EP1175534B1 - Water-saving toilet arrangement - Google Patents

Water-saving toilet arrangement Download PDFInfo

- Publication number

- EP1175534B1 EP1175534B1 EP00908897A EP00908897A EP1175534B1 EP 1175534 B1 EP1175534 B1 EP 1175534B1 EP 00908897 A EP00908897 A EP 00908897A EP 00908897 A EP00908897 A EP 00908897A EP 1175534 B1 EP1175534 B1 EP 1175534B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- outlet pipe

- section

- accordance

- fact

- pipe

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E03—WATER SUPPLY; SEWERAGE

- E03D—WATER-CLOSETS OR URINALS WITH FLUSHING DEVICES; FLUSHING VALVES THEREFOR

- E03D11/00—Other component parts of water-closets, e.g. noise-reducing means in the flushing system, flushing pipes mounted in the bowl, seals for the bowl outlet, devices preventing overflow of the bowl contents; devices forming a water seal in the bowl after flushing, devices eliminating obstructions in the bowl outlet or preventing backflow of water and excrements from the waterpipe

- E03D11/18—Siphons

Definitions

- the invention relates to a drain sheet for a water-saving toilet installation according to Preamble of claim 1.

- US-A-2,055,490 discloses a drainage arch with the mer- malenals of the preamble of claim 1, which is after a narrowed and vertical area below in a horizontally extending L-shaped outflow ends. So in the sequence sheet a closed Flow can be formed, however, is comparatively a lot of rinse water required.

- a water-saving flushing device for a toilet is through DE 298 07 813 U1 proposed.

- To a toilet with comparatively to be able to rinse a small amount of rinse water effectively is Bottom of the odor trap a nozzle arranged through which during a rinse, a portion of the rinse water at an angle into the outlet is injected.

- the nozzle is located at a front End of a discharge slope, leaving a negative pressure in the drain is generated when a curved discharge pipe is filled. Through the nozzle should a downward pulling force of the watercourse be strengthened.

- Vacuum toilets have the disadvantage that a vacuum source is installed must be, which is relatively expensive and additional Claimed space. In addition, there are noises in the vacuum actuation hard to avoid. For toilet facilities with a Nozzle in the odor trap are corresponding lines to this Nozzle required. This nozzle makes the production of the toilet bowl more expensive considerably. In addition, the nozzle can clog, resulting in Disruptions leads.

- FR-A-1,148,893 discloses a toilet installation with a drain, which is bent several times.

- the invention is based on the object of a water-saving To create toilet facility, which has the above-mentioned disadvantages avoids and still effective and reliable and cost-effective can be produced.

- the water-saving toilet system is neither a vacuum source another nozzle in the odor trap required.

- the Essential features of the invention relate to the process. This is essentially a flow sheet be formed, the said vertical Area with the comparatively small free cross-section owns and essentially to every common toilet bowl can be grown. A significant advantage The invention is thus seen in that such a flow sheet attached to existing toilet bowls and thus very cost-effective a reduction of water consumption possible is.

- the drain bend can be made of plastic as a fitting and allows very different installation situations. In particular, a floor drain or a wall connection possible. When draining the floor leads the drain line through the building floor and the wall connection through the building wall. Experiments have shown that efficient rinsing with about 4.5 liters of rinse water or even less possible is. According to a development of the invention, the Drain underneath said vertical area a deflection arc on, which has a free cross-section, the larger is as the free cross section of said vertical Range.

- the invention thus relates to a drain sheet for a water-saving toilet facility.

- This is preferably a Shaped for connection to a nozzle of a toilet bowl runs horizontally at the upper end. At this end The drain bend can be attached to the neck of the bowl become.

- At the lower end of the discharge bend is preferably also provided a horizontally extending area. in the horizontal area is a deflection arc in which Forms a flush after a so-called swamp. Of the free cross section of the deflection arc is greater than the free one Cross section of the vertical area.

- the drain bend is connected to the disposal line. This can, as mentioned, vertically through the building floor or pass horizontally through a building wall.

- the toilet unit 1 contains a toilet with a bowl 8, for example, made of ceramic or plastic is. Attached is the bowl 8, for example a support frame 6, which has two trusses 6b, where attached to the bowl 8, for example, is screwed.

- the frame 6 has at the bottom of feet 6 a, which on a Building floor 7 are and are attached to this.

- the support frame 6 is at a distance to a Building wall 33 arranged.

- a discharge bend 14 In the space between the building wall 33 and the support frame 6 is a discharge bend 14, at its lower end 19 via an intermediate piece 20 is connected to a disposal line 21.

- a wall connection not shown here, in which a correspondingly shaped intermediate piece 20, the lower end 19 with a disposal line in the building wall 33 connects.

- cistern 2 is provided to the Rinse operation has at least one key 3 and after the rinsing process via a supply line 4 again filled becomes.

- the cistern 2 can also by a pressure line or another flushing device to be replaced.

- a rinsing process includes basically the cleaning of the bowl 8, the removal the feces and refilling an odor trap 10. On the individual steps of the flushing process is detailed below.

- a cylindrical neck 12 integrally formed, which has a free cross-section A and seen in the flow direction after the odor trap. 8 is arranged.

- a preferably circular opening 12a of the Stutzens 12 leads into the flow sheet 14, with an upper, substantially horizontally extending end 15 to the Nozzle 12 is connected.

- a rubber-elastic gasket 13 seals the nozzle 12 against the drain bend 14 off.

- the end 15 leads via a bend 16 in a vertical region 17, which has a free cross-section C. and, as can be seen, arranged behind the support frame 6 is.

- the vertical area 17 is essential longer than wide and leads to a lower end Deflection arc 18, which after a rising portion 18 a on a horizontal outflow end 19 is connected.

- the deflector 18 is preferably formed by a bend 25, which at the vertical portion 17 and the outlet end 19 is formed.

- the drain sheet 14 thus forms with the deflection arc 18 and the expiry end 19 a unit.

- the flow sheet 14 is preferably made of plastic, in principle is however also another material, for example metal, conceivable.

- the drain end 19 has a circular opening 19a, through which the sheet 14 is connected to the intermediate piece 20 is.

- the free cross section C is much smaller than the free cross-section A of the neck 12.

- the free cross-section E of the discharge end 19 is smaller than the cross section D of the deflection arc 18.

- the free cross-section D is again larger as the cross section C.

- the ratio of the cross section C to Cross-section A is preferably less than 0.7.

- the free one Cross-section D is, as mentioned, larger than the free cross-section C. He is preferably larger by the measure, which is formed by the height d of the backwater 22 ( Figure 2b).

- the cross-section E of the discharge end 19 is preferably about same as the free section C of the vertical section 17.

- the stowage height H shown in Figure 3, which by the Overflow edge 28 is defined, is much larger than the diameter of the vertical pipe section 14.

- the water level H is 4 to 7 times bigger than the inner one Diameter of vertical area 14.

- the inside diameter of the flow sheet 14 in the vertical region 17 is, for example 50 mm.

- the inner diameter according to the cross section B for example 100 mm.

- the diameter in the region of the cross section A is for example, about 70 to 80 mm. Seen in the flow direction the free cross section after the nozzle 12 is thus essential close. In the region of the deflection 18 then takes place again an extension and then again a narrowing.

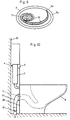

- FIG. 3 shows schematically the system 1 in the idle state.

- the odor trap 10 is filled with water 11.

- the level 24 of the water 11 is determined by the overflow edge 28.

- the water 11 seals the interior 34 of the bowl 8 from the drain sheet 14 from.

- FIG. 4 shows the beginning of a rinsing process in which through the nozzles 9a in the direction of the arrows 23 water in the Interior 34 flows.

- the level 24 rises accordingly and in flow sheet 14 forms a flow 27.

- By steering the flow through the Swamp the flow is distributed in the cross section E, that an air inlet at the cross section E is prevented.

- the Drain sheet 14 is formed comparatively quickly a closed Flow 27 ', as Figure 5 shows.

- the level 24 Now rises approximately to the top 30 of the deflection arc 37, as Figure 5 clearly shows.

- the rinsing effect can be further increased if according to Figure 9, the inlet nozzles 9a with respect to the bowl edge 8a run diagonally. This forms during refilling and Cleaning the bowl, a rinse roll 32 shown in Figure 9, which extends from the edge 8a to the drain opening 31 and the faster filling of the bowl 8 and a stronger rinsing and thus a more intensive cleaning of the Bowl 8 causes.

- the vortex 32 thus supports the above explained effect of the flow sheet 14.

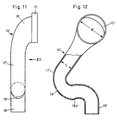

- FIGS. 10 to 12 show a drainage bend 14 ', which is a upper and substantially horizontally extending end 15 ', a region 17 ', a deflecting bend 18' and an outlet end 19 '.

- This drain sheet 14 ' is preferably for a near-wall and vertical ground connection provided, such as this is shown in FIG.

- This drain sheet 14 ' needed little space between a building wall 35 and the Back 36 of a toilet bowl 8. It is essential in this Drainage 14 'that is essential for a backwater Deflection arc 18 'with the vertical portion 17' in a plane which is substantially perpendicular to the longitudinal axis of the nozzle 12 runs. In this plane preferably also runs the drain end 19 ', which extends vertically down here.

- the area at the outlet bend 14 vertically extending 17 is an oblique region in this variant 17 '.

- the diameter C 'of this area 17' is also essential smaller than the diameter B 'of the connection bend 16 '. Since the drainage arch 14 'takes up little space in the depth, the toilet bowl 8 can be especially close to the building wall 35 are mounted, which is especially true for small spaces a significant advantage. It is also advantageous that the Drain sheet 14 'can be made in one piece and a Intermediate piece 20 is not required. The drain sheet 14 ' thus allows a particularly simple installation.

- the drainage bend 14 "shown in FIGS. 13 to 16 is preferably a blow molding of plastic and is at an upper edge 41 on the rear wall 8 a of the bowl eighth attached. At a lower, vertical end 19 " is the flow sheet 14 '' by means of a rubber seal 40 at the disposal line 21 connected.

- the deflecting bend 43 forms a receiving space 45 for the flowing through the nozzle 12 in the flow sheet 14 "flowing Water.

- a constriction 44 which the free inner cross-section B "on the smaller inner cross section C " The constriction 44 and the lower end 19 "is the discharge bend 14 '' S-shaped in a parallel to the back 8a Plane bent.

- An upper arch S 1 of this S-shaped area has a plurality of inwardly directed ribs 46 to 51 and forms an angle ⁇ , which is preferably greater than 90 °.

- An upper rib 46 forms the upper end of the sheet S 1 and a lower rib 51 forms the lower end of the sheet S 1 .

- Between the two completely circumferential ribs 46 to 51 are further completely circumferential ribs 47 and 49 and only partially circumferential ribs 48 and 50.

- Another rib 52 is disposed directly at the upper end of the discharge end 19 ''.

- the exact course of the S-shaped region as well as the arrangement of the ribs 46 to 52 can be seen in FIGS. 13 to 15. The operation of the sequence sheet 14 "will be explained below.

- ribs 46 to 52 are the flow of rinse water break and thus the formation of a closed flow support. It is also advantageous that such ribs 46 to 52 in the blow molding relatively easy to produce are. As explained the curves of the drain bend 14 "in a plane parallel to the rear side 8a, the space requirement is comparatively small. After all Also the assembly of the drain bend 14 "is very easy.

Landscapes

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Engineering & Computer Science (AREA)

- Hydrology & Water Resources (AREA)

- Public Health (AREA)

- Water Supply & Treatment (AREA)

- Sanitary Device For Flush Toilet (AREA)

- Sink And Installation For Waste Water (AREA)

- Bidet-Like Cleaning Device And Other Flush Toilet Accessories (AREA)

Abstract

Description

Die Erfindung betrifft einen Ablaufbogen für eine wassersparende Toilettenanlage gemäss

Oberbegriff des Anspruchs 1.The invention relates to a drain sheet for a water-saving toilet installation according to

Preamble of

Bemühungen, den Wasserverbrauch beim Spülen von Toilettenanlagen

zu senken, sind schon sehr alt. Bereits im Jahr 1888 wurde durch

die US 380,854 eine Toilettenanlage vorgeschlagen, die eine Vakuumquelle

aufweist, mit welcher bei jeder Spülung ein Unterdruck

erzeugt wird, welcher den Absaugvorgang verstärken soll.

Eine weitere Vakuumtoilette wird auch durch die US 5,487,193

vorgeschlagen. Bei dieser trennt eine flexible Membran eine Wasserkammer

von einer Vakuumkammer. Mittels einer Feder wird bei

einem Spülvorgang diese Membran schlagartig bewegt. Einerseits

wird dadurch Spülwasser gefördert und andererseits wird im Ablauf

ein Unterdruck erzeugt. Dieser soll hier ebenfalls die

Spülwirkung verbessern mit dem Ziel, mit weniger Spülwasser dennoch

eine hinreichende Spülwirkung zu erreichen. Die US-A-2,055,490

offenbart einen Ablaufbogen mit den Merhmalen der Oberbegrifft der Anspruch 1, der nach einem verengten

und vertikalen Bereich unten in ein horizontal verlaufendes

L-förmiges Ablaufende mündet. Damit im Ablaufbogen eine geschlossene

Strömung gebildet werden kann, ist jedoch vergleichsweise

viel Spülwasser erforderlich.Efforts to reduce water consumption when flushing toilet facilities

to lower, are already very old. Already in 1888 was through

US 380,854 proposed a toilet facility which is a vacuum source

having, with which at each flushing a negative pressure

is generated, which should reinforce the suction.

Another vacuum toilet is also described by US 5,487,193

proposed. In this case, a flexible membrane separates a water chamber

from a vacuum chamber. By means of a spring is at

a flushing this membrane abruptly moves. On the one hand

This will promote rinse water and on the other hand is in the process

generates a negative pressure. This should also here the

Rinse effect improve with the goal, with less rinse water nevertheless

to achieve a sufficient rinsing effect. US-A-2,055,490

discloses a drainage arch with the mer- malenals of the preamble of

Eine wassersparende Spüleinrichtung für eine Toilette wird durch die DE 298 07 813 U1 vorgeschlagen. Um eine Toilette mit vergleichsweise wenig Spülwasser wirksam spülen zu können, ist im Boden des Geruchsverschlusses eine Düse angeordnet, durch welche bei einem Spülvorgang ein Teil des Spülwassers schräg in den Abgang eingespritzt wird. Die Düse befindet sich an einem vorderen Ende eines Ableitungsabhangs, so dass ein Unterdruck im Ablauf erzeugt wird, wenn ein gebogenes Ableitungsrohr vollgefüllt ist. Durch die Düse soll eine abwärtswirkende Zugkraft des Wasserlaufs verstärkt werden.A water-saving flushing device for a toilet is through DE 298 07 813 U1 proposed. To a toilet with comparatively to be able to rinse a small amount of rinse water effectively is Bottom of the odor trap a nozzle arranged through which during a rinse, a portion of the rinse water at an angle into the outlet is injected. The nozzle is located at a front End of a discharge slope, leaving a negative pressure in the drain is generated when a curved discharge pipe is filled. Through the nozzle should a downward pulling force of the watercourse be strengthened.

Vakuumtoiletten haben den Nachteil, dass eine Vakuumquelle installiert werden muss, was vergleichsweise aufwendig ist und zusätzlichen Platz beansprucht. Zudem sind Geräusche bei der Vakuumbetätigung kaum zu vermeiden. Bei Toilettenanlagen mit einer Düse im Geruchsverschluss sind entsprechende Leitungen zu dieser Düse erforderlich. Diese Düse verteuert die Herstellung der Toilettenschüssel erheblich. Zudem kann die Düse verstopfen, was zu Störungen führt.Vacuum toilets have the disadvantage that a vacuum source is installed must be, which is relatively expensive and additional Claimed space. In addition, there are noises in the vacuum actuation hard to avoid. For toilet facilities with a Nozzle in the odor trap are corresponding lines to this Nozzle required. This nozzle makes the production of the toilet bowl more expensive considerably. In addition, the nozzle can clog, resulting in Disruptions leads.

Die FR-A-1,148,893 offenbart eine Toilettenanlage mit einem Ablauf, der mehrfach gebogen ist.FR-A-1,148,893 discloses a toilet installation with a drain, which is bent several times.

Der Erfindung liegt die Aufgabe zugrunde, eine wassersparende Toilettenanlage zu schaffen, welche die oben genannten Nachteile vermeidet und die trotzdem wirksam und zuverlässig sowie kostengünstig herstellbar ist.The invention is based on the object of a water-saving To create toilet facility, which has the above-mentioned disadvantages avoids and still effective and reliable and cost-effective can be produced.

Die Aufgabe ist bei einem Ablaufbogen der genannten Gattung

gemäss Anspruch 1 gelöst. Eine besonders geeignete

Toilettenanlage ist Gegenstand des Anspruchs 9. The task is in a flow sheet of the type mentioned

solved according to

Bei der wassersparenden Toilettenanlage ist weder eine Vakuumquelle noch eine Düse im Geruchsverschluss erforderlich. Die wesentlichen Merkmale der Erfindung betreffen den Ablauf. Dieser wird im wesentlichen durch einen Ablaufbogen gebildet werden, der den genannten vertikalen Bereich mit dem vergleichsweise kleinen freien Querschnitt besitzt und der im wesentlichen an jede übliche Toilettenschüssel angebaut werden kann. Ein wesentlicher Vorteil der Erfindung wird somit darin gesehen, dass ein solcher Ablaufbogen an bestehende Klosettschüsseln angebracht und damit sehr kostengünstig eine Senkung des Wasserverbrauches möglich ist. Der Ablaufbogen kann aus Kunststoff als Formstück hergestellt werden und ermöglicht sehr unterschiedliche Einbausituationen. Insbesondere ist ein Bodenablauf oder ein Wandanschluss möglich. Beim Bodenablauf führt die Ablaufleitung durch den Gebäudeboden und beim Wandanschluss durch die Gebäudewand. Versuche haben ergeben, dass eine effiziente Ausspülung mit etwa 4,5 Liter Spülwasser oder sogar weniger möglich ist. Nach einer Weiterbildung der Erfindung weist der Ablauf unterhalb des genannten vertikalen Bereichs einen Umlenkbogen auf, der einen freien Querschnitt besitzt, der grösser ist als der freie Querschnitt des genannten vertikalen Bereichs.The water-saving toilet system is neither a vacuum source another nozzle in the odor trap required. The Essential features of the invention relate to the process. This is essentially a flow sheet be formed, the said vertical Area with the comparatively small free cross-section owns and essentially to every common toilet bowl can be grown. A significant advantage The invention is thus seen in that such a flow sheet attached to existing toilet bowls and thus very cost-effective a reduction of water consumption possible is. The drain bend can be made of plastic as a fitting and allows very different installation situations. In particular, a floor drain or a wall connection possible. When draining the floor leads the drain line through the building floor and the wall connection through the building wall. Experiments have shown that efficient rinsing with about 4.5 liters of rinse water or even less possible is. According to a development of the invention, the Drain underneath said vertical area a deflection arc on, which has a free cross-section, the larger is as the free cross section of said vertical Range.

Die Erfindung betrifft somit einen Ablaufbogen für eine wassersparende Toilettenanlage. Dieser ist vorzugsweise ein Formstück, das zum Anschluss an einen Stutzen einer Toilettenschüssel am oberen Ende horizontal verläuft. An diesem Ende kann der Ablaufbogen am Stutzen der Schüssel befestigt werden. Am unteren Ende des Ablaufbogens ist vorzugsweise ebenfalls ein horizontal verlaufender Bereich vorgesehen. Im horizontalen Bereich befindet sich ein Umlenkbogen, in dem sich nach einer Spülung ein sogenannter Sumpf bildet. Der freie Querschnitt des Umlenkbogens ist grösser als der freie Querschnitt des vertikalen Bereichs. Am unteren horizontalen Bereich wird der Ablaufbogen an die Entsorgungsleitung angeschlossen. Diese kann, wie erwähnt, vertikal durch den Gebäudeboden oder horizontal durch eine Gebäudewand führen. The invention thus relates to a drain sheet for a water-saving toilet facility. This is preferably a Shaped for connection to a nozzle of a toilet bowl runs horizontally at the upper end. At this end The drain bend can be attached to the neck of the bowl become. At the lower end of the discharge bend is preferably also provided a horizontally extending area. in the horizontal area is a deflection arc in which Forms a flush after a so-called swamp. Of the free cross section of the deflection arc is greater than the free one Cross section of the vertical area. At the bottom horizontal Area, the drain bend is connected to the disposal line. This can, as mentioned, vertically through the building floor or pass horizontally through a building wall.

Weitere vorteilhafte Merkmale ergeben sich aus den abhängigen

Patentansprüchen, der nachfolgenden Beschreibung sowie der

Zeichnungen.

Ein Ausführungsbeispiel der Erfindung wird nachfolgend anhand

der Zeichnungen näher erläutert. Dabei zeigen die Figuren 1-12 nicht alle wesentliche Merhmale der Erfindung. Es zeigen:

Figur 1- schematisch einen vertikalen Schnitt durch eine Toilettenanlage,

- Figur 2a

- schematisch eine Ansicht der Rückseite der

Toilettenanlage gemäss

Figur 1, - Figur 2b

- einen Schnitt durch den unteren Teil eines Ablaufbogens,

Figuren 3 bis 9- schematisch einzelne Schritte des Spülvorgangs,

Figur 10- schematisch im Teilschnitt eine Toilettenanlage mit einem Ablaufbogen,

Figur 11- eine Ansicht des Ablaufbogens gemäss

Figur 10, Figur 12- eine weitere, teilweise geschnittene Ansicht

des Bogens gemäss

Figur 11, Figur 13- schematisch eine Ansicht der Rückseite einer Toilettenanlage gemäss einem Ausführungsbeispiel

Figur 14- eine Draufsicht auf die Anlage gemäss

Figur 13, Figur 15- ein Teilschnitt durch den Ablaufbogen der

Anlage gemäss

Figur 14 und Figur 16- ein Schnitt durch das obere Ende des Ablaufbogens

gemäss

Figur 15.

An embodiment of the invention will be explained in more detail with reference to the drawings. In this case, Figures 1-12 do not show all the essential Merhmale of the invention. Show it:

- FIG. 1

- schematically a vertical section through a toilet facility,

- FIG. 2a

- 1 schematically shows a view of the rear side of the toilet installation according to FIG. 1,

- FIG. 2b

- a section through the lower part of a drain sheet,

- FIGS. 3 to 9

- schematically individual steps of the rinsing process,

- FIG. 10

- schematically in partial section a toilet system with a drain sheet,

- FIG. 11

- a view of the flow sheet according to Figure 10,

- FIG. 12

- a further, partially sectional view of the sheet according to Figure 11,

- FIG. 13

- schematically a view of the back of a toilet installation according to an embodiment

- FIG. 14

- a plan view of the system according to Figure 13,

- FIG. 15

- a partial section through the flow sheet of the system according to Figure 14 and

- FIG. 16

- a section through the upper end of the flow sheet according to Figure 15.

Die Toilettenanlage 1 enthält ein Klosett mit einer Schüssel

8, die beispielsweise aus Keramik oder Kunststoff hergestellt

ist. Befestigt ist die Schüssel 8 beispielsweise an

einem Traggestell 6, das zwei Traversen 6b besitzt, an denen

die Schüssel 8 befestigt, beispielsweise angeschraubt ist. The

Das Gestell 6 weist am unteren Ende Füsse 6a auf, die auf einem

Gebäudeboden 7 stehen und an diesem befestigt sind. Wie

die Figur 1 zeigt, ist das Traggestell 6 im Abstand zu einer

Gebäudewand 33 angeordnet. Im Zwischenraum zwischen der Gebäudewand

33 und dem Traggestell 6 befindet sich ein Ablaufbogen

14, der an seinem unteren Ende 19 über ein Zwischenstück

20 an eine Entsorgungsleitung 21 angeschlossen ist.

Möglich ist jedoch auch ein hier nicht gezeigter Wandanschluss,

bei welchem ein entsprechend geformtes Zwischenstück

20 das untere Ende 19 mit einer Entsorgungsleitung in der Gebäudewand

33 verbindet.The

Zum Spülen der Toilettenschüssel 8 ist ein in Figur 1 lediglich

schematisch gezeigter Spülkasten 2 vorgesehen, der zur

Spülbetätigung wenigstens eine Taste 3 aufweist und der nach

dem Spülvorgang über eine Versorgungsleitung 4 wieder gefüllt

wird. Der Spülkasten 2 kann jedoch auch durch eine Druckleitung

oder eine andere Spülvorrichtung ersetzt sein.For rinsing the

Das aus dem Spülkasten 2 fliessende Spülwasser gelangt über

einen Ablaufbogen 5 in einen Spülkanal 9 am oberen Rand der

Schüssel 8 und über Düsen 9a schliesslich in den beckenförmigen

Innenraum 34 der Schüssel 8. Ein Spülvorgang umfasst

grundsätzlich die Reinigung der Schüssel 8, den Abtransport

der Fäkalien sowie ein Nachfüllen eines Geruchsverschlusses

10. Auf die einzelnen Schritte des Spülvorganges wird

weiter unten näher eingegangen.The flushing water flowing out of the

An der Rückwand 8a der Schüssel 8 ist ein zylindrischer Stutzen

12 angeformt, der einen freien Querschnitt A aufweist und

der in Strömungsrichtung gesehen nach dem Geruchsverschluss 8

angeordnet ist. Eine vorzugsweise kreisrunde Öffnung 12a des

Stutzens 12 führt in den Ablaufbogen 14, der mit einem oberen,

im wesentlichen horizontal verlaufenden Ende 15 an den

Stutzen 12 angeschlossen ist. Eine gummielastische Dichtungsmanschette

13 dichtet den Stutzen 12 gegenüber dem Ablaufbogen

14 ab. Das Ende 15 führt über eine Biegung 16 in einen

vertikalen Bereich 17, der einen freien Querschnitt C aufweist

und, wie ersichtlich, hinter dem Traggestell 6 angeordnet

ist. Der vertikale Bereich 17 ist, wie ersichtlich, wesentlich

länger als breit und führt am unteren Ende zu einem

Umlenkbogen 18, der nach einem ansteigenden Bereich 18a an

ein horizontales Ablaufende 19 angeschlossen ist. Der Umlenkbogen

18 wird vorzugsweise durch ein Bogenstück 25 gebildet,

welches an den vertikalen Bereich 17 sowie das Ablaufende 19

angeformt ist. Der Ablaufbogen 14 bildet somit mit dem Umlenkbogen

18 und dem Ablaufende 19 eine Einheit. Der Ablaufbogen

14 besteht vorzugsweise aus Kunststoff, grundsätzlich

ist jedoch auch ein anderer Werkstoff, beispielsweise Metall,

denkbar.On the

Das Ablaufende 19 weist eine kreisrunde Öffnung 19a auf,

durch welche der Bogen 14 mit dem Zwischenstück 20 verbunden

ist.The

Beim Ablauf sind nun die freien bzw. hydraulischen Querschnitte

A und C von besonderer Bedeutung. Der freie Querschnitt

C ist wesentlich kleiner als der freie Querschnitt A

des Stutzens 12. Vorzugsweise ist zudem der freie Querschnitt

E des Ablaufendes 19 kleiner als der Querschnitt D des Umlenkbogens

18. Der freie Querschnitt D ist wiederum grösser

als der Querschnitt C. Das Verhältnis des Querschnittes C zum

Querschnitt A ist vorzugsweise kleiner als 0,7. Der freie

Querschnitt D ist, wie erwähnt, grösser als der freie Querschnitt

C. Er ist vorzugsweise um das Mass grösser, welches

durch die Höhe d des Stauwassers 22 (Figur 2b) gebildet ist.

Der Querschnitt E des Ablaufendes 19 ist vorzugsweise etwa

gleich wie der freie Querschnitt C des vertikalen Bereichs

17. Die in Figur 3 gezeigte Stauhöhe H, welche durch die

Überlaufkante 28 definiert ist, ist wesentlich grösser als

der Durchmesser des vertikalen Rohrabschnitts 14. Vorzugsweise

ist die Stauhöhe H 4 bis 7 mal grösser als der innere

Durchmesser des vertikalen Bereiches 14. Der Innendurchmesser

des Ablaufbogens 14 im vertikalen Bereich 17 beträgt beispielsweise

50 mm. Im Bereich der Biegung 16 beträgt der Innendurchmesser

gemäss dem Querschnitt B beispielsweise

100 mm. Der Durchmesser im Bereich des Querschnitts A beträgt

beispielsweise etwa 70 bis 80 mm. In Strömungsrichtung gesehen

wird der freie Querschnitt nach dem Stutzen 12 somit wesentlich

enger. Im Bereich des Umlenkbogens 18 erfolgt dann

wieder eine Erweiterung und anschliessend nochmals eine Verengung.The process now includes the free or hydraulic cross sections

A and C are of particular importance. The free cross section

C is much smaller than the free cross-section A

of the

Nachfolgend wird anhand der Figuren 3 bis 9 die Wirkungsweise näher erläutert.Hereinafter, the mode of action will be described with reference to FIGS. 3 to 9 explained in more detail.

Die Figur 3 zeigt schematisch die Anlage 1 im Ruhezustand.

Der Geruchsverschluss 10 ist mit Wasser 11 gefüllt. Das Niveau

24 des Wassers 11 ist durch die Überlaufkante 28 bestimmt.

Das Wasser 11 dichtet den Innenraum 34 der Schüssel 8

gegenüber dem Ablaufbogen 14 ab.FIG. 3 shows schematically the

Die Figur 4 zeigt den Beginn eines Spülvorganges, bei welchem

durch die Düsen 9a in Richtung der Pfeile 23 Wasser in den

Innenraum 34 strömt. Das Niveau 24 steigt entsprechend an und

im Ablaufbogen 14 bildet sich eine Strömung 27. Infolge der

oben erwähnten Verengung im vertikalen Bereich 17 des Ablaufbogens

14 strömt nun in diesem Bereich mehr Wasser, als weggeführt

werden kann. Durch die Lenkung der Strömung durch den

Sumpf wird die Strömung dermassen im Querschnitt E verteilt,

dass ein Lufteintritt beim Querschnitt E verhindert wird. Im

Ablaufbogen 14 bildet sich vergleichsweise schnell eine geschlossene

Strömung 27', wie die Figur 5 zeigt. Das Niveau 24

steigt nun etwa bis zur Oberseite 30 des Umlenkbogens 37, wie

die Figur 5 deutlich zeigt. In der vertikalen geschlossenen

Strömung 27' bildet sich aufgrund der hier herrschenden höheren

Strömungsgeschwindigkeit ein Unterdruck. Dieser bewirkt

ein beschleunigtes Leersaugen des Geruchsverschlusses. Durch

dieses Absaugen werden die Flüssigkeit 11 sowie darin enthaltene

Teile und Fäkalien mitgerissen und in den Ablaufbogen 14

sowie die Entsorgungsleitung 21 transportiert. Das Wasserniveau

24 sinkt entsprechend schnell und sinkt schliesslich bis

in den unteren Bereich des Geruchsverschlusses 10, wie die

Figur 6 zeigt. Nun fliesst Luft gemäss Figur 7 durch den Geruchsverschluss

10 in den Ablaufbogen 14 und unterbricht die

geschlossene Strömung 27'. Die Saugwirkung ist damit unterbrochen

und der Geruchsverschluss 10 kann nun durch nachfolgendes

Spülwasser wieder nachgefüllt werden, bis der in Figur

3 gezeigte Ausgangszustand wieder erreicht ist. Der Spülkasten

2 wird nach dem Schliessen des Spülventils wieder mit

Spülwasser gefüllt und anschliessend ist die Anlage 1 für eine

weitere Spülung bereit.FIG. 4 shows the beginning of a rinsing process in which

through the

Die Spülwirkung kann noch weiter erhöht werden, wenn gemäss

Figur 9 die Einlaufdüsen 9a bezüglich des Schüsselrandes 8a

schräg verlaufen. Dadurch bildet sich beim Nachfüllen und

Reinigen der Schüssel ein in Figur 9 gezeigter Spülwirbel 32,

der sich vom Rand 8a bis zur Ablauföffnung 31 erstreckt und

der eine schnellere Vollfüllung der Schüssel 8 sowie eine

stärkere Ausspülung und damit eine intensivere Reinigung der

Schüssel 8 bewirkt. Der Wirbel 32 unterstützt somit die oben

erläuterte Wirkung des Ablaufbogens 14.The rinsing effect can be further increased if according to

Figure 9, the

Die Figuren 10 bis 12 zeigen einen Ablaufbogen 14', der ein

oberes und im wesentlich horizontal verlaufendes Ende 15',

einen Bereich 17', einen Umlenkbogen 18' sowie ein Ablaufende

19' aufweist. Dieser Ablaufbogen 14' ist vorzugsweise für einen

wandnahen und lotrechten Bodenanschluss vorgesehen, wie

dies in Figur 10 gezeigt ist. Dieser Ablaufbogen 14' benötigt

wenig Zwischenraum zwischen einer Gebäudewandung 35 und der

Rückseite 36 einer Klosettschüssel 8. Wesentlich ist bei diesem

Ablaufbogen 14', dass der für einen Rückstau wesentliche

Umlenkbogen 18' mit dem vertikalen Bereich 17' in einer Ebene

liegt, die im wesentlichen senkrecht zur Längsachse des Stutzens

12 verläuft. In dieser Ebene verläuft vorzugsweise auch

das Ablaufende 19', das sich hier vertikal nach unten erstreckt.

Der beim Ablaufbogen 14 vertikal verlaufende Bereich

17 ist bei dieser Variante ein schräg verlaufender Bereich

17'. Der Durchmesser C' dieses Bereichs 17' ist ebenfalls wesentlich

kleiner als der Durchmesser B' des Anschlussbogens

16'. Da der Ablaufbogen 14' in der Tiefe wenig Raum beansprucht,

kann die Klosettschüssel 8 besonders nahe der Gebäudewand

35 montiert werden, was besonders bei kleinen Räumen

ein wesentlicher Vorteil ist. Vorteilhaft ist zudem, dass der

Ablaufbogen 14' einstückig hergestellt werden kann und ein

Zwischenstück 20 nicht erforderlich ist. Der Ablaufbogen 14'

ermöglicht somit eine besonders einfache Montage.FIGS. 10 to 12 show a drainage bend 14 ', which is a

upper and substantially horizontally extending end 15 ',

a region 17 ', a deflecting bend 18' and an outlet end

19 '. This drain sheet 14 'is preferably for a

near-wall and vertical ground connection provided, such as

this is shown in FIG. This drain sheet 14 'needed

little space between a

Der in den Figuren 13 bis 16 gezeigte Ablaufbogen 14'' ist

vorzugsweise ein Blasformteil aus Kunststoff und

ist an einem oberen Rand 41 an der Rückwand 8a der Schüssel 8

befestigt. An einem unteren, vertikal verlaufenden Ende 19"

ist der Ablaufbogen 14'' mittels einer Gummidichtung 40 an

die Entsorgungsleitung 21 angeschlossen.The

In Strömungsrichtung gesehen nach dem Rand 41 ist ein Umlenkbogen

43 angeordnet, dessen Formgebung der Figur 16 entnommen

werden kann. Der Umlenkbogen 43 bildet einen Aufnahmeraum 45

für das durch den Stutzen 12 in den Ablaufbogen 14" fliessende

Wasser. Unterhalb des Umlenkbogens 43 befindet sich

eine Verengung 44, welche den freien Innenquerschnitt B" auf

den kleineren Innenquerschnitt C" verkleinert. Zwischen der

Verengung 44 und dem unteren Ende 19" ist der Ablaufbogen

14'' S-förmig in einer zur Rückseite 8a parallel verlaufenden

Ebene gebogen. Seen in the flow direction after the

Ein oberer Bogen S1 dieses S-förmigen Bereichs weist mehrere

nach innen gerichtete Rippen 46 bis 51 auf und bildet einen

Winkel α, der vorzugsweise grösser als 90° ist. Eine obere

Rippe 46 bildet das obere Ende des Bogens S1 und eine untere

Rippe 51 das untere Ende des Bogens S1. Zwischen den beiden

vollständig umlaufenden Rippen 46 bis 51 befinden sich weitere

vollständig umlaufende Rippen 47 und 49 sowie lediglich

teilweise umlaufende Rippen 48 und 50. Eine weitere Rippe 52

ist unmittelbar am oberen Ende des Ablaufendes 19'' angeordnet.

Der genaue Verlauf des S-förmigen Bereichs so wie die

Anordnung der Rippen 46 bis 52 kann den Figuren 13 bis 15

entnommen werden. Nachfolgend wird die Funktionsweise des Ablaufbogens

14" erläutert.An upper arch S 1 of this S-shaped area has a plurality of inwardly directed

Bei einer Spülung gelangt das Spülwasser durch den Stutzen 12

in den Umlenkbogen 43, wobei das Schluckvermögen des Aufnahmeraums

45 vergleichsweise gross ist. Das Spülwasser gelangt

nun durch die partielle Verengung 44 in den anschliessenden

Bereich, der den engeren Querschnitt C'' besitzt. Durch diese

Verengung bildet sich eine geschlossene Strömung, durch welche

das Spülwasser wirksam in die Leitung 21 abgesaugt wird.

Die Rippen 46 bis 52 bilden weitere Verengungen, welche die

Bildung der geschlossenen Strömung und damit die Absaugwirkung

unterstützen und verstärken. Wie oben erläutert, soll

mit möglichst wenig Spülwasser gespült werden können. Damit

eine geschlossene Strömung gebildet werden kann, ist jedoch

eine minimale Spülwassermenge erforderlich. Die Rippen 46 bis

52 ermöglichen es, diese erforderliche Menge weiter zu verkleiner.

Die Wirkung der Rippen 46 bis 52 dürfte wesentlich

auch darin gesehen werden, dass sie die Strömung des Spülwassers

brechen und damit die Bildung einer geschlossenen Strömung

unterstützen. Vorteilhaft ist zudem, dass solche Rippen

46 bis 52 im Blasformverfahren vergleichsweise einfach herstellbar

sind. Da wie erläutert die Kurven des Ablaufbogens

14" in einer zur Rückseite 8a parallelen Ebene verlaufen,

ist die Raumbeanspruchung vergleichsweise klein. Schliesslich

ist auch die Montage des Ablaufbogens 14" sehr einfach.When flushing the rinse water passes through the nozzle 12th

in the

Claims (21)

- Outlet pipe for a toilet system, with a toilet bowl (8), containing a trap (10), and with a flush device with which the toilet bowl (8) can be rinsed, wherein the outlet pipe (14), which, behind the trap as seen in direction of the flow, is to be connected to a waste pipe (21) and through which, during the flushing, rinse water and the items contained therein are transported to the waste pipe (21), the curved outlet pipe (14) containing a substantially vertical section (17) that has a smaller available cross section (C) than the upper section of the curved outlet pipe (A), such that, during the flushing operation, significantly more water enters the afore-mentioned vertical section (17) than can drain off, resulting in the formation of a closed flow (27') and accompanying suction which essentially empties the trap (10) characterized in that the curved outlet pipe (14) includes, after the vertical section (17), an upper and a lower bend (S1, S2), forming an S-shape, wherein the outlet pipe (14) has inward ribs (46-52) which form additional contractions.

- Outlet pipe in accordance with Claim 1, characterized by the fact that the curved outlet pipe (14) below the afore-mentioned vertical pipe section (17) has an available cross section (D) which is larger than the available cross section (C) of the vertical section (17).

- Outlet pipe in accordance with Claim 1 or 2, characterized by the fact that the ratio of the available cross section (C) of the vertical pipe section (17) to the available hydraulic cross section (A) of the connecting piece (12) is basically equal to or lower than 0.8.

- Outlet pipe in accordance with Claim 2 or 3, characterized by the fact that the outlet pipe (14) is formed in such a way that, after a flushing operation, water collects in the settling basin (22), and that the available cross section (D) of the outlet pipe behind the settling basin is larger than the available cross section (C) of the afore-mentioned vertical pipe section.

- Outlet pipe in accordance with one of the Claims 2 through 4, characterized by the fact that the lower section of the curved outlet pipe (14) contains an outlet end (19) with an available cross section (E) that is approximately equal to the available cross section (C) of the afore-mentioned vertical pipe section (17).

- Outlet pipe in accordance with one of the Claims 1 through 5, characterized by the fact that the lower section of the outlet pipe (14) forms a banking height (H) that is several times as large as the diameter of the vertical section (17).

- Outlet pipe in accordance with Claim 6, characterized by the fact that this ratio lies between 4: 1 to 7: 1.

- Outlet pipe in accordance with one of the Claims 1 through 7, characterized by the fact that the curved outlet pipe (14) is made of synthetic material.

- Toilet system or toilet system with a toilet bowl (8), containing a trap (10), and with a flushing device with which the toilet bowl (8) can be rinsed and with an outlet pipe (14) according to Claim 1, wherein the outlet pipe (14) behind the trap (10) as seen in the direction of the flow is to be connected to a waste pipe (21) and through which, during the flushing, rinse water and the items contained therein are transported to the waste pipe (21), and wherein the outlet pipe is manufactured separately and can be attached to the connecting piece (12) of the toilet bowl (8).

- Outlet pipe in accordance with Claim 7, characterized by the fact that the curved outlet pipe has been manufactured through moulding.

- Toilet system in accordance with Claim 9 or outlet pipe in accordance with Claim 10, characterized by the fact that the curved outlet pipe forms a settling basin (22) at its lower end and directs the current in such a way that it is distributed over the cross section (E) and prevents air from entering.

- Outlet pipe in accordance with one of the Claims 8, 10 or 11 or toilet system in accordance with Claim 9, characterized by the fact that the two bends (S1, S2) are positioned in a level that is perpendicular to the longitudinal axis of the connecting piece (12) of the toilet bowl (8).

- Outlet pipe in accordance with Claim 12, characterized by the fact that the curved outlet pipe has a perpendicular outlet end (19').

- Outlet pipe in accordance with Claim 12 or 13, characterized by the fact that the upper bend (S1) and a connecting bend (16') are connected to a diagonal pipe section (17').

- Toilet system in accordance with Claim 9, characterized by the fact that the available cross section (B", C") narrows below a diversion pipe (43).

- Outlet pipe in accordance with Claim 1, characterized by the fact that, to the lower bend (S2), a perpendicular outlet end (19') is attached, which is open at the bottom.

- Outlet pipe in accordance with Claim 16, characterized by the fact that the two bends (S1, S2) have different aperture angles (α, β)

- Outlet pipe in accordance with Claim 17, characterized by the fact that the aperture angle (α) of the upper bend (S1) is greater than 900.

- Outlet pipe in accordance with Claim 17 or 18, characterized by the fact that the aperture angle (β) of the upper bend (S2) is smaller than 90°.

- Outlet pipe in accordance with Claim 19, characterized by the fact that the ribs (46 - 52) are arranged in the area of the two bends (S1, S2).

- Toilet system in accordance with Claim 9 or 10 or outlet pipe in accordance with one of the Claims 10 to 20, characterized by the fact, that the outlet pipe has been manufactured through blow moulding from synthetic material.

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CH82799 | 1999-05-04 | ||

| CH82799 | 1999-05-04 | ||

| CH137899 | 1999-07-27 | ||

| CH137899 | 1999-07-27 | ||

| PCT/CH2000/000160 WO2000066841A1 (en) | 1999-05-04 | 2000-03-20 | Water-saving toilet arrangement |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1175534A1 EP1175534A1 (en) | 2002-01-30 |

| EP1175534B1 true EP1175534B1 (en) | 2005-04-27 |

Family

ID=25685820

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP00908897A Expired - Lifetime EP1175534B1 (en) | 1999-05-04 | 2000-03-20 | Water-saving toilet arrangement |

Country Status (7)

| Country | Link |

|---|---|

| EP (1) | EP1175534B1 (en) |

| AT (1) | ATE294287T1 (en) |

| AU (1) | AU3141300A (en) |

| CA (1) | CA2370152A1 (en) |

| DE (1) | DE50010169D1 (en) |

| MX (1) | MXPA01010465A (en) |

| WO (1) | WO2000066841A1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP4183945A1 (en) * | 2021-11-23 | 2023-05-24 | Roger Vidale | Plumbing fitting for hanging toilet |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10314640A1 (en) * | 2003-04-01 | 2004-10-14 | Keramag Keramische Werke Ag | WC and associated installation element |

| US8321967B2 (en) | 2008-08-01 | 2012-12-04 | Kohler Co. | Wall installed toilet |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US380854A (en) | 1888-04-10 | boyle | ||

| US2055490A (en) * | 1935-02-02 | 1936-09-29 | Pierce John B Foundation | Evacuator |

| US2055489A (en) * | 1935-04-04 | 1936-09-29 | Pierce John B Foundation | Adjustable evacuator |

| FR1148893A (en) * | 1955-03-18 | 1957-12-17 | Siphon branch and its application to water closets | |

| JPS6475741A (en) * | 1987-09-16 | 1989-03-22 | Toto Ltd | Water closet |

| US5487193A (en) | 1992-04-17 | 1996-01-30 | Fluidmaster, Inc. | Enhanced operation toilet |

| DE29807813U1 (en) | 1998-04-30 | 1998-07-30 | Top Valve Co., Ltd., Taipeh/T'ai-pei | Water-saving flushing device for the toilet |

-

2000

- 2000-03-20 AT AT00908897T patent/ATE294287T1/en not_active IP Right Cessation

- 2000-03-20 WO PCT/CH2000/000160 patent/WO2000066841A1/en active IP Right Grant

- 2000-03-20 AU AU31413/00A patent/AU3141300A/en not_active Abandoned

- 2000-03-20 DE DE50010169T patent/DE50010169D1/en not_active Expired - Fee Related

- 2000-03-20 MX MXPA01010465A patent/MXPA01010465A/en unknown

- 2000-03-20 EP EP00908897A patent/EP1175534B1/en not_active Expired - Lifetime

- 2000-03-20 CA CA002370152A patent/CA2370152A1/en not_active Abandoned

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP4183945A1 (en) * | 2021-11-23 | 2023-05-24 | Roger Vidale | Plumbing fitting for hanging toilet |

| FR3129418A1 (en) * | 2021-11-23 | 2023-05-26 | Roger VIDALE | PLUMBING CONNECTION FOR HANGING TOILETS |

Also Published As

| Publication number | Publication date |

|---|---|

| WO2000066841A1 (en) | 2000-11-09 |

| EP1175534A1 (en) | 2002-01-30 |

| AU3141300A (en) | 2000-11-17 |

| ATE294287T1 (en) | 2005-05-15 |

| CA2370152A1 (en) | 2000-11-09 |

| MXPA01010465A (en) | 2002-05-06 |

| DE50010169D1 (en) | 2005-06-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1247910B1 (en) | Odour-trap for waterless urinal | |

| DE9416495U1 (en) | Roof water inlet | |

| EP1600676A1 (en) | Drain valve for condensation water | |

| DE202015003331U1 (en) | Wall drain with siphon trap | |

| EP1335076B1 (en) | Outlet fitting for a sanitary device, in particular a urinal | |

| AT5032U1 (en) | SUCTION SIPHON FOR A RINSING DEVICE | |

| EP1910627B1 (en) | Odour seal | |

| EP1175534B1 (en) | Water-saving toilet arrangement | |

| DE69023285T2 (en) | TOILET BOWL. | |

| DE69420099T2 (en) | Vacuum valve | |

| EP1120500B1 (en) | Toilet bowl | |

| EP1832689A1 (en) | Low pressure wastewater device | |

| DE202021106357U1 (en) | Flush toilet | |

| DE10204683B4 (en) | pool | |

| CH716366B1 (en) | Flush water distributor for a sanitary article. | |

| EP0916775B1 (en) | Tank body for a flushing cistern | |

| EP3825480A1 (en) | Flush water distributor | |

| DE102019125459A1 (en) | Wall-mounted siphon toilet | |

| EP1416098B1 (en) | Siphon for a drain installation | |

| WO2001053618A2 (en) | Sanitary system | |

| DE29807813U1 (en) | Water-saving flushing device for the toilet | |

| EP3825479A1 (en) | Flush water distributor | |

| EP1138839B1 (en) | Two-piece urinal | |

| WO2019002332A1 (en) | Odour trap element for installation in an outflow, in particular in the outflow of a waterless urinal | |

| EP0757135A1 (en) | Flushing cistern |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20011025 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL PAYMENT 20011025;LT PAYMENT 20011025;LV PAYMENT 20011025;MK PAYMENT 20011025;RO PAYMENT 20011025;SI PAYMENT 20011025 |

|

| 17Q | First examination report despatched |

Effective date: 20040224 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO SI |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20050427 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20050427 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: ISLER & PEDRAZZINI AG Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 50010169 Country of ref document: DE Date of ref document: 20050602 Kind code of ref document: P |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20050518 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20050727 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20050727 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20050727 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20051010 |

|

| LTIE | Lt: invalidation of european patent or patent extension |

Effective date: 20050427 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20060117 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20060207 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20060209 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20060213 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20060215 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20060217 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20060303 Year of fee payment: 7 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| ET | Fr: translation filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060331 Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060331 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20060331 Year of fee payment: 7 |

|

| 26N | No opposition filed |

Effective date: 20060130 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PCAR Free format text: ISLER & PEDRAZZINI AG;POSTFACH 1772;8027 ZUERICH (CH) |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070320 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20070320 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20071001 |

|

| BERE | Be: lapsed |

Owner name: *GEBERIT TECHNIK A.G. Effective date: 20070331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070331 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20071130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20071001 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20071002 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070331 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070320 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070402 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20050427 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070320 |