EP0790384B1 - Retractable closure - Google Patents

Retractable closure Download PDFInfo

- Publication number

- EP0790384B1 EP0790384B1 EP19970102522 EP97102522A EP0790384B1 EP 0790384 B1 EP0790384 B1 EP 0790384B1 EP 19970102522 EP19970102522 EP 19970102522 EP 97102522 A EP97102522 A EP 97102522A EP 0790384 B1 EP0790384 B1 EP 0790384B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- closure

- closure according

- sheet

- flexible sheet

- flexible

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B9/00—Screening or protective devices for wall or similar openings, with or without operating or securing mechanisms; Closures of similar construction

- E06B9/52—Devices affording protection against insects, e.g. fly screens; Mesh windows for other purposes

- E06B9/54—Roller fly screens

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B9/00—Screening or protective devices for wall or similar openings, with or without operating or securing mechanisms; Closures of similar construction

- E06B9/52—Devices affording protection against insects, e.g. fly screens; Mesh windows for other purposes

- E06B9/54—Roller fly screens

- E06B2009/543—Horizontally moving screens

Definitions

- This invention relates to a retractable closure for a building opening, said closure comprising a flexible sheet having opposite first and second lateral edges and a third edge extending transverse to said first and second lateral edges, a retractor mechanism connected to the third edge, with the flexible sheet being capable of being extended over said building opening to an extended position in opposition to the retractor mechanism, while being retractable to a retracted position by the retractor mechanism, first and second guide tracks positioned to receive said first and second lateral edges respectively for movement therealong, and engagement members secured to at least one of said first and second lateral edges to keep said at least one lateral edge in engagement with the relevant one of said first and second guide tracks.

- Such a closure is inter alia known from United States Patent 3,149,665, which describes a roller type screen with particular reference to an insect screen for window openings.

- the insect screen according to US 3,149,665 is provided with a series of spaced engagement members on each side edge of the screen to restrain these side edges from being drawn out of their guide channels.

- a retractable closure in accordance with the present invention is characterised in that said engagement members comprise pliable tongues biased to deflect from the flexible sheet in the extended position thereof and to be substantially flush with the flexible sheet in the retracted position thereof.

- the structure according to the present invention securely holds the edges of the sheet of the closure to the respective guide tracks against the action of mere gusts of wind. Notwithstanding this more secure restraining of the sheet, it can still be disengaged from the guide tracks under excessive mechanical force without damage.

- This kind of conditions may occur when persons accidentally walk through the closure if extended in a door opening or when playing children throw balls against the closure.

- closure sheet can simply be put back in engagement with its side guidings whereupon the closure can be opened as before.

- the flexible sheet can take a number of different forms, but the invention is particularly useful when the flexible sheet is a screen material, such as an insect screen.

- both of said first and second lateral edges have engagement members secured thereto in the form of said pliable tongues.

- the or each engagement member comprises a base portion and a flexible tongue attachment portion connected to said base portion and only said base portion is attached to said flexible sheet.

- the retractor member may be a spring biased roller.

- the guide tracks will be in the form of a channel, which may be partially closed by a flexible strip to prevent the ingress of dirt.

- the engagement member(s) are adhered to the sheet by a hot-melt adhesive, which may be applied to the sheet for form a continuous tape rigidifying the edges of the sheet.

- Figure 1 shows a retractable closure 1 mounted on a wall 3 in front of a building opening 5.

- the closure essentially comprises a flexible sheet 7 which can be a decorative fabric material, a mere functional insect screen, an energy conservation shield or the like.

- One vertical edge of the flexible sheet 7 is attached to a header bar 13 which is guided along the upper and lower guide tracks 9, 11.

- the opposite vertical edge of the flexible sheet 7 is concealed within a vertical box 15 which houses a retractor mechanism, of conventional type such as a spring biased roller.

- the retractor mechanism within box 15 either collects the flexible sheet material upon movement of the header bar 13 to an open position or pays out the sheet material upon movement of the header bar 13 to a closed position of the closure.

- Figure 2 shows a portion of the bottom guide track 11 and a portion of the flexible sheet 7 guided therein.

- the guide track 11 which is in the form of a guide channel has its upwardly directed opening partially closed off by a flexible guiding strip 17. To reduce friction on the flexible sheet 7 during opening and closing of the structure the flexible strip 17 preferably does not bear against the flexible sheet.

- Figure 3 shows a cross-section of the structure of Figure 2 in which it can be seen that the lower edge of the flexible sheet 7 is provided with a pliable tongue 19.

- the pliable tongue 19 has a free edge 21, also visible in Figure 2, which is deflected and spaced from the flexible sheet 7.

- Figure 3 also shows that the flexible guiding strip 17 is engaged in a channel 23 provided for that purpose in the upper end of the guiding channel. If the flexible sheet 7 is subjected to minor forces such as gusts of wind then the pliable tongue 19 will be securely retained within the guide track 11 by the guiding strip 17. However, if forces are applied to the sheet 7 of a more excessive magnitude then the flexibility of the pliable tongue 19 and the flexible guiding strip 17 will allow the sheet 7 to escape from the guide track 11.

- Figure 4 represents a partial cross-sectional perspective view of a lower guide channel.

- the flexible sheet 7 in this embodiment is represented as an insect screen mesh. At the lower edge of this screen mesh is attached an engagement member in the form of a pliable tongue 19A.

- Attachment of the engagement member to the lower screen edge can be by any suitable means, such as welding, gluing or by an overlying flexible adhesive tape.

- an adhesive strip can be formed on the flexible sheet by a hot-melt adhesive deposition thereon.

- Such hot-melt deposition can be brought into contact with the engagement members while being deposited thereon, or be remelted at a later stage to receive the engagement members.

- the bottom guide track 11 is represented as a short section to allow the interior to be viewed. It should be understood that the guide track will in reality be much longer than the section illustrated in Figure 4. Similarly it should be understood that for simplicity the structure according to the present invention is described with respect to the lower guide track 11, but could be similarly provided on the upper track 9 or on both tracks at the same time.

- the pliable tongue 19A is cutout from a base plate 25, which has a flat shape as illustrated in Figure 5.

- the shape of the engagement member illustrated in Figure 5 can advantageously be obtained by die cutting of a suitable material such as polyester sheet material.

- Hot-melt adhesive can advantageously be used in this manner as it loses its stickiness upon solidification.

- the guiding strip 17A is formed as an integral extrusion having a mounting socket 29 which directly engages in the guide track 11 and a flexible flap portion 31.

- the guiding strip 17A is suitably extruded from polycarbonate plastic.

- One suitable type of adhesive is an acrylate type adhesive which may be applied to a tape 27 as shown in Figure 5.

- the flexible sheet 7 is an insect screen mesh it may be necessary to place an additional tape or foil material on the opposite side of the mesh to prevent the adhesive from seeping through.

- the tape 27 may alternatively be formed in situ on the flexible sheet material as a hot-melt adhesive deposition.

- a substantial voluminous shape of the engagement members may be achieved when the flexible sheet is in a flattened and extended position.

- the pliable tongues lie substantially flush with the surface of the rolled up sheet and do not significantly add to the thickness of the rolled layers.

- plastic material for the pliable tongues and guiding strips may be used.

- the materials mentioned hereinbefore are merely indicative of one suitable embodiment.

Landscapes

- Engineering & Computer Science (AREA)

- Structural Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- Insects & Arthropods (AREA)

- Pest Control & Pesticides (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Operating, Guiding And Securing Of Roll- Type Closing Members (AREA)

Description

- This invention relates to a retractable closure for a building opening, said closure comprising a flexible sheet having opposite first and second lateral edges and a third edge extending transverse to said first and second lateral edges,a retractor mechanism connected to the third edge, with the flexible sheet being capable of being extended over said building opening to an extended position in opposition to the retractor mechanism, while being retractable to a retracted position by the retractor mechanism, first and second guide tracks positioned to receive said first and second lateral edges respectively for movement therealong, and engagement members secured to at least one of said first and second lateral edges to keep said at least one lateral edge in engagement with the relevant one of said first and second guide tracks.

- Such a closure is inter alia known from United States Patent 3,149,665, which describes a roller type screen with particular reference to an insect screen for window openings. The insect screen according to US 3,149,665 is provided with a series of spaced engagement members on each side edge of the screen to restrain these side edges from being drawn out of their guide channels.

- It has been found that gusts of wind sometimes cause the side edges of these roller screens to escape from their side guide tracks. Sometimes this is not noticed by the user and subsequent retraction of the closure may cause irreversible damage to the screen material.

- It is an object of the present invention to improve the engagement of the edges of the closure in the guide tracks.

- A retractable closure in accordance with the present invention is characterised in that said engagement members comprise pliable tongues biased to deflect from the flexible sheet in the extended position thereof and to be substantially flush with the flexible sheet in the retracted position thereof.

- The structure according to the present invention securely holds the edges of the sheet of the closure to the respective guide tracks against the action of mere gusts of wind. Notwithstanding this more secure restraining of the sheet, it can still be disengaged from the guide tracks under excessive mechanical force without damage.

- This kind of conditions may occur when persons accidentally walk through the closure if extended in a door opening or when playing children throw balls against the closure.

- Under such conditions the closure sheet can simply be put back in engagement with its side guidings whereupon the closure can be opened as before.

- The flexible sheet can take a number of different forms, but the invention is particularly useful when the flexible sheet is a screen material, such as an insect screen.

- Preferably both of said first and second lateral edges have engagement members secured thereto in the form of said pliable tongues.

- In an advantageous construction, the or each engagement member comprises a base portion and a flexible tongue attachment portion connected to said base portion and only said base portion is attached to said flexible sheet.

- The retractor member may be a spring biased roller. Normally the guide tracks will be in the form of a channel, which may be partially closed by a flexible strip to prevent the ingress of dirt.

- Advantageously the engagement member(s) are adhered to the sheet by a hot-melt adhesive, which may be applied to the sheet for form a continuous tape rigidifying the edges of the sheet.

- Above-mentioned and other (more detailed) aspects of the invention are further described and illustrated with reference to the accompanying drawing, wherein

- Figure 1 is a general view of one type of closure according to the present invention,

- Figure 2 is a lower portion of the closure of Figure 1 relating to a first embodiment of the invention,

- Figure 3 is a cross-section of the lower portion shown in Figure 2,

- Figure 4 is a further embodiment of the invention illustrated with respect to a lower portion of the closure of Figure 1,

- Figure 5 is a first type of engagement member of the embodiment of Figure 4,

- Figure 6 shows a guiding strip of the embodiment of Figure 4, and

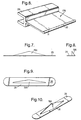

- Figures 7, 8, 9 and 10 show different views of a second type of engagement member of the embodiment of Figure 4.

-

- In the figures corresponding parts are referred to by similar reference signs.

- Figure 1 shows a retractable closure 1 mounted on a

wall 3 in front of a building opening 5. The closure essentially comprises aflexible sheet 7 which can be a decorative fabric material, a mere functional insect screen, an energy conservation shield or the like. - It is further seen that there are positioned upper and

lower guide tracks - One vertical edge of the

flexible sheet 7 is attached to aheader bar 13 which is guided along the upper andlower guide tracks flexible sheet 7 is concealed within avertical box 15 which houses a retractor mechanism, of conventional type such as a spring biased roller. - The retractor mechanism, within

box 15 either collects the flexible sheet material upon movement of theheader bar 13 to an open position or pays out the sheet material upon movement of theheader bar 13 to a closed position of the closure. - It should be understood that the arrangement of Figure 1 is only one of a number of possibilities and that the

horizontal guide tracks box 15 horizontally. - Figure 2 shows a portion of the

bottom guide track 11 and a portion of theflexible sheet 7 guided therein. - The

guide track 11 which is in the form of a guide channel has its upwardly directed opening partially closed off by a flexible guidingstrip 17. To reduce friction on theflexible sheet 7 during opening and closing of the structure theflexible strip 17 preferably does not bear against the flexible sheet. - Figure 3 shows a cross-section of the structure of Figure 2 in which it can be seen that the lower edge of the

flexible sheet 7 is provided with apliable tongue 19. Thepliable tongue 19 has afree edge 21, also visible in Figure 2, which is deflected and spaced from theflexible sheet 7. - Figure 3 also shows that the flexible guiding

strip 17 is engaged in achannel 23 provided for that purpose in the upper end of the guiding channel. If theflexible sheet 7 is subjected to minor forces such as gusts of wind then thepliable tongue 19 will be securely retained within theguide track 11 by the guidingstrip 17. However, if forces are applied to thesheet 7 of a more excessive magnitude then the flexibility of thepliable tongue 19 and the flexible guidingstrip 17 will allow thesheet 7 to escape from theguide track 11. - Such extreme forces could occur if someone by accident collides with the closed closure or when objects such as balls are thrown against the closure. It will then of course be necessary to reposition the sheet edges into the guide channel whereupon normal operation of the closure may be resumed.

- A modification of the above described embodiment is illustrated in Figure 4 which represents a partial cross-sectional perspective view of a lower guide channel.

- The

flexible sheet 7 in this embodiment is represented as an insect screen mesh. At the lower edge of this screen mesh is attached an engagement member in the form of apliable tongue 19A. - Attachment of the engagement member to the lower screen edge can be by any suitable means, such as welding, gluing or by an overlying flexible adhesive tape. Alternatively an adhesive strip can be formed on the flexible sheet by a hot-melt adhesive deposition thereon. Such hot-melt deposition can be brought into contact with the engagement members while being deposited thereon, or be remelted at a later stage to receive the engagement members. The

bottom guide track 11 is represented as a short section to allow the interior to be viewed. It should be understood that the guide track will in reality be much longer than the section illustrated in Figure 4. Similarly it should be understood that for simplicity the structure according to the present invention is described with respect to thelower guide track 11, but could be similarly provided on theupper track 9 or on both tracks at the same time. - In the embodiment of Figure 4 the

pliable tongue 19A is cutout from abase plate 25, which has a flat shape as illustrated in Figure 5. - The shape of the engagement member illustrated in Figure 5 can advantageously be obtained by die cutting of a suitable material such as polyester sheet material.

- This then can be attached to the sheet material by any of the means mentioned above. One favourable method places an

adhesive tape 27 in Figure 5 in dash-dotted lines partially over thebase plate 25. By placing an edge of the adhesive tape between thetongue 19A and thebase plate 25 thetongue 19A can be deflected from the surface of the sheet by a certain amount. - If adhesive such as a hot-melt adhesive is used, then this is applied between the sheet material and the

base plate 25. It has been found advantageous if using hot-melt adhesive to also apply this as a tape so as to benefit from the rigidifying effect this has on the sheet edges. Hot-melt adhesive can advantageously be used in this manner as it loses its stickiness upon solidification. - In Figure 6 a modified form of guiding

strip 17A as used in the embodiment of Figure 4 is shown. - In this embodiment the guiding

strip 17A is formed as an integral extrusion having amounting socket 29 which directly engages in theguide track 11 and aflexible flap portion 31. The guidingstrip 17A is suitably extruded from polycarbonate plastic. - For certain applications a more pronounced deflection of the

pliable tongue 19A may be required. - Such may be the case when the

distal edge 33 of the flexible guidingstrip 17A is required to be spaced at a larger distance from theflexible sheet 7. - In such situations it is conceived that the cut-out

tongue 19A of the engagement member of Figure 5 is additionally thermoformed into the bulbous shape illustrated in Figures 7 to 10. - It has further been found to be advantageous to leave the

tongue attachment portion 35 of thebase plate 25 unattached to the sheet material. This is achieved by the tape connection illustrated in Figure 5, but could also be achieved by keepingportion 35 free from adhesive or from welding as may be the case. - Leaving such a portion unattached not only enhances the flexibility and behaviour of the pliable tongue when it has to escape from the guide track, but also prevents the collection of dirt.

- The latter could occur when the tongue opens upwardly in a bottom track as shown in Figure 4.

- One suitable type of adhesive is an acrylate type adhesive which may be applied to a

tape 27 as shown in Figure 5. - If the

flexible sheet 7 is an insect screen mesh it may be necessary to place an additional tape or foil material on the opposite side of the mesh to prevent the adhesive from seeping through. As explained above thetape 27 may alternatively be formed in situ on the flexible sheet material as a hot-melt adhesive deposition. - As seen in Figures 7 to 10 a substantial voluminous shape of the engagement members may be achieved when the flexible sheet is in a flattened and extended position. However when the sheet is retracted such as on a roller the pliable tongues lie substantially flush with the surface of the rolled up sheet and do not significantly add to the thickness of the rolled layers.

- Other methods of retracting such as pleating or folding may be practised using the same effect.

- In roll-aside type shades and insect screens such as illustrated in Figure 1 it has been found that four engagement members of the type described are usually sufficient for lengths up to 1.5 metres. Further it has been found that the first two engagement members adjacent the

header bar 13 should be spaced at a pitch of 150 to 200 mm while the remainder of the engagement members can be spaced apart at a distance between 200 mm and 300 mm. With the flexible material of the closure fully extended it is further advantageous if the last engagement member is arranged to be relatively close to thebox 15 which houses the retractor mechanism. - Other combinations of plastic material for the pliable tongues and guiding strips may be used. The materials mentioned hereinbefore are merely indicative of one suitable embodiment.

- The invention is not limited to the above-mentioned embodiments. Within the scope of the invention a man ordinarily skilled in the art may provide some further embodiments.

Claims (11)

- Retractable closure for a building opening, said closure comprising a flexible sheet (7) having opposite first and second lateral edges and a third edge extending transverse to said first and second lateral edges, a retractor mechanism (15) connected to the third edge, with the flexible sheet (7) being capable of being extended over said building opening to an extended position in opposition to the retractor mechanism, while being retractable to a retracted position by the retractor mechanism, first and second guide tracks (9, 10) positioned to receive said first and second lateral edges respectively for movement therealong, and engagement members (19) secured to at least one of said first and second lateral edges to keep said at least one lateral edge in engagement with the relevant one of said first and second guide tracks, characterised in that said engagement members comprise pliable tongues (19, 19A) biased to deflect from the flexible sheet in the extended position thereof and to be substantially flush with the flexible sheet in the retracted position thereof.

- A closure according to claim 1, characterised in that said flexible sheet (7) is a screen material.

- A closure according to claim 1 or 2, characterised in that both of said first and second lateral edges have engagement members secured thereto in the form of said pliable tongue (19, 19A).

- A closure according to claim 1, 2 or 3, characterised in that the or each engagement member comprises a base portion (25) and a flexible tongue attachment portion (35) connected to said base portion.

- A closure according to claim 4, characterised in that only said base portion (25) is attached to said flexible sheet (7).

- A closure according to any preceding claim, characterised in that said closure is adapted to retract in a horizontal direction.

- A closure according to any preceding claim, characterised in that said retractor member (15) is a spring biased roller.

- A closure according to any preceding claim, characterised in that each guide track (9,11) is in the form of a channel.

- A closure according to claim 8, characterised in that a flexible guide strip (17) partially closes said channel.

- A closure according to any preceding claim, characterised in that said engagement member(s) are adhered to said sheet (7) by a hot-melt adhesive.

- A closure according to claim 10, characterised in that the hot-melt adhesive is applied to the sheet to form a continuous tape rigidifying the edges of the sheet.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP19970102522 EP0790384B1 (en) | 1996-02-19 | 1997-02-17 | Retractable closure |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP96200477 | 1996-02-19 | ||

| EP96200477 | 1996-02-19 | ||

| EP19970102522 EP0790384B1 (en) | 1996-02-19 | 1997-02-17 | Retractable closure |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0790384A1 EP0790384A1 (en) | 1997-08-20 |

| EP0790384B1 true EP0790384B1 (en) | 2002-05-02 |

Family

ID=26142538

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19970102522 Expired - Lifetime EP0790384B1 (en) | 1996-02-19 | 1997-02-17 | Retractable closure |

Country Status (1)

| Country | Link |

|---|---|

| EP (1) | EP0790384B1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9624722B2 (en) | 2013-02-28 | 2017-04-18 | Odl, Incorporated | Retractable flexible-panel door |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CA2393077C (en) * | 1999-12-06 | 2004-07-06 | Screenline Innovations, Inc. | Screen door fastening method and apparatus |

| MX2007016101A (en) * | 2005-06-16 | 2011-11-18 | Screenline Innovations | Retractable screen door housing handle balancing system. |

| NL2003830C2 (en) | 2009-11-19 | 2011-05-23 | Unilux Nederland B V | INSEKTENHOR. |

| DE102013018390A1 (en) * | 2013-11-02 | 2015-05-07 | Gardinia Home Decor Gmbh | Roller blind with profiled bar |

| ITUA20163337A1 (en) * | 2016-05-11 | 2017-11-11 | Mv Line S P A | Concealed guiding and tensioning device for sliding screens |

| EP3998391A1 (en) | 2020-01-10 | 2022-05-18 | REMIS Gesellschaft für Entwicklung und Vertrieb von technischen Elementen mbH Köln | System for guiding a flexible curtain |

| WO2024236412A1 (en) * | 2023-05-18 | 2024-11-21 | Dfm S.R.L. | Shielding device for environments |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3149665A (en) * | 1962-01-19 | 1964-09-22 | Hunter Douglas Int Quebec Ltd | Roller type screens for windows |

| NL8200456A (en) * | 1982-02-05 | 1983-09-01 | Cornelis Maria Van Wesenbeeck | ROLLER HORSE DOOR. |

| FR2602539B1 (en) * | 1986-08-11 | 1989-06-09 | Hayashiguchi Seizo | WINDOW SCREEN |

| GB2211540A (en) * | 1987-08-27 | 1989-07-05 | Hunter Douglas Ind Bv | Latch for blind |

| GB2249809A (en) * | 1990-11-15 | 1992-05-20 | Hunter Douglas Ind Bv | A retractable, flexible closure for a door or window opening |

-

1997

- 1997-02-17 EP EP19970102522 patent/EP0790384B1/en not_active Expired - Lifetime

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9624722B2 (en) | 2013-02-28 | 2017-04-18 | Odl, Incorporated | Retractable flexible-panel door |

| US10047558B2 (en) | 2013-02-28 | 2018-08-14 | Odl, Incorporated | Retractable flexible-panel door |

| US10947779B2 (en) | 2013-02-28 | 2021-03-16 | Larson Manufacturing Company Of South Dakota, Inc. | Method for mounting a flexible-panel door to a door frame of a building |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0790384A1 (en) | 1997-08-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US4148953A (en) | Air pervious weatherstrip | |

| US7231953B2 (en) | Rollup door with direct connected drive motor unit | |

| US5515902A (en) | Reinforced shutter panel | |

| EP0810178B1 (en) | Door sill arrangement for an elevator car | |

| US5819474A (en) | Temporary shelter and method of making same | |

| US4792178A (en) | Truck tonneau cover assembly | |

| EP0790384B1 (en) | Retractable closure | |

| EP0099454B1 (en) | Sun visor, especially for vehicles | |

| EP2633146A1 (en) | Window screen device | |

| EP1112875A2 (en) | Sunroof | |

| KR20010021729A (en) | Roll-up door with low friction edges | |

| WO2010099934A1 (en) | Sealing device for sealing a joint between two building components | |

| US20070284052A1 (en) | Door with retractable screen | |

| PL209071B1 (en) | Door assembly | |

| DE60124162T2 (en) | Dimming device for windows and / or vehicle opening with application of rods, and corresponding vehicle | |

| US5983570A (en) | Safety device for sliding glass doors | |

| DE19756021C1 (en) | Roof for motor vehicle | |

| EP0419985A1 (en) | Sliding roof and/or sliding lifting roof, especially for motor vehicles | |

| WO1990002861A1 (en) | An arrangement in doors | |

| EP1046534A2 (en) | Lid for closing of a roof opening in a car roof | |

| JPH0513910Y2 (en) | ||

| GB2123069A (en) | Window screen | |

| DE19647450A1 (en) | Use of an adhesive hook for fly screens | |

| CA1081113A (en) | Valances | |

| DE19830195B4 (en) | Locking device for entry openings, in particular garages |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): CH DE FR IT LI NL SE |

|

| 17P | Request for examination filed |

Effective date: 19980209 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| 17Q | First examination report despatched |

Effective date: 20010515 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): CH DE FR IT LI NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20020502 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20020502 Ref country code: FR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20020502 Ref country code: CH Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20020502 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 69712241 Country of ref document: DE Date of ref document: 20020606 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20020802 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20020803 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| EN | Fr: translation not filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20030204 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20050203 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060901 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20060901 |