted, the slider 7 which is inserted through the same

stringer 2 is pulled down so as to abut the box 12, and in this

state, the insert pin 11 which is mounted to the other stringer

2 is fit-inserted into the slider 7 and the insert pin insertion

portion 39 of the box 12 by gripping the reinforcement piece

13. Then the slider 7 is pulled up and slid, and both fastener

elements 5 are coupled with each other as shown in Fig. 10, and

the coupled state of the fastener chain 1 is thereby achieved.

In order to separate and release the fastener chain 1, after

the slider 7 is pulled down to the box 12, the reinforcement

piece 13 at the side of the insert pin 11 is gripped and the

insert pin 11 is taken out from the insert pin insertion portion

39 of the box 12 and from the slider 7, and then both stringers

2 are separated.

In the modified example of the reinforcement piece 13

shown Fig. 11, at a portion of the reinforcement piece which

is close to the outer side edge 22 of fastener tape 4, for example

a portion A shown in the drawing, part of the warp yarns are

omitted, or alternately part of the warp yarns are pulled toward

one side edge of the fastener tape 4, and the fastener tape 4

is formed with a rough weaving or knitting structure in which

air space of fiber passing through the fastener tape 4 in the

direction of the front and rear surfaces of the fastener tape

is larger than that of the other portions. In addition, the

reinforcement piece 13 is molded by injection molding to the

fastener tape 4, the resin of the outer side portion 15 of the

reinforcement piece 13 can be easily permeated and solidified

through the roughness within the weaving or knitting structure.

Thus the outer side portion 15 of the reinforcement piece 13

can be fixed firmly to the fastener tape 4 and stripping of the

reinforcement piece 13 from the fastener tape 4 can be prevented

certainly. Further, the lower end 14 of the reinforcement piece

13 in the vicinity of the box pin 10 or the insert pin 11 is

not provided with the V-shaped grooves 21 formed therein. As

a result, breakage of the projecting start edge portion of the

reinforcement piece 13 becomes difficult.

Further, a welding yarn, which is formed from a synthetic

fiber yarn having a same level of or lower melting point as that

of the same resin used for the reinforcement piece 13, is woven

as a warp yarn or knitted as a warp knitted yarn at a portion

A, a portion of the fastener tape 4 being close to the outer

side edge 22 of the fastener tape 4. And the, when the

reinforcement piece 13 is molded by injection molding, the

welding yarn is melted and integrated with the reinforcement

piece 13. As a result, the outer side portion 15 of the

reinforcement piece 13 is firmly fixed and stripping of the

reinforcement piece 13 from the fastener tape 4 is prevented.

Figs. 12 and 13 show a modified example of the

reinforcement piece 13 in which a sheet-like projecting piece

19 is continuously provided with the outer side portion 15 of

the reinforcement piece 13, and as shown in Fig. 13, the

projecting piece 19 is extended to the rear surface of the

fastener tape 4, such that it holds and nips the outer side edge

22 of fastener tape 4. And this, the reinforcement piece 13

is firmly fixed to fastener tape 4 and stripping of the

reinforcement piece 13 from the fastener tape 4 is prevented

certainly.

In the reinforcement piece 13 modified examples shown in

Figs. 14 and 15, injection molding of the reinforcement piece

13 is carried out such that the lower end 14 of the reinforcement

piece 13 and the lower end 23 of the fastener tape 4 are aligned,

and the lower end 14 and the lower end 23 are welded together

in order to prevent the thread from fraying at the lower end

23 which is a cut end of the fastener tape 4. One means for

aligning the lower end 14 of the reinforcement piece 13 and the

lower end 23 of the fastener tape 4 is to mold the lower end

14 of the reinforcement pieces 13 on the fastener tape 4 such

that it extends so as to project further downward than the box

pin 10 or the insert pin 11. After the molding, this extended

portion is cut together with the fastener tape 4 and thereby

caused to be aligned. The cutting is carried out by press-cutting.

and the lower end 14 of the reinforcement piece 13 and

the lower end 23 of the fastener tape 4 are melted and

respectively welded together by the heat generated by the

press-cutting. In addition, a slope portion 18 is formed at

an edge portion of the reinforcement piece 13, which is

continuous with the inclined portion 17, the outer side portion

15 and the lower end 14, and thus the reinforcement piece 13

becomes difficult to catch other objects.

In the reinforcement piece 13 of the modified example

shown in Fig. 16, reinforcement pieces 13 and 20 which have the

same configuration are molded by injection molding onto both

front and rear surfaces of the fastener tape 4, and the fastener

tape 4 is held and nipped by the reinforcement pieces 13 and

20. Thus even if the reinforcement pieces 13 and 20 deform in

accordance with the deformation of the fastener tape 4, breakage

at all the portions of the reinforcement pieces 13 and 20 becomes

difficult.

The difference between the reinforcement piece 13 in the

modified example shown in Figs. 17 and 18 and the example of

the first embodiment is the shape of the inclined portion 17

of the reinforcement piece 13. As shown in Fig. 18, the flexible

sheet-like reinforcement piece 13 provided only on the front

surface of the fastener tape 4, is molded integrally by

injection molding from the side face of the box pin 10 or the

insert pin 11. As shown in Fig. 17, the inclined portion 17,

which inclines in a substantially linear shape from the side

of an upper end of the box pin 10 or the insert pin 11 toward

the outer side edge 22 close to the lower end 23 of the fastener

tape 4, is provided, and the space between the lower end 14 of

the reinforcement piece 13 and the inclined portion 17 is

gradually getting narrow toward the outer side portion 15 of

the reinforcement piece 13, and the entire reinforcement piece

13 has a substantially triangular shape.

Finally, as a thermoplastic resin used for the fastener

elements 5, the box pin 10, the insert pin 11, the reinforcement

pieces 13 and 20, the box 12 and an upper stopper in the fastener

chain 1, a polyactetal resin is preferably used when

consideration is given to molding and color matching of the

members. In order to make the reinforcement pieces 13 and 20

flexible, a soft acetal resin or a soft acetal copolymer resin

is used. Especially, by using a resin having the specific

properties of a tensile strength (Mpa) in the range of 45 to

60, a pull and stretch (%) in the range of 60 to 300, and a melt

index (g/min) in the range of 6 to 25, the reinforcement piece

13 which has the smallest thickness of the resin members listed

above, can be provided with a suitable amount of flexibility.

Thus, a slide fastener having a separable bottom end stop, in

which the fastener chain 1 is soft to the touch, is completed.