EP0729795A2 - Gerät und Verfahren zur Verschlussinspektion - Google Patents

Gerät und Verfahren zur Verschlussinspektion Download PDFInfo

- Publication number

- EP0729795A2 EP0729795A2 EP96301242A EP96301242A EP0729795A2 EP 0729795 A2 EP0729795 A2 EP 0729795A2 EP 96301242 A EP96301242 A EP 96301242A EP 96301242 A EP96301242 A EP 96301242A EP 0729795 A2 EP0729795 A2 EP 0729795A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- closures

- stations

- closure

- turret

- testing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 238000000034 method Methods 0.000 title description 2

- 238000012360 testing method Methods 0.000 claims abstract description 36

- 238000004519 manufacturing process Methods 0.000 claims abstract description 12

- 239000002184 metal Substances 0.000 claims description 12

- 230000007306 turnover Effects 0.000 claims description 9

- 238000010998 test method Methods 0.000 claims description 2

- 238000005259 measurement Methods 0.000 abstract description 11

- 230000032258 transport Effects 0.000 abstract 1

- 150000001875 compounds Chemical class 0.000 description 6

- 230000000994 depressogenic effect Effects 0.000 description 3

- 235000013305 food Nutrition 0.000 description 3

- 229920001944 Plastisol Polymers 0.000 description 2

- 235000013361 beverage Nutrition 0.000 description 2

- 238000007689 inspection Methods 0.000 description 2

- 230000002093 peripheral effect Effects 0.000 description 2

- 239000004999 plastisol Substances 0.000 description 2

- 238000009987 spinning Methods 0.000 description 2

- LFOIDLOIBZFWDO-UHFFFAOYSA-N 2-methoxy-6-[6-methoxy-4-[(3-phenylmethoxyphenyl)methoxy]-1-benzofuran-2-yl]imidazo[2,1-b][1,3,4]thiadiazole Chemical compound N1=C2SC(OC)=NN2C=C1C(OC1=CC(OC)=C2)=CC1=C2OCC(C=1)=CC=CC=1OCC1=CC=CC=C1 LFOIDLOIBZFWDO-UHFFFAOYSA-N 0.000 description 1

- 235000008452 baby food Nutrition 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 230000000295 complement effect Effects 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 238000004806 packaging method and process Methods 0.000 description 1

- 238000012856 packing Methods 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 230000003252 repetitive effect Effects 0.000 description 1

- 230000000007 visual effect Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B07—SEPARATING SOLIDS FROM SOLIDS; SORTING

- B07C—POSTAL SORTING; SORTING INDIVIDUAL ARTICLES, OR BULK MATERIAL FIT TO BE SORTED PIECE-MEAL, e.g. BY PICKING

- B07C5/00—Sorting according to a characteristic or feature of the articles or material being sorted, e.g. by control effected by devices which detect or measure such characteristic or feature; Sorting by manually actuated devices, e.g. switches

- B07C5/36—Sorting apparatus characterised by the means used for distribution

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B07—SEPARATING SOLIDS FROM SOLIDS; SORTING

- B07C—POSTAL SORTING; SORTING INDIVIDUAL ARTICLES, OR BULK MATERIAL FIT TO BE SORTED PIECE-MEAL, e.g. BY PICKING

- B07C5/00—Sorting according to a characteristic or feature of the articles or material being sorted, e.g. by control effected by devices which detect or measure such characteristic or feature; Sorting by manually actuated devices, e.g. switches

- B07C5/34—Sorting according to other particular properties

- B07C5/3404—Sorting according to other particular properties according to properties of containers or receptacles, e.g. rigidity, leaks, fill-level

Definitions

- This invention relates to the inspecting of closures for packaging containers, particularly (but not exclusively) vacuum closures of metal for food and beverage product containers subsequent to their manufacture.

- an apparatus for inspecting metal closures after their manufacture comprising:

- an apparatus for inspecting metal closures after their manufacture comprising:

- At least some of the testing stations include a lifting means for lifting a closure to a raised position at which the associated testing means may be effective. Means may also be provided for rotating the closure while testing is taking place.

- a method of inspecting a metal closure after its manufacture comprising feeding closures in turn to closure holders of a turret which is intermittently rotated to present and halt the closures at a plurality of stations operatively associated with the turret.

- Figures 1 and 2 show a typical vacuum closure for a jar of baby food.

- the closure is stamped from a sheet metal disc and has a generally plane closure panel 10 to overlie the mouth of the jar and a skirt 12 which depends from the closure panel peripherary.

- the cut edge 14 of the metal is located in an inturned curl 15 forming the free edge of the skirt.

- a tamper evident button 16 is generally formed centrally in the closure panel by a metal forming operation.

- the button has a plane central post 18 and inner annular portions 20, 22.

- the button has a raised stable position as shown and an unstable depressed position to which it is moved by a vacuum which is found in the container headspace when the closure is first fitted to the jar by the food packer.

- the closure is of the kind commonly known as a "PT (Press-on Twist-off) cap” and accordingly has an interior lining 24 of a compound such as "plastisol” (trade mark) which covers a peripheral margin 26 of the closure panel and an adjacent part 28 of the skirt.

- PT Pressure-on Twist-off

- plastisol trademark

- the part of the compound located in the closure panel will serve to provide a hermetic seal for the jar, whereas that part which is located on the skirt will conform itself permanently to screw threads formed on the neck of the jar so as to provide a complementary screw thread formation for the closure.

- FIGS 3 and 4 show an alternative form of closure which can be tested with the apparatus of the present invention.

- This type of closure is known as a "Twist Open” or “Lug” cap.

- This closure is also stamped from a sheet metal disc and has a generally plane closure panel 40 to overlie the mouth of a jar and a skirt 42 which depends substantially at right angles from the peripherary of the panel 40.

- the cut edge 44 of the metal is located in an inturned curl 45 which forms the free edge of the skirt.

- the free edge includes three or more lugs 50 (here four are shown) equispaced about its peripherary for gripping threads on the container onto which it is placed.

- a tamper evident button 46 may be formed in the centre of the closure panel 40.

- a lining compound 54 covers only a peripheral margin 56 of the closure panel so as to provide a hermetic seal for the container.

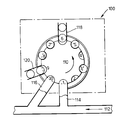

- FIG. 5 of the drawings an apparatus is shown for testing a vacuum closure such as is shown in figures 1 and 2 or figures 3 and 4.

- the automatic inspection machine comprises a ten headed index machine 100. The individual heads move during testing to each of ten stations which are numbered 1 to 10 in the figure.

- the stations are mounted around an indexing turret 110 comprising a ten pocket starwheel adjacent to the conveyor 112 along which caps arrive following manufacture.

- Access to and from the inspection machine is provided by infeed air conveyor 114 and outfeed air conveyor 116 respectively or, alternatively, by belts.

- two turn over points 118, 120 are provided so as to invert the caps for testing.

- the turret indexes by rotation in an anti-clockwise direction as shown in the figure so as to move the caps in turn to the next station.

- Stations 2 and 4 are idle stations which are required due to the space needed for individual machines for testing at stations 3 and 5. Further measurements are carried out at stations 7 and 8. The stations 3 and 5 are provided for making internal measurements with each cap in the orientation with which it is fed onto the machine.

- All measurements are carried out by moving a mandrel into the closure to engage and lift the cap out of the head (star wheel pocket) for measurement. Spinning of the closure is also possible so as to make measurements at different points around the closure.

- Station 3 measures the thickness of the lining compound within the cap and the internal curl diameter.

- the thickness of the compound on both the closure panel and on the skirt side wall is measured, whereas for lug caps, only the panel measurement is required as there is no compound within the skirt (see figure 3).

- Station 5 is used to measure the dimensions of each lug by spinning the cap to each lug in turn and is an idle station for PT caps.

- the caps move to turn over point 118 which comprises a standard turn over unit known in the art. Once the cap has been turned over, it is moved by rotation of the turret to station 7 for testing of the tamper evident button.

- Station 7 is a vacuum station at which the cap is engaged by a mandrel and a vacuum is applied to the inside of the cap so as to cause the tamper evident button to be depressed.

- a microphone is used so as to detect audibly the point at which the button is depressed and pressure at which this occurs is noted automatically.

- the vacuum is applied until a pressure transducer measures a predetermined fixed pressure at which the vacuum is switched off.

- the return pressure at which the button flips back to its original stable position is noted and the audible signal due to this return motion is also measured.

- the final measurement station conducts measurement of overall dimensions of the cap such as panel depth and height, crown and curl diameter and overall height. Following these measurements, the caps are turned back to their original orientation at turn over point 120 adjacent to station 9 and, at station 10, the cap is taken back onto the conveyor 112 via outfeed conveyor 116.

- VDU visual display unit

- caps are returned to the production line or are removed if a fault has been detected. No damage to the caps arises from the testing. It can be seen that the machine is capable of testing either PT or lug caps and heads are dimensioned so as to accomodate standard sizes of vacuum caps ranging from 27mm diameter to 82mm diameter with an overall height of between 9mm and 15mm.

Landscapes

- Examining Or Testing Airtightness (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| GB9504191 | 1995-03-01 | ||

| GBGB9504191.9A GB9504191D0 (en) | 1995-03-02 | 1995-03-02 | A lamp having a translucent shade |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0729795A2 true EP0729795A2 (de) | 1996-09-04 |

| EP0729795A3 EP0729795A3 (de) | 1998-05-20 |

Family

ID=10770524

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP96301242A Withdrawn EP0729795A3 (de) | 1995-03-01 | 1996-02-23 | Gerät und Verfahren zur Verschlussinspektion |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0729795A3 (de) |

| GB (1) | GB9504191D0 (de) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107377414A (zh) * | 2017-01-11 | 2017-11-24 | 温州职业技术学院 | 一种纽扣分色机 |

| CN113275269A (zh) * | 2021-04-30 | 2021-08-20 | 马鞍山海森控电气有限公司 | 基于机器视觉的锂电池回收用筛选装置 |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2135447A (en) * | 1983-02-22 | 1984-08-30 | Metal Closures Ltd | Inspecting screw cap bottle closures |

| FR2590811B1 (fr) * | 1985-12-03 | 1989-08-25 | Pont A Mousson | Machine automatique de controle et de tri de pieces, en particulier cylindriques |

| US4879025A (en) * | 1988-01-21 | 1989-11-07 | Zapata Technologies, Inc. | Apparatus for sorting parts |

-

1995

- 1995-03-02 GB GBGB9504191.9A patent/GB9504191D0/en active Pending

-

1996

- 1996-02-23 EP EP96301242A patent/EP0729795A3/de not_active Withdrawn

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107377414A (zh) * | 2017-01-11 | 2017-11-24 | 温州职业技术学院 | 一种纽扣分色机 |

| CN113275269A (zh) * | 2021-04-30 | 2021-08-20 | 马鞍山海森控电气有限公司 | 基于机器视觉的锂电池回收用筛选装置 |

Also Published As

| Publication number | Publication date |

|---|---|

| GB9504191D0 (en) | 1995-04-19 |

| EP0729795A3 (de) | 1998-05-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US4511044A (en) | Seal force monitor apparatus, system, and method for in-process determination of integrity of sealed containers | |

| EP1103513B1 (de) | Vorrichtung und Verfahren zur Dichtigkeitsprufung einer Schraubverschlusskappe auf einem Behälter | |

| US4807770A (en) | Composite, tamper evident, vacuum indicating closure and container | |

| CA2847557C (en) | Method for establishing the presence of specified characteristics of a container product and device for performing said method | |

| US5388707A (en) | Apparatus for inspecting the exterior finish of containers and associated method | |

| EP0158477A2 (de) | Unverletzlicher Verschluss und seine Herstellung | |

| JPH07148469A (ja) | 容器の検査および選別 | |

| JP2009008637A (ja) | ボトル・キャップ組立体におけるキャップ巻締角度検査装置 | |

| EP0081513B1 (de) | Verfahren und vorrichtung zum identifizieren zerbrochener, zerbrechlicher artikel | |

| US6237418B1 (en) | Method and apparatus for detecting misapplied caps on containers | |

| AU2012306763A1 (en) | Method for establishing the presence of specified characteristics of a container product and device for performing said method | |

| CN112004762B (zh) | 输送物品筛选装置 | |

| EP0729795A2 (de) | Gerät und Verfahren zur Verschlussinspektion | |

| US5714699A (en) | Apparatus and method for inspecting closures | |

| US6430991B1 (en) | Method for monitoring closed containers | |

| US11644379B2 (en) | Leak detection | |

| JPH06507138A (ja) | 缶封じ装置のヘッドの状態をオンライン・モニタできる缶封じ装置 | |

| JPH0123373B2 (de) | ||

| US3461649A (en) | Capping apparatus for accommodating bottles with and without bumper rolls | |

| JP2002166996A (ja) | 容器の識別マーク付与方法 | |

| CN219870115U (zh) | 一种真空旋盖机 | |

| JP3546480B2 (ja) | キャッパの打込荷重検出装置 | |

| JPH03176397A (ja) | 深絞り加工された回転式閉鎖部材並びに回転式閉鎖部材を製作する閉鎖ヘツドのための深絞り加工装置 | |

| US20240270556A1 (en) | Automated system for carrying out capping tests | |

| CN209753459U (zh) | 一种塑瓶生产线缺盖检测装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): DE ES GB IT |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): DE ES GB IT |

|

| 17P | Request for examination filed |

Effective date: 19981105 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: CARNAUDMETALBOX SA Owner name: CARNAUDMETALBOX PLC |

|

| 17Q | First examination report despatched |

Effective date: 20000929 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20010210 |