EP0906885B1 - Brake for textile threads - Google Patents

Brake for textile threads Download PDFInfo

- Publication number

- EP0906885B1 EP0906885B1 EP98116792A EP98116792A EP0906885B1 EP 0906885 B1 EP0906885 B1 EP 0906885B1 EP 98116792 A EP98116792 A EP 98116792A EP 98116792 A EP98116792 A EP 98116792A EP 0906885 B1 EP0906885 B1 EP 0906885B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- thread

- clip

- brake according

- thread brake

- bearing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04B—KNITTING

- D04B15/00—Details of, or auxiliary devices incorporated in, weft knitting machines, restricted to machines of this kind

- D04B15/38—Devices for supplying, feeding, or guiding threads to needles

- D04B15/48—Thread-feeding devices

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H59/00—Adjusting or controlling tension in filamentary material, e.g. for preventing snarling; Applications of tension indicators

- B65H59/10—Adjusting or controlling tension in filamentary material, e.g. for preventing snarling; Applications of tension indicators by devices acting on running material and not associated with supply or take-up devices

- B65H59/20—Co-operating surfaces mounted for relative movement

- B65H59/22—Co-operating surfaces mounted for relative movement and arranged to apply pressure to material

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04B—KNITTING

- D04B15/00—Details of, or auxiliary devices incorporated in, weft knitting machines, restricted to machines of this kind

- D04B15/38—Devices for supplying, feeding, or guiding threads to needles

- D04B15/44—Tensioning devices for individual threads

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2701/00—Handled material; Storage means

- B65H2701/30—Handled filamentary material

- B65H2701/31—Textiles threads or artificial strands of filaments

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H59/00—Adjusting or controlling tension in filamentary material, e.g. for preventing snarling; Applications of tension indicators

- B65H59/10—Adjusting or controlling tension in filamentary material, e.g. for preventing snarling; Applications of tension indicators by devices acting on running material and not associated with supply or take-up devices

- B65H59/20—Co-operating surfaces mounted for relative movement

- B65H59/22—Co-operating surfaces mounted for relative movement and arranged to apply pressure to material

- B65H59/225—Tension discs

Definitions

- the invention relates to a thread brake with two resiliently pressed against each other by load means disc or plate-shaped brake elements, between which can be carried out at least one thread to be braked and of which at least one braking element is a central one Has opening.

- disc or plate thread brakes are in various forms in textile technology in use. Particularly advantageous, modern constructions are described, for example, in DE 41 04 663 C1 and in DE 43 01 507 C2, both to the applicant decline.

- the latter of these two publications is the generic term of claim 1. They have pin-shaped storage means throughout on through the central opening at least one Braking element are arranged and on which at least this one braking element is rotatably mounted.

- the diameter a bearing pin forming the pin-shaped bearing means is much smaller than the diameter of the middle Opening the brake elements so that they swing freely are hung from the bearing pin.

- pin-shaped storage means that are in the form of a Bolts are formed, the diameter of which is only slight is smaller than the opening diameter of the brake elements (compare, for example, FIG. 5 of DE 41 04 663 C1), the brake elements are provided with plastic bearing bushes are their storage conditions on the bolt or a ceramic bearing bush pushed onto this improve.

- the brake elements are elastic against each other oppressive burden means are either after conventional type compression springs or there are too permanent magnetic rings are used for this purpose cup-shaped, made of ferromagnetic material existing brake elements are inserted.

- Thread guide means usually provided at least partially directly on the mounting means which the bearing pin or bolt for carry the braking elements.

- the arrangement is mostly hit such that the bearing pin or pin on the Bracket is overhung.

- the braking elements such as mentioned, oscillating on a small diameter bearing pin are suspended, the braking elements at a distance assigned lateral stop elements, which otherwise limit and prevent free movement in the axial direction, that the braking elements are released from their bearing means.

- the holding means with which the thread brake, for example. is attached to the housing of a thread delivery device, are consistently designed to be relatively expensive applies in particular if the thread brake with a Vibration generator cooperates that the Brake elements set in oscillatory movements, the are mainly directed transversely to the bearing axis (DE 41 04 663 C1) or in a direction perpendicular to it act (DE 44 09 450 C2). Because of the braking elements or their bearing means vibrated the lint deposits that otherwise occur, Soiling, etc., originating from difficult to process Yarns can be largely prevented. The The measure has therefore proven itself in practice proven.

- Thread brakes of the aforementioned type are fundamental Bulk item, which means manufacturing cost vital to the economic Success comes. They also have to be easy to maintain and in particular, to be cleaned, what usually through Blow off by means of a compressed air jet. there should be avoided that the braking elements from their Free storage materials or that have blown off Dirt particles, lint and the like in corners or blind spots of mounting elements, bearing parts, etc. accumulate the thread brake and thus in the long run Endanger operational safety.

- the object of the invention is therefore a thread brake to create oneself with simple, inexpensive Construction due to few dirt deposits distinguished and easy cleaning, as well as necessary disassembly and assembly of your parts allowed, while at the same time a perfectly even Braking of the thread guaranteed over long operating periods is.

- the thread brake according to the invention the features of the characterizing part of claim 1 on.

- the holder means on the new thread brake for which the disc or plate-shaped brake elements bearing, pin-shaped bearing means essentially one U-shaped bracket with two spaced apart on both sides of the brake elements trending thighs on a preferred Embodiment is a one-piece wire bent part.

- the pin-shaped bearing means are on this bracket a bearing part which preferably accommodates them on both sides attached that connected to the stirrup legs or on this is trained.

- This bearing part can be in one preferred embodiment in the form of an essentially U-shaped frame formed and made of plastic his.

- the bracket can be two parallel to each other Have bracket sections with which he in a receiving part is stored at a suitable location on a Machine frame or the like but also on the housing a thread delivery device can be attached.

- the Temple sections can be moved longitudinally in the receiving part be stored, which is particularly important is when at least one of the bracket sections for coupling with a back and forth oscillating motion of the bracket issuing vibration generating device is set up. In this way, as already mentioned, effectively prevents the deposition of fluff, etc. become.

- this can be the pin-shaped bearing means receiving bearing part designed to be removable from the bracket so that the bearing means together with the bearing part to be able to exchange.

- the bearing part can the bracket can also be arranged adjustable, for example To facilitate cleaning of the thread brake or around the To change thread travel.

- the bearing part as a U-shaped Frame formed, so the frame on the bracket between an operating position and a folded down position Position pivotable and in the operating position on the Bracket designed to be lockable.

- the correct position on the bracket in the operating position found frame only needs to be folded down be accessible to the pin-shaped storage means to make them blown off on all sides or otherwise can be cleaned.

- the pin-shaped storage means on the frame i.e. more generally on the bearing part, releasably attached, so they can with the frame folded down simply removed and replaced.

- the thread brake can also be designed so that the whole frame with the bearing means and the brake elements can be replaced without the bracket or others Parts of the thread brake are removed or disassembled would. Folding down and, if necessary, removing the Framework, as well as the exchange of storage resources done without tools.

- the bearing pins a much cheaper support the pin-shaped storage means guaranteed. This allows it with straight bearing pins of relatively small diameter to find the end of it without also having to Vibration exposure by a vibration generator accepted an increased risk of breakage should be. Since these bearing pins usually consist of one hard material, for example ceramic, hard material and the like exist and are relatively expensive achieve a significant price advantage in this way. Other developments of the new thread brake are the subject of subclaims.

- the new thread brake is particularly suitable for use suitable for a thread delivery device that with a Housing, a thread delivery drum rotatably mounted on the housing and one connected to the thread delivery drum Drive device, as well as arranged on the housing Thread guide means is formed.

- the thread guide serve the one of a thread supply, for example Spool coming to be supplied to a thread consumer Feed the thread to the thread delivery drum on the input side or from this on the output side the thread to the thread consumer to lead away.

- a thread delivery device is on the housing on the thread inlet side a thread brake according to the invention arranged.

- the bracket two mutually parallel bracket sections with which it is mounted in a receiving part can the parallel bracket sections directly in the Housing or in a part connected to this, for example. the receiving part be stored.

- the thread delivery device with a vibration generating device housed in the housing equipped it follows with the thread brake on the housing immediately a coupling of the bracket with this vibration generating device.

- at least one of the Strap sections for coupling with the one back and forth Vibration generating device which gives rise to the oscillating movement set up.

- one of the bracket sections with it elastic to a predetermined End position for pressing return spring means be loaded so that it is sufficient that the bracket section on a cam or pusher of the vibration generating device supports without being form-fitting to have to be coupled.

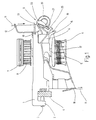

- the thread delivery device shown in Figure 1 is known in its basic structure (compare For example, Figure 1 of DE 43 01 507 C2). It has a housing 1 on that by means of a molded holder 2 and a Clamping screw 3 on a support ring indicated at 4, For example, a circular knitting machine can be attached.

- the housing is vertical in the position of use, through shaft 5 rotatably mounted.

- the wave is on its lower end with one below the housing 1 arranged and designed in the form of a rod cage Thread delivery drum 6 rotatably connected. She is wearing its upper end one rotatably via a coupling 7 couplable pulley 8, the drive device forms and over which the yarn delivery drum 6 from one Endless toothed belt or perforated belt, not shown or the like can be set in rotation.

- Thread brake 9 On the opposite end of the holder 2 Housing 1 is a thread brake 9, the two Identical, essentially disc-shaped brake plates 10, between which a thread to be braked 11 passes through.

- the thread path extends from one thread bobbin not shown by a on the Housing 1 fastens thread eyelet 12, a knot catcher 13 and the thread brake 9 to a base or Receiving part 14 provided via an integrally formed arm 15 Thread inlet eye 16, from the thread 11 on the input side runs onto the thread delivery drum 6.

- Thread delivery drum 6 On the Thread delivery drum 6, the thread 11 forms a storage roll 17, from which it is attached to the housing 1 via a Thread outlet eyelet 18 runs to the thread consumer.

- the thread brake 9 has a one-piece bent wire part trained, substantially U-shaped bracket 19 on which the holding means for the brake discs or plate 10 and their bearing means in the form of a cylindrical Bearing pin 20 forms.

- the bracket 19 has two legs 21 running parallel to each other one end through a crosspiece 22 with each other are connected, each including a right angle to the bracket legs 21.

- On at their other end are the two bracket legs 21 each via a bend 23 of approx. 30 ° and intermediate appropriately designed intermediate sections 24 with two straight bracket sections 25 parallel to one another connected.

- the parallel bracket sections 25 based on the in the Position of use horizontal crossbar 22, in different Height and close the web 22 and the two bracket legs 21 containing imaginary level an angle of approx. 30 °.

- the bracket sections 25 can also optionally with the intermediate sections 24, are at the same level, just a few possible arrangements to mention.

- bracket 19 With its two parallel bracket sections 25 is the bracket 19 in the housing-shaped base or receiving part 14 mounted longitudinally displaceable, as is the case in particular can be seen from Figure 2.

- 14 points two from the front to the back continuous, cylindrical bearing bores 26, in which the bracket sections 25 with in the use position horizontal alignment are guided longitudinally.

- the straight bracket sections 25 are both in height ( Figure 2) and laterally offset from each other ( Figure 5) arranged.

- the overhead bracket section 25 supports its over the back of the base or receptacle 14 protruding end an existing plastic, in Essentially in the form of a cylindrical cap 27 formed coupling part for a in the housing 1st arranged vibration generator, not shown, only one of them in FIG indicated by an arrow 28, back and forth Movement executing drive stamp 29 illustrated is.

- the drive stamp 29 is from one to the shaft 5 the thread delivery device according to FIG. 1, actuated cam, not shown, with which it engages stands.

- the base or receiving part 14 is one compression spring 30 surrounding the upper straight bracket section 26 arranged, which is against an axial spring abutment 31st is supported and endeavors, the coupling piece 27 in plant to hold on the drive stamp 29.

- the compression spring 30 therefore forms return spring means.

- the lower straight bracket section 25 projects, for example the rear of the base or receiving part 14 at 31 something, as indicated by dashed lines in Fig. 2. It is located on the housing 1 base or Receiving part 14 on part of the metallic housing 1 and thus causes electrical grounding of the metallic Bügels 19. Alternatively or in addition to Improvement of the earthing conditions of the bracket 19 also an earth spring (not shown) against the housing 1 press on, and / or the base 14 and / or the cap 27 consists of an electrically conductive material.

- a fastening screw indicated at 32 from the front of the base or receptacle 14 can be actuated.

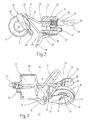

- FIG. 4 On the normal shown in Figure 2 Operating position with the vertical at an angle of approx. 30 ° inclusive, lying on a common level parallel leg 21 of the bracket 19 is a bearing part in Shape of a plastic, essentially U-shaped frame 33 in which the bearing pin 20 for the brake discs 10 at both ends is held, as can be seen in particular from FIG. 4.

- the frame 33 has two mutually parallel, spaced apart frame legs 34, which by an integrally formed frame web 35 at one end are connected.

- the two parallel frame legs 34 are facing the viewer in FIG Inside each with a gutter-shaped Well 36 formed in the vicinity of the free One end of the frame leg protrudes 37.

- the Lugs 37 are on the groove-shaped recesses 36th delimiting on the side of the U-shaped opening of the frame 33 Wall 38 formed. They serve the Frame 33 in the operating position with the legs 21 of the Bracket 19 releasably latch, as is still the case will be explained.

- the frame web 35 is on the outside with a molded bearing shell or claw 39 provided For example, in Fig. 2, 4 is visible and the on the bracket 19 mounted frame 33 elastically engages the crossbar 22, so that the frame 33 is pivotable on the web 22 is stored.

- the bearing shell or claw 39 is there resiliently designed such that the frame 33 overcoming the snap connection formed by her can simply be removed from the bracket 19.

- the frame web 35 On its inside facing the bearing pin 20 is the frame web 35 as a support or support cushion 40 trained for the brake discs or plates 10.

- the frame leg 35 can, for example, inside be provided with a wear-resistant coating.

- one made of wear-resistant Material existing pen or a corresponding one Molding is used in the frame 33, the forms the support or support cushion 40.

- the conditions of use also include cases where a particularly wear-resistant training this in the Rule the entire space between the two frame legs 34 engaging support or support cushion 40 dispensed with becomes.

- the hardened steel, possibly with a wear-resistant coating, made of ceramic or one suitable hard material, thin, cylindrical Bearing pin 20 is on its one, lower in Figure 4 End inserted into a bearing bore 41 which in the Inner wall 38 is formed.

- the bearing pin 20 is in one on the associated side Frame leg 34 provided to the gutter-like Recess 36 open bearing half shell 43 added, which is molded onto the frame leg 34.

- the depth of the Bearing half shell 43 is chosen such that the used bearing pin 20 with its lateral surface somewhat protrudes over the bottom of the groove-shaped recess 36.

- the Bearing pin 20 can also be made of non-conductive material, for example Ceramics exist, which should be mentioned for the sake of order.

- the two brake actuators 10 are on the bearing pin 20 freely suspended. You are in for this purpose in particular from FIGS. 5, 6 each with a central, cylindrical, continuous Opening 44 formed, the diameter of which many times over is larger than the diameter of the bearing pin 20th The diameter ratio is typically about 6: 1 and more.

- the bowl-shaped cambered cross section Brake plate 10 can along the edge of the Opening 44 each formed with a cylindrical lip Hub 45 may be designed to withstand the stress the brake plate 10 and the bearing pin 20 to reduce and cutting the brake plate into the bearing pin 20 to prevent.

- the edges of the Opening 44 in each of the brake actuators 10 also by one used hub ring made of plastic or a suitable bearing pairing with the bearing pin 20 resulting Material can be edged, as is shown in FIG. 10 will be explained.

- the size of the loading force determines the braking effect on the thread running through.

- the two frame legs 34 in the assembled state in considerable lateral distance from the two brake actuators 10.

- the two brake plates 10 resting against each other are therefore considerable in the axial direction Length of the bearing pin 2C freely movable.

- the frame 33 is on the used bearing pin 20 hanging brake actuators 10 with its bearing shell or claw 39 on the horizontal Web 22 of bracket 19 clipped on. Besides, he's around Axis of the web 22 folded up so far that the two Leg 21 in the groove-shaped recesses 36 of the Frame legs 34 are included and the frame 33 with the legs 21 is locked over the locking lugs 37.

- the Thread brake thus has that shown in Figures 1, 2 State in which the between the brake actuators 10 continuous thread 11 in the by the attraction the permanent magnet rings 46 given the amount evenly braked becomes.

- each other Brake actuator 10 of which around the bearing pin 20 or one not shown in the drawing by the Openings 44 of the brake discs 10 extending and in the Frame legs 34 held deflected thread deflecting pin Thread 11 driven frictionally, so that it is a perform a common rotational movement around the bearing pin 20.

- This orbital movement is a wobbling movement in the axial direction superimposed, since, as mentioned, the two brake actuators 10 have no firm lateral guidance. On this ensures that the thread 11 is not in can cut the braking surfaces of the brake plate 10, but that the braking surfaces over their entire circumference progressively engage the thread.

- bracket 19 is over the drive stamp 29 of the vibration generating device vibrating movement issued, under whose Impact of the support points on the opening edge of the Brake actuator 10 on the bearing pin 20 continuously change, so that the brake plate 10 an irregular Carry out movement that the deposit of fluff and the like prevented.

- the bearing pin 20 at one end of the bearing half-shell 43 pushed up out so that he are pulled axially out of the bearing bore 41 can. Since the frame 33 is made of plastic and in unfolded state not by the bracket legs 21 is reinforced, it is elastically deformable so that the described disassembly of the bearing pin 20 easily possible is. A new bearing pin 20 can be reversed be inserted again.

- the arrangement could also be made in such a way that the bearing pin 20 from the frame 33 directly axially is extractable by following it in at least one outside opening bearing bore 41 is supported.

- the bearing pin 20 would then be in its operating position in frame 33 by a locking mechanism, such as in the form of a Locking mechanism or through partial training as a threaded bolt secured.

- a locking mechanism such as in the form of a Locking mechanism or through partial training as a threaded bolt secured.

- Other embodiments that the serve the same purpose are conceivable.

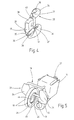

- the two are Bow leg 21 of the U-shaped wire bracket 19a each an eyelet 47 is bent, the cylindrical bearing bore 41 limited.

- the two eyelets 47 are in alignment their bearing bores 41, in which the bearing pin 20th is plugged in.

- the bearing pin 20 is on both sides clamped elastically by the ring eyelets 47. Erforderlichefalls it can be located in the area of at least one bearing bore 41 also a recess, for example in the form of a circumferential one Rastnut, have to additionally or alternatively a form-fitting connection with the respective To produce stirrup legs 21.

- the bearing bore 41 each completely looping eyelets 47

- the bracket legs 21st also be curved so that they have ⁇ -shaped eyelets 47a, as illustrated in Figure 6b, right representation is.

- the bow legs 21 will be loop-shaped.

- the ring eyelets 47 and the eyelets 47a can also be clipped onto the respective stirrup leg 21 and there hook-shaped held frictionally Bracket claw 48 occur, as shown in Figure 6b, left Figure is shown.

- the preferably made of plastic manufactured claws 48 are the end of the Bearing pin 20 attached. They reach around with their jaws 49 the respective stirrup leg 21 on which it is frictionally engaged, are kept immovable.

- one straight bracket section 25 by the compression spring 30 ( Figure 2) in elastic contact with the actuating plunger 29 (or an actuating cam) of the vibration generating device held.

- the coupling part designed as a plastic cap 27 serves the coupling part designed as a plastic cap 27.

- the compression spring 30 it would also be conceivable, the resetting of the bracket 19 or the pressure whose bracket section 25 on the drive tappet 29 to achieve that that the bracket 19 forming Bent wire part with a corresponding elastic prestress is trained.

- positively driven embodiments with two support points of this bent wire part the drive stamp 29 or on the drive cam are possible. Such a variant is indicated in FIG. 6.

- the Temple sections 25 are approximately at right angles to one another at 470 assigning turned. Between the spaced bent bracket parts 470 could, for example Drive stamp or tappet 26 coupled.

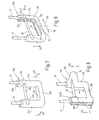

- the one-piece, substantially U-shaped frame 33a with a to the back opening, all-round, gutter-shaped Recess 36a formed over the Frame leg 34a and the frame web 35a extends.

- the Frame 33a is through the appropriate dimensioning of the recess 36a on the bracket legs 21 and the bracket web 22 jammed. Overall, he can decrease to the front are, as indicated by the two arrows 480 is.

- the bearing pin 20 is in the frame 33a, similar to in Figure 4.

- a bearing approach and the bearing half shell are designated 42a and 43a.

- FIG. 8 is how by the way, in all embodiments - the frame 33b Made of plastic. His two frame legs 34b and the frame web 35b are each one in the plane of the two stirrup legs 21 lying and towards the outside open, groove-shaped recess 36b formed in the the bracket legs 21 are. In this way it is possible the whole frame 33b in the direction of arrows 490 to move the stirrup legs 21, for example by the operating conditions to change the thread brake.

- the Frame 33b is on the temple legs 21 in its respective Position held by friction.

- the bearing pin 20 is in this case one end in its own, the assigned U-shaped arms 21 encompass and friction with this coupled leg section 340b supported, possibly with the leg 21 also can be locked.

- the bearing pin 20 At its other end is the bearing pin 20 in a groove-like recess open on one side 50 of the associated frame leg 34 recorded and in it locks or jams.

- the bearing pin 20th folded out around the left leg 21 as by an arrow 51 is indicated. He can then from his Leg section 340b are pulled out.

- An actuating tab 52 formed on the frame 33b allows the displacement of the frame 33b in the sense of Arrows 490.

- the frame 33c formed in two parts.

- the frame legs 34c and the Frame web 35c are with a continuous, channel-shaped Provide recess 36c, which corresponds to that of the two stirrup legs 21 limited space towards each other open assigning.

- the whole frame 33c can therefore in Direction of arrows 53 downward on legs 21 moved or subtracted from them entirely.

- Optional can also the two frame legs 34c, the along a parting line 55 in the frame web 35c from one another are separated, laterally subtracted from the legs 21 become. This is indicated by two arrows 56.

- the Support of the bearing pin 20 on the frame legs 34c is solved similarly as in Figure 4. Corresponding parts are provided with corresponding reference symbols.

- the support or support pad 40 for the brake discs 10 not illustrated in detail. It can be similar be designed as in the frame 33 of Figure 4. It in any case serves the brake actuator 10 in operation limit their outer circumference radially in their path of movement.

- the brake actuators 10 hanging on the bearing pin 20 are in their operating position shown in Figure 2 on the bottom of the support or support cushion 40 from which they wobble in the course of their irregular Rotational movement more or less often during operation take off.

- embodiment a) are on the brake discs or plate 10 consisting of a suitable plastic clipped annular caps 60, with their all-round protruding edge areas 61, 62 the brake plate 10 on the outer circumference and along the circumference of the Overlap opening 44 so that they on the brake actuators 10 are locked.

- the caps 60 cover the cavity the cambered brake actuator 10 in the illustrated Way, while they the permanent magnet rings 46th fix in the correct position so that additional gluing, etc. is generally no longer required.

- the edge 62 bordering the opening 44 forms at the same time a substantially tubular hub, optionally is arched in cross section. To this This results in particularly favorable storage conditions the brake actuator 10 on the bearing pin 20th

- annular disk-shaped inside Mold lip 63 as shown in the illustration b) shows.

- the ring-shaped lips 63 result a small axial width of the bearing surface and thus a increased surface pressure. This can be an advantage if it must be expected that the bearing pin 20 sizing or other resinous or sticky deposits build up.

- FIG Figure c illustrates the washer-shaped Lip also in the form of an annular disc 63a be placed on the permanent magnet ring 46a, the is provided with an annular shoulder 64 for this purpose.

- the permanent magnet rings 46a are with the brake actuators 10 glued, the washers 63a each between its edge and the ring shoulder 64 of the corresponding Permanent magnet rings 46a are inserted.

- Cover 65 can also have an annular disk-shaped lip 65a of a small thickness, which is the hub of the brake actuators 10 forms, so that there are similar storage conditions as in Figures b) and c).

- the invention is not is limited to embodiments in which the Brake actuator 10 oscillating on a thin bearing pin 20 are hung. It can also be used for thread brakes, where the brake plate on a bearing pin or -pin are only rotatably supported with play.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Braking Arrangements (AREA)

- Tension Adjustment In Filamentary Materials (AREA)

- Spinning Or Twisting Of Yarns (AREA)

- Portable Nailing Machines And Staplers (AREA)

- Clamps And Clips (AREA)

- Knitting Machines (AREA)

Description

Die Erfindung betrifft eine Fadenbremse mit zwei durch Belastungsmittel nachgiebig gegeneinander gedrückten scheiben- oder tellerförmigen Bremselementen, zwischen denen zumindest ein zu bremsender Faden durchführbar ist und von denen wenigstens ein Bremselement eine mittige Öffnung aufweist.The invention relates to a thread brake with two resiliently pressed against each other by load means disc or plate-shaped brake elements, between which can be carried out at least one thread to be braked and of which at least one braking element is a central one Has opening.

Derartige sogenannte Scheiben- oder Tellerfadenbremsen

sind in der Textiltechnik in vielfältigen Ausführungsformen

im Einsatz. Besonders vorteilhafte, moderne Konstruktionen

sind bspw. beschrieben in der DE 41 04 663 C1

und in der DE 43 01 507 C2, die beide auf die Anmelderin

zurückgehen.

Letztere dieser beiden Druckschriften liegt dem Oberbegriff

des Anspruches 1 zugrunde.

Sie weisen durchgehend stiftförmige Lagermittel

auf, die durch die mittige Öffnung wenigstens eines

Bremselementes verlaufend angeordnet sind und auf denen

wenigstens dieses eine Bremselement drehbar gelagert ist.

Dabei gibt es Ausführungsformen bei denen der Durchmesser

eines die stiftförmigen Lagermittel bildenden Lagerstiftes

wesentlich kleiner ist als der Durchmesser der mittigen

Öffnung der Bremselemente, so dass diese frei pendelnd auf

dem Lagerstift aufgehängt sind. Andere Ausführungsformen

verwenden stiftförmige Lagermittel, die in Gestalt eines

Bolzens ausgebildet sind, dessen Durchmesser nur geringfügig

kleiner ist als der Öffnungsdurchmesser der Bremselemente

(vergleiche bspw. Figur 5 der DE 41 04 663 C1),

wobei die Bremselemente mit Kunststofflagerbuchsen versehen

sind, um ihre Lagerverhältnisse auf dem Bolzen bzw.

einer auf diesen aufgeschobenen keramischen Lagerbuchse zu

verbessern. Die die Bremselemente elastisch gegeneinander

drückenden Belastungsmittel sind hierbei entweder nach

herkömmlicher Art Druckfedern oder es werden aber zu

diesem Zwecke dauermagnetische Ringe verwendet, die in die

schalenförmig gestalteten, aus ferromagnetischem Material

bestehenden Bremselemente eingelegt sind.Such so-called disc or plate thread brakes

are in various forms in textile technology

in use. Particularly advantageous, modern constructions

are described, for example, in

Um den zu bremsenden Faden ordnungsgemäß zwischen den Bremselementen zu führen, sind, abhängig von der jeweiligen Konstruktion, Fadenumlenkstifte, Fadenösen und dergleichen Fadenleitmittel vorgesehen, die in der Regel zumindest teilweise unmittelbar an den Halterungsmitteln vorgesehen sind, welche den Lagerstift oder -bolzen für die Bremselemente tragen. Die Anordnung ist dabei meist derart getroffen, dass der Lagerstift oder -bolzen an den Halterungsmitteln fliegend gelagert ist. Außerdem sind bei den Ausführungsformen, bei denen die Bremselemente, wie erwähnt, auf einem Lagerstift kleinen Durchmessers pendelnd aufgehängt sind, den Bremselementen im Abstand seitliche Anschlagelemente zugeordnet, die deren sonst freie Bewegung in Achsialrichtung begrenzen und verhüten, dass die Bremselemente von ihren Lagermitteln freikommen.In order to properly brake the thread between the Braking elements depend on the respective one Construction, thread deflecting pins, thread eyelets and the like Thread guide means usually provided at least partially directly on the mounting means are provided which the bearing pin or bolt for carry the braking elements. The arrangement is mostly hit such that the bearing pin or pin on the Bracket is overhung. In addition, at the embodiments in which the braking elements, such as mentioned, oscillating on a small diameter bearing pin are suspended, the braking elements at a distance assigned lateral stop elements, which otherwise limit and prevent free movement in the axial direction, that the braking elements are released from their bearing means.

Die Halterungsmittel mit denen die Fadenbremse bspw.

am Gehäuse einer Fadenliefervorrichtung befestigt ist,

sind durchweg verhältnismäßig aufwendig gestaltet, was

insbesondere dann gilt, wenn die Fadenbremse mit einer

Schwingungserzeugungseinrichtung zusammenwirkt, die die

Bremselemente in Schwingungsbewegungen versetzt, die

hauptsächlich quer zu der Lagerachse gerichtet sind (DE 41

04 663 C1) oder in einer rechtwinklig dazu weisenden Richtung

wirken (DE 44 09 450 C2). Dadurch dass die Bremselemente

oder deren Lagermittel in Schwingungen versetzt

werden, können die sonst auftretenden Flusenablagerungen,

Verschmutzungen etc., herrührend von schwierig zu verarbeitenden

Garnen, weitgehend verhindert werden. Die

Maßnahme hat sich deshalb in der Praxis ausgezeichnet

bewährt.The holding means with which the thread brake, for example.

is attached to the housing of a thread delivery device,

are consistently designed to be relatively expensive

applies in particular if the thread brake with a

Vibration generator cooperates that the

Brake elements set in oscillatory movements, the

are mainly directed transversely to the bearing axis (

Fadenbremsen der vorgenannten Art sind grundsätzlich Massenartikel, was bedeutet, dass den Herstellungskosten eine entscheidende Bedeutung für den wirtschaftlichen Erfolg zukommt. Außerdem müssen sie leicht zu warten und insbesondere zu reinigen sein, was in der Regel durch Abblasen mittels eines Druckluftstrahles geschieht. Dabei soll vermieden werden, dass die Bremselemente von ihren Lagermitteln freikommen oder dass sich abgeblasene Schmutzpartikel, Flusen und dergleichen in Ecken oder toten Winkeln von Halterungselementen, Lagerteilen, etc. der Fadenbremse ansammeln und damit auf die Dauer deren Betriebssicherheit gefährden.Thread brakes of the aforementioned type are fundamental Bulk item, which means manufacturing cost vital to the economic Success comes. They also have to be easy to maintain and in particular, to be cleaned, what usually through Blow off by means of a compressed air jet. there should be avoided that the braking elements from their Free storage materials or that have blown off Dirt particles, lint and the like in corners or blind spots of mounting elements, bearing parts, etc. accumulate the thread brake and thus in the long run Endanger operational safety.

Außerdem wird an eine Fadenbremse häufig die Forderung nach leichter Montage und Demontage, zusätzlich zu der Möglichkeit einer bequemen und wirksamen Reinigung gestellt.In addition, the requirement is often a thread brake after easy assembly and disassembly, in addition to the possibility of convenient and effective cleaning posed.

Aufgabe der Erfindung ist es deshalb, eine Fadenbremse zu schaffen, die sich bei einfachem, kostengünstigem Aufbau durch wenig Schmutzablagerungsmöglichkeiten auszeichnet und die eine leichte Reinigung, sowie erforderlichenfalls eine Demontage und Montage ihrer Teile erlaubt, wobei gleichzeitig eine einwandfrei gleichmäßige Bremsung des Fadens über lange Betriebszeiträume gewährleistet ist.The object of the invention is therefore a thread brake to create oneself with simple, inexpensive Construction due to few dirt deposits distinguished and easy cleaning, as well as necessary disassembly and assembly of your parts allowed, while at the same time a perfectly even Braking of the thread guaranteed over long operating periods is.

Zur Lösung dieser Aufgabe weist die Fadenbremse

gemäß der Erfindung die Merkmale des kennzeichnenden Teils des Patentanspruchs 1

auf.To solve this task, the thread brake

according to the invention the features of the characterizing part of

Bei der neuen Fadenbremse weisen die Halterungsmittel für die die scheiben- oder tellerförmigen Bremselemente tragenden, stiftförmigen Lagermittel einen im Wesentlichen U-förmigen Bügel mit zwei im Abstand beidseitig der Bremselemente verlaufenden Schenkeln auf, der in eine bevorzugten Ausführungsform ein einstückiges Drahtbiegeteil ist. An diesem Bügel sind die stiftförmigen Lagermittel mittels eines sie vorzugsweise beidseitig aufnehmenden Lagerteiles befestigt, das mit den Bügelschenkeln verbunden oder an diesen ausgebildet ist. Dieses Lagerteil kann in einer bevorzugten Ausführungsform in Form eines im Wesentlichen U-förmigen Rahmens ausgebildet und aus Kunststoff hergestellt sein. Der Bügel kann zwei zueinander parallele Bügelabschnitte aufweisen, mit denen er in einem Aufnahmeteil gelagert ist, dass an geeigneter Stelle an einen Maschinenrahmen oder dergleichen aber auch an dem Gehäuse einer Fadenliefervorrichtung befestigt werden kann. Die Bügelabschnitte können in dem Aufnahmeteil längsverschieblich gelagert sein, was insbesondere dann von Bedeutung ist, wenn wenigstens einer der Bügelabschnitte zur Kupplung mit einer dem Bügel eine hin- und hergehende Schwingungsbewegung erteilenden Schwingungserzeugungseinrichtung eingerichtet ist. Auf diese Weise kann, wie bereits erwähnt, die Ablagerung von Flusen, etc. wirksam verhindert werden.The holder means on the new thread brake for which the disc or plate-shaped brake elements bearing, pin-shaped bearing means essentially one U-shaped bracket with two spaced apart on both sides of the brake elements trending thighs on a preferred Embodiment is a one-piece wire bent part. The pin-shaped bearing means are on this bracket a bearing part which preferably accommodates them on both sides attached that connected to the stirrup legs or on this is trained. This bearing part can be in one preferred embodiment in the form of an essentially U-shaped frame formed and made of plastic his. The bracket can be two parallel to each other Have bracket sections with which he in a receiving part is stored at a suitable location on a Machine frame or the like but also on the housing a thread delivery device can be attached. The Temple sections can be moved longitudinally in the receiving part be stored, which is particularly important is when at least one of the bracket sections for coupling with a back and forth oscillating motion of the bracket issuing vibration generating device is set up. In this way, as already mentioned, effectively prevents the deposition of fluff, etc. become.

In der Regel kann das die stiftförmigen Lagermitteln aufnehmende Lagerteil von dem Bügel abnehmbar ausgebildet sein, um damit die Lagermittel gemeinsam mit dem Lagerteil austauschen zu können. Abhängig von dem Einsatzzweck und der Konstruktion der Fadenbremse, kann das Lagerteil auf dem Bügel auch verstellbar angeordnet sein, bspw. um die Reinigung der Fadenbremse zu erleichtern oder um den Fadenlaufweg zu verändern. Ist das Lagerteil als U-förmiger Rahmen ausgebildet, so kann der Rahmen an dem Bügel zwischen einer Betriebsstellung und einer abgeklappten Stellung verschwenkbar und in der Betriebsstellung an dem Bügel feststellbar ausgebildet sein.As a rule, this can be the pin-shaped bearing means receiving bearing part designed to be removable from the bracket so that the bearing means together with the bearing part to be able to exchange. Depending on the application and the construction of the thread brake, the bearing part can the bracket can also be arranged adjustable, for example To facilitate cleaning of the thread brake or around the To change thread travel. Is the bearing part as a U-shaped Frame formed, so the frame on the bracket between an operating position and a folded down position Position pivotable and in the operating position on the Bracket designed to be lockable.

Dies ergibt eine besonders einfache Wartungsmöglichkeit der Fadenbremse:This results in a particularly simple maintenance option the thread brake:

Der in der Betriebsstellung lagerichtig an dem Bügel festgestellte Rahmen braucht lediglich abgeklappt zu werden, um damit die stiftförmigen Lagermittel zugänglich zu machen, so dass diese allseitig abgeblasen oder sonstwie gereinigt werden können. Sind die stiftförmigen Lagermittel an dem Rahmen, d.h. allgemeiner an dem Lagerteil, lösbar befestigt, so können sie bei abgeklapptem Rahmen einfach herausgenommen und ausgetauscht werden. Alternativ kann die Fadenbremse auch so gestaltet sein, dass der ganze Rahmen mit den Lagermitteln und den Bremselementen ausgetauscht werden kann, ohne dass der Bügel oder andere Teile der Fadenbremse abgenommen bzw. zerlegt werden müssten. Das Abklappen und gegebenenfalls Abnehmen des Rahmens, wie auch der Austausch der Lagermittel, können ohne Zuhilfenahme von Werkzeugen geschehen. Da die stiftförmigen Lagermittel in dem Lagerteil beidseitig gelagert sind, ist im Vergleich zu der bekannten fliegenden Lagerung der Lagerstifte eine wesentlich günstigere Abstützung der stiftförmigen Lagermittel gewährleistet. Dies erlaubt es mit geraden Lagerstiften verhältnismäßig kleinen Durchmessers das Auslangen zu finden, ohne dass auch bei Schwingungsbeaufschlagung durch eine Schwingungserzeugungseinrichtung eine erhöhte Bruchgefahr in Kauf genommen werden müsste. Da diese Lagerstifte in der Regel aus einem harten Material, bspw. Keramik, Hartstoff und dergleichen bestehen und verhältnismäßig teuer sind, lässt sich auf diese Weise ein beträchtlicher Preisvorteil erzielen. Andere Weiterbildungen der neuen Fadenbremse sind Gegenstand von Unteransprüchen.The correct position on the bracket in the operating position found frame only needs to be folded down be accessible to the pin-shaped storage means to make them blown off on all sides or otherwise can be cleaned. Are the pin-shaped storage means on the frame, i.e. more generally on the bearing part, releasably attached, so they can with the frame folded down simply removed and replaced. alternative the thread brake can also be designed so that the whole frame with the bearing means and the brake elements can be replaced without the bracket or others Parts of the thread brake are removed or disassembled would. Folding down and, if necessary, removing the Framework, as well as the exchange of storage resources done without tools. Because the pen-shaped Storage means stored on both sides in the storage part are compared to the known flying storage the bearing pins a much cheaper support the pin-shaped storage means guaranteed. This allows it with straight bearing pins of relatively small diameter to find the end of it without also having to Vibration exposure by a vibration generator accepted an increased risk of breakage should be. Since these bearing pins usually consist of one hard material, for example ceramic, hard material and the like exist and are relatively expensive achieve a significant price advantage in this way. Other developments of the new thread brake are the subject of subclaims.

Die neue Fadenbremse ist insbesondere zur Verwendung bei einer Fadenliefervorrichtung geeignet, die mit einem Gehäuse, einer an dem Gehäuse drehbar gelagerten Fadenliefertrommel und einer mit der Fadenliefertrommel verbundenen Antriebseinrichtung, sowie mit an dem Gehäuse angeordneten Fadenleitmitteln ausgebildet ist. Die Fadenleitmittel dienen dazu, den von einem Fadenvorrat, bspw. einer Spule kommenden, einem Fadenverbraucher zuzuliefernden Faden der Fadenliefertrommel eingangsseitig zuzuleiten bzw. von dieser ausgangsseitig den Faden zu dem Fadenverbraucher hin wegzuleiten. Bei einer solchen Fadenliefervorrichtung ist an dem Gehäuse auf der Fadeneinlaufseite eine erfindungsgemäße Fadenbremse angeordnet. Bei der erläuterten Ausführungsform der neuen Fadenbremse mit einem als Drahtbiegeteil ausgebildeten U-förmigen Bügel, deren Bügel zwei zueinander parallele Bügelabschnitte aufweist, mit denen er in einem Aufnahmeteil gelagert ist, können die parallelen Bügelabschnitte unmittelbar in dem Gehäuse oder in einem mit diesem verbundenen Teil, bspw. dem Aufnahmeteil gelagert sein. Ist die Fadenliefervorrichtung mit einer in dem Gehäuse untergebrachten Schwingungserzeugungseinrichtung ausgerüstet, so ergibt sich mit dem Aufsetzen der Fadenbremse auf das Gehäuse unmittelbar eine Kopplung des Bügels mit dieser Schwingungserzeugungseinrichtung. Zu diesem Zwecke ist wenigstens einer der Bügelabschnitte zur Kupplung mit der ihm eine hin- und hergehende Schwingungsbewegung erteilenden Schwingungserzeugungseinrichtung eingerichtet. Gleichzeitig kann einer der Bügelabschnitte mit ihn elastisch auf eine vorbestimmte Endstellung zu drückenden Rückstellfedermitteln belastet sein, so dass es genügt, dass der Bügelabschnitt sich auf einem Nocken oder Stössel der Schwingungserzeugungseinrichtung abstützt, ohne mit diesem formschlüssig gekuppelt werden zu müssen. The new thread brake is particularly suitable for use suitable for a thread delivery device that with a Housing, a thread delivery drum rotatably mounted on the housing and one connected to the thread delivery drum Drive device, as well as arranged on the housing Thread guide means is formed. The thread guide serve the one of a thread supply, for example Spool coming to be supplied to a thread consumer Feed the thread to the thread delivery drum on the input side or from this on the output side the thread to the thread consumer to lead away. With such a thread delivery device is on the housing on the thread inlet side a thread brake according to the invention arranged. In the explained embodiment of the new thread brake with a U-shaped bracket designed as a bent wire part, the bracket two mutually parallel bracket sections with which it is mounted in a receiving part, can the parallel bracket sections directly in the Housing or in a part connected to this, for example. the receiving part be stored. Is the thread delivery device with a vibration generating device housed in the housing equipped, it follows with the thread brake on the housing immediately a coupling of the bracket with this vibration generating device. For this purpose, at least one of the Strap sections for coupling with the one back and forth Vibration generating device which gives rise to the oscillating movement set up. At the same time one of the bracket sections with it elastic to a predetermined End position for pressing return spring means be loaded so that it is sufficient that the bracket section on a cam or pusher of the vibration generating device supports without being form-fitting to have to be coupled.

Weiterbildungen der neuen Fadenbremsem sind Gegenstand von Unteransprüchen.Further developments of the new thread brakes are the subject of subclaims.

In der Zeichnung sind Ausführungsbeispiele des Gegenstandes der Erfindung dargestellt. Es zeigen:

Figur 1- eine Fadenliefervorrichtung mit einer Fadenbremse gemäß der Erfindung, in einer Seitenansicht,

Figur 2- die Fadenbremse der Fadenliefervorrichtung nach

Figur 1, in einer Seitenansicht und in einem anderen Maßstab, Figur 3- die Fadenbremse nach

Figur 2, in einer perspektivischen Darstellung bei abgeklapptem Rahmen und in einem anderen Maßstab, Figur 4- den Rahmen mit dem Lagerstift der Fadenbremse

nach

Figur 2, in einer vergrößerten perspektivischen Darstellung, Figur 5- die Fadenbremse nach

Figur 2, in perspektivischer Darstellung, Figur 6- den als Drahtbiegeteil ausgebildeten Bügel, die Bremselemente und deren zugeordneten Dauermagnetringe, in perspektivischer, auseinandergezogener Darstellung, in einem anderen Maßstab,

- Figur 6a

- den Bügel nach Fig. 6 in einer abgewandelten Ausführungsform, in einer entsprechenden perspektivischen Darstellung,

- Figur 6b

- den Bügel nach Fig. 6a, im Ausschnitt unter Veranschaulichung zweier unterschiedlicher Ausbildungen der Lagerteile, jeweils in perspektivischer Darstellung.

Figuren 7bis 9- drei verschiedene Ausführungsbeispiele des Rahmens der Fadenbremse nach Figur 2, jeweils in schematischer, perspektivischer Darstellung, unter Veranschaulichung eines Teils des als Drahtbiegeteil ausgebildeten Bügels, sowie in einem anderen Maßstab und

Figur 10- die Bremsteller und die Lagermittel der Fadenbremse nach Fig. 1 in fünf verschiedenen Ausführungsformen, jeweils in axialen Schnitt, in einer schematischen Seitenansicht und in einem anderen Maßstab.

- Figure 1

- a thread delivery device with a thread brake according to the invention, in a side view,

- Figure 2

- 1, in a side view and on a different scale,

- Figure 3

- 2, in a perspective view with the frame folded down and on a different scale,

- Figure 4

- the frame with the bearing pin of the thread brake according to Figure 2, in an enlarged perspective view,

- Figure 5

- the thread brake according to Figure 2, in a perspective view,

- Figure 6

- the bracket formed as a bent wire part, the brake elements and their associated permanent magnet rings, in a perspective, exploded view, on a different scale,

- Figure 6a

- 6 in a modified embodiment, in a corresponding perspective view,

- Figure 6b

- the bracket of Fig. 6a, in a section illustrating two different designs of the bearing parts, each in a perspective view.

- Figures 7 to 9

- three different embodiments of the frame of the thread brake according to Figure 2, each in a schematic, perspective view, illustrating a part of the bracket designed as a bent wire part, and on a different scale and

- Figure 10

- 1 in five different embodiments, each in an axial section, in a schematic side view and on a different scale.

Die in Figur 1 dargestellte Fadenliefervorrichtung

ist in ihrem grundsätzlichen Aufbau bekannt (vergleiche

bspw. Figur 1 der DE- 43 01 507 C2). Sie weist ein Gehäuse

1 auf, dass mittels eines angeformten Halters 2 und einer

Klemmschraube 3 an einem bei 4 angedeuteten Tragring,

bspw. einer Rundstrickmaschine befestigt werden kann. In

dem Gehäuse ist eine in der Gebrauchslage vertikale,

durchgehende Welle 5 drehbar gelagert. Die Welle ist an

ihrem unteren Ende mit einer unterhalb des Gehäuses 1

angeordneten und in Gestalt eines Stabkäfigs ausgebildeten

Fadenliefertrommel 6 drehfest verbunden. Sie trägt an

ihrem oberen Ende eine über eine Kupplung 7 drehfest

ankuppelbare Riemenscheibe 8, die ihre Antriebseinrichtung

bildet und über die die Fadenliefertrommel 6 von einem

nicht weiter dargestellten, endlosen Zahn- oder Lochriemen

oder dergleichen in Umdrehung versetzt werden kann.The thread delivery device shown in Figure 1

is known in its basic structure (compare

For example, Figure 1 of

An der dem Halter 2 gegenüberliegenden Stirnseite des

Gehäuses 1 ist eine Fadenbremse 9 angeordnet, die zwei

gleichgestaltete, im Wesentlichen scheibenförmige Bremsteller

10 aufweist, zwischen denen ein zu bremsender Faden

11 durchläuft. Der Fadenlaufweg erstreckt sich von einer

nicht weiter dargestellen Fadenspule aus durch eine an dem

Gehäuse 1 befestigt Fadenöse 12, einen Knotenfänger 13

und die Fadenbremse 9 zu einer an einem Sockel- oder

Aufnahmeteil 14 über einen angeformten Arm 15 vorgesehenen

Fadeneinlauföse 16, von der aus der Faden 11 eingangsseitig

auf die Fadenliefertrommel 6 aufläuft. Auf der

Fadenliefertrommel 6 bildet der Faden 11 einen Speicherwickel

17, von dem aus er über eine an dem Gehäuse 1 befestigte

Fadenauslauföse 18 zu dem Fadenverbraucher läuft.On the opposite end of the

Wie insbesondere den Figuren 3 bis 6 zu entnehmen,

weist die Fadenbremse 9 einen als einstückiges Drahtbiegeteil

ausgebildeten, im Wesentlichen U-förmigen Bügel 19

auf, der die Halterungsmittel für die Bremsscheiben oder

-teller 10 und deren Lagermittel in Gestalt eines zylindrischen

Lagerstiftes 20 bildet. Der Bügel 19 verfügt über

zwei parallel zueinander verlaufende Schenkel 21, die an

ihrem einen Ende durch einen Quersteg 22 miteinander

verbunden sind, der sich jeweils unter Einschluss eines

rechten Winkels an die Bügelschenkel 21 anschliesst. An

ihrem anderen Ende sind die beiden Bügelschenkel 21 jeweils

über eine Abkröpfung 23 von ca. 30° und dazwischenliegende,

entsprechend gestaltete Zwischenabschnitte 24

mit zwei zueinander parallelen geraden Bügelabschnitten 25

verbunden. Bei diesem Ausführungsbeispiel liegen die

parallelen Bügelabschnitte 25, bezogen auf den in der

Gebrauchslage horizontalen Quersteg 22, in unterschiedlicher

Höhe und schliessen mit einer den Steg 22 und die

beiden Bügelschenkel 21 enthaltenden, gedachten Ebene

einen Winkel von ca. 30° ein. Die Bügelabschnitte 25

können auch gegebenenfalls mit den Zwischenabschnitten 24,

auf gleicher Höhe liegen, um nur einige Anordnungsmöglichkeiten

zu erwähnen.As can be seen in particular from FIGS. 3 to 6,

the

Mit seinen beiden parallelen Bügelabschnitten 25 ist

der Bügel 19 in dem gehäuseförmigen Sockel- oder Aufnahmeteil

14 längsverschieblich gelagert, wie dies insbesondere

aus Figur 2 zu ersehen ist. Das im Wesentlichen quaderförmige,

aus Kunststoff bestehende Sockel- oder Aufnahmeteil

14 weist zu diesem Zwecke zwei von der Vorder- zur Rückseite

durchgehende, zylindrische Lagerbohrungen 26 auf, in

denen die Bügelabschnitte 25 mit in der Gebrauchslage

horizontaler Ausrichtung längsverschieblich geführt sind.

Die geraden Bügelabschnitte 25 sind sowohl der Höhe nach

(Figur 2) als auch seitlich gegeneinander versetzt (Figur

5) angeordnet. Der obenliegende Bügelabschnitt 25 trägt an

seinem über die Rückseite des Sockel- oder Aufnahmeteils

14 vorragenden Ende ein aus Kunststoff bestehendes, im

Wesentlichen in Gestalt einer zylindrischen Kappe 27

ausgebildetes Kupplungsteil für eine in dem Gehäuse 1

angeordnete, nicht weiter dargestellte Schwingungserzeugungseinrichtung,

von der in Figur 2 lediglich ein eine

durch einen Pfeil 28 angedeutete, hin- und hergehende

Bewegung ausführender Antriebsstempel 29 veranschaulicht

ist. Der Antriebsstempel 29 wird von einem auf die Welle 5

der Fadenliefervorrichtung nach Figur 1 aufgesetzten,

nicht dargestellten Nocken betätigt, mit dem er in Eingriff

steht.With its two

In dem Sockel- oder Aufnahmeteil 14 ist eine den

oberen geraden Bügelabschnitt 26 umgebende Druckfeder 30

angeordnet, die sich gegen ein axiales Federwiderlager 31

abstützt und bestrebt ist, das Kupplungsstück 27 in Anlage

an dem Antriebsstempel 29 zu halten. Die Druckfeder 30

bildet deshalb Rückstellfedermittel.In the base or receiving

Der untere gerade Bügelabschnitt 25 ragt bspw. auf

der Rückseite des Sockel- oder Aufnahmeteils 14 bei 31

etwas vor, wie dies in Fig. 2 gestrichelt angedeutet ist.

Er liegt bei an dem Gehäuse 1 montiertem Sockel- oder

Aufnahmeteil 14 an einem Teil des metallischen Gehäuses 1

an und bewirkt damit eine elektrische Erdung des metallischen

Bügels 19. Alternativ oder zusätzlich kann zur

Verbesserung der Erdungsverhältnisse der Bügel 19 auch

eine (nicht dargestellte) Erdungsfeder gegen das Gehäuse 1

andrücken, und/oder der Sockel 14 und/oder die Kappe 27

besteht aus einem elektrisch leitenden Material. The lower

Zur Befestigung des Sockel- oder Aufnahmeteils 14 an

dem Gehäuse 1 dient eine bei 32 angedeutete Befestigungsschraube,

die von der Vorderseite des Sockel- oder Aufnahmeteils

14 aus betätigbar ist.To attach the base or receiving

Auf die in der in Figur 2 dargestellten normalen

Betriebslage mit der Vertikalen einen Winkel von ca. 30°

einschliessenden, in einer gemeinsamen Ebene liegenden

parallelen Schenkel 21 des Bügels 19 ist ein Lagerteil in

Gestalt eines aus Kunststoff hergestellten, im Wesentlichen

U-förmigen Rahmens 33 aufgesetzt, in dem der Lagerstift

20 für die Bremsscheiben 10 an seinen beiden Enden

gehalten ist, wie dies insbesondere aus Figur 4 hervorgeht.

Der Rahmen 33 weist zwei zueinander parallele,

voneinander beabstandete Rahmenschenkel 34 auf, die durch

einen angeformten Rahmensteg 35 an einem Ende miteinander

verbunden sind. Die beiden zueinander parallelen Rahmenschenkel

34 sind auf der in Figur 4 dem Betrachter zugewandten

Innenseite jeweils mit einer rinnenförmigen

Vertiefung 36 ausgebildet, in die in der Nähe des freien

Rahmenschenkelendes jeweils eine Rastnase 37 ragt. Die

Rastnasen 37 sind an der die rinnenförmige Vertiefungen 36

auf der Seite der U-förmigen Öffnung des Rahmens 33 begrenzenden

Wand 38 ausgebildet. Sie dienen dazu, den

Rahmen 33 in der Betriebsstellung mit den Schenkeln 21 des

Bügels 19 lösbar zu verrasten, wie dies im Einzelnen noch

erläutert werden wird.On the normal shown in Figure 2

Operating position with the vertical at an angle of approx. 30 °

inclusive, lying on a common level

Der Rahmensteg 35 ist auf seiner Außenseite mit einer

angeformten Lagerschale oder -pratze 39 versehen, die

bspw. in Fig. 2, 4 sichtbar ist und die bei auf den Bügel

19 aufgesetztem Rahmen 33 den Quersteg 22 elastisch umgreift,

so dass der Rahmen 33 schwenkbar an dem Steg 22

gelagert ist. Die Lagerschale oder -pratze 39 ist dabei

elastisch nachgiebig derart ausgebildet, dass der Rahmen

33 unter Überwindung der von ihr gebildeten Rastverbindung

einfach von dem Bügel 19 abgenommen werden kann. The

Auf seiner dem Lagerstift 20 zugewandten Innenseite

ist der Rahmensteg 35 als Auflage- oder Abstützkissen 40

für die Bremsscheiben oder -teller 10 ausgebildet. Zu

diesem Zweck kann der Rahmenschenkel 35 innen bspw. mit

einem verschleissfesten Überzug versehen sein. Es sind

auch Ausführungsformen denkbar, bei denen ein aus verschleissfestem

Material bestehender Stift oder ein entsprechendes

Formteil in den Rahmen 33 eingesetzt ist, das

das Auflage- oder Abstützkissen 40 bildet. Abhängig von

den Einsatzbedingungen gibt es auch Fälle, bei denen auf

eine besonders verschleißfeste Ausbildung dieses in der

Regel den ganzen Raum zwischen den beiden Rahmenschenkeln

34 einnehmenden Auflage- oder Abstützkissens 40 verzichtet

wird.On its inside facing the bearing

Der aus gehärtetem Stahl, gegebenenfalls mit einer

verschleißfesten Beschichtung, aus Keramik oder aus einem

geeigneten Hartstoff bestehende, dünne, zylindrische

Lagerstift 20 ist auf seinem einen, in Figur 4 unteren

Ende in eine Lagerbohrung 41 eingesteckt, die in der

Innenwand 38 ausgebildet ist. Auf seiner gegenüberliegenden

Seite ist der Lagerstift 20 in einer an dem zugeordneten

Rahmenschenkel 34 vorgesehen, zu der rinnenartigen

Vertiefung 36 hin offenen Lagerhalbschale 43 aufgenommen,

die an den Rahmenschenkel 34 angeformt ist. Die Tiefe der

Lagerhalbschale 43 ist dabei derart gewählt, dass der

eingesetzte Lagerstift 20 mit seiner Mantelfläche etwas

über den Boden der rinnenförmigen Vertiefung 36 vorragt.

Damit wird erreicht, dass bei in der Gebrauchsstellung mit

den Bügelschenkeln 21 verrastetem Rahmen 33 der in diesem

Falle metallische Lagerstift 20 gegen die Bügelschenkel 21

elektrisch leitend elastisch angepresst ist, so dass eine

einwandfreie Erdung des Lagerstiftes 20 über den metallischen

Bügel 19 und das Gehäuse 1 sichergestellt ist. Der

Lagerstift 20 kann auch aus nichtleitendem Material, etwa

Keramik bestehen, was der Ordnung halber erwähnt sei.The hardened steel, possibly with a

wear-resistant coating, made of ceramic or one

suitable hard material, thin,

An dem Lagerstift 20 sind die beiden Bremsteller 10

frei pendelnd aufgehängt. Sie sind zu diesem Zwecke in der

insbesonders aus den Figuren 5, 6 zu entnehmenden Weise

jeweils mit einer mittigen, zylindrischen, durchgehenden

Öffnung 44 ausgebildet, deren Durchmesser um ein Vielfaches

größer ist als der Durchmesser des Lagerstiftes 20.

Das Durchmesserverhältnis beträgt typischerweise etwa 6:1

und mehr. Die im Querschnitt schalenförmig bombiert ausgebildeten

Bremsteller 10 können längs der Berandung der

Öffnung 44 jeweils mit einer als zylindrische Lippe angeformten

Nabe 45 ausgebildet sein, um damit die Beanspruchung

der Bremsteller 10 und des Lagerstiftes 20 zu verringern

und ein Einschneiden der Bremsteller in den Lagerstift

20 zu verhindern. Alternativ kann die Berandung der

Öffnung 44 bei jedem der Bremsteller 10 auch von einem

eingesetzten Nabenring aus Kunststoff oder einem eine

geeignete Lagerpaarung mit dem Lagerstift 20 ergebenden

Material eingefasst sein, wie dies anhand der Fig. 10 noch

erläutert werden wird. In die torusförmige Vertiefung der

Bremsteller 10 sind von außen her Dauermagnetringe 46

eingesetzt, die so magnetisiert sind, dass sie die Bremsteller

10 aufeinander zu drücken und damit deren Belastungsmittel

bilden, wobei die Größe der Belastungskraft

die Bremswirkung auf den durchlaufenden Faden bestimmt.The two

Wie bspw. aus den Figuren 3, 5 hervorgeht, stehen die

beiden Rahmenschenkel 34 im montierten Zustand in beträchtlichem

seitlichem Abstand von den beiden Bremstellern

10. Die beiden aneinander anliegenden Bremsteller 10

sind deshalb in Achsialrichtung über eine beträchtliche

Länge des Lagerstiftes 2C frei beweglich. Sie können im

Betrieb eine Pendel- und Taumelbewegung ausführen. Sie

sind aber von den beiden Rahmenschenkeln 34 im Zusammenwirken

mit dem dünnen Lagerstift 20 unverlierbar in dem

Rahmen 33 gehalten.As can be seen, for example, from FIGS. 3 and 5, the

two

Im Betriebszustand ist der Rahmen 33 mit den auf dem

eingesetzten Lagerstift 20 hängenden Bremstellern 10 mit

seine Lagerschale oder -pratze 39 auf den horizontalen

Steg 22 des Bügels 19 aufgeklippst. Außerdem ist er um die

Achse des Steges 22 so weit hochgeklappt, dass die beiden

Schenkel 21 in den rinnenförmigen Vertiefungen 36 der

Rahmenschenkel 34 aufgenommen sind und der Rahmen 33 mit

den Schenkeln 21 über die Rastnasen 37 verrastet ist. Die

Fadenbremse weist damit den in den Figuren 1, 2 dargestellten

Zustand auf, in dem der zwischen den Bremstellern

10 durchlaufende Faden 11 in dem durch die Anziehungskraft

der Dauermagnetringe 46 gegebenen Maß gleichmäßig gebremst

wird. Dabei werden die beiden gegeneinander gedrückten

Bremsteller 10 von dem um den Lagerstift 20 oder um einen

in der Zeichnung nicht weiter dargestellten, durch die

Öffnungen 44 der Bremsscheiben 10 verlaufenden und in den

Rahmenschenkeln 34 gehalterten Fadenumlenkstift umgelenkten

Faden 11 reibschlüssig angetrieben, so dass sie eine

gemeinsame Drehbewegung um den Lagerstift 20 ausführen.

Dieser Umlaufbewegung ist eine Taumelbewegung in Achsialrichtung

überlagert, da, wie erwähnt, die beiden Bremsteller

10 keine feste seitliche Führung aufweisen. Auf

diese Weise wird erreicht, dass sich der Faden 11 nicht in

die Bremsflächen der Bremsteller 10 einschneiden kann,

sondern dass die Bremsflächen über ihren gesamten Umfang

fortschreitend mit dem Faden in Eingriff kommen.In the operating state, the

Gleichzeitig wird dem Bügel 19 über den Antriebsstempel

29 der Schwingungserzeugungseinrichtung eine hinund

hergehenden Schwingungsbewegung erteilt, unter deren

Einwirkung die Auflagestellen an der Öffnungsberandung der

Bremsteller 10 auf dem Lagerstift 20 sich fortwährend

verändern, so dass die Bremsteller 10 eine unregelmäßige

Bewegung ausführen, die die Ablagerung von Flusen und

dergleichen verhindert.At the same time the

Da die Bremsteller 10 in der beschriebenen Weise

lediglich von dem U-förmigen Rahmen 33 und dem als Drahtbiegeteil

ausgebildeten U-förmigen Bügel 19 gehaltert

sind, sind an der ganzen Fadenbremse wenig Flächen vorhanden,

auf denen sich überhaupt Flusen absetzen können.

Gleichzeitig sind hervorragende Reinigungsverhältnisse

gegeben, weil die Fadenbremse 9 keine toten Winkel oder

Ecken aufweist, in denen sich beim Abblasen mittels eines

Druckluftstrahls Schmutz oder dergleichen ansammeln könnte.Since the

Beispielsweise um die Reinigung nach dem Verarbeiten

von besonders stark verschmutztem Garn weiter zu vereinfachen

oder um den Lagerstift 20 auszustauschen, kann der

Rahmen 33 aus der Betriebsstellung nach Figur 2 unter

Überwindung der Rastnasen 37 einfach um den Steg 22 in

eine Stellung nach Fig. 3 herabgeklappt werden, in der die

beiden Bremsteller 10 aus dem Raum zwischen den beiden

Bügelschenkeln 21 herausgeklappt sind. In dieser Stellung

sind die beiden Bremsteller 10 frei zugänglich.For example, after cleaning after processing

of particularly heavily soiled yarn

or to replace the

Um die Bremsteller 10 aus dem Rahmen 33 zu entnehmen,

wird der Lagerstift 20 an seinem einem Ende aus der Lagerhalbschale

43 nach oben zu herausgedrückt, so dass er

achsial aus der Lagerbohrung 41 herausgezogen werden

kann. Da der Rahmen 33 aus Kunststoff besteht und im

aufgeklappten Zustand nicht durch die Bügelschenkel 21

verstärkt ist, ist er elastisch so verformbar, dass die

geschilderte Demontage des Lagerstiftes 20 leicht möglich

ist. Ein neuer Lagerstift 20 kann in der umgekehrten Weise

wieder eingefügt werden.In order to remove the

Alternativ kann auch derart vorgegangen werden, dass

der ganze Rahmen 33 mit dem Lagerstift 20 und den

Bremstellern 10, in bereits geschilderter Weise, von dem

Bügelsteg 22 abgenommen und gegebenenfalls durch einen

neuen Rahmen 33 ersetzt wird. Nach Abschluss der Reinigungsarbeiten

oder nach Austausch des Lagerstiftes 20 oder

der Bremsteller 10, etc., wird der Rahmen 33 aus der

abgeklappten Stellung einfach wieder in die Betriebsstellung

nach Figur 2, 5 hochgeklappt und in dieser Stellung

über die Rastnasen 37 mit den Schenkeln 21 des Bügels 19

verrastet. Die Bügelschenkel 21 verlaufen, wie Figur 2

zeigt, in der Betriebsstellung beidseitig der Bremsteller

10, so dass diese in der U-förmigen Öffnung des Bügels 19

zwischen dessen beiden Schenkeln 21 aufgenommen sind.Alternatively, one can also proceed in such a way that

the

Es könnte die Anordnung auch derart getroffen sein,

dass der Lagerstift 20 aus dem Rahmen 33 direkt axial

herausziehbar ist, in dem er in wenigstens einer sich nach

außen öffnenden Lagerbohrung 41 gehaltert ist. Der Lagerstift

20 wäre dann in seiner Betriebsstellung im Rahmen 33

durch einen Feststellmechanismus, etwa in Form eines

Rastmechanismus oder durch teilweise Ausbildung als Gewindebolzen

gesichert. Auch andere Ausführungsformen die dem

gleichen Zweck dienen, sind denkbar.The arrangement could also be made in such a way

that the bearing

Es sind auch Ausführungsformen der neuen Fadenbremse

denkbar, bei denen auf den Rahmen 33 ganz verzichtet ist

und der Lagerstift 20 unmittelbar an den Bügelschenkeln 21

des Drahtbügels gehalten ist. Solche Ausführungsvarianten

sind beispielhaft in den Figuren 6a, 6b dargestellt:There are also embodiments of the new thread brake

conceivable in which the

Bei der Ausführungsform nach Figur 6a sind die beiden

Bügelschenkel 21 des U-förmigen Drahtbügels 19a jeweils zu

einer Ringöse 47 gebogen, die die zylindrische Lagerbohrung

41 begrenzt. Die beiden Ringösen 47 fluchten mit

ihren Lagerbohrungen 41, in welche der Lagerstift 20

eingesteckt ist. Der Lagerstift 20 ist dabei beidseitig

von den Ringösen 47 elastisch festgeklemmt. Erforderlichefalls

kann er im Bereiche wenigstens einer Lagerbohrung 41

auch eine Rastvertiefung, etwa in Gestalt einer ringsumlaufenden

Rastnut, aufweisen, um zusätzlich oder alternativ

eine formschlüssig Verbindung mit dem jeweiligen

Bügelschenkel 21 herzustellen. Anstelle der Ausbildung mit

den geschilderten, die Lagerbohrung 41 jeweils vollständig

umschlingenden Ringösen 47, können die Bügelschenkel 21

auch so gebogen sein, dass sie Ω-förmige Ösen 47a aufweisen,

wie dies in Figur 6b, rechte Darstellung, veranschaulicht

ist. In the embodiment according to FIG. 6a, the two are

Schliesslich kann gegebenenfalls auch darauf verzichtet

werden die Bügelschenkel 21 ösenförmig zu biegen. An

die Stelle der Ringösen 47 bzw. der -förmigen Ösen 47a

kann auch eine auf den jeweiligen Bügelschenkel 21 aufgeklippste

und dort reibschlüssig gehaltene hakenförmige

Halterungsklaue 48 treten, wie sie in Figur 6b, linke

Abbildung, dargestellt ist. Die vorzugsweise aus Kunststoff

hergestellten Halteklauen 48 sind endseitig auf den

Lagerstift 20 aufgesteckt. Sie umgreifen mit ihrem Haltemaul

49 den jeweiligen Bügelschenkel 21, auf dem sie reibschlüssig,

unverschieblich gehalten sind.Finally, it can also be omitted if necessary

the

Bei den beschriebenen Ausführungsformen wird der eine

gerade Bügelabschnitt 25 durch die Druckfeder 30 (Figur 2)

in elastischer Anlage an dem Betätigungsstössel 29 (oder

einem Betätigungsnocken) der Schwingungserzeugungseinrichtung

gehalten. Zur Verschleißminderung an der Kontaktstelle

dient das als Kunststoffkappe ausgebildete Kupplungsteil

27. Anstelle der Druckfeder 30 wäre es auch

vorstellbar, die Rückstellung des Bügels 19 bzw. die Anpressung

dessen Bügelabschnitts 25 an dem Antriebsstössel

29 dadurch zu erzielen, dass das den Bügel 19 bildende

Drahtbiegeteil mit einer entsprechenden elastischen Vorspannung

ausgebildet ist. Auch zwangsgeführte Ausführungsformen

mit zwei Auflagestellen dieses Drahtbiegeteils an

dem Antriebsstempel 29 bzw. an der Antriebsnocke sind möglich.

Eine solche Variante ist in Figur 6 angedeutet. Die

Bügelabschnitte 25 sind bei 470 etwa rechtwinklig aufeinander

zuweisend abgebogen. Zwischen den im Abstand stehenden,

abgebogenen Bügelteilen 470 könnte bspw. der

Antriebsstempel oder -stössel 26 gekuppelt sein.In the described embodiments, one

Wird die Fadenbremse 9 ohne Schwingungserzeugungseinrichtung

verwendet, so werden die geraden Bügelabschnitte

25 in dem Sockel- oder Aufnahmeteil 14, bspw. mittels

Klemmschrauben fixiert.If the

In den Figuren 7 bis 10 sind drei verschiedene alternative

Ausführungsformen des Rahmens 33 veranschaulicht:In Figures 7 to 10 there are three different alternatives

Embodiments of

Bei der Ausführungsform nach Figur 7 ist der einstückige,

im Wesentlichen U-förmige Rahmen 33a mit einer

zur Rückseite hin sich öffnenden, ringsumlaufenden, rinnenförmigen

Vertiefung 36a ausgebildet, die sich über die

Rahmenschenkel 34a und den Rahmensteg 35a erstreckt. Der

Rahmen 33a ist durch die entsprechende Bemessung der Vertiefung

36a auf den Bügelschenkeln 21 und dem Bügelsteg 22

verklemmt. Er kann insgesamt nach vorne zu abgenommen

werden, wie dies durch die beiden Pfeile 480 angedeutet

ist. Der Lagerstift 20 ist in dem Rahmen 33a, ähnlich wie

in Figur 4, gehaltert. Ein Lageransatz und die Lagerhalbschale

sind mit 42a bzw. 43a bezeichnet.In the embodiment according to FIG. 7, the one-piece,

substantially

Bei der Ausführungsform nach Figur 8 ist, - wie

übrigens bei allen Ausführungsformen - der Rahmen 33b aus

Kunststoff hergestellt. Seine beiden Rahmenschenkel 34b

und der Rahmensteg 35b sind jeweils mit einer in der Ebene

der beiden Bügelschenkel 21 liegenden und nach außen hin

offenen, rinnenförmigen Vertiefung 36b ausgebildet, in der

die Bügelschenkel 21 liegen. Auf diese Weise ist es möglich,

den ganzen Rahmen 33b in Richtung der Pfeile 490 auf

den Bügelschenkeln 21 zu verschieben, bspw. um die Betriebsverhältnisse

der Fadenbremse zu verändern. Der

Rahmen 33b ist auf den Bügelschenkeln 21 in seiner jeweiligen

Stellung reibschlüssig gehalten. Der Lagerstift 20

ist in diesem Falle einends in einem eigenen, den zugeordneten

Bügelschenkel 21 U-förmig umfassenden und reibschlüssig

mit diesem gekuppelten Schenkelabschnitt 340b

gehaltert, der gegebenenfalls mit dem Schenkel 21 auch

verrastet sein kann. An seinem anderen Ende ist der Lagerstift

20 in einer einseitig offenen, nutartigen Vertiefung

50 des zugeordneten Rahmenschenkels 34 aufgenommen und in

dieser verrastet oder verklemmt. Um den Lagerstift 20 oder

die Bremsteller 10 auszutauschen, wird der Lagerstift 20

um den linken Schenkel 21 herausgeklappt, wie dies durch

einen Pfeil 51 angedeutet ist. Er kann sodann aus seinem

Schenkelabschnitt 340b herausgezogen werden.In the embodiment of Figure 8 is how

by the way, in all embodiments - the

Eine an dem Rahmen 33b angeformte Betätigungsnase 52

erlaubt die Verschiebung des Rahmens 33b im Sinne der

Pfeile 490.An

Bei der Ausführungsform nach Figur 9 ist der Rahmen

33c zweiteilig ausgebildet. Die Rahmenschenkel 34c und der

Rahmensteg 35c sind mit einer durchgehenden, rinnenförmigen

Vertiefung 36c versehen, die sich zu dem von den

beiden Bügelschenkeln 21 begrenzten Raum hin aufeinander

zuweisend öffnen. Der ganze Rahmen 33c kann deshalb in

Richtung der Pfeile 53 nach unten zu auf den Schenkeln 21

verschoben oder von diesen ganz abgezogen werden. Wahlweise

können aber auch die beiden Rahmenschenkel 34c, die

längs einer Trennfuge 55 in dem Rahmensteg 35c voneinander

getrennt sind, seitlich von den Schenkeln 21 abgezogen

werden. Dies ist durch zwei Pfeile 56 angedeutet. Die

Halterung des Lagerstiftes 20 an den Rahmenschenkeln 34c

ist ähnlich wie in Figur 4 gelöst. Entsprechende Teile

sind mit entsprechenden Bezugsbezeichen versehen.9 is the

Bei den Ausführungsformen nach den Figuren 8, 9 ist

das Auflage- oder Abstützkissen 40 für die Bremsscheiben

10 im Einzelnen nicht veranschaulicht. Es kann ähnlich,

wie bei dem Rahmen 33 nach Figur 4 gestaltet sein. Es

dient in jedem Falle dazu die Bremsteller 10 im Betrieb an

ihrem Außenumfang radial in ihrem Bewegungsweg zu begrenzen.

Die an dem Lagerstift 20 hängenden Bremsteller 10

liegen in ihrer in Figur 2 dargestellten Betriebsstellung

unten auf dem Auflage- oder Abstützkissen 40 auf, von dem

sie sich im Verlaufe ihrer unregelmäßigen Taumel- und

Drehbewegung während des Betriebes mehr oder weniger oft

abheben.In the embodiments according to FIGS. 8, 9

the support or

Wie bereits früher erwähnt, kann es, bspw. abhängig

von den Einsatzbedingungen der Fadenbremse 9, zweckmäßig

sein, insbesondere die Lagerverhältnisse deren Bremsscheiben

oder -teller 10 auf dem Lagerstift 20 an die jeweiligen

Einsatzbedingungen anzupassen. Beispiele dafür sind in

Fig. 10 schematisch dargestellt:As mentioned earlier, it can depend, for example

from the operating conditions of the

Bei der Ausführungsform a) sind auf die Bremsscheiben

oder -teller 10 aus einem geeigneten Kunststoff bestehende

ringförmige Kappen 60 aufgeklippst, die mit ihren ringsumlaufenden

vorstehenden Randbereichen 61, 62 die Bremsteller

10 auf dem Außenumfang und längs des Umfangs der

Öffnung 44 übergreifen, derart, dass sie an den Bremstellern

10 verrastet sind. Die Kappen 60 decken die Höhlung