EP0778110A3 - Method for modifying the operation mode of a fluid driven percussion mechanism and percussion mechanism for carrying out the method - Google Patents

Method for modifying the operation mode of a fluid driven percussion mechanism and percussion mechanism for carrying out the method Download PDFInfo

- Publication number

- EP0778110A3 EP0778110A3 EP96119281A EP96119281A EP0778110A3 EP 0778110 A3 EP0778110 A3 EP 0778110A3 EP 96119281 A EP96119281 A EP 96119281A EP 96119281 A EP96119281 A EP 96119281A EP 0778110 A3 EP0778110 A3 EP 0778110A3

- Authority

- EP

- European Patent Office

- Prior art keywords

- stroke

- percussion mechanism

- time delay

- return stroke

- percussion piston

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25D—PERCUSSIVE TOOLS

- B25D9/00—Portable percussive tools with fluid-pressure drive, i.e. driven directly by fluids, e.g. having several percussive tool bits operated simultaneously

- B25D9/14—Control devices for the reciprocating piston

- B25D9/26—Control devices for adjusting the stroke of the piston or the force or frequency of impact thereof

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25D—PERCUSSIVE TOOLS

- B25D9/00—Portable percussive tools with fluid-pressure drive, i.e. driven directly by fluids, e.g. having several percussive tool bits operated simultaneously

- B25D9/14—Control devices for the reciprocating piston

- B25D9/145—Control devices for the reciprocating piston for hydraulically actuated hammers having an accumulator

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- Mechanical Engineering (AREA)

- Automation & Control Theory (AREA)

- Percussive Tools And Related Accessories (AREA)

Abstract

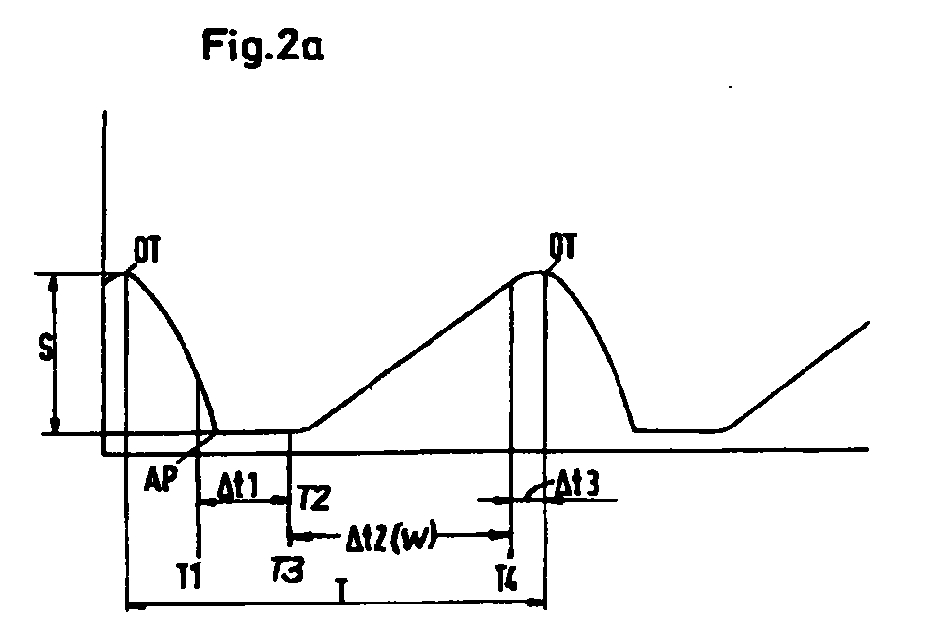

Die Erfindung befaßt sich mit der Beeinflussung des Betriebsverhaltens eines fluidbetriebenen Schlagwerks (1) mit einem Schlagkolben (3), der unter Einwirkung einer Steuerung (5) wechselweise einen Arbeitshub und einen Rückhub ausführt. Während des Arbeitshubs wird wegabhängig vom Schlagkolben (3) zu einem Anfangszeitpunkt (T1) ein Auslösesignal erzeugt, welches die Umschaltung der Steuerung in die Rückhubstellung einleitet; diese wird mit einer für alle Schlagzyklen nahezu konstanten Zeitverzögerung Δt1 zu einem nach Vollendung des Arbeitshubs liegenden Zeitpunkt erreicht.The invention is concerned with influencing the operating behavior of a fluid-powered percussion mechanism (1) with a percussion piston (3), the under the action of a controller (5) alternately a working stroke and executes a return stroke. During the work stroke it becomes path-dependent a trigger signal from the percussion piston (3) at an initial time (T1) generated, which switches the control in the return stroke position initiates; this becomes almost constant for all stroke cycles Time delay Δt1 to after completion of the working stroke lying point reached.

Mit der Erfindung wird der Vorschlag unterbreitet, eine zweite Zeitverzögerung Δt2 in Lauf zu setzen mit der Folge, daß der Schlagkolben (3) während der Zeitverzögerung Δt1 zunächst einen vom Reflexionsgrad des zu bearbeitenden Materials abhängigen Rückhub und - nach Umschalten der Steuerung in die Rückhubstellung - einen Rest-Rückhub ausführt, wobei zum Endzeitpunkt der zweiten Zeitverzögerung Δt2 unabhängig von der Schlagkolbenstellung die Umschaltung der Steuerung (5) in die Arbeitshubstellung eingeleitet wird. The invention proposes to start a second time delay Δt2, with the result that during the time delay Δt1 the percussion piston (3) first has a return stroke dependent on the reflectance of the material to be processed and - after switching the control to the return stroke position - executes a residual return stroke, the switchover of the control (5) to the working stroke position being initiated at the end of the second time delay .DELTA.t2, regardless of the percussion piston position.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE1995145708 DE19545708A1 (en) | 1995-12-07 | 1995-12-07 | Method for influencing the operating behavior of a fluid-operated hammer mechanism and hammer mechanism suitable for carrying out the method |

| DE19545708 | 1995-12-07 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0778110A2 EP0778110A2 (en) | 1997-06-11 |

| EP0778110A3 true EP0778110A3 (en) | 1998-06-10 |

Family

ID=7779480

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP96119281A Withdrawn EP0778110A3 (en) | 1995-12-07 | 1996-12-02 | Method for modifying the operation mode of a fluid driven percussion mechanism and percussion mechanism for carrying out the method |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0778110A3 (en) |

| JP (1) | JPH09174461A (en) |

| DE (1) | DE19545708A1 (en) |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19923680B4 (en) * | 1999-05-22 | 2004-02-26 | Atlas Copco Construction Tools Gmbh | Method for determining the operating time and the operating state of a hydraulic impact unit, in particular hydraulic hammer, and device for carrying out the method |

| JP4463381B2 (en) * | 2000-06-01 | 2010-05-19 | 古河機械金属株式会社 | Damper pressure control device for hydraulic drill |

| SE520460C2 (en) | 2001-05-10 | 2003-07-15 | Morphic Technologies Ab | Apparatus and method of material processing using high kinetic energy |

| KR100569198B1 (en) * | 2003-05-06 | 2006-04-07 | 이일재 | Hydraulic percussion device |

| JP4488694B2 (en) * | 2003-06-25 | 2010-06-23 | 甲南電機株式会社 | Hydraulic striking device |

| FI117548B (en) * | 2005-03-24 | 2006-11-30 | Sandvik Tamrock Oy | The impactor, |

| FR2983760B1 (en) * | 2011-12-09 | 2014-08-15 | Montabert Roger | METHOD FOR SWITCHING THE STROKE STROKE OF A STRIPPER PISTON OF A PERCUSSION APPARATUS |

| US9840000B2 (en) | 2014-12-17 | 2017-12-12 | Caterpillar Inc. | Hydraulic hammer having variable stroke control |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2248912A1 (en) * | 1973-10-29 | 1975-05-23 | Dresser Ind | |

| DE3443542A1 (en) * | 1984-11-29 | 1986-06-05 | Fried. Krupp Gmbh, 4300 Essen | HYDRAULIC BEATER |

| EP0461565A1 (en) * | 1990-06-14 | 1991-12-18 | Krupp Maschinentechnik Gesellschaft Mit Beschränkter Haftung | Method and device for the determination of characteristic features of an impact motor |

| EP0486898A1 (en) * | 1990-11-20 | 1992-05-27 | Krupp Maschinentechnik Gesellschaft Mit Beschränkter Haftung | Method and device for adjustment of working caracteristics of an impact mechanism to the hardness of the material to be destroyed |

| DE19507348A1 (en) * | 1995-03-02 | 1996-09-05 | Krupp Maschinentechnik | Method of controlling work-rate of hydraulic crushing hammer |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3115361A1 (en) * | 1981-04-16 | 1982-10-28 | Hydroc Gesteinsbohrtechnik GmbH, 5960 Olpe | Hydraulic percussion device |

| SE8106907L (en) * | 1981-11-20 | 1983-05-21 | Atlas Copco Ab | WAY TO CONTROL A PERFORMANCE AND PERFORMANCE |

| DE4019016A1 (en) * | 1990-06-14 | 1991-06-13 | Krupp Maschinentechnik | Hydraulically operated percussion tool - has system to vary mode of operation according to hardness of material |

-

1995

- 1995-12-07 DE DE1995145708 patent/DE19545708A1/en not_active Ceased

-

1996

- 1996-12-02 EP EP96119281A patent/EP0778110A3/en not_active Withdrawn

- 1996-12-06 JP JP8327089A patent/JPH09174461A/en active Pending

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2248912A1 (en) * | 1973-10-29 | 1975-05-23 | Dresser Ind | |

| DE3443542A1 (en) * | 1984-11-29 | 1986-06-05 | Fried. Krupp Gmbh, 4300 Essen | HYDRAULIC BEATER |

| EP0461565A1 (en) * | 1990-06-14 | 1991-12-18 | Krupp Maschinentechnik Gesellschaft Mit Beschränkter Haftung | Method and device for the determination of characteristic features of an impact motor |

| EP0486898A1 (en) * | 1990-11-20 | 1992-05-27 | Krupp Maschinentechnik Gesellschaft Mit Beschränkter Haftung | Method and device for adjustment of working caracteristics of an impact mechanism to the hardness of the material to be destroyed |

| DE19507348A1 (en) * | 1995-03-02 | 1996-09-05 | Krupp Maschinentechnik | Method of controlling work-rate of hydraulic crushing hammer |

Also Published As

| Publication number | Publication date |

|---|---|

| DE19545708A1 (en) | 1997-06-12 |

| JPH09174461A (en) | 1997-07-08 |

| EP0778110A2 (en) | 1997-06-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0778110A3 (en) | Method for modifying the operation mode of a fluid driven percussion mechanism and percussion mechanism for carrying out the method | |

| CA2422270C (en) | Installation tool for installing swage type threaded fasteners | |

| EP0965698A4 (en) | Method and device for controlling construction machine | |

| KR20000025354A (en) | Hydraulic unit for drive cylinder | |

| KR900004440A (en) | Casting process control method by adjusting piston movement amount of fluid working cylinder and apparatus for executing the method | |

| DE102004049109A1 (en) | A cutter or gripper with means for detecting the completion of work | |

| US4327568A (en) | Method for the cold rolling of parts | |

| EP1287978A3 (en) | Process and apparatus for metal powder compression in a pressed body | |

| US4509330A (en) | Pneumatically controlled pressure transducer for operating hydraulic work tools | |

| US3177688A (en) | Forging machine for the internal profiling of tubular workpieces, particularly of barrels for firearms | |

| AU596732B2 (en) | Stop position correction apparatus of bucket | |

| US5273217A (en) | Method and apparatus for improving the crushing action of demolition tools | |

| US6240627B1 (en) | Apparatus for mechanical joining | |

| DE3638149C2 (en) | ||

| US5524534A (en) | Dual hydraulic cylinder compacting apparatus | |

| EP0473968B1 (en) | Hydraulic operated impact drilling device, especially for bolt drilling | |

| EP1075902A3 (en) | Pliers for mechanical treatment of work pieces | |

| DE19507348A1 (en) | Method of controlling work-rate of hydraulic crushing hammer | |

| CA2235404C (en) | Filter press with weight-responsive bumping of filter plates | |

| CN108421837A (en) | The method and apparatus for monitoring the functional status of the formed tooth arrangement on shaping jig | |

| EP0829318A3 (en) | Method for controlling the stroke frequency of a forging press and forging press for carrying out the method | |

| RU2049572C1 (en) | Product stretcher straightening apparatus | |

| EP0447839B1 (en) | Method to forge with a swaging machine, and a swaging machine suitable to carry out the method | |

| JPH0225585Y2 (en) | ||

| US6907765B2 (en) | Ram-side ejector device for workpieces in single-or multi-stage presses |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): DE FR IT |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): DE FR IT |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN WITHDRAWN |

|

| 18W | Application withdrawn |

Withdrawal date: 19980914 |