EP0908570B1 - Construction with a membrane whereby the roof is made of a three dimensional metallic or composite frame - Google Patents

Construction with a membrane whereby the roof is made of a three dimensional metallic or composite frame Download PDFInfo

- Publication number

- EP0908570B1 EP0908570B1 EP97440095A EP97440095A EP0908570B1 EP 0908570 B1 EP0908570 B1 EP 0908570B1 EP 97440095 A EP97440095 A EP 97440095A EP 97440095 A EP97440095 A EP 97440095A EP 0908570 B1 EP0908570 B1 EP 0908570B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- beams

- profile bar

- construction according

- receiving

- several

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000010276 construction Methods 0.000 title claims description 44

- 239000002131 composite material Substances 0.000 title claims description 5

- 239000012528 membrane Substances 0.000 title 1

- 229910052751 metal Inorganic materials 0.000 claims abstract description 7

- 239000002184 metal Substances 0.000 claims description 5

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 5

- 238000003466 welding Methods 0.000 claims description 4

- 239000011165 3D composite Substances 0.000 abstract description 3

- 239000002905 metal composite material Substances 0.000 abstract description 2

- 210000005069 ears Anatomy 0.000 description 8

- 239000004744 fabric Substances 0.000 description 4

- 239000000463 material Substances 0.000 description 3

- 230000000694 effects Effects 0.000 description 2

- 238000007789 sealing Methods 0.000 description 2

- 229910000838 Al alloy Inorganic materials 0.000 description 1

- 241000735470 Juncus Species 0.000 description 1

- 229910000831 Steel Inorganic materials 0.000 description 1

- 238000004026 adhesive bonding Methods 0.000 description 1

- 238000007599 discharging Methods 0.000 description 1

- 238000009413 insulation Methods 0.000 description 1

- 238000003754 machining Methods 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

- 230000000475 sunscreen effect Effects 0.000 description 1

- 239000000516 sunscreening agent Substances 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B7/00—Roofs; Roof construction with regard to insulation

- E04B7/14—Suspended roofs

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B7/00—Roofs; Roof construction with regard to insulation

- E04B7/08—Vaulted roofs

- E04B7/10—Shell structures, e.g. of hyperbolic-parabolic shape; Grid-like formations acting as shell structures; Folded structures

- E04B7/105—Grid-like structures

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04H—BUILDINGS OR LIKE STRUCTURES FOR PARTICULAR PURPOSES; SWIMMING OR SPLASH BATHS OR POOLS; MASTS; FENCING; TENTS OR CANOPIES, IN GENERAL

- E04H15/00—Tents or canopies, in general

- E04H15/32—Parts, components, construction details, accessories, interior equipment, specially adapted for tents, e.g. guy-line equipment, skirts, thresholds

- E04H15/64—Tent or canopy cover fastenings

- E04H15/642—Tent or canopy cover fastenings with covers held by elongated fixing members locking in longitudinal recesses of a frame

- E04H15/644—Tent or canopy cover fastenings with covers held by elongated fixing members locking in longitudinal recesses of a frame the fixing members being a beading

Definitions

- the invention relates to a flexible cover construction, at least the part forming the roof is defined by a framework metallic or three-dimensional composite consisting of basic structure or a juxtaposition of several of these last of which each has at least two beams parallels connected by means of crosspieces and from which extend diagonals defining, as the case may be, two or more farms joined together by their top or one or a succession of pyramid-shaped modules in space internal bounded by such a basic structure being underpinned at least one soft cover, double type curvature.

- this type of construction makes call for a metal frame consisting of an assembly of profiles coming to define, at least as regards the part forming the roof, a three-dimensional framework with the interior of which are one or more roofing elements made of flexible material, usually double curvature type.

- such a three-dimensional metal frame uses profiles metallic elementary dimension that we just connect the relative to each other using link nodes of so as to define basic modules (as described, for example, by DE 11 70 604C), often in the form of pyramids. So many of these basic modules can be associated with each other, again using the nodes above to finally reach the size of the roof suitable for construction. It will be noted that very often these basic modules, often pyramid-shaped, are also connected to each other by their top.

- a basic module has two parallel beams, also connected to each other using sleepers. Relative to these beams extend diagonals that come to define, or a pyramidal shape, these diagonals coming to meet at the same node, or two or more farms connected by their top.

- the objective of the present invention consists in designing a construction comprising, in particular in its roof-forming part, a frame of the type three-dimensional whose assembly is not only easy because lacking often very expensive connecting nodes, but which, in addition, is able to receive, with great ease and reduced assembly time, double cover elements curvature intended to be underpinned at this framework.

- the present invention aims to provide a solution to the problem of modularity of constructions for use temporary.

- a structure base has a third spar parallel to the previous one from the summits, as the case may be, farms or pyramid-shaped modules defined by the diagonals.

- the means intended for reception with a view to fixing the ends of the diagonals and / or crosspieces at a profile defining a beam are presented in the form of ears attached to said profile or else in the form of a continuous or discontinuous wing added or coextruded.

- Such a profile is moreover preferably designed in aluminum alloy, knowing that it could also be designed in a composite material.

- this type of construction offers rental companies the opportunity to optimize their stock of equipment. Indeed, through a simple juxtaposition of several basic structures, we can definitive, reach all building dimensions desired whether in length or in width. In as a result, it gives them better rotation of their equipment.

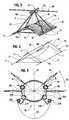

- the present invention relates to a construction 1 of which at least the part forming roof 2 is defined by a metal or composite frame of three-dimensional type. In fact, it consists of a basic structure 4 or as shown in this Figure 1, a juxtaposition of several of these.

- a such basic structure 4 comprises at least two beams parallels 5, 6 between which and, ultimately, are intended to extend one or more double blankets curvature 7, these longitudinal members 5, 6 being, moreover, connected between them using sleepers 8.

- these longitudinal members 5, 6 are caused to extend from the diagonals 9, 9A, 9B, 9C which, in a configuration shown, FIG. 4, are brought to define at least two farms F1, F2 rendered united by their vertex S so as to constitute a module Me.

- such diagonals 9, 9A, 9B, 9C define, as shown in Figures 1 to 3, attached drawings, one or a succession of modules M, M1, M2, M3 pyramid-shaped.

- the two longitudinal members 5, 6 are each defined by a profile 10 of which Figures 5 and 6 show, in section, different modes of achievement.

- a profile 10 comprise at least a shooting groove 11A, 11B for receiving a rod 12 (shown in broken lines) from the two longitudinal edges 13, 14 of a flexible double cover curvature 7 intended to be subtended on this structure of base 4.

- such a profile 10 designing a beam 5, 6 is advantageously provided with means 15 for receiving, with a view to their attachment, the ends 16, 16A of the diagonals 9, 9A, 9B, 9C and / or crosspieces 8.

- two juxtaposed basic structures 4 come share the same spar for fixing one of the edges longitudinal 13, 14 of their double curvature cover 7 respective.

- such beam is also designed to be able to receive the diagonals corresponding to each of these basic structures 4, juxtaposed as well as, if necessary, the crosspieces 8 connecting the side members 5, 6 of each of the latter.

- such a profile 10 is advantageously designed to symmetrically about a vertical plane of symmetry 17 and consequently comprises two shooting grooves 11A, 11B for receiving the rod 12 fitted to the longitudinal edge respectively 13, 14 of the double curvature covers 7 corresponding, precisely, to two basic structures 4 juxtaposed.

- ears 30, 30A As for the means 15 intended for the reception of the ends 16 diagonals 9, 9A, 9B, 9C, or the corresponding 16A to a cross 8, they can appear as shown in Figures 6 and 7, in the form of ears 30, 30A reported, particularly equidistantly, on said profiled 10. Such ears 30, 30A come, of course, extend from this profile 10 with an angle of inclination 18 adapted to the orientation which must be communicated to the diagonals 9, 9A, 9B, 9C or even a cross member 8.

- ears 30, 30A can be reported directly, for example by welding, gluing or screwing, on a profile 10.

- a weld has tendency to modify the mechanical characteristics of said profiled, especially if it is of metallic type.

- a mechanical connection, of the screwing type requires a wall thickness at this profile which is sufficient to ensure a good connection.

- a solution has been devised, consisting in providing a profile 10 of ears 30, 30A through pieces of junction 31 of external section 32 adjusted to the internal section 33 of the otherwise defined tubular type profile.

- a junction piece 31 preferably of the type metallic, in particular steel, are ultimately reported, for example by welding and along generators, said ears 30, 30A, while a profile 10 is defined by one or more sections of profile 10A, 10B at the ends 34A, 34B from which are joined connecting pieces 31, fitted with ears 30, 30A.

- the actual connection between a connecting piece 31 and a section of profile 10A, 10B can be obtained by means of a pin 35 for example.

- these ends 34A, 34B of the section sections 10A, 10B are advantageously, notched, axially, for the passage of ears 30, 30A, and thus allow to ensure perfect continuity at the junction of two sections of profile 10A, 10B.

- these include a length corresponding to the spacing of the connections of diagonals and / or cross members on a beam 5, 6. In fact, this length is substantially that of a module M, M1, M2, M3 or M '.

- such means 15 intended for the reception of the ends 16, 16A as the case may be, of diagonals 9, 9A, 9B, 9C or even sleepers 8, adopt a symmetrical configuration with respect to the plane of symmetry vertical 17 around profile 10.

- a profile 10 can receive a second pair of grooves 20A, 20B arranged at a level significantly lower than the gorges llA, llB for the reception of the rod corresponding to a lining fabric of two basic structures 4, juxtaposed.

- the side members 5, 6 constitute the lower part of the roof that define, specifically, these double curvature covers 7. In these conditions, they are led to collect runoff water which must be evacuated.

- a profile 10 or another section of profile 10A, 10B defining this spar 5, 6 is provided of tubular type, its internal part designing a gutter suitable for collecting and discharging water from runoff.

- Such an embodiment poses, however, the problem of sealing between two sections 10 or sections of sections 10A, 10B coupled, successively, one behind the other in view to define a basic structure of increased length and adapt to the size of construction 1 to be produced. If one such sealing is technically feasible, it often leads to the use of seals which, when successive dismantling and reassembly of the construction are caused to deteriorate fairly quickly. In this regard, he should particularly take into account the because of the size of this type of construction 1, it is difficult, if not impossible, to confer on the longitudinal members 5, 6, any slope in order to facilitate the evacuation of runoff water.

- connecting lugs 21A, 21B, bearing at their ends the grooves 22A, 22B are configured so that said gutter-shaped canvas 23 extends, perfectly, below these beams 5, 6 aptly to collect all runoff from covers 7.

- a basic structure 4 preferably comprises at least a third spar 25, again defined by a profile 10 'comprising means 15 for the reception with a view to fixing the diagonals 9, 9A, 9B, 9C (see Figure 8).

- This spar 25 thus comes to connect between them, either the vertices S of the farms F1, F2, or the vertices 24 of several M, M1, M2, M3 of the same structure of base 4 or corresponding to several base 4 structures juxtaposed.

- a spar 25 can be provided with means 15 for receiving sleepers 8A, able to connect these two side members 25 in pairs.

- Such a third spar 25 can be devoid of grooves, nothing prevents it from being provided with one or more, this similar to a profile 10 or a section of profile 10A, 10B defining the longitudinal members 5, 6.

- Such grooves can in particular receive the rods of a canvas, more particularly a grid, which we extend in some way so above the double curvature covers 7 in sight, either to protect them from dirt, for example leaves, or to create sunscreen.

- the profile 10 'intended for define such a spar 25 is configured, in its part lower 36, in the form of a rail 37 for receiving one or several trolleys 39 (shown diagrammatically) to which are fixed one or more cables 38 for energizing the or blankets with double curvature 7.

- trolleys 39 shown diagrammatically

- the carriages 39 are engaged simultaneously on the spar 25 to which the tensioning cable (s) are attached.

- such a construction 1, in accordance with the invention turns out to be very modular through the use of standard parts which, moreover, make it possible to overcome connecting nodes, often corresponding to parts particularly expensive. Indeed, such connecting nodes frequently use numerous design tools welding, stamping, machining and other operations, operations which are particularly streamlined in the present case.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- Tents Or Canopies (AREA)

- Rod-Shaped Construction Members (AREA)

- Laminated Bodies (AREA)

- Roof Covering Using Slabs Or Stiff Sheets (AREA)

- Joining Of Building Structures In Genera (AREA)

Abstract

Description

L'invention concerne une construction à couverture souple dont au moins la partie formant toiture est définie par une ossature métallique ou composite tridimensionnelle constituée d'une structure de base ou d'une juxtaposition de plusieurs de ces dernières dont chacune comporte au moins deux longerons parallèles reliés à l'aide de traverses et d'où s'étendent des diagonales définissant, selon le cas, deux ou davantage de fermes rendues solidaires par leur sommet ou encore un ou une succession de modules de forme pyramidale, dans l'espace interne délimité par une telle structure de base étant sous-tendue au moins une couverture souple, de type à double courbure.The invention relates to a flexible cover construction, at least the part forming the roof is defined by a framework metallic or three-dimensional composite consisting of basic structure or a juxtaposition of several of these last of which each has at least two beams parallels connected by means of crosspieces and from which extend diagonals defining, as the case may be, two or more farms joined together by their top or one or a succession of pyramid-shaped modules in space internal bounded by such a basic structure being underpinned at least one soft cover, double type curvature.

L'on connaít d'ores-et-déjà des constructions répondant à la description ci-dessus. En fait, ce type de construction fait appel à une charpente métallique constituée par un assemblage de profilés venant à définir, tout au moins en ce qui concerne la partie formant toiture, une ossature tridimensionnelle à l'intérieur de laquelle sont sous-tendus un ou plusieurs éléments de couverture en matériau souple, habituellement du type à double courbure.We already know constructions that meet the description above. In fact, this type of construction makes call for a metal frame consisting of an assembly of profiles coming to define, at least as regards the part forming the roof, a three-dimensional framework with the interior of which are one or more roofing elements made of flexible material, usually double curvature type.

En fait, il convient d'observer que, jusqu'à présent, une telle ossature métallique tridimensionnelle fait appel à des profilés métalliques de dimension élémentaire que l'on vient relier les uns par rapport aux autres à l'aide de noeuds de liaison de manière à définir des modules de base (tels que décrits, par exemple, par DE 11 70 604C), souvent sous forme de pyramides. Ainsi, plusieurs de ces modules de base peuvent être associés les uns aux autres, là encore à l'aide des noeuds précités pour aboutir, finalement, à la taille de la toiture adaptée à la construction. On notera, que très souvent, ces modules de base, souvent de forme pyramidale, sont en outre reliés les uns aux autres par leur sommet.In fact, it should be observed that, so far, such a three-dimensional metal frame uses profiles metallic elementary dimension that we just connect the relative to each other using link nodes of so as to define basic modules (as described, for example, by DE 11 70 604C), often in the form of pyramids. So many of these basic modules can be associated with each other, again using the nodes above to finally reach the size of the roof suitable for construction. It will be noted that very often these basic modules, often pyramid-shaped, are also connected to each other by their top.

De manière plus détaillée, un module de base comporte deux longerons parallèles, par ailleurs reliés entre eux à l'aide de traverses. Par rapport à ces longerons s'étendent des diagonales qui viennent définir, soit une forme pyramidale, ces diagonales venant se rejoindre au niveau d'un même noeud, soit deux ou davantage de fermes reliées par leur sommet.In more detail, a basic module has two parallel beams, also connected to each other using sleepers. Relative to these beams extend diagonals that come to define, or a pyramidal shape, these diagonals coming to meet at the same node, or two or more farms connected by their top.

L'on comprend, évidemment, que plusieurs de ces modules peuvent être juxtaposés de manière à concevoir une rangée que l'on a défini comme étant une structure de base dans la suite de la description sachant, précisément, que plusieurs de ces structures de base peuvent là encore être associées les unes aux autres pour aboutir à la taille souhaitée de la construction.It is obvious, of course, that several of these modules can be juxtaposed so as to design a row that we have defined as a basic structure in the rest of the description knowing, precisely, that several of these again basic structures can be combined to others to achieve the desired size of the construction.

Le problème que pose, à l'heure actuelle, ce type de construction comportant, en tant que toiture, une ossature métallique tridimensionnelle consiste en ce que leur temps de montage est particulièrement long, ceci d'autant plus que l'on fait appel, usuellement, à des techniques de laçage pour tendre, au niveau d'une telle ossature, les éléments de couverture en matériau souple à double courbure. En fait, la mise sous tension de ces éléments de couverture s'effectue, le plus fréquemment, à hauteur des noeuds de liaison.The current problem with this type of construction comprising, as a roof, a framework three-dimensional metallic is that their time of assembly is particularly long, especially since we usually uses lacing techniques to stretch, at the level of such a framework, the elements of cover in flexible material with double curvature. In fact, the these cover elements are energized, the more frequently, at the level of the linking nodes.

Au vu de ce constat, l'on comprend, évidemment, que ces constructions particulières ne sont nullement adaptées à une utilisation temporaire dans la mesure où, précisément, les opérations de montage et de démontage s'avèrent particulièrement onéreuse. Aussi, ces constructions à ossature tridimensionnelle, sous-tendues de toiles à double courbure, bien que présentant une esthétique particulièrement attrayante, ne voient leur utilité que dans la conception de bâtiments à usage permanent, tandis que pour accueillir une activité temporaire l'on n'a pas d'autre solution que de faire appel à des constructions plus classiques.In view of this observation, we understand, of course, that these particular constructions are in no way suitable for a temporary use insofar as, precisely, the assembly and disassembly operations are particularly expensive. Also, these frame constructions three-dimensional, subtended with double curvature fabrics, although having a particularly attractive aesthetic, see their utility only in the design of buildings with permanent use, while hosting an activity temporary we have no other solution than to call on more classic constructions.

Celles-ci font appel, selon le cas, à une ossature sensiblement plane qui, pour former la toiture reçoit une ou plusieurs couvertures à double courbure, notamment en forme de chapeau chinois, dont la mise sous tension s'effectue souvent depuis l'intérieur. A noter, à ce propos qu'il est également connu de tendre ces toiles à double courbure depuis l'extérieur du bâtiment à l'aide de haubans fixés à des mâts prévus à cet effet.These call, as the case may be, for a framework substantially flat which, to form the roof receives one or more double curvature blankets, especially hat-shaped Chinese, often powered up from the interior. Note, in this regard that it is also known to stretch these double curvature fabrics from outside the building using guy wires attached to masts provided for effect.

En fait, plus usuellement l'on fera appel à des constructions du type chapiteau ou analogue dont la structure est constituée par une succession de portiques reliés de manière équidistante entre eux et constitués par un assemblage de profilés à gorge pour la réception entre deux portiques successifs, d'un élément de couverture en matériau souple dont les bords longitudinaux sont prééquipés d'un jonc. Celui-ci est, ainsi, à même de coulisser à l'intérieur des gorges des profilés précités.In fact, more usually we will use constructions of the marquee or similar type, the structure of which consists by a succession of gantries equidistantly connected between them and constituted by an assembly of grooved profiles for the reception between two successive gantries, of an element roofing in flexible material with longitudinal edges are pre-equipped with a rod. This is thus able to slide inside the grooves of the aforementioned profiles.

L'on s'aperçoit que les deux solutions exposées ci-dessus et utilisées pour la conception de bâtiments à usage temporaire posent le problème de leur modularité. Ainsi, si le type de construction présenté en dernier lieu est le plus répandu car conduisant à un temps de montage réduit, il est difficile d'en adapter la forme ou encore les dimensions, strictement à l'usage auquel il est destiné ou encore à l'emplacement qui lui est réservé. En effet, les entreprises qui proposent ce type de construction à la location ne disposent que d'un nombre très limité de portiques aux dimensions différentes. De plus, si une telle entreprise de location veut être à même de satisfaire, une large demande de sa clientèle, il lui faut disposer, en stock, non seulement des éléments, à savoir structures et couvertures, correspondant aux constructions les plus usitées, mais également ceux destinés à la conception de construction aux dimensions plus particulières demandées qu'exceptionnellement par cette clientèle. Ceci pose, par conséquent, le problème de la rotation et, donc, de la rentabilité de ces éléments propres à des constructions de dimension spéciale.We can see that the two solutions exposed above and used for the design of temporary buildings raise the problem of their modularity. So if the type of construction presented last is the most widespread because leading to reduced assembly time, it is difficult to adapt the shape or the dimensions, strictly to the use for which it is intended or the location which is reserved. Indeed, companies that offer this type of construction for hire only have a very number limited gantries with different dimensions. In addition, if a such a rental company wants to be able to satisfy, a large demand from its customers, it must have, in stock, not only elements, namely structures and covers, corresponding to the most commonly used constructions, but also those intended for construction design to the more specific dimensions requested only exceptionally by this clientele. This poses, by Therefore, the problem of rotation and, therefore, of the profitability of these elements specific to constructions of special dimension.

En définitive, l'objectif visé par la présente invention consiste à concevoir une construction comportant, notamment dans sa partie formant toiture, une ossature du type tridimensionnel dont, non seulement, l'assemblage est aisé car dépourvu des noeuds de liaison souvent très onéreux, mais qui, en outre, est à même de recevoir, avec une grande facilité et un temps de montage réduit, les éléments de couverture à double courbure destinés à être sous-tendus au niveau de cette ossature.Ultimately, the objective of the present invention consists in designing a construction comprising, in particular in its roof-forming part, a frame of the type three-dimensional whose assembly is not only easy because lacking often very expensive connecting nodes, but which, in addition, is able to receive, with great ease and reduced assembly time, double cover elements curvature intended to be underpinned at this framework.

Du même coup, la présente invention a pour but d'apporter une solution au problème de la modularité des constructions à usage temporaire.At the same time, the present invention aims to provide a solution to the problem of modularity of constructions for use temporary.

A cet effet, l'invention concerne une construction à couverture souple dont au moins la partie formant toiture est définie par une ossature métallique ou composite tridimensionnelle constituée d'une structure de base ou d'une juxtaposition de plusieurs de ces dernières dont chacune comporte au moins deux longerons parallèles reliés à l'aide de traverses et d'où s'étendent des diagonales définissant, selon le cas, au moins deux fermes rendues solidaires par leur sommet et formant un module ou encore un ou une succession de modules de forme pyramidale, dans l'espace interne délimité par chacune de ces structures de base étant sous-tendue au moins une couverture souple, du type à double courbure, caractérisée par le fait que:

- les deux longerons parallèles d'une structure de base sont définis, chacun, par un profilé comportant au moins une gorge filante pour la réception d'un jonc équipant deux bords longitudinaux de la ou des couvertures souples à double courbure destinées à être sous-tendues au niveau de ladite structure de base;

- et qu'un tel profilé est pourvu de moyens pour la réception en vue de leur fixation des extrémités des diagonales et/ou des traverses.

- the two parallel longitudinal members of a basic structure are each defined by a profile comprising at least one shooting groove for the reception of a rod equipping two longitudinal edges of the flexible cover (s) with double curvature intended to be subtended at said base structure;

- and that such a profile is provided with means for receiving them with a view to fixing the ends of the diagonals and / or crosspieces.

Selon une particularité de la présente invention, une structure de base comporte un troisième longeron parallèle au précédent venant relier les sommets, selon le cas, des fermes ou des modules de forme pyramidale définis par les diagonales.According to a feature of the present invention, a structure base has a third spar parallel to the previous one from the summits, as the case may be, farms or pyramid-shaped modules defined by the diagonals.

Avantageusement, les moyens destinés à la réception en vue de la fixation des extrémités des diagonales et/ou des traverses au niveau d'un profilé définissant un longeron se présentent sous forme d'oreilles rapportées sur ledit profilé ou encore sous forme d'une aile continue ou discontinue rapportée ou coextrudée.Advantageously, the means intended for reception with a view to fixing the ends of the diagonals and / or crosspieces at a profile defining a beam are presented in the form of ears attached to said profile or else in the form of a continuous or discontinuous wing added or coextruded.

Un tel profilé est par ailleurs conçu, préférentiellement, en alliage d'aluminium, sachant qu'il pourrait également être conçu en un matériau composite.Such a profile is moreover preferably designed in aluminum alloy, knowing that it could also be designed in a composite material.

Les avantages découlant de la présente invention consistent en ce qu'au travers des profilés destinés à concevoir les longerons correspondant à une structure de base, il est possible de s'affranchir des noeuds de liaison auxquels on fait usuellement appel pour la conception d'ossatures métalliques tridimensionnelles. De plus, ces longerons, se présentant sous forme de profilés à gorge, sont aptes à accueillir, par coulissement, les joncs d'une couverture souple dont la mise en place est, de ce fait, considérablement facilitée.The advantages of the present invention consist of that through profiles intended to design the stringers corresponding to a basic structure it is possible to get rid of the connecting nodes that we do usually called for the design of metal frameworks three-dimensional. In addition, these beams, appearing under shaped groove profiles, are able to accommodate, for sliding, the rods of a flexible cover whose setting place is, therefore, considerably facilitated.

En fin de compte, l'on aboutit, au travers de la présente invention, à une construction qui, tout en étant équipée d'une telle ossature métallique ou composite tridimensionnelle, s'avère d'un temps de montage et de démontage particulièrement réduit, ce qui est un avantage considérable lorsqu'elle est destinée à un usage temporaire.In the end, we end up, through this invention, to a construction which, while being equipped with a such a metal or three-dimensional composite frame, turns out to be a time of assembly and disassembly particularly which is a considerable advantage when it is intended for temporary use.

Finalement, ce type de construction, conforme à l'invention, offre la possibilité aux entreprises de location d'optimiser leur stock de matériel. En effet, au travers d'une simple juxtaposition de plusieurs structures de base, on peut en définitive, atteindre toutes les dimensions de bâtiment souhaitées que ce soit en longueur ou en largeur. En conséquence, cela leur assure une meilleure rotation de leur matériel.Finally, this type of construction, in accordance with the invention, offers rental companies the opportunity to optimize their stock of equipment. Indeed, through a simple juxtaposition of several basic structures, we can definitive, reach all building dimensions desired whether in length or in width. In as a result, it gives them better rotation of their equipment.

D'autres buts et avantages de la présente invention apparaítront au cours de la description qui va suivre se rapportant à un mode de réalisation qui n'est donné qu'à titre d'exemple indicatif et non limitatif.Other objects and advantages of the present invention will appear during the description which follows relating to an embodiment which is given only as indicative and non-limiting example.

La compréhension de cette description sera facilitée en se

référant aux dessins joints en annexe dans lesquels :

Tel que représenté dans la figure 1, la présente invention

concerne une construction 1 dont au moins la partie formant

toiture 2 est définie par une ossature métallique ou composite

de type tridimensionnel. En fait, celle-ci est constituée d'une

structure de base 4 ou encore comme représenté dans cette

figure 1, d'une juxtaposition de plusieurs de ces dernières. As shown in Figure 1, the present invention

relates to a construction 1 of which at least the

Comme visible plus particulièrement dans les figures 2 à 4, une

telle structure de base 4 comporte au moins deux longerons

parallèles 5, 6 entre lesquels et, en définitive, sont

destinées à s'étendre une ou plusieurs couvertures à double

courbure 7, ces longerons 5, 6 étant, par ailleurs, reliés

entre eux à l'aide de traverses 8. De plus, depuis ces

longerons 5, 6 sont amenés à s'étendre des diagonales 9, 9A,

9B, 9C qui, dans une configuration représentée, figure 4, sont

amenées à définir au moins deux fermes F1, F2 rendues

solidaires par leur sommet S de manière à constituer un module

M'. En fait, plus usuellement, de telles diagonales 9, 9A, 9B,

9C définissent, comme représenté dans les figures 1 à 3 des

dessins ci-joints, un ou une succession de modules M, M1, M2,

M3 de forme pyramidale.As can be seen more particularly in FIGS. 2 to 4, a

such basic structure 4 comprises at least two

Selon une particularité de la présente invention, les deux

longerons 5, 6, sont définis, chacun, par un profilé 10 dont

les figures 5 et 6 représentent, en section, différents modes

de réalisation. Ainsi, un tel profilé 10 comportent au moins

une gorge filante 11A, 11B pour la réception d'un jonc 12

(représenté en traits discontinus) venant équiper les deux

bords longitudinaux 13, 14 d'une couverture souple à double

courbure 7 destinée à être sous-tendue sur cette structure de

base 4.According to a feature of the present invention, the two

De plus, un tel profilé 10 concevant un longeron 5, 6 est

pourvu, avantageusement, de moyens 15 pour la réception, en vue

de leur fixation, des extrémités 16, 16A des diagonales 9, 9A,

9B, 9C et/ou des traverses 8.In addition, such a

Il convient d'observer que selon un mode de réalisation

préférentiel, deux structures de base 4 juxtaposées viennent

partager un même longeron pour la fixation de l'un des bords

longitudinaux 13, 14 de leur couverture à double courbure 7

respective. Dans ces conditions il est opportun qu'un tel

longeron soit en outre conçu pour être à même de recevoir les

diagonales correspondant à chacune de ces structures de base 4,

juxtaposées ainsi que, le cas échéant, les traverses 8 reliant

les longerons 5, 6 de chacune de ces dernières.It should be observed that according to one embodiment

preferential, two juxtaposed basic structures 4 come

share the same spar for fixing one of the edges

longitudinal 13, 14 of their

Dans ce but, un tel profilé 10 est conçu, avantageusement, de

manière symétrique par rapport à un plan de symétrie vertical

17 et comporte, en conséquence, deux gorges filantes 11A, 11B

pour la réception du jonc 12 équipant le bord longitudinal

respectivement 13, 14 des couvertures à double courbure 7

correspondant, précisément, à deux structures de base 4

juxtaposées.For this purpose, such a

Quant aux moyens 15 destinés à la réception des extrémités 16

des diagonales 9, 9A, 9B, 9C, ou encore celle 16A correspondant

à une traverse 8, ils peuvent se présenter comme représentés

dans les figures 6 et 7, sous forme d'oreilles 30, 30A

rapportées, notamment de manière équidistante, sur ledit

profilé 10. De telles oreilles 30, 30A viennent, bien sûr,

s'étendre depuis ce profilé 10 avec un angle d'inclinaison 18

adapté à l'orientation qui doit être communiquée aux diagonales

9, 9A, 9B, 9C ou encore à une traverse 8.As for the

Il convient d'observer que de telles oreilles 30, 30A, peuvent

être rapportées directement, par exemple par soudure, collage

ou vissage, sur un profilé 10. Toutefois, une soudure a

tendance à modifier les caractéristiques mécaniques dudit

profilé, notamment si celui-ci est de type métallique. Par

ailleurs, une liaison mécanique, du type vissage, nécessite une

épaisseur de paroi au niveau de ce profilé qui soit suffisante

pour assurer une bonne liaison.It should be observed that

Pour cela, il a été imaginé une solution, consistant à pourvoir

un profilé 10 d'oreilles 30, 30A au travers de pièces de

jonction 31 de section externe 32 ajustée à la section interne

33 du profilé par ailleurs défini de type tubulaire. Sur une

telle pièce de jonction 31, préférentiellement de type

métallique, notamment en acier, sont, en définitive,

rapportées, par exemple par soudure et le long de génératrices,

lesdites oreilles 30, 30A, tandis qu'un profilé 10 est défini

par un ou plusieurs tronçons de profilé 10A, 10B aux extrémités

34A, 34B desquelles sont enfilées des pièces de jonction 31,

équipées d'oreilles 30, 30A. La liaison proprement dite entre

une pièce de jonction 31 et un tronçon de profilé 10A, 10B peut

être obtenu au moyen d'une goupille 35 par exemple. De plus,

ces extrémités 34A, 34B des tronçons de profilé 10A, 10B sont

avantageusement, entaillées, axialement, pour le passage des

oreilles 30, 30A, et permettre, ainsi, d'assurer une parfaite

continuité au niveau de la jonction de deux tronçons de profilé

10A, 10B.For this, a solution has been devised, consisting in providing

a

En fin de compte, on observera que ces derniers comportent une

longueur correspondant à l'écartement des liaisons de

diagonales et/ou de traverses sur un longeron 5, 6. En fait,

cette longueur est sensiblement celle d'un module M, M1, M2, M3

ou M'.In the end, we will observe that these include a

length corresponding to the spacing of the connections of

diagonals and / or cross members on a

Tel que représenté plus particulièrement dans la figure 5, de

tels moyens 15 destinés à la réception des extrémités 16 des

diagonales 9, 9A, 9B, 9C ou encore celle 16A correspondant à

une traverse 8 peuvent emprunter, plus simplement, la forme

d'une ou plusieurs ailes 19, 19A, et/ou de tronçons d'ailes

s'étendant radialement en périphérie du profilé 10.As shown more particularly in FIG. 5, of

Comme pour les gorges 11A, 11B, de tels moyens 15 destinés à la

réception des extrémités 16, 16A, selon le cas, de diagonales

9, 9A, 9B, 9C ou encore de traverses 8, adoptent une

configuration symétrique par rapport au plan de symétrie

vertical 17 autour du profilé 10. As for the

Il convient, encore, d'observer qu'il peut être opportun,

notamment pour des raisons d'isolation thermique, de doubler

une couverture à double courbure 7 de manière à délimiter entre

cette dernière et la partie interne à la construction 1, un

matelas d'air isolant. Pour ce faire, un profilé 10 peut

recevoir une seconde paire de gorges 20A, 20B disposée à un

niveau sensiblement inférieur aux gorges llA, llB pour la

réception du jonc correspondant à une toile de doublure de deux

structures de base 4, juxtaposées.It should also be noted that it may be appropriate,

especially for reasons of thermal insulation, to double

a

Tel que cela ressort des figures 2 à 4, illustrant deux modes

de réalisation d'une couverture à double courbure 7 sous-tendue

au niveau d'une structure de base 4, les longerons 5, 6

constituent la partie basse de la toiture que définissent,

précisément, ces couvertures à double courbure 7. Dans ces

conditions, ils sont amenés à recueillir l'eau de ruissellement

dont il y a lieu d'assurer l'évacuation.As shown in Figures 2 to 4, illustrating two modes

of a double-

Aussi, selon un premier mode de réalisation, un profilé 10 ou

encore un tronçon de profilé 10A, 10B définissant ce longeron

5, 6 est prévu de type tubulaire, sa partie interne concevant

une gouttière apte à recueillir et à évacuer les eaux de

ruissellement.Also, according to a first embodiment, a

Un tel mode de réalisation pose, toutefois, le problème de

l'étanchéité entre deux profilés 10 ou tronçons de profilés

10A, 10B accouplés, successivement, l'un derrière l'autre en

vue de définir une structure de base de longueur accrue et

adapter à la taille de la construction 1 à réaliser. Si une

telle étanchéité est techniquement parlant réalisable, elle

conduit, souvent, à l'usage de joints d'étanchéité qui, lors du

démontage et du remontage successifs de la construction sont

amenés à se détériorer assez rapidement. A ce propos, il

convient tout particulièrement de prendre en considération le

fait qu'en raison de la taille de ce type de construction 1, il

est difficile, voire impossible, de conférer aux longerons 5,

6, une quelconque pente en vue de faciliter l'évacuation des

eaux de ruissellement.Such an embodiment poses, however, the problem of

sealing between two

Aussi, l'on a imaginé un second mode de réalisation permettant

à ces longerons 5, 6 de remplir plus efficacement ce rôle de

gouttière d'évacuation des eaux de ruissellement. Selon ce

second mode de réalisation ledit profilé 10 ou tronçon de

profilé 10A, 10B est équipé directement ou encore par

l'intermédiaire de pattes de liaison 21A, 21B, d'une troisième

paire de gorges 22A, 22B pour la réception des joncs d'une

toile étanchéifiée 23 apte à s'étendre en forme de gouttière

sous un tel profilé 10 donc un longeron 5, 6.Also, we imagined a second embodiment allowing

these

L'on observera que les pattes de liaison 21A, 21B, portant à

leur extrémité les gorges 22A, 22B sont configurées de sorte

que ladite toile en forme de gouttière 23 s'étende,

parfaitement, au-dessous de ces longerons 5, 6 de manière apte

à recueillir toutes les eaux de ruissellement en provenance des

couvertures 7.It will be observed that the connecting

De manière à éviter l'emploi de noeuds de liaison au niveau du

sommet S des fermes F1, F2 définies par des diagonales ou, plus

particulièrement, à hauteur des sommets 24 correspondant à un

module M, M1, M2, M3 de forme pyramidale, une structure de base

4 comporte, préférentiellement, au moins un troisième longeron

25, là encore défini par un profilé 10' comportant des moyens

15 pour la réception en vue de la fixation des diagonales 9,

9A, 9B, 9C (voir figure 8). Ce longeron 25 vient, ainsi, relier

entre eux, soit les sommets S des fermes F1, F2, soit les

sommets 24 de plusieurs M, M1, M2, M3 d'une même structure de

base 4 ou correspondant à plusieurs structures de base 4

juxtaposées. A noter, là encore, qu'un tel longeron 25 peut

être pourvu de moyens 15 pour la réception de traverses 8A,

aptes à relier deux à deux ces longerons 25. In order to avoid the use of link nodes at the

vertex S of farms F1, F2 defined by diagonals or, more

particularly, at the height of the

Si un tel troisième longeron 25 peut être dépourvu de gorges,

rien n'empêche qu'il en soit pourvu d'une ou de plusieurs, ceci

de manière similaire à un profilé 10 ou un tronçon de profilé

10A, 10B définissant les longerons 5, 6. De telles gorges

peuvent notamment recevoir les joncs d'une toile, plus

particulièrement une grille, que l'on vient étendre en quelque

sorte au-dessus des couvertures à double courbure 7 en vue,

soit de protéger celles-ci des saletés, par exemple des

feuilles, soit de créer un écran solaire.If such a

Comme visible dans la figure 8, le profilé 10' destiné à

définir un tel longeron 25 est configuré, dans sa partie

inférieure 36, en forme d'un rail 37 pour la réception d'un ou

plusieurs chariots 39 (représentés schématiquement) auxquels

sont fixés un ou des câbles 38 de mise sous tension de la ou

des couvertures à double courbure 7. Ainsi, en venant enfiler

les joncs 12 d'une couverture à double courbure 7 dans les

gorges 11A, 11B des longerons 5, 6 d'une structure de base 4

l'on engage, simultanément, sur le longeron 25, les chariots 39

auxquels sont accrochés le ou les câbles de mise sous tension.As shown in Figure 8, the profile 10 'intended for

define such a

Au vu de la description qui précède l'on comprend, évidemment,

que le montage et le démontage de ces dernières est

considérablement facilité d'autant plus que la mise en place

des couvertures à double courbure 7 s'obtient avec une très

grande aisance, tandis que leur mise sous tension s'effectue au

travers d'une traction exercée sensiblement dans une seule

direction. Bien entendu, l'on évite, en outre, les différentes

opérations de laçage particulièrement fastidieuses.In view of the above description, we understand, of course,

that the assembly and disassembly of the latter is

considerably facilitated all the more since the establishment

blankets with

Finalement, une telle construction 1, conforme à l'invention, s'avère être d'une très grande modularité moyennant l'usage de pièces standard qui, par ailleurs, permettent de s'affranchir des noeuds de liaison, correspondant souvent à des pièces particulièrement coûteuses. En effet, de tels noeuds de liaison font appel, fréquemment, pour leur conception, à de nombreuses opérations de soudure, d'emboutissage, d'usinage et autre, opérations qui sont particulièrement rationalisées dans le présent cas d'espèce.Finally, such a construction 1, in accordance with the invention, turns out to be very modular through the use of standard parts which, moreover, make it possible to overcome connecting nodes, often corresponding to parts particularly expensive. Indeed, such connecting nodes frequently use numerous design tools welding, stamping, machining and other operations, operations which are particularly streamlined in the present case.

L'on remarquera, en outre, que la présente invention a su répondre, astucieusement, au problème de l'étanchéité de ce type de construction à ossature tridimensionnelle et à couverture souple, ce qui correspond, là encore, à un avantage non négligeable.It will also be noted that the present invention has known cleverly answer the problem of the watertightness of this type of construction with three-dimensional frame and soft cover, which again represents an advantage not negligible.

Claims (14)

- Construction with a flexible cover at least the portion of which forming the roof (2) is defined by a three-dimensional metal or composite framework (3) comprised of a basic structure (4) or a juxtaposition of several of these latter, each of which includes at least two parallel longitudinal beams (5, 6) connected by means of cross-beams (8) and from which extend diagonal beams (9, 9A, 9B, 9C) defining, as the case may be, at least two girders (F1, F2) made integral by their top (S) and forming a module (M1), or even one or a series of pyramidally-shaped modules (M, Ml, M2, M3), in the inner space delimited by each of these basic structures (4) being subtended at least one flexible cover (7) of the type with a double curvature, characterised in that:both parallel longitudinal beams (5, 6) of a basic structure (4) are each defined by a profile bar (10) including at least a through-groove (11A, 11B) for receiving a retaining strip (12) provided for at two longitudinal edges (13, 14) of the flexible cover or covers (7) with a double curvature aimed at being subtended at the level of said basic structure (4);and that such a profile bar (10) is provided with means (15) for receiving the ends (16, 16A) of the diagonal beams (9, 9A, 9B, 9C) and/or of the cross-beams (8), with a view to their fixing.

- Construction according to claim 1, characterised in that a profile bar (10) aimed at defining a longitudinal beam (5, 6) is made symmetrical with respect to a vertical plane of symmetry (17) and includes two through-grooves (11A, 11B) for receiving a retaining strip (12) provided for at the longitudinal edge (13, 14), respectively, of the covers with a double curvature (7) corresponding to two juxtaposed basic structures (4).

- Construction according to claim 2, characterised in that a profile bar (10) aimed at forming a longitudinal beam (5, 6) includes a second pair of grooves (20A, 20B) arranged at a level substantially lower than the grooves (11A, 11B) for receiving the retaining strip corresponding to a lining canvas of juxtaposed basic structures (4).

- Construction according to any of the preceding claims, characterised in that the means (15) for receiving the ends (16; 16A) of the diagonal beams (9, 9A, 9B, 9C) and/or the cross-beams (8) are in the shape of lugs (30, 30A) inserted, viz. equidistantly, on said profile bar (10).

- Construction according to claim 4, characterised in that the lugs extend from a profile bar (10) according to an angle of inclination (18) adapted to the orientation to be imparted to the diagonal beam or beams (9, 9A, 9B, 9C) and/or to the cross-beams (8).

- Construction according to any of claims 4 or 5, characterised in that the lugs (30, 30A) are inserted, viz. by welding and alongside generating lines, on a joining part (31) with an outer cross-section (32) adjusted to the inner cross-section (33) of the profile bar (10) of a tubular type and defined by one or several profile bar lengths (10A, 10B) at the ends (34A, 34B) of which are inserted such joining parts (31).

- Construction according to claim 6, characterised in that the ends (34A, 34B) of the profile bar length or lengths (10A, 10B) are axially notched for the passing through of the lugs (30, 30A) and for ensuring the continuity at the level of the joining of two profile bar lengths (10A, 10B).

- Construction according to any of claims 1 to 3, characterised in that the means (15) for receiving the ends (16; 16A) of the diagonal beams (9, 9A, 9B, 9C) and/or of the cross-beams (8) are in the shape of one or several wings (19; 19A) and/or of wing lengths radially extending at the periphery of the profile bar (10).

- Construction according to claim 2 and any of claims 4 through 8, characterised in that the means (15) for receiving the ends (16; 16A), as the case may be, of the diagonal beams (9, 9A, 9B, 9C) or of the cross-beams (8) adopt a symmetrical configuration with respect to the vertical plane of symmetry (17) around the profile bar (10).

- Construction according to any of the preceding claims, characterised in that a profile bar (10) defining a longitudinal beam (5, 6) is foreseen of the tubular type, its inner portion being capable of forming a gutter capable of collecting and evacuating running water coming from the covers with a double curvature (7).

- Construction according to any of claims 1 through 9, characterised in that a profile bar (10) aimed at forming a longitudinal beam (5, 6) is provided, directly or through connecting lugs (21A, 21B), with a pair of grooves (22A, 22B) for receiving the retaining strips of a water-proof canvas (23) capable of extending in the shape of a gutter under such a profile bar (10).

- Construction according to any of the preceding claims, characterised in that a basic structure (4) includes at least a third longitudinal beam (25) defined by a profile bar (10') and including means (15) for receiving, with a view to the fixing, diagonal beams (9, 9A, 9B, 9C) and/or cross-beams (8A), such a longitudinal beam (25) connecting to each other the tops (S; 24) either of several girders (F1, F2) defined by the diagonal beams (9, 9A, 9B, 9C) or of several modules (M', M, M1, M2, M3) corresponding to one and the same basic structure (4) or to several juxtaposed basic structures (4).

- Construction according to claim 12, characterised in that the profile bar (10') defining the longitudinal beam (25) includes one or several grooves for receiving retaining strips corresponding to a canvas, viz. a netting, capable of being stretched over the flexible covers with a double curvature (7).

- Construction according to claims 12 or 13, characterised in that the profile bar (10') defining a longitudinal beam (25) is, in its lower portion (36), configured in the shape of a rail (37) for receiving one or several slides to which are capable of being fixed one or several cables (38) for tensioning the cover or covers with a double curvature (7).

Priority Applications (11)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| ES97440095T ES2134059T3 (en) | 1997-10-13 | 1997-10-13 | CONSTRUCTION OF FLEXIBLE COVERAGE WHICH ROOF AT LEAST IS CONSTITUTED BY A METALLIC OR COMPOSITE FRAME. |

| AT97440095T ATE179772T1 (en) | 1997-10-13 | 1997-10-13 | CONSTRUCTION WITH A TENT SKIN WHERE THE ROOF CONSISTS OF A THREE-DIMENSIONAL FRAME MADE OF METAL OR COMPOSITE MATERIAL |

| EP97440095A EP0908570B1 (en) | 1997-10-13 | 1997-10-13 | Construction with a membrane whereby the roof is made of a three dimensional metallic or composite frame |

| SI9730006T SI0908570T1 (en) | 1997-10-13 | 1997-10-13 | Construction with a membrane whereby the roof is made of a three dimensional metallic or composite frame |

| DK97440095T DK0908570T3 (en) | 1997-10-13 | 1997-10-13 | Structure with a flexible covering, in which at least the roof structure comprises a three-dimensional frame of meta |

| DE69700213T DE69700213T2 (en) | 1997-10-13 | 1997-10-13 | Construction with a tent skin where the roof consists of a three-dimensional frame made of metal or composite material |

| CA002249957A CA2249957C (en) | 1997-10-13 | 1998-10-09 | Flexible-roof construction of which at least the roof consists of a three-dimensional metal or composite framework |

| AU89282/98A AU737616B2 (en) | 1997-10-13 | 1998-10-13 | Construction with a flexible cover at least the roof of which is formed of a three-dimensional metal or composite framework |

| JP29037398A JP4098418B2 (en) | 1997-10-13 | 1998-10-13 | A building with a flexible cover at least on the roof, formed from a three-dimensional metal or composite framework |

| US09/170,025 US6134848A (en) | 1997-10-13 | 1998-10-13 | Tent roof construction with a flexible cover at least the roof of which is formed of a three-dimensional metal or composite framework |

| GR990402007T GR3030923T3 (en) | 1997-10-13 | 1999-08-04 | Construction with a membrane whereby the roof is made of a three dimensional metallic or composite frame |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP97440095A EP0908570B1 (en) | 1997-10-13 | 1997-10-13 | Construction with a membrane whereby the roof is made of a three dimensional metallic or composite frame |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0908570A1 EP0908570A1 (en) | 1999-04-14 |

| EP0908570B1 true EP0908570B1 (en) | 1999-05-06 |

Family

ID=8229997

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP97440095A Expired - Lifetime EP0908570B1 (en) | 1997-10-13 | 1997-10-13 | Construction with a membrane whereby the roof is made of a three dimensional metallic or composite frame |

Country Status (11)

| Country | Link |

|---|---|

| US (1) | US6134848A (en) |

| EP (1) | EP0908570B1 (en) |

| JP (1) | JP4098418B2 (en) |

| AT (1) | ATE179772T1 (en) |

| AU (1) | AU737616B2 (en) |

| CA (1) | CA2249957C (en) |

| DE (1) | DE69700213T2 (en) |

| DK (1) | DK0908570T3 (en) |

| ES (1) | ES2134059T3 (en) |

| GR (1) | GR3030923T3 (en) |

| SI (1) | SI0908570T1 (en) |

Families Citing this family (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6345638B1 (en) * | 1999-02-15 | 2002-02-12 | Tentnology Ltd. | Multiple peak cable tent |

| RU2200807C2 (en) * | 2000-07-11 | 2003-03-20 | Увакин Валентин Федорович | Corrugated envelope |

| FR2826030B1 (en) | 2001-06-13 | 2003-09-12 | Walter | CROSS-JOINT DEVICE FOR FLEXIBLE MATERIAL COVERING ELEMENTS |

| US20060137267A1 (en) * | 2002-07-19 | 2006-06-29 | Stackenwalt Richard D | Canopy-like decorative structure |

| DE10143113A1 (en) * | 2001-08-27 | 2003-03-20 | Guenter W Schneider | Tree-pierced roofing comprises domed segments forming adjacently connected square with segment corner holes for trees and center opening with fixer ring for rope hanging system of bearer and tension ropes. |

| US7464511B2 (en) * | 2002-12-12 | 2008-12-16 | Paul James Kosch | Slat wall assembly |

| EP1642493B1 (en) * | 2003-06-13 | 2014-06-11 | Kawada Construction Co., Ltd. | Greening apparatus |

| NL1025210C2 (en) * | 2004-01-09 | 2005-07-12 | Klimrek I E B V | Cap construction for a greenhouse. |

| FR2957961B1 (en) * | 2010-03-26 | 2015-03-27 | Catherine Dalo | LIGHT MODULE OF HOUSING AND MODULAR BUILDING |

| FR2957959B1 (en) | 2010-03-26 | 2015-03-27 | Catherine Dalo | FALSE CEILING SUSPENDED FOR LIGHT MODULE OF HOUSING |

| US8733380B1 (en) * | 2010-12-09 | 2014-05-27 | Thomas W. Roberts | Garaged vehicle cover |

| DK3084102T3 (en) | 2013-12-20 | 2019-10-14 | Sitecover Aps | ONSITE MOBILE FACILITY |

| EP2886742A1 (en) * | 2013-12-20 | 2015-06-24 | SiteCover ApS | On-site mobile facility |

| WO2016118953A1 (en) * | 2015-01-23 | 2016-07-28 | Richard Kramer | Improved fabricated building |

| EP3112546B1 (en) * | 2015-07-02 | 2018-11-07 | Saint-Gobain Placo SAS | Ceiling and ceiling suspension system |

| GB2603724B (en) * | 2019-10-01 | 2023-09-06 | Seikaly Abeer | A multi-layered structural and material system assembly |

| CN113737943B (en) * | 2021-09-17 | 2025-04-29 | 上海通正铝结构建设科技有限公司 | Suspended aluminum alloy grid structure system and its construction method |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2914074A (en) * | 1957-03-01 | 1959-11-24 | Fuller Richard Buckminster | Geodesic tent |

| DE1784534A1 (en) * | 1968-08-16 | 1971-08-12 | Roehm Gmbh | Roof skin, especially for hanging roofs |

| US3731450A (en) * | 1969-08-14 | 1973-05-08 | Chateau S Du | Metal structure and sections |

| SE360134B (en) * | 1972-01-20 | 1973-09-17 | Barracudaverken Ab | |

| US3863659A (en) * | 1974-03-19 | 1975-02-04 | Robert E Gillis | Shelter structure |

| US3909994A (en) * | 1974-04-03 | 1975-10-07 | Temcor | Dome construction |

| DE2422990A1 (en) * | 1974-05-13 | 1975-11-27 | Stromeyer & Co Gmbh L | Cantilever-bracket-suspended membrane roofing - firstly fixed and secondly stretched between brackets, forming cross-sectional angle-piece |

| DE3271948D1 (en) * | 1982-10-14 | 1986-08-14 | Canada Inc 116736 | Canopy system for a building structure |

| US4683698A (en) * | 1986-07-11 | 1987-08-04 | Butler Manufacturing Company | Load transfer clip for roof panel support trusses |

| IT1197845B (en) * | 1986-08-05 | 1988-12-06 | Riri Italia Spa | PAVILION REMOVABLE PARTICULARLY FOR THE TEMPORARY RECOVERY OF PEOPLE |

| US4878322A (en) * | 1987-08-10 | 1989-11-07 | Ikege, Inc. | Insulating plastic film structures and method |

| DE19526197A1 (en) * | 1995-07-18 | 1997-01-23 | Waco Wackerbauer & Co | Roof arrangement with tarpaulins and a plurality of the tarpaulins between the lattice girders and lattice girders for such a roof arrangement |

| CN1931423A (en) * | 2005-09-13 | 2007-03-21 | 鸿富锦精密工业(深圳)有限公司 | Nanometer particle synthesizing apparatus and process |

-

1997

- 1997-10-13 ES ES97440095T patent/ES2134059T3/en not_active Expired - Lifetime

- 1997-10-13 DE DE69700213T patent/DE69700213T2/en not_active Expired - Lifetime

- 1997-10-13 AT AT97440095T patent/ATE179772T1/en not_active IP Right Cessation

- 1997-10-13 SI SI9730006T patent/SI0908570T1/en unknown

- 1997-10-13 EP EP97440095A patent/EP0908570B1/en not_active Expired - Lifetime

- 1997-10-13 DK DK97440095T patent/DK0908570T3/en active

-

1998

- 1998-10-09 CA CA002249957A patent/CA2249957C/en not_active Expired - Lifetime

- 1998-10-13 AU AU89282/98A patent/AU737616B2/en not_active Ceased

- 1998-10-13 US US09/170,025 patent/US6134848A/en not_active Expired - Lifetime

- 1998-10-13 JP JP29037398A patent/JP4098418B2/en not_active Expired - Fee Related

-

1999

- 1999-08-04 GR GR990402007T patent/GR3030923T3/en unknown

Also Published As

| Publication number | Publication date |

|---|---|

| ATE179772T1 (en) | 1999-05-15 |

| US6134848A (en) | 2000-10-24 |

| EP0908570A1 (en) | 1999-04-14 |

| DK0908570T3 (en) | 1999-11-15 |

| JPH11190060A (en) | 1999-07-13 |

| AU8928298A (en) | 1999-09-16 |

| CA2249957A1 (en) | 1999-04-13 |

| AU737616B2 (en) | 2001-08-23 |

| SI0908570T1 (en) | 1999-10-31 |

| GR3030923T3 (en) | 1999-11-30 |

| ES2134059T3 (en) | 1999-09-16 |

| DE69700213D1 (en) | 1999-06-24 |

| JP4098418B2 (en) | 2008-06-11 |

| DE69700213T2 (en) | 2000-01-05 |

| CA2249957C (en) | 2003-05-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0908570B1 (en) | Construction with a membrane whereby the roof is made of a three dimensional metallic or composite frame | |

| EP2486199B1 (en) | Collapsible lattice beam, truss and construction including such a beam | |

| FR2948394A1 (en) | Interposable type beam for light shelter in swimming pool, has slides associated with gutter for collecting rain water from mobile part of structure of light shelter guiding in displacement by slides forming guide rail | |

| FR2620999A1 (en) | METHOD FOR ASSEMBLING THE PANELS OF A VEHICLE BODY AND PROFILE DESIGNED FOR THE IMPLEMENTATION OF THIS PROCESS | |

| EP1130193A1 (en) | Fast build construction | |

| WO2019034818A1 (en) | Device for producing a reinforced swimming pool | |

| FR2738857A1 (en) | DEVICE FOR SUPPORTING A DOOR ELEMENT AWAY FROM THE VERTICAL FACADE OF A CURTAIN WALL OF A BUILDING OR SIMILAR CONSTRUCTION | |

| EP2103756A2 (en) | Solar protection structure | |

| EP0172770A1 (en) | Covering device for spaces or surfaces, for example of swimming pools | |

| EP3301240A1 (en) | Pergola in dismountable kit | |

| FR2599118A1 (en) | New section for the purpose of manufacturing shelter frameworks, especially for covering pools, greenhouses etc., and shelters produced by means of this section | |

| CA1285369C (en) | Free standing element for the construction of a building roof, including a metal framework as part of a one piece insulating roofing structure, metal framework and insulating roofing structure thus made up, and resulting roof | |

| EP2894278A1 (en) | Device for manufacturing a swimming pool | |

| CA2389201A1 (en) | Modular shelter against sun and rain, and installation method | |

| FR2614054A1 (en) | Method for constructing walls of buildings | |

| FR2719618A1 (en) | Dome-shaped shelter for use over swimming pools which can be opened or closed | |

| EP1479854A1 (en) | Post with semicircular grooves to support welded wired panels and a hand rail and fence with such posts | |

| FR2657909A1 (en) | SINGLE AND DOUBLE BEAMS AND POSTS, CONSISTING OF THE MEETING OF RIGHT-Z SECTION PROFILES, IN PARTICULAR FOR THE PRODUCTION OF A PORTIC OR A POTENCY FOR A BUILDING CONSTRUCTION. | |

| EP0323940A1 (en) | Wind screen | |

| FR2608198A1 (en) | Prefabricated tiers | |

| WO2006108932A1 (en) | Prefabricated building and a framing therefor | |

| EP0249274A1 (en) | Light-weight construction having a generally rounded cover | |

| EP3043003A1 (en) | Stringer for producing a slab frame for a false wall comprising solid areas defining reinforcement areas | |

| CH694702A5 (en) | Modular construction with at least four vertical posts and braces. | |

| FR3133869A1 (en) | Canopy-type installation for an exterior building door |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| 17P | Request for examination filed |

Effective date: 19980425 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL PAYMENT 981102;LT PAYMENT 981102;LV PAYMENT 981102;RO PAYMENT 981102;SI PAYMENT 981102 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL PAYMENT 19981102;LT PAYMENT 19981102;LV PAYMENT 19981102;RO PAYMENT 19981102;SI PAYMENT 19981102 |

|

| REF | Corresponds to: |

Ref document number: 179772 Country of ref document: AT Date of ref document: 19990515 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: FRENCH |

|

| REF | Corresponds to: |

Ref document number: 69700213 Country of ref document: DE Date of ref document: 19990624 |

|

| ITF | It: translation for a ep patent filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19990726 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2134059 Country of ref document: ES Kind code of ref document: T3 |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: SC4A Free format text: AVAILABILITY OF NATIONAL TRANSLATION Effective date: 19990730 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| AKX | Designation fees paid |

Free format text: AT BE CH DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AXX | Extension fees paid |

Free format text: AL PAYMENT 19981102;LT PAYMENT 19981102;LV PAYMENT 19981102;RO PAYMENT 19981102;SI PAYMENT 19981102 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20021011 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FI Payment date: 20021014 Year of fee payment: 6 Ref country code: DK Payment date: 20021014 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: MC Payment date: 20021016 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 20021029 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20031013 Ref country code: FI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20031013 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20031013 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20031031 Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20031031 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: TP |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PUE Owner name: WALTER S.A.S. Free format text: WALTER#ZONE INDUSTRIELLE NORD - CD 58#67170 BRUMATH (FR) -TRANSFER TO- WALTER S.A.S.#CD 58 - RUE DE L'INDUSTRIE#67170 BRUMATH (FR) |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 732E |

|

| LTLA | Lt: lapse of european patent or patent extension |

Effective date: 20031013 |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: PC4A Free format text: WALTER S.A.S. FR Effective date: 20040514 |

|

| NLS | Nl: assignments of ep-patents |

Owner name: WALTER S.A.S. |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: PC2A |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PFA Owner name: LOSBERGER FRANCE SAS Free format text: WALTER S.A.S.#CD 58 - RUE DE L'INDUSTRIE#67170 BRUMATH (FR) -TRANSFER TO- LOSBERGER FRANCE SAS#ZONE INDUSTRIELLE - CD 58#67170 BRUMATH (FR) Ref country code: CH Ref legal event code: NV Representative=s name: ISLER & PEDRAZZINI AG |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: TD Effective date: 20110413 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: PC2A Owner name: LOSBERGER FRANCE SAS Effective date: 20110617 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 69700213 Country of ref document: DE Representative=s name: PATENTANWAELTE UND RECHTSANWALT WEISS, ARAT & , DE Ref country code: DE Ref legal event code: R082 Ref document number: 69700213 Country of ref document: DE Representative=s name: PATENTANWAELTE UND RECHTSANWALT DR. WEISS, ARA, DE |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 19 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20161018 Year of fee payment: 20 Ref country code: DE Payment date: 20161020 Year of fee payment: 20 Ref country code: CH Payment date: 20161020 Year of fee payment: 20 Ref country code: IE Payment date: 20161020 Year of fee payment: 20 Ref country code: NL Payment date: 20161019 Year of fee payment: 20 Ref country code: GB Payment date: 20161020 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PT Payment date: 20161007 Year of fee payment: 20 Ref country code: GR Payment date: 20161019 Year of fee payment: 20 Ref country code: ES Payment date: 20161011 Year of fee payment: 20 Ref country code: SE Payment date: 20161019 Year of fee payment: 20 Ref country code: BE Payment date: 20161019 Year of fee payment: 20 Ref country code: IT Payment date: 20161024 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 69700213 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MK Effective date: 20171012 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 Expiry date: 20171012 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MK9A |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MK Effective date: 20171013 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20171013 Ref country code: PT Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20171020 Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20171012 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20180508 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20171014 |