EP0907574B1 - Systeme de fermeture recyclable - Google Patents

Systeme de fermeture recyclable Download PDFInfo

- Publication number

- EP0907574B1 EP0907574B1 EP97924781A EP97924781A EP0907574B1 EP 0907574 B1 EP0907574 B1 EP 0907574B1 EP 97924781 A EP97924781 A EP 97924781A EP 97924781 A EP97924781 A EP 97924781A EP 0907574 B1 EP0907574 B1 EP 0907574B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- closure

- sealing means

- frame

- closure system

- closure frame

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D41/00—Caps, e.g. crown caps or crown seals, i.e. members having parts arranged for engagement with the external periphery of a neck or wall defining a pouring opening or discharge aperture; Protective cap-like covers for closure members, e.g. decorative covers of metal foil or paper

- B65D41/02—Caps or cap-like covers without lines of weakness, tearing strips, tags, or like opening or removal devices

- B65D41/04—Threaded or like caps or cap-like covers secured by rotation

- B65D41/0435—Threaded or like caps or cap-like covers secured by rotation with separate sealing elements

- B65D41/045—Discs

Definitions

- the present invention relates to closure systems for a container for pourable material in particular for pourable material for human consumption such as beverages.

- the closure system relates to a beverage bottle having a screw cap closure system.

- the closure system comprises a closure frame providing the physical stability and protection of the closure system and a sealing means which is removably joined to the closure frame to provide appropriate sealing of the container.

- the present invention allows to recycle or reuse the closure frame and to recycle the sealing means.

- Twist off caps or screw cap closure systems for bottles are well-known in the art.

- these systems comprise a closure frame which has integrally joined to it a sealing means to provide a barrier between the environment and the content of the bottle.

- these bottles are provided under a reduced internal pressure such that the twist off cap is slightly deformed by being pulled into the bottle and upon releasing the seal provides an audible signal indicating an intact temper proof.

- the sealing means used in these twist off caps is usually provided by polyvinylchloride material.

- Polyvinylchloride (herinafter abreviated by PVC) does provide certain benefits to the sealing means e. g. the repeatable ability to undergo deformations to provide proper sealing.

- PVC Polyvinylchloride

- these advantages are balanced with certain disadvantages which are in particular environmental concerns with PVC.

- PVC polyvinylchloride

- This removal of the PVC and paint is usually achieved by burning but has become very uneconomical due to ecological concerns about PVC fumes and the resulting precautions for the process.

- PVC has a high affinity to absorb organic compounds. Therefore twist of cap closures having PVC sealing means cannot be reused for containers comprising materials for human consumption because the sealing means will become contaminated, i.e. loaded with the organic compounds present in the container content. Reuse or recycling of sealing means having such contamination is of course prohibited under many local regulatory laws.

- the present invention relates to a recylable closure system for a container for pourable material such as a bottle for liquids preferably a bottle for beverages in accordance with claim 1.

- the closure system is separable from the container, i.e the present invention does not relate to closure systems which are kept connected to the container while the container is open and some of the container content is removed from the container.

- the closure system according to the present invention comprises a closure frame and a sealing means where the sealing means is removably joined to the closure frame.

- the closure frame can be recycled or even be reused and at least 90% by weight of the frame is provided by a single closure frame material.

- the sealing means can at least be recycled due to being removably joined to the closure frame.

- removably joined refers to a connection between the sealing means and the closure frame which under usual use conditions will maintain their connection such that they appear to be one system.

- removal of the sealing means from the closure frame does not cause any undue burton or special effort if carried out by a mechanical device or by a person.

- no part of the closure frame will be scratched or damaged due to the automated removal of the sealing means. Most preferably this is achieved by frictional measures, constructive measures, or combination thereof.

- adhesives which leave no or an acceptable residue on the closure frame can also be employed in the context of the present invention.

- reusable means the possibility of using the same item for the same purpose again at least one time, but preferably several times.

- a reusable closure frame is therefore more limited than the term "a recyclable closure frame” since this term as used hereinafter refers to a closure frame which can be reused or which is made of materials such that it allows to use the material again in order to provide new articles of manufacture.

- This new article of manufacture is the same article of manufacture from which the recycled material is provided (this can alternatively be termed "complete recycling").

- the closure system according to the present invention is a screw cap system and can be separated from the container which it closes by unscrewing.

- the closure system is a "twist off' system which is removable by unscrewing the closure system with about one quarter or even less turn of the closure frame.

- the sealing means according to the present invention is essentially made of one single material preferably a polymeric material in particular polyethylene material which is known for its good recyclability.

- the closure frame can be provided by many materials, however, it is preferable that the closure frame be provided by a relatively stable and durable material such that it is substantially undeformable.

- Such materials can be for example ceramics, but sheet metal materials such as tin metal or other iron comprising metals are particular preferred especially when recycling of the closure frame material into new closure frames is desired.

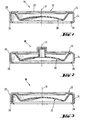

- Figure 1 is a cross-sectional view of the closure system according to the present invention.

- Figure 2 is a cross-sectional view of an alternative closure system according to the present invention having an alternative joining means.

- Figure 3 is a cross-sectional view of yet another alternative closure system according to the present invention .

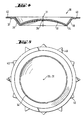

- Figure 4 is a cross sectional view of a sealing means similar to that shown in the closure system in figure 1.

- Figure 5 is a bottom plan of view of the sealing mean of figure 4.

- a closure system as defined in claim 1 for pourable materials in containers is provided.

- the pourable materials can be any kind of liquid or solids in a pourable form, i.e. typically granules or powders.

- the materials for which the closure systems of the present invention are designed are liquids for human consumption and in that respect particularly fruit juice or other organic compound comprising beverages such as milk, fruit juice or aroma comprising refreshment drinks, colas, or lemonades.

- fruit juice or other organic compound comprising beverages such as milk, fruit juice or aroma comprising refreshment drinks, colas, or lemonades.

- the container according to the present invention for which the closure systems can beneficially be used can in principal be any kind of container.

- bottles particularly bottles which are transparent such as PET-bottles, glas bottles or bottles of other transparent polymeric materials are preferred, with glas bottles being the most preferred containers.

- FIG 1 the closure system (10) is shown in a cross-sectional view comprising the closure frame (20) and the sealing means (30).

- the closure frame (20) comprises a flat portion (22) having a perimeter (23).

- the flat portion (22) need not to be absolutely flat but can be provided with minor depressions or raises parallel to the central axis (31).

- the flange has a proximal edge (25) which joins the flange to the flat portion (22) along the perimeter (23) and a distal edge (26) which is furthest away from the proximal edge (25) of the flange (24).

- the closure frame (20) can have and preferably has a folded rim (28). For screw cap systems or twist-off systems portions of this rim provide extending tongues which provide the screw threat for such a screw cap system.

- the closure frame (20) can also have different shapes as can be seen in figure 2 showing an alternative embodiment of the closure frame having a central portion raised in order to form a central circular notch into which a portion of the sealing means can be inserted to provide a removable joining between them.

- the closure frame (20) provides stability to the screw cap system and protects the sealing means (30). It therefore is preferably made out of a material which is dourable and shape stable. Particularly iron comprising metal sheet material such as tin is preferred.

- closure frame such that it can be recycled after the separation from the sealing means to provide a raw material source for new articles of manufacture.

- materials for the closure frame which allow to provide new closure frames by recycling and most preferred according to the present invention are those materials and designs which are capable of reuse of the closure frame at least one, but preferably several times.

- Such a closure frame could be made of metal coated with a durable coating of paint on both sides. It would then be possibile to provide indications on the screw cap of the number of reuses in order to sort out closure frames after a preset number of reuses for example after five times reusing the closure frame.

- closure frames can also be optionally present in embodiments according to the present invention.

- easy grip ripples on the flange, sorting and positioning aids are common in this respect.

- the sealing means (30) is shown in figures 1, 2 and 3 in a cross-sectional view through its rotational symetry axis or central axis (31).

- the sealing means (30) has the function to connect at its periphery with the rim of the aperture of the container which is to be sealed. Mechanically this is achieved by placing the closure frame over the container opening with the sealing means inbetween such that the sealing means is pressed onto the rim of the aperture in the container to be sealed.

- the sealing means comprises a flexible concave disk portion (32) having a substantially circular perimeter (34).

- the concave disk (32) in a relaxed state has a concave shape in which the centre (36) of the concave disk (32) bends away from the container.

- the sealing means (30) has a circular flange (38) depending from the perimeter (34) of the concave disk (32).

- the flange depending from the concave disk (32) has a conical portion (39) a fixation portion (37) for joining the sealing means (30) to the closure frame (20).

- the fixation portion (37) preferably ends in a number of tongues (40), preferably in a number of pointy tongues (40) as shown in figure 5.

- the term pointy in this context includes tongues having a slightly rounded or a cutoff tip without loosing the generally pointy appearance.

- the tongues (40) can be present in any number but are preferably provided symmetrical around the circular periphery of the fixation portion (37), i.e. there should be at least 2 tongues (40). Most preferred are the sealing means with 24 or more tongues (40).

- the sealing means (30) can be made of any material which provides the necessary flexibility and elasticity to create the desired seal of the aperture in the container to be closed. Most preferred and economically desirable are thermoplastic materials such as PVC, polyethylene, polypropylene but also cured polymeric materials such as synthetic rubber or similar materials can be used.

- the sealing means (30) can be provided by combinations of material which satisfy the different functions of the sealing means better than one single material would.

- sealing means having tongues (40) made of material which in conjunction with the closure frame has a high coefficient of friction but using a different material for the conical portion (39) and/or for the concave disk portion (32) are considered.

- the sealing means should also provide indication of weather the content of the container prior to initial opening has been exposed to the environment.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Closures For Containers (AREA)

- Separation By Low-Temperature Treatments (AREA)

- Threshing Machine Elements (AREA)

- Soil Working Implements (AREA)

- Lock And Its Accessories (AREA)

- Centrifugal Separators (AREA)

- Ropes Or Cables (AREA)

Claims (6)

- Système de fermeture recyclable (10) pour un conteneur, ledit système de fermeture (10) étant un système de bouchon fileté comprenant un châssis de fermeture (20), et des moyens d'étanchéité (30) reliés de manière amovible audit châssis de fermeture (20), ledit système de fermeture (10) étant caractérisé en ce qu'au moins 90 % en poids dudit châssis de fermeture (20) est fourni par un seul matériau de châssis de fermeture, lequel matériau de châssis de fermeture peut être recyclé pour fournir de nouveaux châssis de fermeture (20), et lesdits moyens d'étanchéité (30) sont constitués pratiquement d'un seul matériau de moyens d'étanchéité, lequel matériau de moyens d'étanchéité peut être recyclé pour fournir de nouveaux articles de fabrication ou peut être brûlé en tant que combustible (recyclage thermique).

- Système de fermeture recyclable (10) selon la revendication 1, dans lequel au moins 95 % en poids dudit châssis de fermeture (20) est fourni par un seul et unique matériau.

- Système de fermeture recyclable (10) selon l'une quelconque des revendications précédentes, dans lequel ledit châssis de fermeture (20) est constitué d'un seul matériau, de préférence un matériau contenant du fer, de la manière la plus préférée de l'étain, et d'un revêtement, de préférence de peinture, sur ledit matériau.

- Système de fermeture recyclable (10) selon l'une quelconque des revendications précédentes, dans lequel ledit châssis de fermeture (20) peut être recyclé par réutilisation après nettoyage.

- Système de fermeture recyclable (10) selon l'une quelconque des revendications précédentes, dans lequel lesdits moyens d'étanchéité (30) sont sensiblement constitués d'un matériau thermoplastique de polymère qui peut être recyclé pour fournir de nouveaux articles de fabrication.

- Système de fermeture recyclable (10) selon l'une quelconque des revendications précédentes, dans lequel lesdits moyens d'étanchéité (30) sont constitués de polyéthylène.

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP97924781A EP0907574B1 (fr) | 1996-05-20 | 1997-05-20 | Systeme de fermeture recyclable |

| GR20000401205T GR3033514T3 (en) | 1996-05-20 | 2000-05-26 | Recyclable closure system |

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP96107986 | 1996-05-20 | ||

| EP96107986 | 1996-05-20 | ||

| PCT/US1997/008530 WO1997044260A1 (fr) | 1996-05-20 | 1997-05-20 | Systeme de fermeture recyclable |

| EP97924781A EP0907574B1 (fr) | 1996-05-20 | 1997-05-20 | Systeme de fermeture recyclable |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0907574A1 EP0907574A1 (fr) | 1999-04-14 |

| EP0907574B1 true EP0907574B1 (fr) | 2000-05-03 |

Family

ID=8222797

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP97924781A Expired - Lifetime EP0907574B1 (fr) | 1996-05-20 | 1997-05-20 | Systeme de fermeture recyclable |

Country Status (8)

| Country | Link |

|---|---|

| EP (1) | EP0907574B1 (fr) |

| AT (1) | ATE192400T1 (fr) |

| AU (1) | AU3009797A (fr) |

| DE (1) | DE69701874T2 (fr) |

| ES (1) | ES2145603T3 (fr) |

| GR (1) | GR3033514T3 (fr) |

| PT (1) | PT907574E (fr) |

| WO (1) | WO1997044260A1 (fr) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105691860A (zh) * | 2014-08-19 | 2016-06-22 | 冯林 | 一种瓶盖 |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| SE402535B (sv) * | 1975-09-08 | 1978-07-10 | Skane Emballage Ab | Sett att framstella ett med gengingreppsflikar forsett runt lock av valsad plat |

| JPS5695856A (en) * | 1979-12-19 | 1981-08-03 | Crown Cork Japan | Vessel cover provided with liner* ashesive characteristic thereof to shell is improved |

| NL185834C (nl) * | 1987-04-13 | 1990-08-01 | Skillpack Bv | Afsluitinrichting voor een houder en membraan voor een dergelijke afsluitinrichting. |

-

1997

- 1997-05-20 PT PT97924781T patent/PT907574E/pt unknown

- 1997-05-20 EP EP97924781A patent/EP0907574B1/fr not_active Expired - Lifetime

- 1997-05-20 AT AT97924781T patent/ATE192400T1/de not_active IP Right Cessation

- 1997-05-20 ES ES97924781T patent/ES2145603T3/es not_active Expired - Lifetime

- 1997-05-20 WO PCT/US1997/008530 patent/WO1997044260A1/fr not_active Ceased

- 1997-05-20 DE DE69701874T patent/DE69701874T2/de not_active Expired - Fee Related

- 1997-05-20 AU AU30097/97A patent/AU3009797A/en not_active Abandoned

-

2000

- 2000-05-26 GR GR20000401205T patent/GR3033514T3/el not_active IP Right Cessation

Also Published As

| Publication number | Publication date |

|---|---|

| ES2145603T3 (es) | 2000-07-01 |

| EP0907574A1 (fr) | 1999-04-14 |

| AU3009797A (en) | 1997-12-09 |

| PT907574E (pt) | 2000-08-31 |

| WO1997044260A1 (fr) | 1997-11-27 |

| DE69701874T2 (de) | 2001-02-01 |

| ATE192400T1 (de) | 2000-05-15 |

| GR3033514T3 (en) | 2000-09-29 |

| DE69701874D1 (de) | 2000-06-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US4699290A (en) | Sanitary tamperproof double closure container end cap | |

| US5450973A (en) | Tamper-evident closure apparatus | |

| US5411157A (en) | Container and the manufacture thereof | |

| US4721219A (en) | Composite, vacuum indicating closure | |

| US4076152A (en) | Fitment-retaining closure | |

| CA2140273A1 (fr) | Fermeture inviolable | |

| US4678082A (en) | Vacuum indicating thermoplastic closure | |

| WO1983000674A1 (fr) | Couvercle de fermeture indiquant une manipulation abusive | |

| US5873484A (en) | Cover locking mechanism | |

| EP0681967B1 (fr) | Couvercle de contenant | |

| CA2022340A1 (fr) | Capuchon composite, vissant pour hermetiser un contenant en plastique | |

| US5494200A (en) | Closure and sifter assemblage having automatically releasable, interlocking bead retainer structures | |

| CA2144857A1 (fr) | Capsule | |

| EP0907575B1 (fr) | Systeme de fermeture reutilisable | |

| US4921117A (en) | Pop-art tumbler | |

| US6302287B1 (en) | Reusable closure system | |

| EP0907574B1 (fr) | Systeme de fermeture recyclable | |

| US6095357A (en) | Tamper proof for reusable closure system | |

| US3095109A (en) | Premium container | |

| AU639359B2 (en) | A rigid container under residual vacuum provided with a tamper-evident device | |

| GB2074974A (en) | Container Sealing Device | |

| US3446380A (en) | Sealing system for containers | |

| WO1996010522A3 (fr) | Fermeture de recipient | |

| JPH10287351A (ja) | 注出栓 | |

| JPH06345133A (ja) | 薬瓶用二重容器の分別回収構造 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19981123 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE DK ES FI FR GB GR IE IT LI LU NL PT SE |

|

| 17Q | First examination report despatched |

Effective date: 19990415 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK ES FI FR GB GR IE IT LI LU NL PT SE |

|

| REF | Corresponds to: |

Ref document number: 192400 Country of ref document: AT Date of ref document: 20000515 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: RITSCHER & SEIFERT Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REF | Corresponds to: |

Ref document number: 69701874 Country of ref document: DE Date of ref document: 20000608 |

|

| ET | Fr: translation filed | ||

| ITF | It: translation for a ep patent filed | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2145603 Country of ref document: ES Kind code of ref document: T3 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: SC4A Free format text: AVAILABILITY OF NATIONAL TRANSLATION Effective date: 20000529 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DK Payment date: 20020319 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PT Payment date: 20020325 Year of fee payment: 6 Ref country code: NL Payment date: 20020325 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20020403 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20020404 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IE Payment date: 20020424 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GR Payment date: 20020426 Year of fee payment: 6 Ref country code: FI Payment date: 20020426 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20020503 Year of fee payment: 6 Ref country code: FR Payment date: 20020503 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20020520 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 20020522 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20020531 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20020613 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20020618 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030520 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030520 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030520 Ref country code: FI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030520 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030520 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030521 Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030521 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030531 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030531 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030531 |

|

| BERE | Be: lapsed |

Owner name: THE *PROCTER & GAMBLE CY Effective date: 20030531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20031130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20031201 Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20031201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20031202 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20031203 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP |

|

| EUG | Se: european patent has lapsed | ||

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20030520 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040130 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20031201 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Ref country code: PT Ref legal event code: MM4A Free format text: LAPSE DUE TO NON-PAYMENT OF FEES Effective date: 20031130 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20030521 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050520 |