EP0754854A2 - Injection valve for compression ignition engines - Google Patents

Injection valve for compression ignition engines Download PDFInfo

- Publication number

- EP0754854A2 EP0754854A2 EP19960109742 EP96109742A EP0754854A2 EP 0754854 A2 EP0754854 A2 EP 0754854A2 EP 19960109742 EP19960109742 EP 19960109742 EP 96109742 A EP96109742 A EP 96109742A EP 0754854 A2 EP0754854 A2 EP 0754854A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- injection

- base body

- cylinder head

- line

- injection valve

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M61/00—Fuel-injectors not provided for in groups F02M39/00 - F02M57/00 or F02M67/00

- F02M61/14—Arrangements of injectors with respect to engines; Mounting of injectors

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M55/00—Fuel-injection apparatus characterised by their fuel conduits or their venting means; Arrangements of conduits between fuel tank and pump F02M37/00

- F02M55/004—Joints; Sealings

- F02M55/005—Joints; Sealings for high pressure conduits, e.g. connected to pump outlet or to injector inlet

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M55/00—Fuel-injection apparatus characterised by their fuel conduits or their venting means; Arrangements of conduits between fuel tank and pump F02M37/00

- F02M55/02—Conduits between injection pumps and injectors, e.g. conduits between pump and common-rail or conduits between common-rail and injectors

Definitions

- the invention relates to an injection valve for air-compressing internal combustion engines, which is inserted into a bore in a cylinder head and which consists of a base body with a lateral connection of an injection line and which has a connection for the drainage of oil and the injection valve by means of a claw in the axial direction against the cylinder head is clamped, and is sealed at the injection end by means of a seal against the cylinder head.

- an injection valve which can be inserted into a bore in a cylinder head and which is fixed in the axial direction with a claw.

- the injection line is screwed directly into the injection valve and sealed against the main body of the injection valve with a conical seat.

- An axial bore is provided in the base body to discharge the leak oil.

- Such direct attachment of an injection line by screwing in the base body can only be achieved with injection nozzles of larger diameter.

- the injection nozzle itself differs from standardized embodiments and is correspondingly expensive, which is very disadvantageous in series production.

- the union screw used here affects the freedom of design of the injection line.

- the object of the invention is to design a connection between the injection line and the injection nozzle in such a way that it can also be used on standardized injection nozzles of small diameter and that the design of the injection line is not restricted by using a standardized union nut. .

- the two O-rings provide a safe seal against leakage oil and it can be drained off via the annulus and a leakage oil line.

- the leak oil can be drained through a hole in the cylinder head.

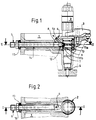

- Figure 1 shows a section I-I through the cylinder head 1 with an inserted injector 2, which is pressed by a claw 3 against the cylinder head 1 and sealed against it with a seal 4.

- the fuel is fed to the injection valve via an injection line 5.

- this injection line 5 is not screwed directly into a threaded bore of the injection valve, but into a threaded bore 8 of a clamping body 6, which completely encompasses a base body 7 of the injection valve 2.

- the injection line 5 is pressed against the base body 7 by the threaded bore 8 of the clamping body 6 for sealing via a conical sealing surface 9.

- an annular groove 10 is screwed into the base body 7 at the level where the injection line 5 opens.

- Two O-rings 11a, 11b are provided on both sides of this annular groove between the base body 2 and the clamping body 6 in order to seal the annular groove 10 against the clamping body 6.

- an annular space 12 is arranged in the clamping body 6, via which leak oil can flow into a leak oil line 13.

- the injection line 5 is led to the outside through a bore 14 and sealed by means of an outer seal 15.

- a threaded hole in the base body 7 of the injection valve 2 itself is avoided by the clamping body 6.

- internal combustion engines in particular those with vertical, centrally and approximately centrally arranged injection nozzles, only injection valves of relatively small diameter can be used, which do not allow a threaded hole in the base body due to static considerations.

- the tensioning body 6 also considerably simplifies the installation and removal of the injection valve 2.

- a standard-style injection valve can be used, which is of considerable cost advantage in the case of a mass-produced article such as an internal combustion engine for commercial vehicles.

- Figure 2 shows the cylinder head 1 in section II-II and the injector 2 used in an axial view.

- the injection line 5 can be screwed into the clamping body 6 by means of a hexagon 16.

- the outer seal 15 is provided for sealing against escaping engine oil.

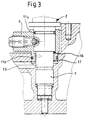

- FIG. 3 shows an alternative design for drainage of oil.

- the base body 7 of the injection valve 2 is sealed with an O-ring 11a against the clamping body 6.

- An annular space 16 is arranged between the base body 7 and the clamping body 6 for drainage of oil, which continues in an annular gap 17 and opens into the drain line 13.

- the leak oil is drained directly through a hole in the cylinder head 1.

- the clamping body 6 does not require a connection for the leak oil drain.

- the second O-ring 11b seals the clamping body 6 against the cylinder head 1.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Fuel-Injection Apparatus (AREA)

- Cylinder Crankcases Of Internal Combustion Engines (AREA)

Abstract

Description

Die Erfindung bezieht sich auf ein Einspritzventil für luftverdichtende Brennkraftmaschinen, welches in eine Bohrung eines Zylinderkopfes eingesetzt ist und das aus einem Grundkörper mit seitlichem Anschluß einer Einspritzleitung besteht und das einen Anschluß für die Leckölabführung aufweist und das Einspritzventil mittels einer Pratze in axialer Richtung gegen den Zylinderkopf verspannt wird, sowie am einspritzseitigen Ende mittels Dichtung gegen den Zylinderkopf abgedichtet ist.The invention relates to an injection valve for air-compressing internal combustion engines, which is inserted into a bore in a cylinder head and which consists of a base body with a lateral connection of an injection line and which has a connection for the drainage of oil and the injection valve by means of a claw in the axial direction against the cylinder head is clamped, and is sealed at the injection end by means of a seal against the cylinder head.

Aus DE 43 12 936 A1 ist ein Einspritzventil bekannt, welches in eine Bohrung eines Zylinderkopfes einsetzbar ist und welches mit einer Pratze in axialer Richtung fixiert ist. Die Einspritzleitung ist unmittelbar in das Einspritzventil eingeschraubt und mit einem Kegelsitz gegen den Grundkörper des Einspritzventils abgedichtet. Zur Ableitung des Lecköls ist im Grundkörper eine axiale Bohrung vorgesehen. Eine derartige unmittelbare Befestigung einer Einspritzleitung durch Verschraubung im Grundkörper ist nur bei Einspritzdüsen größeren Durchmessers zu bewerkstelligen. Zudem weicht die Einspritzdüse selbst von standardisierten Ausführungsformen ab und wird entsprechend teuer, was bei Serienfertigung sehr nachteilig ist. Die hier verwendete Überwurfschraube beeinträchtigt die Gestaltungsfreiheit der Einspritzleitung.From DE 43 12 936 A1 an injection valve is known which can be inserted into a bore in a cylinder head and which is fixed in the axial direction with a claw. The injection line is screwed directly into the injection valve and sealed against the main body of the injection valve with a conical seat. An axial bore is provided in the base body to discharge the leak oil. Such direct attachment of an injection line by screwing in the base body can only be achieved with injection nozzles of larger diameter. In addition, the injection nozzle itself differs from standardized embodiments and is correspondingly expensive, which is very disadvantageous in series production. The union screw used here affects the freedom of design of the injection line.

Ausgehend von einem Einspritzventil gemäß dem Oberbegriff liegt der Erfindung die Aufgabe zugrunde, eine Verbindung von Einspritzleitung und Einspritzdüse so zu gestalten, daß sie auch auf standardisierte Einspritzdüsen kleinen Durchmessers anwendbar ist und daß die Einspritzleitung durch Verwendung einer standardisierten Überwurfmutter in ihrer Gestaltung nicht eingeschränkt ist..Starting from an injection valve according to the preamble, the object of the invention is to design a connection between the injection line and the injection nozzle in such a way that it can also be used on standardized injection nozzles of small diameter and that the design of the injection line is not restricted by using a standardized union nut. .

Gelöst wird diese Aufgabe durch die kennzeichnenden Merkmale des Patentanspruches 1.This object is achieved by the characterizing features of

Dadurch, daß die Verschraubung der Einspritzleitung von der Einspritzdüse selbst in den Spannkörper verlegt wird, kann eine Einspritzdüse in Standardausführung mit rotationsymmetrischen Bearbeitungen am Grundkörper verwendet werden, es sind lediglich Ausdrehungen für die Aufnahme der O-Ringe erforderlich. Dies hat eine Einsparung zur Folge, wie sie bei Serienfertigung besonders ins Gewicht fällt. Für Brennkraftmaschinen mit senkrechten, mittig und annähernd mittig angeordneten Einspritzdüsen sind wegen beschränkten Einbauraumes nur Einspritzdüsen Kleineren Durchmessers anwendbar, wo die Einspritzleitungen nicht mehr unmittelbar in den Grundkörper eingeschraubt wer-den können. Durch die erfindungsgemäße Verbindung wird das Gewinde in der Ein-spritzdüse vermieden. Die Außendichtung mischen Einspritzleitung und Zylinderkopf ermöglicht den Einbau der Einspritzdüse in den Ölraum des Zylinderkopfes.Because the screw connection of the injection line is moved from the injection nozzle itself into the clamping body, a standard-style injection nozzle with rotationally symmetrical machining on the base body can be used; all that is required is to remove the O-rings. This results in savings that are particularly significant in series production. For internal combustion engines with vertical, centrally and approximately centrally arranged injection nozzles, only injection nozzles of smaller diameter can be used due to the limited installation space, where the injection lines can no longer be screwed directly into the base body. The connection according to the invention avoids the thread in the injection nozzle. The outer seal mix injection line and cylinder head enables the injection nozzle to be installed in the oil space of the cylinder head.

Eine vorteilhafte Weiterbildung kann Anspruch 2 entnommen werden.An advantageous further development can be found in

Durch die beiden O-Ringe wird gegen Lecköl sicher abgedichtet und es kann über den Ringraum und eine Leckölleitung abgeführt werden.The two O-rings provide a safe seal against leakage oil and it can be drained off via the annulus and a leakage oil line.

Eine alternative Lösung zur Leckölabdichtung kann dem Anspruch 3 entnommen werden.An alternative solution to leak oil sealing can be found in claim 3.

Die Leckölabführung kann hier durch eine Bohrung im Zylinderkopf erfolgen.The leak oil can be drained through a hole in the cylinder head.

Ausführungsbeispiele der Erfindung sind in Zeichnungen dargestellt. Es zeigt:

- Fig. 1

- ein in einen Zylinderkopf eingesetztes Einspritzventil mit Spannkörper im Schnitt I-I

- Fig. 2

- einen Schnitt II-II durch den Zylinderkopf mit dem Einspritzventil in axialer Richtung gesehen

- Fig. 3

- eine alternative Ausbildung der Leckölrückführung

- Fig. 1

- an injector inserted into a cylinder head with a clamping body in section II

- Fig. 2

- a section II-II seen through the cylinder head with the injection valve in the axial direction

- Fig. 3

- an alternative embodiment of the leakage oil return

Figur 1 zeigt einen Schnitt I-I durch den Zylinderkopf 1 mit eingesetzter Einspritzdüse 2, welche durch eine Pratze 3 gegen den Zylinderkopf 1 gepreßt und gegen diesen mit Dichtung 4 abgedichtet ist. Der Brennstoff wird dem Einspritzventil über eine Einspritzleitung 5 zugeführt. Erfindungsgemäß wird diese Einspritzleitung 5 nicht unmittelbar in eine Gewindebohrung des Einspritzventils eingeschraubt, sondern in eine Gewindebohrung 8 eines Spannkörpers 6, welcher einen Grundkörper 7 des Einspritzventils 2 vollständig umfaßt. Die Einspritzleitung 5 wird durch die Gewindebohrung 8 des Spannkörpers 6 zur Abdichtung über eine kegelige Dichtfläche 9 gegen den Grundkörper 7 gepreßt. Zur Abführung eines evtl. aus der Dichtflache 9 austretenden Lecköls ist in Höhe der Einmündung der Einspritzleitung 5 in den Grundkörper 7 eine Ringnut 10 eingedreht. Zu beiden Seiten dieser Ringnut sind zwischen Grundkörper 2 und dem Spannkörper 6 zwei O-Ringe 11a, 11b vorgesehen, um die Ringnut 10 gegen den Spannkörper 6 abzudichten. In der Umgebung der kegeligen Dichtfläche 9 ist im Spannkörper 6 ein Ringraum 12 angeordnet, über den anfallendes Lecköl in eine Leckölleitung 13 abfließen kann.Figure 1 shows a section I-I through the

Bei Einbau des Einspritzventils 2 in einen Ölraum des Zylinderkopfes 1 wird die Einspritzleitung 5 durch eine Bohrung 14 nach außen geführt und mittels einer Außendichtung 15 abgedichtet.When the

Durch den Spannkörper 6 wird eine Gewindebohrung im Grundkörper 7 des Einspritzventils 2 selbst vermieden. Bei Brennkraftmaschinen, insbesondere solche mit senkrechten, mittig und annähernd mittig angeordneten Einspritzdüsen sind nur Einspritzventile relativ Kleinen Durchmessers anwendbar, welche eine Gewindebohrung im Grundkörper aus statischen Erwägungen heraus gar nicht zulassen. Durch den Spannkörper 6 wird auch Ein- und Ausbau des Einspritzventils 2 erheblich erleichtert. Ferner kann ein Einspritzventil in Standartausführung verwendet werden, was bei einem Massenartikel wie einer Brennkraftmaschine für Nutzfahrzeuge von erheblichem Kostenvorteil ist.A threaded hole in the

Figur 2 zeigt den Zylinderkopf 1 im Schnitt II-II und die eingesetzte Einspritzdüse 2 in axialer Ansicht. Die Einspritzleitung 5 kann mittels eines Sechskantes 16 in den Spannkörper 6 eingeschraubt werden. Zur Abdichtung gegen austretendes Motoröl ist die Außendichtung 15 vorgesehen.Figure 2 shows the

Eine alternative Ausbildung zur Leckölabführung zeigt Figur 3. Hier ist der Grundkörper 7 des Einspritzventils 2 mit einem O-Ring 11a gegen den Spannkörper 6 abgedichtet. Zwischen Grundkörper 7 und Spannkörper 6 ist zur Leckölabführung ein Ringraum 16 angeordnet, welcher sich in einem Ringspalt 17 fortsetzt und dieser in die Leckölleitung 13 mündet. Die Leckölabführung erfolgt unmittelbar über eine Bohrung im Zylinderkopf 1. Der Spannkörper 6 bedarf keines Anschlusses für die Leckölabführung. Der zweite O-Ring 11b dichtet den Spannkörper 6 gegen den Zylinderkopf 1 ab.FIG. 3 shows an alternative design for drainage of oil. Here, the

Claims (3)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE1995126693 DE19526693A1 (en) | 1995-07-21 | 1995-07-21 | Injection valve for air-compressing internal combustion engines |

| DE19526693 | 1995-07-21 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP0754854A2 true EP0754854A2 (en) | 1997-01-22 |

Family

ID=7767448

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19960109742 Withdrawn EP0754854A2 (en) | 1995-07-21 | 1996-06-18 | Injection valve for compression ignition engines |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0754854A2 (en) |

| DE (1) | DE19526693A1 (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0922852A2 (en) | 1997-12-09 | 1999-06-16 | LUCAS INDUSTRIES public limited company | Fuel system |

| EP1001162A2 (en) * | 1998-11-12 | 2000-05-17 | Lucas Industries Limited | Injector and injector assembly |

| WO2005035970A1 (en) * | 2003-10-06 | 2005-04-21 | Robert Bosch Gmbh | Injection nozzle |

| CN111120169A (en) * | 2019-11-21 | 2020-05-08 | 浙江赫洛金属制品有限公司 | Connecting joint for automobile fuel injector |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1776183A1 (en) * | 1967-01-07 | 1971-07-01 | Daimler Benz Ag | Low-profile pressure connection, thermoplastic film |

| US3845748A (en) * | 1972-09-29 | 1974-11-05 | Mack Trucks | Fuel injection nozzle holder installation |

| GB2197386B (en) * | 1986-11-07 | 1990-08-29 | Lucas Ind Plc | Fuel injection nozzle |

| DE9206268U1 (en) * | 1992-05-09 | 1993-09-09 | Robert Bosch Gmbh, 70469 Stuttgart | Fuel supply device for an injection nozzle |

| DE4239173C1 (en) * | 1992-11-21 | 1993-09-02 | Mercedes-Benz Aktiengesellschaft, 70327 Stuttgart, De | Cylinder-head for fuel-injection engine - has pressure pipe passing through clamping screw and with union at protruding end for injection pipe |

| DE4427717C1 (en) * | 1994-08-05 | 1995-08-31 | Daimler Benz Ag | High pressure conduit connection for nozzle holder of fuel injection valve on IC engine cylinder head |

-

1995

- 1995-07-21 DE DE1995126693 patent/DE19526693A1/en not_active Ceased

-

1996

- 1996-06-18 EP EP19960109742 patent/EP0754854A2/en not_active Withdrawn

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0922852A2 (en) | 1997-12-09 | 1999-06-16 | LUCAS INDUSTRIES public limited company | Fuel system |

| EP0922852A3 (en) * | 1997-12-09 | 2000-06-07 | Lucas Industries Limited | Fuel system |

| EP1001162A2 (en) * | 1998-11-12 | 2000-05-17 | Lucas Industries Limited | Injector and injector assembly |

| EP1001162A3 (en) * | 1998-11-12 | 2001-07-04 | Delphi Technologies, Inc. | Injector and injector assembly |

| WO2005035970A1 (en) * | 2003-10-06 | 2005-04-21 | Robert Bosch Gmbh | Injection nozzle |

| CN111120169A (en) * | 2019-11-21 | 2020-05-08 | 浙江赫洛金属制品有限公司 | Connecting joint for automobile fuel injector |

| CN111120169B (en) * | 2019-11-21 | 2021-03-12 | 浙江赫洛金属制品有限公司 | Connecting joint for automobile fuel injector |

Also Published As

| Publication number | Publication date |

|---|---|

| DE19526693A1 (en) | 1997-01-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE4239173C1 (en) | Cylinder-head for fuel-injection engine - has pressure pipe passing through clamping screw and with union at protruding end for injection pipe | |

| EP0461212B1 (en) | Electrically controlled fuel injection pump for internal combustion engines, especially pump nozzle | |

| DE3821827C2 (en) | ||

| DE19853090A1 (en) | Fuel injection system | |

| DE202004009755U1 (en) | Device for pulling out a nozzle stick | |

| EP0627553B1 (en) | Holding device for a fuel injection valve in a diesel engine | |

| DE4315233A1 (en) | Direct injection internal combustion engine | |

| EP1129286B1 (en) | Fuel injection valve for an internal combustion engine | |

| DE19581050B3 (en) | Combustion gas seal assembly for fuel injector | |

| DE19508636A1 (en) | Fuel injection valve for internal combustion engines | |

| DE3128523C2 (en) | ||

| EP2321521A1 (en) | Fuel injection valve for arrangement in a combustion chamber of an internal combustion engine | |

| DE19753518A1 (en) | Fuel supply device | |

| DE3010328A1 (en) | IC engine fuel injection nozzle - has radial pipe connection with sealing force along nozzle axis | |

| EP0754854A2 (en) | Injection valve for compression ignition engines | |

| DE19536330A1 (en) | Fuel injection valve for IC engines | |

| DE4427717C1 (en) | High pressure conduit connection for nozzle holder of fuel injection valve on IC engine cylinder head | |

| DE19608572A1 (en) | Fuel supply device | |

| DE19705227A1 (en) | High pressure fuel injector | |

| DE4307650C2 (en) | High pressure line connection | |

| DE4301521A1 (en) | Pressure valve | |

| DE3907958A1 (en) | FUEL INJECTION NOZZLE FOR INTERNAL COMBUSTION ENGINES | |

| EP1241348B1 (en) | High pressure connection for fuel injection system | |

| DE19627952A1 (en) | Sparking plug for IC engine arranged at least one per cylinder at combustion chamber | |

| DE19543506C2 (en) | Connection of an injection line to an injection valve |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): DE FR GB IT SE |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19991231 |