EP0596085B1 - Actuating device for curtain strips - Google Patents

Actuating device for curtain strips Download PDFInfo

- Publication number

- EP0596085B1 EP0596085B1 EP93911721A EP93911721A EP0596085B1 EP 0596085 B1 EP0596085 B1 EP 0596085B1 EP 93911721 A EP93911721 A EP 93911721A EP 93911721 A EP93911721 A EP 93911721A EP 0596085 B1 EP0596085 B1 EP 0596085B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- pull

- curtain

- shaft

- gear system

- strips

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 230000004913 activation Effects 0.000 abstract 2

- 239000002243 precursor Substances 0.000 description 8

- 230000005540 biological transmission Effects 0.000 description 3

- 238000010276 construction Methods 0.000 description 2

- 230000001419 dependent effect Effects 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 239000000969 carrier Substances 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 230000000284 resting effect Effects 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B9/00—Screening or protective devices for wall or similar openings, with or without operating or securing mechanisms; Closures of similar construction

- E06B9/24—Screens or other constructions affording protection against light, especially against sunshine; Similar screens for privacy or appearance; Slat blinds

- E06B9/26—Lamellar or like blinds, e.g. venetian blinds

- E06B9/36—Lamellar or like blinds, e.g. venetian blinds with vertical lamellae ; Supporting rails therefor

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S160/00—Flexible or portable closure, partition, or panel

- Y10S160/90—Vertical type venetian blind

Definitions

- the invention relates to an actuating device according to the preamble of claim 1.

- An actuator of this type is known from DE-A-26 37 067.

- the train here is a cord that is led outwards and on which the curtain strips can be moved both horizontally and pivoted about their vertical axes.

- This actuating device requires a special towing vehicle for horizontally moving the curtain strips, this towing vehicle itself not carrying a curtain strip.

- this towing vehicle moves unintentionally when the curtain strips are pivoted, which makes it almost impossible or very difficult to align the curtain strips evenly.

- PE-A-0 381 203 discloses an actuating device with a pull cord and a turning shaft, the turning shaft here not being rotatable with the pull cord, but having to be actuated separately.

- Two spherical parts are attached to the pull cord, which work together with locking receptacles of two pulling carriages and thereby form a detachable locking seat.

- An actuating device with two separately actuated drive elements is also shown in US Pat. No. 4,653,564.

- the invention has for its object to provide a device of the type mentioned, with which the curtain strips can be actuated more precisely and which is also simpler in construction and thus less expensive to manufacture. The object is achieved according to claim 1.

- the precursor is not moved by means of the shaft, but rather directly with the carriers of the train, which can be a cord train.

- the shaft does not have to be rotated, which means a significant reduction in the operating noise and the torsion of the shaft.

- the low torsion also allows very long actuators, for example with a length of 4 m.

- the transmission for transmitting the movement of the train to the shaft can be stationary, for example attached to the curtain rail, which allows a much simpler assembly and less expensive manufacture.

- the precursor can then largely be designed like the other sliders. A special train carriage is therefore not necessary. It is also essential that in the actuating device according to the invention the force for rotating the curtain strips is better separated from the force for displacing the curtain strips.

- the curtain strips can be moved much faster than with the previously known actuating device and the curtain can thus be closed more quickly.

- the actuating device according to the invention can be implemented with fewer individual parts and with a simpler construction.

- the actuating device has a curtain rail 1 with the cross section shown in FIG. 4. At one end of the rail 1, an end housing 4 is placed, in which a bevel gear 10 is mounted. This housing 4 is closed with a cover, not shown here. At the other end of the rail 1 there is a further end housing, not shown here, in which deflection rollers 7 for a cord 8 are accommodated.

- the curtain rail 1 is attached to a building ceiling in front of a window.

- a plurality of sliding elements 24 are arranged in the curtain rail 1, a foremost sliding element 24a forming a forerunner.

- Each sliding element 24 and also the forerunner 24a each have a pivotable axis 29 to which a curtain strip 34 is attached.

- the attachment is carried out here with a cam 30 formed on the lower end of the axis 29.

- the sliding elements 24 are guided with rollers 25 on side lugs 3 of the curtain rail 1 so that they can slide.

- the axes 29 of the sliding elements 24 project outwards through a longitudinal slot 2 which extends over the entire length of the rail 1. When the sliding elements 24 are moved, the curtain strips 34 are accordingly also moved in the longitudinal direction of the rail 1.

- Each sliding element 24, including the precursor 24a, has a continuous round opening 40 through which a control shaft 23 extends, which is connected in a rotationally fixed manner in each sliding element 24 to a worm 27 of a worm gear 26.

- the axis 29 is pivotably supported to a limited extent and has a worm wheel 28 which meshes with the worm 27.

- the control shaft 23 is rotated, the axis 29 and thus the curtain strip 34 attached to it at the bottom are pivoted in one direction or the other.

- worm gears are known, for example, from EP-W 0 181 465 of the application.

- the control shaft 23 is pivoted by means of the cord 8, which is connected to the gear 10 mounted in the end housing 4.

- This bevel gear 10 has a gear 13 which is pushed onto the shaft 23 with a through opening 13b and is connected to the shaft 23 in a rotationally secure manner.

- the gear 13 is rotatably supported by a cylindrical projection 13a which engages in a circular opening 6 of the end housing 4.

- a gear part 14 shown in more detail in FIGS. 6a and 6b has two spaced-apart slide bearings 12a and 12b, which are inserted into corresponding bearing points 5 of the end housing 4 and are fixed by means of latching.

- the bearings 12a and 12b are formed on a shaft 16 which carries a gear wheel 15 at one end and which is connected via a slip clutch 18 to two drive wheels 19 and 20 arranged at a distance from one another.

- the wheels 19 and 20 are firmly connected to a part 21 of the slip clutch 18 and are arranged at a distance from one another such that there is a groove 22 between them, in which the cable 8 engages in its deflection area and by friction when the cable 8 is pulled the wheel 15 rotates in one direction or the other.

- the cord 8 can thus the shaft 23 about its longitudinal axis in one or the other Direction.

- the axes 29 can be pivoted to a limited extent in both pivoting directions. If the axes 29 are pivoted up to a stop, the control shaft 23 can no longer be rotated in the same direction.

- the slipping clutch 14 now allows the cord 8 and 2 to be firmly connected to the driver 9 in the same direction as before.

- the curtain strips 34 are now moved in the longitudinal direction of the curtain rail 1, as will be explained below with reference to FIGS. 1 to 3.

- Recesses 19a and 20a on the circumference of the wheels 19 and 20 and corresponding recesses on the deflection rollers 7 ensure that the drivers 9 do not line up at the deflection points.

- the cord pull 8 on the strand 8b is moved downward in the direction of the arrow 38, as shown in FIG.

- the driver 9 located in the transmission 10 in FIG. 1 now runs unhindered around the transmission part 14 and through the comparatively large openings 32 until, according to FIG.

- the precursor 24a is now carried to the left by the cord 8, and the remaining sliding elements 24 are also moved in turn to the left by the distance limiting member 31.

- the curtain strips 34 are shifted to the left in the direction of the arrow 36, these again not being pivoted as a result of stops in the gears 26.

- the shaft 23 stands still during the entire longitudinal displacement of the curtain strips 34 and the slip clutch 21 rotates.

- the distances between the sliding elements 24 are all the same, which is determined by the distance limiting member 31.

- the curtain strips 34 can thus be opened or opened in both directions of the curtain rail Closing the curtain are moved, the respective shaft 23 is not rotated and the curtain strips 34 are not pivoted.

- FIG. 3 The pivoting of the curtain strips 34 is shown in FIG. 3.

- these can be pivoted in the direction of the arrow 37, but not in the opposite direction, since this is prevented by appropriate stops in the gears 26.

- the strand 8a is moved downwards in the direction of the arrow 39.

- the driver 9 still resting on the precursor 24 according to FIG. 3 now moves to the right away from the precursor 24a.

- the drivers 9 now have no effect on the sliding elements 24 and accordingly they are not moved in a longitudinal direction of the curtain rail 1.

- the cord 8 now rotates due to its friction on the gear part 14 in the direction of arrow 42 about its axis of rotation.

- the slip clutch 21 takes the gearwheel 15 with it and accordingly the shaft 23 is rotated in the direction of arrow 43.

- the gears 26 transmit the movement of the shaft 23 to the curtain strips 34, which are pivoted in the direction of the arrow 37 as desired.

- the curtain strips 34 run transversely to the curtain rail 1

- Curtain strips 34 are pivoted by approximately 160 ° with respect to the arrangement according to FIG. 3 and, moreover, cannot be pivoted further as a result of stops in the gears 26. If, starting from this end position, the strand 8b is moved downward in the direction of the arrow 38, the curtain strips 34 pivot in the opposite direction of the arrow 37 up to the end position shown in FIG. 3.

- any desired intermediate position of the curtain strips 34 is easily possible. It is now essential that during the mentioned pivoting movements of the curtain strips 34, the drivers 9 do not line up with the precursor 24a and move it. The distance between the drivers 9 must therefore not be less than a certain value. The distance is particularly dependent on the gear ratio of the gears 26.

- the drivers 9 are preferably fixedly attached to the cord 8, as a result of which the said distance is then fixed.

- the curtain strips 34 are thus also pivoted by actuating the cord pull 8.

- the actuation is carried out by hand, but motor actuation in itself is not excluded.

- the cord pull 8 can also be another suitable actuating element, for example an endless chain.

Landscapes

- Engineering & Computer Science (AREA)

- Structural Engineering (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Curtains And Furnishings For Windows Or Doors (AREA)

- Materials For Medical Uses (AREA)

Abstract

Description

Die Erfindung betrifft eine Betätigungsvorrichtung nach dem Oberbegriff des Anspruchs 1.The invention relates to an actuating device according to the preamble of

Eine Betätigungsvorrichtung dieser Gattung ist durch die DE-A-26 37 067 bekannt geworden. Der Zug ist hier ein Schnurzug, der nach aussen geführt ist und an dem die Vorhangstreifen sowohl horizontal verschoben als auch um ihre vertikalen Achsen verschwenkt werden können. Erforderlich ist bei dieser Betätigungsvorrichtung ein spezieller Zugwagen zum horizontalen Verschieben der Vorhangstreifen, wobei dieser Zugwagen selbst keinen Vorhangstreifen trägt. In der Praxis hat es sich nun gezeigt, dass dieser Zugwagen selbst nach dem einbau einer geeigneten Bremseinrichtung beim Verschwenken der Vorhangstreifen sich ungewollt verschiebt, was es nahezu unmöglich oder sehr schwierig macht, die Vorhangstreifen gleichmässig auszurichten.An actuator of this type is known from DE-A-26 37 067. The train here is a cord that is led outwards and on which the curtain strips can be moved both horizontally and pivoted about their vertical axes. This actuating device requires a special towing vehicle for horizontally moving the curtain strips, this towing vehicle itself not carrying a curtain strip. In practice, it has now been shown that even after the installation of a suitable braking device, this towing vehicle moves unintentionally when the curtain strips are pivoted, which makes it almost impossible or very difficult to align the curtain strips evenly.

Die PE-A-0 381 203 offenbart eine Betätigungsvorrichtung mit einer Zugschnur und einer Wendewelle, wobei die Wendewelle hier nicht mit der Zugschnur verdrehbar ist, sondern separat betätigt werden muss. An der Zugschnur sind zwei Kugelteile angebracht, die mit Arretierungsaufnahmen zweier Zugwagen zusammenarbeiten und dadurch ein lösbarer Arretiersitz gebildet wird. Eine Betätigungsvorrichtung mit zwei separat zu betätigenden Antriebsorganen zeigt auch die US-A-4,653,564. Der Erfindung liegt die Aufgabe zugrunde, eine Vorrichtung der genannten Gattung zu schaffen, mit der die Vorhangstreifen präziser betätigbar sind und die zudem im Aufbau einfacher und damit kostengünstiger herstellbar ist. Die Aufgabe ist gemäss Anspruch 1 gelöst.PE-A-0 381 203 discloses an actuating device with a pull cord and a turning shaft, the turning shaft here not being rotatable with the pull cord, but having to be actuated separately. Two spherical parts are attached to the pull cord, which work together with locking receptacles of two pulling carriages and thereby form a detachable locking seat. An actuating device with two separately actuated drive elements is also shown in US Pat. No. 4,653,564. The invention has for its object to provide a device of the type mentioned, with which the curtain strips can be actuated more precisely and which is also simpler in construction and thus less expensive to manufacture. The object is achieved according to

Bei der erfindungsgemässen Betätigungsvorrichtung wird der Vorläufer nicht mittels der Welle, sondern direkt mit den Mitnehmern des Zuges, der ein Schnurzug sein kann, verschoben. Beim Verschieben der Vorhangstreifen muss somit die Welle nicht gedreht werden, was eine wesentliche Minderung der Betätigungsgeräusche sowie der Torsion der Welle bedeutet. Die geringe Torsion erlaubt auch sehr lange Betätigungsvorrichtungen, beispielsweise mit einer Länge von 4 m.In the actuating device according to the invention, the precursor is not moved by means of the shaft, but rather directly with the carriers of the train, which can be a cord train. When moving the curtain strips, the shaft does not have to be rotated, which means a significant reduction in the operating noise and the torsion of the shaft. The low torsion also allows very long actuators, for example with a length of 4 m.

Das Getriebe zur Uebertragung der Bewegung des Zuges auf die Welle kann stationär, beispielsweise an der Vorhangschiene angebracht sein, was eine wesentlich einfachere Montage und eine kostengünstigere Herstellung erlaubt. Der Vorläufer kann dann weitgehend wie die übrigen Gleiter ausgebildet sein. Ein spezieller Zugwagen ist somit nicht erforderlich. Wesentlich ist auch, dass bei der erfindungsgemässen Betätigungsvorrichtung die Kraft zum Verdrehen der Vorhangstreifen besser von der Kraft zum Verschieben der Vorhangstreifen getrennt ist.The transmission for transmitting the movement of the train to the shaft can be stationary, for example attached to the curtain rail, which allows a much simpler assembly and less expensive manufacture. The precursor can then largely be designed like the other sliders. A special train carriage is therefore not necessary. It is also essential that in the actuating device according to the invention the force for rotating the curtain strips is better separated from the force for displacing the curtain strips.

Da der Zug direkt am Vorläufer angreift, können die Vorhangstreifen wesentlich schneller als bei der vorbekannten Betätigungsvorrichtung verschoben und damit der Vorhang schneller geschlossen werden. Trotz der genannten Vorteile ist die erfindungsgemässe Betätigungsvorrichtung mit weniger Einzelteilen und konstruktiv einfacher realisierbar.Since the train acts directly on the forerunner, the curtain strips can be moved much faster than with the previously known actuating device and the curtain can thus be closed more quickly. Despite the advantages mentioned, the actuating device according to the invention can be implemented with fewer individual parts and with a simpler construction.

Weitere vorteilhafte Merkmale ergeben sich aus den abhängigen Ansprüchen, der nachfolgenden Beschreibung sowie der Zeichnung. Ein Ausführungsbeispiel der Erfindung wird nachfolgend anhand der Zeichnung näher erläutert. Es zeigen:

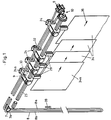

- Fig. 1 bis 3 perspektivische Teilansichten der erfindungsgemässen Betätigungsvorrichtung, wobei einige Teile aus darstellerischen Gründen weggelassen sind,

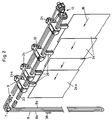

- Fig. 4 ein Querschnitt durch eine erfindungsgemässe Betätigungsvorrichtung,

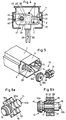

- Fig. 5 eine perspektivische Teilansicht der erfindungsgemässen Betätigungsvorrichtung,

- Fig. 6a eine perspektivische Ansicht eines Getriebeteils, und

- Fig. 6b ein Teilschnitt durch den Getriebeteil gemäss Fig. 6a.

- 1 to 3 are perspective partial views of the actuating device according to the invention, some parts being omitted for illustrative reasons,

- 4 shows a cross section through an actuating device according to the invention,

- 5 is a partial perspective view of the actuating device according to the invention,

- 6a is a perspective view of a gear part, and

- 6b shows a partial section through the gear part according to FIG. 6a.

Die Betätigungsvorrichtung weist eine Vorhangschiene 1 mit dem in Fig. 4 gezeigten Querschnitt auf. An dem einen Ende der Schiene 1 ist ein Endgehäuse 4 aufgesetzt, in dem ein Kegelradgetriebe 10 gelagert ist. Dieses Gehäuse 4 ist mit einem hier nicht gezeigten Deckel verschlossen. Am anderen Ende der Schiene 1 ist ein weiteres hier nicht gezeigtes Endgehäuse angebracht, in dem Umlenkrollen 7 für einen Schnurzug 8 untergebracht sind. Ueblicherweise wird die Vorhangschiene 1 vor einem Fenster an einer Gebäudedecke befestigt.The actuating device has a

In der Vorhangschiene 1 sind mehrere Gleitelemente 24 angeordnet, wobei ein vorderstes Gleitelement 24a einen Vorläufer bildet. Jedes Gleitelement 24 und auch der Vorläufer 24a weisen jeweils eine begrenzt verschwenkbare Achse 29 auf, an der ein Vorhangstreifen 34 befestigt ist. Die Befestigung erfolgt hier mit einem am unteren Ende der Achse 29 angeformten Nocken 30. Die Gleitelemente 24 sind mit Laufrollen 25 auf seitlichen Ansätzen 3 der Vorhangschiene 1 verschiebbar geführt. Die Achsen 29 der Gleitelemente 24 ragen unten durch einen sich über die ganze Länge der Schiene 1 erstreckenden Längsschlitz 2 nach aussen. Beim Verschieben der Gleitelemente 24 werden somit entsprechend auch die Vorhangstreifen 34 in Längsrichtung der Schiene 1 verschoben.A plurality of

Jedes Gleitelement 24 einschliesslich des Vorläufers 24a weisen eine durchgehende runde Oeffnung 40 auf, durch welche eine Steuerwelle 23 hindurchgreift, die in jedem Gleitelement 24 drehfest mit einer Schnecke 27 eines Schneckengetriebes 26 verbunden ist. Im Gehäuse 41 des Gleitelementes 24 ist die Achse 29 begrenzt verschwenkbar gelagert und weist ein Schneckenrad 28 auf, das mit der Schnecke 27 kämmt. Beim Verdrehen der Steuerwelle 23 wird somit die Achse 29 und somit der unten an dieser befestigte Vorhangstreifen 34 in der einen oder anderen Richtung verschwenkt. Solche Schneckengetriebe sind beispielsweise aus der EP-W 0 181 465 des Anmeldes bekannt.Each

Das Verschwenken der Steuerwelle 23 erfolgt mittels des Schnurzuges 8, der mit dem im Endgehäuse 4 gelagerten Getriebe 10 verbunden ist. Dieses Kegelradgetriebe 10 weist ein Zahnrad 13 auf, das mit einer durchgehenden Oeffnung 13b auf die Welle 23 aufgeschoben und drehsicher mit dieser verbunden ist. Das Zahnrad 13 ist mit einem zylindrischen Ansatz 13a, der in eine kreisrunde Oeffnung 6 des Endgehäuses 4 eingreift, drehbar gelagert.The

Ein in den Fig. 6a und 6b näher gezeigte Getriebeteil 14 weist zwei im Abstand zueinander angeordnete Gleitlager 12a und 12b auf, die in entsprechende Lagerstellen 5 des Endgehäuses 4 eingesetzt und durch Rastung fixiert sind. Die Lager 12a und 12b sind an einer Welle 16 angeformt, die an einem Ende ein Zahnrad 15 trägt und die über eine Rutschkupplung 18 mit zwei im Abstand zueinander angeordneten Antriebsrädern 19 und 20 verbunden ist. Die Räder 19 und 20 sind fest mit einem Teil 21 der Rutschkupplung 18 verbunden und so im Abstand zueinander angeordnet, dass zwischen ihnen eine Rille 22 besteht, in welche der Seilzug 8 in seinem Umlenkbereich eingreift und durch Reibung beim Ziehen des Schnurzuges 8 das Rad 15 in der einen oder anderen Richtung dreht. Mit dem Schnurzug 8 kann somit die Welle 23 um ihre Längsachse in der einen oder anderen Richtung gedreht werden. Wie oben erwähnt, sind die Achsen 29 in beiden Schwenkrichtungen begrenzt verschwenkbar. Sind die Achsen 29 bis zu einem Anschlag verschwenkt, so kann die Steuerwelle 23 in der gleichen Richtung nicht mehr weiter gedreht werden. Die Rutschkupplung 14 erlaubt nun trotzdem, den Schnurzug 8 und 2 fest mit diesem verbundene Mitnehmer 9 in der gleichen Richtung wie vorher zu bewegen. Hierbei werden nun die Vorhangstreifen 34 in Längsrichtung der Vorhangschiene 1 verschoben, wie nachfolgend anhand der Figuren 1 bis 3 erläutert wird. Ausnehmungen 19a und 20a am Umfang der Räder 19 und 20 und entsprechende Ausnehmungen an den Umlenkrollen 7 gewährleisten, dass die Mitnehmer 9 an den Umlenkstellen nicht anstehen.A

Bei der Anordnung gemäss Fig. 1 wird angenommen, dass der Schnurzug 8 am Trum 8a in Richtung des Pfeiles 39 nach unten bewegt wird. Der hier punktiert dargestellte Mitnehmer 9 wird dann nach rechts bewegt und steht hier an der vergleichweise kleinen Oeffnung 33 an. Der genannte Mitnehmer 9 schiebt den Vorläufer 24a nach rechts, der auf die nachfolgenden Gleitelemente 24 auffährt und diese ebenfalls nach rechts verschiebt. Die Vorhangstreifen 34 werden entsprechend ebenfalls gemäss Pfeil 35 nach rechts verschoben, bis sie zu einem Paket zusammengeführt sind. Anschläge der Getriebe 26 verhindern hierbei eine Schwenkbewegung der Vorhangstreifen 34. Die Welle 23 steht deshalb still und die Schleifkupplung 21 dreht während der genannten horizontalen Bewegung der Vorhangstreifen 34 durch. Bei der Bewegung des Schnurzuges 8 in Richtung des Pfeiles 39 werden somit die Vorhangstreifen 34 auf die Seite geschoben und beispielsweise ein Durchblick durch ein Fenster freigegeben.In the arrangement according to FIG. 1, it is assumed that the cord pull 8 on the

Zum Schliessen des Vorhangs wird gemäss Fig. 2 der Schnurzug 8 am Trum 8b in Richtung des Pfeiles 38 nach unten bewegt. Der in Fig. 1 beim Getriebe 10 befindliche Mitnehmer 9 läuft nun um den Getriebeteil 14 und durch die vergleichsweise grossen Oeffnungen 32 ungehindert hindurch bis er gemäss Fg. 2 ebenfalls auf der rechten Seite am Vorläufer 24a ansteht. Der Vorläufer 24a wird nun durch den Schnurzug 8 nach links mitgenommen, und durch das Abstandsbegrenzungsorgan 31 werden der Reihe nach auch die übrigen Gleitelemente 24 nach links bewegt. Entsprechend werden die Vorhangstreifen 34 in Richtung des Pfeiles 36 nach links verschoben, wobei diese wieder in folge von Anschlägen in den Getrieben 26 nicht verschwenkt werden. Auch hier steht somit während der gesamten Längsverschiebung der Vorhangstreifen 34 die Welle 23 still und die Schleifkupplung 21 dreht durch. Bei geschlossenem Vorhang sind die Abstände zwischen den Gleitelementen 24 alle gleich, was durch das Abstandsbegrenzungsorgan 31 bestimmt ist.To close the curtain, the cord pull 8 on the

Mit dem Schnurzug 8 können die Vorhangstreifen 34 somit in beiden Richtungen der Vorhangschiene zum Oeffnen oder Schliessen des Vorhanges verschoben werden, wobei jeweils die Welle 23 nicht gedreht und die Vorhangstreifen 34 nicht verschwenkt werden.With the

Das Verschwenken der Vorhangstreifen 34 ist in Fig. 3 gezeigt. Bei der in Fig. 3 gezeigten Anordnung der Vorhangstreifen 34 können diese in Richtung des Pfeiles 37, jedoch nicht in der Gegenrichtung verschwenkt werden, da dies durch entsprechende Anschläge in den Getrieben 26 verhindert ist. Um die Vorhangstreifen 34 in Richtung des Pfeiles 37 zu verschwenken, wird der Trum 8a in Richtung des Pfeiles 39 nach unten bewegt. Der am Vorläufer 24 gemäss Fig. 3 noch anliegende Mitnehmer 9 bewegt sich nun nach rechts vom Vorläufer 24a weg. Die Mitnehmer 9 haben nun vorläufig keine Wirkung auf die Gleitelemente 24 und entsprechend werden diese auch nicht in einer Längsrichtungen der Vorhangschiene 1 verschoben. Der Schnurzug 8 dreht nun infolge seiner Reibung am Getriebeteil 14 dieses in Richtung des Pfeiles 42 um seine Drehachse. Da nun eine Drehung der Welle 23 durch die Anschläge in den Getrieben 26 nicht gehindert ist, nimmt die Schleifkupplung 21 das Zahnrad 15 mit und entsprechend wird die Welle 23 in Richtung des Pfeiles 43 gedreht. Die Getriebe 26 übertragen die Bewegung der Welle 23 auf die Vorhangstreifen 34, die wie gewünscht in Richtung des Pfeiles 37 verschwenkt werden. In einer Zwischenstellung verlaufen die Vorhangstreifen 34 quer zur Vorhangschiene 1. In einer Endstellung sind die Vorhangstreifen 34 gegenüber der Anordnung gemäss Fig. 3 um etwa 160° verschwenkt und können darüberhinaus infolge von Anschlägen in den Getrieben 26 nicht weiter verschwenkt werden. Wird ausgehend von dieser Endstellung der Trum 8b in Richtung des Pfeiles 38 nach unten bewegt, so verschwenken die Vorhangstreifen 34 in der Gegenrichtung des Pfeiles 37 bis zu der in Fig. 3 gezeigten Endposition. Jede gewünschte Zwischenstellung der Vorhangstreifen 34 ist ohne weiteres möglich. Wesentlich ist nun, dass während den genannten Schwenkbewegungen der Vorhangstreifen 34 die Mitnehmer 9 nicht am Vorläufer 24a anstehen und diesen verschieben. Der Abstand zwischen den Mitnehmern 9 darf somit einen bestimmten Wert nicht unterschreiten. Der Abstand ist insbesondere abhängig von der Uebersetzung der Getriebe 26. Vorzugsweise sind die Mitnehmer 9 fest am Schnurzug 8 fixiert, wodurch dann der genannte Abstand fest eingestellt ist. Das Verschwenken der Vorhangstreifen 34 erfolgt somit ebenfalls durch eine Betätigung des Schnurzuges 8. In der Regel erfolgt die Betätigung von Hand, an sich ist aber eine motorische Betätigung nicht ausgeschlossen. Es versteht sich auch, dass der Schnurzug 8 auch ein anderes geeignetes Betätigungsorgan, beispielsweise eine endlose Kette sein kann.The pivoting of the curtain strips 34 is shown in FIG. 3. In the arrangement of the curtain strips 34 shown in FIG. 3, these can be pivoted in the direction of the

Claims (4)

- Actuating device for horizontally movable curtain sections (34) capable of pivoting together about their longitudinal axis, with sliding elements (24) running in a curtain rail (1) in such a way as to be capable of longitudinal movement and connected to one another by distance limiters (31), each of which carries a curtain section (34) hanging free on a pivoting pin (29) capable of limited rotation, and with a drive mechanism having a pull (8), and a shaft (23) passing through the sliding elements (24) and capable of being rotated to pivot the curtain sections (34) by means of the pull (8), each sliding element (24) containing a gear system (26) which connects a pivoting pin (29) with the shaft (23), characterized in that the pull (8) has two drivers (9) at a specific distance apart which can be made to engage the foremost sliding element (24) serving as a front runner (24a) in order to move the latter in one direction or the other of the curtain rail (1), that a gear system (10) is permanently mounted on the curtain rail (1) connecting the pull (8) with the shaft (23), that the gear system (10) is disposed at one end of the curtain rail (1), and this gear system (10) has a clutch (14), in particular a slip clutch, which makes it possible to move the pull (8) beyond the final positions of the pivoting pins capable of turning to a limited degree for the purpose of moving the curtain sections (34) longitudinally by means of the drivers (9), without causing the shaft (23) to turn as well.

- Device according to Claim 1, characterized in that the drivers (9) are bulges or projections on the pull (8) and the front runner (24a) has an opening (33) which is smaller than the said bulge, and that the other sliding elements have an opening (32) for the pull (8) to pass through which is larger than the said bulges.

- Device according to Claim 1 or 2, characterized in that the pull (8) is an endless cord pull.

- Device according to one of Claims 1 to 3, characterized in that the gear system (10) has two wheels (19, 20) a certain distance apart, between which the pull (8) engages to give a friction drive.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CH1658/92 | 1992-05-22 | ||

| CH1658/92A CH684780A5 (en) | 1992-05-22 | 1992-05-22 | Actuating device for curtain strips. |

| PCT/CH1993/000123 WO1993024726A1 (en) | 1992-05-22 | 1993-05-17 | Actuating device for curtain strips |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0596085A1 EP0596085A1 (en) | 1994-05-11 |

| EP0596085B1 true EP0596085B1 (en) | 1997-03-19 |

Family

ID=4215612

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP93911721A Expired - Lifetime EP0596085B1 (en) | 1992-05-22 | 1993-05-17 | Actuating device for curtain strips |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US5547007A (en) |

| EP (1) | EP0596085B1 (en) |

| JP (1) | JPH07503508A (en) |

| AT (1) | ATE150519T1 (en) |

| AU (1) | AU659747B2 (en) |

| CH (1) | CH684780A5 (en) |

| DE (1) | DE59305859D1 (en) |

| WO (1) | WO1993024726A1 (en) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AU690778B2 (en) * | 1995-01-16 | 1998-04-30 | K. Bratschi, Silent Gliss | Strip blind with self-actuating, free-wheel coupling |

| US5848633A (en) * | 1995-11-27 | 1998-12-15 | Chou; Tser-Wen | Extrusion track for blinds |

| US5630457A (en) * | 1995-11-27 | 1997-05-20 | Chou; Tser-Wen | Extrusion track for blinds |

| US5950701A (en) * | 1997-06-30 | 1999-09-14 | Exactocraft (Proprietary) Limited | Drive gear unit for vertical blind systems |

| US6863111B1 (en) | 2000-10-03 | 2005-03-08 | Tser-Wen Chou | Positive engagement end stop for window covering systems |

| EP1342880A1 (en) * | 2002-03-08 | 2003-09-10 | Silent Gliss International Ag | Slat blind |

| US20070284059A1 (en) * | 2006-06-07 | 2007-12-13 | Chin-Fu Chen | Vertical blind structure with an easy change of curtain cloth |

| WO2013005678A1 (en) * | 2011-07-01 | 2013-01-10 | 立川ブラインド工業 株式会社 | Vertical blind and tilt clutch device for blind |

| JP6348767B2 (en) * | 2014-05-01 | 2018-06-27 | 立川ブラインド工業株式会社 | Vertical blinds and runner hooks |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2437040A1 (en) * | 1974-08-01 | 1975-08-07 | Andreas Kruell | Vertically slatted venetian blind - has end piece accommodating lead-deflecting and guiding rollers insertable in rail recess |

| DE2648550C3 (en) * | 1974-10-23 | 1978-09-07 | Ets. Carpano & Pons, Cluses, Haute- Savoie (Frankreich) | Drive device |

| US4316493B1 (en) * | 1977-08-15 | 1997-06-24 | Newell Operating Co | Vertical blind controls |

| US4261408A (en) * | 1979-06-13 | 1981-04-14 | Levolor Lorentzen, Inc. | Traverse cord lock for vertical blind |

| FI70978C (en) * | 1981-12-07 | 1986-10-27 | Bratschi Silent Gliss | LAMELLGARDIN |

| IT8217722A0 (en) * | 1982-06-29 | 1982-06-29 | Menichetti Pier Luigi | DEVICE TO SLIDE AND ROTATE HANGING STRIPS FOR VERTICAL AWNINGS |

| US4653564A (en) * | 1984-07-06 | 1987-03-31 | Norbert Marocco | Track for blinds |

| US4844139A (en) * | 1987-09-30 | 1989-07-04 | Home Fashions, Inc. | Vertical louver blind having clutched operating mechanism |

| DE8901384U1 (en) * | 1989-02-03 | 1989-05-03 | Howald, Gerald, 2000 Hamburg | Track |

-

1992

- 1992-05-22 CH CH1658/92A patent/CH684780A5/en not_active IP Right Cessation

-

1993

- 1993-05-17 EP EP93911721A patent/EP0596085B1/en not_active Expired - Lifetime

- 1993-05-17 WO PCT/CH1993/000123 patent/WO1993024726A1/en active IP Right Grant

- 1993-05-17 DE DE59305859T patent/DE59305859D1/en not_active Expired - Fee Related

- 1993-05-17 AU AU42588/93A patent/AU659747B2/en not_active Ceased

- 1993-05-17 AT AT93911721T patent/ATE150519T1/en not_active IP Right Cessation

- 1993-05-17 JP JP6500054A patent/JPH07503508A/en active Pending

- 1993-05-17 US US08/182,052 patent/US5547007A/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JPH07503508A (en) | 1995-04-13 |

| ATE150519T1 (en) | 1997-04-15 |

| EP0596085A1 (en) | 1994-05-11 |

| CH684780A5 (en) | 1994-12-30 |

| DE59305859D1 (en) | 1997-04-24 |

| US5547007A (en) | 1996-08-20 |

| WO1993024726A1 (en) | 1993-12-09 |

| AU4258893A (en) | 1993-12-30 |

| AU659747B2 (en) | 1995-05-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3303032B1 (en) | Air vent having a control device | |

| DE10253138B4 (en) | Door device for a vehicle and method for controlling movement of a door | |

| DE102013204881A1 (en) | sliding door | |

| DE10245458A1 (en) | actuator | |

| DE102021106582A1 (en) | Drive device for the independent activation of at least two devices by means of a single drive unit | |

| DE2338856A1 (en) | CURTAIN WITH SLIDING AND SWIVELING CURTAINS | |

| EP2325430B1 (en) | Door drive for a swing door of a passenger vehicle | |

| EP0596085B1 (en) | Actuating device for curtain strips | |

| EP1740426A1 (en) | Roller blind system for a vehicle roof | |

| EP0782833A1 (en) | Drawing device for a curtain | |

| DE2507893C3 (en) | Window lifter for vertically subdivided motor vehicle sliding windows | |

| DE202013000449U1 (en) | Folding door with two or more self-contained Faltladenelementen with alternating non-buckling and buckling element edges and actuator for this purpose | |

| EP0794310B1 (en) | Folding wing door | |

| DE3319950A1 (en) | MANUAL REMOTE CONTROL DEVICE | |

| DE1559776C3 (en) | Window lock | |

| DE1559775B1 (en) | Device for opening and closing windows or the like. | |

| DE19654558C2 (en) | sunroof | |

| DE2853763A1 (en) | VERTICAL BLINDS WITH BLADES SWIVELING AROUND THEIR RIGHT AXIS AND SLIDING SLIDES | |

| DE9207895U1 (en) | Attachment gear of a window or door fitting | |

| DE2804604C2 (en) | Flexible cover for a console slot, in particular in motor vehicles | |

| DE202004019232U1 (en) | control cable | |

| DE3523290C2 (en) | ||

| DE69720627T2 (en) | Locking device for roller shutters, with a freely rotatable winding shaft | |

| DE10123423B4 (en) | Drive for a closing element of a vehicle roof | |

| DE102014118194A1 (en) | Adjusting device for a wing and device for setting multiple wings |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19940201 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE FR GB IT LI NL SE |

|

| 17Q | First examination report despatched |

Effective date: 19951012 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE FR GB IT LI NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19970319 |

|

| REF | Corresponds to: |

Ref document number: 150519 Country of ref document: AT Date of ref document: 19970415 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19970319 |

|

| REF | Corresponds to: |

Ref document number: 59305859 Country of ref document: DE Date of ref document: 19970424 |

|

| ITF | It: translation for a ep patent filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19970517 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19970531 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19970531 Ref country code: BE Effective date: 19970531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19970619 |

|

| ET | Fr: translation filed | ||

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| BERE | Be: lapsed |

Owner name: K. BRATSCHI SILENT GLISS Effective date: 19970531 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19980409 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19980417 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19980429 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990517 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19990517 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000301 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050517 |