EP1210520B1 - Magnetically driven pump - Google Patents

Magnetically driven pump Download PDFInfo

- Publication number

- EP1210520B1 EP1210520B1 EP00960799A EP00960799A EP1210520B1 EP 1210520 B1 EP1210520 B1 EP 1210520B1 EP 00960799 A EP00960799 A EP 00960799A EP 00960799 A EP00960799 A EP 00960799A EP 1210520 B1 EP1210520 B1 EP 1210520B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- partition

- rotor

- magnets

- pump according

- pump

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D29/00—Details, component parts, or accessories

- F04D29/04—Shafts or bearings, or assemblies thereof

- F04D29/046—Bearings

- F04D29/047—Bearings hydrostatic; hydrodynamic

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D13/00—Pumping installations or systems

- F04D13/02—Units comprising pumps and their driving means

- F04D13/021—Units comprising pumps and their driving means containing a coupling

- F04D13/024—Units comprising pumps and their driving means containing a coupling a magnetic coupling

- F04D13/025—Details of the can separating the pump and drive area

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D29/00—Details, component parts, or accessories

- F04D29/04—Shafts or bearings, or assemblies thereof

- F04D29/043—Shafts

Definitions

- the sealing wall is particularly important when the pumped liquid corrosive character, which is frequently the case in chemistry or electroplating.

- the motor 1 is connected to the centrifugal wheel 2 by an axis 3 and a rigid coupling device 4.

- the wheel 2 rotates in the pump body 5 which communicates with the suction pipe 6 and the discharge pipe. pump body at the passage of the axis 3 is ensured by the friction seal 8.

- a second potential defect concerns the sealing itself which can not be guaranteed in a perfect way, because of the small surface defects that can be meet on the rubbing support faces, and the inevitable creation of a film liquid between these surfaces.

- FIG. 2 shows the motor 11, the wheel 12, the pump body 15, the suction pipes 16 and discharge 17.

- the sealing is here ensured by the continuous partition 18 assembled rigidly and hermetically between the body of pump 15 and the spacer 19 providing the connection with the motor flange 11.

- the drive rotor 20 On the axis of the motor 11 is rigidly mounted the drive rotor 20 in which is inserted, for example by overmoulding, a series of magnets 21.

- the driven rotor 22 integral with the wheel 12 is equipped with a series of magnets 23.

- the magnets 21, 23 are organized so that a north pole side drive is in face of a south pole driven side, and vice versa. We thus obtain a coupling magnetic field without mechanical contact, which must be sufficient to withstand without stalling the maximum torque absorbed by the wheel.

- Document FR-A-2311201 describes a pump with magnetic drive, in which the turbine is equipped with a magnetic core and is driven by the magnetic crown through a watertight bulkhead.

- the rotary turbine is supported by a fixed shaft, which is guided by a pair of bearings on the magnetic ring in connection with the motor shaft.

- the presence of bearings in addition to the output bearing of the motor shaft gives the whole a door to fake important, and additional embedding.

- the axial size of the pump is important, and the positioning of the turbine shaft does not allow to achieve perfect alignment.

- the axis of the motor is advantageously prolonged by a length sufficient for him allow to get into the heart of the driven rotor. It follows that the axis of the engine encompasses the axis of the wheel which, fixed, becomes turning. This is obviously not this rotation which is sought after, but the fact of having for the first rotor driven, a rigid support and perfectly aligned with the motor axis.

- the first driven rotor has a second ring which pivots on a first ring integral with the fixed partition.

- the bearing integrated in the partition comprises at least one self-lubricating ring constituting a thermal bridge for the evacuation of the calories generated by the trunnion of the first rotor driven to the radiator formed by the motor shaft.

- the sealing partition must not be interrupted, so it is necessary to complicate a little shape to make it bypass the extended tip, which belongs to the area external to the pumping circuit, whereas the axis 24 according to FIG. 2 of the prior art belonged to the inner zone.

- the partition will have to present a second cylindrical part coming to engage on the end of the axis motor, with the interposition of a friction sleeve, made for example in self-lubricating material.

- this axis now ensures the positioning of the rotor driven with precision and the rigidity wanted, this function does not have to be ensured by the partition sealing, which can be significantly lightened.

- this partition can be made in one piece, in a material chemically compatible with the pumped liquid.

- the part must be able to withstand the pressure of the liquid around the driven rotor, a sizeable pressure since it can be close to the discharge pressure of the pump. In cases where this pressure is high, and where there is no chemically compatible material having the sufficient mechanical strength, one can be reduced to a solution of composite partition with a mechanically strong outer shell, and a chemically compatible inner shell.

- the configuration described above has an obvious advantage, as far as it is appear a thermal bridge of strong section and thin thickness between the bearing driven rotor and the motor shaft.

- this advantage is mitigated by the it is necessary to evacuate in addition the calories produced by the rotation of the mouthpiece additional engine shaft in its own landing, but we're out there of reaching the pumped liquid, which makes it possible to use components classic mechanicals, whose performance is excellent.

- the sealing partition is shaped for chemical compatibility, while accuracy and mechanical strength are provided by an additional piece partially matching the shape of the partition, and made of a material having good mechanical strength.

- the room may be made of metal alloy, in particular steel stainless steel, and includes a ferrule inserted into the gap between the two series of magnets. The thickness of the ferrule is less than that of the envelope of the partition.

- a tip 42 extends the motor shaft 41, which it can be an integral part, or on which it can be assembled with rigidity and precision.

- the tip 42 is arranged to receive the fixing of the second drive rotor 30, this attachment being provided by any suitable mechanical means.

- the sealing partition consists of a casing 48 made of material chemically compatible with the pumped liquid, and a cylindrical shell 52 made of mechanically resistant material, especially stainless steel. This ferrule makes it possible to bring the resistance to the internal pressure, insofar as the constituent material of the envelope 48 may be insufficiently resistant.

- the envelope 48 is extended inwards by a sheath portion, in which axially introduces the tip 42.

- the ring 35 and the sleeve 53 may advantageously be overmoulded in the envelope of the partition 48 during the molding thereof.

- the sealing partition is therefore completely discharged from the centering function, and no longer has to be very rigid. On the contrary, it is desirable that it presents a minimum flexibility, so as not to upset the centering imposed by the tip 42.

- the device of FIG. evacuation to the outside of the calories generated by the rotation of the rotor wheel 32, the motor shaft 41 acting as a radiator via the nozzle 42.

- the calories pass successively through pieces 35, 48, 53, 54 and 54 'but all these transfers involve small thicknesses and large sections, which leads to a sufficiently efficient thermal bridge.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- Structures Of Non-Positive Displacement Pumps (AREA)

- External Artificial Organs (AREA)

- Sealing Devices (AREA)

- Electromagnetic Pumps, Or The Like (AREA)

Abstract

Description

L'invention est relative à une pompe à entraínement magnétique comprenant :

- un élément de pompe pourvu d'un premier rotor entraíné en forme de roue montée à rotation dans un corps associé à des tuyauteries d'aspiration et de refoulement,

- une première série d'aimants solidaires du premier rotor,

- un moteur d'entraínement doté d'un arbre de transmission sur lequel est monté un deuxième rotor d'entraínement portant une deuxième série d'aimants, les deux séries d'aimants étant disposées concentriquement pour réaliser un couplage magnétique en rotation,

- et un dispositif d'étanchéité ayant une cloison fixe s'étendant dans l'entrefer entre les deux séries d'aimants en assurant une séparation étanche entre l'élément de pompe et le moteur.

- a pump element provided with a first rotor driven in the form of a wheel rotatably mounted in a body associated with suction and discharge pipes,

- a first series of magnets secured to the first rotor,

- a drive motor provided with a transmission shaft on which is mounted a second drive rotor carrying a second series of magnets, the two sets of magnets being arranged concentrically to achieve a magnetic coupling in rotation,

- and a sealing device having a fixed partition extending in the gap between the two sets of magnets providing a sealed separation between the pump element and the motor.

La paroi d'étanchéité est particulièrement importante quand le liquide pompé présente un caractère corrosif, ce qui est fréquemment le cas dans la chimie ou la galvanoplastie.The sealing wall is particularly important when the pumped liquid corrosive character, which is frequently the case in chemistry or electroplating.

Pour ces applications, qui supportent mal les arrêts, il est par ailleurs important que les interventions de maintenance soient aussi réduites que possible, voire supprimées. For these applications, which do not support the stops, it is also important that maintenance interventions are as small as possible, or even deleted.

On peut classer les pompes utilisées actuellement en deux grandes catégories :

- les pompes à garniture d'étanchéité ( figure 1), comportant des pièces en frottement montées en partie fixe d'une part, et en partie tournante d'autre part, la nature des matériaux en présence et la qualité de leur état de surface permettant d'obtenir une étanchéité satisfaisante ;

- les pompes à entraínement magnétique (figure 2), qui ont été conçues pour remédier aux inconvénients précités, assurant l'étanchéité, non plus par des pièces en frottement, mais par une cloison continue. De part et d'autre de cette cloison, se trouvent un rotor d'entraínement lié au moteur, et un rotor entraíné lié à la roue de la pompe. Les deux rotors portent des aimants disposés de telle sorte qu'ils assurent un couplage magnétique entre les deux rotors.

- seal-filled pumps (FIG. 1), comprising friction parts mounted in fixed part on the one hand, and partly rotating part, on the other hand, the nature of the materials present and the quality of their surface state allowing to obtain a satisfactory seal;

- magnetic drive pumps (Figure 2), which were designed to overcome the aforementioned drawbacks, ensuring the seal, no longer by friction parts, but by a continuous partition. On either side of this partition, there is a drive rotor connected to the motor, and a driven rotor connected to the pump impeller. Both rotors carry magnets arranged so that they provide a magnetic coupling between the two rotors.

Sur la figure 1, le moteur 1 est relié à la roue centrifuge 2 par un axe 3 et un

dispositif d'accouplement rigide 4. La roue 2 tourne dans le corps de pompe 5 qui

communique avec les tuyauteries d'aspiration 6 et de refoulement 7. L'étanchéité du

corps de pompe au passage de l'axe 3 est assurée par le joint à frottement 8.In FIG. 1, the

Le premier défaut qu'on peut reprocher à ce type de pompe est que les pièces en

frottement constituant ce joint sont sujettes à usure, et qu'il faut donc les remplacer

périodiquement, ce qui donne lieu à des arrêts pour maintenance. Cette opération

de remplacement est d'autant plus délicate que le joint 8 est localisé dans une zone

peu accessible.The first flaw that can be blamed on this type of pump is that the parts in

This seal is subject to wear and must be replaced.

periodically, resulting in maintenance shutdowns. This operation

replacement is all the more delicate as the

Un second défaut potentiel concerne l'étanchéité elle-même qui ne peut être garantie de façon parfaite, en raison des petits défauts de surface qu'on peut rencontrer sur les faces d'appui en frottement, et de la création inévitable d'un film liquide entre ces surfaces.A second potential defect concerns the sealing itself which can not be guaranteed in a perfect way, because of the small surface defects that can be meet on the rubbing support faces, and the inevitable creation of a film liquid between these surfaces.

Sur la figure 2, on retrouve le moteur 11, la roue 12, le corps de pompe 15, les

tuyauteries d'aspiration 16 et de refoulement 17. L'étanchéité est ici assurée par la

cloison continue 18 assemblée rigidement et hermétiquement entre le corps de

pompe 15 et l'entretoise 19 assurant la liaison avec la bride du moteur 11. Sur l'axe

du moteur 11 est monté rigidement le rotor d'entraínement 20 dans lequel est

insérée, par exemple par surmoulage, une série d'aimants 21.FIG. 2 shows the

Le rotor entraíné 22 solidaire de la roue 12 est équipé par une série d'aimants 23.

Les aimants 21, 23 sont organisés pour qu'un pôle nord côté entraínement soit en

face d'un pôle sud côté entraíné, et inversement. On obtient ainsi un couplage

magnétique sans contact mécanique, couplage qui doit donc être suffisant pour

supporter sans décrochage le couple maximum absorbé par la roue.The driven

Une bonne efficacité du couplage exige que l'entrefer entre les deux familles d'aimants soit aussi réduit que possible. Cet entrefer étant constitué par l'épaisseur de la cloison 18 et par les jeux présents de part et d'autre de celle-ci, on voit qu'il faut chercher :

- à minimiser l'épaisseur de la cloison, ce qui suppose qu'on ne la sollicite pas trop sur le plan mécanique, et/ou qu'on la réalise dans un matériau présentant une bonne rigidité ;

- à réduire les jeux, ce qui suppose une bonne maítrise dimensionnelle des pièces concernées, ainsi que de leur positionnement.

- to minimize the thickness of the partition, which supposes that it is not stressed too much mechanically, and / or that it is made of a material having good rigidity;

- to reduce the games, which assumes a good dimensional control of the parts concerned, as well as their positioning.

Sur le premier point, il peut y avoir contradiction entre la tenue mécanique de la cloison et sa compatibilité chimique avec le liquide pompé, avec lequel elle est en contact par sa face interne. On the first point, there may be a contradiction between the mechanical strength of the bulkhead and its chemical compatibility with the pumped liquid, with which it is contact by its internal face.

Une solution couramment utilisée consiste à réaliser cette cloison par juxtaposition de deux matériaux :

- extérieurement, une partie métallique amagnétique fournissant précision et rigidité.

- intérieurement, une partie en matériau synthétique chimiquement compatible.

- externally, a non-magnetic metal part providing precision and rigidity.

- internally, a part made of chemically compatible synthetic material.

Cette disposition résout assez bien le problème, mais elle présente deux inconvénients non négligeables :

- augmentation de l'épaisseur, et donc de l'entrefer.

- présence de courants de Foucault dans la paroi métallique, ces courants étant induits par la rotation du flux des aimants. Ces courants de Foucault constituent une source d'échauffement qui peut devenir prohibitive, notamment pour de grosses unités.

- increase of the thickness, and therefore of the gap.

- presence of eddy currents in the metal wall, these currents being induced by the rotation of the flux of the magnets. These eddy currents are a source of heating that can become prohibitive, especially for large units.

Pour aborder le second point, à savoir les jeux, le dispositif de positionnement et de guidage en rotation de la roue 12 selon la figure 2, est constitué :

- d'un axe fixe 24, monté avec rigidité et précision sur la

cloison 18, - d'une bague fixe 25 solidaire de l'axe 24,

- et d'une bague tournante 26 solidaire de la

roue 12.

- a

fixed axis 24 mounted rigidly and precisely on thepartition 18, - a

fixed ring 25 integral with theaxis 24, - and a rotating

ring 26 secured to thewheel 12.

La qualité et la disposition des bagues 24, 25 sont évidemment essentielles pour la tenue de la pompe, avec notamment :

- un dimensionnement aussi large que possible des surfaces en contact.

- un choix judicieux des matériaux (céramique, carbure de silicium, graphite....) et de leur état de surface.

- une utilisation judicieuse du liquide pompé pour assurer la lubrification

- une évacuation aussi bonne que possible des calories générées par le frottement.

- as large a dimensioning as possible of the surfaces in contact.

- a judicious choice of materials (ceramic, silicon carbide, graphite ....) and their surface condition.

- judicious use of the pumped liquid to ensure lubrication

- an evacuation as good as possible of the calories generated by the friction.

L'examen de la figure 2 montre clairement les inconvénients inhérents au montage

de l'axe 24 en ce qui concerne la précision, donc la maítrise des jeux. Son

positionnement par rapport à l'axe du moteur (avec lequel il doit théoriquement être

aligné), passe en effet par deux pièces dont la précision et la rigidité peuvent poser

problème : l'entretoise 19 et surtout la cloison 18. On a vu en effet que cette

dernière doit être mince pour passer dans l'entrefer et ne pas produire trop de

courants de Foucault.The examination of Figure 2 clearly shows the inherent disadvantages of mounting

of the

Il sera donc très difficile d'obtenir un bon encastrement de l'axe 24. Il a été proposé

d'améliorer la tenue mécanique en installant un palier additionnel à l'autre extrémité

de la roue, mais cette solution augmente notablement la complexité sans résoudre

parfaitement le problème.It will therefore be very difficult to obtain a good embedding of the

Enfin, concernant l'évacuation des calories absorbées par l'axe 24, il faut noter

qu'elle doit se faire à travers la cloison 18 qui s'y prête assez mal, toujours du fait de

sa minceur.Finally, concerning the evacuation of the calories absorbed by the

Le document FR-A-2311201 décrit une pompe à entraínement magnétique, dans laquelle la turbine est équipée d'un noyau magnétique et est entraínée par la couronne magnétique à travers une cloison étanche. La turbine rotative est supportée par un arbre fixe, lequel est guidé par une paire de roulements sur la couronne magnétique en liaison avec l'arbre moteur. La présence des roulements en plus du roulement de sortie de l'arbre moteur confère à l'ensemble un porte à faux important, et un encastrement supplémentaire. L'encombrement axial de la pompe est important, et le positionnement de l'arbre de la turbine ne permet pas d'obtenir un alignement parfait.Document FR-A-2311201 describes a pump with magnetic drive, in which the turbine is equipped with a magnetic core and is driven by the magnetic crown through a watertight bulkhead. The rotary turbine is supported by a fixed shaft, which is guided by a pair of bearings on the magnetic ring in connection with the motor shaft. The presence of bearings in addition to the output bearing of the motor shaft gives the whole a door to fake important, and additional embedding. The axial size of the pump is important, and the positioning of the turbine shaft does not allow to achieve perfect alignment.

L'objet du présent brevet est de proposer une solution permettant de remédier aux inconvénients ci-dessus, c'est-à-dire d'assurer d'une part un centrage parfait de l'axe de rotation de la roue de la pompe, tout en déchargeant la cloison d'étanchéité de cette fonction, et d'autre part en recherchant une évacuation efficace des calories vers un élément de refroidissement.The purpose of this patent is to propose a solution to remedy disadvantages above, that is to say to ensure on the one hand a perfect centering of the axis of rotation of the pump impeller while unloading the watertight bulkhead this function, and on the other hand by seeking effective evacuation of calories to a cooling element.

La pompe selon l'invention est caractérisée en ce que :

- le premier rotor entraíné tourillonne sur une portée cylindrique dont le positionnement et le soutien sont assurés par un embout axial s'étendant dans le prolongement de l'arbre du moteur,

- un palier cylindrique femelle sert de logement concentrique à l'embout pour obtenir un soutien mécanique et un centrage précis de la cloison et du premier rotor entraíné.

- the first rotor driven rotates on a cylindrical seat whose positioning and support are provided by an axial endpiece extending in the extension of the motor shaft,

- a cylindrical female bearing serves as a concentric housing at the end to obtain mechanical support and precise centering of the partition and the first driven rotor.

L'axe du moteur est prolongé avantageusement d'une longueur suffisante pour lui permettre de s'introduire au coeur du rotor entraíné. Il en résulte que l'axe du moteur englobe l'axe de la roue qui, de fixe, devient tournant. Ce n'est évidemment pas cette rotation qui est recherchée, mais le fait de disposer pour le premier rotor entraíné, d'un support rigide et parfaitement aligné avec l'axe moteur.The axis of the motor is advantageously prolonged by a length sufficient for him allow to get into the heart of the driven rotor. It follows that the axis of the engine encompasses the axis of the wheel which, fixed, becomes turning. This is obviously not this rotation which is sought after, but the fact of having for the first rotor driven, a rigid support and perfectly aligned with the motor axis.

Selon un mode de réalisation préférentiel,. le premier rotor entraíné comporte une deuxième bague qui tourillonne sur une première bague solidaire de la cloison fixe. Le palier intégré à la cloison comprend au moins une bague autolubrifiante constituant un pont thermique pour l'évacuation des calories générées par le tourillonnement du premier rotor entraíné vers le radiateur formé par l'arbre moteur.According to a preferred embodiment ,. the first driven rotor has a second ring which pivots on a first ring integral with the fixed partition. The bearing integrated in the partition comprises at least one self-lubricating ring constituting a thermal bridge for the evacuation of the calories generated by the trunnion of the first rotor driven to the radiator formed by the motor shaft.

La cloison d'étanchéité ne devant pas être interrompue, il faut donc compliquer un

peu sa forme pour lui faire contourner l'embout prolongé, qui appartient à la zone

externe au circuit de pompage, alors que l'axe 24 selon la figure 2 de l'art antérieur

appartenait à la zone interne.The sealing partition must not be interrupted, so it is necessary to complicate a

little shape to make it bypass the extended tip, which belongs to the area

external to the pumping circuit, whereas the

En plus de la partie cylindrique présente dans l'entrefer, la cloison devra donc présenter une seconde partie cylindrique venant s'engager sur l'extrémité de l'axe moteur, avec interposition d'une douille de frottement, réalisée par exemple en matériau autolubrifiant. In addition to the cylindrical part in the air gap, the partition will have to present a second cylindrical part coming to engage on the end of the axis motor, with the interposition of a friction sleeve, made for example in self-lubricating material.

Cet axe assurant maintenant le positionnement du rotor entraíné avec la précision et la rigidité voulues, cette fonction n'a plus à être assurée par la cloison d'étanchéité, qui peut donc être sensiblement allégée. Dans le mode de réalisation le plus simple, cette cloison peut être réalisée en une seule pièce, dans un matériau chimiquement compatible avec le liquide pompé.This axis now ensures the positioning of the rotor driven with precision and the rigidity wanted, this function does not have to be ensured by the partition sealing, which can be significantly lightened. In the embodiment the simplest, this partition can be made in one piece, in a material chemically compatible with the pumped liquid.

Il faut toutefois noter que la pièce doit rester capable de supporter la pression du liquide présent autour du rotor entraíné, pression non négligeable puisqu'elle peut être voisine de la pression de refoulement de la pompe. Dans les cas où cette pression est élevée, et où il n'existe pas de matériau chimiquement compatible présentant la tenue mécanique suffisante, on peut être ramené à une solution de cloison mixte comportant une enveloppe externe mécaniquement résistante, et une enveloppe interne chimiquement compatible.It should be noted, however, that the part must be able to withstand the pressure of the liquid around the driven rotor, a sizeable pressure since it can be close to the discharge pressure of the pump. In cases where this pressure is high, and where there is no chemically compatible material having the sufficient mechanical strength, one can be reduced to a solution of composite partition with a mechanically strong outer shell, and a chemically compatible inner shell.

On n'est pas pour autant ramené aux mêmes contraintes qu'avec les pompes classiques correspondant à la figure 2. En effet, la tenue à la pression interne est bien plus facile à assurer que la rigidité et la précision.However, we are not reduced to the same constraints as with pumps corresponding to Figure 2. In fact, the resistance to internal pressure is much easier to ensure than rigidity and precision.

L'enveloppe externe pourra donc être beaucoup plus mince, ce qui permet d'envisager de la réaliser :

- soit en métal amagnétique, comme dans la solution classique, mais en adoptant une épaisseur très faible, ce qui ramène les pertes par courants de Foucault à une valeur admissible ;

- soit en matériau synthétique (polyamide ou polycarbonate chargés par exemple), ce qui impose une augmentation modérée de l'entrefer, mais supprime totalement les courants de Foucault.

- either of non-magnetic metal, as in the conventional solution, but adopting a very low thickness, which reduces the eddy current losses to a permissible value;

- either of synthetic material (polyamide or polycarbonate loaded for example), which imposes a moderate increase in the air gap, but completely eliminates eddy currents.

Concernant l'évacuation des calories générées par la rotation, la configuration décrite ci-dessus présente un avantage évident, dans la mesure où elle fait apparaítre un pont thermique de forte section et de faible épaisseur entre le palier du rotor entraíné et l'arbre du moteur. Bien entendu, cet avantage est atténué par le fait qu'il faut évacuer en plus les calories produites par la rotation de l'embout additionnel de l'arbre du moteur dans son propre palier, mais on se trouve là hors d'atteinte du liquide pompé, ce qui permet de faire appel à des composants mécaniques classiques, dont le rendement est excellent.Regarding the evacuation of the calories generated by the rotation, the configuration described above has an obvious advantage, as far as it is appear a thermal bridge of strong section and thin thickness between the bearing driven rotor and the motor shaft. Of course, this advantage is mitigated by the it is necessary to evacuate in addition the calories produced by the rotation of the mouthpiece additional engine shaft in its own landing, but we're out there of reaching the pumped liquid, which makes it possible to use components classic mechanicals, whose performance is excellent.

Selon une autre caractéristique de l'invention, la cloison d'étanchéité est conformée pour la compatibilité chimique, tandis que la précision et la tenue mécanique sont assurées par une pièce additionnelle épousant partiellement la forme de la cloison, et réalisée dans un matériau ayant une bonne tenue mécanique. La pièce additionnelle peut être réalisée en alliage métallique, notamment en acier inoxydable, et comprend une virole s'insérant dans l'entrefer ménagé entre les deux séries d'aimants. L'épaisseur de la virole est inférieure à celle de l'enveloppe de la cloison.According to another characteristic of the invention, the sealing partition is shaped for chemical compatibility, while accuracy and mechanical strength are provided by an additional piece partially matching the shape of the partition, and made of a material having good mechanical strength. The room may be made of metal alloy, in particular steel stainless steel, and includes a ferrule inserted into the gap between the two series of magnets. The thickness of the ferrule is less than that of the envelope of the partition.

D'autres avantages et caractéristiques ressortiront plus clairement de la description qui va suivre à travers les dessins annexés, donnés à titre d'exemples non limitatifs, et dans lesquels :

- la figure 1 représente une vue en élévation schématique d'un ensemble motopompe classique avec garniture d'étanchéité à frottement.

- la figure 2 représente une vue en élévation schématique d'un ensemble motopompe classique à entraínement magnétique.

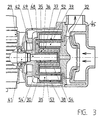

- la figure 3 représente une vue en élévation et en coupe d'un entraínement magnétique selon l'invention.

- Figure 1 shows a schematic elevational view of a conventional motor pump unit with friction seal.

- FIG. 2 represents a diagrammatic elevational view of a conventional motor pump unit with magnetic drive.

- Figure 3 shows an elevational view in section of a magnetic drive according to the invention.

Ce mode de réalisation est illustré par la figure 3 dans laquelle on retrouve :

- le moteur d'entraínement 29,

- la roue du

premier rotor entraíné 32, équipée de la première série d'aimants 33 et d'un tube enacier 37, - le deuxième rotor d'entraínement 30, équipé de la deuxième série d'aimants 31 et

d'un tube en

acier 38, lestubes 37 et 38 ayant pour fonction d'assurer le bouclage du flux magnétique des aimants permanents 31, 33.Les tubes - la bague fixe 35 et la bague tournante 36 constituant le palier de rotation de la roue,

- le corps de pompe 45,

- et l'entretoise 49 assurant la liaison entre le moteur 29 et le corps de pompe 45.

- the

drive motor 29, - the wheel of the first driven

rotor 32, equipped with the first series ofmagnets 33 and asteel tube 37, - the second drive rotor 30, equipped with the second series of

magnets 31 and asteel tube 38, thetubes permanent magnets tubes magnets wheel 32 by any appropriate means, in particular by overmolding, - the fixed

ring 35 and therotating ring 36 constituting the rotation bearing of the wheel, - the

pump body 45, - and the

spacer 49 providing the connection between themotor 29 and thepump body 45.

Un embout 42 prolonge l'arbre moteur 41, dont il peut faire partie intégrante, ou sur

lequel il peut être assemblé avec rigidité et précision. En plus de sa fonction

première, qui est de supporter et de centrer la roue de la pompe, l'embout 42 est

agencé pour recevoir la fixation du deuxième rotor d'entraínement 30, cette fixation

étant assurée par tout moyen mécanique approprié.A

La cloison d'étanchéité se compose d'une enveloppe 48 réalisée en matériau

chimiquement compatible avec le liquide pompé, et d'une virole cylindrique 52

réalisée en matériau mécaniquement résistant, notamment en acier inoxydable.

Cette virole permet d'apporter la tenue à la pression interne, dans la mesure où le

matériau constitutif de l'enveloppe 48 peut être insuffisamment résistant.

L'enveloppe 48 se prolonge vers l'intérieur par une partie formant fourreau, dans

laquelle s'introduit axialement l'embout 42.The sealing partition consists of a

Dans cette zone centrale, l'enveloppe 48 porte :

- extérieurement, la bague fixe 35, sur laquelle vient tourillonner la roue 32, par

l'intermédiaire de

sa bague solidaire 36. - intérieurement, un fourreau en acier 53, dans lequel viendront s'emmancher les bagues autolubrifiantes 54, 54' qui s'engagent elles-mêmes sur l'embout 42.

- externally, the fixed

ring 35, on which is journalled thewheel 32, through itsintegral ring 36. - internally, a

steel sleeve 53, into which the self-lubricating rings 54, 54 'engage, which engage themselves on theend piece 42.

La bague 35 et le fourreau 53 peuvent être avantageusement surmoulés dans

l'enveloppe de la cloison 48 lors du moulage de celle-ci. The

Le centrage de la bague 35, et de la roue du rotor 32, est maintenant assuré avec

précision par l'embout 42. Il en résulte une bonne concentricité des pièces 35, 53,

54, 54', et le jeu entre l'embout 42 et les douilles 54, 54' est très réduit.The centering of the

La cloison d'étanchéité est donc totalement déchargée de la fonction de centrage, et

n'a donc plus à être très rigide. Il est au contraire souhaitable qu'elle présente un

minimum de souplesse, afin de ne pas contrarier le centrage imposé par l'embout

42.The sealing partition is therefore completely discharged from the centering function, and

no longer has to be very rigid. On the contrary, it is desirable that it presents a

minimum flexibility, so as not to upset the centering imposed by the

En plus de la fonction de centrage, le dispositif de la figure 3 permet une bonne

évacuation vers l'extérieur des calories générées par la rotation de la roue du rotor

32, l'arbre moteur 41 jouant le rôle de radiateur par l'intermédiaire de l' embout 42.

Les calories traversent successivement les pièces 35, 48, 53, 54 et 54' mais tous

ces transferts mettent en jeu des épaisseurs faibles et des sections importantes, ce

qui conduit à un pont thermique suffisamment efficace.In addition to the centering function, the device of FIG.

evacuation to the outside of the calories generated by the rotation of the

En variante, on peut envisager de remplacer les douilles 54, 54' par des roulements

à aiguilles. Cette solution sera particulièrement intéressante si une grande

résistance et une grande longévité sont recherchées. Par contre, elle sera moins

efficace sous l'aspect pont thermique. Des solutions mixtes combinant douilles à

frottement et roulements à aiguilles sont également envisageables.Alternatively, it is conceivable to replace the

Claims (8)

- A magnetically driven pump comprising:characterized in that the rotating connection piece (42) linked to the shaft (41) is continued axially by a sufficient length to insert it inside a female cylindrical bearing in the core of the first driven rotor (32) to provide mechanical support and accurate centering of the partition (48) and of the first driven rotor (32).a pump element fitted with a first driven rotor (32) in the form of a wheel mounted to rotate in a body (45) connected to the suction and discharge piping,a first series of magnets (33) integral with the first rotor (32),a driving motor (29) fitted with a drive shaft (41) on which is mounted a second driving rotor (30) carrying a second series of magnets (31 ), both series of magnets (33, 31) being laid out concentrically to provide rotation magnetic coupling,a sealing device having a fixed partition (48) extending in the gap between both series of magnets (33, 31) while providing tight separation between the pump element and the motor (29),and a connection piece (42) of the shaft (41) on which is mounted the second driving rotor (30),

- A pump according to claim 1, characterized in that the first driven rotor (32) comprises a second ring (36) which rotates on a first ring (35) integral with the fixed partition (48).

- A pump according to claim 1 or 2, characterized in that the bearing integral with the partition (48) comprises at least one self-lubricating ring (54, 54') forming a thermal bridge for the evacuation of the calories generated by the rotation of the first driven rotor (32) towards the heater formed by the motor shaft (41 ).

- A pump according to claim 1 or 2, characterized in that the bearing comprises the needle bearings resting on the connection piece (42).

- A pump according to the claim 1, characterized in that the partition (48) is a monobloc part in a material that is chemically compatible with the pumped liquid, and possesses sufficient mechanical stability to sustain notably the pressure of the pumped liquid.

- A pump according to claim 1, characterized in that the partition (48) is formed for better chemical compatibility, while precision and mechanical stability are provided by an additional part matching partially the shape of the partition (48) and made of a material with good mechanical stability.

- A pump according to claim 6, characterized in that the additional part is made of metal alloy, notably stainless steel, and comprises a ferrule (52) engaging into the gap provided between both series of magnets (31, 33).

- A pump according to claim 7, characterized in that the thickness of the ferrule (52) is smaller than that of the envelope of the partition (48).

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR9911242 | 1999-09-06 | ||

| FR9911242A FR2798169B1 (en) | 1999-09-06 | 1999-09-06 | MAGNETIC DRIVE PUMP |

| PCT/FR2000/002446 WO2001018401A1 (en) | 1999-09-06 | 2000-09-06 | Magnetically driven pump |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1210520A1 EP1210520A1 (en) | 2002-06-05 |

| EP1210520B1 true EP1210520B1 (en) | 2003-11-19 |

Family

ID=9549645

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP00960799A Expired - Lifetime EP1210520B1 (en) | 1999-09-06 | 2000-09-06 | Magnetically driven pump |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US6672818B1 (en) |

| EP (1) | EP1210520B1 (en) |

| JP (1) | JP2003508689A (en) |

| AT (1) | ATE254723T1 (en) |

| DE (1) | DE60006689T2 (en) |

| ES (1) | ES2211599T3 (en) |

| FR (1) | FR2798169B1 (en) |

| WO (1) | WO2001018401A1 (en) |

Families Citing this family (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2006501179A (en) * | 2002-06-27 | 2006-01-12 | ニトロメッド インコーポレーティッド | Cyclooxygenase-2 selective inhibitors, compositions and methods of use |

| US7131825B2 (en) * | 2004-01-30 | 2006-11-07 | Isothermal Systems Research, Inc. | Spindle-motor driven pump system |

| ATE411473T1 (en) * | 2004-03-16 | 2008-10-15 | Ebm Papst St Georgen Gmbh & Co | ARRANGEMENT WITH AN ELECTRONICALLY COMMUTATED OUTDOOR MOTOR |

| GB2418074A (en) * | 2004-09-14 | 2006-03-15 | Dana Automotive Ltd | A method of making a permanent magnet electric motor rotor |

| JP4297859B2 (en) * | 2004-09-28 | 2009-07-15 | 三洋電機株式会社 | HUB UNIT FOR ELECTRIC WHEEL AND VEHICLE HAVING THE HUB UNIT |

| ATE420292T1 (en) * | 2004-10-06 | 2009-01-15 | Ebm Papst St Georgen Gmbh & Co | ARRANGEMENT FOR CONVEYING FLUIDS |

| CN1828027B (en) * | 2005-02-28 | 2011-10-19 | 台达电子工业股份有限公司 | Liquid cooling type heat radiation module |

| CN1983778B (en) * | 2005-12-08 | 2011-01-26 | 刘素荣 | Non-impeller centrifugal pump with liquefied metal magnetic drive |

| ITBS20060079A1 (en) * | 2006-03-30 | 2007-09-30 | Metelli S P A | PERFECT MAGNETIC DRIVING PUMP |

| US8575802B2 (en) * | 2010-02-03 | 2013-11-05 | Src Electrical Llc | Locomotive starter motor |

| DE102012024130B4 (en) * | 2012-12-11 | 2014-09-11 | Klaus Union Gmbh & Co. Kg | Slit pot for magnetically coupled pumps and manufacturing process |

| FR3011895B1 (en) * | 2013-10-14 | 2016-03-04 | Pompes Salmson Sa | CUSHION ASSEMBLY, BUSHING SUPPORT FOR A CIRCULATION PUMP |

| EP2899855B1 (en) * | 2014-01-23 | 2022-08-24 | Pierburg Pump Technology GmbH | Electrically operated motor vehicle coolant pump |

| US9771938B2 (en) | 2014-03-11 | 2017-09-26 | Peopleflo Manufacturing, Inc. | Rotary device having a radial magnetic coupling |

| US9920764B2 (en) | 2015-09-30 | 2018-03-20 | Peopleflo Manufacturing, Inc. | Pump devices |

| KR101968162B1 (en) * | 2016-07-04 | 2019-04-11 | 주식회사 아모텍 | Water pump |

| US11193493B2 (en) | 2016-07-04 | 2021-12-07 | Amotech Co., Ltd. | Water pump |

| WO2018008896A1 (en) * | 2016-07-04 | 2018-01-11 | 주식회사 아모텍 | Water pump |

| FR3074622B1 (en) * | 2017-12-04 | 2021-07-30 | Ifp Energies Now | DEVICE FOR COMPRESSION OF A FLUID DRIVEN BY AN ELECTRIC MACHINE WITH A ROTOR SHAFT HAVING AN AMAGNETIC FRET |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3172364A (en) * | 1962-10-01 | 1965-03-09 | P G Products Mfg Co Inc | Pump |

| FR2311201A1 (en) * | 1975-05-12 | 1976-12-10 | Siebec Filtres | Rotor support stub in magnetic pump - is retainable allowing stable seal fitment between stub and dividing wall |

| US4207485A (en) * | 1978-04-24 | 1980-06-10 | The Garrett Corporation | Magnetic coupling |

| US4645432A (en) * | 1986-02-14 | 1987-02-24 | General Motors Corporation | Magnetic drive vehicle coolant pump |

| JPH01125591A (en) * | 1987-11-06 | 1989-05-18 | Sanyo Electric Co Ltd | Magnet pump |

| JPH0276191U (en) * | 1988-11-30 | 1990-06-11 | ||

| DE3927391A1 (en) * | 1989-08-19 | 1991-02-21 | Bosch Gmbh Robert | DEVICE FOR HEATING THE PASSENGER COMPARTMENT OF A MOTOR VEHICLE |

| JPH05252800A (en) * | 1992-02-28 | 1993-09-28 | Fuji Oozx Kk | Control method and equipment for power transmission equipment using eddy current joint |

| FR2715442B1 (en) * | 1994-01-26 | 1996-03-01 | Lorraine Carbone | Centrifugal pump with magnetic drive. |

| US5833437A (en) * | 1996-07-02 | 1998-11-10 | Shurflo Pump Manufacturing Co. | Bilge pump |

| GB9717866D0 (en) * | 1997-08-23 | 1997-10-29 | Concentric Pumps Ltd | Improvements to rotary pumps |

-

1999

- 1999-09-06 FR FR9911242A patent/FR2798169B1/en not_active Expired - Lifetime

-

2000

- 2000-09-06 ES ES00960799T patent/ES2211599T3/en not_active Expired - Lifetime

- 2000-09-06 AT AT00960799T patent/ATE254723T1/en not_active IP Right Cessation

- 2000-09-06 JP JP2001521905A patent/JP2003508689A/en not_active Ceased

- 2000-09-06 DE DE60006689T patent/DE60006689T2/en not_active Expired - Lifetime

- 2000-09-06 EP EP00960799A patent/EP1210520B1/en not_active Expired - Lifetime

- 2000-09-06 WO PCT/FR2000/002446 patent/WO2001018401A1/en active IP Right Grant

- 2000-09-06 US US10/069,358 patent/US6672818B1/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| DE60006689T2 (en) | 2004-10-07 |

| ES2211599T3 (en) | 2004-07-16 |

| DE60006689D1 (en) | 2003-12-24 |

| FR2798169A1 (en) | 2001-03-09 |

| EP1210520A1 (en) | 2002-06-05 |

| JP2003508689A (en) | 2003-03-04 |

| US6672818B1 (en) | 2004-01-06 |

| FR2798169B1 (en) | 2001-11-16 |

| WO2001018401A1 (en) | 2001-03-15 |

| ATE254723T1 (en) | 2003-12-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1210520B1 (en) | Magnetically driven pump | |

| EP0882892B1 (en) | Scroll type machine | |

| FR2588323A1 (en) | MAGNETICALLY DRIVEN CENTRIFUGAL PUMP | |

| EP0665378A1 (en) | Centrifugal pump with magnetic drive | |

| EP1838965B1 (en) | Multi-shaft vacuum pump with circular transaltion cycle | |

| CA2838919A1 (en) | Turbine engine drive shaft device | |

| FR3063776A1 (en) | BEARING ARRANGEMENT FOR A DRIVE SHAFT OF A TURBOMACHINE, AND A TURBOMACHINE HAVING SUCH A BEARING ARRANGEMENT | |

| WO1999050573A1 (en) | Improved blade wheel | |

| FR2608228A1 (en) | Liquid pump, especially water pump, particularly for motor vehicles | |

| FR2752444A1 (en) | Vane vacuum pump | |

| EP0882893B1 (en) | Scroll fluid displacement machine | |

| FR2890251A1 (en) | ROTOR TYPE CAGE. | |

| EP0494006A1 (en) | Turbopump with bleed flow booster pump | |

| EP3811506B1 (en) | Superconducting rotating machine | |

| FR2881587A1 (en) | Reversible electrical rotating machine cooling device for motor vehicle, has tube assembled on external periphery of stator of electrical rotating machine by surrounding stator, and lower and upper walls of tube having same thickness | |

| FR3047776B1 (en) | TURBOMACHINE AND METHOD OF MOUNTING | |

| FR2514079A1 (en) | RADIAL PISTON MACHINE, IN PARTICULAR A BALLPOINT PISTON PUMP | |

| EP0612135A1 (en) | Rotating device for a canned motor | |

| EP0291780B1 (en) | Pump with a magnetic drive | |

| FR2611818A1 (en) | Molecular rotary vacuum pump of the Gaëde channel type | |

| FR2864157A1 (en) | Power transfer assembly for micro-turbine motor, has power turbine made of inconel, and transition portion connected to turbine by inertia welding and connected to pinion gear by electron beam welding | |

| EP3921922B1 (en) | Device for compressing a fluid driven by an electric machine with a compression shaft passing through the rotor | |

| BE1000978A5 (en) | Integrated electric motor and pump unit - uses lateral inlet and outlet pipes and has motor unit formed around rotating sleeve which has internal pumping elements | |

| EP2469093B1 (en) | Fluid circulation pump and use thereof | |

| EP0823027B1 (en) | Magnetic drive centrifugal pump |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20020226 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20031119 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20031119 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20031119 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20031119 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20031119 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 60006689 Country of ref document: DE Date of ref document: 20031224 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: FRENCH |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040219 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040219 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040219 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20040223 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2211599 Country of ref document: ES Kind code of ref document: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040906 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040930 Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040930 |

|

| 26N | No opposition filed |

Effective date: 20040820 |

|

| BERE | Be: lapsed |

Owner name: SOC. *SIEBEC Effective date: 20040930 |

|

| BERE | Be: lapsed |

Owner name: SOC. *SIEBEC Effective date: 20040930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040419 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20070905 Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: TP |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20080926 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20081002 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20081021 Year of fee payment: 9 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20080906 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080906 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090930 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090906 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20110714 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110704 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090907 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 60006689 Country of ref document: DE Representative=s name: PATRONUS IP PATENT- & RECHTSANWAELTE BERNHARD , DE |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20150908 Year of fee payment: 16 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 17 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 60006689 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170401 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 18 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20190927 Year of fee payment: 20 |