EP0734788A2 - Sortiermaschine - Google Patents

Sortiermaschine Download PDFInfo

- Publication number

- EP0734788A2 EP0734788A2 EP96200821A EP96200821A EP0734788A2 EP 0734788 A2 EP0734788 A2 EP 0734788A2 EP 96200821 A EP96200821 A EP 96200821A EP 96200821 A EP96200821 A EP 96200821A EP 0734788 A2 EP0734788 A2 EP 0734788A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- receptacle

- conveyor belt

- garbage

- arrangement according

- sorting arrangement

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 230000000750 progressive effect Effects 0.000 claims abstract description 8

- 239000000203 mixture Substances 0.000 claims abstract description 6

- 230000008878 coupling Effects 0.000 claims description 11

- 238000010168 coupling process Methods 0.000 claims description 11

- 238000005859 coupling reaction Methods 0.000 claims description 11

- 238000000034 method Methods 0.000 abstract description 5

- 101100334009 Caenorhabditis elegans rib-2 gene Proteins 0.000 description 6

- 238000010276 construction Methods 0.000 description 4

- 229910000831 Steel Inorganic materials 0.000 description 1

- 238000010924 continuous production Methods 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B07—SEPARATING SOLIDS FROM SOLIDS; SORTING

- B07B—SEPARATING SOLIDS FROM SOLIDS BY SIEVING, SCREENING, SIFTING OR BY USING GAS CURRENTS; SEPARATING BY OTHER DRY METHODS APPLICABLE TO BULK MATERIAL, e.g. LOOSE ARTICLES FIT TO BE HANDLED LIKE BULK MATERIAL

- B07B13/00—Grading or sorting solid materials by dry methods, not otherwise provided for; Sorting articles otherwise than by indirectly controlled devices

- B07B13/04—Grading or sorting solid materials by dry methods, not otherwise provided for; Sorting articles otherwise than by indirectly controlled devices according to size

- B07B13/05—Grading or sorting solid materials by dry methods, not otherwise provided for; Sorting articles otherwise than by indirectly controlled devices according to size using material mover cooperating with retainer, deflector or discharger

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B07—SEPARATING SOLIDS FROM SOLIDS; SORTING

- B07B—SEPARATING SOLIDS FROM SOLIDS BY SIEVING, SCREENING, SIFTING OR BY USING GAS CURRENTS; SEPARATING BY OTHER DRY METHODS APPLICABLE TO BULK MATERIAL, e.g. LOOSE ARTICLES FIT TO BE HANDLED LIKE BULK MATERIAL

- B07B13/00—Grading or sorting solid materials by dry methods, not otherwise provided for; Sorting articles otherwise than by indirectly controlled devices

- B07B13/02—Apparatus for grading using pockets for taking out particles from aggregates

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B07—SEPARATING SOLIDS FROM SOLIDS; SORTING

- B07B—SEPARATING SOLIDS FROM SOLIDS BY SIEVING, SCREENING, SIFTING OR BY USING GAS CURRENTS; SEPARATING BY OTHER DRY METHODS APPLICABLE TO BULK MATERIAL, e.g. LOOSE ARTICLES FIT TO BE HANDLED LIKE BULK MATERIAL

- B07B13/00—Grading or sorting solid materials by dry methods, not otherwise provided for; Sorting articles otherwise than by indirectly controlled devices

- B07B13/04—Grading or sorting solid materials by dry methods, not otherwise provided for; Sorting articles otherwise than by indirectly controlled devices according to size

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B07—SEPARATING SOLIDS FROM SOLIDS; SORTING

- B07B—SEPARATING SOLIDS FROM SOLIDS BY SIEVING, SCREENING, SIFTING OR BY USING GAS CURRENTS; SEPARATING BY OTHER DRY METHODS APPLICABLE TO BULK MATERIAL, e.g. LOOSE ARTICLES FIT TO BE HANDLED LIKE BULK MATERIAL

- B07B13/00—Grading or sorting solid materials by dry methods, not otherwise provided for; Sorting articles otherwise than by indirectly controlled devices

- B07B13/14—Details or accessories

- B07B13/16—Feed or discharge arrangements

Definitions

- the present invention relates to a sorting arrangement for sorting a mixture of, for example, garbage, provided with at least a first and a second supporting roller, for supporting a conveyor belt equipped with cross ribs, the first supporting roller being positioned higher than the second supporting roller, causing the conveyor belt to exhibit a progressive inclination, and with drive means for driving the conveyor belt in the drive direction, such that from a mixture present on the conveyor belt the finer garbage is thrown off near the first supporting roller.

- a sorting arrangement for sorting a mixture of, for example, garbage, provided with at least a first and a second supporting roller, for supporting a conveyor belt equipped with cross ribs, the first supporting roller being positioned higher than the second supporting roller, causing the conveyor belt to exhibit a progressive inclination, and with drive means for driving the conveyor belt in the drive direction, such that from a mixture present on the conveyor belt the finer garbage is thrown off near the first supporting roller.

- a sorting arrangement of this type is known from the patent specification EP-B-0 265 669.

- the sorting arrangement described there, too, is intended for separating garbage.

- the conveyor belt in the known arrangement is tilted transversely, causing coarse garbage, which cannot be moved along by the cross ribs, in due course to leave the conveyor belt at the lower side.

- a drawback of the known arrangement is that the moment at which this coarse garbage leaves the conveyor belt cannot be chosen. That moment is effectively determined by the tilt and the width of the conveyor belt, both tilt and width being fixed.

- the sorting arrangement according to the present invention which is not tilted laterally, eliminates this drawback.

- the conveyor belt can be left running for a shorter or longer time, until the moment that only coarser garbage remains on the conveyor belt, when this coarser garbage can be removed separately in a virtually continuous process.

- a receptacle which can be coupled with the conveyor belt, for collecting any remaining coarser garbage.

- An advantageous embodiment of the invention is characterized in that the width of the receptacle is larger than or equal to the width of the conveyor belt, and that the receptacle is provided with coupling means for coupling the receptacle with the conveyor belt. In this way the receptacle will be moved along by the conveyor belt, with the coarser garbage continuously tumbling back and ending up in the receptacle.

- the coupling means comprise a ridge, extending along the width of the receptacle, which can hook on a rib of the conveyor belt.

- a suitable point for coupling the receptacle with the conveyor belt is found at the second supporting roller, because at that point the conveyor belt is free from garbage that could thwart the coupling.

- Yet another advantageous embodiment of the invention is therefore characterized in that there are provided guiding means for guiding the receptacle to the second supporting roller, to enable the coupling means to hook on a rib of the conveyor belt.

- the guiding means are also arranged for decoupling the receptacle, near the first supporting roller, when the receptacle can be emptied without the need for the conveyor belt to be stopped, resulting in a virtually continuous sorting process.

- a trajectory can be constructed for the receptacle to move along, in order to achieve the desired guiding.

- the progressive inclination is chosen such that it follows the curvature of a circle segment, which entails that the guiding must also achieve a trajectory shaped like a circle segment.

- An uncomplicated implementation of the guiding means is then characterized in that the guiding means comprise a shaft, positioned in the centre of the circle segment, and provided with a drive for rotating the receptacle around the shaft.

- carry-off means which are positioned near the first supporting roller. It is very advantageous for the carry-off means to be positioned at a considerable elevation, because in a subsequent sorting process the coarser garbage is further processed, which is as a rule done by hand. By causing this sorting to take place from an elevated second conveyor belt it is possible for the sorted material to be disposed of directly into containers placed on the floor. According to the invention the sorting arrangement is thus used also as a means for transporting coarser garbage to a higher level, obviating the need for additional transport means.

- the receptacle comprises a trough-shaped element, of which at least one end is open, the carry-off means comprising a slide, which pushes the coarser garbage laterally from the receptacle. In the process the coarser garbage will generally drop on the second conveyor belt for further processing.

- a third conveyor belt is provided and the receptacle is open at both ends, the slide pushing the coarser garbage alternately at one side on to the second conveyor belt and at the other side on to the third conveyor belt.

- Fig. 1 shows a possible embodiment in side view of the sorting arrangement according to the invention, in which an endless conveyor belt 1, equipped with ribs 2, is guided over a first supporting roller 3 and a second supporting roller 4, preferably such that conveyor belt 1 exhibits a progressive inclination near first supporting roller 3.

- First supporting roller 3 and second supporting roller 4 are provided with drive means, for example hydraulic motors, and are supported in a usual manner, for example using a construction of steel beams. If near the flatter part of conveyor belt 1 a mixture of coarser garbage and finer garbage is dumped, the finer garbage will be carried upwards by ribs 2, whereas coarser garbage tumbles back continuously, gathering on the flatter part of conveyor belt 1. When the finer garbage has been carried off to a sufficient degree, the coarser garbage gathered on the flatter part of conveyor belt 1 can be carried off by advancing a receptacle 6, with the aid of the guiding means 5, which are here implemented as a rotation shaft.

- Receptacle 6 has a width which is at least equal to the width of conveyor belt 1, and is equipped with a ridge 7, which can hook on a rib 2.

- guiding means 5 In cooperation with guiding means 5, receptacle 6 will be moved along by conveyor belt 1, with the coarser garbage ending up in receptacle 6.

- guiding means 5 are here represented without the drive means, such as an hydraulic motor and supporting constructions known in the art.

- the drive means of guiding means 5 for example moving the receptacle 6 close to the meeting point, in anticipation of the approach of a rib 2, which approach can be detected mechanically or electrically, upon which the drive means move receptacle 6 on to the meeting point.

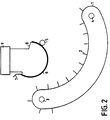

- Fig. 2 shows the same embodiment of the sorting arrangement in side view, with the guiding means 5 and conveyor belt 1 having moved the receptacle 6 to its highest position.

- the decoupling of ridge 7 and rib 2 has taken place spontaneously at the spot where conveyor belt 1 no longer follows the curvature of a circle segment, which occurs near first supporting roller 3.

- the speeds of conveyor belt 1 and ridge 7 of receptacle 6 are balanced such that the coupling of ridge 7 and rib 2 is at least substantially maintained all the time, but when approaching the decoupling point ridge 7 is advancing relative to rib 2.

- a slide 8 which is positioned in line with receptacle 6, and which can push the coarser garbage collected in receptacle 6, with the aid of a linear drive 9, for example an hydraulic pressure cylinder, laterally from receptacle 6.

- a linear drive 9 for example an hydraulic pressure cylinder

- guiding means 5 can, for example by completing the rotation around the guiding means 5, which are implemented here as a rotation shaft, move receptacle 6 again in the direction of the second supporting roller 4, in preparation for the next sorting cycle.

- Fig. 3 shows the same embodiment in front view, with receptacle 6 in the highest position above the rib-clad conveyor belt 1, and with the guiding means 5, which are shown here for the sake of clarity without the drive means and supporting constructions known in the art. Also visible are the slide 8, which is attached to linear drive 9, a second conveyor belt 10 and a third conveyor belt 11, those conveyor belts, in successive sorting cycles, being alternately loaded with coarser garbage by slide 8. It is of course also possible to implement the arrangement with conveyor belt 11 only, but in that case slide 8 needs to be moved back to its starting position every time after pushing the coarser garbage from receptacle 6.

Landscapes

- Combined Means For Separation Of Solids (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| NL9500622 | 1995-03-31 | ||

| NL9500622 | 1995-03-31 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0734788A2 true EP0734788A2 (de) | 1996-10-02 |

| EP0734788A3 EP0734788A3 (de) | 1997-04-23 |

Family

ID=19865780

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP96200821A Ceased EP0734788A3 (de) | 1995-03-31 | 1996-03-26 | Sortiermaschine |

Country Status (1)

| Country | Link |

|---|---|

| EP (1) | EP0734788A3 (de) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113663919A (zh) * | 2021-08-19 | 2021-11-19 | 浙江锦溪环保科技有限公司 | 一种生活垃圾分拣转运系统 |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3636650A1 (de) * | 1986-10-28 | 1988-05-05 | Bezner Maschf | Sortiermaschine |

-

1996

- 1996-03-26 EP EP96200821A patent/EP0734788A3/de not_active Ceased

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113663919A (zh) * | 2021-08-19 | 2021-11-19 | 浙江锦溪环保科技有限公司 | 一种生活垃圾分拣转运系统 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0734788A3 (de) | 1997-04-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US5638959A (en) | Rotary materials separator | |

| EP0381256B1 (de) | Vorrichtung zum Überführen von Gegenständen, wie gefüllten Säcken, von einem Förderer zu einer Sammelvorrichtung, wie einem Karton, der unter diesem Förderer steht | |

| US4067506A (en) | Machine for tearing waste bags and separating out plastic film bag material | |

| CN1051406A (zh) | 用于收集和分布道碴的机械 | |

| US4438851A (en) | Method and apparatus for the sorting out of plastic foils from a mixture of refuse | |

| US5918726A (en) | Apparatus for transferring separate products, such as eggs and fruit, from a feed conveyor to a packaging apparatus | |

| US4662507A (en) | Belt scraping devices accommodating a reversing condition | |

| JP2003509213A (ja) | サイズの異なる小片のための仕分け装置 | |

| US5220965A (en) | Vehicle for beach cleaning | |

| EP0583569B1 (de) | Schälmaschine für Pflanzengut | |

| EP0734788A2 (de) | Sortiermaschine | |

| EP0489832A1 (de) | Schubladen zur verwendung in einer sortiervorrichtung. | |

| AU645289B2 (en) | Modified plastic bag opening apparatus | |

| CA1206810A (en) | Ballast cleaning machine | |

| CN1008266B (zh) | 夹带式卸载输送机 | |

| US4369877A (en) | Stockpile reclaiming apparatus | |

| EP0422715A1 (de) | Vorrichtung zur Trennung einer Flüssigkeit von einer Feststoffflüssigkeitsmischung | |

| EP0190038B1 (de) | Gerät zum Abtragen von Schüttgut aus einem Behälter | |

| EP0648694B1 (de) | Transportvorrichtung | |

| EP0924147A1 (de) | Förderer | |

| US5018619A (en) | Conveyor belt dumping mechanism using horizontal idlers and impact slides | |

| CA2023501C (en) | Modified plastic bag opening apparatus | |

| JP2002037447A (ja) | コンベア装置 | |

| SU1114520A1 (ru) | Элеваторное загрузочное устройство | |

| WO1985002316A1 (en) | A straw conveyor device in a combine harvester |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): BE CH DE GB IT LI NL |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): BE CH DE GB IT LI NL |

|

| 17P | Request for examination filed |

Effective date: 19970313 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| 17Q | First examination report despatched |

Effective date: 19990503 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN REFUSED |

|

| 18R | Application refused |

Effective date: 19991023 |