EP0822285A2 - Verfahren zum Verbinden von zwei Bahnen, insbesondere faserige Bahnen - Google Patents

Verfahren zum Verbinden von zwei Bahnen, insbesondere faserige Bahnen Download PDFInfo

- Publication number

- EP0822285A2 EP0822285A2 EP97401826A EP97401826A EP0822285A2 EP 0822285 A2 EP0822285 A2 EP 0822285A2 EP 97401826 A EP97401826 A EP 97401826A EP 97401826 A EP97401826 A EP 97401826A EP 0822285 A2 EP0822285 A2 EP 0822285A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- blanks

- fibrous material

- jet

- blank

- water

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 238000000034 method Methods 0.000 title claims abstract description 15

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims abstract description 24

- 239000000463 material Substances 0.000 claims abstract description 20

- 239000000835 fiber Substances 0.000 claims abstract description 19

- 239000002657 fibrous material Substances 0.000 claims abstract description 19

- 238000005507 spraying Methods 0.000 claims abstract description 3

- 239000004744 fabric Substances 0.000 claims description 7

- 238000006073 displacement reaction Methods 0.000 claims description 5

- 239000006260 foam Substances 0.000 description 5

- 239000004033 plastic Substances 0.000 description 4

- 238000009958 sewing Methods 0.000 description 3

- 239000000758 substrate Substances 0.000 description 3

- 102100040428 Chitobiosyldiphosphodolichol beta-mannosyltransferase Human genes 0.000 description 2

- 238000004026 adhesive bonding Methods 0.000 description 1

- 238000003490 calendering Methods 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 230000000149 penetrating effect Effects 0.000 description 1

- 239000002985 plastic film Substances 0.000 description 1

- 230000001681 protective effect Effects 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H13/00—Other non-woven fabrics

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/44—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties the fleeces or layers being consolidated by mechanical means, e.g. by rolling

- D04H1/46—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties the fleeces or layers being consolidated by mechanical means, e.g. by rolling by needling or like operations to cause entanglement of fibres

Definitions

- the present invention relates to a method for connecting along a line, at least two blanks.

- the present invention aims to overcome these drawbacks.

- water jet means any jet of fluid likely to generate the same results or results of the same order.

- the fibrous material is an integral part of at least one of said exterior blanks.

- This outer blank may in particular include at at least one layer of fiber mat and / or at least one layer of a fiber cloth.

- said fibrous material can be lined with at least one other layer of another material.

- the fibrous material can be placed inside and said jet of water projected onto said other material, or placed outside and said jet of water projected onto said fibrous material.

- the material fibrous is fed continuously as the displacement of the water jet, and is simultaneously secured by this jet of water to said blank and embedded in said others blanks.

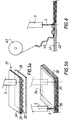

- Figures 1a and 1b illustrate the implementation case of the simplest invention, where a blank of fibrous material such as a fabric or mat 1 is "sewn" onto a substrate 2.

- the blanks of materials 1 and 2 are first put in contact, then a nozzle 3 for projecting a water jet 4 is brought above the assembly thus obtained, on the side of the blank 1, at the start of a connection line to be obtained between the blanks, or tablecloths, 1 and 2.

- the nozzle 3 is then moved so that the water jet 4 follows the planned connection line.

- the water jet strikes the fibers of the material 1 and drives them, in their providing part of its kinetic energy, in contact with blank 2. Because of this energy, the fibers penetrate into the material 2.

- the power of the water jet is however adjusted by so that the fibers, while penetrating into the substrate, remain linked to the blank 1. These fibers thus ensure the connection between the blanks 1 and 2 along the planned connecting line.

- the fabric or the mat 1 is thus "sewn", along the connecting line, such a line being represented in the figure 1b.

- jet diameters (nozzle 3) of of the order of 0.15 mm were suitable, with pressures of the order from 1000 to 4000 bar and jet displacement speeds between 25 and 400 mm / s.

- each parameter must be chosen between two limits, one where the connection is not made, and the other where the blanks are cut by the violence of the jet.

- the principle is the same as before, except that the blank 1 of fibrous material is here doubled on the outside of a layer 5, especially of any suitable plastic such as, for example, a foam.

- the assembly consisting of layers 1 and 5 is placed against the blank 2 and the water jet 4 is directed against the layer 5.

- the water jet crosses, at least locally, layer 5 of so that the fibers of the blank 1 ensure the connection between the blanks 2 and 5.

- FIG. 3a and 3b A variant is shown in Figures 3a and 3b where the layer 5 is replaced by a two-layer structure. This last one is made of a plastic sheet 10, for example foam, bonded, for example by calendering, to a protective sheet 11. The assembly is assembled as previously to substrate 2.

- FIG. 5 it provides the connection between a blank 30 of plastic, and a composite blank 31, consisting of a fiber mat 32, foam 33, and fabric 34 pre-assembled anyway suitable.

- the mat 32 is opposite of the blank 30.

- the jet 4 is applied on the side of the fabric 34. Fibers of this last therefore cross foam 33 and mix with certain fibers of mat 32 to become embedded in the blank material 30. Along the line of displacement of the nozzle, the fabric 34 is therefore pressed against the blank 30 by crushing the foam 33 and mat 32. This results in a "style line" 35, a sort of false saddle stitching. Two such parallel lines are shown in Figure 5b.

- FIG. 6 illustrates another embodiment in which the fibrous bonding material 40 is not part of a blanks to be assembled, namely blanks 41 and 42, for example of plastic.

- the material 40 is here brought under the nozzle 3, for example in the form of a wire, a wick or a ribbon of mat, from a reel 43.

- material 40 is fed at the speed of advance of the nozzle 3, so that its fibers penetrate and become embedded in the material of the blanks 41 and 42, ensuring the connection of the latter as in the previous embodiments.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Mechanical Engineering (AREA)

- Treatment Of Fiber Materials (AREA)

- Nonwoven Fabrics (AREA)

- Manufacture And Refinement Of Metals (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR9609708 | 1996-08-01 | ||

| FR9609708A FR2751993B1 (fr) | 1996-08-01 | 1996-08-01 | Procede de liaison de deux flans, notamment fibreux |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0822285A2 true EP0822285A2 (de) | 1998-02-04 |

| EP0822285A3 EP0822285A3 (de) | 2000-10-11 |

Family

ID=9494722

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP97401826A Withdrawn EP0822285A3 (de) | 1996-08-01 | 1997-07-30 | Verfahren zum Verbinden von zwei Bahnen, insbesondere faserige Bahnen |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0822285A3 (de) |

| FR (1) | FR2751993B1 (de) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2011026881A1 (de) * | 2009-09-03 | 2011-03-10 | Siemens Aktiengesellschaft | Turbinenschaufel aus faserverbundwerkstoff und die geeigneten herstellungsverfahren |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS52140667A (en) * | 1976-05-14 | 1977-11-24 | Kogyo Gijutsuin | Manufacturing method and apparatus for unwoven fabric by jet flow |

| DD254134A1 (de) * | 1986-12-03 | 1988-02-17 | Textiltech Forsch | Verfahren zur herstellung von fuellkoerpern |

| JPS6461555A (en) * | 1987-08-28 | 1989-03-08 | Mitsubishi Rayon Co | Production of composite sheet |

| FR2645180B1 (de) * | 1989-03-31 | 1991-10-25 | Picardie Lainiere |

-

1996

- 1996-08-01 FR FR9609708A patent/FR2751993B1/fr not_active Expired - Fee Related

-

1997

- 1997-07-30 EP EP97401826A patent/EP0822285A3/de not_active Withdrawn

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2011026881A1 (de) * | 2009-09-03 | 2011-03-10 | Siemens Aktiengesellschaft | Turbinenschaufel aus faserverbundwerkstoff und die geeigneten herstellungsverfahren |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0822285A3 (de) | 2000-10-11 |

| FR2751993A1 (fr) | 1998-02-06 |

| FR2751993B1 (fr) | 1998-10-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0853452B1 (de) | Verfahren und vorrichtung zum verbinden von stoffstücken oder dgl. und so hergestellter artikel wie bekleidungsstück | |

| FR2667622A1 (fr) | Montisse lie hydrauliquement et son procede de fabrication. | |

| MX9804960A (es) | Bolsa para polvo de alta eficiencia. | |

| FR2739319A1 (fr) | Machine pour fabriquer une bande de carton ondule, doublee au moins sur une face | |

| EP1397546B1 (de) | Vernadelungsmaschine mit glattem tisch | |

| EP0822285A2 (de) | Verfahren zum Verbinden von zwei Bahnen, insbesondere faserige Bahnen | |

| FR2797892A1 (fr) | Procede et dispositif de fabrication de plaques composites | |

| EP1190132B1 (de) | Vorrichtung zur behandlung von folienmaterialen durch druckwasserstrahlen | |

| FR2574017A1 (fr) | Procede et appareil de coupe et de fixation par ultrasons, en particulier pour materiau textile en feuille | |

| FR2802015A1 (fr) | Cable plat et enclume rotative modulaire pour sa fabrication | |

| FR3018287A1 (fr) | Procede de fabrication d'une piece d'equipement interieur de vehicule automobile comportant une couche d'endroit velours, et piece associee | |

| EP0782501A1 (de) | Verfahren zum herstellen einer platte beschichtet mit einer verblendungsfläche, insbesondere textil | |

| FR2714397A1 (fr) | Armature textile utilisable pour la réalisation de matériaux composites. | |

| EP0730498B1 (de) | Düse zur oberflächenbehandlung sowie vorrichtung und verfahren zur oberflächenbehandlung mit einer solchen düse | |

| FR2848227A1 (fr) | Etoffe textile apte a etre integree dans une armature de renforcement, et machine pour la realisation de telles etoffes | |

| FR2605264A1 (fr) | Procede et dispositif d'assemblage par ultrasons | |

| EP0689785B1 (de) | Vandalenresistentes Sitz-Element | |

| FR2472351A1 (fr) | Procede de fixation d'un element tel qu'un bouton sur un tissu, bouton et appareil de fixation pour la mise en oeuvre de ce procede | |

| CN115320114B (zh) | 窗帘无缝拼接工艺及拼接窗帘 | |

| FR3033515A1 (fr) | Procede de laminage perfectionne par ultrasons d'un article thermofusible, et dispositif de laminage pour la mise en œuvre dudit procede | |

| FR2724396A1 (fr) | Dispositif pour la transformation d'un voile de fibres de grand format en une bande de fibres | |

| EP0250336B1 (de) | Verfahren zur Herstellung von ultraschallgeschweissten Bodenbelägen, Vorrichtung zur Durchführung desselben | |

| EP1230069A1 (de) | Formende bearbeitung von glasscheiben | |

| WO1981001498A1 (fr) | Procede et dispositif de fixation par ultrasons d'un element tel qu'un bouton sur un tissu | |

| EP0017996A1 (de) | Verfahren und Vorrichtung zum Extrudieren mehrschichtiger Folienschläuche mit innerer Verstärkungseinlage |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): DE ES FR GB IT |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 20010406 |

|

| AKX | Designation fees paid |

Free format text: AT BE CH DE DK LI |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): DE ES FR GB IT |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20040203 |