EP0861908A1 - Method of manufacturing sintered ore and sintering machine therefor - Google Patents

Method of manufacturing sintered ore and sintering machine therefor Download PDFInfo

- Publication number

- EP0861908A1 EP0861908A1 EP97935796A EP97935796A EP0861908A1 EP 0861908 A1 EP0861908 A1 EP 0861908A1 EP 97935796 A EP97935796 A EP 97935796A EP 97935796 A EP97935796 A EP 97935796A EP 0861908 A1 EP0861908 A1 EP 0861908A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- sintering

- raw mixture

- pressure

- mixture bed

- gas

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22B—PRODUCTION AND REFINING OF METALS; PRETREATMENT OF RAW MATERIALS

- C22B1/00—Preliminary treatment of ores or scrap

- C22B1/14—Agglomerating; Briquetting; Binding; Granulating

- C22B1/16—Sintering; Agglomerating

- C22B1/20—Sintering; Agglomerating in sintering machines with movable grates

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22B—PRODUCTION AND REFINING OF METALS; PRETREATMENT OF RAW MATERIALS

- C22B1/00—Preliminary treatment of ores or scrap

- C22B1/14—Agglomerating; Briquetting; Binding; Granulating

- C22B1/16—Sintering; Agglomerating

- C22B1/20—Sintering; Agglomerating in sintering machines with movable grates

- C22B1/205—Sintering; Agglomerating in sintering machines with movable grates regulation of the sintering process

Definitions

- the present invention relates to a method of producing sintered ore, which is a raw material used for making pig iron by a blast furnace, and a sintering machine to which the method of producing sintered ore is applied. More particularly, the present invention relates to a method of producing sintered ore and a sintering machine therefor, in which a combustion and melting zone on a layer to be sintered is moved from an upper portion to a lower portion on pallets, and after a sintered layer of a predetermined thickness has been obtained, a volume of gas containing oxygen is increased, so that a pressure drop is increased and a sintering speed of the combustion and melting zone is extremely increased so as to enhance the productivity, quality and product yield of sintered ore.

- the Dwight Lloyd type sintering machine When iron ore is sintered, the Dwight Lloyd type sintering machine is commonly used. Sintering operation is conducted by the Dwight Lloyd type sintering machine as follows. In preparation for blended raw material to be process by the sintering machine, fluxes such as limestone and quartz, fuel such as coke breeze, and water are added to fine iron ore and mixed with each other and granulated. The above blended raw material is charged onto sintering pallets which are arranged like a caterpillar. In this way, a raw mixture bed is formed on the pallets. The sintering pallets are successively moved in the horizontal direction, and a surface of the raw mixture bed is ignited in an ignition furnace.

- fluxes such as limestone and quartz

- fuel such as coke breeze

- the sintering time is approximately 20 to 40 minutes.

- the above Dwight Lloyd sintering machine is of a continuous type. Therefore, the above Dwight Lloyd sintering machine is suitable for mass production. That is the reason why the above Dwight Lloyd sintering machine is commonly used.

- the size of the presently used Dwight Lloyd sintering machine is increased, for example, there is provided a Dwight Lloyd sintering machine, the width of which is 5 m and the length of which is 100 m.

- the productivity of the Dwight Lloyd sintering machine is approximately 34 to 43 t/d/m 2 .

- Japanese Examined Patent Publication (Kokoku) No. 55-19299 discloses the following technique. "There is provided a first half hood section of negative pressure in the first half of the upper portion of the strand. There is also provided a second half hood section of positive pressure in the second half of the upper portion of the strand.

- Japanese Examined Patent Publication (Kokoku) No. 56-19556 discloses the following technique. "There is provided a positive pressure hood to form a positive pressure sintering zone. At the end portion of the positive pressure hood on the ore feed and discharge sides, there is also provided a negative pressure hood to form a negative pressure zone.

- an object of this method is to prevent pressurized air from leaking into the atmosphere from the start end portion to supply raw material into the housing and also to prevent compressed air from leaking into the atmosphere from the conveying end portion to convey out sintered ore from the housing, wherein leakage of air from the above end portions are problems of the compressed sintering method of the conventional method.

- Japanese Unexamined Patent Publication (Kokai) No. 61-243131 discloses the following technique. "In order to eliminate a large pressure-tight housing necessary for the compressed sintering method, there is provided a hood on the upper surface of sintered ore on the endless pallets, and air is forcibly fed into the hood so that the pressure in a wind box under the endless pallets is made negative. In this way, the cost can be decreased.”

- an object of the above patent publication is to decrease a total electric power of the forced fan and the ventilating fan, and no explanations are made for enhancing the productivity by increasing a moving speed of the combustion and melting zone on the raw mixture bed.

- the sintering machine of the conventional method in order to maintain a pressure drop between the upper portion and the lower portion of the raw mixture bed, which is an air pressure necessary for the sintering process, to be constant, the pressure of the forced draft fan and that of the ventilating fan are balanced with each other, and air at high temperature, the volume of which is expanded, is entirely exhausted.

- air at the room temperature is supplied into the apparatus, so that the total electric power can be decreased.

- the sintering speed of the combustion and melting zone on the raw mixture bed is not positively increased for the purpose of enhancing the productivity.

- Japanese Examined Patent Publication (Kokoku) No. 5-55574 discloses the following technique. "There are provided a plurality of divided wind boxes arranged in the longitudinal direction of the pallets. For each wind box divided in this way, in accordance with the sintering reaction of materials to be sintered which are charged and packed on the pallets, negative pressure for suction is decreased in the beginning of sintering reaction as compared with the negative pressure in normal operation, and is increased in the middle of the sintering reaction, and again is decreased in the final near to the end of sintering reaction. Due to the above control, it is possible to enhance the product yield on the upper layer of the sintering bed, the shatter Index (SI) and RDI.

- SI shatter Index

- the above techniques of the conventional method aim at improving costs of equipment and operation. Therefore, all techniques of the conventional method are based on the operating conditions in which blended raw material is charged onto the sintering pallets by the thickness of 400 to 600 mm, and fuel contained in the blended raw material is ignited in the ignition furnace.

- Productivity of the sintering machine greatly depends upon the moving speed at which the combustion and melting zone on the raw mixture bed is gradually moved from the surface layer to the lower layer.

- the moving speed of the combustion and melting zone is low in the process of firing the raw material from the upper layer to the lower layer in the strand and from the igniting section to the sintered ore discharging section of the sintering machine. Accordingly, as long as the moving speed of the combustion and melting zone is the same as that of the conventional method, when the thickness of the raw mixture layer is increased or the moving speed of the sintering pallets is increased, the sintering machine length and the sintering time must be increased to complete sintering. Therefore, the productivity cannot be enhanced.

- the negative pressure of a blower is increased so as to increase the flow velocity of sucked gas, and that a volume of oxygen supplied to the raw mixture bed is increased.

- the objects of the present invention are to provide a method of producing sintered ore by which the productivity of a sintering machine can be greatly enhanced when the thickness of the raw mixture bed and the moving speed of sintering pallets are increased, to provide a method of producing sintered ore having low SiO 2 , and to provide a sintering machine to which the above methods can be applied.

- Fig. 1 is a schematic illustration showing an embodiment of the sintering machine according to the examples 1a and 3a of the present invention.

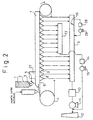

- Fig. 2 is a schematic illustration showing an embodiment of the sintering machine according to the example 1b of the present invention.

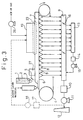

- Fig. 3 is a schematic illustration showing an embodiment of the sintering machine according to the examples 1c to 1e and 3b of the present invention.

- Fig. 4 is a schematic illustration showing an embodiment of the sintering machine according to the examples 2a to 2d and 3c of the present invention.

- Fig. 5 is a schematic illustration showing another embodiment of the sintering machine of the present invention.

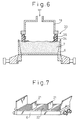

- Fig. 6 is a cross-sectional view showing the sealing mechanism of the pressure hood of the sintering machine of the present invention.

- Fig. 7 is a perspective view showing sintered ore supporting stands of the sintering machine of the present invention.

- Fig. 8(a) is a schematic illustration showing a transition of the combustion and melting zone on the pallets in the present invention

- Fig. 8(b) is a cross-sectional view of the combustion and melting zone taken on line A - A' in Fig. 8(a) of the present invention

- Fig. 8(c) is a schematic illustration showing a transition of the combustion and melting zone on the strand in the case of cooling in the present invention.

- sintered ore is produced in such a manner that blended raw material containing fine iron ore, flux and fuel is charged onto pallets of the Dwight Lloyd type sintering machine so that a raw mixture bed can be formed on the pallets, and it is ignited in the igniting section, and then the raw mixture bed is moved to the sintercake discharging section of the sintering machine while gas containing oxygen is being sucked downward through the raw mixture bed from a lower portion. Accordingly, sintering is conducted on the raw mixture bed in the direction from an upper portion to a lower portion of the raw mixture bed.

- sintering can be conducted in accordance with the direction of the strand length, and in order to clarify understanding, the present invention will be explained using the strand length, hereinafter.

- Fig. 8(a) is a schematic illustration showing an example of a transition of the combustion and melting zone on the pallets in the present invention.

- reference numeral I is an initial raw material zone

- reference numeral II is a wet zone (water condensing zone)

- reference numeral III is a drying zone

- reference numeral IV is a combustion zone

- reference numeral V is a melting zone

- reference numeral VI is a sintering zone.

- Fig. 8(b) is a cross-sectional view of the central portion taken on line A - A' in Fig. 8(a).

- point B represents a position closest to the ignition furnace at which the combustion and melting zone is formed in the initial stage in the present invention and a volume of gas containing oxygen to be supplied onto the raw mixture bed is changed so that it can be increased

- point C represents a combustion completion point.

- operation is usually conducted so that the sintering completion point can be located at a constant position.

- operation is conducted in such a manner that the sintering completion point is made to come near to the sintercake discharging side as closely as possible.

- the sintering completion point is made to be a constant position so that it comes near onto the ignition furnace side while a distant space corresponding to one or two times of wind box length is left.

- cooling is conducted on the raw mixture bed on the strand, for example, as shown in Fig. 8(c), operation is conducted in such a manner that the sintering completion point C' is changed to an intermediate portion of the strand.

- a volume of gas containing oxygen supplied to the raw mixture bed may be changed at the layer thickness or the position in the strand length direction in accordance with the present invention disclosed below.

- the sintering completion point is located at a position distant from the igniting section by the distance of 95% of the strand length.

- the air blasting pressure and the suction pressure are shown by the pressure with respect to the atmospheric pressure.

- a range in the distance not more than 30% of the strand length from the igniting section approximately corresponds to a sintering area of 20% of the upper layer.

- the product yield and quality of the upper layer of the raw material is inferior to that of the intermediate and the lower layer.

- the coke burning speed on the upper layer, by which a quantity of heat necessary for the sintering reaction is given is not sufficiently high immediately after the ignition, and further heat is emitted from the surface of the upper layer. Accordingly, it is necessary to ensure a quantity of heat required for the sintering reaction on the upper layer.

- the moving speed of the combustion and melting zone is increased in the sintering process of the upper layer of the raw material, because the product yield and quality of sintered ore is deteriorated.

- this range is a sintering area of the upper layer of the raw material, is kept in a negative pressure of suction in the same manner as that of the conventional method, it becomes possible to ensure a period of time in which the upper layer of the raw material is held at a high temperature. Therefore, the product yield and quality of the upper layer of the raw material can be maintained high.

- a quantity of heat generated by sintering may be increased in this upper layer.

- the negative pressure of suction is lowered in this section, the coke segregation is occurred in the upper portion of the raw mixture bed, and coke breeze is made to flow onto the surface layer.

- it is possible to give heat from the outside of the raw mixture bed for example, a hot blast is supplied to this portion, or alternatively induction heating of microwaves may be conducted.

- a range from the igniting section to a position distant from the igniting section by 30 to 95% of the strand length corresponds to a sintering area of the intermediate and the lower layer of the raw material.

- the gas permeability resistance in the sintering zone on the upper layer is low.

- thickness of the combustion and melting zone of the intermediate layer and that of the lower layer are large, so that the gas permeability resistance is high thereon.

- the gas permeability is deteriorated and a quantity of heat generated by sintering is increased too large.

- Gas containing oxygen is forcibly supplied from the upper portion to the combustion and melting zone, the pressure loss of which is large, in the range (the range from the igniting section to the position distant from the igniting section by 30 to 95% of the strand length) on the intermediate and the lower layer.

- a mass flow rate of gas containing oxygen is increased 1.01 to 2.6 times as high as that of gas containing oxygen supplied to the raw mixture bed in the range of the strand except for the aforementioned range.

- the coke burning speeds on the intermediate and the lower layer are increased, so that the moving speed of the combustion and melting zone is increased, and further the cooling speed of the cooling zone above the combustion and melting zone is increased.

- the gas permeability can be enhanced while a quantity of heat necessary for sintering is ensured and thickness of the combustion and melting zone is decreased.

- a mass flow rate represents a mass of gas flowing per unit time.

- the unit of mass flow rate is expressed by kg/s.

- a rate of flow commonly used represents a volumetric flow rate.

- This volumetric flow rate represents a volume of gas flowing per unit time.

- the unit of the volumetric flow rate is expressed by m 3 /s.

- Gas containing oxygen described in the present invention includes the atmosphere, exhaust gas discharged from a sintering machine, exhaust gas discharged from other processes, mixed gas in which the atmosphere is mixed with exhaust gas, and gas enriched with oxygen gas. It is preferable that the oxygen concentration in gas is 12 to 40 vol%.

- the reason why a mass flow rate of gas containing oxygen supplied to the charged raw mixture bed in the range from the igniting section to the position distant from the igniting section by 30 to 95% of the strand length is adjusted to be 1.01 to 2.6 times as high as the mass flow rate of gas containing oxygen supplied to the raw mixture bed in the ranges except for the aforementioned range, is described as follows.

- the mass flow rate of gas containing oxygen is lower than 1.01 times, the moving speed of the combustion and melting zone is seldom changed.

- the mass flow rate of gas containing oxygen is higher than 2.6 times, the flow velocity of gas is increased too high, and the combustion and melting zone is undercooled.

- the mass flow rate of gas containing oxygen supplied to the raw mixture bed in the range from the igniting section to the position distant from the igniting section by 50 to 85% of the strand length is adjusted to be 1.1 to 1.8 times as high as the mass flow rate of gas containing oxygen fed to the raw mixture bed in the range except for the aforementioned range.

- a pressure drop in the direction of the thickness of the raw mixture bed in the range from the igniting section to the position distant from the igniting section by 30 to 95% of the strand length is made to be 1.1 to 5.0 times as high as that in the direction of the thickness of the raw mixture bed in the strand range except for the aforementioned range.

- the gas permeability resistance in the range of 30 to 95% of the strand length is 1.5 to 5 times higher than that of other ranges.

- the pressure drop when the pressure drop is smaller than 1.1 times, the moving speed of the combustion and melting zone is not sufficiently attained by an increase in the gas volume.

- the pressure drop exceeds 5.0 times, the flow velocity of gas is increased too high, and the cooling speed is greatly increased. Therefore, it becomes difficult to ensure a period of time in which the raw mixture bed is kept at high temperature, and the raw mixture bed is compressed and the density is increased, and the gas permeability is deteriorated.

- the pressure drop is smaller than 1.1 time and the pressure drop exceeds 5.0 times. From the viewpoint of enhancing the productivity, it is most preferable that the pressure drop is kept at 1.2 to 2.0 times.

- a volume of gas to be supplied is gradually increased when it comes from the igniting section side to the sintercake discharging side so that the moving speed of the combustion and melting zone and the cooling speed can come close to each other.

- the reason why the volume of gas to be supplied is gradually increased is described as follows. When the volume of gas to be supplied is suddenly increased, the cooling speed is increased higher than the burning speed of coke although its period of time is short. Therefore, it becomes impossible to keep a sufficiently large quantity of heat for sintering in some portions. As a result, the product yield and quality of sintered ore in these portions are deteriorated.

- the present inventors found the following. When gas is sucked from a lower portion of the raw mixture bed and at the same time gas is supplied with pressure from an upper portion of the raw mixture bed so that a mass flow rate of gas containing oxygen can be increased, it is possible to avoid a deterioration of gas permeability caused by a compressed raw mixture bed, and a mass flow rate of gas containing oxygen supplied to the raw mixture bed in the range from the igniting section to the position distant from the igniting section by 30 to 95% of the strand length is adjusted to be 1.01 to 2.6 times as high as the mass flow rate of gas containing oxygen supplied to the raw mixture bed in the ranges except for the aforementioned range, and a pressure drop in the direction of the thickness of the raw mixture bed is adjusted to be 1.1 to 5.0 times as high as that in the direction of the thickness of the raw mixture bed in the strand range except for the aforementioned range. Due to the foregoing, it is possible to increase the moving speed of the combustion and melting zone, and the yield and quality of

- a pressure hood covering the raw mixture bed that has been charged onto the sintering pallets.

- the pressure hood is compressed, and gas containing oxygen is supplied from an upper portion onto the raw mixture bed, and at the same time gas is sucked and exhausted from a wind box arranged immediately below the pallets. While a pressure drop between the upper portion and the lower portion of the raw mixture bed is controlled in this way, gas is made to flow from the upper portion to the lower portion of the raw mixture bed.

- the atmospheric pressure is kept on the raw mixture bed, and gas is sucked from a lower portion of the raw mixture bed so as to maintain a static pressure on the raw mixture bed.

- a static pressure on the raw mixture bed can be increased by the way described above.

- the pressure drop between the upper portion and the lower portion of the raw mixture bed of the method of the present invention is the same as that of the method of the conventional method in which the atmosphere is sucked, it is possible to increase a mass flow rate of gas supplied to the raw mixture bed by the present invention as compared with the method of the conventional method, and further the density of gas in the raw mixture bed can be increased as compared with the method of the conventional method.

- a volume of gas containing oxygen supplied into the raw mixture bed is increased, and the burning speed of coke on the raw mixture bed can be increased.

- the moving speed of the combustion and melting zone can be increased, and furthermore the moving speed of the cooling zone can be increased.

- the static pressure in the raw mixture bed is increased, a rate of heat transfer between gas and solid is also increased. Accordingly, the combustion and melting zone can be positively moved, and the cooling zone can be effectively cooled.

- gas can be supplied to the combustion and melting zone, in which a reaction is caused, through the sintered zone, the resistance of gas permeability of which is low, forming a uniform gas flow.

- resistance of gas permeability is given by the wet zone, the resistance of gas permeability of which is relatively high, and also resistance of gas permeability is given by the combustion and melting zone in which the sintering reaction is caused. Due to the resistance of gas permeability described above, gas flows preferentially in a portion, in which the resistance of gas permeability is low.

- the gas flow forcibly supplied from the upper portion can form a uniform gas flow compared with the gas flow of suction from the lower portion. Therefore, the oxygen consumption efficiency can be enhanced, and the unit requirement of gas volume necessary for producing sintered ore can be decreased.

- pressure in the pressure hood arranged in an upper portion of the raw mixture bed is increased to a value in the range from 100 to 3000 mm, and gas, the pressure of which is -2000 to -1 mmAq, is sucked from a lower portion of the raw mixture bed.

- gas the pressure of which is -2000 to -1 mmAq

- the productivity cannot be enhanced so high as that in the operation of the conventional method.

- the pressure in the upper portion of the raw mixture bed is higher than 3000 mmAq, a pressure drop between the upper and the lower portion of the raw mixture bed is excessively increased.

- the raw mixture bed is too strongly compressed by both gravity and gas pressure. Accordingly, density of the raw mixture bed is increased too high, and gas permeability is deteriorated. When gas pressure is further increased, leakage of gas is increased between the hood and a member coming into contact with the hood, so that it becomes difficult to seal, and equipment cost is increased.

- a negative pressure of suction given to the wind box arranged immediately below the pallets is set in the range from -2000 to -1 mmAq. The reason why the negative pressure of suction given to the wind box is set as described above will be explained as follows.

- the negative pressure is lower than -2000 mmAq, even if the upper portion of the raw mixture bed is compressed, the static pressure in the raw mixture bed is substantially the same as that of the method of the conventional method. Accordingly, a rate of heat transfer caused by the increase in the coke burning speed and the increase in gas density is low.

- the negative pressure is higher than -1 mmAq, it becomes impossible to suck exhaust gas.

- a pressure drop between the upper and the lower portion of the raw mixture bed in the range from the igniting section to a position distant from the igniting section by 30 to 95% of the strand length is 1000 to 3000 mmAq.

- the pressure drop between the upper and the lower portion of the raw mixture bed is smaller than 1000 mmAq, the pressure drop in the raw mixture bed is smaller than that of the method of the conventional method. Accordingly, a bad influence is exerted by the reduction of gas velocity rather than the effect obtained by increasing the static pressure.

- a mass flow rate of gas containing oxygen sucked into the raw mixture bed in the range from the igniting section to the position distant from the igniting section by 30 to 95% of the strand length is adjusted to be 1.01 to 2.6 times as high as the mass flow rate of gas containing oxygen supplied to the raw mixture bed in the ranges except for the aforementioned range, and a pressure drop in the direction of the thickness of the raw mixture bed is adjusted to be 1.1 to 5.0 times as high as that in the direction of the thickness of the raw mixture bed in the strand range except for the aforementioned range.

- gas is supplied from an upper portion of the raw mixture bed by the pressure of 100 to 1000 mmAq, and the negative pressure of suction from the wind box arranged immediately below the pallets is set at -1000 to -1 mmAq.

- the pressure drop between the upper and the lower portion of the raw material layer is adjusted at 300 to 2000 mmAq, so that the pressure drop is made to be the same as or smaller than the pressure drop of the conventional suction conducted from a lower portion. In this way, the period of time for holding a high temperature can be ensured or extended, and a quantity of heat necessary for sintering can be obtained.

- the oxygen supplying rate onto the upper layer of the raw material is increased at this time, it is possible to obtain an effect of enhancing the burning property of coke in the same manner as that of enrichment with oxygen. Accordingly, it is possible to further enhance the product yield and quality of the upper layer in the raw material.

- the pressure hood is arranged in a range from the igniting section to the position distant from the igniting section by 30 to 95% of the strand length. Further, when pressure hood is divided into a plurality of portions in the longitudinal direction of the strand, it becomes possible to change stepwise a mass flow rate from the igniting section side to the sintercake discharging section side.

- the resistance of gas permeability in a portion of the raw mixture bed close to the side wall of the pallets, which is distant from the side wall by a distance not larger than 5% in the width direction, is not higher than the resistance of gas permeability at the center of the raw mixture bed. Accordingly, the moving speed of the combustion and melting speed is high in this portion. Therefore, when the pressure hood is arranged in a range from 5 to 95% of the raw mixture bed in the width direction and gas is applied so that the moving speed of the combustion and melting zone can be made uniform in the width direction, the effect of increasing the moving speed of the combustion and melting zone can be further enhanced.

- the pressure hood is arranged in an upper portion of the sintering pallets which are moving, in order to prevent the leakage of a blast of gas, it is preferable to arrange a sealing mechanism at a lower end of the pressure hood.

- a sealing mechanism is shown in Fig. 6, a sheet 24 is arranged at the lower end portion of the pressure hood 19. When the sheet 24 is pressed against an upper surface of the raw mixture bed 7 by the internal pressure of the pressure hood 19, sealing can be attained. When the pallets are moved, the sheet 24 slides on the upper surface of the raw mixture bed 7.

- the sealing mechanism is not limited to the above specific example. For example, several stages of sealing mechanisms may be arranged, or air is blown to between the pressure hood 19 and the raw mixture bed 7 from the outside of the pressure hood 19, or alternatively a sealing mechanism may be arranged by utilizing the side walls of the pallets 6.

- gas the oxygen concentration of which has already been adjusted to a value in the range from 12 to 21 vol%

- the generation of magnetite effective for enhancing RDI can be enhanced, and the oxidation of nitrogen contained in coke into NOx can be suppressed. That is, it is effective for improving RDI and suppressing the generation of NOx.

- the capacity of a blower for circulating exhaust gas is designed by giving consideration to the negative pressure of suction, gas volume and size of the apparatus so that exhaust gas can be sent to an exhaust gas control device after it has been fed from an upper portion of the raw mixture bed.

- the concentration of oxygen is lower than 21 vol%, RDI can be improved because the generation of magnetite is enhanced, and further the oxidation of nitrogen contained in coke to NOx can be suppressed because the concentration of oxygen is low.

- the concentration of oxygen is lower than 12 vol%, a bad influence caused by the reduction of productivity becomes remarkable.

- the concentration of oxygen is maintained not lower than 12 vol% and lower than 21 vol%.

- RDI can be remarkably improved and the generation of NOx can be effectively suppressed.

- a sintering machine includes a plurality of plate-shaped sintered ore supporting stands arranged in parallel with the pallet advancing direction in the width direction, so that sintered ore can be supported by the plurality of plate-shaped sintered ore supporting stands. Due to the above arrangement, a load of sintered ore is not given to the lower layer of the raw material layer. Therefore, the gas permeability on the lower layer of the raw material can be improved. As a result, the productivity can be greatly improved. In accordance with the reduction of the load of sintered ore, it becomes possible to increase a pressure drop between an upper portion and a lower portion of the raw mixture bed. Therefore, the productivity can be further enhanced.

- the most appropriate number of the plate-shaped sintered ore supporting stands 21 depends upon the size of the pallet 6. For example, in the case of a sintering machine, the width of the pallet of which is 4 m, the length of the pallet of which is 1.5 m, the thickness of the raw mixture bed of which is 500 to 600 mm, it is preferable that the number of the plate-shaped sintered ore supporting stands 21 is 2 to 10 and the height is 200 to 400 mm. The larger the number of the sintered ore supporting stands is, the higher effect can be provided for supporting sintered ore. However, when the number of the sintered ore supporting stands exceeds 10, a volume occupied by the sintered ore supporting stands is increased.

- the productivity is deteriorated on the contrary.

- the gas permeability can be further enhanced, and the burning rate of coke is increased. Accordingly, the generation of CO is increased, and a chemical reaction to reduce NO by CO gas generated in the above process becomes active. In this way, the generation of NOx can be suppressed.

- a plurality of sintered ore supporting stands are arranged according to the present invention, it is possible to realize the suppression of generation of NOx, the enhancement of productivity, the enhancement of production yield and the enhancement of quality of sintered ore, which are difficult to be compatible with each other by the method of the conventional method.

- the present invention is effective especially when sintered ore containing SiO 2 by 3.9 to 4.9 mass% is produced.

- the reason is described as follows.

- SiO 2 content is not higher than 4.9 mass%, a compounding ratio of lime stone is lowered, and the principal components of slag such as CaO and SiO 2 are decreased. Due to the foregoing, the productivity and RDI starts being deteriorated, and when SiO 2 content becomes lower than 3.9 mass%, it is impossible to improve the productivity and RDI even by the present invention.

- a mass flow rate of gas containing oxygen sucked to the raw mixture bed in the range from the igniting section to the position distant from the igniting section by 30 to 95% of the strand length is adjusted to be only 2.6 times as high as the mass flow rate of gas containing oxygen sucked to the raw mixture bed in the ranges except for the aforementioned range. Therefore, in the sintering operation in which the thickness of the raw mixture bed is 400 to 600 mm which is the layer thickness of the conventional method, it is possible to increase the moving speed of the sintering pallets twice as high as that of the method of the conventional method.

- the thickness of the raw mixture bed is 600 to 1500 mm which is more than twice as large as the thickness of the method of the conventional method. Due to the foregoing, it is possible to enhance the productivity of the sintering machine twice as high as the productivity of the sintering machine of the conventional method at the maximum. In this way, the productivity can be greatly enhanced, and the product yield and quality can be enhanced and further the unit requirement of exhaust gas volume can be reduced. It is also possible to enhance the product yield and quality and decrease the unit requirement of exhaust gas volume while the productivity is kept constant.

- the sintering machine used for the method of producing sintered ore of the present invention is composed as follows.

- a plurality of wind boxes arranged in a lower portion of the sintering strand are connected with a suction duct in parallel with each other, and a main blower is arranged in the suction duct.

- another blower is arranged for sucking gas from the duct in a range from the igniting section to a position distant from the igniting section by 30% of the length of the suction duct, and for discharging gas into the suction duct.

- a mass flow rate of gas containing oxygen sucked into the raw mixture bed in the range from the igniting section to the position distant from the igniting section by 30 to 95% of the strand length is adjusted to be 1.01 to 2.6 times as high as the mass flow rate of gas containing oxygen applied to the raw mixture bed in the ranges except for the aforementioned range, and a difference in pressure in the direction of the thickness of the raw mixture bed further can be adjusted to be 1.1 to 5.0 times as high as that in the direction of the thickness of the raw mixture bed in the strand range except for the aforementioned range.

- the suction duct is divided into a range located from the igniting section to the position distant from the igniting section by 30 to 95% of the strand length and a residual range, and blowers are independently arranged in the respective divided regions.

- the blowers may be respectively arranged in the first stage, intermediate stage and latter stage.

- the first stage and the latter stage are connected with each other, and two blowers are arranged, wherein one blower is used for the intermediate stage in the range from the igniting section to the position distant from the igniting section by 30 to 95% of the strand length, and the other blower is used for the ranges except for the aforementioned range.

- a hood is arranged above the raw mixture bed to be pressurized, so that pressure is given inside the hood, and pressure in the hood and pressure in the wind box located below the hood are measured. Further, it is preferable that a sealing mechanism is arranged between the hood and the raw material packed layer and/or between the hood and the pallets.

- Figs. 1 to 3 are schematic illustrations showing an example of the sintering machine of the present invention.

- Blended sintering material 1 is continuously supplied from the surge hopper 2 onto the pallets 6 via the drum feeder 3 and raw material charging device 5.

- blended sintering material 1 is fed onto the pallets 6, it is laminated on the pallets 6 as a raw mixture bed 7.

- the sprocket 4 arranged on the raw material feeding side is rotated, so that the pallets 6 are moved at a predetermined speed, and at the same time, gas is sucked by the blower 11 via a plurality of wind boxes 8 arranged on the lower side of the pallets 6, main duct 9 and dust collector 10 for collecting dust from exhaust gas.

- a sub-duct 13 through which gas is sucked by the blower 15 via the dust collector 14 for collecting dust from exhaust gas.

- the thus sucked exhaust gas is returned to the main duct 9. It is possible to discharge exhaust gas, which has been sucked by the blower 15, from the stack 12. It is preferable to arrange dampers 16 in the main duct 9 to adjust negative pressure in the duct.

- This sintering machine is continuously operated as follows. An upper surface of the raw mixture bed is ignited by the ignition furnace 27, and the moving speed of the pallets 6 is controlled so that the entire raw mixture bed 7 on the pallets 6 can be sintered until it reaches the sintercake discharging section. Exhaust gas can be circulated from a portion before the stack 12 into the pressure hood 19 by the blower 18, and at the same time air can be mixed with exhaust gas.

- the sealing mechanism 23 is arranged between the surface layer of the raw material and the lower end portion of the pressure hood 19 as shown in Fig. 6. Internal pressure of the pressure hood 19 can be kept by the action of this sealing mechanism 23.

- the inventors did not particularly aim at producing sintered ore of low SiO 2 , but they adopted a conventional common composition, that is, various iron ores, lime stone, quick lime, serpentine, scale, returned ore and coke breeze were adjusted so that SiO 2 content in sintered ore could be 5.8 mass%, Al 2 O 3 content in sintered ore could be 1.8 mass% and the basicity of sintered ore could be 1.7.

- a ratio of returned iron ore to new raw material was determined to be 15% with respect to 100 of new raw material, and it was kept constant.

- a ratio of coke to new raw material was determined to be 4.2% with respect to 100 of new raw material, and it was kept constant.

- the composition of the comparative example and that of the inventive example were the same.

- Example 1a sintering operation was conducted in the following operational conditions. Thickness of the raw material layer was 550 mm. Gas was sucked downward in such a manner that pressure in a range from the igniting section to the position distant from the igniting section by 30% of the strand length was -1500 mmAq, and also pressure in a range from the position distant from the igniting section by 95% of the strand length to the sintercake discharging section was -1500 mmAq, and also pressure in a range from the position distant from the igniting section by 30% of the strand length to the position distant from the igniting section by 95% of the strand length was -2500 mmAq, and an upper portion of the raw material layer was open to the atmosphere.

- a mass flow rate in the range of the strand length of 30 to 95% with respect to the ranges except for the aforementioned range was 1.26

- a pressure drop in the layer thickness direction was 2500 mmAq.

- Example 1b sintering operation was conducted in the following operational conditions. Thickness of the raw material layer was 550 mm. Gas was sucked downward by the pressure of -1000 mmAq in the range from the igniting section to the sintercake discharging section. Pressure of 1500 mmAq was given to the inside of the pressure hood arranged in an upper portion of the raw mixture bed in the range from 30 to 95% of the strand length. In this case, a mass flow rate in the range of the strand length of 50 to 95% with respect to the ranges except for the aforementioned range was 1.27, and a difference in pressure in the layer thickness direction was 2500 mmAq.

- Example 1c sintering operation was conducted in the following operational conditions. Thickness of the raw material layer was 550 mm. Gas was sucked downward in such a manner that pressure in a range from the igniting section to the position distant from the igniting section by 30% of the strand length was -500 mmAq, and also pressure in a range from the position distant from the igniting section by 95% of the strand length to the sintercake discharging section was -500 mmAq. The pressure hood was continuously arranged in the aforementioned ranges, and pressure of 500 mmAq was given to the inside of the pressure hood.

- Example 1d sintering operation was conducted in the following operational conditions. Thickness of the raw material layer was 550 mm. Gas was sucked downward by the pressure of -1000 mmAq in the range from the igniting section to the sintercake discharging section. Exhaust gas before the stack was circulated in the pressure hood arranged in the range of 50 to 90% of the strand length and 10 to 90% in the width direction of the pallets, and the concentration of oxygen was adjusted to 18 vol% and the pressure of 1500 mmAq was given into the pressure hood. In this case, in the range of 50 to 90% of the strand length, a mass flow rate was 1.27 with respect to the ranges except for the aforementioned range, and a difference in pressure in the layer thickness direction was 2500 mmAq.

- Example 1e sintering operation was conducted in the following conditions.

- the layer thickness was 550 mm.

- On the pallet there were arranged four plate-shaped sintered ore supporting stands in the pallet width direction at regular intervals. Gas was sucked downward by the negative pressure of -1000 mmAq in the range from the igniting section to the sintercake discharging direction.

- the pressure of 1500 mmAq was given to the inside of the pressure hood arranged in the range of 50 to 90% of the strand length and 10 to 90% in the pallet width direction.

- a mass flow rate was 1.27 with respect to the ranges except for the aforementioned range, and a difference in pressure in the layer thickness direction was 2500 mmAq.

- Example 1f the layer thickness was 800 mm, and other conditions were the same as those of Example 1e.

- a mass flow rate was 1.27 with respect to the ranges except for the aforementioned range, and a pressure drop in the layer thickness direction was 2500 mmAq.

- the same blended raw material as that of the inventive example was charged onto the pallets by the layer thickness of 550 mm, and the atmosphere was sucked in the range from the igniting section to the sintercake discharging section while the negative pressure of -1500 mmAq was kept constant, so that the blended raw material layer was sintered in the negative pressure according to the method of the conventional method.

- Figs. 4 and 5 are schematic illustrations showing another example of the sintering machine of the present invention. Different points of this example from the example shown in Figs. 1 to 3 are that the main duct 9 is completely divided and the blowers 11, 15 are independently arranged. Further, the blower 29 may be arranged in this example. When a plurality of pressure patterns are set, a plurality of blowers may be arranged as described above.

- Blended raw material used in this example was the same as that of Example 1, and the pallet moving speed was adjusted so that the sintering completion point could be the same position as that of the sintercake discharging section.

- Example 2a sintering operation was conducted in the following conditions. Thickness of the raw mixture bed was 550 mm. Gas was sucked downward in such a manner that pressure was kept at -1000 mmAq in the range from the igniting section to a position distant from the igniting section by 50% of the strand length, and also pressure was kept at -1500 mmAq in the range from a position distant from the igniting section by 80% of the strand length to the sintercake discharging section. An upper portion of the raw mixture bed was open to the atmosphere.

- Example 2b sintering operation was conducted in the following conditions. Thickness of the raw mixture bed was 550 mm. Gas was sucked downward at the negative pressure of -500 mmAq in the range from the igniting section to a position distant from the igniting section by 50% of the strand length, and the pressure hood was further arranged in this range, and pressure of 500 mmAq was given to the inside of the pressure hood. Gas was sucked downward at the negative pressure of -1000 mmAq in the range from a position distant from the igniting section by 80% of the strand length to the sintercake discharging section, and the pressure of 500 mmAq was given to the inside of the pressure hood.

- Example 2c the layer thickness was 800 mm, and other conditions were the same as those of Example 2a.

- a mass flow rate was 1.52 with respect to the ranges except for the aforementioned range, and a pressure drop in the layer thickness direction was 2500 mmAq.

- Example 2d the layer thickness was 800 mm.

- Four plate-shaped sintered ore supporting stands were arranged on the pallet in the pallet width direction at regular intervals. Other points of this example were the same as those of Example 2a.

- a mass flow rate was 1.52 with respect to the ranges except for the aforementioned range, and a pressure drop in the layer thickness direction was 2500 mmAq.

- Comparative Example 1 sintering operation was conducted according to the method of the conventional method in which the same blended raw material as that of Examples 2a to 2d was used and the thickness of the raw mixture bed was set at 550 mm. The atmosphere was sucked at the negative pressure of -1500 mmAq in the range from the igniting section to the sintercake discharging section, so that the blended raw material layer was sintered in the negative pressure.

- Example 3 The same sintering machine as that of Examples 1 and 2 was used in Example 3.

- various iron ores, lime stone, quick lime, serpentine, scale, returned ore and coke breeze were adjusted so that SiO 2 contained in sintered ore could be 4.6 mass%, Al 2 O 3 contained in sintered ore could be 1.85 mass% and the basicity of sintered ore could be 1.9.

- a ratio of returned iron ore to new raw material was determined to be 15% with respect to 100 of new raw material, and it was kept constant.

- a ratio of coke to new raw material was determined to be 3.5% with respect to 100 of new raw material, and it was kept constant.

- the composition of the comparative example and that of the inventive example were the same.

- Example 3a sintering operation was conducted in the following operational conditions. Thickness of the raw material layer was 550 mm. Gas was sucked downward in such a manner that pressure in a range from the igniting section to the position distant from the igniting section by 60% of the strand length was -1500 mmAq, and also pressure in a range from the position distant from the igniting section by 80% of the strand length to the ore discharging section was -1500 mmAq. The atmosphere was sucked downward in the range from 60 to 80% of the strand length at the negative pressure of -2500 mmAq. In this case, a mass flow rate in the range of the strand length of 60 to 80% with respect to the ranges except for the aforementioned range was 1.26, and a difference in pressure in the layer thickness direction was 2500 mmAq.

- Example 3b sintering operation was conducted in the following conditions. Thickness of the raw mixture bed was 550 mm. Gas was sucked downward at the negative pressure of -1500 mmAq in the initial stage of sintering from the igniting section to the position distant from the igniting section by 60% of the strand length and also in the final stage of sintering from the position distant from the igniting section by 80% of the strand length to the sintercake discharging section.

- a portion of exhaust gas discharged from the above range was mixed with air so that the oxygen concentration could be 16 vol%, and the thus mixed gas was circulated into an upper portion of the pallet located in the range from 60 to 80% of the strand length and sucked downward at the negative pressure of -2500 mmAq.

- a mass flow rate in the range of the strand length of 60 to 80% with respect to the ranges except for the aforementioned range was 1.38, and a pressure drop in the layer thickness direction was 2500 mmAq.

- Example 3c sintering operation was conducted in the following operational conditions. Thickness of the raw material layer was 550 mm. Gas was sucked downward in such a manner that pressure in a range from the igniting section to the position distant from the igniting section by 60% of the strand length was -500 mmAq, and also pressure in a range from the position distant from the igniting section by 80% of the strand length to the sintercake discharging section was -500 mmAq. The pressure hood was continuously arranged in the aforementioned ranges, and pressure of 500 mmAq was given to the inside of the pressure hood.

- Gas was sucked downward in the range from 60 to 80% of the strand length by the negative pressure of -1500 mmAq, and the pressure of 1000 mmAq was given to the inside of the pressure hood.

- the oxygen concentration of a portion of exhaust gas before the stack was adjusted to 16%, and gas was blown with pressure.

- a mass flow rate in the range of the strand length of 60 to 80% with respect to the ranges except for the aforementioned range was 1.56, and a pressure drop in the layer thickness direction was 2500 mmAq.

- Comparative Example 2 sintering operation was conducted according to the method of the conventional method in which the same blended raw material as that of Examples 3a to 3c was used and the thickness of the raw mixture bed was set at 550 mm. The atmosphere was sucked at the negative pressure of -1500 mmAq in the range from the igniting section to the sintercake discharging section, so that the blended raw material layer was sintered in the negative pressure.

- the negative pressure in the process of sintering, the oxygen concentration of sucked gas and the sucking time are not limited to the above specific examples, but it is possible to change them in accordance with the directivity to improvements in productivity and JIS-RI, and also in accordance with the directivity to suppression of exhausted NOx and decrease in the volume of exhaust gas.

- the present invention it is possible to greatly increase the thickness of a blended raw material layer and also it is possible to greatly increase the pallet moving speed which is difficult according to the method of the conventional method. Therefore, the productivity of a sintering machine can be greatly enhanced. Further, the product yield, RDI and JIS-RI can be improved by the present invention, and further a volume of exhaust gas can be decreased. As described above, it is possible for the present invention to provide the effects, which are incompatible with each other according to the method of the conventional method, at the same time, that is, the effects provided by the present invention are very great.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Manufacturing & Machinery (AREA)

- Geochemistry & Mineralogy (AREA)

- Geology (AREA)

- General Life Sciences & Earth Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Environmental & Geological Engineering (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Manufacture And Refinement Of Metals (AREA)

Abstract

Description

| Comparative Example 1 | Inventive Example | ||||||

| 1a | 1b | 1c | 1d | 1e | 1f | ||

| Productivity (t/d/m2) | 37.0 | 51.2 | 53.6 | 60.2 | 50.3 | 59.8 | 61.9 |

| Product yield (%) | 85.7 | 86.7 | 88.0 | 89.4 | 86.6 | 88.8 | 91.7 |

| RDI (%) | 35.0 | 33.8 | 33.2 | 32.9 | 33.5 | 31.0 | 32.6 |

| JIS-RI (%) | 68.3 | 72.3 | 73.9 | 74.8 | 73.5 | 76.8 | 75.3 |

| Consumption unit of exhausted NOx (Nm3/t) | 0.32 | 0.31 | 0.27 | 0.26 | 0.31 | 0.25 | 0.26 |

| Comparative example 2 | Inventive example | |||

| 3a | 3b | 3c | ||

| Productivity (t/d/m2) | 35.8 | 45.7 | 42.2 | 46.5 |

| Product yield (%) | 80.1 | 80.9 | 80.5 | 81.6 |

| RDI (%) | 35.4 | 33.2 | 33.8 | 33.9 |

| JIS-RI (%) | 65.6 | 74.6 | 72.7 | 72.5 |

| Consumption unit of exhausted NOx (Nm3/t) | 0.34 | 0.30 | 0.26 | 0.27 |

- 1

- Blended sintering material

- 2

- Surge hopper

- 3

- Drum feeder

- 4

- Sprocket

- 5

- Raw material charging device

- 6

- Pallet

- 7

- Raw mixture bed

- 8

- Wind box

- 9

- Main duct

- 10

- Exhaust gas dust collector

- 11

- Blower

- 12

- Stack

- 13

- Sub-duct

- 14

- Exhaust gas dust collector

- 15

- Blower

- 16

- Damper

- 17

- Exhaust gas dust collector

- 18

- Blower

- 19

- Pressure hood

- 21

- Sintered ore supporting stand

- 22

- Grate bar

- 23

- Sealing mechanism

- 24

- Sheet

- 25

- Sponge

- 26

- Blower

- 27

- Ignition furnace

Claims (17)

- A method of producing sintered ore, the product yield and the product quality of which are high, comprising the steps of:charging blended raw material containing fine ore, flux and fuel onto pallets of a sintering machine so as to form a raw mixture bed on the pallets; andsubsequently igniting a surface layer of the raw mixture bed so as to cause a sintering reaction on the raw mixture bed in the direction from an upper portion to a lower portion, wherein when the upper layer of the raw material has been sufficiently sintered, a mass flow rate of gas containing oxygen supplied onto the raw mixture bed is changed to a value 1.01 to 2.6 times as high as that of gas containing oxygen supplied in the sintering of the upper layer of the raw material.

- A method of continuously producing sintered ore, the product yield and the product quality of which are high, comprising the steps of:charging blended raw material containing powder ore, flux and fuel onto pallets of a sintering machine so as to form a raw mixture bed on the pallets; andsubsequently igniting a surface layer of the raw mixture bed while a combustion and melting zone is being moved from an upper portion to a lower portion, wherein when an end of a forming range of the combustion and melting zone has reached a position lower than a position located at 20% of the height of the raw mixture bed from the surface layer, a mass flow rate of gas containing oxygen supplied onto the raw mixture bed is changed to a value 1.01 to 2.6 times as high as that of gas containing oxygen supplied in the range of sintering of the raw mixture bed before reaching said position.

- A method of producing sintered ore according to claim 1 or 2, further comprising the steps of:arranging a pressure hood for giving pressure to gas containing oxygen on the raw mixture bed on the sintering pallets;giving pressure of 100 to 3000 mmAq to gas in the pressure hood with respect to the atmospheric pressure; andsucking gas from a lower portion of the raw mixture bed by the negative pressure of -2000 to -1 mmAq with respect to the atmospheric pressure.

- A method of producing sintered ore according to any one of claims 1 to 3, further comprising the steps of:arranging a pressure hood for giving pressure to gas containing oxygen in a range from 5 to 95% in the pallet width direction on the raw mixture bed on the sintering pallets; andgiving pressure of 100 to 3000 mmAq to gas in the pressure hood with respect to the atmospheric pressure.

- A method of producing sintered ore according to claim 3 or 4, further comprising the steps of:arranging a pressure hood for giving pressure to gas containing oxygen on the raw material layer in a range after an end of a forming range of the combustion and melting zone has reached a position located at 20% of the height of the raw mixture bed from the surface layer; andgiving pressure of 100 to 3000 mmAq to gas in the pressure hood with respect to the atmospheric pressure.

- A method of producing sintered ore according to any one of claims 3 to 5, wherein sintering exhaust gas is circulated in the pressure hood for giving pressure to gas containing oxygen arranged on the raw mixture bed layer.

- A method of producing sintered ore according to any one of claims 1 to 6, wherein sintering is conducted on iron ore by a Dwight Lloyd type sintering machine in which a plurality of plate-shaped sintered ore supporting stands are arranged on the grates of the sintering pallets substantially in parallel with the pallet advancing direction.

- A method of producing sintered ore according to any one of claims 1 to 7, wherein sintered ore containing SiO2 of 3.9 to 4.9 mass% in chemical composition is produced by the method.

- A method of producing sintered ore according to any one of claims 1 to 8, wherein layer thickness of the raw mixture bed layer is 600 to 1500 mm.

- A sintering machine of down-suction type comprising:a plurality of wind boxes arranged in a lower portion of the sintering strand, the wind boxes being connected with a suction duct in parallel with each other;a main blower arranged in the suction duct; andanother blower for sucking gas from the duct in a range from 30% of the length from the igniting section to the sintercake discharging section, to the sintering completion point, and for discharging gas into the suction duct.

- A sintering machine comprising:a plurality of wind boxes arranged in a lower portion of the sintering strand, the wind boxes being connected with a suction duct in parallel with each other, wherein the suction duct is divided into a range from 30% of the length of the strand from the igniting section to the sintercake discharging section, to the sintering completion point, and into a residual range; andblowers independently arranged in the ranges.

- A sintering machine according to claim 10 or 11, further comprising a pressure hood for feeding and compressed gas containing oxygen, arranged on the raw mixture bed on the sintering pallets.

- A sintering machine according to claim 10 or 11, further comprising a pressure hood for supplying and compressed gas containing oxygen, arranged on the raw mixture bed in a range in which an end of a forming range of the combustion and melting zone has reached a position located lower than the surface layer of the raw mixture bed by a distance of 20% of the height of the raw mixture bed.

- A sintering machine according to claim 12 or 13, further comprising a pressure hood for supplying and compressed gas containing oxygen, arranged on the raw mixture bed on the sintering pallets in a range of 5 to 95% in the pallet width direction.

- A sintering machine according to any one of claims 12 to 14, wherein sintering exhaust gas is circulated in the pressure hood for supplying and compressed oxygen arranged on the raw mixture bed layer.

- A sintering machine according to any one of claims 12 to 15, wherein a sealing mechanism is arranged in a lower end portion of the pressure hood for supplying and compressed gas containing oxygen.

- A sintering machine of the down-suction type according to any one of claims 10 to 16, further comprising a plurality of plate-shaped sintered ore supporting stands arranged on the grates of the sintering pallets substantially in parallel with the pallet advancing direction.

Applications Claiming Priority (10)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP23369696 | 1996-08-16 | ||

| JP233696/96 | 1996-08-16 | ||

| JP23369696 | 1996-08-16 | ||

| JP27858696 | 1996-10-01 | ||

| JP27858696 | 1996-10-01 | ||

| JP278586/96 | 1996-10-01 | ||

| JP18026597 | 1997-06-23 | ||

| JP18026597 | 1997-06-23 | ||

| JP180265/97 | 1997-06-23 | ||

| PCT/JP1997/002843 WO1998007891A1 (en) | 1996-08-16 | 1997-08-15 | Method of manufacturing sintered ore and sintering machine therefor |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0861908A1 true EP0861908A1 (en) | 1998-09-02 |

| EP0861908A4 EP0861908A4 (en) | 1998-10-07 |

| EP0861908B1 EP0861908B1 (en) | 2002-10-09 |

Family

ID=27324816

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP97935796A Expired - Lifetime EP0861908B1 (en) | 1996-08-16 | 1997-08-15 | Method of manufacturing sintered ore and sintering machine therefor |

Country Status (8)

| Country | Link |

|---|---|

| EP (1) | EP0861908B1 (en) |

| JP (1) | JP3930570B2 (en) |

| KR (1) | KR100257441B1 (en) |

| CN (1) | CN1062913C (en) |

| AU (1) | AU697445B2 (en) |

| BR (1) | BR9706625A (en) |

| DE (1) | DE69716231T2 (en) |

| WO (1) | WO1998007891A1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2007082694A1 (en) * | 2006-01-19 | 2007-07-26 | Siemens Vai Metals Technologies Gmbh & Co | Process for sintering on a sintering machine |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101074893B1 (en) * | 2005-10-31 | 2011-10-19 | 제이에프이 스틸 가부시키가이샤 | Process for producing sintered ore |

| JP4590001B2 (en) * | 2008-02-27 | 2010-12-01 | 新日本製鐵株式会社 | Method for producing sintered ore and sintering machine |

| JP5488209B2 (en) * | 2010-06-02 | 2014-05-14 | 新日鐵住金株式会社 | Method for producing sintered ore, design method for sinter cake support stand, and method for determining layer thickness of raw material packed bed |

| CN101881559B (en) * | 2010-07-22 | 2011-11-16 | 张健 | Novel energy-saving sintering machine |

| CN104797720B (en) | 2012-11-20 | 2017-05-24 | 杰富意钢铁株式会社 | Oxygen-gas fuel supply device for sintering machine |

| CN103033064B (en) * | 2012-12-28 | 2015-03-11 | 北京世纪源博科技股份有限公司 | Device for recovering waste heat of sintering flue gas |

| CN103033063B (en) * | 2012-12-28 | 2016-05-18 | 北京世纪源博科技股份有限公司 | Sinter fume exhaust heat recovering method |

| JP7099700B2 (en) | 2017-06-19 | 2022-07-12 | ユニチカ株式会社 | Bismaleimide modified product and its manufacturing method |

| JP7384268B2 (en) * | 2020-02-27 | 2023-11-21 | Jfeスチール株式会社 | Method for producing sintered ore |

| CN113215390B (en) * | 2020-12-24 | 2022-07-22 | 北京高能时代环境技术股份有限公司 | Copper-containing sludge sintering method |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0273924A (en) * | 1988-09-09 | 1990-03-13 | Nippon Steel Corp | Oxygen-enriching operation in sintering machine |

| JPH0543951A (en) * | 1991-08-13 | 1993-02-23 | Nippon Steel Corp | Method for operating sintering machine |

| EP0535727B1 (en) * | 1991-10-03 | 1995-11-02 | METALLGESELLSCHAFT Aktiengesellschaft | Method for sintering iron oxide containing material on a sintering machine |

| JPH08100222A (en) * | 1994-08-03 | 1996-04-16 | Nippon Steel Corp | Production of sintered ore |

-

1997

- 1997-08-15 CN CN97191095A patent/CN1062913C/en not_active Expired - Lifetime

- 1997-08-15 BR BR9706625-7A patent/BR9706625A/en not_active Application Discontinuation

- 1997-08-15 WO PCT/JP1997/002843 patent/WO1998007891A1/en active IP Right Grant

- 1997-08-15 JP JP51056998A patent/JP3930570B2/en not_active Expired - Lifetime

- 1997-08-15 AU AU38653/97A patent/AU697445B2/en not_active Expired

- 1997-08-15 EP EP97935796A patent/EP0861908B1/en not_active Expired - Lifetime

- 1997-08-15 DE DE69716231T patent/DE69716231T2/en not_active Expired - Lifetime

-

1998

- 1998-04-16 KR KR1019980702769A patent/KR100257441B1/en active IP Right Grant

Non-Patent Citations (2)

| Title |

|---|

| No further relevant documents disclosed * |

| See also references of WO9807891A1 * |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2007082694A1 (en) * | 2006-01-19 | 2007-07-26 | Siemens Vai Metals Technologies Gmbh & Co | Process for sintering on a sintering machine |

| US7914731B2 (en) | 2006-01-19 | 2011-03-29 | Siemens Vai Metals Technology GmbH & Co. | Process for sintering on a sintering machine |

| AU2007207112B2 (en) * | 2006-01-19 | 2011-07-21 | Primetals Technologies Austria GmbH | Process for sintering on a sintering machine |

Also Published As

| Publication number | Publication date |

|---|---|

| CN1062913C (en) | 2001-03-07 |

| EP0861908A4 (en) | 1998-10-07 |

| EP0861908B1 (en) | 2002-10-09 |

| JP3930570B2 (en) | 2007-06-13 |

| DE69716231T2 (en) | 2003-08-14 |

| AU697445B2 (en) | 1998-10-08 |

| CN1198779A (en) | 1998-11-11 |

| WO1998007891A1 (en) | 1998-02-26 |

| AU3865397A (en) | 1998-03-06 |

| KR100257441B1 (en) | 2000-05-15 |

| BR9706625A (en) | 1999-11-23 |

| DE69716231D1 (en) | 2002-11-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN100510004C (en) | Coke oven flue gas sharing | |

| CN100463975C (en) | Production of sponge iron | |

| EP0861908B1 (en) | Method of manufacturing sintered ore and sintering machine therefor | |

| JP6005897B2 (en) | Method for producing sintered ore | |

| WO2001018256A1 (en) | Method and facilities for metal smelting | |

| JP4054505B2 (en) | Exhaust gas circulation method sintering operation method | |

| CN102409126A (en) | Integrated reduction ironmaking furnace and integrated reduction ironmaking process | |

| JP3879408B2 (en) | Method for producing sintered ore and sintered ore | |

| JP4085493B2 (en) | Manufacturing method of high quality sintered ore | |

| JP2000017343A (en) | Two-stage ignition type production of sintered ore | |

| JPH11209827A (en) | Production of sintered ore | |

| CN2509538Y (en) | Air-blast sintering machine | |

| JP3642027B2 (en) | Blast furnace operation method | |

| KR0118997B1 (en) | Method and apparatus for sintering ore | |

| CN2259246Y (en) | External firing coal oxidized pellet ore shaft furnace | |

| JPH09227958A (en) | Operation of endless shifting type sintering machine and high-quality sintered ore | |

| EP4324938A1 (en) | Method for producing agglomerated ore, method for producing reduced iron, agglomerated ore, sintering machine and pellet firing furnace | |

| JPH11279668A (en) | Production of sintered ore and sintering machine | |

| JPH09209049A (en) | Manufacture of sintered ore | |

| JPH11279667A (en) | Production of sintered ore | |

| US3288449A (en) | Apparatus for indurating ore particles | |

| JPH09279261A (en) | Two-stage ignition type sintering method | |

| JPH08100222A (en) | Production of sintered ore | |

| JPH07286216A (en) | Sintering method by waste gas circulation and waste gas circulation equipment | |

| JPS60106927A (en) | Production of sintered ore |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19980513 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): DE FR GB |

|

| A4 | Supplementary search report drawn up and despatched | ||

| AK | Designated contracting states |

Kind code of ref document: A4 Designated state(s): DE FR GB |

|

| 17Q | First examination report despatched |

Effective date: 20000309 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FR GB |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REF | Corresponds to: |

Ref document number: 69716231 Country of ref document: DE Date of ref document: 20021114 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20030710 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 69716231 Country of ref document: DE Representative=s name: VOSSIUS & PARTNER PATENTANWAELTE RECHTSANWAELT, DE Effective date: 20130227 Ref country code: DE Ref legal event code: R082 Ref document number: 69716231 Country of ref document: DE Representative=s name: VOSSIUS & PARTNER, DE Effective date: 20130227 Ref country code: DE Ref legal event code: R081 Ref document number: 69716231 Country of ref document: DE Owner name: NIPPON STEEL & SUMITOMO METAL CORPORATION, JP Free format text: FORMER OWNER: NIPPON STEEL CORP., TOKIO/TOKYO, JP Effective date: 20130227 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: CD Owner name: NIPPON STEEL & SUMITOMO METAL CORPORATION, JP Effective date: 20130913 Ref country code: FR Ref legal event code: CA Effective date: 20130913 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20160809 Year of fee payment: 20 Ref country code: GB Payment date: 20160810 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20160712 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 69716231 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 Expiry date: 20170814 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20170814 |