EP0822151B1 - Tablet dispenser with outer housing and container - Google Patents

Tablet dispenser with outer housing and container Download PDFInfo

- Publication number

- EP0822151B1 EP0822151B1 EP97111506A EP97111506A EP0822151B1 EP 0822151 B1 EP0822151 B1 EP 0822151B1 EP 97111506 A EP97111506 A EP 97111506A EP 97111506 A EP97111506 A EP 97111506A EP 0822151 B1 EP0822151 B1 EP 0822151B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- housing

- cap

- tablet

- container

- closure cap

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D83/00—Containers or packages with special means for dispensing contents

- B65D83/04—Containers or packages with special means for dispensing contents for dispensing annular, disc-shaped, or spherical or like small articles, e.g. tablets or pills

- B65D83/0409—Containers or packages with special means for dispensing contents for dispensing annular, disc-shaped, or spherical or like small articles, e.g. tablets or pills the dispensing means being adapted for delivering one article, or a single dose, upon each actuation

Definitions

- the invention relates to a tablet dispenser, which has an outer Housing and a fitting in this housing, especially against a spring-loaded container with a separating device for when actuated - by the relative displacement between container and housing - tablet to be dispensed in each case has, with the relative displacement movement between Housing and container have a dispensing opening for a single tablet can be released.

- Such tablet dispensers are for medication as well known for sweetener tablets.

- each known tablet dispenser in which a part of the container protrudes from the housing so that it can be moved can be attacked.

- the donation opening is there each on the lower side of this tablet dispenser when in use.

- such a tablet dispenser is known from DE-32 21 719 A1 known in which the container the housing in the use position protrudes at the top of a section so that it looks like a Button for the dispensing process can be pressed down.

- the housing is at the bottom in the position of use Page closed and the donation opening is on one Lateral side in the lower area of this housing.

- blister packs in which each tablet is individually and airtight packed. This is to achieve that even taking a tablet does not cause the remaining tablets with the atmosphere and humidity in Come into contact.

- blister packs have significant disadvantages with regard to their manufacture and disposal.

- the tablet dispensers mentioned at the outset are well suited per se dispense a single tablet at a time, but the rest are Tablets are not protected against humidity.

- the tablet dispenser mentioned at the beginning characterized in that one of the dispensing opening on the housing and the operating area for moving the inner container covering, removable closure cap with cap wall and Cap bottom is provided that the container on the actuation area of the housing overlapped or enclosed by the housing and coincides with the outside edge of the housing and / or a distance therefrom that the housing has a recess or the like, which is in the direction of displacement of the inner container is oriented and extends over the edge area to be moved and that the cap with its cap wall in one opposite their closed position offset position in the recess of the housing fits and engages in such a way that it can be used as a tool or actuation key to move the inner container relative to the housing - during the donation process - serves.

- the closure cap therefore has two functions, by doing one thing above all keeps the humidity from inside the tablet dispenser, however is also required as an actuating part for the dispensing process itself. This also provides child safety.

- the housing and the inner container and the cap an elongated or approximately rectangular Cross section - transverse to the direction of movement of the relative movement between Housing and inner container - and if the cap in a position opposite to their closed position and opposite to the direction the displacement movement in the direction of the longer dimension of the Cross-section laterally offset position with the housing and the slot-shaped recess in particular can be plugged together and can be brought into pressure connection with the inner container that it projects laterally over a narrow side of the container.

- the user So can remove the cap, laterally offset again "attach", with a wall corresponding to the narrow side of the Cap is inserted into the recess around the cap in contact and coupling connection with the inner Bring container, the recess of course so is dimensioned so that in this position the cap can be pressed in a button-like manner to start the actual dispensing process to effect. Then the cap can be from this operating position removed again and plugged in their closed position become.

- a tablet dispenser can be provided in which the displacement of the container within the housing of bottom up so that one released tablet more or less can be output by gravity.

- the one there Removal opening arranged on said narrow side lets in advantageously the laterally released tablet in the fall over this narrow side of the cap, so that this tablet is immediately caught by the cap and cannot accidentally fall to the ground. Even with one The tablet is collected with one hand.

- the cap expediently the outside of the housing overlaps, it has such a dimension that on the housing two corresponding and directly opposite, in particular slot-shaped recesses for engaging the Cap wall are provided during the dispensing process, which at the same time to a stable plug-in coupling between the sealing cap and the housing leads in the actuation position for the dispensing process.

- Embodiments of the closure cap and the housing in particular to improve the usability and also the tightness in Locked position are the subject of claims 5 to 11.

- claims 5 and 6 serve to improve the positioning of the cap in its staggered Position in which they act as an actuator for Moving the inner container is used and a should receive a defined position.

- the Embodiment according to claim 5 also reinforcement and stiffening the cap if the parallel to the short walls provided web also the two longer walls of the cap combines.

- claims 7 to 10 relate primarily to the seat the cap on the housing in the closed position to achieve the best possible seal, especially the claims 9 and 10 contain features that prevent unwanted stripping of the Cap from its seat in the closed position as far as possible exclude.

- Claim 11 contains a combination of features that a particular simple separation in connection with the displacement movement of the inner container.

- the edge of the cap can and the neighboring one in the closed position Wall area of the housing on the outside at least before first use be covered with a film, for example an adhesive tape, which then along the entire edge of the cap and there can circulate with the joint formed and in front of a First use can be deducted.

- a film for example an adhesive tape

- Such are not uncommon Containers are stored for a long time after filling, if necessary also transported over long distances and in one End sales point in turn stored until it is first used and then their content is consumed relatively quickly.

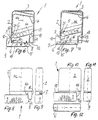

- a tablet dispenser designated as a whole has an outer one Housing 2 and a fitting in this housing 2; by him completely enclosed, against the force of a spring 3, in Embodiment of a leaf spring, sliding container 4, shaped like the inside of a matchbox.

- this tablet dispenser 1 is a whole provided with 5 designated separating device, which in the Actuation, ie when the container 4 is moved relative to the housing 2 one tablet 6 from the supply of several such tablets 6 through a donation opening 7 (see Fig. 7 and 9) issues.

- FIG. 1 to 5 you can see that on the housing 2 one of its dispensing opening 7 and the lower one in the use position Actuation area 8 for moving the inner container 4 covering, removable cap 9 with cap wall 10 and Cap base 11 is provided.

- FIGs 2, 6 and 7 illustrates that the container 4 at the actuation area 8 of the Housing 2, in the embodiment in the lower area, in which the housing 2 is open, from the housing 2 down is overlapped and towered over and inside the housing 2 thereof lower outer edge 12 has a distance a in some areas, which according to Fig.7 in the still to be described actuation for dispensing a tablet 6 is enlarged because the container 4 for the Dispensing process in the position of use shown in the figures must be moved deeper into the housing 2 from the bottom up.

- This distance a is between the edge 12 of the housing 2 and the lower edge 13 of the container 4 facing this in the in Figures 2, 6 and 7 right area largest and can on the opposite side, the dispensing opening 7 almost or disappear entirely.

- this lower edge 13 of the container 4 practical for normal pressure actuation enclosed inaccessible by the housing 2 and its edge 12.

- FIGS 6, 7, 8 and 10 now show that the cap 9 with its cap wall 10 in one opposite according to their closed position shown in Figures 2 and 4 left offset position fits into this recess 14 of the housing 2 and is insertable and engages in such a way that it can be used as a tool or Actuation key for moving the inner container 4 relatively to the housing 2 and against the force of the spring 3 and also the Gravity can serve to dispense a tablet 6.

- the displacement path can also be specified or limited during the donation process. It is the recess 14 is slit-shaped so that it is simultaneously as a guide for the wall 10 of the closure cap which it has received 9 and thus serves for a sufficiently precise adjustment movement.

- housing 2 and the inner container 4 and the cap 9 an elongated or have a rectangular cross-section or floor plan, that is Walls 10 of the cap 9 on an approximately rectangular Cap bottom 11 circulate, with two parallel longer and result in two narrow pieces of wall.

- the closure cap 9 is according to Figure 6, 7, 8 and 10 in one opposite their closed position and in relation to the direction of the displacement movement when dispensing in the direction of the longer dimension of your Cross-section laterally offset position with the housing 2 and the slot-shaped recess 14 in the exemplary embodiment pluggable and with the inner container 4 and its lower Edge 13 can be brought into pressure connection so that it is a narrow side of the Container 4 and the housing protrudes laterally.

- the cap 9 as already mentioned, on the lower side during the dispensing process arranged while the removal or donation opening 7 at the of the cap 9 provided in the actuating position narrow side is what can be clearly seen in Fig. 6 and 7. This will as shown in Fig.

- the cap 9 has a third function in addition to their function as a closure and their operating function. This is a significant one, especially for clumsy users Relief because they don’t use the donated tablet Hand or in any other way, but must this collection of the tablet 6 automatically by the arrangement the cap 9 takes place during the dispensing process when the Cap 9 the position required for this dispensing process occupies.

- Closure cap 9 shows that on the housing 2 two each other corresponding and directly opposite, in the embodiment slot-shaped recesses 14 for engaging the shorter ones To provide cap wall 10 during the dispensing process and are provided.

- the closure cap 9 has a web 15 arranged in its interior, which in parallel Positioning slots arranged to the slot-shaped recesses 14 16 fits, which also on the broad sides of the housing 2 and the container 4 are approximately congruent one behind the other and engages in the positioning web 15 according to Figure 2 when the Cap 9 is arranged in the closed position.

- Positioning slots arranged to the slot-shaped recesses 14 16 fits which also on the broad sides of the housing 2 and the container 4 are approximately congruent one behind the other and engages in the positioning web 15 according to Figure 2 when the Cap 9 is arranged in the closed position.

- In parallel are further slots 17 in turn parallel to each other and arranged to the positioning slot 16 and the recess 14, in the web 15 provided in the cap 9 in the actuating position intervenes as shown in FIG. 7, where it then also lies below Edge 13 of the container 4 is pressurized so that the container 4 is detected when moving at two spaced locations counteracts canting while moving.

- This inside the cap 9 opposite the bottom 11th upright positioning web 15 runs parallel to the short ones Narrow sides and has, as especially in Fig. 2 with the Center line ML clearly visible, opposite one narrow side of the Cap 9 and the housing 2 a smaller distance than opposite the other narrow side, so it is arranged off-center, so that the cap 9 only in the position shown and not rotated about 180 ° about a vertical axis on the housing 2 fits.

- Fig.1 it is shown that the positioning web 15 over the entire Width of the cap 9 is sufficient, that is, the opposite Walls 10 connects. In this case it is Positioning slot 16 also required in the housing 2.

- the bridge 15 could, however, as indicated by dashed lines, be shortened and of the two opposite walls 10 of the closure cap 9 keep enough distance that the housing 2 remains unslotted could and only the inner container 4 a corresponding slot 16 and 17 needed.

- the housing 2 as a seat for the closure cap 9 a wall area 18 from one in Has the plug-in direction of the cap 9 oriented dimension, which corresponds to the depth of the cap 9, so that it according to Fig.1 to 4 forms a tight fit on the housing 2.

- the housing 2 has for the seat of the cap 9 in Closed position a wall area 18 from the rest Wall area of reduced thickness, creating the outside or outside wall of the housing 2 jumps back all around at the seat of the cap 9.

- FIGS. 2, 6 and 7 show the separating device 5 still that the inner container 4 in the area of Tablet delivery or dispensing opening 7 a deformable, in particular towards the inside of the container 4, in Closed position, the projection 7 partially covering projection 21, which is due to the shift in the dispensing position by a inclined surface 22 on it against a restoring force, especially against its own elasticity, inside the Container 4 is movable and pivotable.

- This will give access blocked to the donation opening 7 for another tablet 6 and only when moving back to the starting position and thereby opposite movement of this projection 21 again for a tablet to be made available for the next dispensing process 6 released, while the previously isolated tablet 6 through the donation opening 7 can fall out.

- the tablet dispenser 1 has an outer housing 2 and one in it Interior against a spring force displaceable container 4 with a Separating device 5, so that in each case a single tablet 6 can be output if such a displacement movement of the Container 4 is performed relative to the housing 2. So that Inside of this tablet dispenser 1 against humidity and thereby is protected against premature spoilage of the tablets 6, is on the housing 2 one of its dispensing opening 7 and the actuation area 8 covering, removable cap 9 provided, the same time after removing them in an offset position is put back on the output area and thereby as Actuating tool is used because the container 4 is not itself direct is accessible in the operating area, but there from the housing 2 is enclosed.

- the edge 13 of the container 4 is namely at most at the level of the edge 12 of the housing 2 and jumps even partially back against it, so that it with the wall 10 to act upon the closure cap 9 during the displacement movement is.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Closures For Containers (AREA)

- Agricultural Chemicals And Associated Chemicals (AREA)

Abstract

Description

Die Erfindung betrifft einen Tablettenspender, welcher ein äußeres Gehäuse und einen in dieses Gehäuse passenden, insbesondere gegen eine Federkraft verschiebbaren Behälter mit einer Vereinzelungsvorrichtung für die bei Betätigung - durch die Relativverschiebung zwischen Behälter und Gehäuse - jeweils auszugebende Tablette aufweist, wobei durch die relative Verschiebebewegung zwischen Gehäuse und Behälter eine Spendeöffnung für eine vereinzelte Tablette freigebbar ist.The invention relates to a tablet dispenser, which has an outer Housing and a fitting in this housing, especially against a spring-loaded container with a separating device for when actuated - by the relative displacement between container and housing - tablet to be dispensed in each case has, with the relative displacement movement between Housing and container have a dispensing opening for a single tablet can be released.

Derartige Tablettenspender sind sowohl für Medikamente als auch für Süßstofftabletten bekannt.Such tablet dispensers are for medication as well known for sweetener tablets.

Aus der EP-0 408 774 B1 und aus der EP-0 600 123 B1 sind dabei jeweils Tablettenspender bekannt, bei denen ein Teil des Behälters gegenüber dem Gehäuse vorsteht, so daß zur Verschiebung daran angegriffen werden kann. Die Spendeöffnung befindet sich dabei jeweils an der in Gebrauchsstellung unteren Seite dieser Tablettenspender.From EP-0 408 774 B1 and from EP-0 600 123 B1 are included each known tablet dispenser, in which a part of the container protrudes from the housing so that it can be moved can be attacked. The donation opening is there each on the lower side of this tablet dispenser when in use.

Ferner ist aus DE-32 21 719 A1 ein derartiger Tablettenspender bekannt, bei welchem der Behälter das Gehäuse im in Gebrauchsstellung oberen Bereich an einem Ausschnitt überragt, so daß er wie eine Taste für den Spendevorgang nach unten gedrückt werden kann. Das Gehäuse ist in diesem Falle an der in Gebrauchsstellung unteren Seite abgeschlossen und die Spendeöffnung befindet sich an einer seitlichen.Schmalseite im unteren Bereich dieses Gehäuses.Furthermore, such a tablet dispenser is known from DE-32 21 719 A1 known in which the container the housing in the use position protrudes at the top of a section so that it looks like a Button for the dispensing process can be pressed down. The In this case, the housing is at the bottom in the position of use Page closed and the donation opening is on one Lateral side in the lower area of this housing.

Vor allem bei als Medikamente dienenden Tabletten besteht das Problem, daß sie durch die Luftfeuchtigkeit relativ schnell unbrauchbar werden. Derartige Medikamente werden deshalb häufig in sogenannten Blisterpackungen aufbewahrt, in denen jede Tablette einzeln und Luftdicht verpackt ist. Dadurch soll erreicht werden, daß auch die Entnahme einer Tablette nicht dazu führt, daß die übrigen Tabletten mit der Athmosphäre und der Luftfeuchtigkeit in Berührung kommen. Blisterpackungen haben jedoch erhebliche Nachteile hinsichtlich ihrer Herstellung und Entsorgung.This is particularly the case with tablets used as medicines Problem that they are relatively quick due to the humidity become unusable. Such drugs are therefore becoming common stored in so-called blister packs, in which each tablet is individually and airtight packed. This is to achieve that even taking a tablet does not cause the remaining tablets with the atmosphere and humidity in Come into contact. However, blister packs have significant disadvantages with regard to their manufacture and disposal.

Die eingangs genannten Tablettenspender sind an sich gut geeignet, jeweils eine einzelne Tablette auszugeben, jedoch sind die übrigen Tabletten darin nicht gegen Luftfeuchtigkeit geschützt.The tablet dispensers mentioned at the outset are well suited per se dispense a single tablet at a time, but the rest are Tablets are not protected against humidity.

Es besteht deshalb die Aufgabe, einen Tablettenspender der eingangs genannten Art zu schaffen, der vor und auch nach dem Entnehmen einer Tablette dicht ist, so daß er geeignet ist, durch Luftfeuchtigkeit gefährdete Tabletten aufzunehmen.There is therefore the task of a tablet dispenser of the beginning to create the type mentioned before and even after removing a Tablet is tight so that it is suitable due to humidity to take tablets at risk.

Zur Lösung dieser Aufgabe ist der eingangs genannte Tablettenspender dadurch gekennzeichnet, daß an dem Gehäuse eine dessen Spendeöffnung und den Betätigungsbereich zum Verschieben des inneren Behälters überdeckende, abnehmbare Verschlußkappe mit Kappenwandung und Kappenboden vorgesehen ist, daß der Behälter an dem Betätigungsbereich des Gehäuses von dem Gehäuse übergriffen oder umschlossen ist und im Inneren des Gehäuses mit dessen Außenrand übereinstimmt und/oder davon einen Abstand hat, daß das Gehäuse eine Ausnehmung oder dergleichen hat, die in Verschieberichtung des inneren Behälters orientiert ist und über dessen zu verschiebenden Randbereich reicht und daß die Verschlußkappe mit ihrer Kappenwandung in einer gegenüber ihrer Schließposition versetzten Lage in die Ausnehmung des Gehäuses paßt und derart eingreift, daß sie als Werkzeug oder Betätigungstaste zum Verschieben des inneren Behälters relativ zu dem Gehäuse - während des Spendevorganges - dient.To solve this problem is the tablet dispenser mentioned at the beginning characterized in that one of the dispensing opening on the housing and the operating area for moving the inner container covering, removable closure cap with cap wall and Cap bottom is provided that the container on the actuation area of the housing overlapped or enclosed by the housing and coincides with the outside edge of the housing and / or a distance therefrom that the housing has a recess or the like, which is in the direction of displacement of the inner container is oriented and extends over the edge area to be moved and that the cap with its cap wall in one opposite their closed position offset position in the recess of the housing fits and engages in such a way that it can be used as a tool or actuation key to move the inner container relative to the housing - during the donation process - serves.

Durch diese Anordnung ist es also auch bei abgenommener Verschlußkappe nicht möglich, das Gehäuse direkt zu verschieben und dadurch einen Spendevorgang auszuüben. Der Tablettenspender benötigt also die Verschlußkappe auf jeden Fall, um eine Tablette ausgeben zu können. Durch diese Verschlußkappe wird aber der Spender gegen Luftfeuchtigkeit abgeschlossen, wobei der Benutzer auf die Kappe auch später nicht verzichten kann, weil er sie immer wieder für jeden neuen Spendevorgang benötigt. Somit muß er die Verschlußkappe auch immer wieder in ihre abdichtende Schließposition bringen, um sie platzsparend und für den nächsten Spendevorgang bereit, aufzubewahren.With this arrangement, it is also with the cap removed not possible to move the housing directly and thereby exercising a donation process. The tablet dispenser needs so the cap definitely to dispense a tablet to be able to. With this cap the donor is against Humidity completed, the user on the cap also can not do without later, because he always for them every new donation process is required. So he has the cap bring it back into its sealing closed position again and again they save space and are ready for the next donation process, store.

Die Verschlußkappe hat also zwei Funktionen, indem sie vor allem die Luftfeuchtigkeit vom Inneren des Tablettenspenders abhält, aber auch als Betätigungsteil für den Spendevorgang selbst benötigt wird. Dadurch ist gleichzeitig auch eine Kindersicherung gegeben.The closure cap therefore has two functions, by doing one thing above all keeps the humidity from inside the tablet dispenser, however is also required as an actuating part for the dispensing process itself. This also provides child safety.

Besonders zweckmäßig ist es, wenn das Gehäuse und der innere Behälter sowie die Verschlußkappe einen länglichen oder etwa rechteckigen Querschnitt - quer zur Bewegungsrichtung der Relativbewegung zwischen Gehäuse und innerem Behälter - haben und wenn die Verschlußkappe in einer gegenüber ihrer Schließlage und gegenüber der Richtung der Verschiebebewegung in Richtung der längeren Abmessung des Querschnittes seitlich versetzten Position derart mit dem Gehäuse und der insbesondere schlitzförmigen Ausnehmung zusammensteckbar und mit dem inneren Behälter in Druckverbindung bringbar ist, daß sie eine Schmalseite des Behälters seitlich überragt. Der Benutzer kann also die Verschlußkappe abnehmen, seitlich etwas versetzt wieder "aufstecken", wobei eine der Schmalseite entsprechende Wandung der Verschlußkappe in die Ausnehmung eingeführt wird, um die Verschlußkappe in Kontakt und Kupplungsverbindung mit dem inneren Behälter zu bringen, wobei die Ausnehmung selbstverständlich so bemessen ist, daß in dieser Position dann die Verschlußkappe tastenförmig gedrückt werden kann, umden eigentlichen Spendervorgang zu bewirken. Danach kann die Verschlußkappe aus dieser Betätigungsposition wieder abgezogen und in ihrer Verschlußposition aufgesteckt werden.It is particularly useful if the housing and the inner container and the cap an elongated or approximately rectangular Cross section - transverse to the direction of movement of the relative movement between Housing and inner container - and if the cap in a position opposite to their closed position and opposite to the direction the displacement movement in the direction of the longer dimension of the Cross-section laterally offset position with the housing and the slot-shaped recess in particular can be plugged together and can be brought into pressure connection with the inner container that it projects laterally over a narrow side of the container. The user So can remove the cap, laterally offset again "attach", with a wall corresponding to the narrow side of the Cap is inserted into the recess around the cap in contact and coupling connection with the inner Bring container, the recess of course so is dimensioned so that in this position the cap can be pressed in a button-like manner to start the actual dispensing process to effect. Then the cap can be from this operating position removed again and plugged in their closed position become.

Besonders günstig ist es dabei, wenn die Kappe an der beim Spendevorgang unteren Seite angeordnet ist und die Entnahmeöffnung an der von der Kappe in Betätigungsposition überragten Schmalseite vorgesehen ist. Somit kann ein Tablettenspender vorgesehen werden, bei dem die Verschiebung des Behälters innerhalb des Gehäuses von unten nach oben erfolgt, so daß eine freigegebene Tablette mehr oder weniger durch die Schwerkraft ausgegeben werden kann. Die dabei an der genannten Schmalseite angeordnete Entnahmeöffnung läßt in vorteilhafter Weise die seitlich freigegebene Tablette in die an dieser Stelle über die Schmalseite ragende Verschlußkappe fallen, so daß diese Tablette gleich von der Verschlußkappe aufgefangen wird und nicht versehentlich zu Boden fallen kann. Selbst bei einer Einhandbedienung wird die Tablette aufgefangen.It is particularly advantageous if the cap on the Dispensing process is arranged lower side and the removal opening on the narrow side towered over by the cap in the actuation position is provided. Thus, a tablet dispenser can be provided in which the displacement of the container within the housing of bottom up so that one released tablet more or less can be output by gravity. The one there Removal opening arranged on said narrow side lets in advantageously the laterally released tablet in the fall over this narrow side of the cap, so that this tablet is immediately caught by the cap and cannot accidentally fall to the ground. Even with one The tablet is collected with one hand.

Da die Verschlußkappe das Gehäuse zweckmäßigerweise außenseitig übergreift, hat sie eine derartige Abmessung, daß an dem Gehäuse zwei einander entsprechende und unmittelbar gegenüberliegende, insbesondere schlitzförmige Ausnehmungen zum Eingreifen der Kappenwandung beim Spendevorgang vorgesehen sind, was gleichzeitig zu einer stabilen Steckkupplung zwischen Verschlußkappe und Gehäuse in der Betätigungsposition für den Spendevorgang führt.Since the cap expediently the outside of the housing overlaps, it has such a dimension that on the housing two corresponding and directly opposite, in particular slot-shaped recesses for engaging the Cap wall are provided during the dispensing process, which at the same time to a stable plug-in coupling between the sealing cap and the housing leads in the actuation position for the dispensing process.

Ausgestaltungen der Verschlußkappe und auch des Gehäuses insbesondere

zur Verbesserung der Bedienbarkeit und auch der Dichtigkeit in

Verschlußstellung sind Gegenstand der Ansprüche 5 bis 11. Embodiments of the closure cap and the housing in particular

to improve the usability and also the tightness in

Locked position are the subject of

Die Merkmale der Ansprüche 5 und 6 dienen dabei zu einer Verbesserung

der Positionierung der Verschlußkappe in ihrer versetzt eingesteckten

Position, in der sie gleichzeitig als Betätigungselement beim

Verschieben des inneren Behälters benutzt wird und dazu eine

definierte Position erhalten soll. Gleichzeitig erlaubt die

Ausgestaltung gemäß Anspruch 5 auch eine Verstärkung und Versteifung

der Verschlußkappe, wenn der parallel zu den kurzen Wandungen

vorgesehene Steg auch die beiden längeren Wandungen der Verschlußkappe

verbindet.The features of

Die Merkmale der Ansprüche 7 bis 10 betreffen vor allem den Sitz

der Verschlußkappe am Gehäuse in Verschlußposition zur Erzielung

einer bestmöglichen Abdichtung, wobei insbesondere auch die Ansprüche

9 und 10 Merkmale enthalten, die ein ungewolltes Abstreifen der

Verschlußkappe von ihrem Sitz in Verschlußlage weitestgehend

ausschließen.The features of

Anspruch 11 enthält eine Merkmalskombination, die eine besonders

einfache Vereinzelung im Zusammenhang mit der Verschiebebewegung

des inneren Behälters ermöglicht.

Damit der Inhalt des Tablettenspenders vor allem auch vor seiner ersten Benutzung noch besser gegen Luftfeuchtigkeit und Umwelteinflüsse abgedichtet und geschützt ist, kann der Rand der Verschlußkappe und der diesem in Verschlußstellung benachbarte Wandbereich des Gehäuses außenseitig zumindest vor dem Erstgebrauch mit einer Folie, zum Beispiel einem Klebstreifen überdeckt sein, der dann entlang dem gesamten Rand der Verschlußkappe und der dort mit dem Gehäuse gebildeten Fuge umlaufen kann und vor einer Erstbenutzung abgezogen werden kann. Nicht selten werden solche Behälter nach dem Füllen zunächst längere Zeit gelagert, gegebenenfalls auch über längere Strecken transportiert und in einer Endverkaufsstelle wiederum gelagert, bis sie erstmals benutzt und dann ihr Inhalt relativ zügig verbraucht wird. Durch die vorerwähnte Maßnahme mit Hilfe eines die Fuge zwischen Verschlußkappe und Gehäuse überdeckenden Dichtungsstreifens kann während dieser gesamten Zeit ein noch besserer Schutz gegen Feuchtigkeit oder sonstige Umwelteinflüsse erzielt werden, als er auch durch die Verschlußkappe alleine nach Beginn der Benutzung erzielt wird.So that the content of the tablet dispenser especially before it even better against humidity and environmental influences is sealed and protected, the edge of the cap can and the neighboring one in the closed position Wall area of the housing on the outside at least before first use be covered with a film, for example an adhesive tape, which then along the entire edge of the cap and there can circulate with the joint formed and in front of a First use can be deducted. Such are not uncommon Containers are stored for a long time after filling, if necessary also transported over long distances and in one End sales point in turn stored until it is first used and then their content is consumed relatively quickly. By the aforementioned Measure with the help of a joint between the sealing cap and the housing overlapping weather strip can be used during this entire time an even better protection against moisture or other Environmental influences are achieved as he also through the cap is achieved only after the start of use.

Nachstehend ist ein Ausführungsbeispiel der Erfindung anhand der Zeichnung näher beschrieben. Es zeigt in zum Teil schematisierter Darstellung:

- Fig.1

- einen Längsschnitt parallel zu den kürzeren Schmalseiten eines erfindungsgemäßen Tablettenspenders durch das Gehäuse, den demgegenüber im Inneren gegen eine Rückstellkraft nach oben verschiebbaren Behälter und eine an der Unterseite, von wo aus die Verschiebebewegung durchgeführt wird, angeordnete Verschlußkappe,

- Fig.2

- einen senkrechten Längsschnitt, der rechtwinklig zu dem in Fig.1 und parallel zu den langen Seitenflächen des Tablettenspenders zwischen diesen verläuft,

- Fig.3

- eine Ansicht einer Schmalseite,

- Fig.4

- eine Ansicht einer Breitseite und

- Fig.5

- eine Draufsicht des in den

Figuren 1 und 2 in zwei rechtwinklig zueinander angeordneten Schnitten angeordneten Tablettenspenders, - Fig.6

- einen der Fig.2 entsprechenden Schnitt, nachdem die Verschlußkappe abgenommen und seitlich versetzt wieder aufgesteckt ist, wobei eine Wandung der Verschlußkappe in entsprechende schlitzförmige Aussparungen des Gehäuses eingreift und den inneren Behälter in Schieberichtung beaufschlagt,

- Fig.7

- eine der Fig.6 entsprechende Schnittdarstellung nach dem Eindrücken der Verschlußkappe in die Aussparung, wodurch sie in der dargestellten Anordnung von unten nach oben verschoben wird und dadurch den inneren Behälter gegenüber dem äußeren Gehäuse ebenfalls nach oben gegen eine Rückstellkraft verschiebt, so daß eine zuvor vereinzelte Tablette durch die seitlich angeordnete Spendeöffnung in die durch die seitliche Versetzung seitlich überstehende Verschlußkappe gelangt,

- Fig.8

- eine Ansicht der Breitseite des Spenders nach dem Anordnen der Verschlußkappe in Spendeposition gemäß Fig.6,

- Fig.9

- eine Stirnansicht des Spenders nach dem Versetzen der Verschlußkappe in die Ausgangslage zur Durchführung eines Spendevorganges,

- Fig.10

- eine Ansicht der Breitseite des Spenders nach dem Betätigen des Spendevorganges, wodurch die Verschlußkappe gegenüber ihrer in Fig.8 eingenommenen Position nach oben verschoben ist,

- Fig.11

- eine Ansicht der Schmalseite des Spenders nach dem Verschieben der Verschlußkappe zum Auslösen des Spendevorganges und

- Fig.12

- eine Draufsicht des Spenders in Spendeposition.

- Fig.1

- 2 shows a longitudinal section parallel to the shorter narrow sides of a tablet dispenser according to the invention through the housing, the container, on the other hand, which can be displaced upwards against a restoring force, and a closure cap arranged on the underside, from where the displacement movement is carried out,

- Fig.2

- 2 shows a vertical longitudinal section which runs at right angles to that in FIG. 1 and parallel to the long side faces of the tablet dispenser between them,

- Figure 3

- a view of a narrow side,

- Figure 4

- a view of a broadside and

- Figure 5

- 1 is a top view of the tablet dispenser shown in FIGS. 1 and 2 in two sections arranged at right angles to one another,

- Figure 6

- 2 a section corresponding to FIG. 2 after the closure cap has been removed and laterally displaced, a wall of the closure cap engages in corresponding slot-shaped recesses in the housing and acts on the inner container in the sliding direction,

- Figure 7

- 6 shows a sectional view corresponding to the pressing of the closure cap into the recess, as a result of which it is shifted from bottom to top in the arrangement shown and thereby also moves the inner container relative to the outer housing upward against a restoring force, so that a previously isolated one The tablet passes through the dispensing opening on the side and into the cap protruding laterally due to the lateral displacement,

- Figure 8

- 6 shows a view of the broad side of the dispenser after the closure cap has been arranged in the dispensing position according to FIG. 6,

- Figure 9

- a front view of the dispenser after moving the cap into the starting position for performing a dispensing process,

- Figure 10

- 3 shows a view of the broad side of the dispenser after the dispensing process has been actuated, as a result of which the closure cap is displaced upwards relative to its position assumed in FIG. 8,

- Figure 11

- a view of the narrow side of the dispenser after moving the cap to trigger the dispensing process and

- Figure 12

- a top view of the dispenser in the dispensing position.

Ein im ganzen mit 1 bezeichneter Tablettenspender hat ein äußeres

Gehäuse 2 und einen in dieses Gehäuse 2 passenden; von ihm

vollständig umschlossenen, gegen die Kraft einer Feder 3, im

Ausführungsbeispiel einer Blattfeder, verschiebbaren Behälter 4,

der ähnlich wie das Innere einer Streichholzschachtel geformt ist.

In üblicher Weise ist an diesem Tablettenspender 1 eine im ganzen

mit 5 bezeichnete Vereinzelungsvorrichtung vorgesehen, die bei der

Betätigung, also bei der Verschiebung des Behälters 4 relativ zu

dem Gehäuse 2 jeweils eine Tablette 6 aus dem Vorrat von mehreren

derartigen Tabletten 6 durch eine Spendeöffnung 7 (vgl.Fig.7 und

9) ausgibt.A tablet dispenser designated as a whole has an outer one

Vor allem in den Figuren 1 bis 5 erkennt man, daß an dem Gehäuse

2 eine dessen Spendeöffnung 7 und den in Gebrauchsstellung unteren

Betätigungsbereich 8 zum Verschieben des inneren Behälters 4

überdeckende, abnehmbare Verschlußkappe 9 mit Kappenwandung 10 und

Kappenboden 11 vorgesehen ist. Durch die Figuren 2, 6 und 7 ist

verdeutlicht, daß der Behälter 4 an dem Betätigungsbereich 8 des

Gehäuses 2, im Ausführungsbeispiel also im unteren Bereich, in

welchem das Gehäuse 2 offen ist, von dem Gehäuse 2 nach unten

übergriffen und überragt ist und im Inneren des Gehäuses 2 von dessen

unterem Außenrand 12 bereichsweise einen Abstand a hat, der gemäß

Fig.7 bei der noch zu beschreibenden Betätigung für das Ausgeben

einer Tablette 6 noch vergrößert wird, weil der Behälter 4 für den

Spendevorgang in der in den Figuren dargestellten Gebrauchslage

von unten nach oben tiefer in das Gehäuse 2 verschoben werden muß.

Dabei ist dieser Abstand a zwischen dem Rand 12 des Gehäuses 2 und

dem diesem zugewandten unteren Rand 13 des Behälters 4 in dem in

den Figuren 2, 6 und 7 rechten Bereich am größten und kann an der

gegenüberliegenden, die Spendeöffnung 7 aufweisenden Seite fast

oder ganz verschwinden. Dadurch ist jedoch dieser untere Rand 13

des Behälters 4 für eine normale Druckbetätigung praktisch

unzugänglich von dem Gehäuse 2 und dessen Rand 12 umschlossen.Especially in Figures 1 to 5 you can see that on the

In den Figuren 2, 6, 7, 8 und 10 ist erkennbar, daß das Gehäuse

2 eine in diesem Falle schlitzförmige Ausnehmung 14 an zwei einander

gegenüberliegenden Breitseiten hat, die vom unteren Rand 12 aus

vertikal nach oben in Verschieberichtung des inneren Behälters 4

gerichtet und orientiert ist und über dessen zu verschiebenden

Randbereich 13 reicht, also in Ausgangsstellung gemäß Fig.6 den

Rand 13 "schneidet". Die Figuren 6, 7, 8 und 10 zeigen nun, daß

die Verschlußkappe 9 mit ihrer Kappenwandung 10 in einer gegenüber

ihrer in den Figuren 2 und 4 dargestellten Schließposition nach

links versetzten Lage in diese Ausnehmung 14 des Gehäuses 2 paßt

und einsteckbar ist und derart eingreift, daß sie als Werkzeug oder

Betätigungstaste zum Verschieben des inneren Behälters 4 relativ

zu dem Gehäuse 2 und entgegen der Kraft der Feder 3 sowie auch der

Schwerkraft nach oben dienen kann, um eine Tablette 6 auszugeben.In Figures 2, 6, 7, 8 and 10 it can be seen that the housing

2 a slot-shaped

Ausgehend von der Schließlage in Fig.2 ist also die Verschlußkappe

9 zunächst nach unten abziehbar, dann in der gezeichneten Lage etwas

nach links versetzbar, bis ihr in der Zeichnung am weitesten rechts

befindlicher Bereich ihrer Wandung 10 mit der schlitzförmigen

Ausnehmung 14 fluchtet, wonach die Verschlußkappe 9 wieder nach

oben bewegt werden kann, wobei dieser Bereich ihrer Wandung 10 immer

tiefer in die Ausnehmung 14 eintritt, bis ein Druckkontakt mit dem

Rand 13 des Behälters 4 entsteht. Diese Anordnung ist in Fig.6 und

8 dargestellt.Starting from the closed position in Figure 2 is the

Wird nun die Bewegung der Verschlußkappe nach oben, also entgegen

der Wirkung der Feder 3 fortgesetzt, bis der obere Rand der Wandung

10 das Ende der Aussparung oder Ausnehmung 14 erreicht hat, wird

dadurch der Behälter 4 innerhalb des Gehäuses 2 ebenfalls nach oben

verschoben, also die Spendeöffnung 7 zum Herauslassen der schon

vereinzelten Tablette 6 freigegeben, so daß bei der entgegengesetzten

Bewegung dann eine nächste Tablette 6 in bekannter Weise vereinzelt

werden kann.Now the movement of the closure cap is upwards, that is to say in the opposite direction

the action of the

Durch die Länge der Ausnehmung 14 kann also auch der Verschiebeweg

bei dem Spendevorgang vorgegeben bzw. begrenzt werden. Dabei ist

die Ausnehmung 14 schlitzförmig ausgebildet, so daß sie gleichzeitig

als Führung der von ihr aufgenommenen Wandung 10 der Verschlußkappe

9 und damit für eine genügend genaue Verstellbewegung dient.Due to the length of the

In den Figuren 5 und 12 ist verdeutlicht, daß das Gehäuse 2 und

der innere Behälter 4 sowie die Verschlußkappe 9 einen länglichen

oder etwa rechteckigen Querschnitt oder Grundriß haben, also die

Wandungen 10 der Verschlußkappe 9 an einem etwa rechteckigen

Verschlußkappen-Boden 11 umlaufen, wobei sich zwei parallele längere

und zwei schmale Wandstücke ergeben.In Figures 5 and 12 it is clear that the

Die Verschlußkappe 9 ist gemäß Fig.6, 7, 8 und 10 in einer gegenüber

ihrer Schließlage und gegenüber der Richtung der Verschiebebewegung

beim Spendevorgang in Richtung der längeren Abmessung ihres

Querschnittes seitlich versetzten Position derart mit dem Gehäuse

2 und der im Ausführungsbeispiel schlitzförmigen Ausnehmung 14

zusammensteckbar und mit dem inneren Behälter 4 und dessen unterem

Rand 13 in Druckverbindung bringbar, daß sie eine Schmalseite des

Behälters 4 und des Gehäuses seitlich überragt. Dabei ist die Kappe

9, wie schon erwähnt, an der beim Spendevorgang unteren Seite

angeordnet, während die Entnahme- oder Spendeöffnung 7 an der von

der Kappe 9 in Betätigungsposition überragten Schmalseite vorgesehen

ist, was ganz deutlich in Fig.6 und 7 erkennbar ist. Dadurch wird,

wie in Fig.7 und 12 zusätzlich dargestellt, erreicht, daß eine bei

dem Spendevorgang vereinzelte und ausgegebene Tablette 6 von der

Verschlußkappe 9 aufgefangen wird, also nicht versehentlich zu Boden

fallen kann. Somit erhält die Verschlußkappe 9 eine dritte Funktion

neben ihrer Funktion als Verschluß und ihrer Betätigungsfunktion.

Vor allem für ungeschickte Benutzer stellt dies eine erhebliche

Erleichterung dar, weil sie die gespendete Tablette nicht mit einer

Hand oder in irgend einer sonstigen Weise auffangen müssen, sondern

dieses Auffangen der Tablette 6 automatisch durch die Anordnung

der Verschlußkappe 9 während des Spendevorganges erfolgt, wenn die

Verschlußkappe 9 die für diesen Spendevorgang erforderliche Position

einnimmt.The

Aufgrund der Anordnung der Ausnehmung 14 an einer Längs- oder

Breitseite des Gehäuses 2 und die entsprechende Abmessung der

Verschlußkappe 9 ergibt sich, daß an dem Gehäuse 2 zwei einander

entsprechende und unmittelbar gegenüberliegende, im Ausführungsbeispiel

schlitzförmige Ausnehmungen 14 zum Eingreifen der kürzeren

Kappenwandung 10 beim Spendevorgang vorzusehen und vorgesehen sind. Due to the arrangement of the

Bei den Ansichten gemäß Fig.8 und 10 liegen diese beiden Ausnehmungen

14 in Blickrichtung praktisch deckungsgleich hintereinander und

der Betrachter sieht jeweils eine vordere Ausnehmung 14, während

in den Schnittdarstellungen 2, 6 und 7 jeweils die hintere derartige

Ausnehmung 14 erkennbar ist.These two recesses lie in the views according to FIGS. 8 and 10

14 practically congruent in line of sight and

the viewer sees a

In den Figuren 2, 6 und 7 ist dargestellt, daß die Verschlußkappe

9 einen in ihrem Inneren angeordneten Steg 15 hat, der in parallel

zu den schlitzförmigen Ausnehmungen 14 angeordnete Positionierschlitze

16 paßt, die ebenfalls an den Breitseiten des Gehäuses

2 und des Behälters 4 etwa deckungsgleich hintereinander liegen

und in die der Positioniersteg 15 gemäß Fig.2 eingreift, wenn die

Verschlußkappe 9 in Verschlußstellung angeordnet ist. Parallel dazu

sind jeweils weitere Schlitze 17 wiederum parallel zueinander und

zu dem Positionierschlitz 16 und der Ausnehmung 14 angeordnet, in

die der in der Kappe 9 vorgesehene Steg 15 in Betätigungsposition

gemäß Fig.7 eingreift, wo er dann ebenfalls den dort tieferliegenden

Rand 13 des Behälters 4 mit Druck beaufschlagt, so daß der Behälter

4 beim Verschieben an zwei beabstandeten Stellen erfaßt wird, was

einer Verkantung während des Verschiebens entgegenwirkt.In Figures 2, 6 and 7 it is shown that the

Dieser im Inneren der Verschlußkappe 9 gegenüber deren Boden 11

hochstehende Positioniersteg 15 verläuft dabei parallel zu den kurzen

Schmalseiten und hat, wie vor allem in Fig.2 mit der eingezeichneten

Mittellinie ML gut erkennbar, gegenüber der einen Schmalseite der

Verschlußkappe 9 und des Gehäuses 2 einen geringeren Abstand als

gegenüber der anderen Schmalseite, ist also außermittig angeordnet,

so daß die Verschlußkappe 9 nur in der dargestellten Lage und nicht

etwa 180° um eine senkrechte Achse verdreht auf das Gehäuse 2 paßt.This inside the

In Fig.1 ist dargestellt, daß der Positioniersteg 15 über die gesamte

Breite der Verschlußkappe 9 reicht, also die einander gegenüberliegenden

Wandungen 10 verbindet. In diesem Falle ist der

Positionierschlitz 16 auch im Gehäuse 2 erforderlich. Der Steg 15

könnte jedoch auch, wie gestrichelt angedeutet, verkürzt sein und

von beiden gegenüberliegenden Wandungen 10 der Verschlußkappe 9

so viel Abstand einhalten, daß das Gehäuse 2 ungeschlitzt bleiben

könnte und nur der innere Behälter 4 einen entsprechenden Schlitz

16 und 17 benötigt.In Fig.1 it is shown that the

Beim Ausführungsbeispiel ist vorgesehen, daß das Gehäuse 2 als Sitz

für die Verschlußkappe 9 einen Wandbereich 18 von einer in

Aufsteckrichtung der Verschlußkappe 9 orientierten Abmessung hat,

die der Tiefe der Verschlußkappe 9 entspricht, so daß sie gemäß

Fig.1 bis 4 einen dichten Verschlußsitz an dem Gehäuse 2 bildet.In the embodiment, it is provided that the

Das Gehäuse 2 hat dabei für den Sitz der Verschlußkappe 9 in

Schließstellung einen Wandbereich 18 von gegenüber dem übrigen

Wandbereich verringerter Dicke, wodurch die Außenseite oder Außenwand

des Gehäuses 2 am Sitz der Verschlußkappe 9 umlaufend zurückspringt.

Dabei ist die Spendeöffnung 7 für die vereinzelte Tablette 6 im

hinsichtlich der Wandstärke verminderten Wandbereich 18 des Gehäuses

2 angeordnet, wird also in Schließstellung von der Verschlußkappe

9 automatisch mit verschlossen und abgedichtet. Durch die

Verminderung der Wandstärke im Wandbereich 18 und eine entsprechende

Dicke der Wandungen 10 der Verschlußkappe 9 wird erreicht, daß die

Verschlußkappe 9 gemäß Fig.1 und 2 in Schließposition mit der übrigen

Außenseite des Tablettenspenders 1 und seines Gehäuses 2 bündig

ist. Dabei ist ferner dafür gesorgt, daß sie klemmend festgelegt

ist, damit ein sicherer Verschluß erreicht wird, der nicht ungewollt

geöffnet werden kann. Gegebenenfalls kann noch eine Rastverbindung

in Schließstellung vorgesehen sein.The

In Fig.3 und 4 ist dargestellt, daß der Rand der Verschlußkappe

9 und der diesem in Verschlußstellung benachbarte Wandbereich des

Gehäuses 2, also praktisch die am freien Rand der Verschlußkappenwandung

10 vorhandene aber geschlossene Fuge 19, außenseitig zumindest

vor dem Erstgebrauch mit einer Folie, im Ausführungsbeispiel einem

Klebstreifen 20, abgedeckt ist. Dadurch wird die Luftdichtigkeit

vor allem vor dem ersten Gebrauch erheblich verbessert, obwohl auch

ohne einen solchen schützenden und dichtenden Klebstreifen 20 die

Verschlußkappe 9 zusammen mit dem Wandbereich 18 einen praktisch

luftdichten Verschluß des Tablettenspenders 1 und seines Gehäuses

2 bewirkt.In Figures 3 and 4 it is shown that the edge of the

In den Figuren 2, 6 und 7 erkennt man hinsichtlich der Vereinzelungsvorrichtung

5 noch, daß der innere Behälter 4 im Bereich der

Tablettenausgabe- oder Spendeöffnung 7 einen verformbaren,

insbesondere zum Inneren des Behälters 4 hin verschwenkbaren, in

Schließstellung die Spendeöffnung 7 teilweise abdeckenden Vorsprung

21 hat, der durch die Verschiebung in Spendeposition durch eine

an ihm befindliche Schrägfläche 22 gegen eine Rückstellkraft,

insbesondere gegen seine eigene Elastizität, in das Innere des

Behälters 4 bewegbar und verschwenkbar ist. Dadurch wird der Zugang

zu der Spendeöffnung 7 für eine weitere Tablette 6 versperrt und

erst beim Zurückverschieben in die Ausgangslage und die dadurch

erfolgende entgegengesetzte Bewegung dieses Vorsprunges 21 wieder

für eine für den nächsten Spendevorgang bereitzustellende Tablette

6 freigegeben, während die zuvor schon vereinzelte Tablette 6 durch

die Spendeöffnung 7 herausfallen kann.FIGS. 2, 6 and 7 show the

Insgesamt ergibt sich ein Tablettenspender 1, dessen Innenraum durch

eine den Spende- und Betätigungsbereich dicht umschließende

Verschlußkappe 9 gegen den Zutritt von Luftfeuchtigkeit und

ungünstigen Umwelteinflüssen geschützt ist, wobei gleichzeitig

verhindert wird, daß ein Benutzer diese Schutz- und Verschlußkappe

9 einfach abzieht und wegläßt, weil er sie für den Spendevorgang

benötigt.Overall, there is a

Der Tablettenspender 1 hat ein äußeres Gehäuse 2 und einen in dessen

Innerem gegen eine Federkraft verschiebbaren Behälter 4 mit einer

Vereinzelungsvorrichtung 5, so daß jeweils eine einzelne Tablette

6 ausgegeben werden kann, wenn eine solche Verschiebebewegung des

Behälters 4 relativ zu dem Gehäuse 2 durchgeführt wird. Damit das

Innere dieses Tablettenspenders 1 gegen Luftfeuchtigkeit und dadurch

gegen ein vorzeitiges Verderben der Tabletten 6 geschützt wird,

ist an dem Gehäuse 2 eine dessen Spendeöffnung 7 und den Betätigungsbereich

8 überdeckende, abnehmbare Verschlußkappe 9 vorgesehen,

die gleichzeitig nach ihrem Abnehmen in einer versetzten Position

wieder auf den Ausgabebereich aufgesteckt wird und dadurch als

Betätigungswerkzeug dient, weil der Behälter 4 nicht selbst direkt

im Betätigungsbereich erreichbar ist, sondern dort von dem Gehäuse

2 umschlossen ist. Der Rand 13 des Behälters 4 liegt nämlich

allenfalls auf der Höhe des Randes 12 des Gehäuses 2 und springt

sogar teilweise demgegenüber zurück, so daß er mit der Wandung 10

der Verschlußkappe 9 bei der Verschiebebewegung zu beaufschlagen

ist.The

Claims (12)

- Tablet dispenser (1) comprising an outer housing (2) and a container (4) which fits into this housing (2) and is movable by sliding, in particular, counter to a spring force, having a device (5) for separating off the tablet (6) which is to be delivered on actuation, the relative sliding movement between the housing and the container opening up a dispensing aperture (7) for a separated tablet, characterised in that on the housing (2) is provided a removable closure cap (9) with cap wall (10) and cap base (11), which covers the dispensing aperture (7) and the operating area (8) for moving the inner container (4), in that the housing (2) projects over or encloses the container (4) at the operating area (8) of the housing (2), and inside the housing (2) the container (4) coincides with the outer edge (12) thereof and/or is at a spacing (a) therefrom, in that the housing (2) has a recess (14) or the like which is oriented in the direction of movement of the inner container (4) and extends over the edge portion (13) thereof which is to be moved, and in that the closure cap (9) fits with its wall (10) into the recess (14) in the housing (2) in a position which is offset relative to its closed position and engages therein in such a way as to act as a tool or actuating button for moving the inner container (4) relative to the housing (2).

- Tablet dispenser according to claim 1, characterised in that the housing (2) and the inner container (4) and the closure cap (9) have an oblong or substantially rectangular cross section and in that the closure cap (9) in a position which is laterally offset relative to its closed position and relative to the direction of the sliding movement along the longer side of this cross section can be fitted together with the housing (2) and the, in particular, slot-like recess (14) and can be pressure-connected to the inner container (4) in such a way that it projects laterally over a short side of the container (4).

- Tablet dispenser according to claim 1 or 2, characterised in that the cap (9) is mounted on the side which is at the bottom during the dispensing operation and the dispensing aperture (7) is provided on the short side over which the cap (9) projects in the actuating position.

- Tablet dispenser according to one of claims 1 to 3, characterised in that two corresponding and directly opposite, particularly slot-like recesses (14) are provided on the housing (2) for engaging the cap wall (9) during the dispensing operation.

- Tablet dispenser according to one of claims 1 to 4, characterised in that the closure cap (9) has a strip (15) mounted inside it which fits into positioning slots (16) provided parallel to the slot-like recesses (14) in the container, when the closure cap (9) is in the closed position, and in that additional slots (17) for the strip (15) provided in the cap (9) are arranged parallel thereto in the actuating position.

- Tablet dispenser according to one of claims 1 to 5, characterised in that the positioning strip (15) standing up from the base (11) inside the closure cap (9) extends parallel to the short sides and in particular is at a shorter distance from one short side of the closure cap (9) than from the other short side.

- Tablet dispenser according to one of claims 1 to 6, characterised in that the housing (2) has, as the seat for the closure cap (9), a wall portion (18) with a dimension oriented in the direction of application of the closure cap (9) and corresponding to the depth of the closure cap (9).

- Tablet dispenser according to one of claims 1 to 7, characterised in that in the closed position the housing (2) has, as the seat for the closure cap (9), a wall portion (18) which is less thick than the rest of the wall, the outer wall of the housing (2) being recessed all round at the seat for the closure cap (9).

- Tablet dispenser according to one of claims 1 to 8, characterised in that the dispensing aperture (7) for the separated tablet (6) is provided in that part (18) of the wall of the housing (2) which has a reduced thickness.

- Tablet dispenser according to one of claims 1 to 9, characterised in that in the closed position the closure cap (9) is flush with the remainder of the exterior of the tablet dispenser (1) and in particular can be secured by clamping and/or latching.

- Tablet dispenser according to one of claims 1 to 10, characterised in that the inner container (4) has, in the region of the tablet delivery or dispensing aperture (7), a deformable projection (21) which partly covers the dispensing aperture (7) in the closed position, which is movable into the interior of the container (4) counter to a recoil force, particularly its elasticity; by movement into the dispensing position by a sloping surface (22) provided thereon, so that it blocks access to the dispensing aperture (7) for any other tablets (6) and only releases a tablet (6) in readiness for the next dispensing operation once it has been returned to its starting position.

- Tablet dispenser according to one of the preceding claims, characterised in that the edge of the closure cap (9) and the part of the wall of the housing (2) adjacent thereto in the closed position and hence any joint (19) located between them in the closed position is covered and sealed on the outside, at least before the tablet dispenser (1) is used for the first time, by a film, such as an adhesive strip (20), for example.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19630710A DE19630710C1 (en) | 1996-07-30 | 1996-07-30 | Tablet dispenser |

| DE19630710 | 1996-07-30 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0822151A1 EP0822151A1 (en) | 1998-02-04 |

| EP0822151B1 true EP0822151B1 (en) | 2002-11-27 |

Family

ID=7801262

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP97111506A Expired - Lifetime EP0822151B1 (en) | 1996-07-30 | 1997-07-08 | Tablet dispenser with outer housing and container |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0822151B1 (en) |

| AT (1) | ATE228464T1 (en) |

| DE (2) | DE19630710C1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102008020385A1 (en) | 2008-04-23 | 2009-10-29 | Markus Finger | Globule dispenser for dispensing e.g. pill, has control opening formed in slider and is brought in congruence with fall-out opening by compressing slider using outer projecting button, where fall-out opening is formed in snatching head |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ES2588902T3 (en) | 2012-05-14 | 2016-11-07 | Boehringer Ingelheim International Gmbh | Device for housing a drug blister |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE7836939U1 (en) * | 1978-12-13 | 1979-03-22 | Lingner & Fischer Gmbh Lingner | Container |

| DE8216691U1 (en) * | 1982-06-09 | 1986-04-03 | Müller's Mühle Schneekoppe AG, 4650 Gelsenkirchen | Device for the dosed delivery of tablets |

| DE3716307A1 (en) * | 1987-05-15 | 1988-11-24 | Bramlage Gmbh | CONTAINER FOR SINGLE-PORTIONED DISPENSING OF TABLETS |

| ATE93200T1 (en) * | 1989-07-15 | 1993-09-15 | Kerplas Neuenburg Gmbh Kunstst | TABLET DISPENSER FOR INDIVIDUAL DOSING OF TABLETS. |

| ATE130272T1 (en) * | 1992-12-03 | 1995-12-15 | Kerplas Neuenburg Gmbh Kunstst | TABLET DISPENSER WITH A BOTTOM OUTLET OPENING. |

| GB9312493D0 (en) * | 1993-06-17 | 1993-08-04 | Lilly Industries Ltd | Improvements in or relating to dispensing devices |

-

1996

- 1996-07-30 DE DE19630710A patent/DE19630710C1/en not_active Expired - Fee Related

-

1997

- 1997-07-08 AT AT97111506T patent/ATE228464T1/en not_active IP Right Cessation

- 1997-07-08 EP EP97111506A patent/EP0822151B1/en not_active Expired - Lifetime

- 1997-07-08 DE DE59708802T patent/DE59708802D1/en not_active Expired - Fee Related

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102008020385A1 (en) | 2008-04-23 | 2009-10-29 | Markus Finger | Globule dispenser for dispensing e.g. pill, has control opening formed in slider and is brought in congruence with fall-out opening by compressing slider using outer projecting button, where fall-out opening is formed in snatching head |

Also Published As

| Publication number | Publication date |

|---|---|

| DE19630710C1 (en) | 1997-09-11 |

| DE59708802D1 (en) | 2003-01-09 |

| EP0822151A1 (en) | 1998-02-04 |

| ATE228464T1 (en) | 2002-12-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0199900B1 (en) | Dispenser for tablets | |

| DE3018041C2 (en) | ||

| EP0260250B1 (en) | Tablet dispenser | |

| AT391300B (en) | TABLET DISPENSER | |

| CH647474A5 (en) | CONTAINER FOR SINGLE-PORTIONED DISPENSING OF TABLETS. | |

| DE29514137U1 (en) | Pill dispenser | |

| EP2117959A1 (en) | Refillable single-hand dispenser for tablets | |

| DE6608621U (en) | DEVICE FOR DISPENSING AEROSOLS. | |

| DE3005188A1 (en) | TABLET DISPENSER | |

| EP1154939A1 (en) | Dispenser for dispensing elements in strips | |

| DE2925432C2 (en) | ||

| WO1999007621A1 (en) | Tablet dispenser | |

| EP0675840A1 (en) | Container for individually dispensing tablets or the like | |

| DE2922350A1 (en) | Tablet-dispensing container - comprises caps telescoping together and spring-loaded to control outlet opening | |

| DE69907039T2 (en) | BENDING DRIVE MECHANISM AND DISTRIBUTION DEVICE CONTAINED SUCH MECHANISM | |

| EP0822151B1 (en) | Tablet dispenser with outer housing and container | |

| EP0786420B1 (en) | Tablet dispenser for dispensing individual tablets | |

| EP0408774B1 (en) | Table dispenser for dispensing individual tablets | |

| DE4201995C2 (en) | Dispenser for tablet-shaped objects | |

| DE20304148U1 (en) | Pill dispenser | |

| DE29601042U1 (en) | Tablet dispenser for single dosage of tablets | |

| DE9106623U1 (en) | Tablet dispenser | |

| EP4387497A1 (en) | Dispenser for dispensing sheet-type material and container for sheet-type material | |

| AT378757B (en) | CONTAINER FOR SINGLE-PORTIONED DISPENSING OF TABLETS | |

| EP0089551B1 (en) | Dispenser for paper rolls |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE ES FR GB IT LI LU |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 19980325 |

|

| AKX | Designation fees paid |

Free format text: AT BE CH DE ES FR GB IT LI LU |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AT BE CH DE ES FR GB IT LI LU |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| 17Q | First examination report despatched |

Effective date: 20020624 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE ES FR GB IT LI LU |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20021127 |

|

| REF | Corresponds to: |

Ref document number: 228464 Country of ref document: AT Date of ref document: 20021215 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: HANS RUDOLF GACHNANG PATENTANWALT |

|

| REF | Corresponds to: |

Ref document number: 59708802 Country of ref document: DE Date of ref document: 20030109 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20030401 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20030529 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030708 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030708 |

|

| ET | Fr: translation filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030731 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20030828 |

|

| BERE | Be: lapsed |

Owner name: *KERPLAS NEUENBURG G.M.B.H. KUNSTSTOFFVERPACKUNGEN Effective date: 20030731 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20090610 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20090629 Year of fee payment: 13 Ref country code: DE Payment date: 20090608 Year of fee payment: 13 Ref country code: CH Payment date: 20090724 Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20100708 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20110331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110201 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100731 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100731 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 59708802 Country of ref document: DE Effective date: 20110201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100802 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100708 |